Optical lens machining, polishing and grinding device

An optical lens and grinding device technology, applied in grinding devices, optical surface grinders, grinding drive devices, etc., can solve the problems of not having the function of dust suppression, affecting people's health, etc., and achieve the effect of improving grinding efficiency and reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

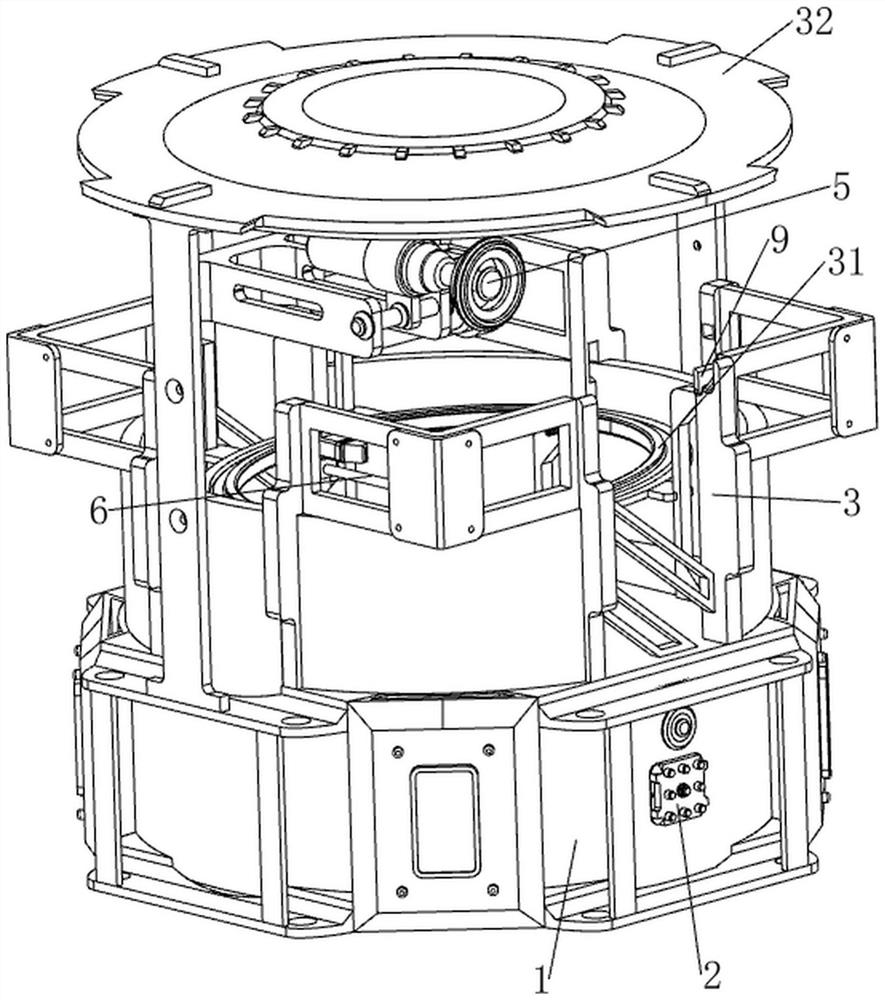

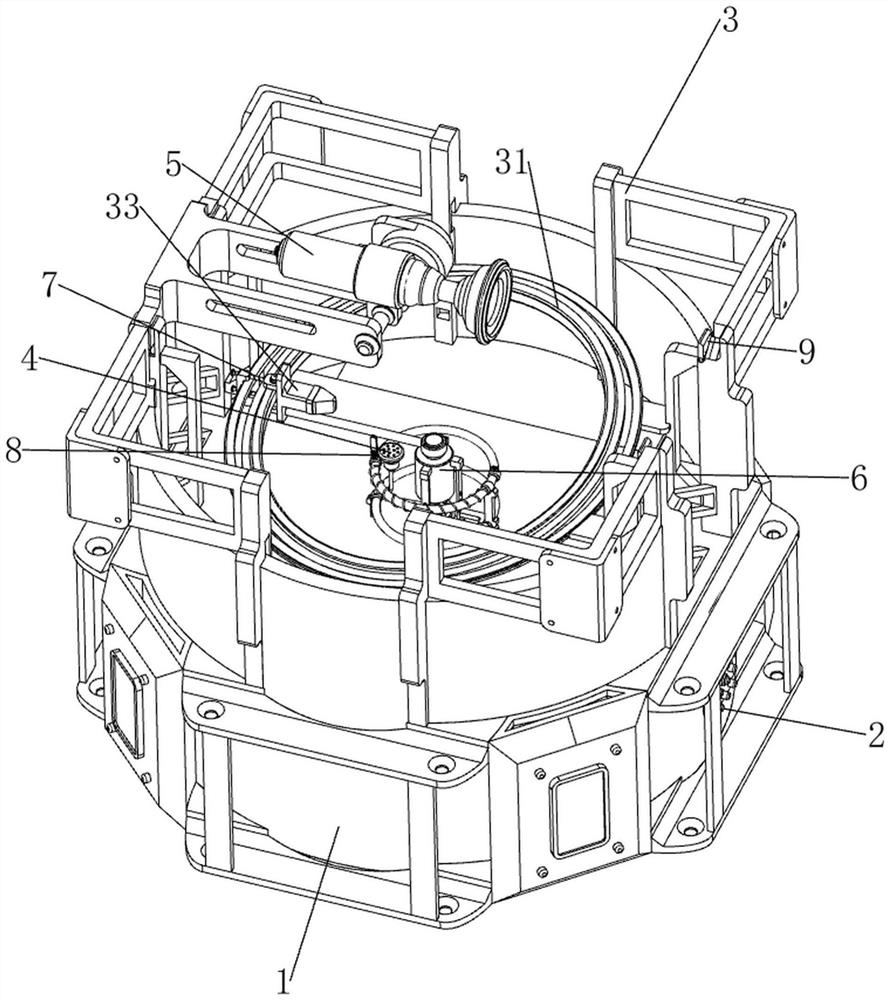

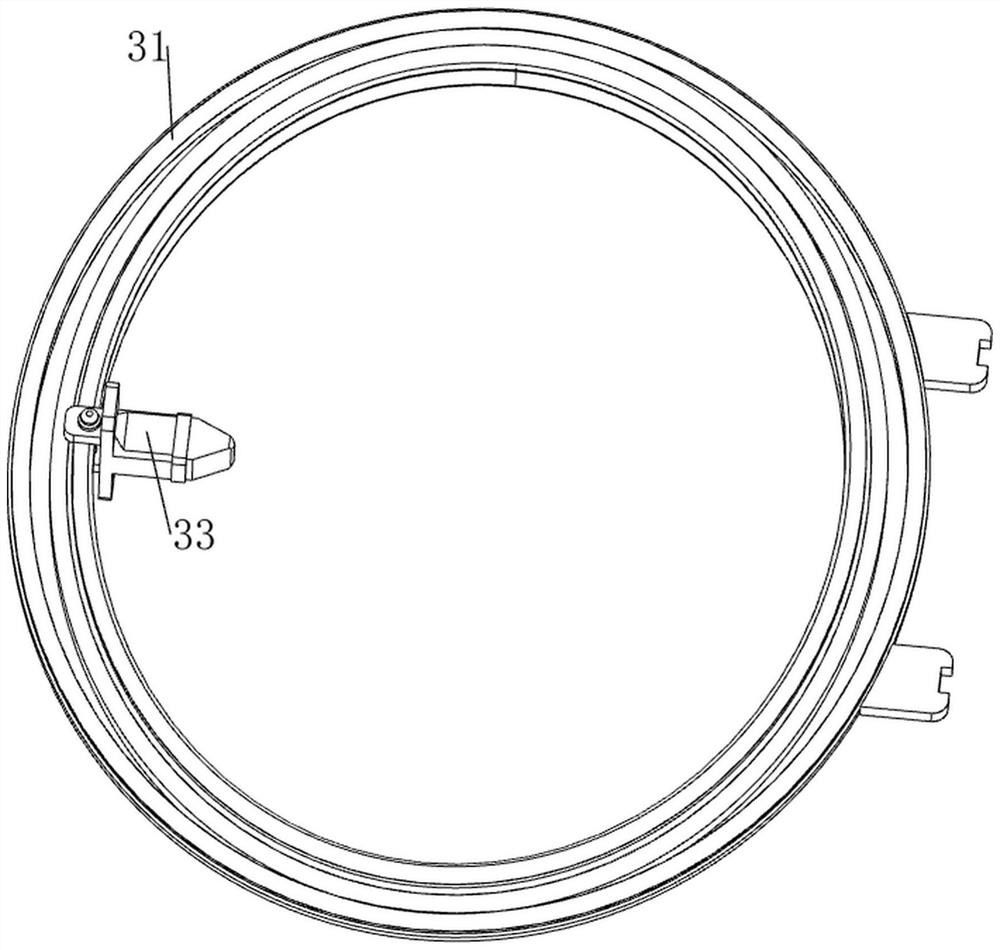

[0039] A polishing and grinding device for optical lens processing, referring to Figure 1-12 , including a water tank 1, a working frame 3, an elliptical orbit 31, a shielding part 32, a grinding part 33, a spraying mechanism 4, a feeding mechanism 5, a rotating mechanism 6 and an adjusting mechanism 7, a blocking block is placed on the front side of the water tank 1, and the water tank 1 The top is provided with a working frame 3, the inside of the working frame 3 is provided with an elliptical track 31, the top of the working frame 3 is provided with a blocking part 32, the inner side of the elliptical track 31 is slidingly provided with a grinding part 33, and the middle of the top of the water tank 1 is provided with a spraying mechanism 4. Frame 3 upper rear side is provided with unloading mechanism 5, is provided with rotating mechanism 6 on 4 parts of spraying mechanism, and elliptical track 31 rear side sliding type is provided with adjusting mechanism 7.

[0040] ref...

Embodiment 2

[0046] On the basis of embodiment 1, with reference to figure 2 , Figure 13 and Figure 14 , also includes a surrounding mechanism 8, the surrounding mechanism 8 includes a sliding sleeve 81, an electromagnet 82, an iron sliding plate 83, a sliding rod 84, a first spring 85, a second spring 86, a ring track 87 and a second distance sensor 88 , the front side of the top of the first fixed part 42 is provided with an annular track 87, and the rear side of the annular track 87 is slidingly provided with a sliding sleeve 81, which is connected with the spraying part 43, and the rear side of the sliding sleeve 81 is provided with an electromagnet 82, and the sliding sleeve Both sides are provided with slide bar 84 on the front and rear upper part of 81 rear sides, and slide bar 84 is provided with irony slide plate 83 slidingly, and irony slide plate 83 contacts with rotating bar 61, and between irony slide plate 83 and slide bar 84 A first spring 85 is connected between them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com