Glass and preparation method thereof

A glass and emulsifier technology, applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems affecting the quality of grinding, uneven joints, easy to burst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

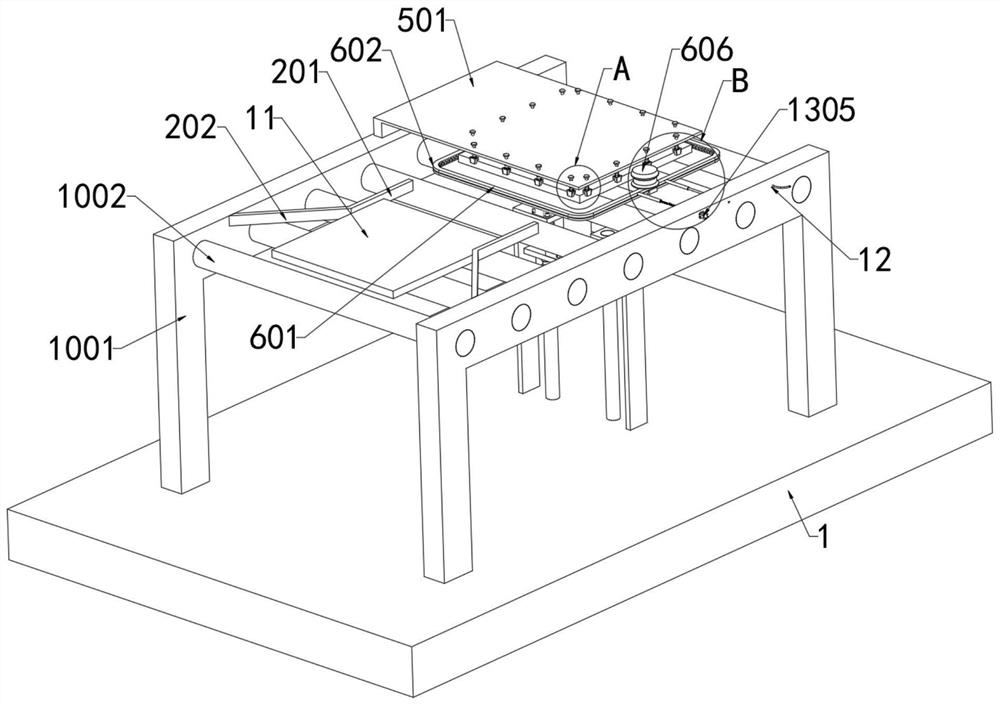

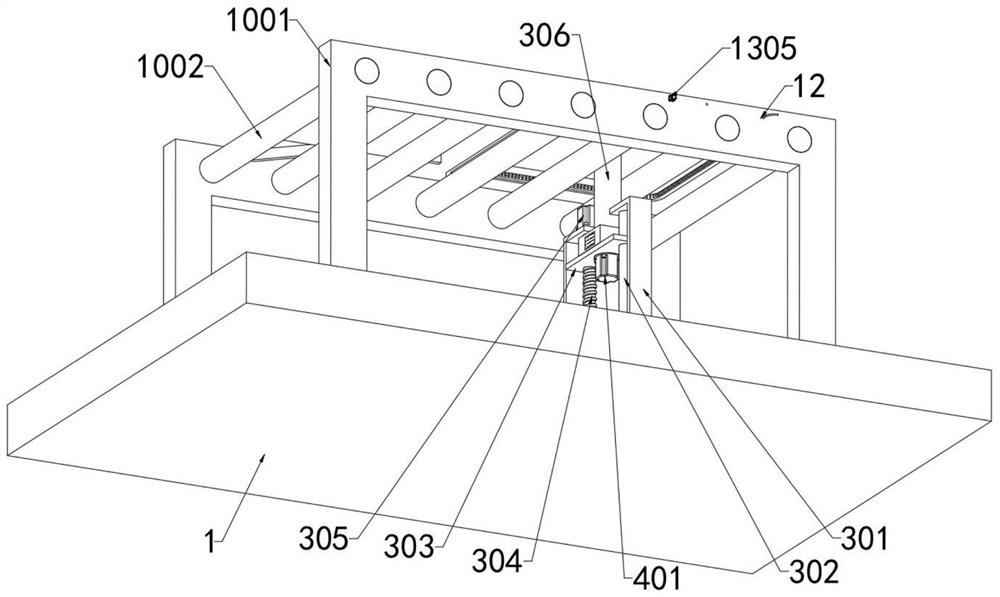

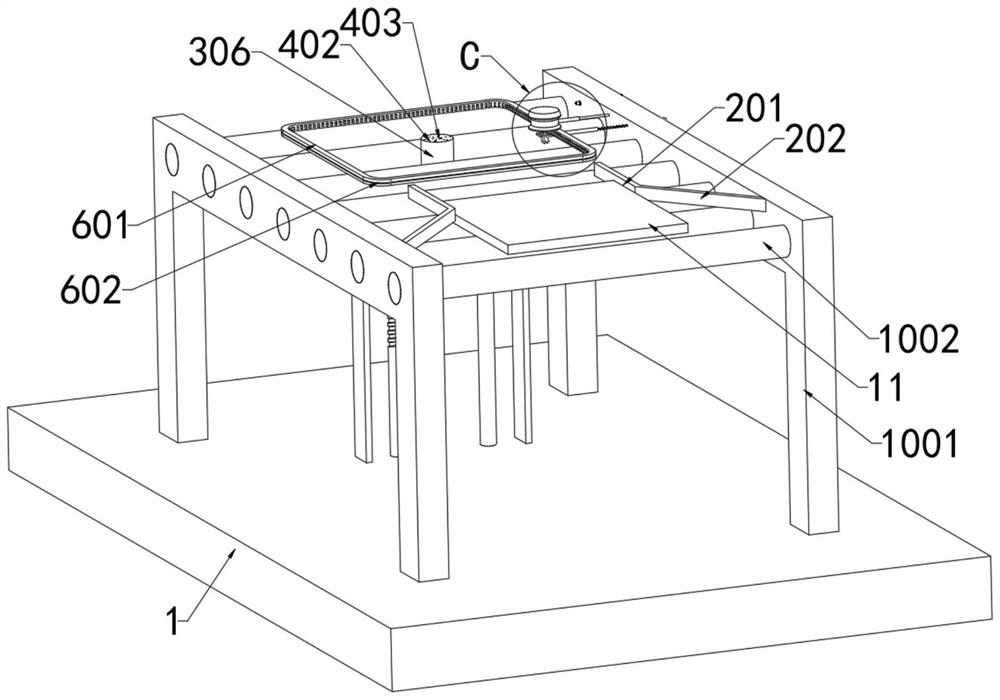

[0041] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0042] Tempered glass is a kind of glass, which belongs to safety glass. It is a kind of prestressed glass. In order to improve the strength of glass, chemical or physical methods are usually used to form compressive stress on the glass surface. When the glass is subjected to external force, the surface stress is first offset. The bearing capacity is improved, and the glass's own wind pressure resistance, cold and heat resistance, impact resistance, etc. are enhanced.

[0043] The inventor conducted in-depth investigation and research on the preparation process of tempered glass and found that; during the preparation of tempered glass, it needs to go through steps such as cutting, edging, washing, drying and temperin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com