System for manufacturing LED

A technology for a workbench and a positioning base, which is applied to parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

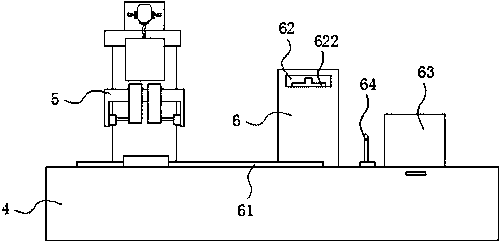

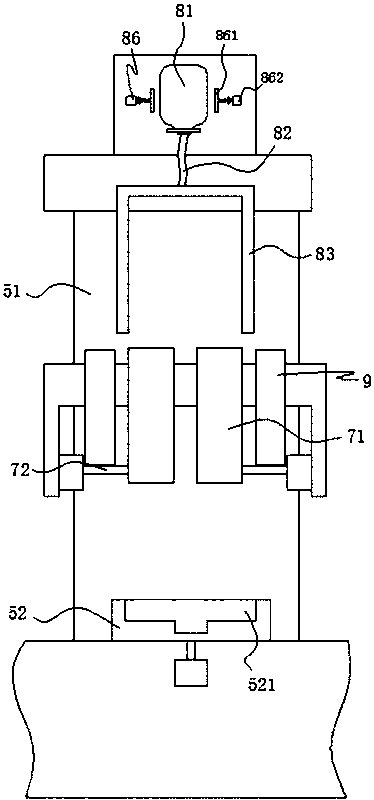

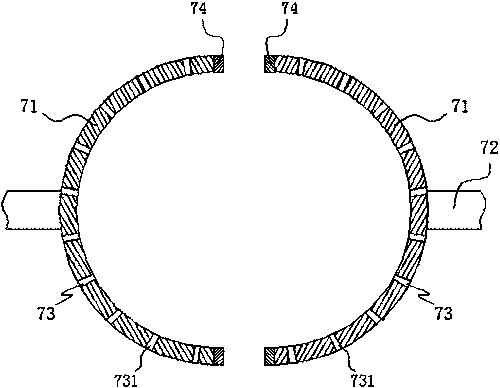

[0030] like Figure 1-9 as shown in Figure 8-9As described above, an LED lamp includes a cylindrical inner core 1 and an outer shell 2 covering the inner core, the outer shell is a cylindrical structure, and the lower part is provided with an opening, and an end cover is screwed to the lower opening; The outer surface of the inner core 1 is provided with multi-turn LED lamp assemblies 11, and these multi-turn LED lamp assemblies 11 are evenly distributed along the length direction of the inner core 1, and each ring of LED lamp assemblies 11 includes a plurality of lamp beads 111 , and the intervals between a plurality of lamp beads 111 are even; the housing 2 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com