Temperature-controlled soil continuous grinding and screening device

A screening device and soil technology, applied in cocoa, grain processing, food science, etc., can solve the problems of interference factors, low processing efficiency, and cumbersome soil processing steps, etc., to facilitate cleaning operations, solve low processing efficiency, and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

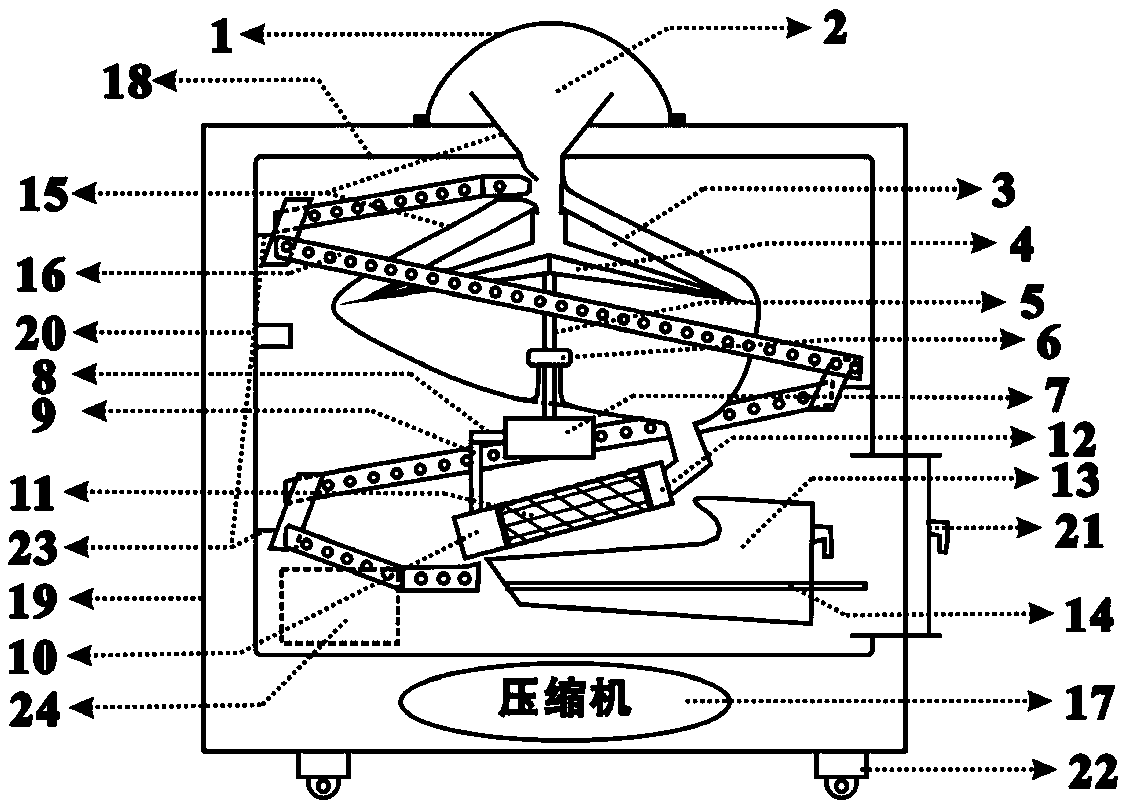

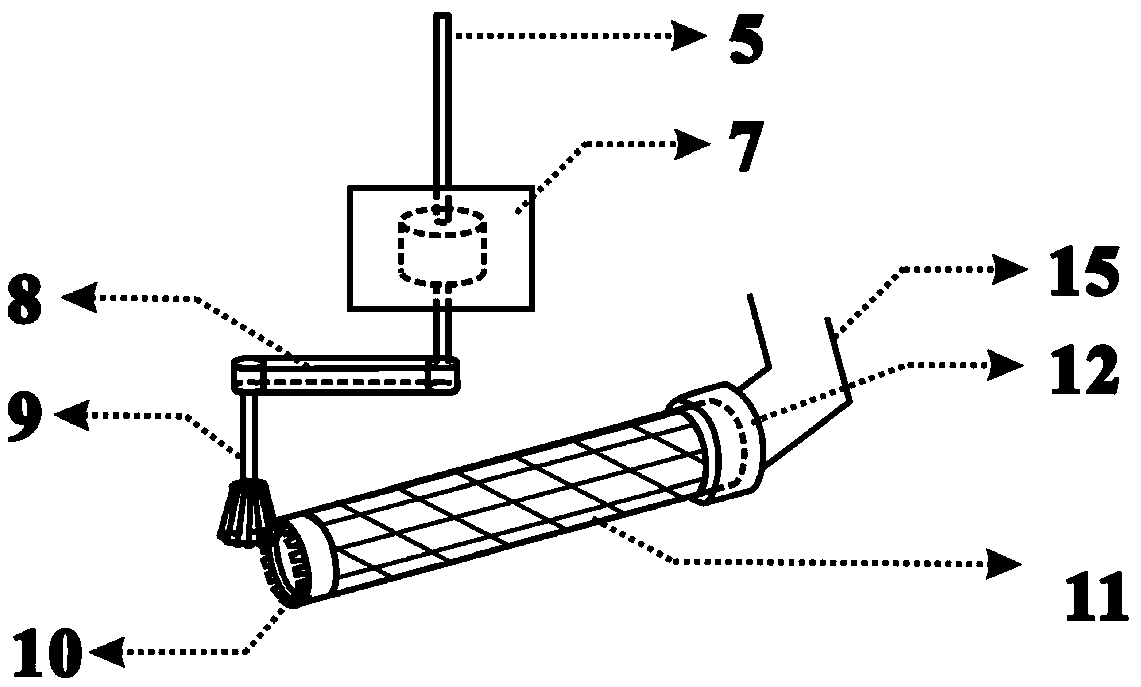

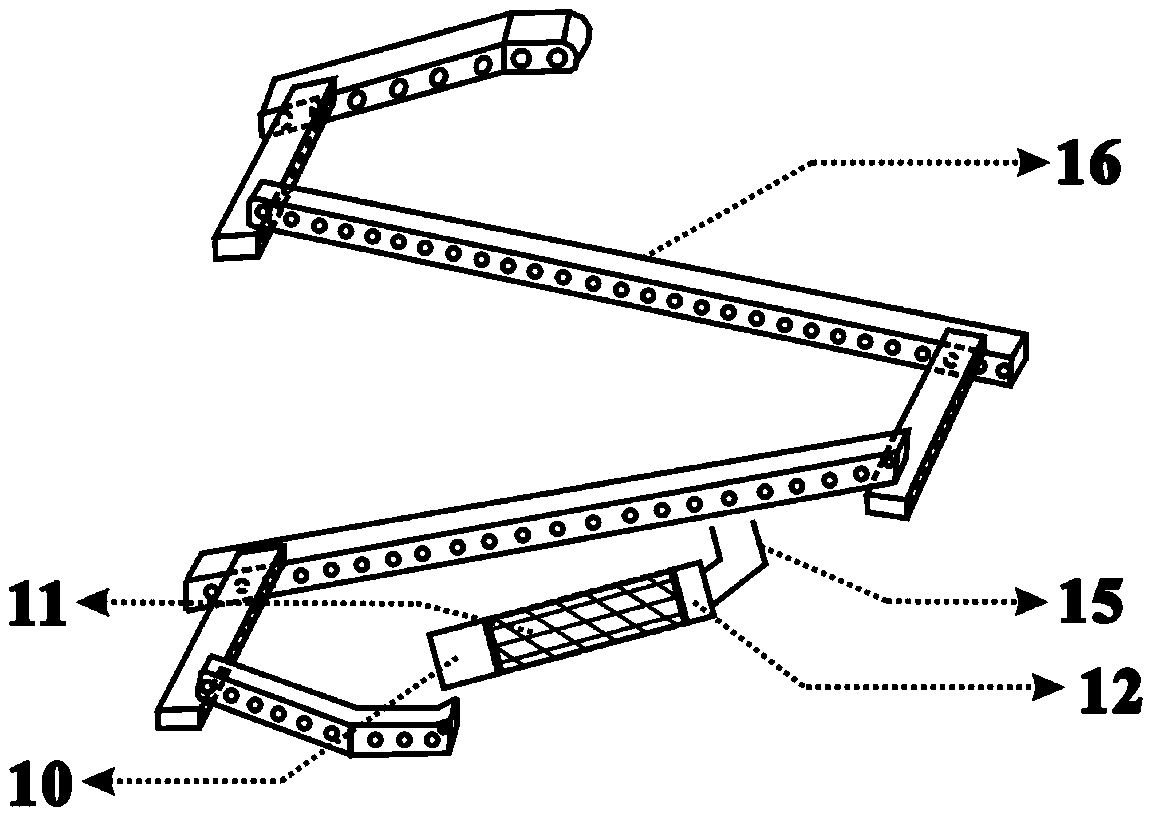

[0018] Such as figure 1 As shown, the soil continuous grinding and screening device of the present invention includes four functional systems: feeding grinding system, screening and conveying system, collection and storage system and temperature control system. The feed grinding system includes a feed hopper 2 , an umbrella-shaped fixed grinding disc 3 , an umbrella-shaped movable grinding disc 4 , a transmission shaft 5 , a sealing ring 6 , a motor 7 and a blanking bin 15 . The screening transmission system includes a transmission mechanism 8 , a shaft 9 , a ring gear 10 , a screen cylinder 11 , a bearing bayonet 12 and a multi-stage conveyor belt 16 . The collection and storage part includes a horizontal guide rail 14 and a collection box 13 . The temperature control system includes a compressor system 17, a temperature sensor 20 and the like.

[0019] The specific structure of the soil continuous grinding and screening device of the present invention is: the outer shell 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com