Patents

Literature

35results about How to "Realize continuous grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

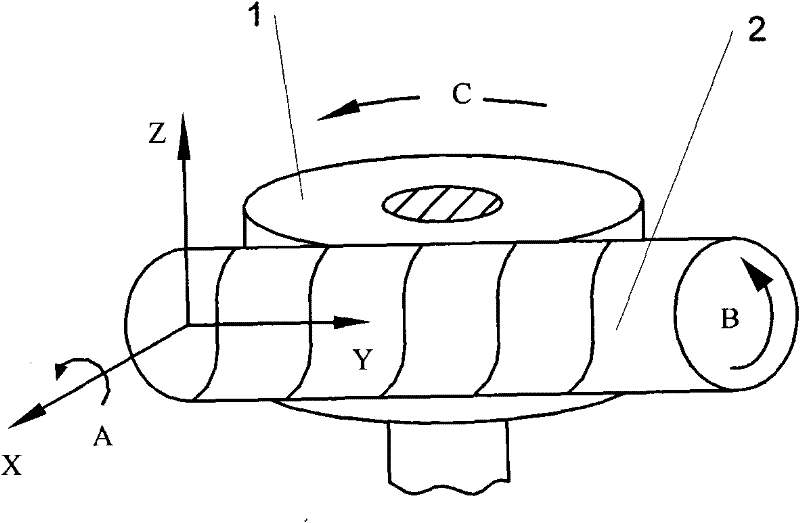

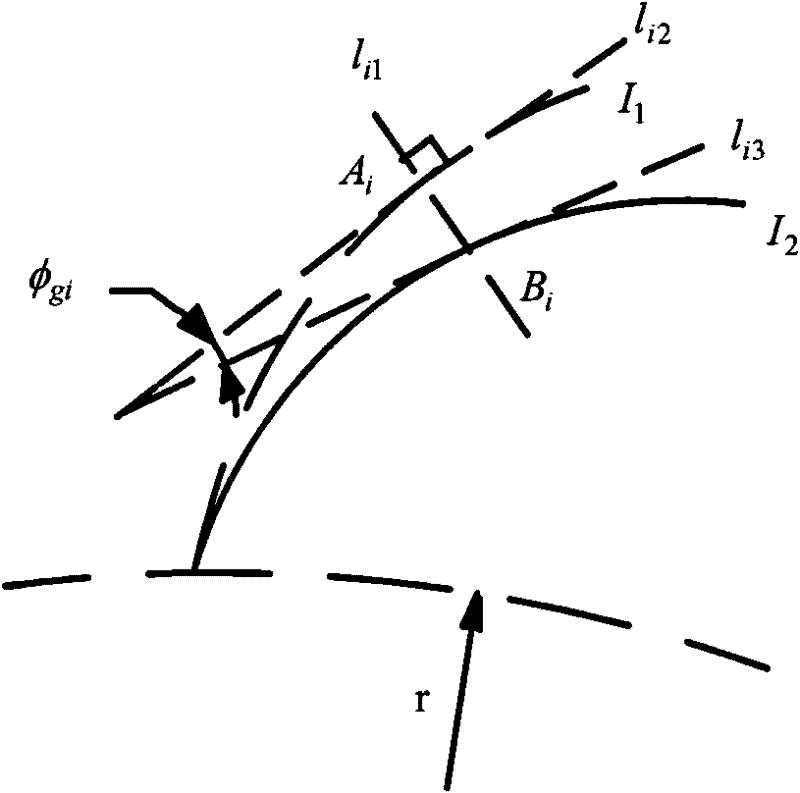

Numerical control grinding and machining method of stepwise variable pressure angle involute gear

InactiveCN101875139ARealize continuous grindingImprove processing efficiencyGear teethInvolute gearGear wheel

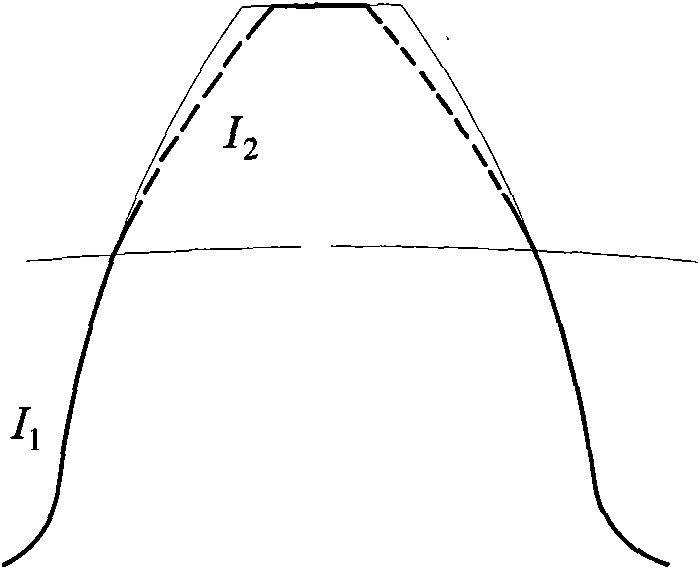

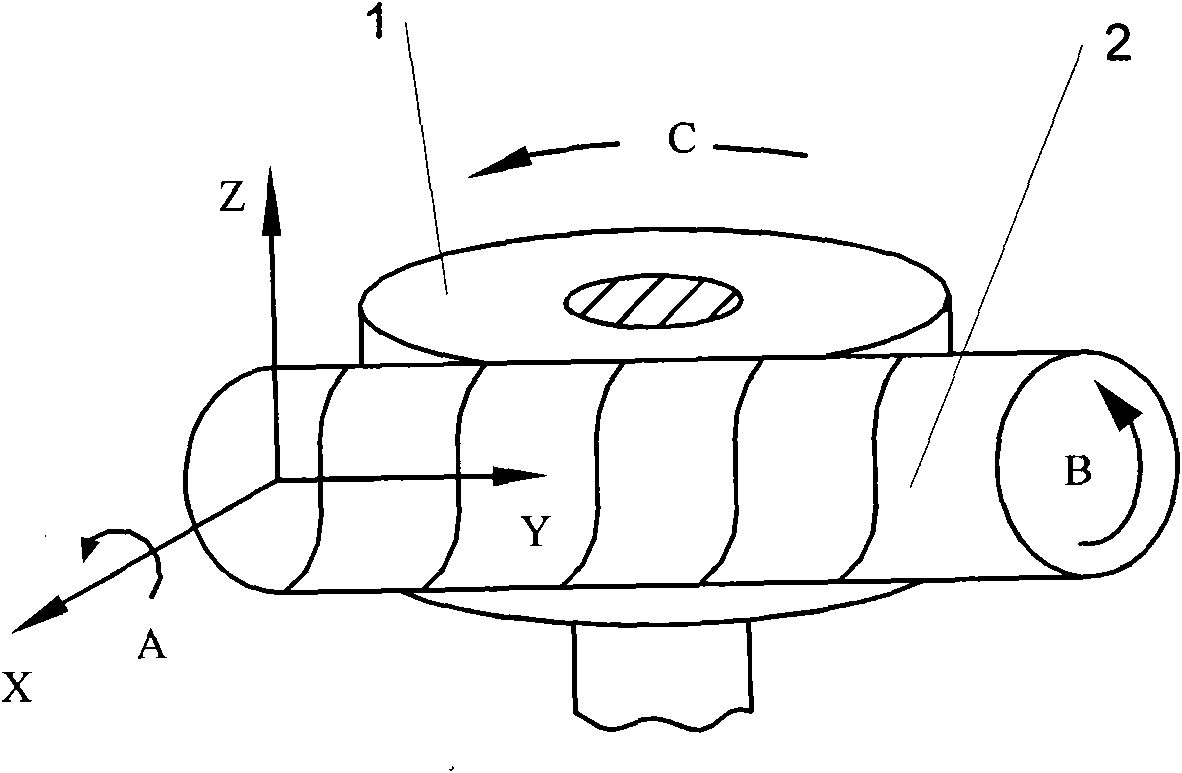

The invention discloses a numerical control grinding and machining method of a stepwise variable pressure angle involute gear. The numerical control grinding and machining method is characterized in that: by utilizing a radial and tangential linkage displacement principle of a grinding wheel, a linkage control model for grinding the stepwise variable pressure angle involute gear by adopting an Archimedes worm wheel on the basis of a six-axis five-linkage numerical control system and a real-time interpolation pulse value calculation method directly used for actual design machining of a machine tool are provided. The invention fills a blank of the technology for grinding and machining the stepwise variable pressure angle involute gear by adopting a fix-axis five-linkage numerical control method and can provide the technical basis for high-precision machining of the stepwise variable pressure angle involute gear.

Owner:HEFEI UNIV OF TECH

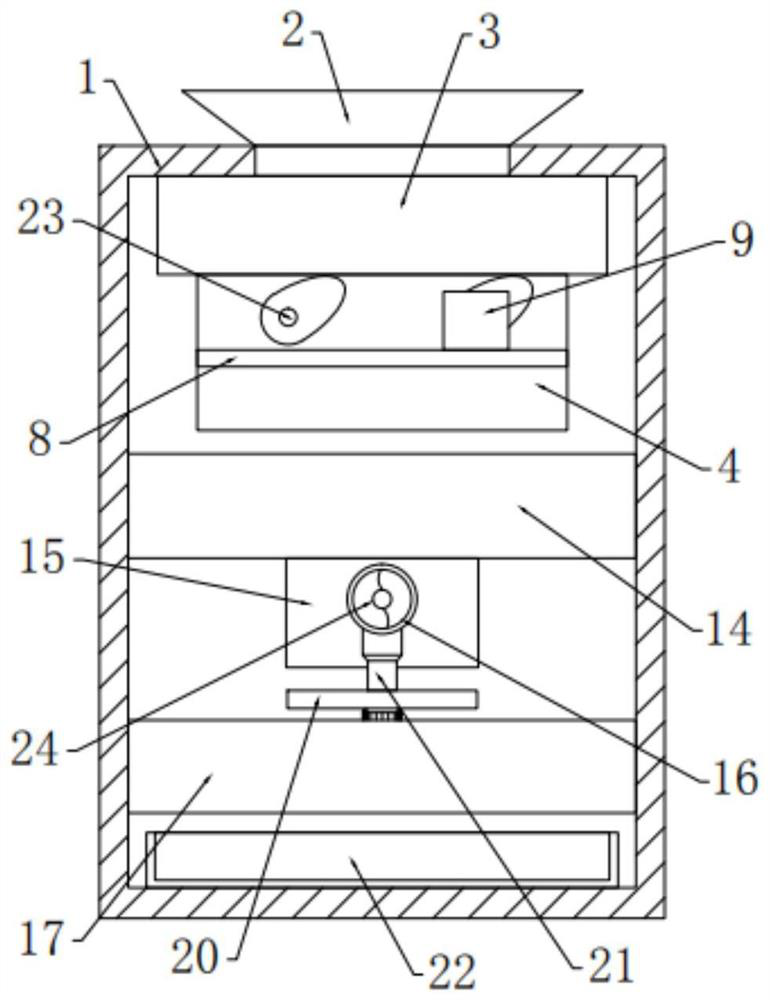

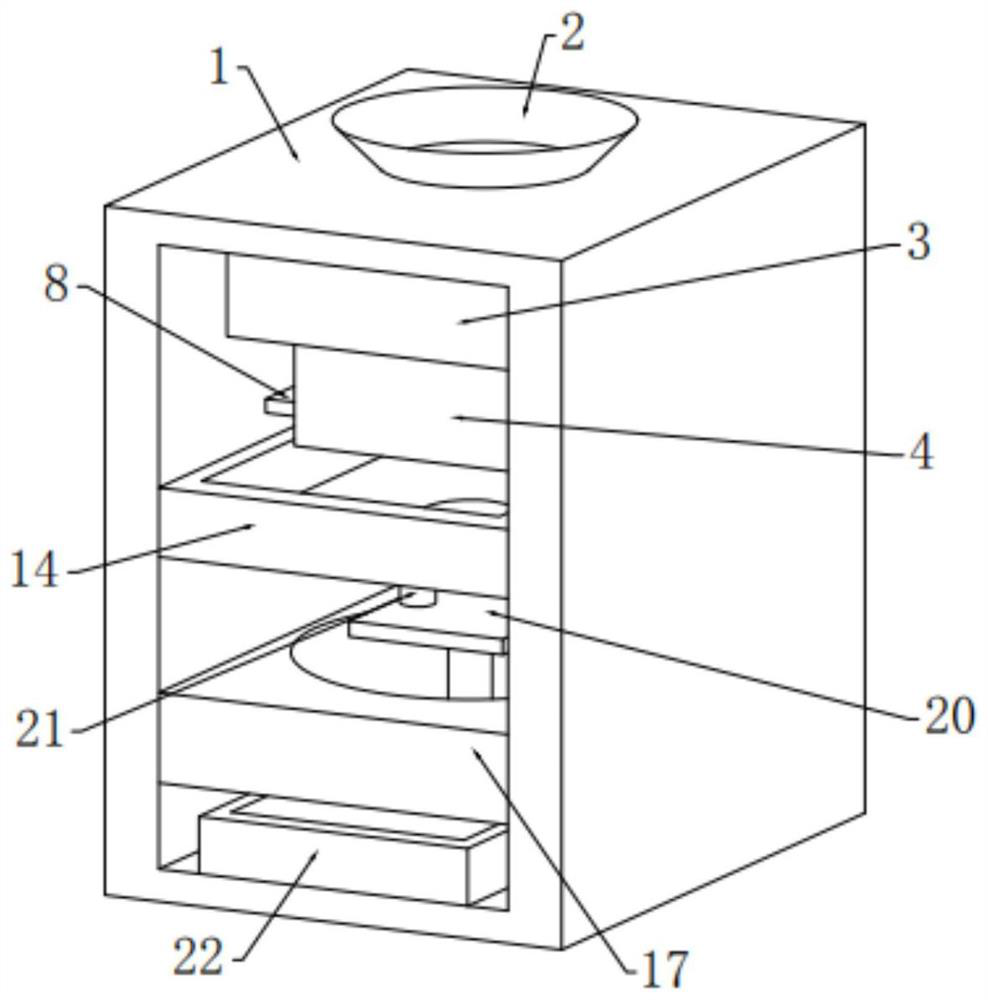

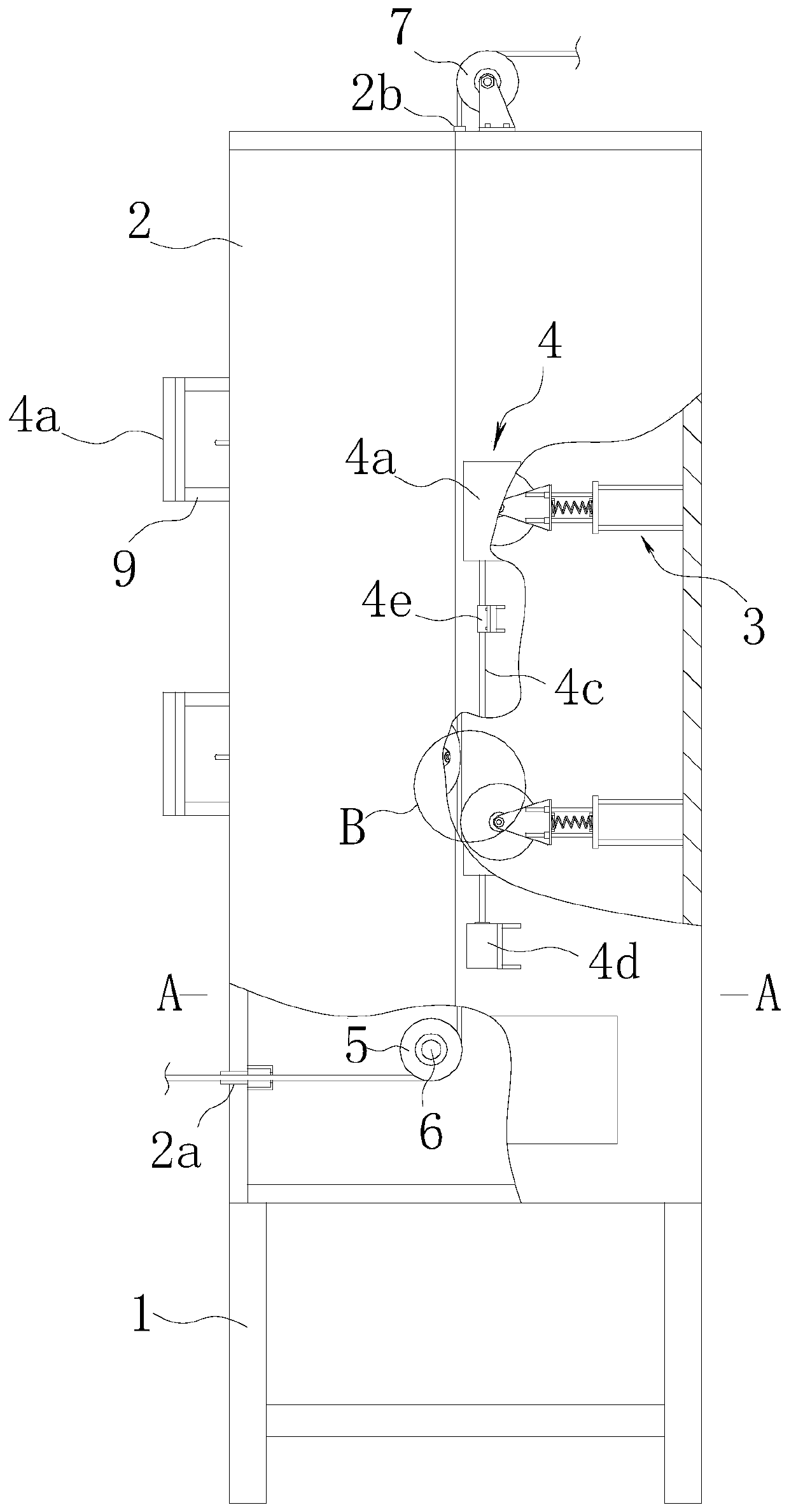

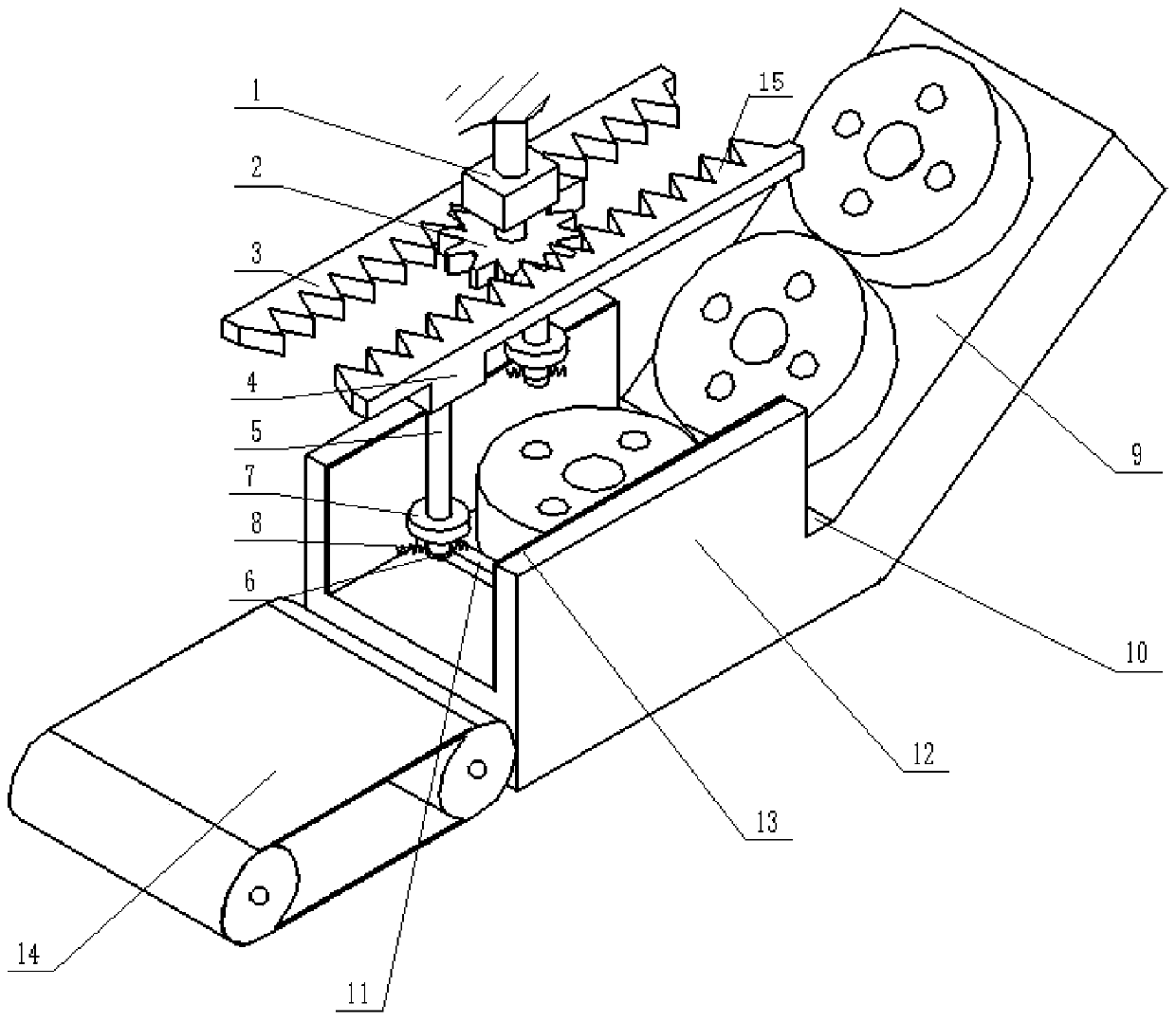

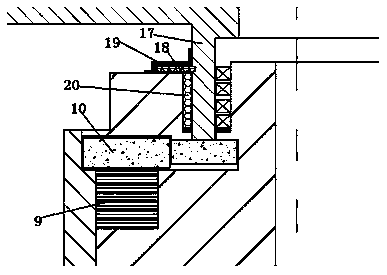

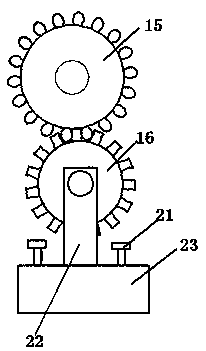

Crushing and grinding device for traditional Chinese medicine processing

InactiveCN111760656ACrushed fullyEasy to GrindCocoaGrain treatmentsProcess engineeringIndustrial engineering

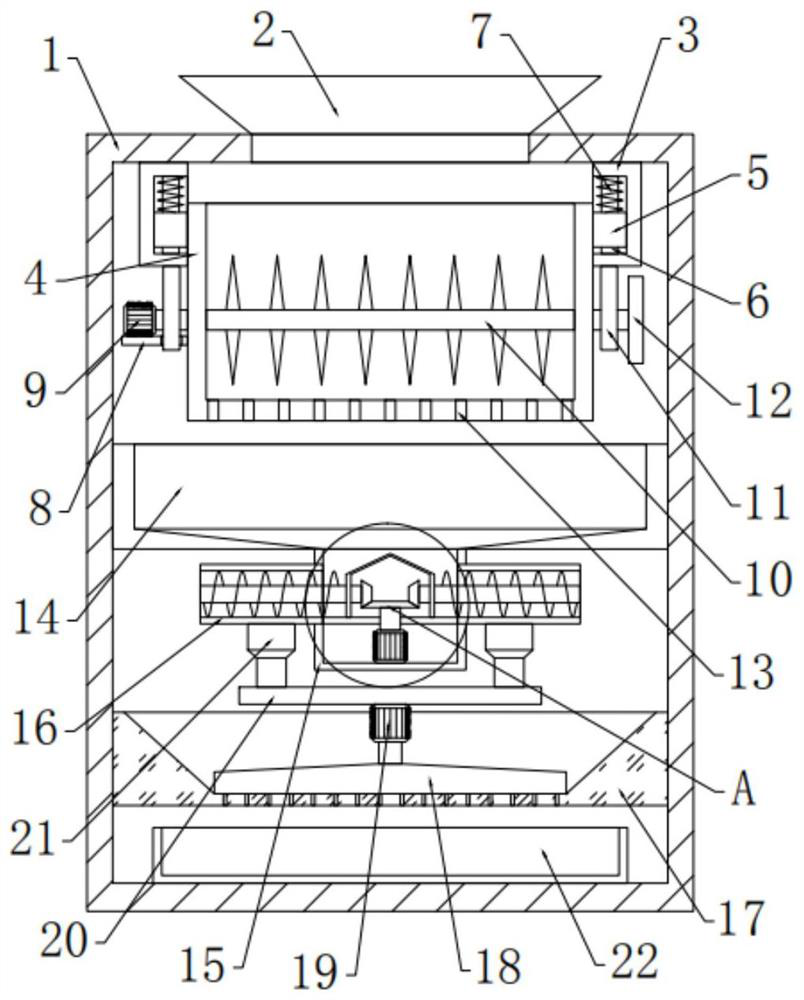

The invention relates to the technical field of traditional Chinese medicine processing, in particular to a crushing and grinding device for traditional Chinese medicine processing. The crushing and grinding device comprises a shell, wherein the top of the shell is provided with a feeding hopper, the lower side of the feeding hopper is provided with a crushing mechanism, the lower side of the crushing mechanism is provided with a grinding mechanism, a discharging mechanism is arranged between the grinding mechanism and the crushing mechanism, and the lower side of the grinding mechanism is provided with a collection box. According to the crushing and grinding device, by arranging the crushing mechanism, traditional Chinese medicinal materials can be crushed through a first crushing rod anda second crushing rod which rotate in opposite directions, so that subsequent grinding of the traditional Chinese medicinal materials is facilitated; by arranging a cam, a crushing box can vibrate upand down through the cam and springs, so that the traditional Chinese medicinal materials in the crushing box can be fully crushed; and by arranging the discharging mechanism, the discharging amountcan be controlled, continuous grinding of the traditional Chinese medicinal materials can be avoided by arranging the grinding mechanism, and the processing efficiency of the device can be improved.

Owner:范吉林

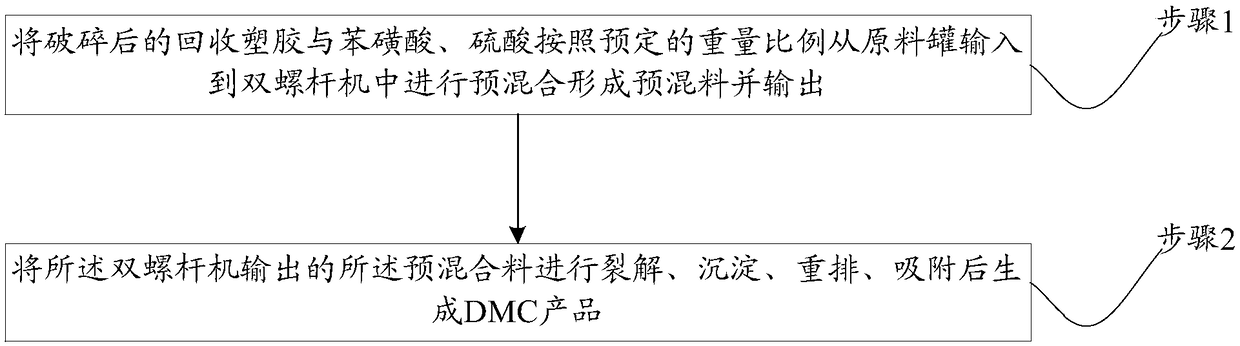

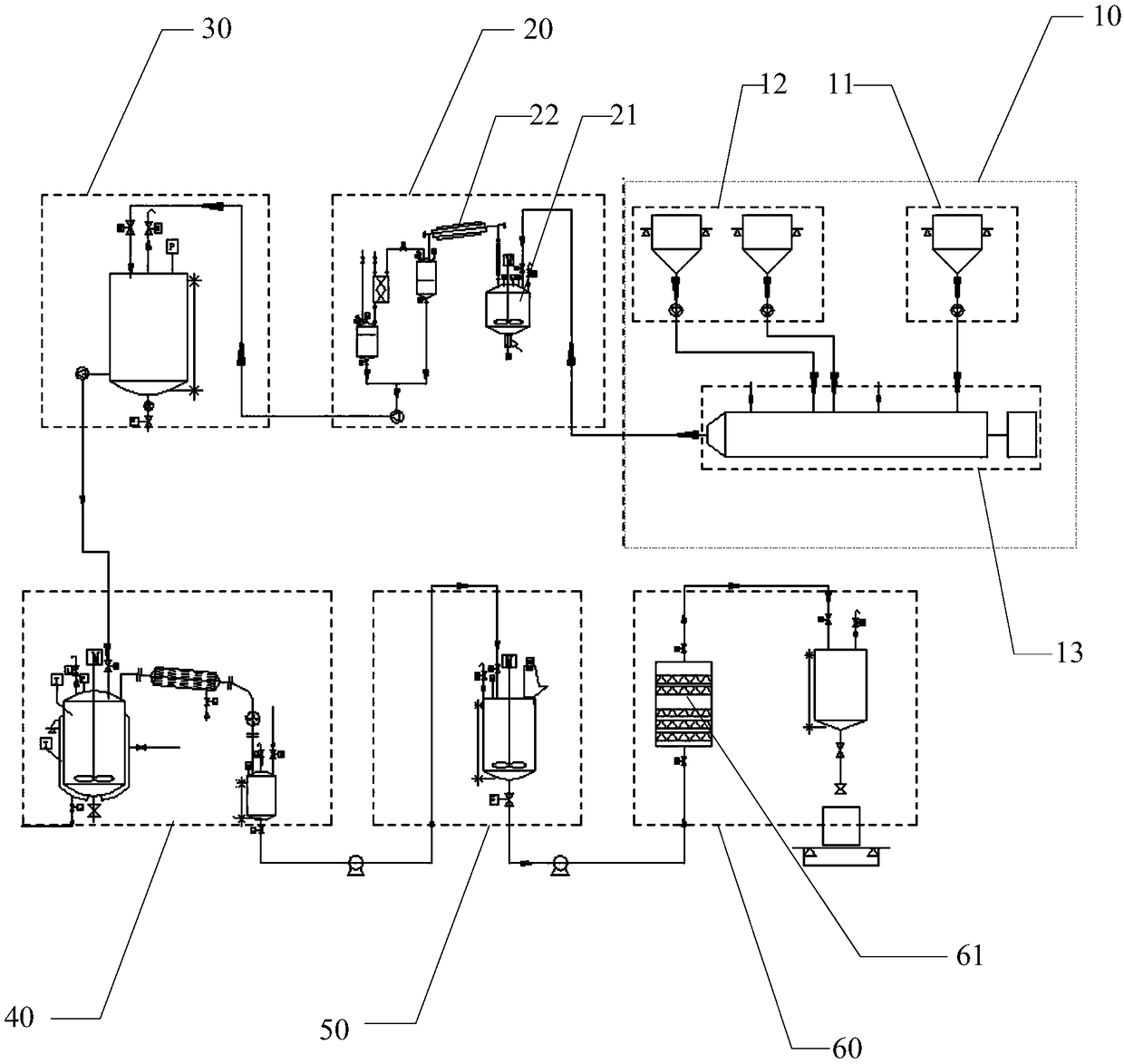

DMC (dimethylcyclosiloxane) production method and DMC production device

PendingCN109400951AWell mixedSmall granularitySilicon organic compoundsPlastic recyclingProcess engineeringBenzenesulfonic acid

The invention discloses a DMC (dimethylcyclosiloxane) production method and a DMC production device. The DMC production method includes step 1, inputting crushed recycled plastic, benzenesulfonic acidand sulfuric acid into a twin-screw machine from a raw material tank according to a preset weight ratio, performing premixing to form a premix and outputting the premix; step 2, subjecting the premixoutput by the twin-screw machine to cracking, precipitation, rearrangement and adsorption to form a DMC product. The DMC production method and the DMC production device have the advantages that the crushed recycled plastic, benzenesulfonic acid and sulfuric acid materials are input into the twin-screw machine according to the preset weight ratio, are mixed and dispersed by the twin-screw machine,and are further mixed and ground according to the characteristics of the twin-screw machine, including a small gap between double screws and a high rotating speed; the ground materials are uniformlymixed, the particle size is small, and continuous grinding can be realized; waste and manual transfer of the materials do not exist in the process, the raw materials can be directly input from the corresponding device, and finished products can be output from the output end, so that labor costs are saved, and the production cycle is shortened.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

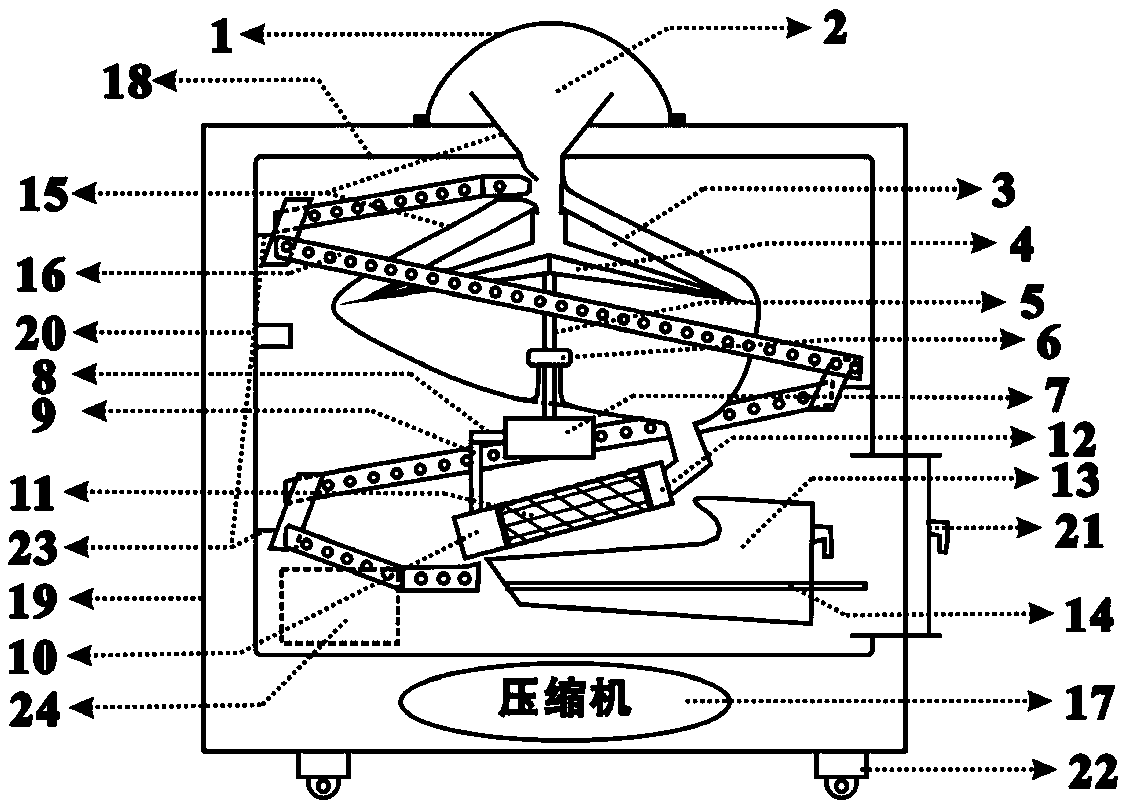

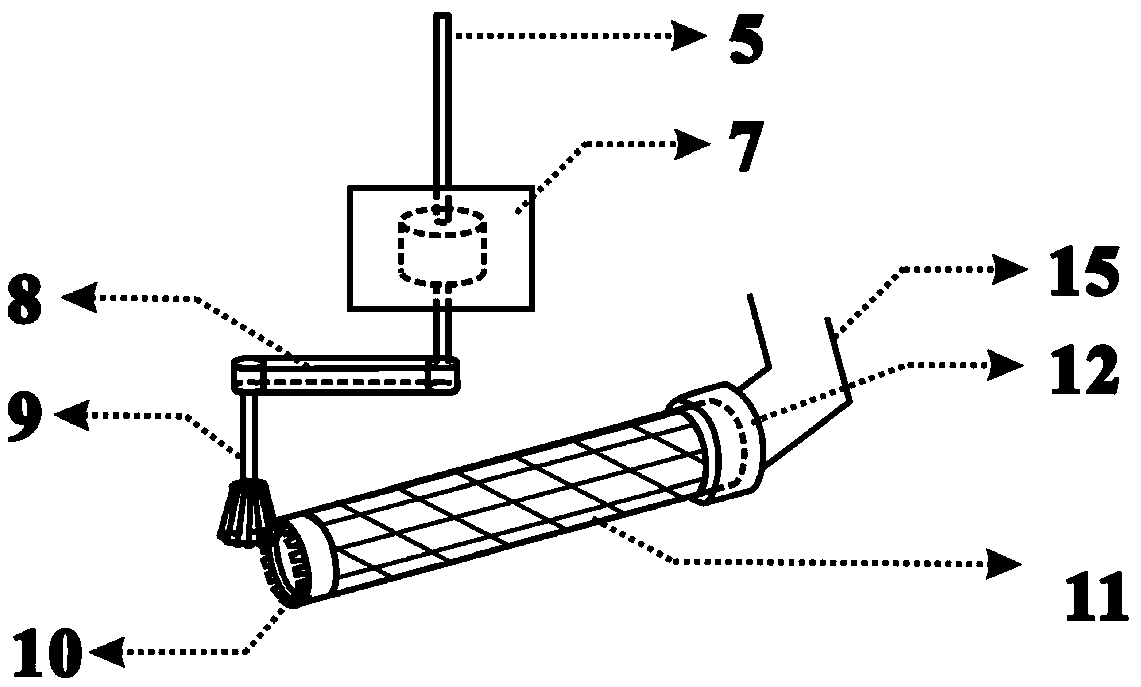

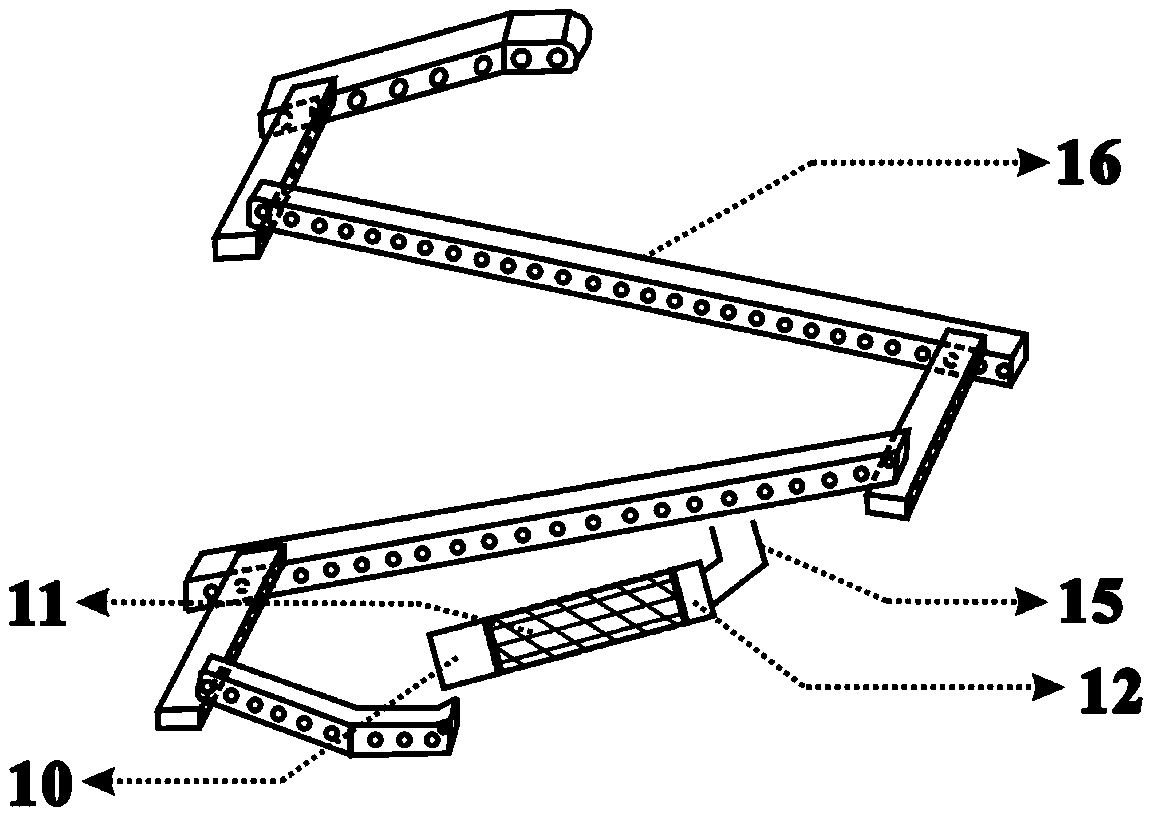

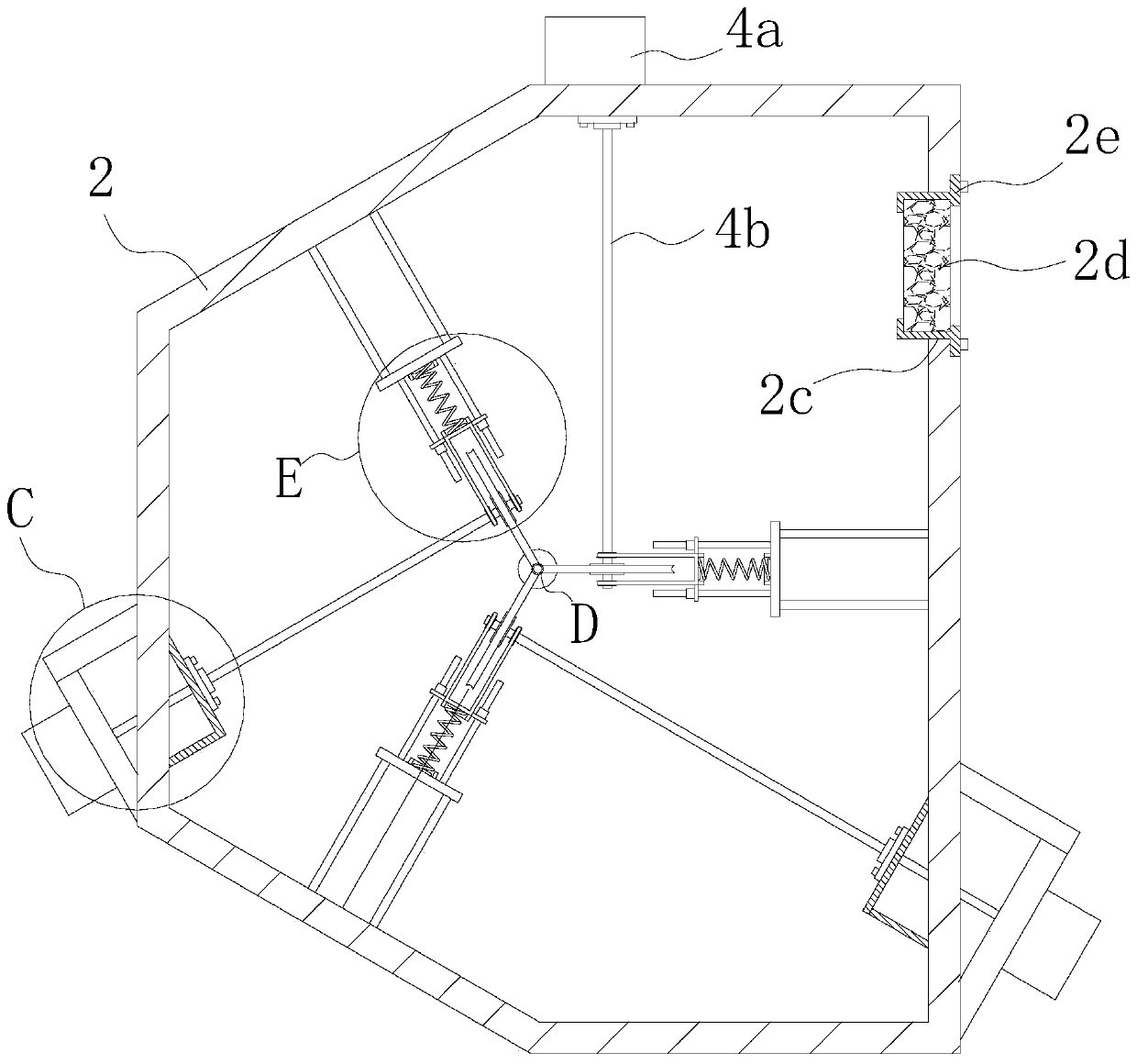

Temperature-controlled soil continuous grinding and screening device

InactiveCN109248741ARealize continuous grindingEasy to disassemble and operateCocoaGrain treatmentsTemperature controlParticulates

The invention relates to a temperature-controlled soil continuous grinding and screening device, which is characterized in that a feeding hopper is arranged at the top of a double-layer composite shell, the lower nozzle of the feeding hopper is connected to the central hole of a umbrella-shaped fixed grinding disc, the lower part of the umbrella-shaped fixed grinding disc is provided with an umbrella-shaped dynamic grinding disc opposite to each other, a discharge elbow is connected to the bottom discharge opening of a material-falling bin, and an inclined screen cylinder is connected to the pipe port of a discharging elbow via a bearing bayonet; a collection box is arranged below the barrel body of the screen cylinder, a multi-stage conveyor belt is arranged in a double-layer composite shell to transport materials layer by layer upwards, the bottom layer belt of the multi-stage conveyor belt extends to the position below the particulate discharging port of the screen cylinder, and thetop belt of the multi-stage conveyor belt extends to the bypass discharge port of a feeding hopper. The temperature-controlled soil continuous grinding and screening device solves the problems of complex steps and low processing efficiency existing in current laboratory soil treatment, effectively overcomes various interference factors in a soil grinding process, and improves the reliability of the research data and the research results.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

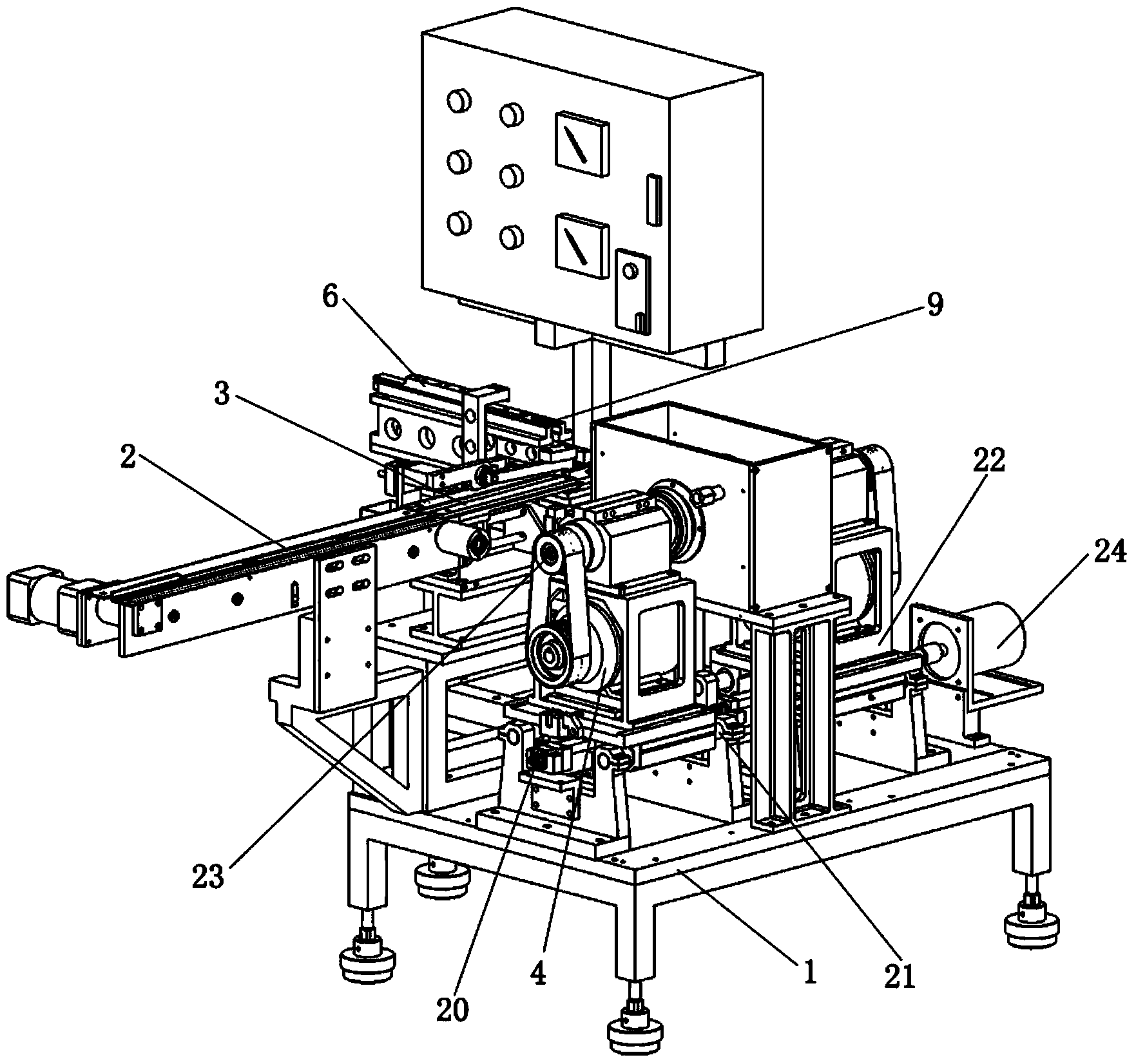

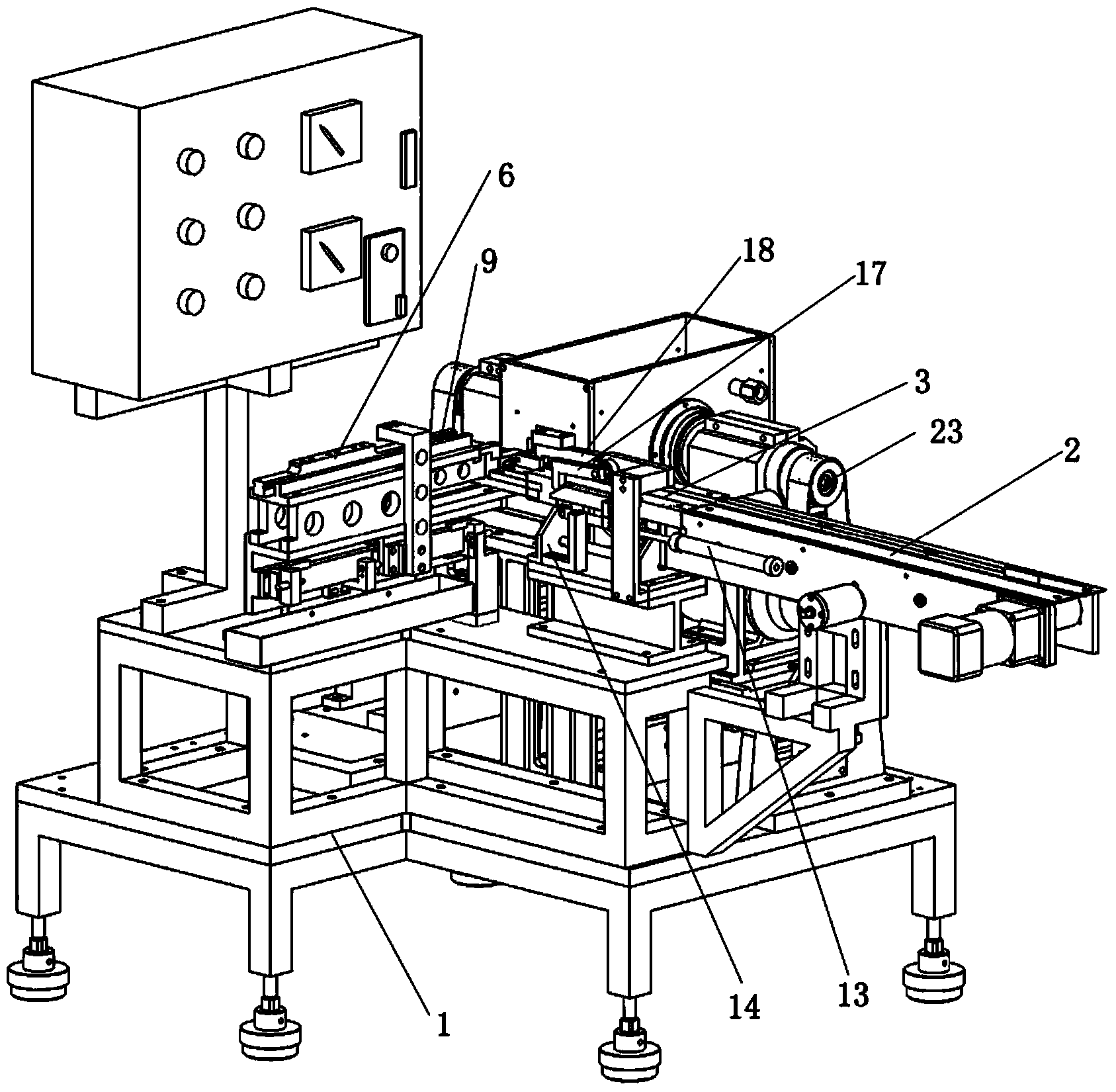

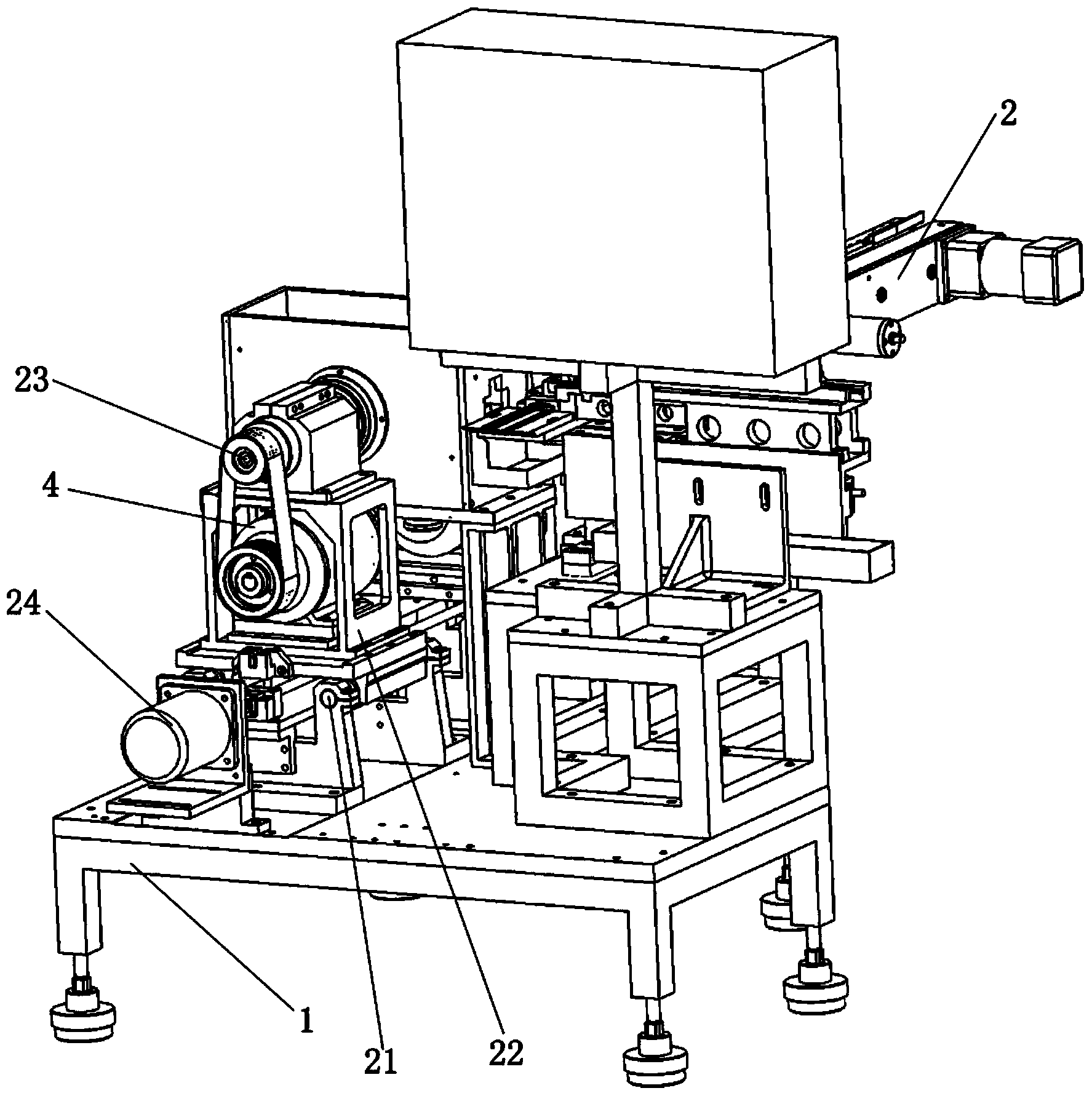

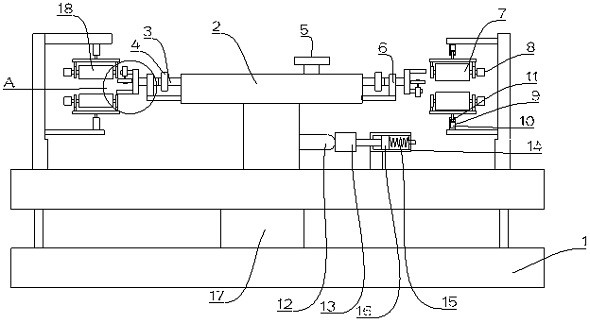

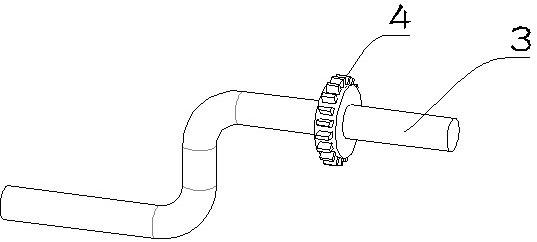

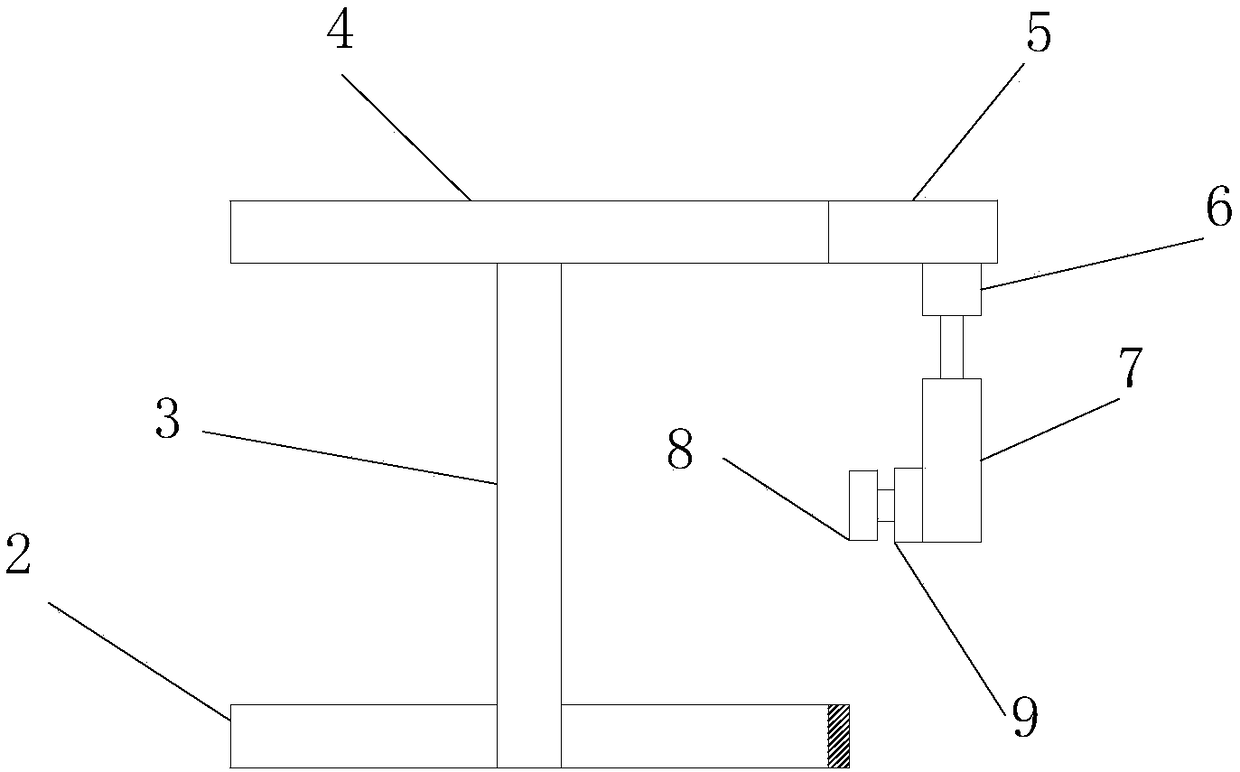

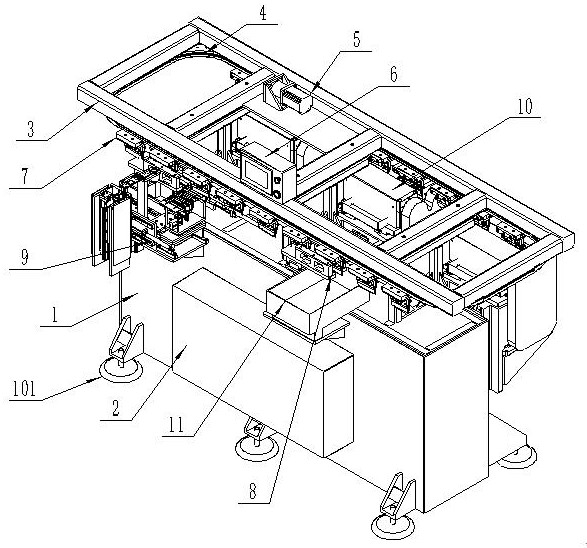

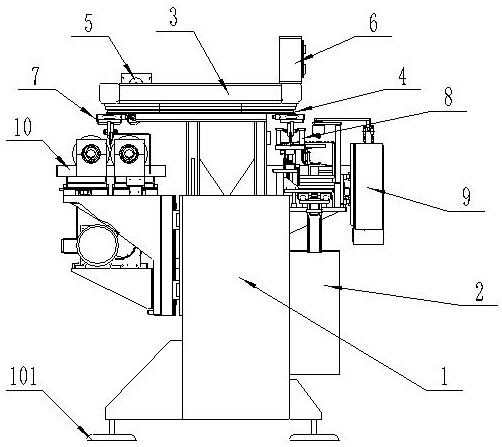

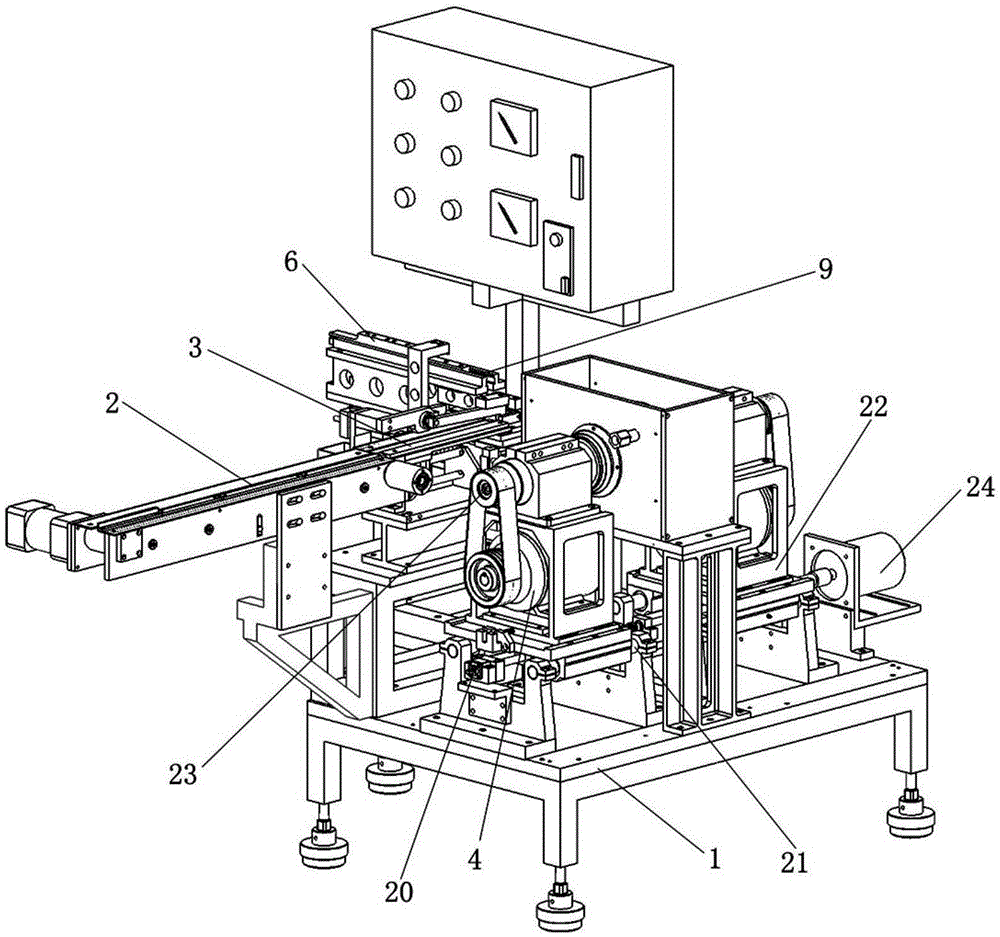

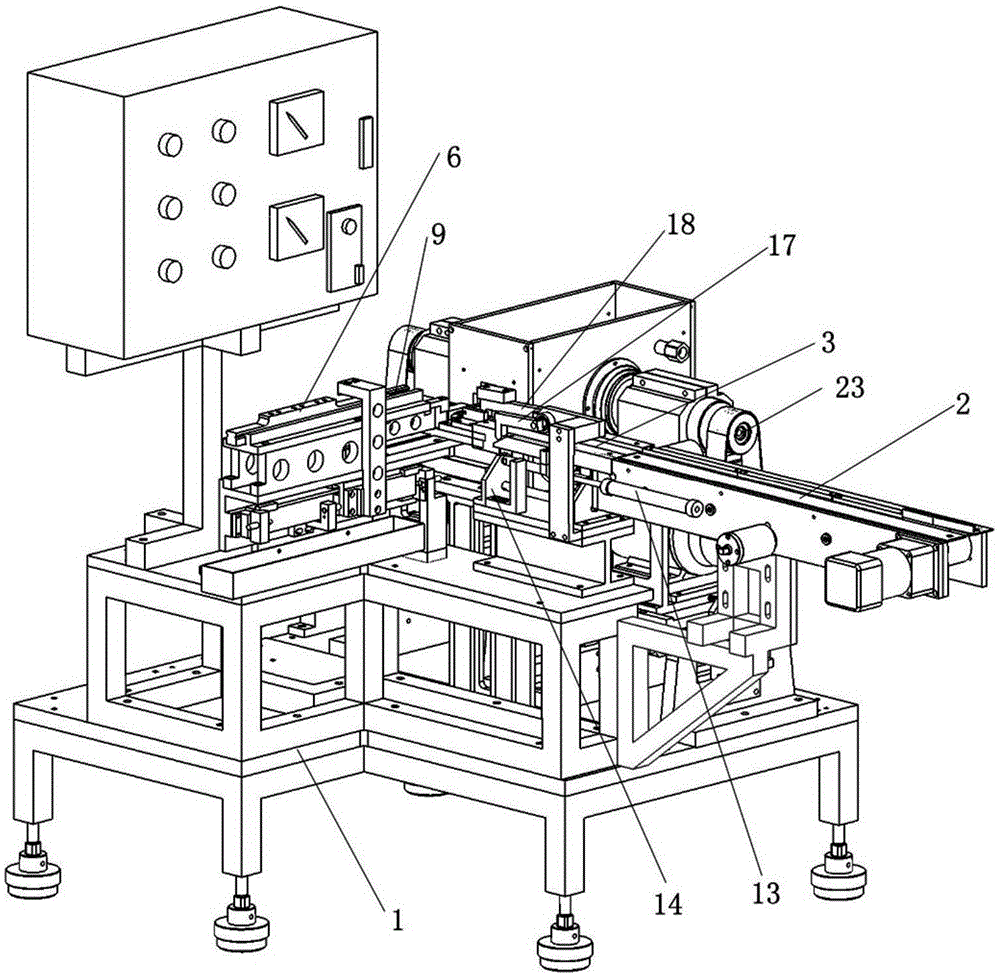

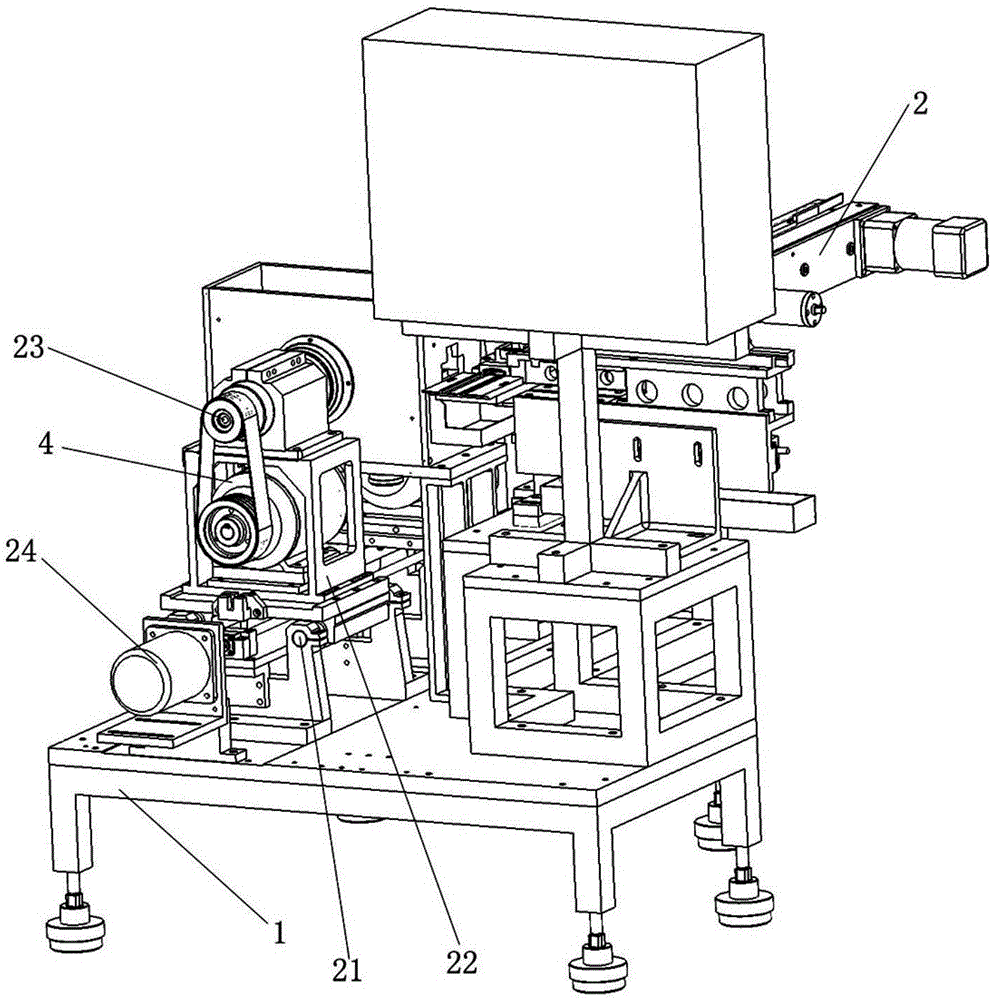

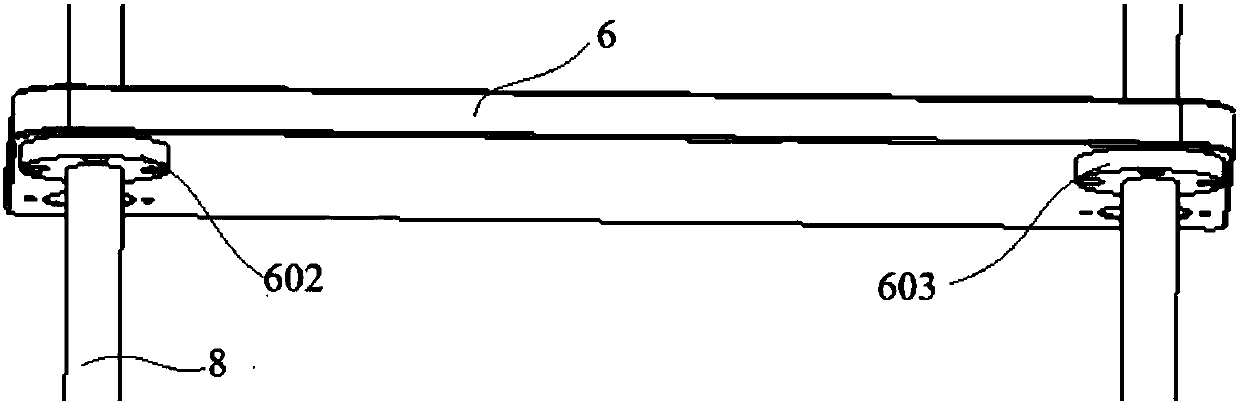

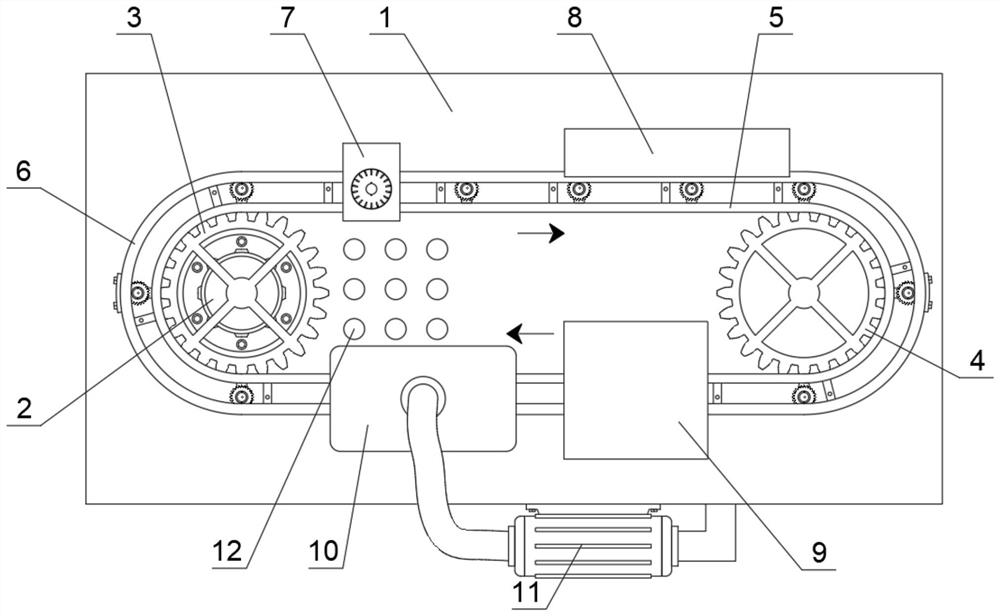

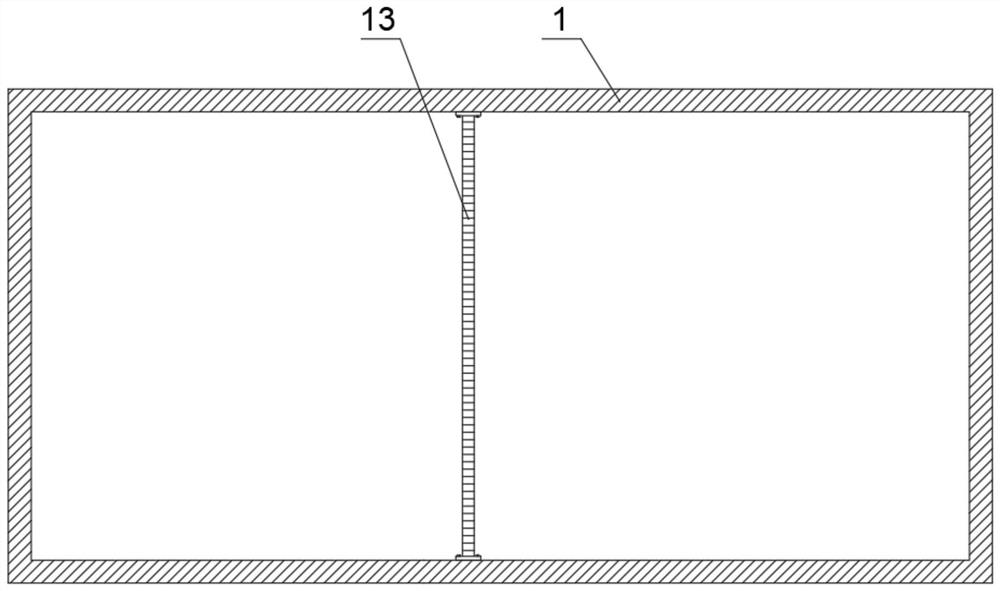

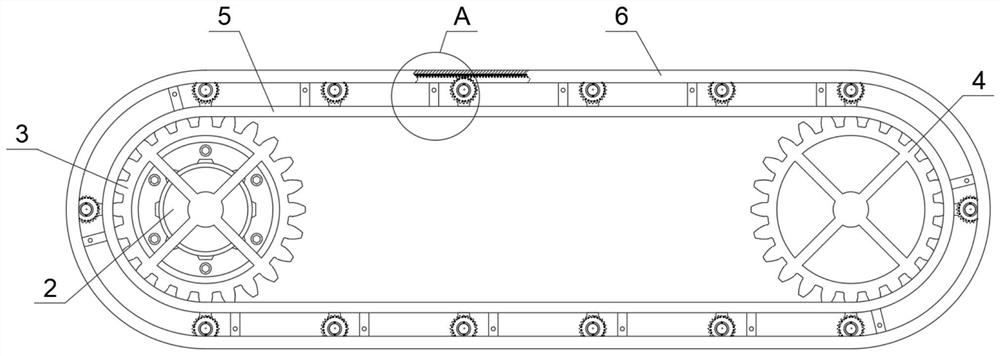

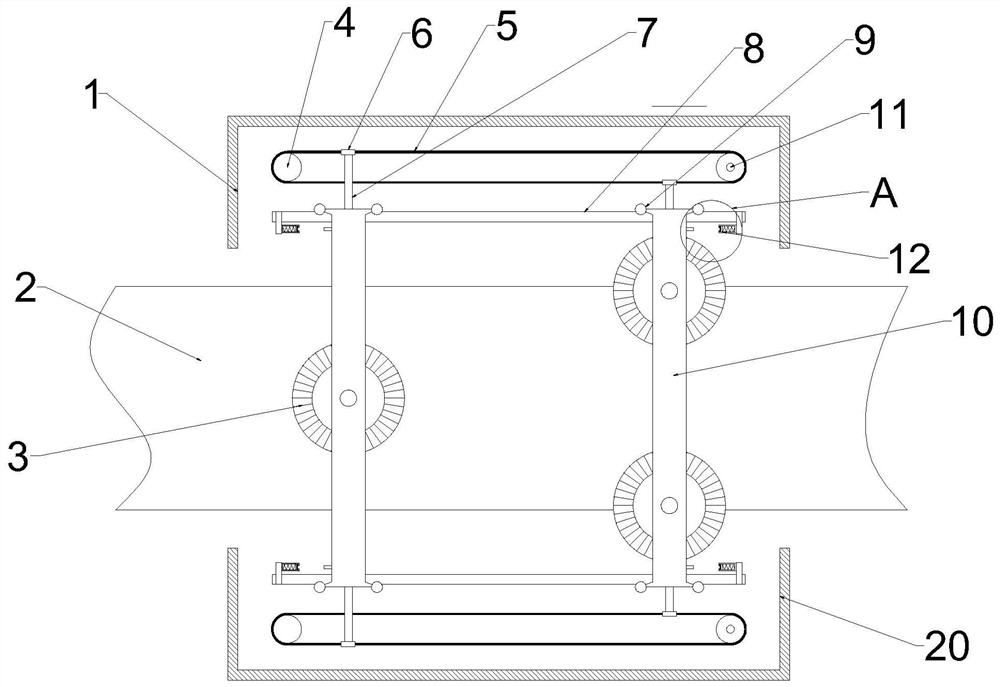

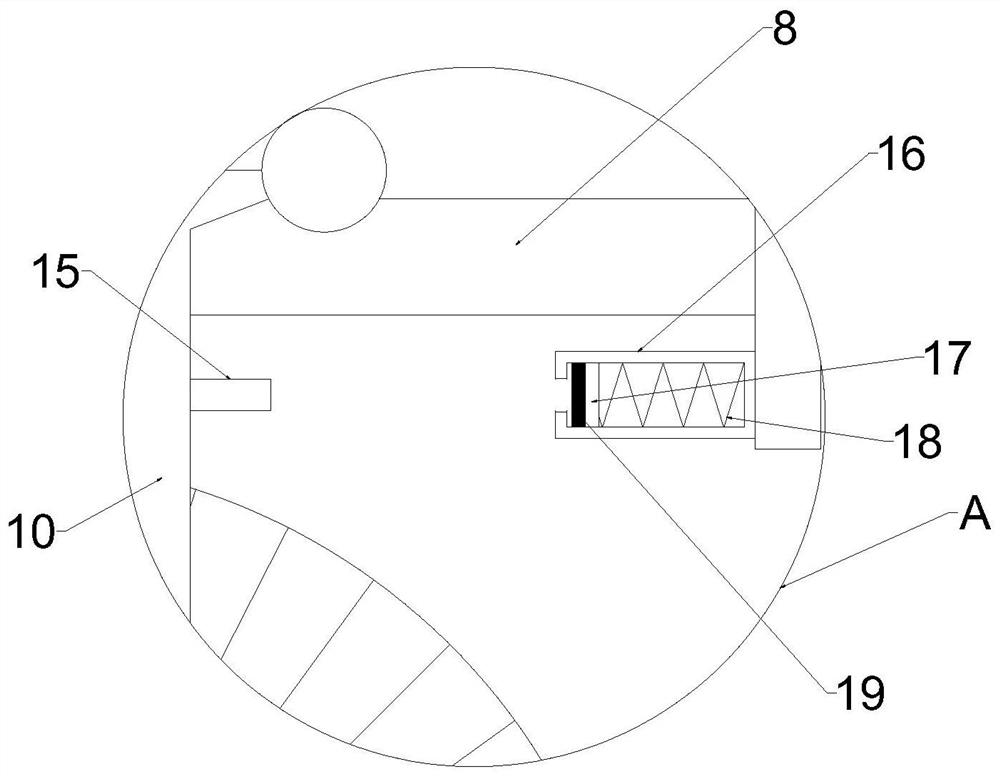

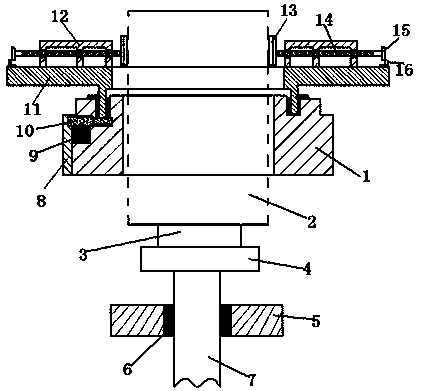

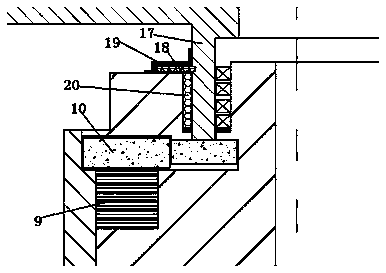

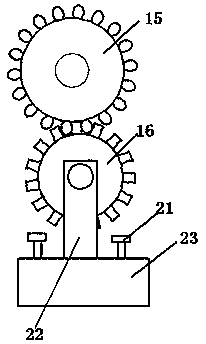

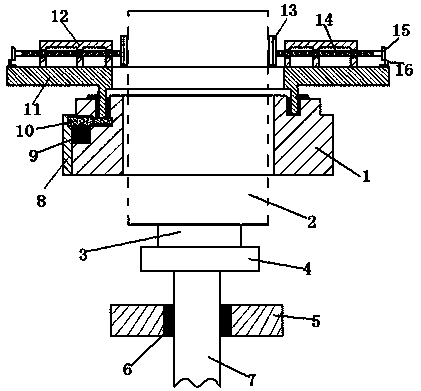

Shaft height grinding machine

ActiveCN104162825AEasy to moveGood directionGrinding drivesGrinding machinesReciprocating motionEngineering

The invention discloses a shaft height grinding machine. The shaft height grinding machine comprises a machine frame (1), a conveying belt (2), a first guide rail (3), two grinding wheels (5), a driving device and a shaft height fixture, wherein the conveying belt (2) is horizontally arranged on the machine frame (1); the first guide rail (3) is arranged in front of the conveying belt (2); the two grinding wheels (5) are arranged on the machine frame (1) and can be driven by a motor (4) to move in a departing mode or an approaching mode, the axes of the two grinding wheels (5) are coaxial, and the grinding wheels (5) are parallel to the conveying belt (2) and located on one side of the first guide rail (3); the driving device is arranged on the machine frame (1) to drive the grinding wheels to move; the shaft height fixture is arranged on the machine frame (1) and is driven by a first air cylinder to conduct reciprocating motion between the two grinding wheels (5) and the first guide rail (3), and the end, close to the grinding wheels (5), of the shaft height fixture is provided with a through hole (7) used for fixing a magnetic tile. The shaft height grinding machine has the advantages that the grinding accuracy of the shaft height of a tile-shaped magnet is improved, and size deviation is reduced; moreover, the shaft height grinding machine also has the advantages of being simple in structure, convenient to operate and stable in running.

Owner:德昌电机(南京)有限公司

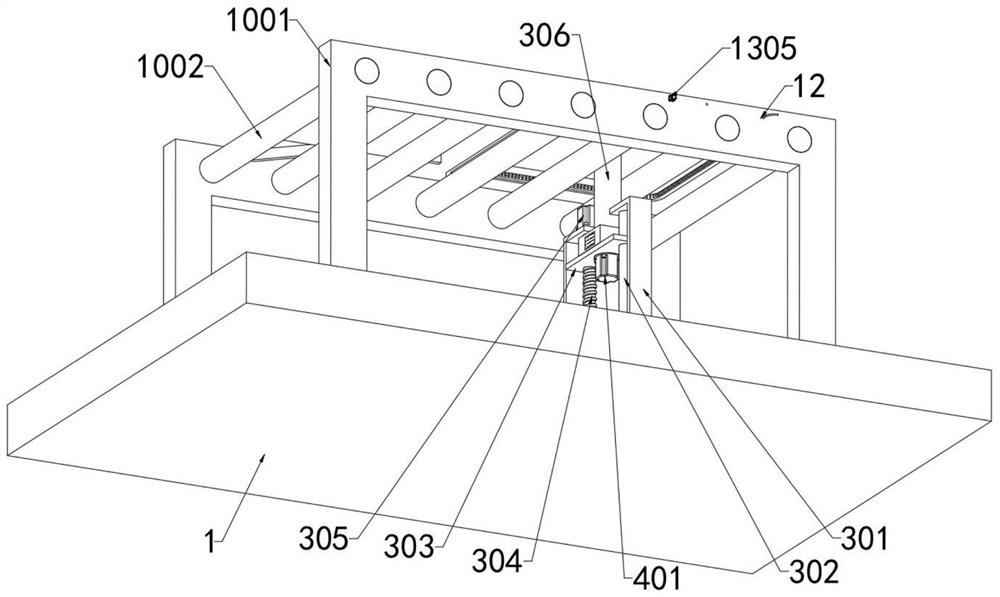

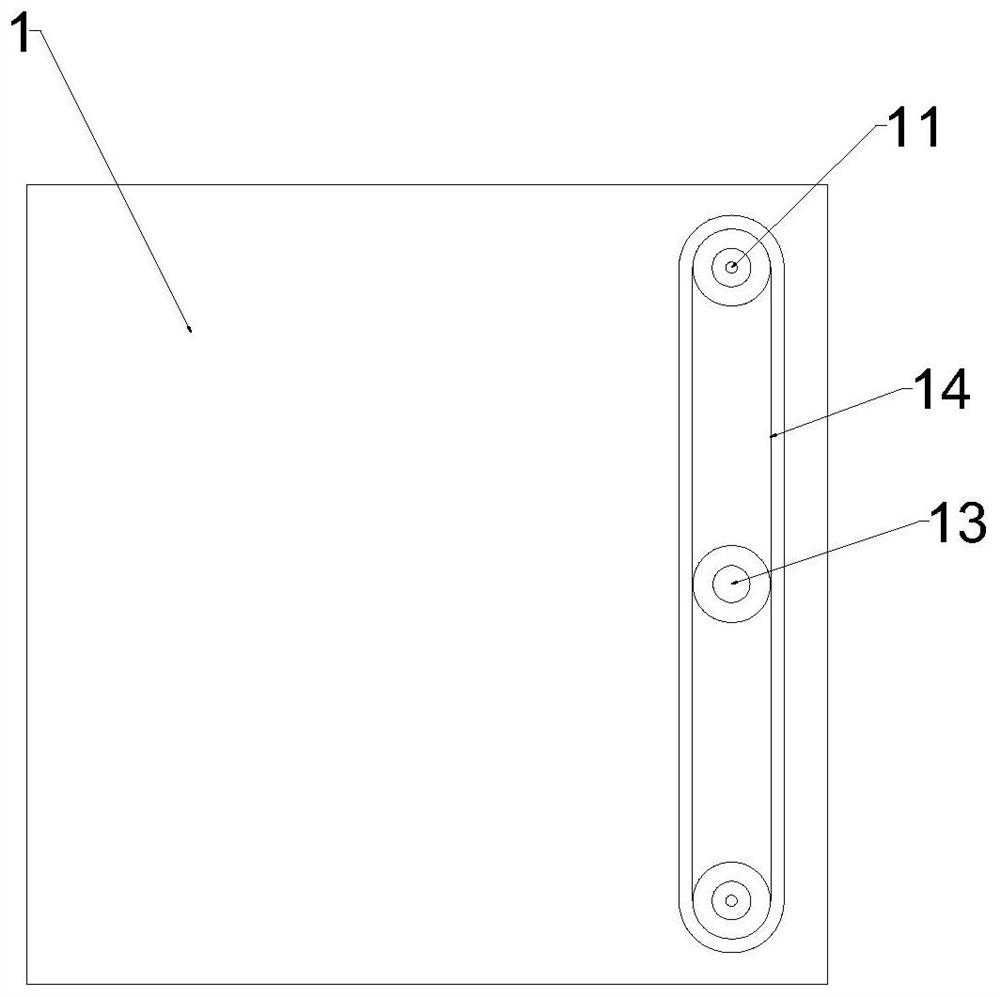

Polishing device for small side plates of table tennis bat handle

InactiveCN104149012AContinuous grindingImprove work efficiencyBelt grinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention relates to a polishing device for small side plates of a table tennis bat handle. The polishing device comprises a base, a polishing assembly, a pressing assembly and a limiting plate assembly. The pressing assembly is mounted on the base and comprises a cross beam, a press rod, a first elastic piece, a limiting rod, a first vertical rod and a baffle, wherein the cross beam is fixed to the two side faces of the base and is higher than the upper surface of the base, one end of the press rod is hinged to end of the upper surface of the cross beam, the other end of the press rod extends along the cross beam, the first elastic piece is arranged on the cross beam and is connected with the press rod, the limiting rod is arranged on the cross beam and is located in the same plane with the press rod, the first vertical rod is connected with the press rod and is located on one side of the cross beam, and the baffle is connected with the lower end of the first vertical rod and is located above a polishing abrasive belt. The limiting plate assembly is located below the cross beam. On one hand, the limiting rod is used for limiting the travel of the press rod, and the polishing unevenness caused by overlarge force for pressing the press rod is avoided; on the other hand, the small side plates are limited to or separated from the limiting plate assembly by using the up-and-down movement of the baffle, in this way, the small side plates can be continuously polished, and working efficiency is improved.

Owner:YANCHENG AST SPORTING GOODS

Polishing device special for up-drawing of oxygen-free copper rod

InactiveCN109746801AReduce the number of replacementsAchieve fine grindingGrinding machine componentsGrinding machinesGrinding wheelOxygen-free copper

The invention discloses a polishing device special for up-drawing of an oxygen-free copper rod, and belongs to the technical field of auxiliary polishing for varnished wire production. According to the technical key points, the polishing device comprises a bracket, a copper powder recovery box is arranged on the bracket in the vertical direction, a plurality of sets polishing units are arranged inthe copper powder recovery box at intervals in the height direction, and the to-be-polished copper rod passes through all the polishing units in the vertical direction; each polishing unit is composed of three or more grinding wheel polishing mechanisms which are evenly distributed at intervals in the circumferential direction of the to-be-polished copper rod and arranged in a staggered mode in the axial direction of the to-be-polished copper rod, and the grinding wheel polishing mechanisms comprise grinding wheels; the grinding wheels are arranged in the vertical direction, and the polishingend faces of the grinding wheels are each in an arc shape; and the total length of arc lines formed by contact between all the grinding wheels located on the same polishing unit and the to-be-polished copper rod is larger than the perimeter of the to-be-polished copper rod. The polishing device special for up-drawing of the oxygen-free copper rod is reasonable in structure, good in polishing effect and convenient to use, and is used for polishing of the oxygen-free copper rod.

Owner:广东金雁电工科技股份有限公司

Polishing device for automobile mechanical key blank machining

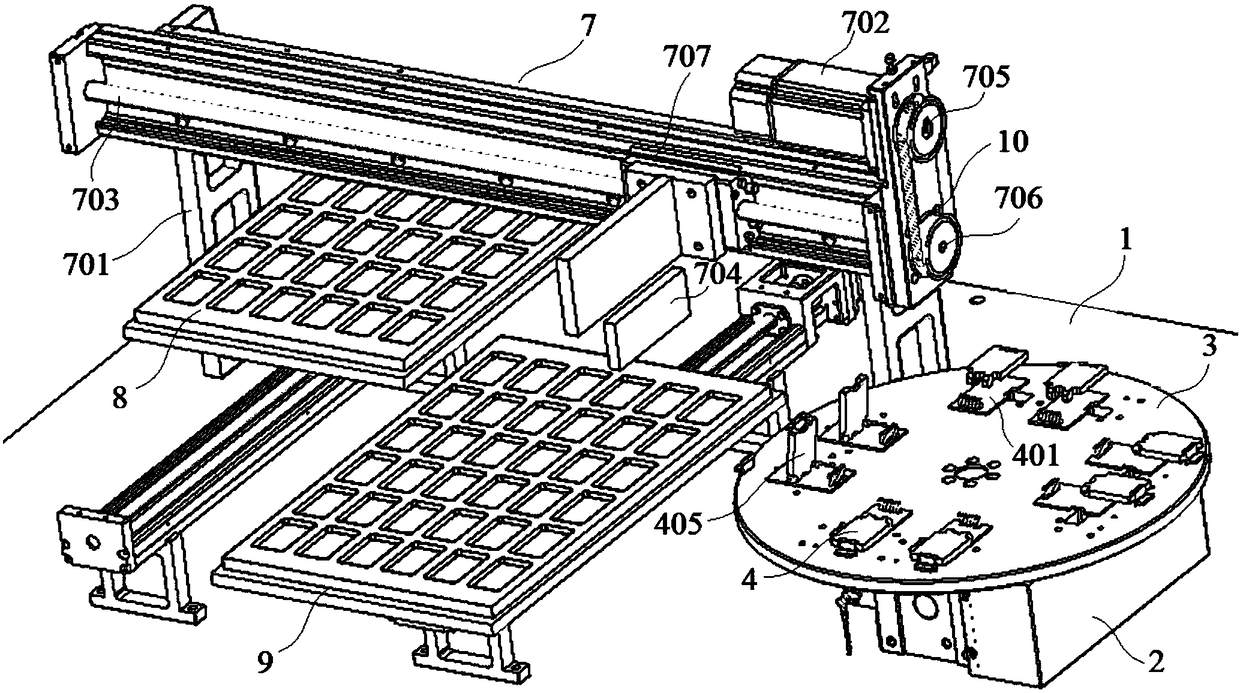

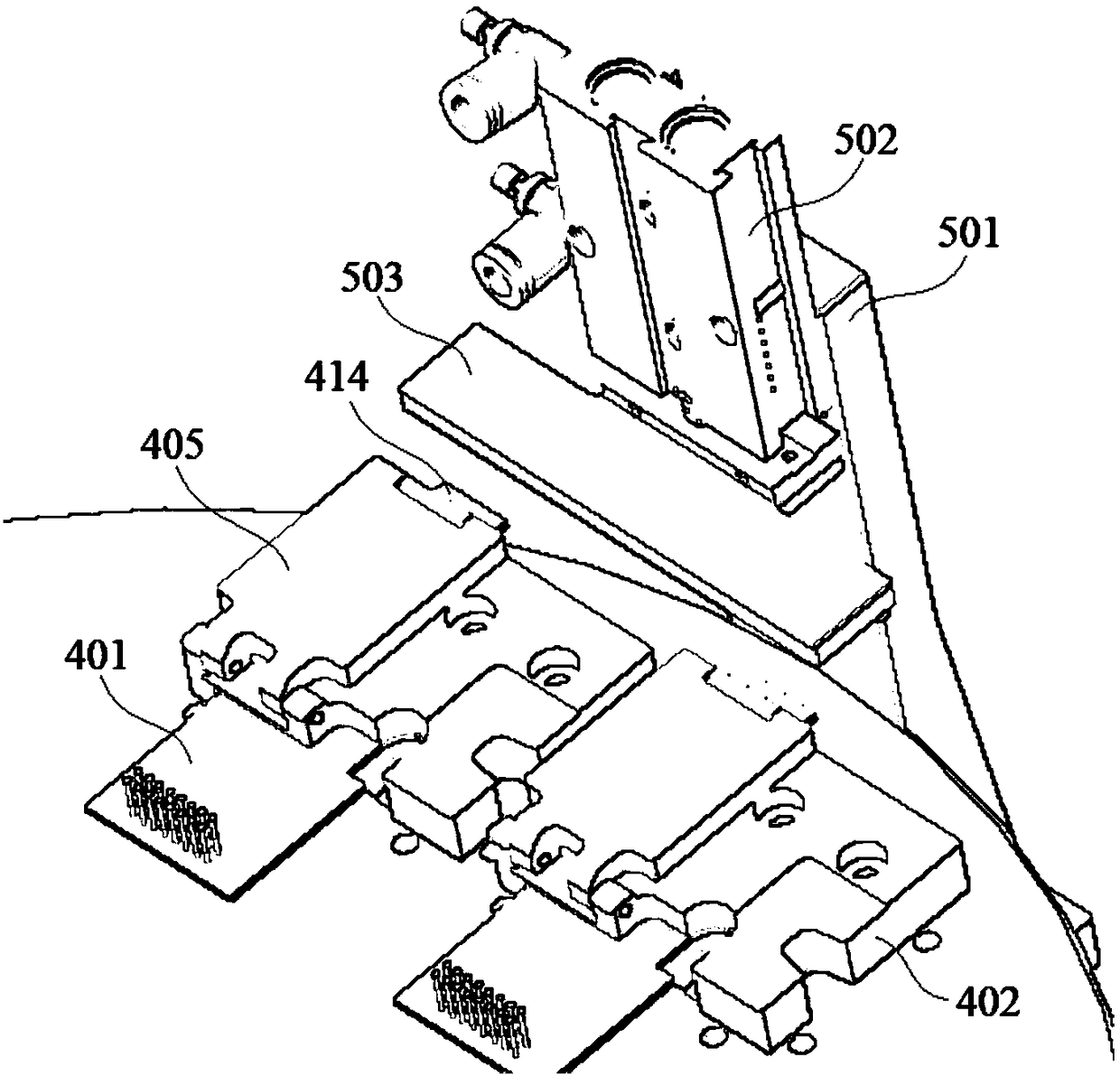

InactiveCN114227455ARealize continuous grindingImprove sanding qualityGrinding drivesGrinding machinesPolishingStructural engineering

The invention is suitable for the technical field of key machining equipment, and provides a polishing device for automobile mechanical key blank machining. Comprising a base; the mounting disc is intermittently and rotatably arranged on the base; a plurality of clamping assemblies used for clamping parts are arranged on the mounting disc in an array mode. The two polishing assemblies and the cleaning assemblies are arranged on the base; the two sets of grinding assemblies are connected. And the turnover mechanism is arranged between the two sets of grinding assemblies, and the turnover mechanism is used for enabling the clamping assemblies to turn over, so that the two different faces of the part are ground between the two sets of grinding assemblies. According to the polishing device, cleaning is achieved in the polishing process, using is convenient, continuous polishing is achieved, parts are polished at different positions, and the polishing quality is improved.

Owner:广州市煊华五金制品有限公司

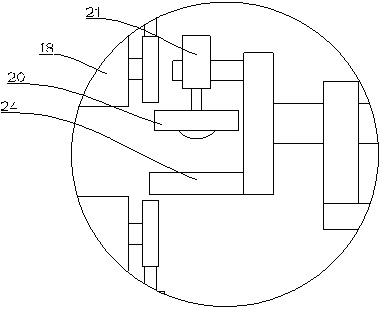

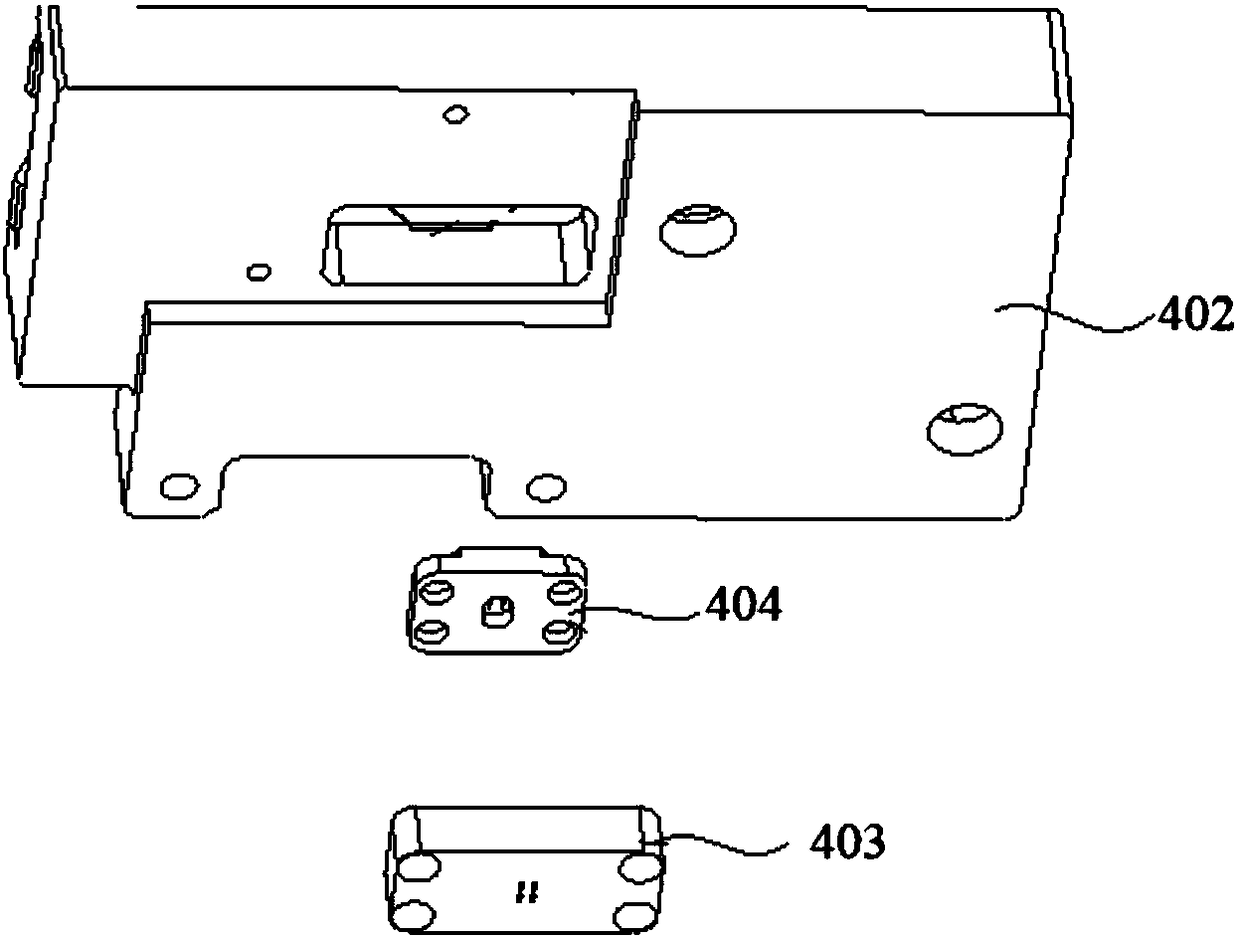

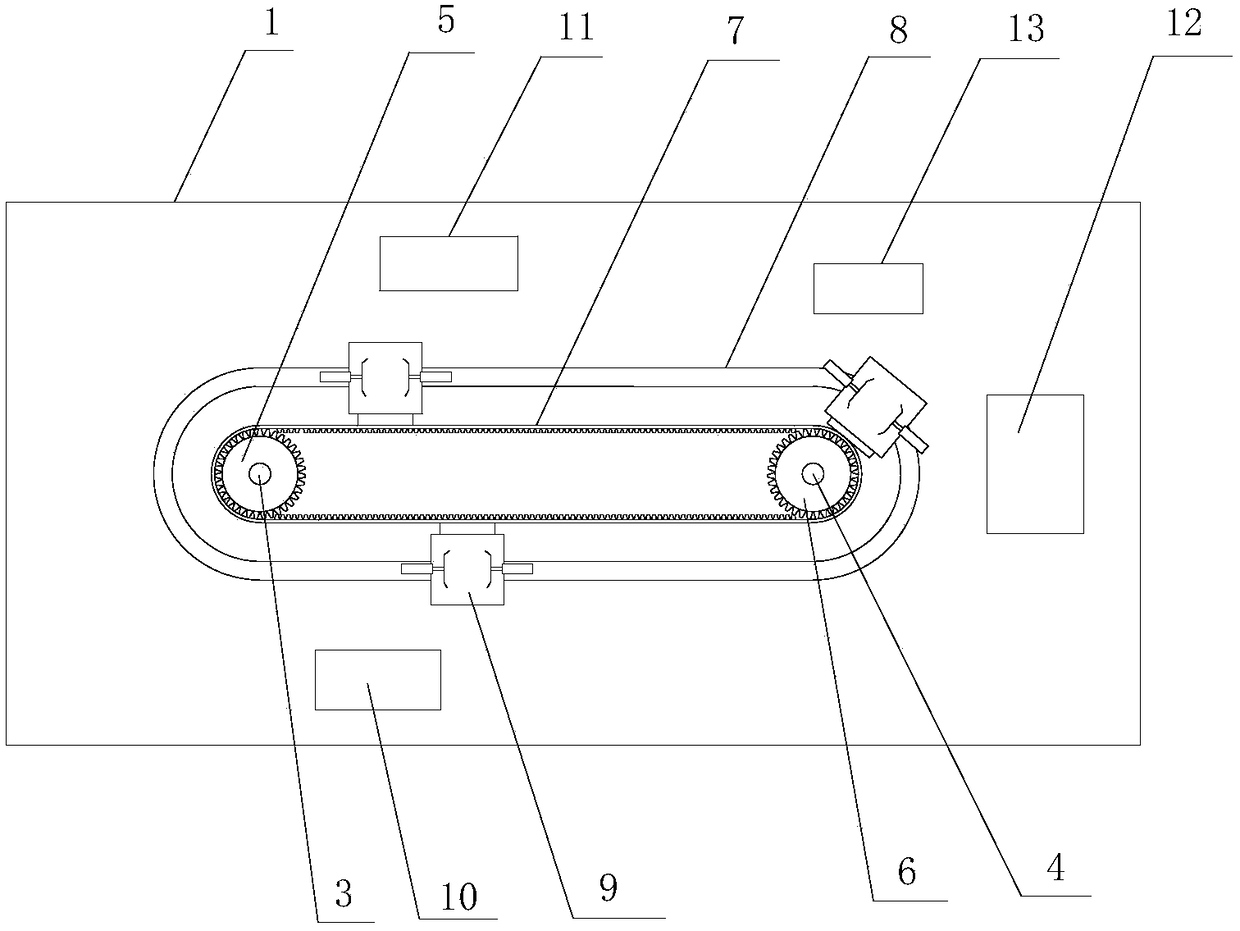

Detection and good product identification device of fingerprint chip

InactiveCN108190141AEasy accessFlexible and convenient settingsPackaging automatic controlIntegrated operationsEngineering

The invention discloses a detection and good product identification device of a fingerprint chip. The detection and good product identification device comprises a bottom plate, a rotary disc seat, a rotary disc, a plurality of testing carriers, a cover opening mechanism and a packaging mechanism, wherein the rotary disc seat, the cover opening mechanism and the packaging mechanism are fixedly mounted on the upper surface of the bottom plate; testing seats are embedded in through holes of carrying plates; testing plates are mounted on the lower surfaces of the carrying plates and are positionedbelow the testing seats; hook parts of buckles are buckled with clamping parts; a movable plate is in contact connection with pressing parts of the buckles of the testing carriers; the packaging mechanism further comprises a material suction mechanism, a good product conveying mechanism and a degraded product conveying mechanism; the good product conveying mechanism and the degraded product conveying mechanism are parallelly arranged; a supporting seat is mounted on the upper surface of the bottom plate; a material suction motor is mounted on the surface of the inner side of one end of the supporting seat; and a suction nozzle is fixedly connected with a sliding block mounted on a material suction screw rod in sleeving manner through a mounting block. According to the detection and good product identification device, detected products are packaged after being separately conveyed through the material suction mechanism, integrated operation of detection and packaging is achieved, and the automation degree is high.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

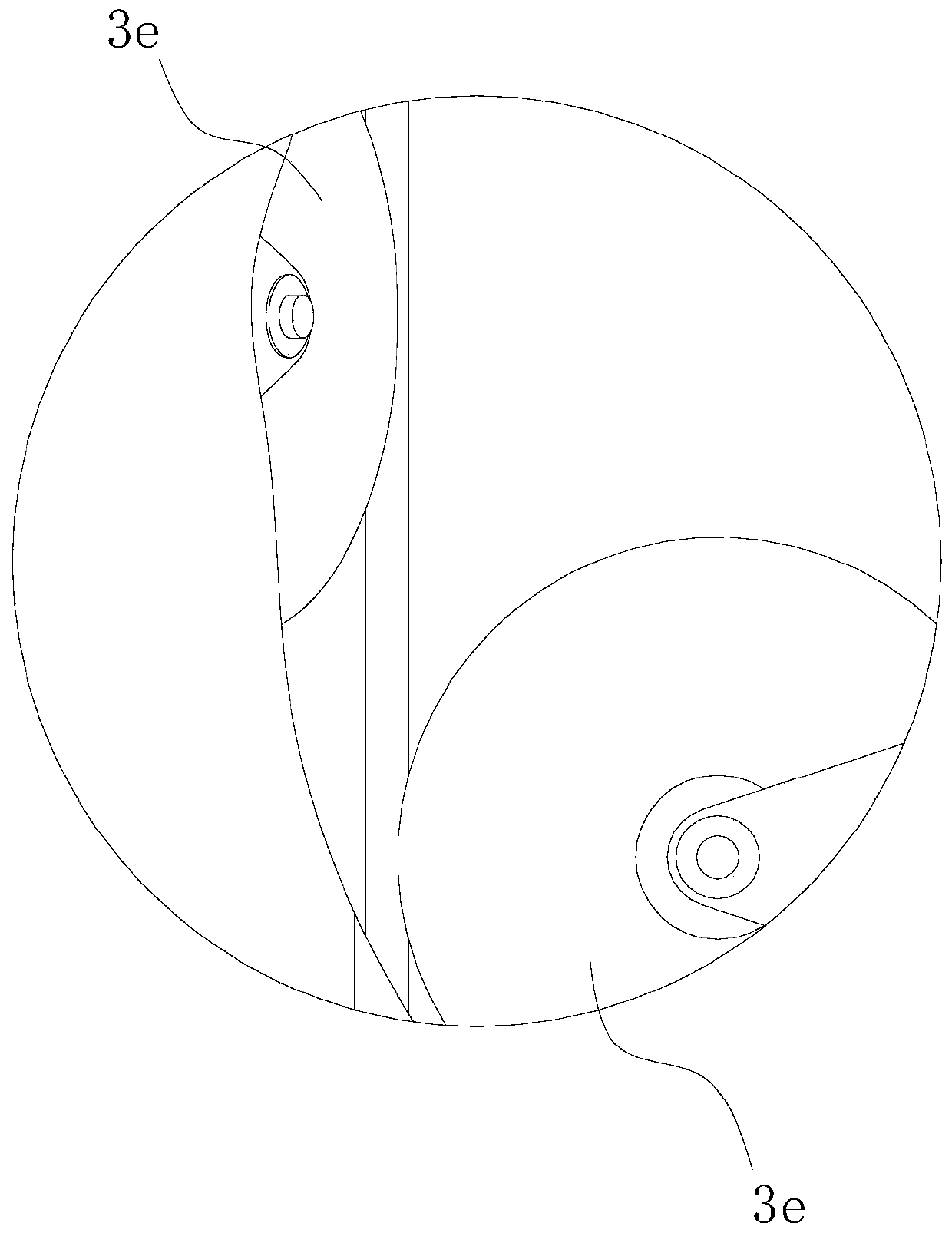

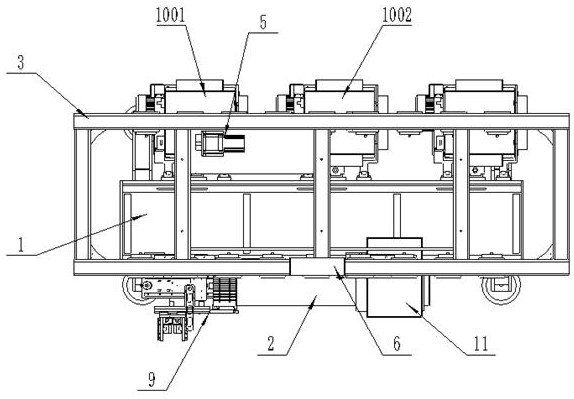

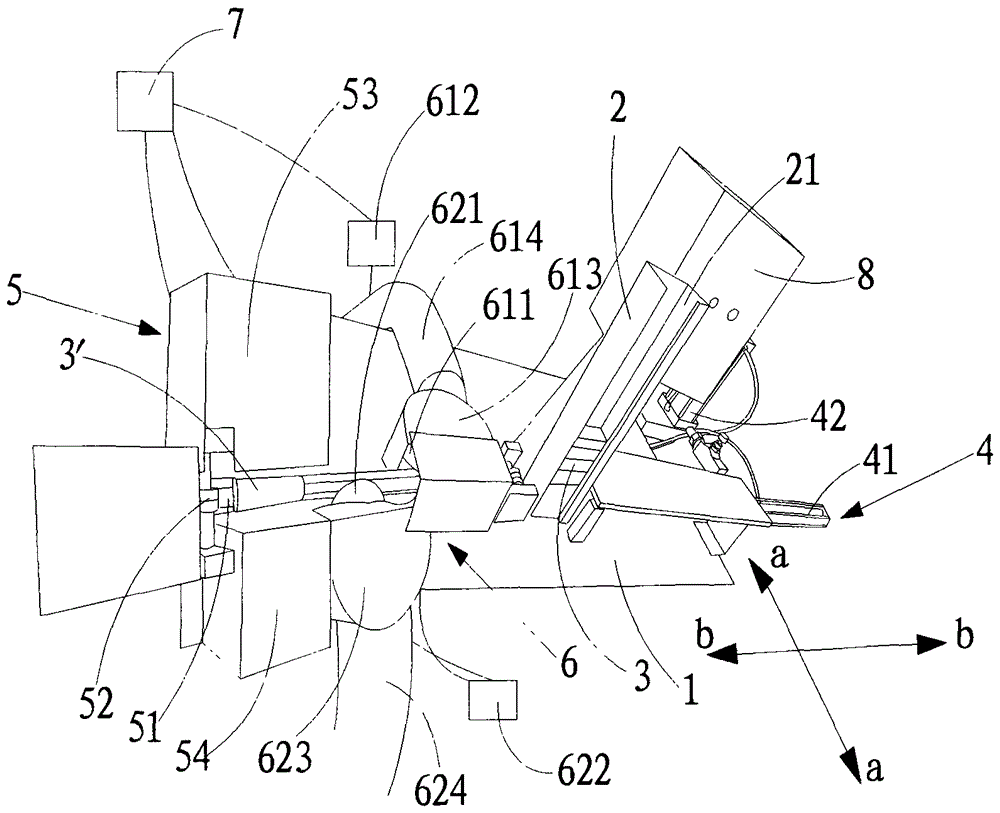

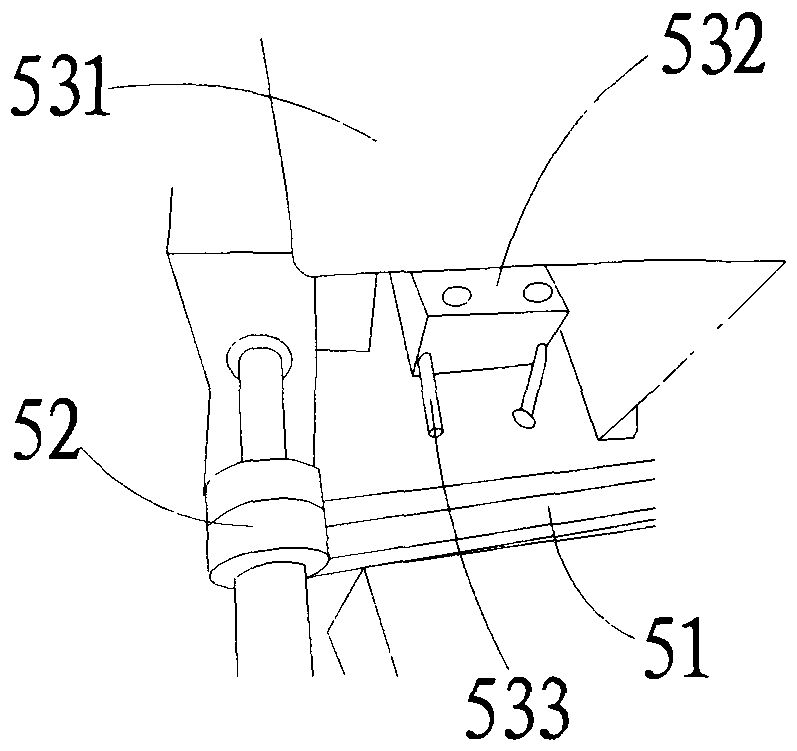

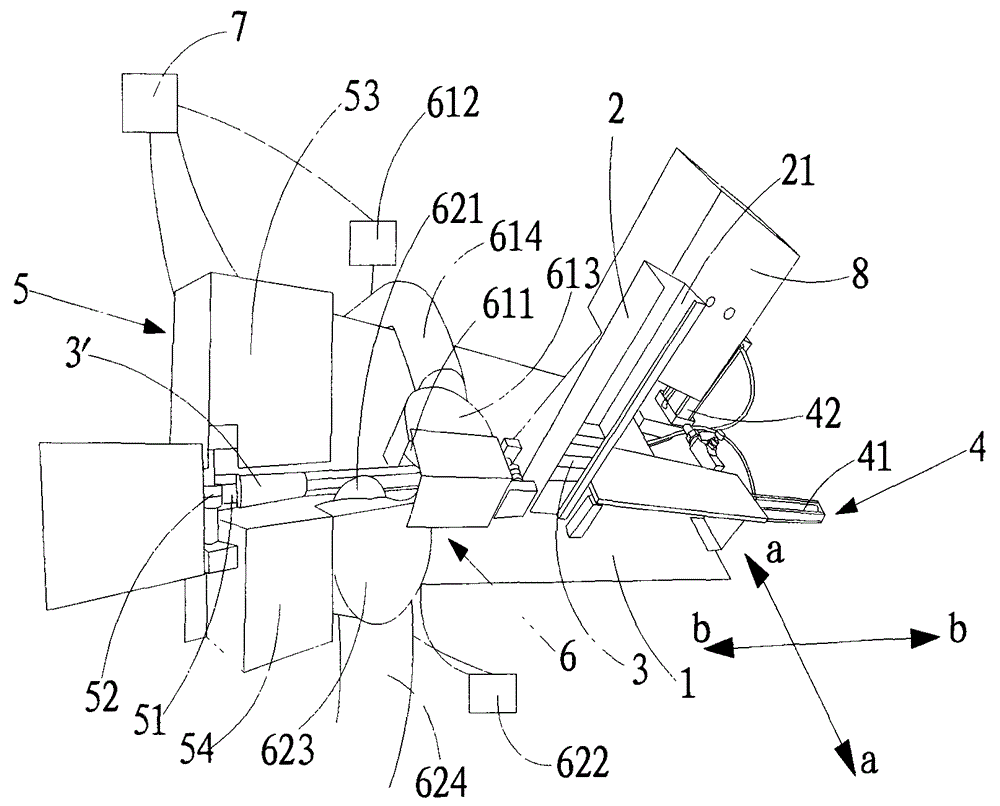

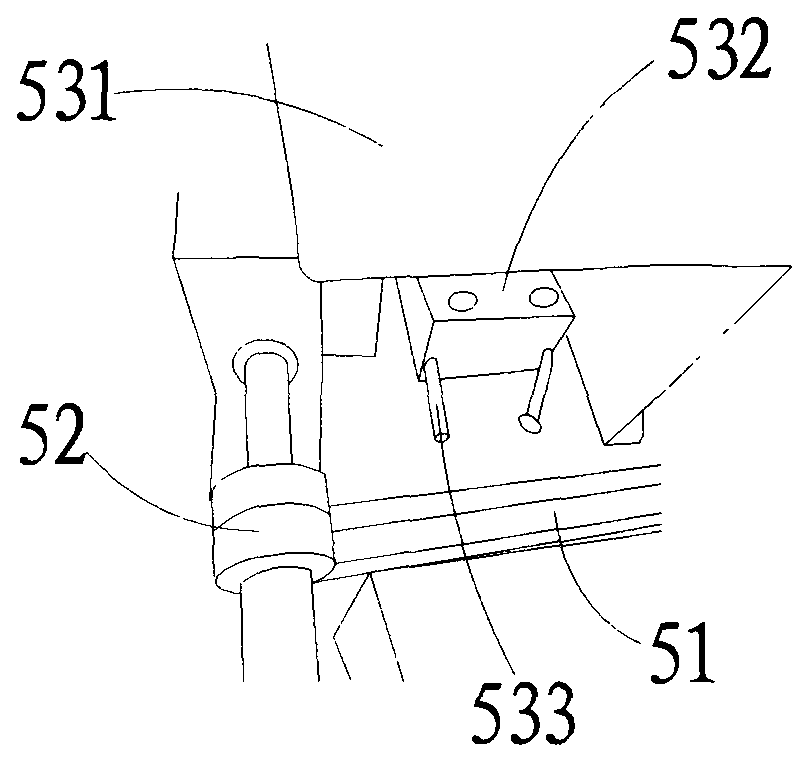

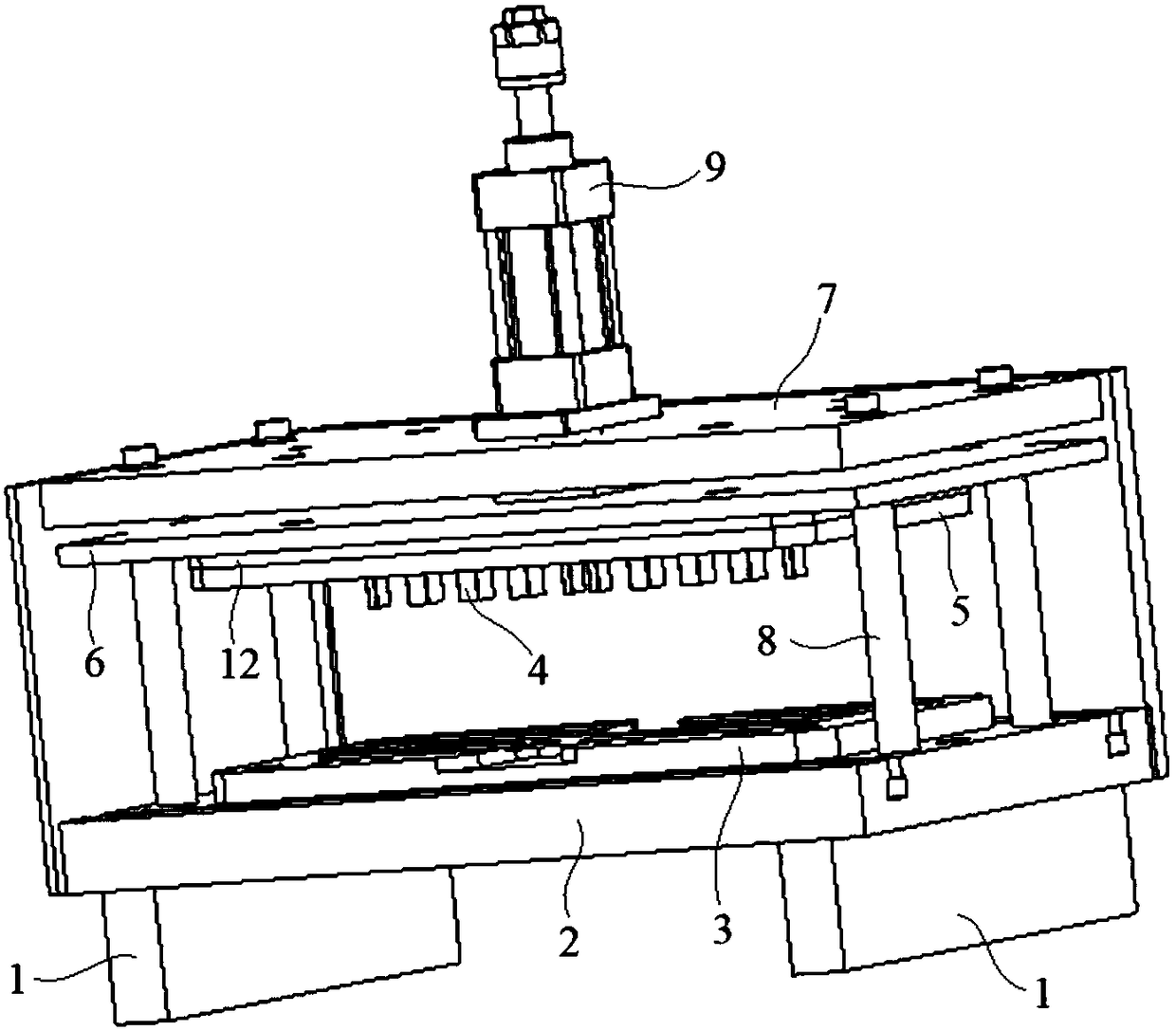

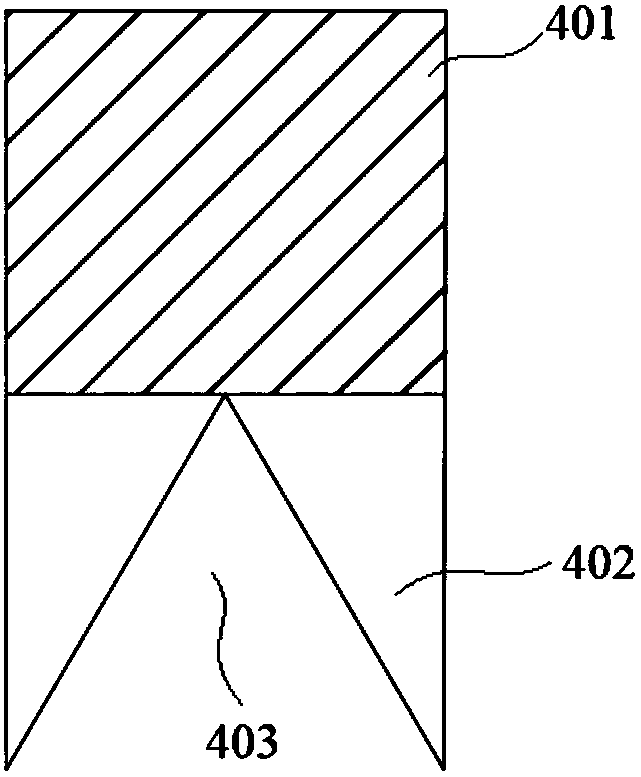

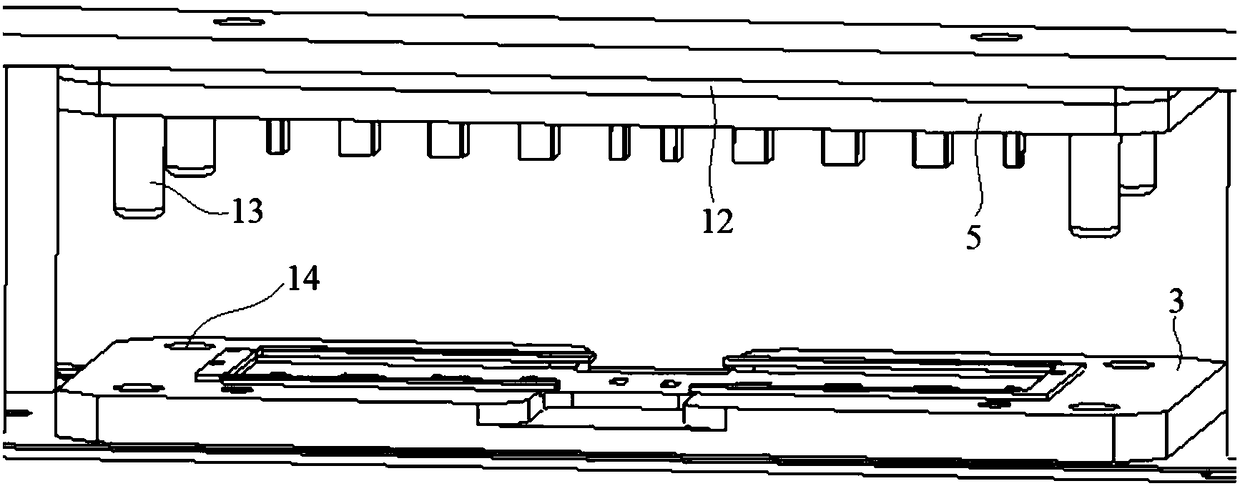

Arc-shaped thin-walled part outer surface grinding machine tool

ActiveCN108608326ARealize continuous grindingAvoid deformationGrinding machinesGrinding work supportsEngineeringGrinding wheel

The invention discloses an arc-shaped thin-walled part outer surface grinding machine tool. The arc-shaped thin-walled part outer surface grinding machine tool comprises a base, N supporting plates, Nrotary shafts, N first driving mechanisms and N grinding mechanisms. The N supporting plates are fixedly mounted on the base. The upper portion of each supporting plate is provided with a rotary plate arranged coaxially with the supporting plate. The other ends of the N rotary shafts penetrate through the N supporting plates correspondingly to be fixedly connected with the N rotary plates. The Nfirst driving mechanisms are fixedly connected with the N rotary shafts correspondingly. The mounting base is mounted on the rotary plates. A second driving mechanism is mounted on the mounting base.The second driving mechanism is connected with a movable block and drives the movable block to move up and down in the vertical direction. A third driving mechanism is mounted on the movable block. The third driving mechanism is connected with a grinding abrasive wheel and used for driving the grinding abrasive wheel to rotate. By arranging the supporting plates, a first clamping device and a second clamping device, arc-shaped parts can be well clamped, the fitting rate of the arc-shaped parts with the supporting plates is high, the contact area is large, and the arc-shaped parts can be effectively prevented from being deformed.

Owner:芜湖中驰机器人科技有限公司

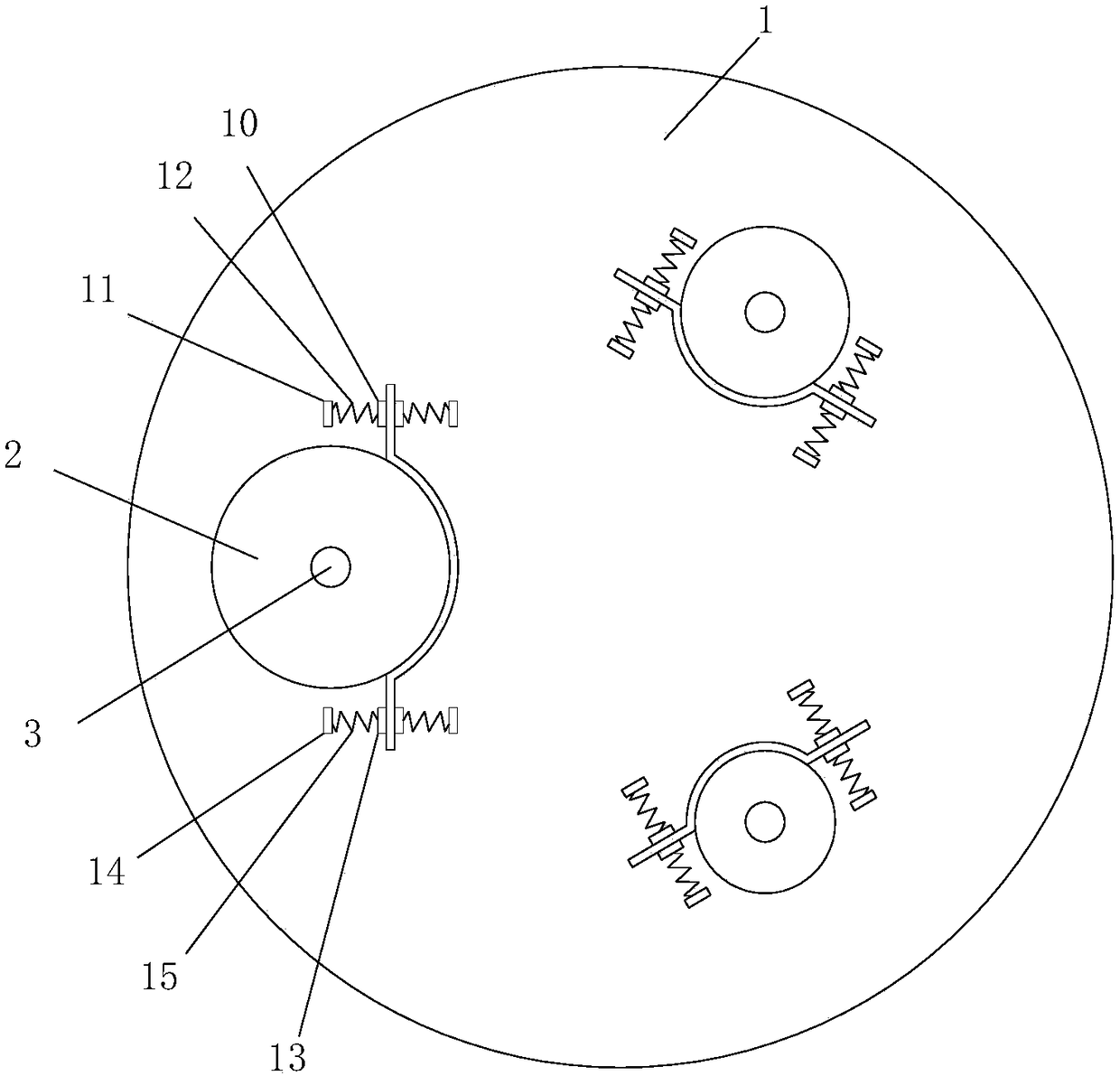

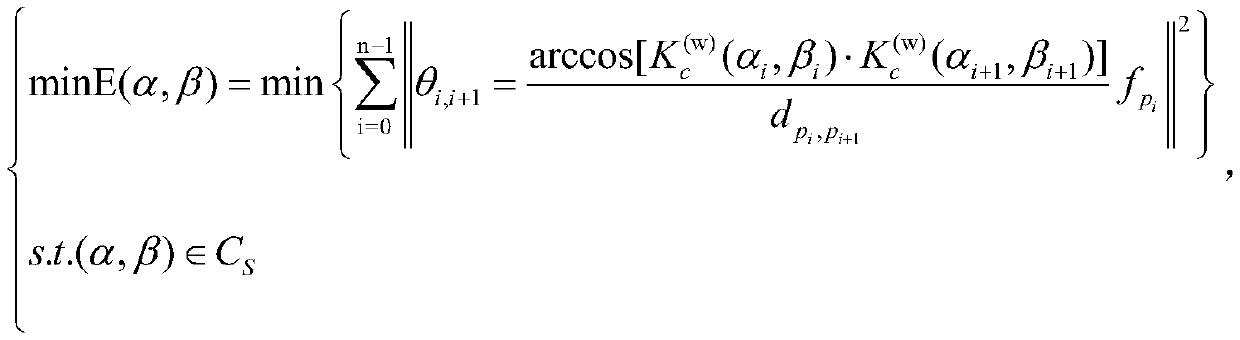

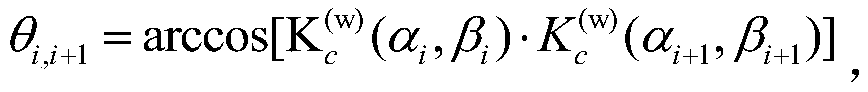

Method for adjusting position and posture of cutter shafts for grinding blade-type parts

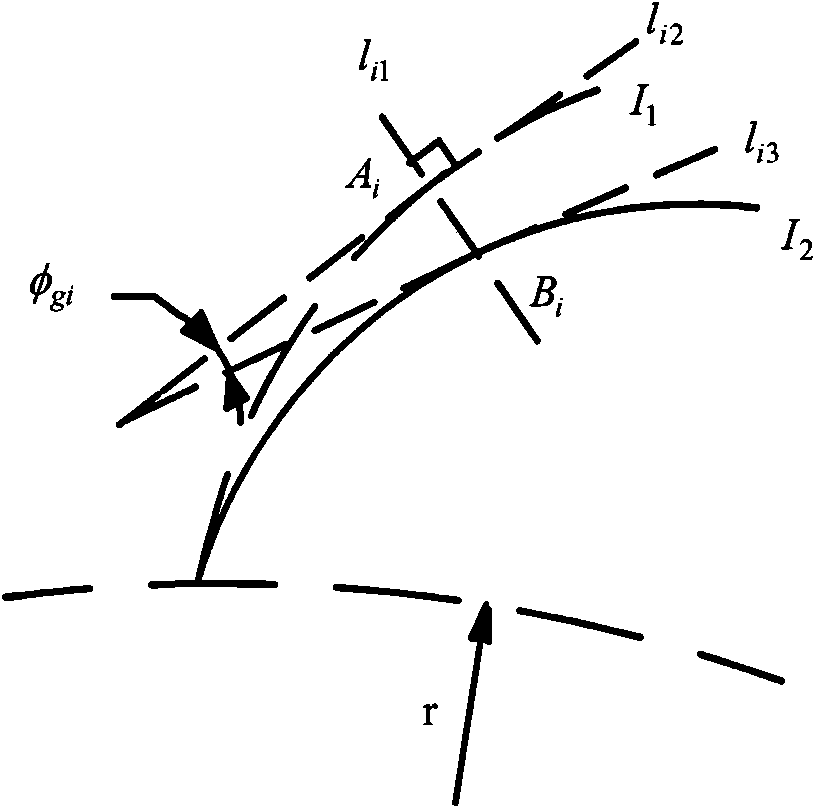

ActiveCN109857060AAchieve smooth transitionEfficient and smoothNumerical controlNumerical controlEngineering

The invention discloses a method for adjusting the position and posture of cutter shafts for grinding blade-type parts. The method comprises the following steps: 1, a cutter contact coordinate systemxi (L) and a workpiece coordinate system xi (w) are established, and cutter shaft vectors are expressed in the workpiece coordinate system as in the specification, wherein in the formula, alpha is a heel angle of the contact face of a cutter and a workpiece, and beta is a slip angle of the contact face of the cutter and the workpiece; 2, cutter contacts are discretized, the included angle theta<i,i+1> between the cutter shaft vector of the i cutter contact and the cutter shaft vector of the <i+1> cutter contact is obtained, and the motion angular speed omega<i, i+1> between the icutter contact and the <i+1> cutter contact is calculated according to the formula; and 3, the optimization target function is established, according to the optimization target function, the cutter shaft vector position and posture meeting the minimum angular speed is solved, and the motion relationship of all the shafts of a numerical control grinder is solved. The cutter can conduct smooth machining in the grinding process, the phenomenon of overcutting or interference at curvature sudden change positions of the blade-type parts is avoided, and the surface machining quality is guaranteed.

Owner:CHONGQING UNIV OF TECH

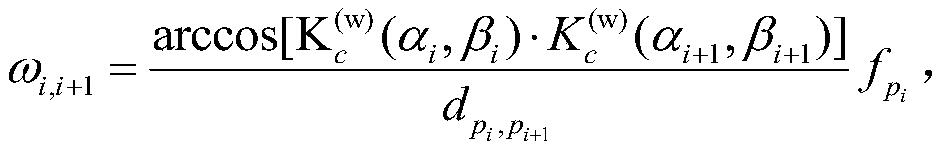

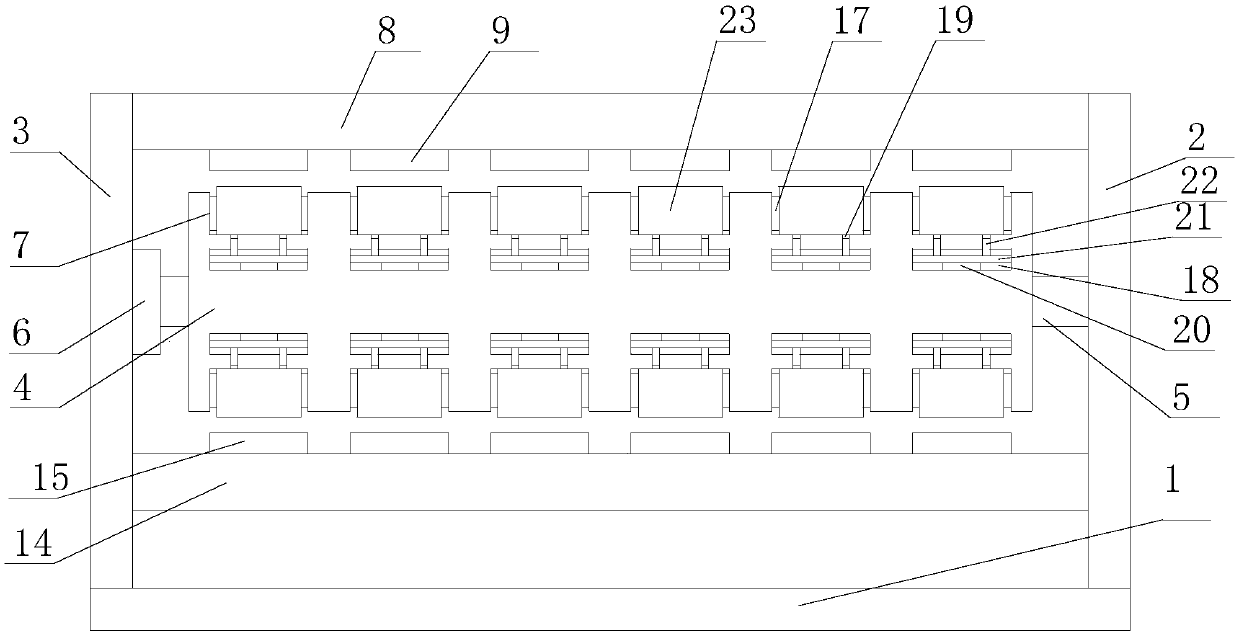

High-precision workpiece polishing machine tool

ActiveCN107309757AGuaranteed pass rateRealize continuous grindingGrinding feed controlAutomatic grinding controlMachine tool

The invention provides a high-precision workpiece polishing machine tool which comprises a base and a workpiece fixing mechanism. The workpiece fixing mechanism comprises a roller, a rotary shaft and a first driving mechanism. N rows of workpiece fixing grooves are formed in the outer wall of the roller in the circumferential direction, and each row of workpiece fixing grooves comprises the M workpiece fixing grooves formed in the axial direction of the roller at intervals; one end of the rotary shaft is rotatably connected with a first side frame, and the other end of the rotary shaft penetrates through the roller to be connected with the first driving mechanism; and a feeding mechanism used for conveying workpieces into the workpiece fixing grooves, a polishing mechanism used for polishing the workpieces fixed into the workpiece fixing grooves, a detecting mechanism used for detecting whether the polished workpieces are qualified or not and a discharging mechanism used for conveying the detected and qualified workpieces out are sequentially arranged on the periphery of the roller in the rotating direction of the roller. According to the high-precision workpiece polishing machine tool, the multiple workpieces can be polished at the same time, and the purpose of continuous polishing of the machine tool can be achieved; and through the detecting mechanism, the polished workpieces are detected, the qualification rate of workpiece polishing is ensured, and the working efficiency is improved.

Owner:芜湖中驰机器人科技有限公司

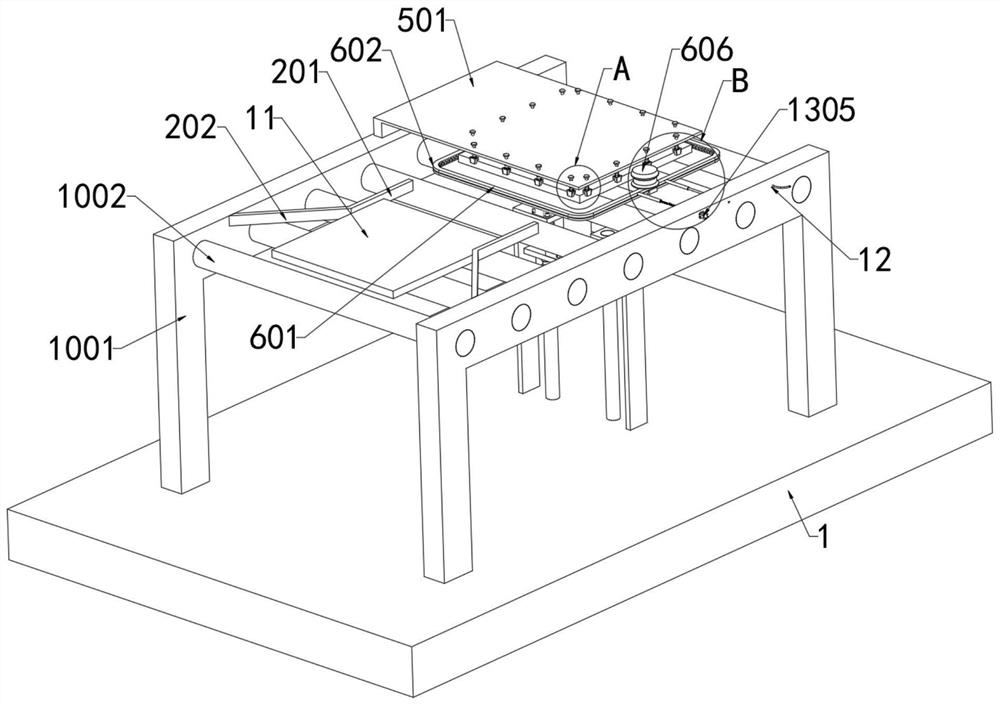

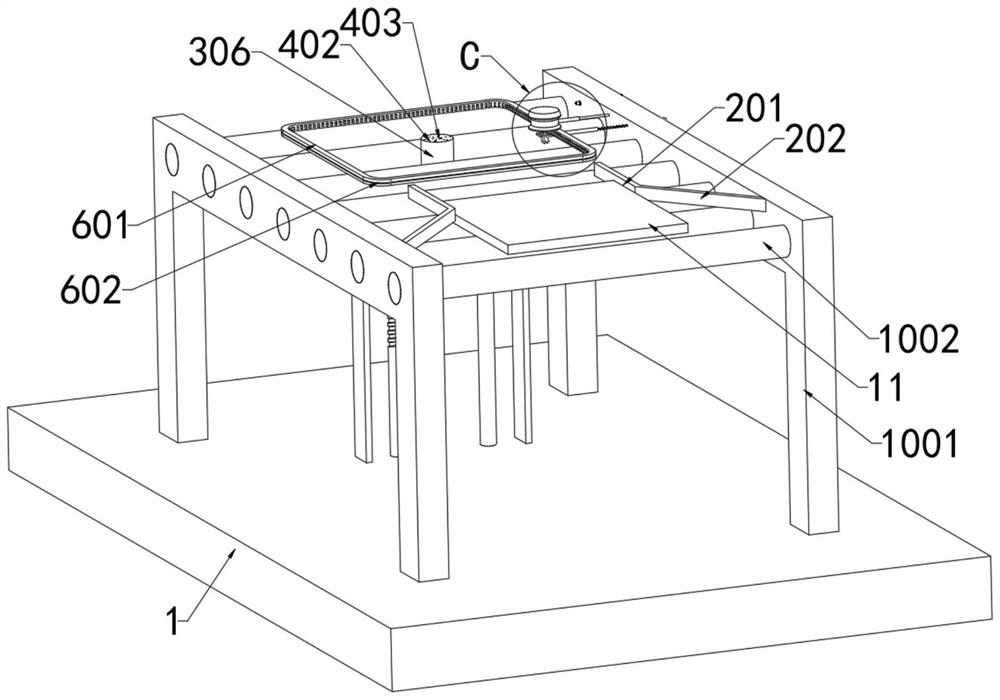

Optical lens machining, polishing and grinding device

InactiveCN114310559AReduce the hassle of manual operationRealize continuous grindingOptical surface grinding machinesGrinding drivesEngineeringOptic lens

The invention relates to a polishing and grinding device, in particular to a polishing and grinding device for optical lens machining. The invention provides an optical lens machining, polishing and grinding device with a dust falling function. An optical lens machining, polishing and grinding device comprises a water tank, a working frame, an oval track, a shielding component, a grinding part, a spraying mechanism, a discharging mechanism and the like, a blocking block is placed on the front side of the water tank, the working frame is arranged at the top of the water tank, the oval track is arranged on the inner side of the working frame, the shielding component is arranged on the top of the working frame, and the grinding part is arranged on the inner side of the oval track in a sliding mode. A spraying mechanism for dust falling is arranged in the middle of the top of the water tank, and a discharging mechanism for conveying the lenses to make contact with the grinding part is arranged on the rear side of the upper portion of the working frame. The water pump is started to pump water in the water tank into the pipeline, the water is sprayed out by the spraying part for water spraying and dust falling, meanwhile, the lens can be cleaned, and dust on the lens is cleared away.

Owner:江西超联光电科技有限公司

Piano hammer head grinding machine

InactiveCN103817574AGuaranteed processing efficiencyClear in timeGrinding machinesGrinding/polishing safety devicesPianoFixed frame

The invention provides a piano hammer head grinding machine. A grinding motor is connected with a sand tray by an adjusting bolt; the grinding motor and an air inlet of a dust sucking pipe are arranged on a support frame; a transmission lead screw and a moving rail are arranged at the same side surface of a worktable; the lower end of the support frame is connected with the transmission lead screw and the moving rail at the same time; a dust storing box is arranged at the tail end of an air outlet of the dust sucking pipe; a motor is connected with a control box connected with a dust storing box, a cylinder and the transmission lead screw; the horizontal position of the support frame is arranged on the worktable; a fixing frame is arranged above the worktable and is provided with the cylinder; the cylinder is connected with a clamp; the transmission lead screw, the moving rail and the clamp are parallel with one another. The continuous grinding on a piano strip is realized by the grinding motor, the transmission lead screw and the moving rail; the dust sucking pipe is adopted to timely clear generated dust; the piano strip is not influenced by the falling dust adhered to the surface of the piano strip in the grinding process, and the machining efficiency of the sand tray is ensured.

Owner:NANJING HONGSHENG FELT PRODION

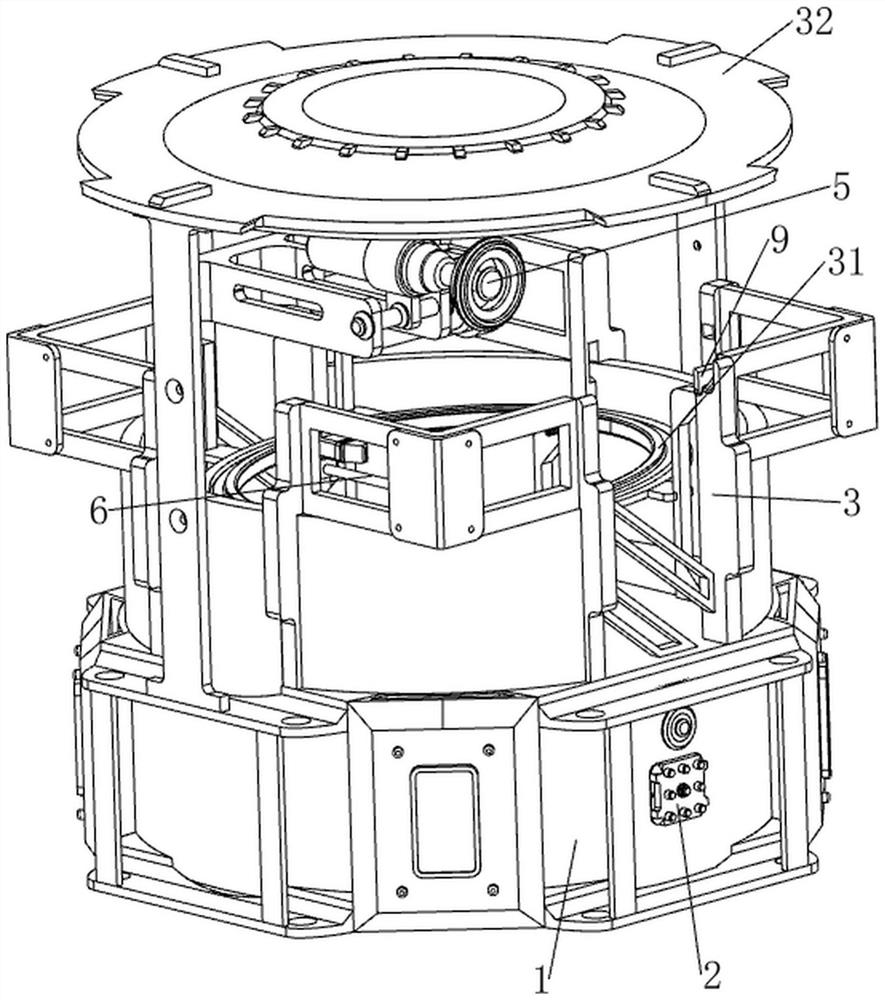

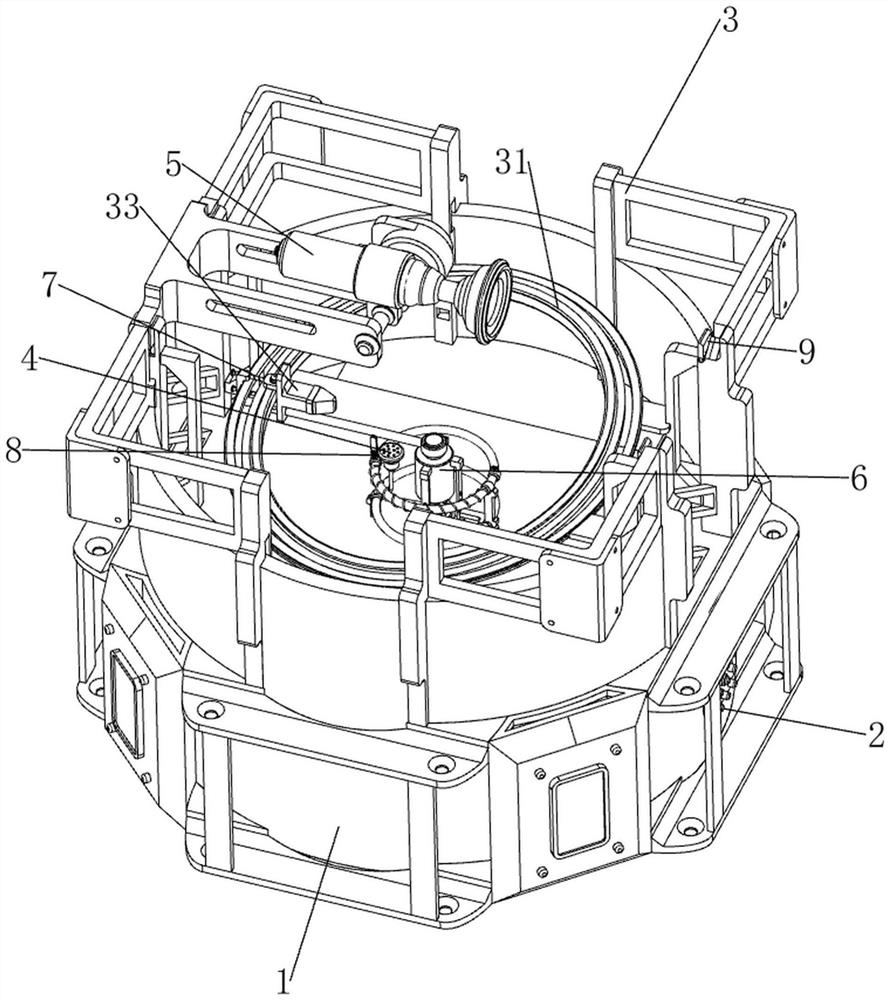

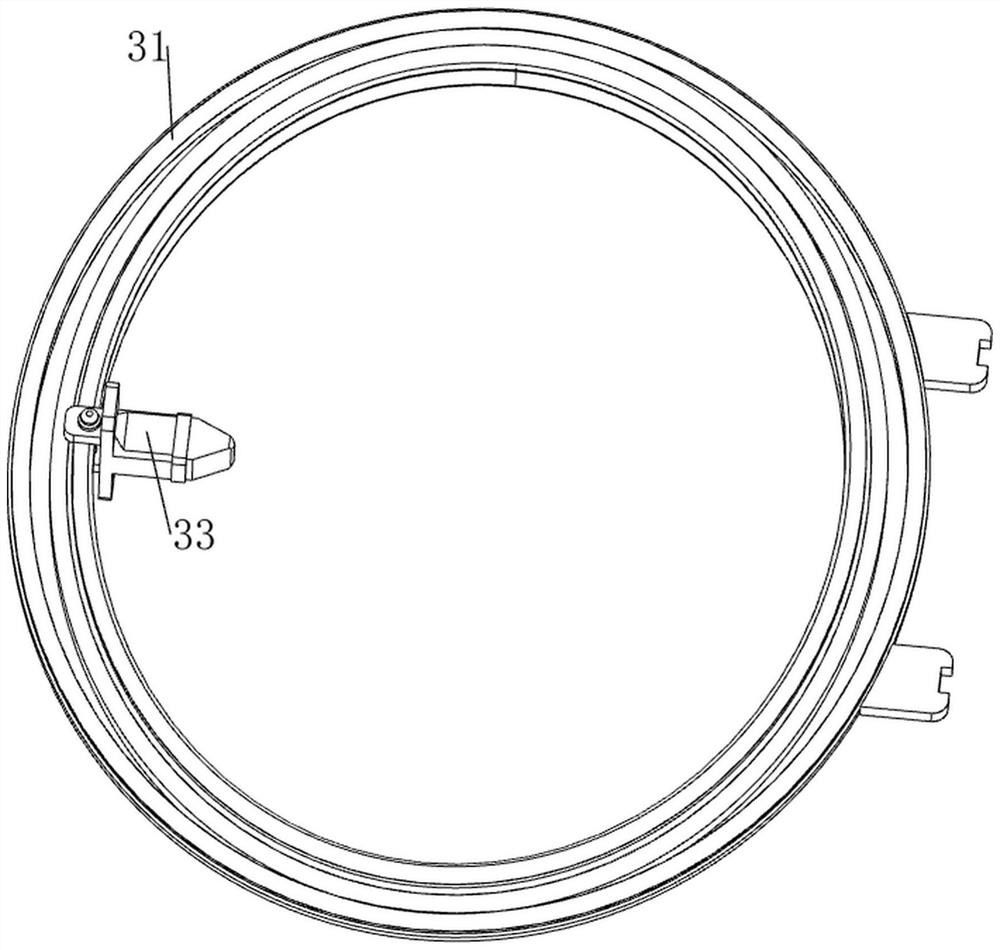

Blade edging equipment

InactiveCN112440161ARealize continuous grindingFully automaticGrinding carriagesOther manufacturing equipments/toolsElectrical controlElectric machinery

The invention belongs to the technical field of production and machining equipment, and particularly relates to blade edging equipment. The blade edging equipment comprises a lower machine base, an electric control box, an upper rack, an annular guide rail, an annular guide rail driving motor, a control screen, an automatic clamp, a discharging mechanism, a synchronous blade feeding mechanism, a spiral grinding wheel set and a receiving container. The equipment has the advantages that the annular guide rail is adopted creatively, continuous grinding of a single blade is achieved, the production efficiency of the blade is greatly improved, and full-automatic efficient production of the single blade is achieved through the automatic clamp, the discharging mechanism, the synchronous blade feeding mechanism and the like. Moreover, the equipment has the greatest advantages of adopting the spiral grinding wheel set, and two cutting edges of the blade can be ground at the same time. The cutter relieving phenomenon during single-face grinding is effectively avoided, and the geometric accuracy and the dimensional accuracy of products are greatly improved.

Owner:湖南泰鑫瓷业有限公司

Glass and preparation method thereof

InactiveCN113698808AMove doesn't happenQuality assuranceEdge grinding machinesGrinding drivesPolymer scienceMeth-

The invention relates to the technical field of glass, in particular to glass and a preparation method thereof. The invention discloses glass, which is prepared from the following raw materials in parts by mass: 70 to 80 parts of water, 4 to 5 parts of emulsifier, 2 to 3 parts of n-butyl acrylate, 6 to 7 parts of polymethylhydrosiloxane, 11 to 12 parts of polydimethylsiloxane, 14 to 15 parts of acrylic acid, 10 to 11 parts of polymethacrylate, 1 to 2 parts of tert-butyl hydroperoxide, 25 to 30 parts of polyurethane resin and 4 to 5 parts of lithium sulfate. The invention has the beneficial effects that when a glass body is polished, it can be guaranteed that the glass body cannot move in the polishing process, the polishing quality is guaranteed, meanwhile, an air pump is started, air exhaust operation is conducted on a supporting pipe, therefore, suction force exists on the glass body at the position of a through hole, the limiting effect is better, and in addition, the corners of the glass body can be continuously polished through one polishing head, the whole polishing operation is completed, the polishing efficiency is higher, polishing is more uniform and smoother, and the polishing quality is guaranteed.

Owner:浙江兆民玻璃技术有限公司

Numerical control grinding and machining method of stepwise variable pressure angle involute gear

InactiveCN101875139BRealize continuous grindingImprove processing efficiencyGear teethInvolute gearGear wheel

Owner:HEFEI UNIV OF TECH

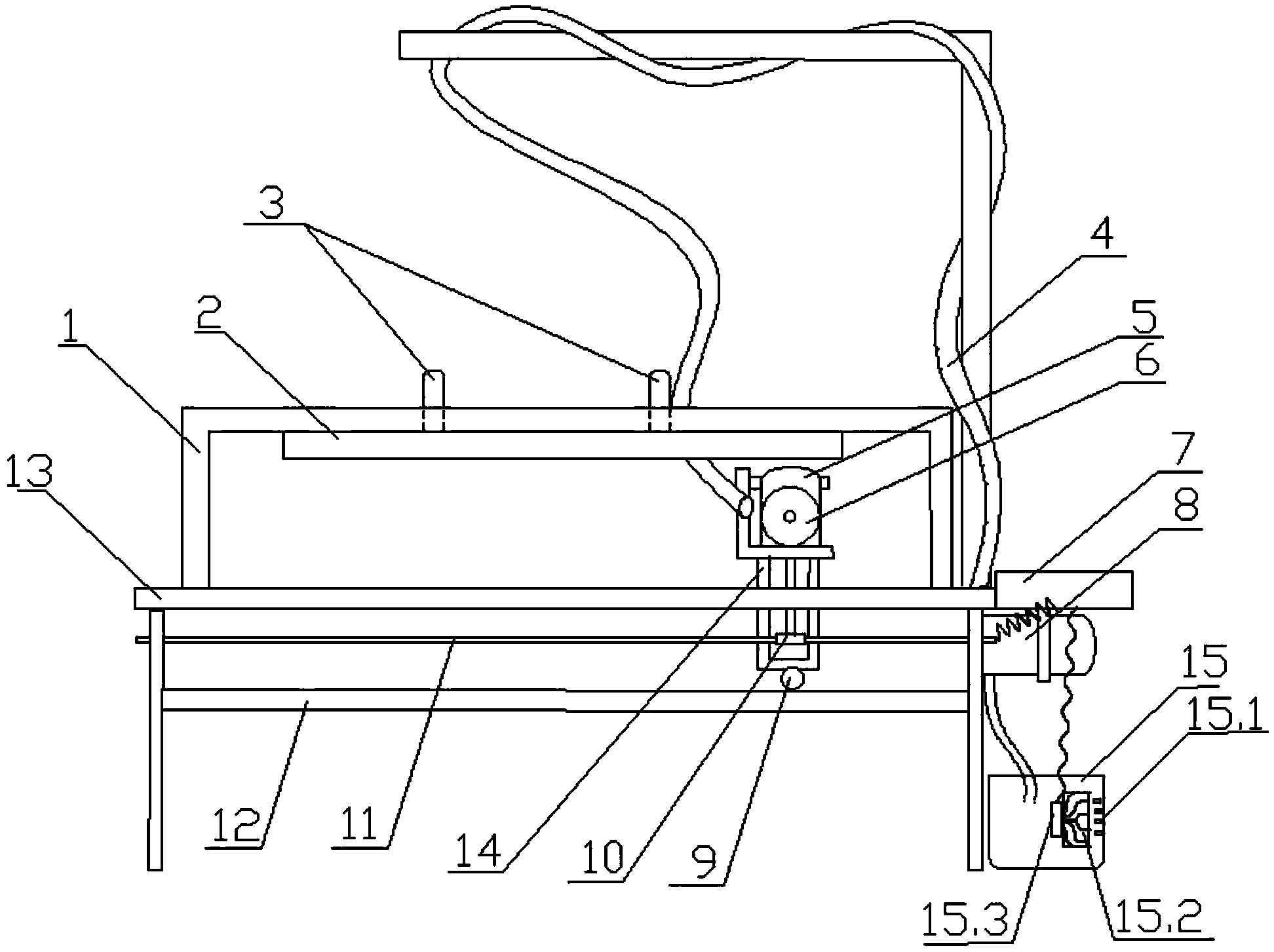

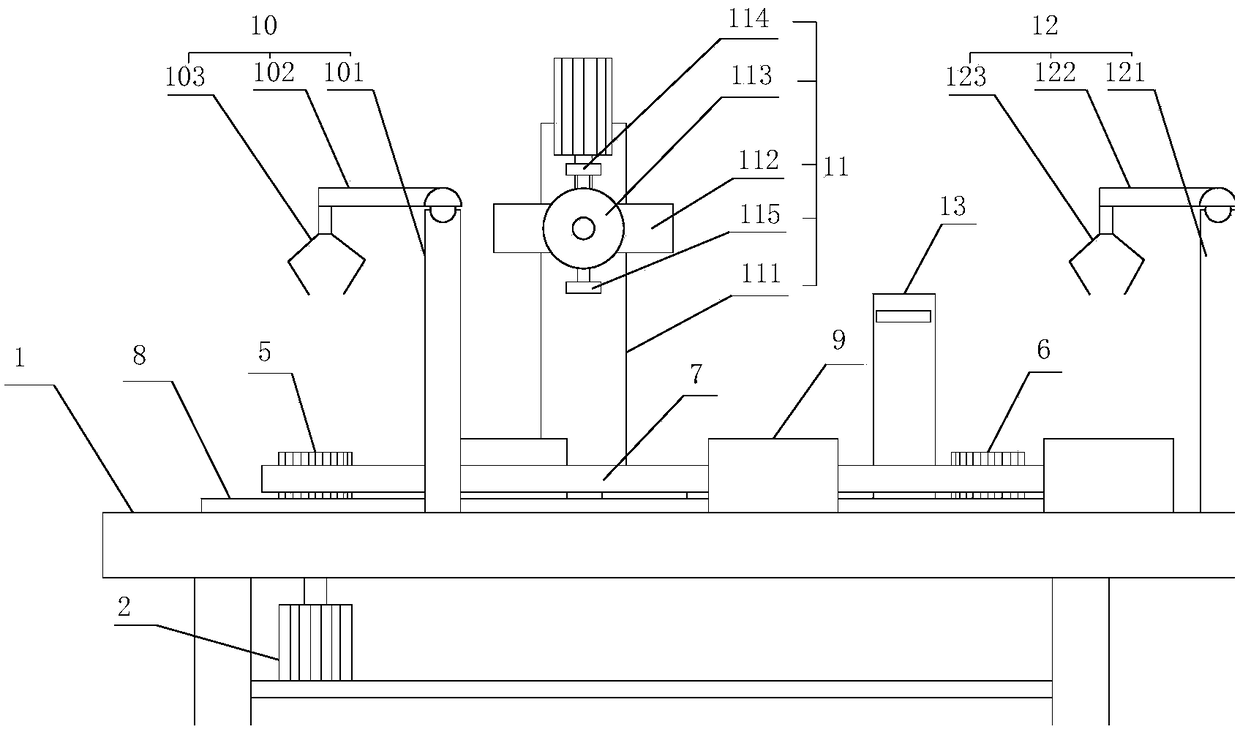

Shaft high grinder

ActiveCN104162825BRealize continuous grindingHigh grinding positioning accuracyGrinding drivesGrinding machinesReciprocating motionGrinding wheel

The invention discloses a shaft height grinding machine. The shaft height grinding machine comprises a machine frame (1), a conveying belt (2), a first guide rail (3), two grinding wheels (5), a driving device and a shaft height fixture, wherein the conveying belt (2) is horizontally arranged on the machine frame (1); the first guide rail (3) is arranged in front of the conveying belt (2); the two grinding wheels (5) are arranged on the machine frame (1) and can be driven by a motor (4) to move in a departing mode or an approaching mode, the axes of the two grinding wheels (5) are coaxial, and the grinding wheels (5) are parallel to the conveying belt (2) and located on one side of the first guide rail (3); the driving device is arranged on the machine frame (1) to drive the grinding wheels to move; the shaft height fixture is arranged on the machine frame (1) and is driven by a first air cylinder to conduct reciprocating motion between the two grinding wheels (5) and the first guide rail (3), and the end, close to the grinding wheels (5), of the shaft height fixture is provided with a through hole (7) used for fixing a magnetic tile. The shaft height grinding machine has the advantages that the grinding accuracy of the shaft height of a tile-shaped magnet is improved, and size deviation is reduced; moreover, the shaft height grinding machine also has the advantages of being simple in structure, convenient to operate and stable in running.

Owner:德昌电机(南京)有限公司

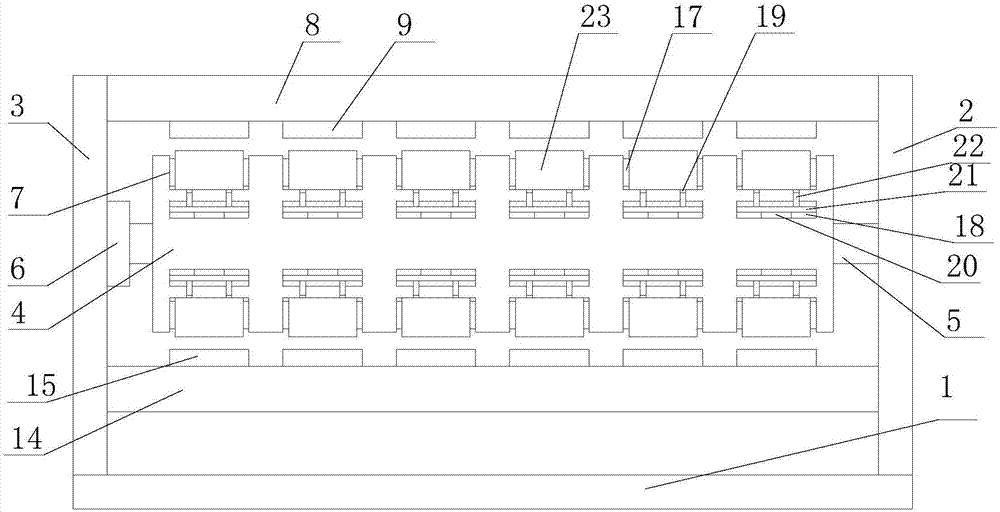

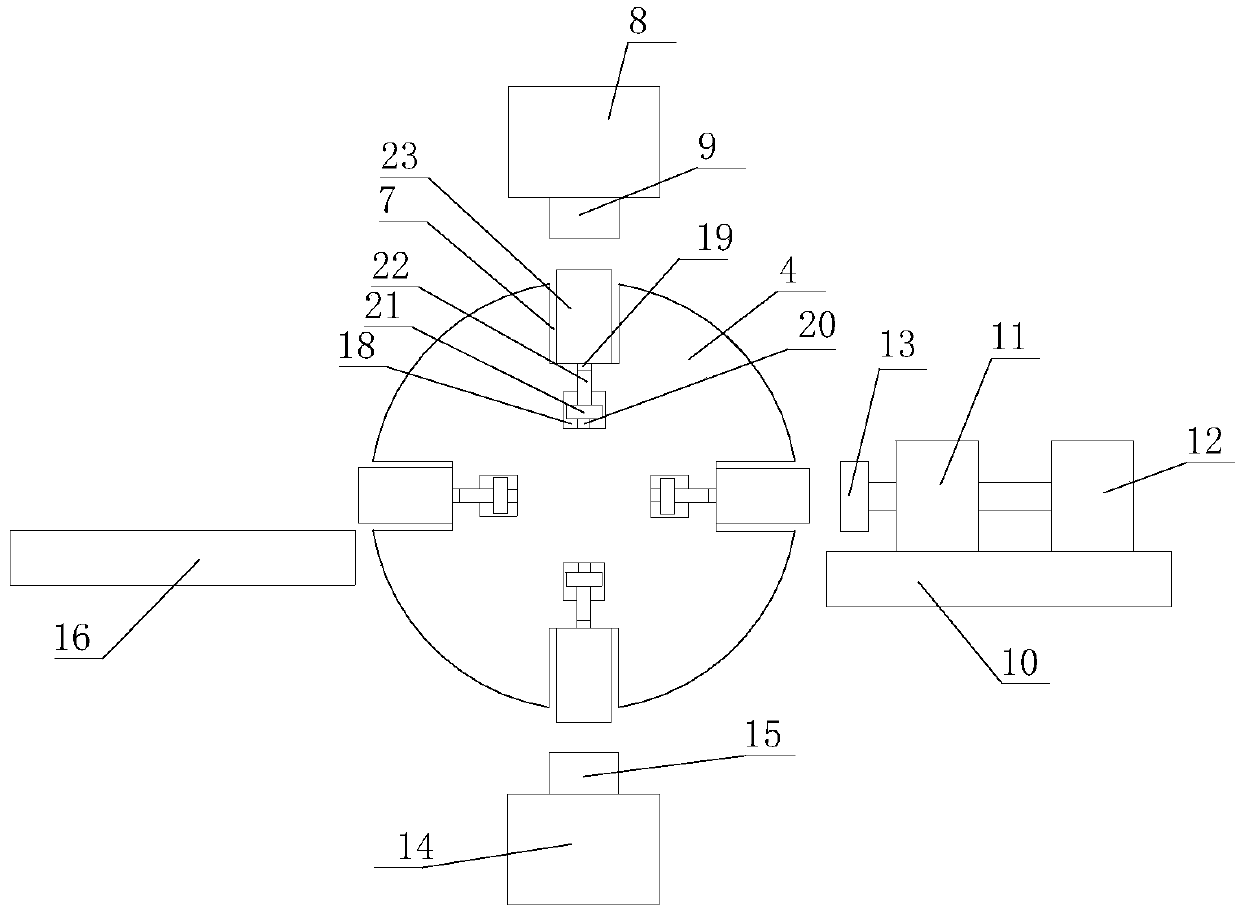

A self-checking high-precision workpiece grinding control system

ActiveCN106112758BMake sure you meet the requirementsImprove pass rateGrinding carriagesGrinding drivesControl systemEmbedded system

The invention discloses a self-detection high-precision workpiece polishing control system. The self-detection high-precision workpiece polishing control system comprises a workbench, a driving device, a slide rail, sliding tables, a feed device, a polishing device, a discharge device, a detection device and a control device; the slide rail is installed on the workbench; the sliding tables are installed on the slide rail; the feed device, the polishing device and the discharge device are annularly arranged on the periphery of the slide rail in sequence; the feed device is used for transferring to-be-polished workpieces to the sliding tables, the polishing device is used for polishing the workpieces on the sliding tables, and the discharge device is used for transferring the polished workpieces out from the sliding tables; the driving device is connected with the sliding tables and used for driving the sliding tables to do cyclic motion from the direction of the feed direction to the directions of the polishing device and the discharge device in sequence; the detection device is located between the polishing device and the discharge device and used for detecting the polished workpieces; and the control device is connected with the feed device, the polishing device and the discharge device and controls the feed device, the polishing device and the discharge device to act according to the detection result of the detection device. According to the self-detection high-precision workpiece polishing control system, the polishing precision is effectively improved.

Owner:芜湖中驰机器人科技有限公司

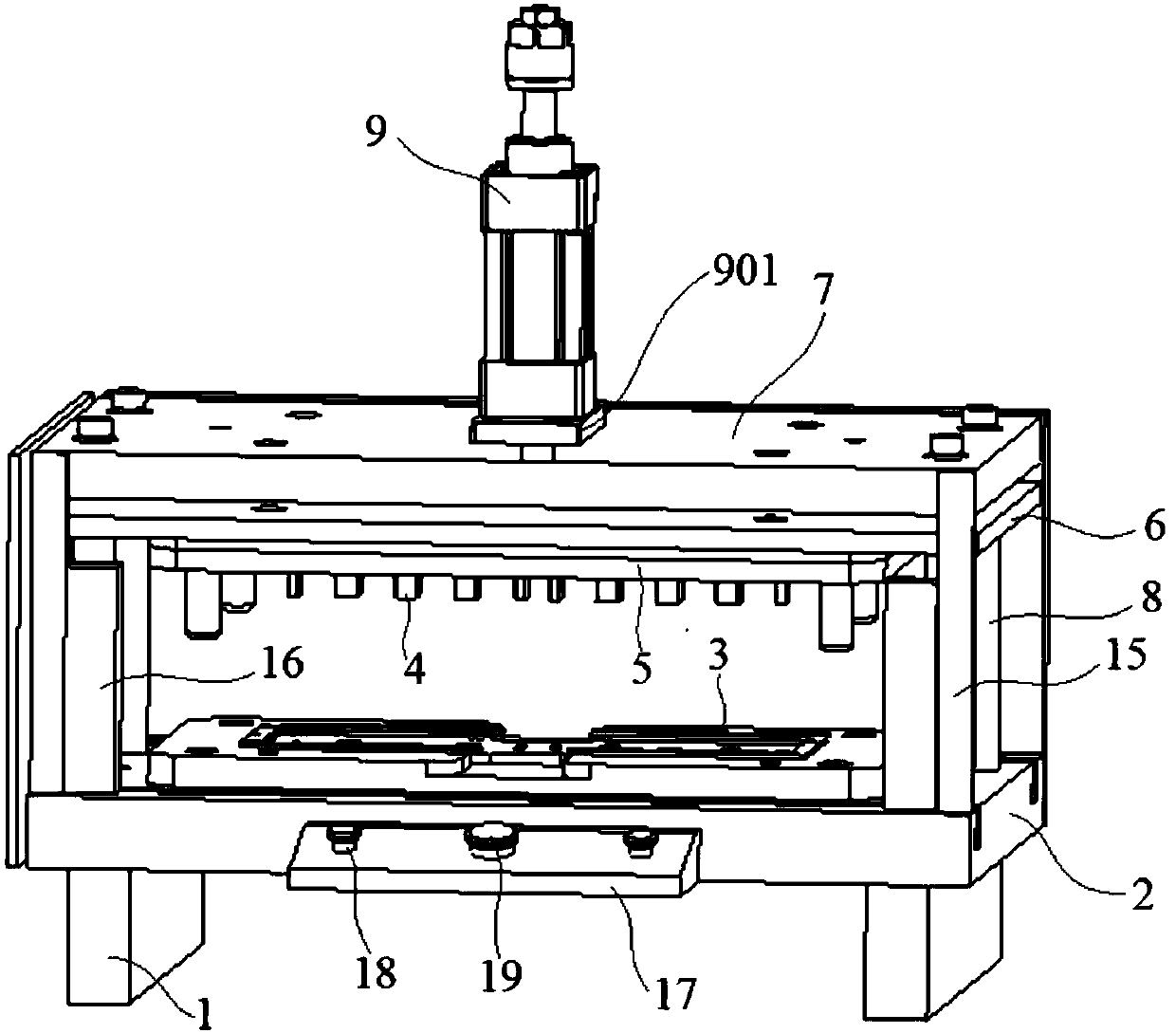

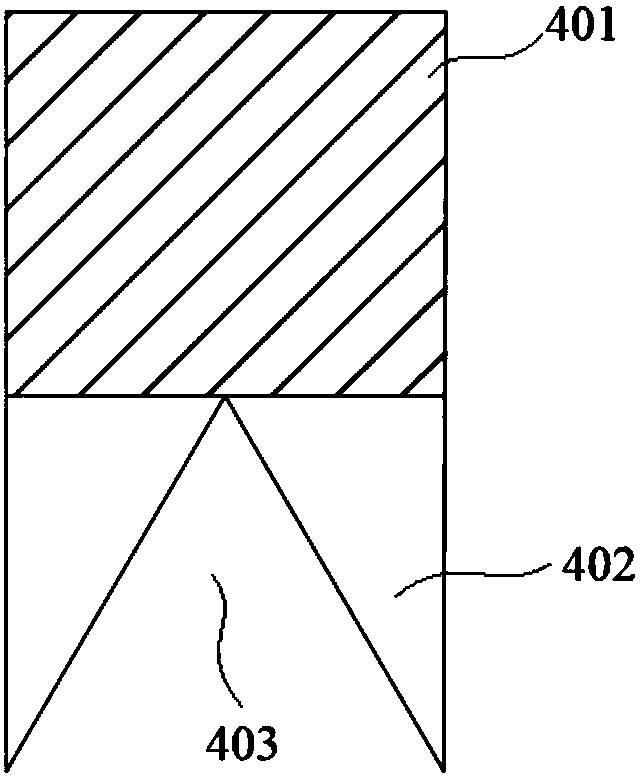

Hole punching machine with guiding column

InactiveCN109968448ASmooth movementGuaranteed accuracyRevolution surface grinding machinesGrinding feedersPunchingEngineering

The invention discloses a hole punching machine with a guiding column. The hole punching machine comprises a base, a base plate, a carrier plate, a pressing plate with a punching head, a moving plateand a fixing plate, the base plate is installed on the upper surface of the base, the upper surface of the fixing plate is provided with an air cylinder, a piston rod of the air cylinder penetrates through the fixing plate to be fixedly connected with the moving plate located below the fixing plate, the pressing plate is installed on the lower surface of the moving plate, the guiding column penetrates through a through hole, a bearing is arranged between the outer side surface of the guiding column and the inner wall of the through hole, each of the two ends of the front side of the base is provided with a connecting column, each of the inner sides of the connecting columns is fixedly provided with an alarming device, an operation table is arranged, and two starting buttons and one emergency stopping button are arranged on the operation table. According to the hole punching machine, a sharp corner part is formed on each of the two sides of the rear end of a punching head through the V-shaped groove arrangement of the punching head part to allow the contacting area of a to-be-punched carrier plate membrane to be greatly reduced to ensure the punching pressure, a better punching effect is achieved, and fringed edges of punched holes can be effectively prevented.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

Motor punching sheet deburring device based on intelligent equipment automation

InactiveCN114378670ARealize continuous grindingAchieve flushingEdge grinding machinesMagnetic bodiesPunchingGear wheel

The motor punching sheet deburring device comprises a punching sheet body and further comprises an oil tank and a grinding assembly, a driving motor is installed at the top of the oil tank, the outer end face of an output shaft of the driving motor is fixedly connected with a driving gear, and a driven gear is installed at the top of the oil tank; and a transmission chain belt is in meshing transmission with the exteriors of the driving gear and the driven gear, a rail frame is arranged on the portion, close to the periphery of the transmission chain belt, of the top of the oil tank, a plurality of mounting blocks are fixedly connected to the outer end face of the transmission chain belt at equal intervals, and transmission gears are rotationally connected to the tops of the mounting blocks through rotating shafts. According to the motor punching sheet machining device, firstly, a circulating production chain machining structure is adopted, continuous grinding, demagnetization and flushing of a production chain are achieved, and therefore the machining efficiency is improved, secondly, an automatic feeding structure is adopted, automatic discharging and feeding of motor punching sheets are completed, and the automation degree of machining is improved.

Owner:南京盈杰信息科技有限公司

Grinding equipment for drive wheels

ActiveCN107984312BTroubleshoot idle technical issuesFast processingRevolution surface grinding machinesGear wheelPolishing

The invention relates to the technical field of grinding devices, and in particular, discloses transmission wheel polishing equipment. The transmission wheel polishing equipment comprises a transmission mechanism, and a working mechanism cooperating with the transmission mechanism; the transmission mechanism comprises a start motor; an output shaft of the start motor is coaxially connected with agear; a first rack and a second rack, engaged with the gear, are respectively arranged on the two sides of the gear; rotating mechanisms are respectively mounted on the first rack and the second rack;the rotating mechanism on the first rack is arranged at the end of the rotating mechanism far from the second rack; the working mechanism comprises a conveying plate aslant arranged, and a baseplatehorizontally arranged; the downwards inclined side of the conveying plate is connected with the baseplate; polishing mechanisms cooperating with rotating columns are arranged on the two sides of the baseplate; the polishing mechanisms comprise sponges; and abrasive papers are arranged on the opposite side walls of the sponges on the two sides. The transmission wheel polishing equipment can improvethe transmission wheel polishing efficiency. The equipment can be widely applied to the transmission machining process.

Owner:宁波江北珂达汽车技术有限公司

Multifunctional casting deburring workbench

InactiveCN112388427AImprove stabilityEasy to polishEdge grinding machinesGrinding drivesDrive wheelTransmission belt

The invention relates to the technical field of grinding equipment, in particular to a multifunctional casting deburring workbench. The workbench comprises a shell and a plurality of grinding discs; the grinding discs are installed inside the shell; a workbench body is arranged below the shell; the plurality of grinding discs are installed on an installation ceiling; pulleys are arranged at the front end and the rear end of the installation ceiling and installed on sliding rails in a left-right sliding mode; the installation ceiling is fixedly connected with fixed blocks through connecting rods; the fixed blocks are installed on a transmission belt; the transmission belt is clamped on a transmission belt wheel; and a transmission belt wheel shaft is installed on the transmission belt wheeland is in transmission connection with a driving wheel through a driving belt. The workbench is simple in structural principle, low in manufacturing cost, and capable of achieving continuous grindingand deburring of castings, and the grinding and deburring efficiency of the castings is greatly improved; and the workbench has the advantages of being long in service life and high in deburring efficiency, assembly line work of deburring is achieved, the automation degree is high, the practicability is extremely high and the workbench is worthy of application and popularization.

Owner:MAANSHAN XINJIA MACHINERY MFG

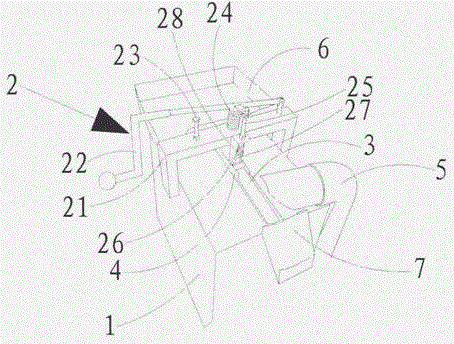

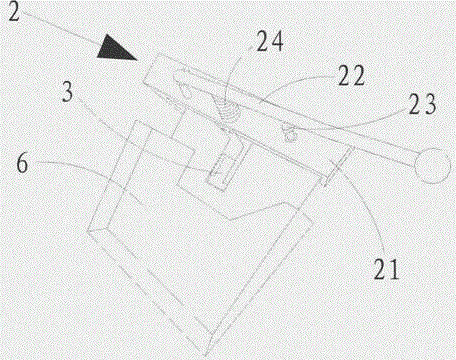

Continuous processing device for the outer surface of the small side plate of the table tennis racket

InactiveCN104149010BRealize continuous grindingReduce operating intensityGrinding machinesGrinding feedersEngineeringTennis racket

The invention relates to a continuous-type table tennis racket small side plate outer side face processing device. The device comprises an operation table, a material feeding rod, a pushing assembly, a material discharging assembly, a polishing assembly and a relay, wherein the material feeding rod is vertically arranged on the operation table; the pushing assembly is used for pushing small side plates to be processed out of a cavity; the material discharging assembly comprises a conveying rod arranged on the other side of the material feeding rod, pushing modules symmetrically arranged on two end sides of the conveying rod and a material discharging hole, and the pushing modules are used for pushing the small side plates conveyed here to the material discharging hole; the polishing assembly is used for polishing the small side plates to be processed into small side plates; the relay is used for controlling a first controller and a second controller to work sequentially. The small side plates to be processed are continuously pushed out from the cavity of the material feeding rod by means of mutual matching of the material feeding rod and the pushing assembly. By means of mutual matching of the polishing assembly and the relay, a first blade and a second blade are controlled to polish the small side plates to be processed in the vertical direction and the horizontal direction sequentially, the small side plates of a table tennis racket are continuously polished and production efficiency is improved.

Owner:YANCHENG AST SPORTING GOODS

A High Precision Workpiece Grinding Machine Tool

ActiveCN107309757BGuaranteed pass rateRealize continuous grindingGrinding feed controlAutomatic grinding controlEngineeringMachine tool

The invention provides a high-precision workpiece polishing machine tool which comprises a base and a workpiece fixing mechanism. The workpiece fixing mechanism comprises a roller, a rotary shaft and a first driving mechanism. N rows of workpiece fixing grooves are formed in the outer wall of the roller in the circumferential direction, and each row of workpiece fixing grooves comprises the M workpiece fixing grooves formed in the axial direction of the roller at intervals; one end of the rotary shaft is rotatably connected with a first side frame, and the other end of the rotary shaft penetrates through the roller to be connected with the first driving mechanism; and a feeding mechanism used for conveying workpieces into the workpiece fixing grooves, a polishing mechanism used for polishing the workpieces fixed into the workpiece fixing grooves, a detecting mechanism used for detecting whether the polished workpieces are qualified or not and a discharging mechanism used for conveying the detected and qualified workpieces out are sequentially arranged on the periphery of the roller in the rotating direction of the roller. According to the high-precision workpiece polishing machine tool, the multiple workpieces can be polished at the same time, and the purpose of continuous polishing of the machine tool can be achieved; and through the detecting mechanism, the polished workpieces are detected, the qualification rate of workpiece polishing is ensured, and the working efficiency is improved.

Owner:芜湖中驰机器人科技有限公司

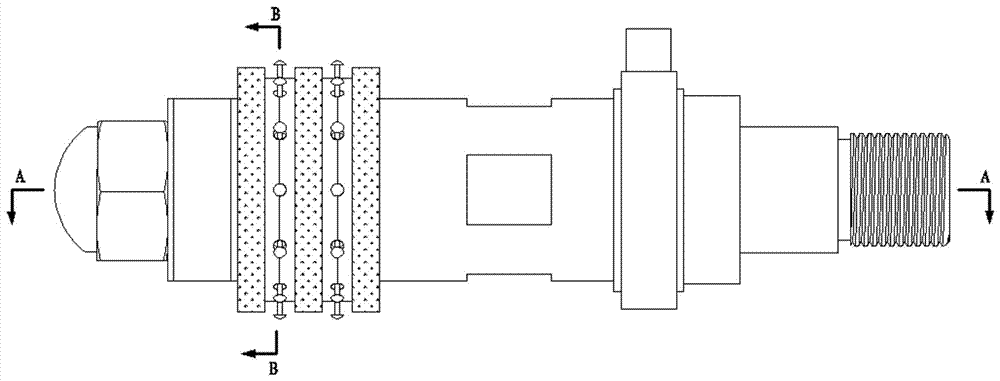

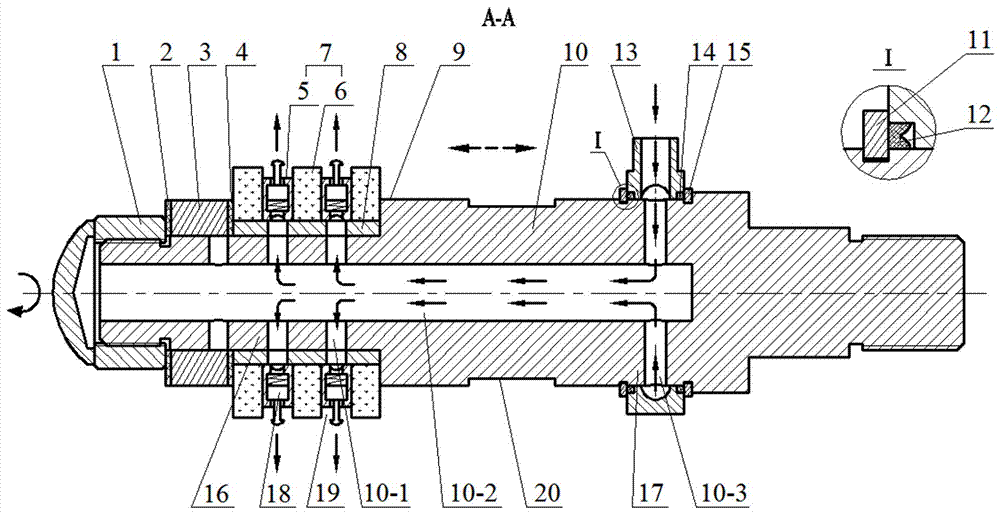

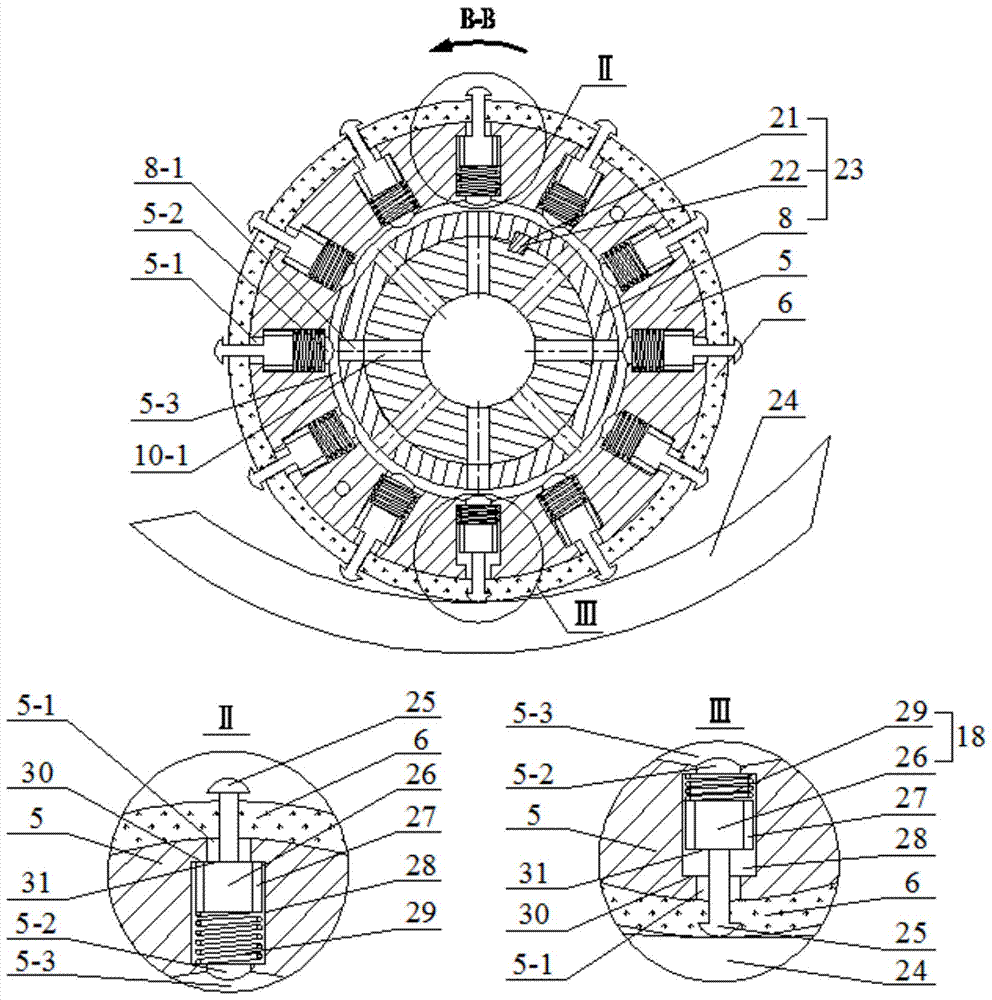

An internal grinding wheel and internal cooling system

ActiveCN105415112BReduce heat damageEffective lubricationRevolution surface grinding machinesGrinding/polishing safety devicesEngineeringGrinding wheel

The invention discloses an internal grinding wheel and an internal cooling system. The internal grinding wheel comprises a sandwich grinding wheel, a liquid supply end, a main shaft, a liquid discharging end, a flow regulating device and an automatic flow direction regulating device, wherein the sandwich grinding wheel consists of grinding rings and isolating rings which are alternately arranged; the isolating rings do not involve with grinding; the liquid supply end comprises a retainer ring, a sealing ring and a liquid supply ring; the liquid supply ring has clearance fit with the main shaft and is axially located by the retainer ring; the liquid discharging end comprises a shaft sleeve small hole, an isolating ring liquid flowing passage and a liquid discharging passage; the main shaft is communicated with the liquid supply end and the liquid discharging end; the flow regulating device comprises a key, a shaft sleeve and a shaft sleeve key slot; the flux and pressure of grinding liquid can be regulated by regulating the circumferential position of the shaft sleeve and the circumferential position of the main shaft; the automatic flow direction regulating device comprises a switch piston and a spring; the automatic flow direction regulating device can be controlled to start or stop by a piston dome on the switch piston, so that automatic regulation on liquid flow direction is realized. The internal grinding wheel disclosed by the invention has the advantages of efficiently utilizing the grinding liquid, reducing the grinding temperature and improving the grinding quality.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Continuous-type table tennis racket small side plate outer side face processing device

InactiveCN104149010ARealize continuous grindingReduce operating intensityGrinding machinesGrinding feedersEngineeringTennis racket

The invention relates to a continuous-type table tennis racket small side plate outer side face processing device. The device comprises an operation table, a material feeding rod, a pushing assembly, a material discharging assembly, a polishing assembly and a relay, wherein the material feeding rod is vertically arranged on the operation table; the pushing assembly is used for pushing small side plates to be processed out of a cavity; the material discharging assembly comprises a conveying rod arranged on the other side of the material feeding rod, pushing modules symmetrically arranged on two end sides of the conveying rod and a material discharging hole, and the pushing modules are used for pushing the small side plates conveyed here to the material discharging hole; the polishing assembly is used for polishing the small side plates to be processed into small side plates; the relay is used for controlling a first controller and a second controller to work sequentially. The small side plates to be processed are continuously pushed out from the cavity of the material feeding rod by means of mutual matching of the material feeding rod and the pushing assembly. By means of mutual matching of the polishing assembly and the relay, a first blade and a second blade are controlled to polish the small side plates to be processed in the vertical direction and the horizontal direction sequentially, the small side plates of a table tennis racket are continuously polished and production efficiency is improved.

Owner:YANCHENG AST SPORTING GOODS

Automatic punching machine for fingerprint module machining

InactiveCN108177190ASmooth movementGuaranteed accuracyRevolution surface grinding machinesGrinding feedersPunchingMachining

The invention discloses an automatic punching machine for fingerprint module machining. The automatic punching machine comprises a base, a base plate, a carrier plate, a pressing plate with a stampinghead, a movable plate and a fixed plate. The base plate is installed on the upper surface of the base, the carrier plate is arranged on the upper surface of the base plate, the base plate and the fixed plate are fixedly connected through at least two guide columns, the upper surface of the fixed plate is provided with an air cylinder, the movable plate is provided with at least two through holesthrough which the guide columns penetrate, the guide columns penetrate through the through holes, bearings are arranged between the outer side surfaces of the guide columns and the inner walls of thethrough holes, a reinforcing plate is arranged above the pressing plate and located between the pressing plate and the movable plate for fixedly connecting the pressing plate with the movable plate, the lower surface of the pressing plate is further provided with a plurality of limiting columns, and the limiting columns are used for being embedded into limiting holes in the upper surface of the carrier plate. By means of arrangement of the limiting columns and the limiting holes, positioning precision between the pressing plate and the carrier plate is ensured, and therefore stamping precisionis ensured.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

Cylinder outer circle continuous grinding device

ActiveCN108202291AImprove grinding efficiencyRealize automatic feedingGrinding drivesLapping machinesEngineeringCenter effect

The invention discloses a cylinder outer circle continuous grinding device. The grinding efficiency of a cylinder type workpiece can be greatly improved by means of the grinding device; meanwhile, when rotary grinding is conducted through grinding heads, the automatic feeding of the workpiece can be realized; since the grinding heads fit the workpiece all the time, the feeding amount of the grinding heads is small, the continuous grinding of the outer circle face of the workpiece can be realized, intermittent grinding traces can not appear, the grinding precision is high, and the surface quality is good; meanwhile, the grinding device closely fits the workpiece, so the grinding quality is greatly ensured, only the grinding heads need to be replaced when workpieces of different diameters need to be ground, and the grinding device is convenient and simple to use; meanwhile, the position of the grinding heads can be adjusted, and the applicability of the grinding device is improved; the centering effect of the grinding heads can be ensured by adjusting an adjusting rod; meanwhile, during grinding, due to the rotation of the grinding heads, self-centered grinding is facilitated, and the grinding effect is improved.

Owner:XUCHANG UNIV

A continuous cylindrical grinding device

ActiveCN108202291BImprove grinding efficiencyRealize automatic feedingGrinding drivesLapping machinesEngineeringMaterials science

The invention discloses a cylinder outer circle continuous grinding device. The grinding efficiency of a cylinder type workpiece can be greatly improved by means of the grinding device; meanwhile, when rotary grinding is conducted through grinding heads, the automatic feeding of the workpiece can be realized; since the grinding heads fit the workpiece all the time, the feeding amount of the grinding heads is small, the continuous grinding of the outer circle face of the workpiece can be realized, intermittent grinding traces can not appear, the grinding precision is high, and the surface quality is good; meanwhile, the grinding device closely fits the workpiece, so the grinding quality is greatly ensured, only the grinding heads need to be replaced when workpieces of different diameters need to be ground, and the grinding device is convenient and simple to use; meanwhile, the position of the grinding heads can be adjusted, and the applicability of the grinding device is improved; the centering effect of the grinding heads can be ensured by adjusting an adjusting rod; meanwhile, during grinding, due to the rotation of the grinding heads, self-centered grinding is facilitated, and the grinding effect is improved.

Owner:XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com