Patents

Literature

132results about How to "Reduce auxiliary work time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

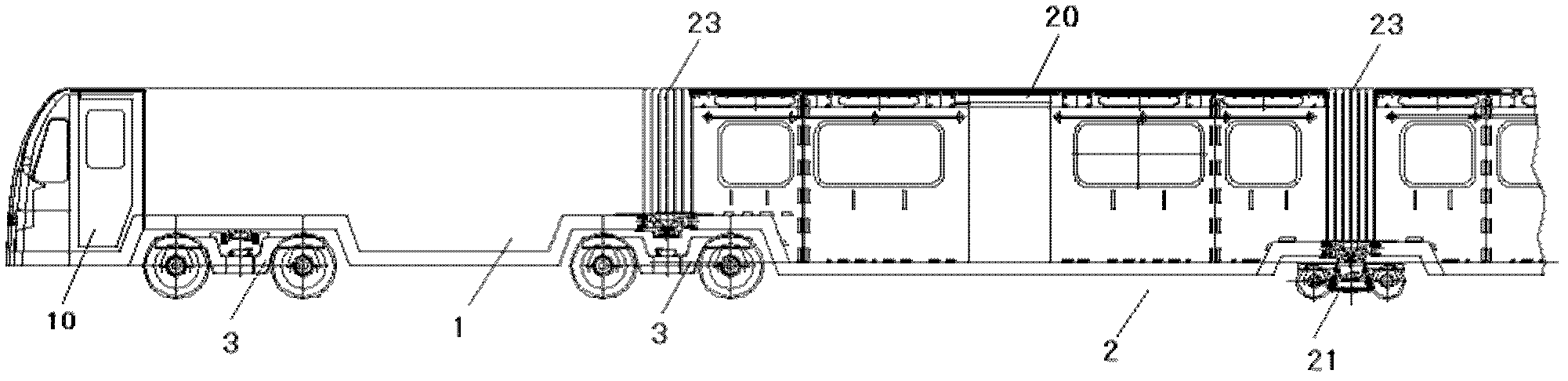

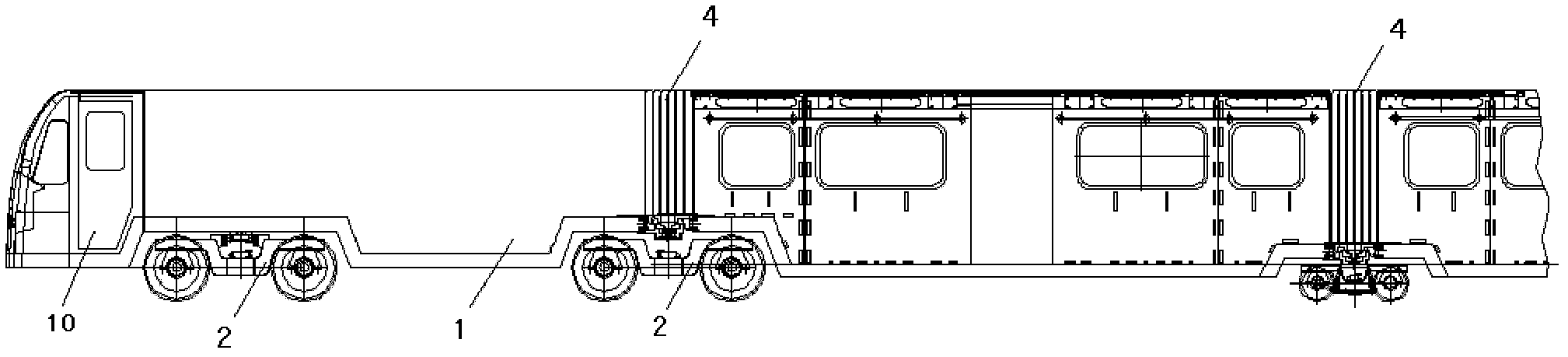

Narrow-gauge electric motor car

ActiveCN102501858AIncreased body lengthReduce volumeElectric locomotivesRailway couplingsLight railCoal mining

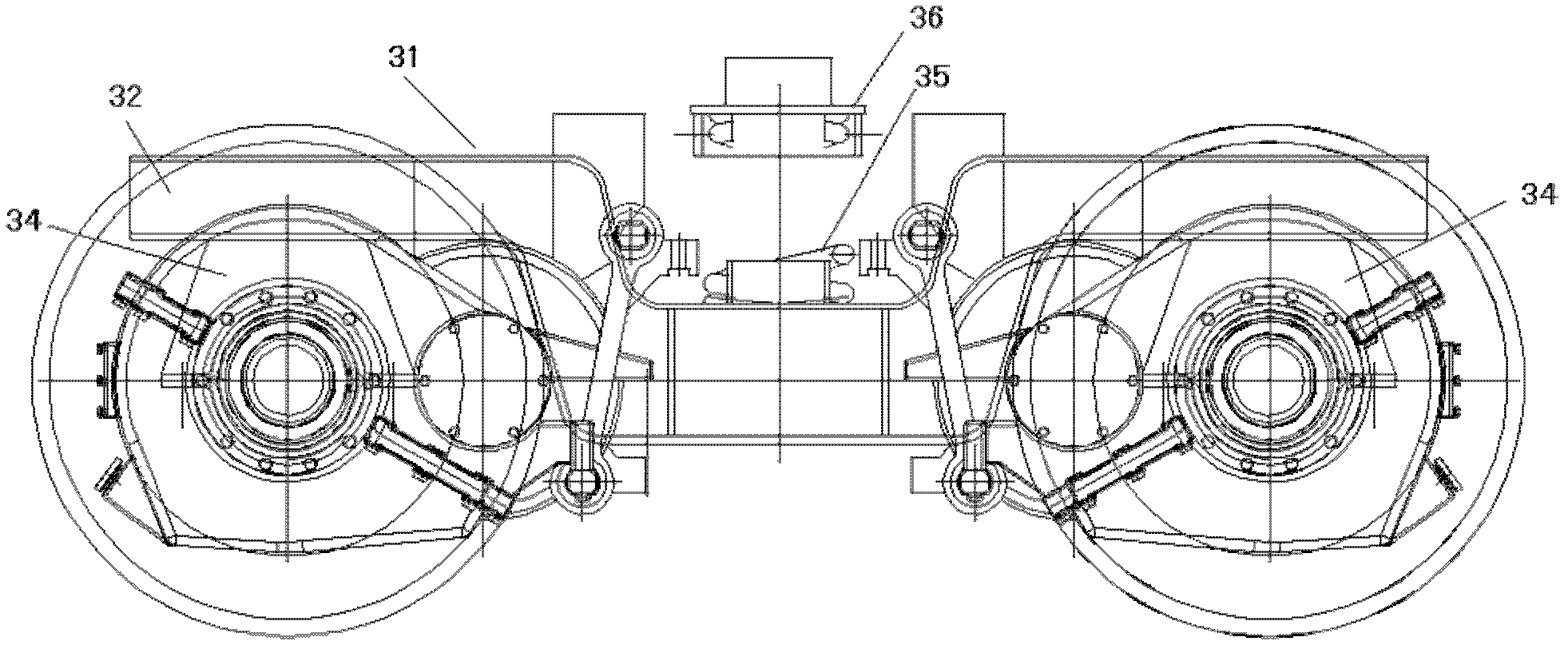

The invention relates to a narrow-gauge electric motor car, which is characterized by comprising two segments of motor cars, wherein a plurality of trail cars are arranged between the two segments of motor cars; an electric control system and a driving power supply are arranged in each segment of motor car; the driving power supply comprises an inverter and a direct-current storage battery connected with the inverter; two power steering bogies are arranged at the bottom of each segment of motor car, one power steering bogie is arranged at the bottom of the car body below the inverter, and the other power steering bogie is arranged between the rear end part of the motor car and the front end part of the adjacent trail car; two traction motors are arranged on each power steering bogie in parallel with the wheel shaft direction; each traction motor is connected with a primary reduction gear through a coupling; and each trail car comprises multiple segments of carriages, a plurality of non-power steering bogies, windscreens connected between carriages, passing platforms and hinge devices. The narrow-gauge electric motor car provided by the invention can be widely used for coal mining, tunnel excavation, light rail subway and other various occasions requiring narrow gauge transport.

Owner:CHANGCHUN GUANGYIN GROUP

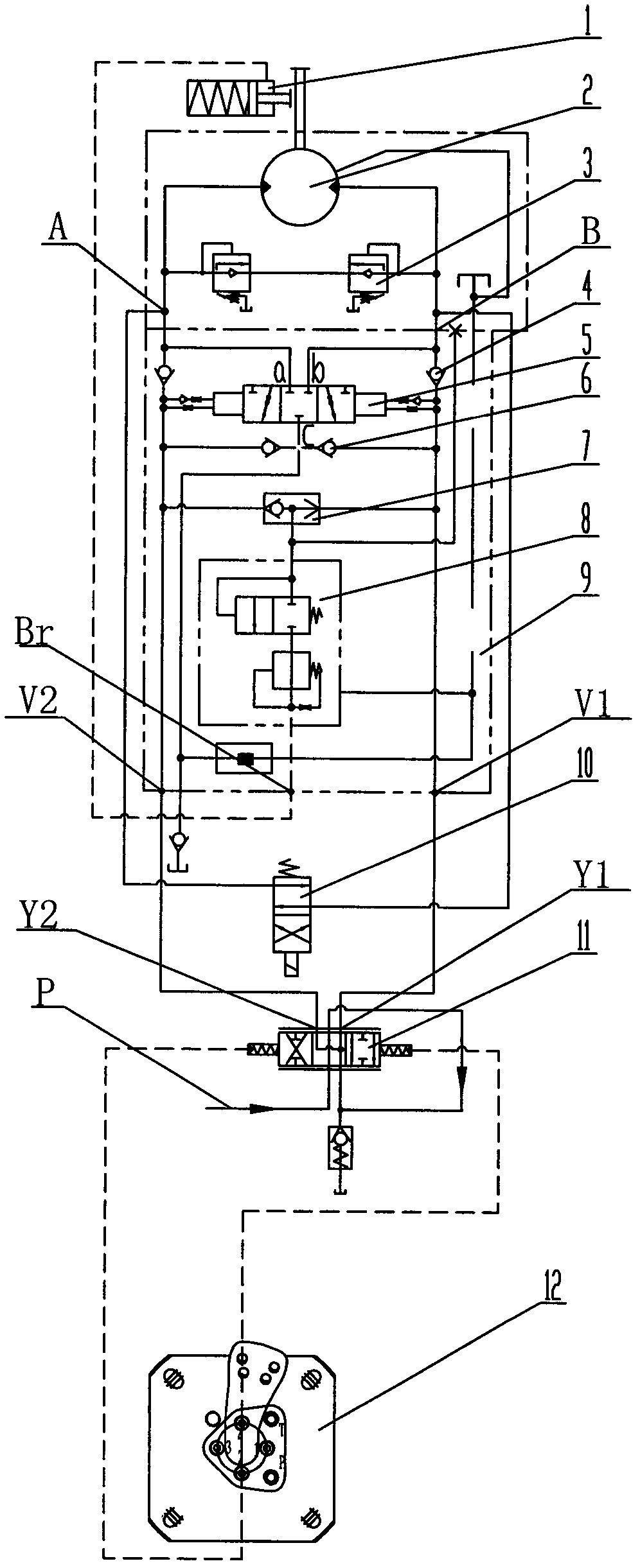

Main winch rapid-descent and confluent return oil regeneration system of rotary drilling rig

ActiveCN102167266ASpeed up the descentReduce auxiliary work timeDrilling rodsWinding mechanismsControl signalIdle speed

The invention discloses a main winch rapid-descent and confluent return oil regeneration system of a rotary drilling rig, which includes a main winch motor, a brake, a main valve and a pilot handle, wherein the pilot handle is communicated with the main valve through an oil path, and a special balance valve block for return oil regeneration is connected between the main winch motor and the main valve through pipelines and is controlled and adjusted by a control device. The invention improves the efficiency, accelerates the descent of the main winch, shortens the pore-forming subsidiary operation time, and improves the pore-forming efficiency. The main winch utilizes the own gravity to do work in the descent process, so that an engine is not required to run with full power but run at an idle speed, thereby saving the fuel oil and reducing the CO2 emission from a main unit; braking and speed adjusting control signals come from the pilot handle, so that the system controllability is better in comparison with the original form that motor +BVD balance valve control signals come from the inside of a BVD balance valve, the problem that the winch slides downwards in a stalled state is basically solved, and the damage to a drilling stem and a drilling rig caused by the fall-off of the drilling stem can be effectively prevented.

Owner:QINGDAO LOVOL EXCAVATOR

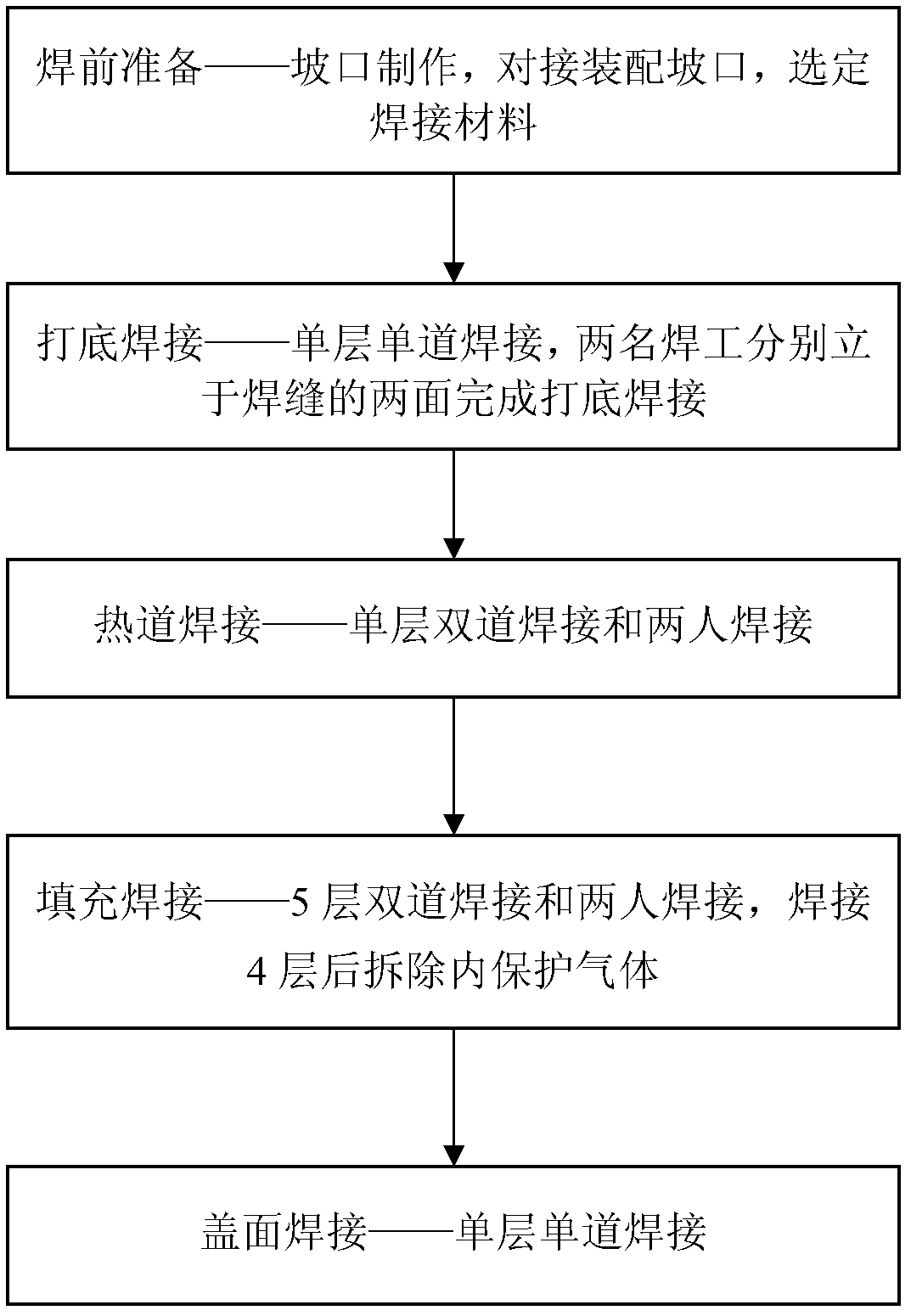

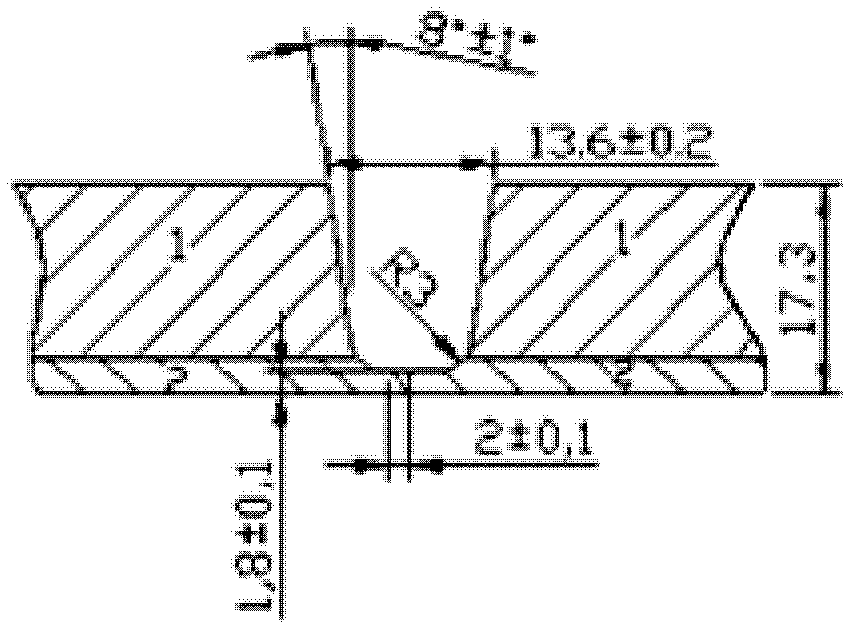

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

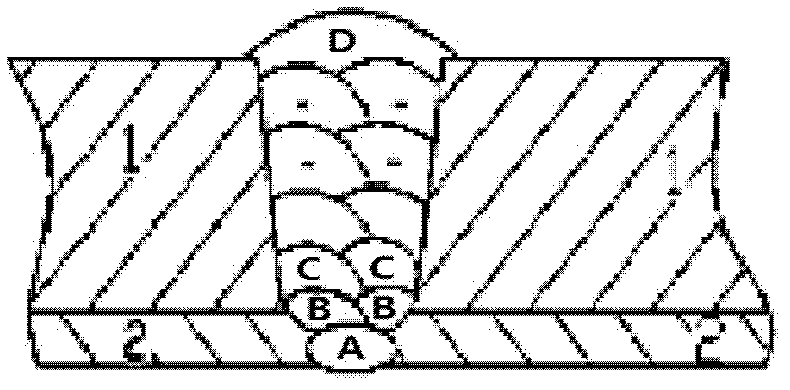

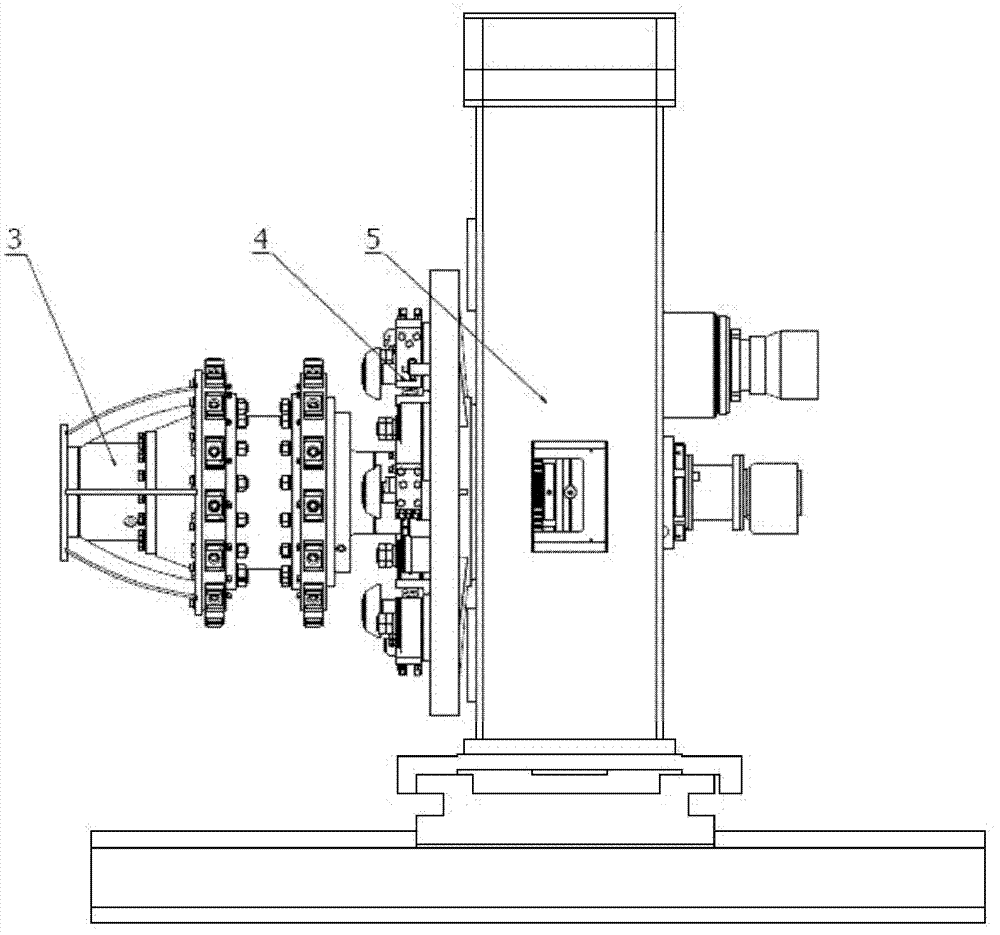

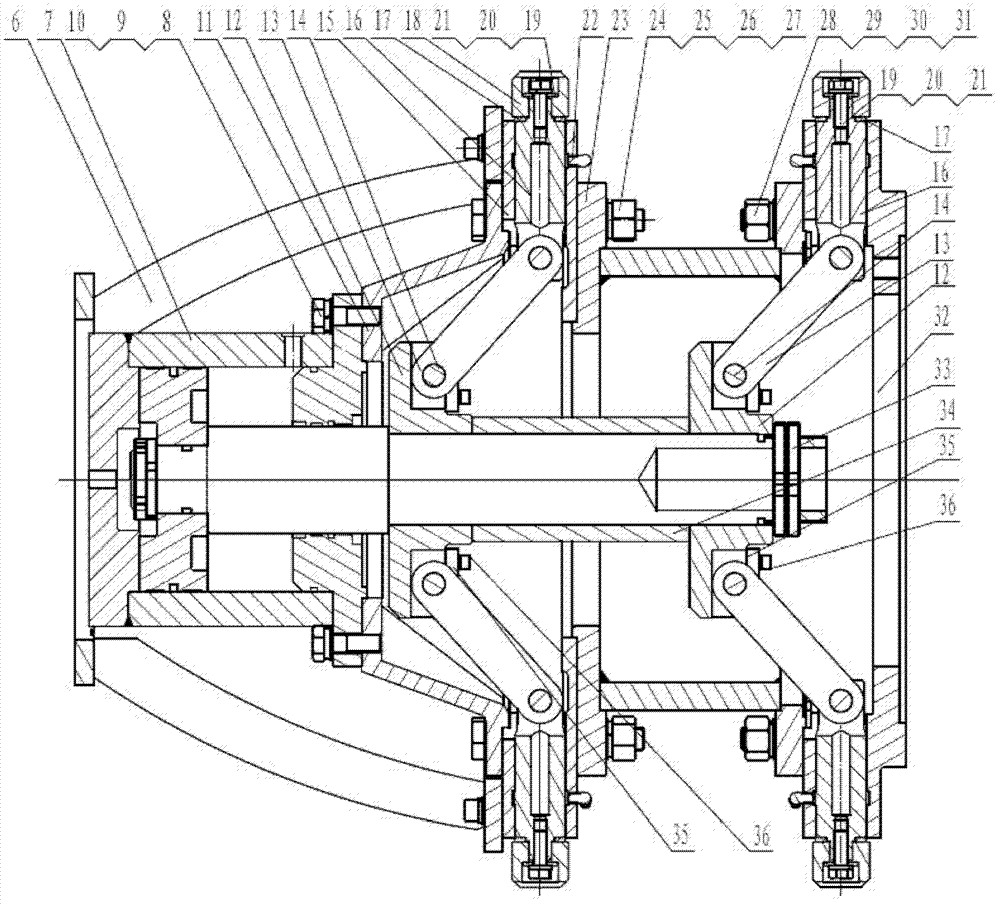

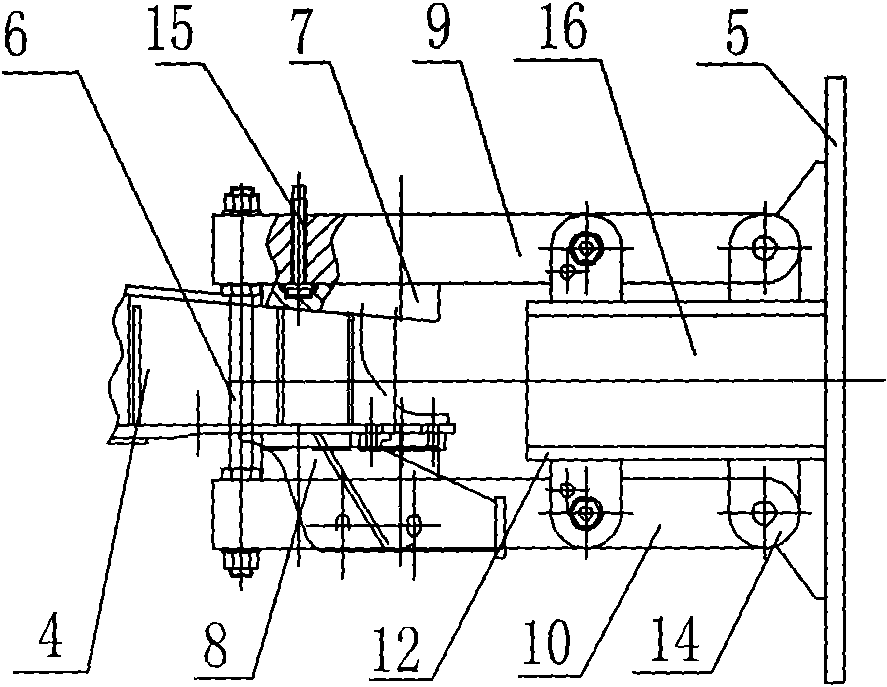

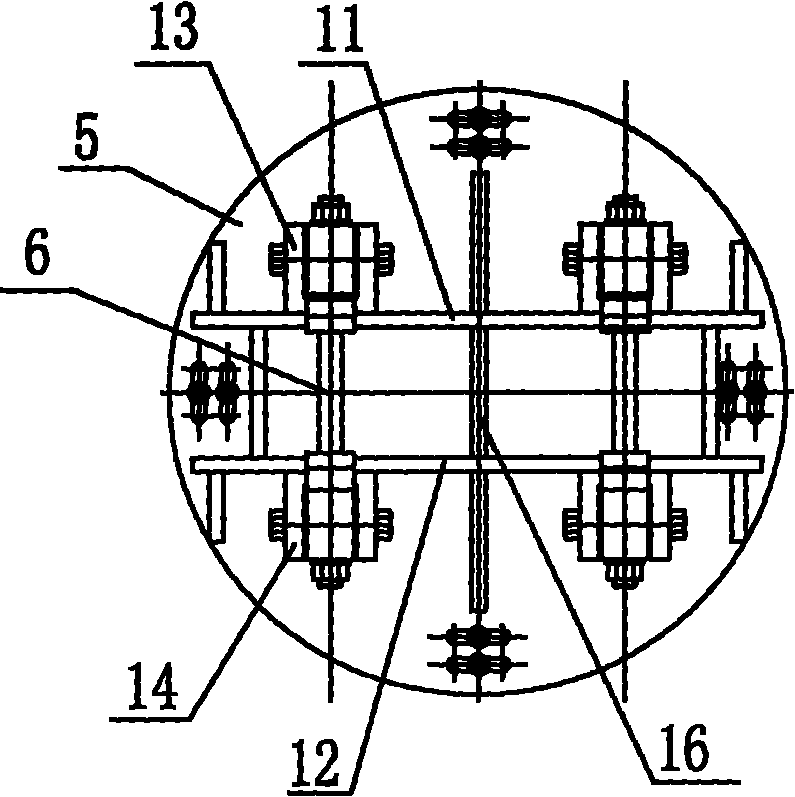

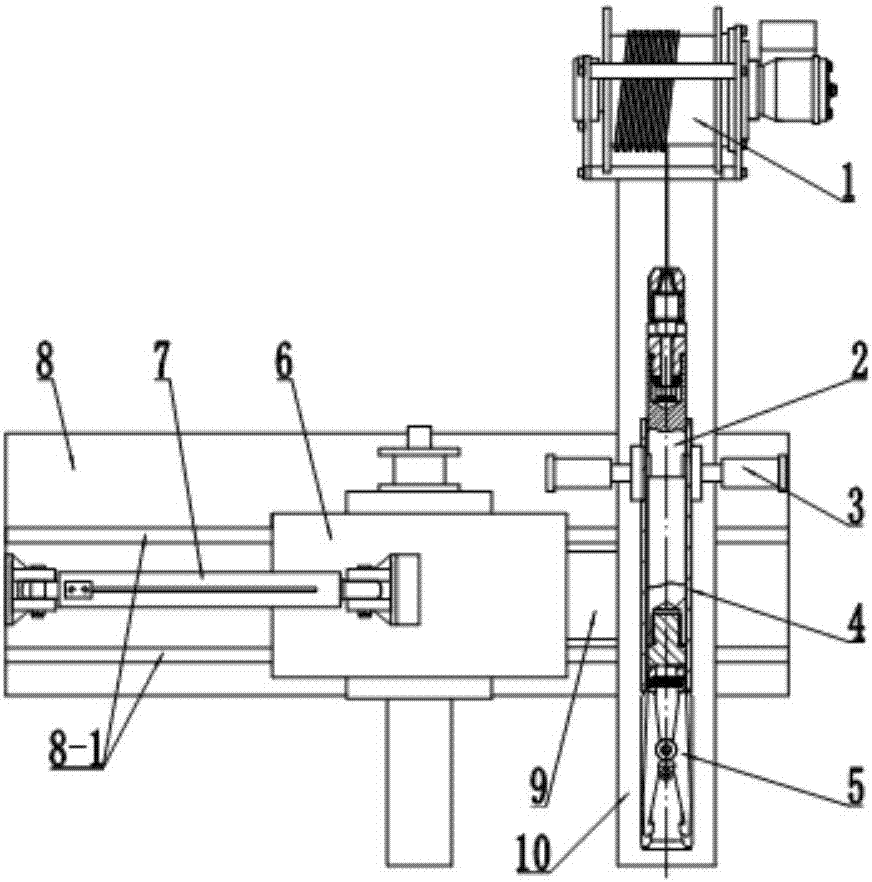

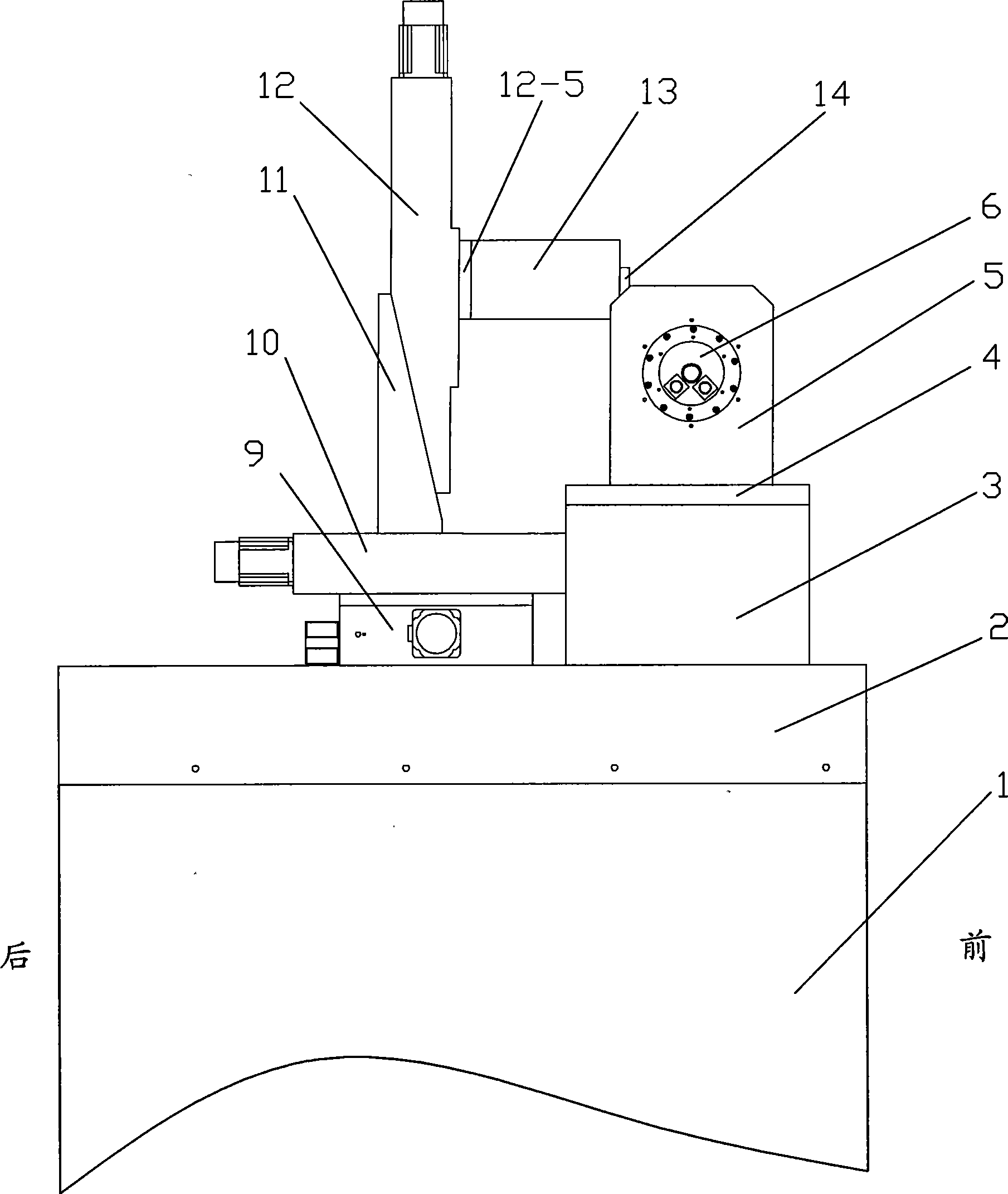

Internal expanding type clamping mechanism of large-caliber hot bend bevelling machine

ActiveCN103358144AImprove processing efficiencyQuick clampingPositioning apparatusMetal-working holdersPiston rodCaliber

The invention discloses an internal expanding type clamping mechanism of a large-caliber hot bend bevelling machine. The end of a piston rod of a hydraulic oil cylinder (7) is fixedly connected with an end disc (11). A thrust disc (12) is installed at the portion, outside the end disc (11), of the piston rod of the hydraulic oil cylinder (7). The other end of the hydraulic oil cylinder (7) is sleeved with a front protective cage (6), and then the outer edge of the end disc (11) is connected with a front expanding body (15) and an ejector rod (16) through the opening edge of the front protective cage (6). One end of a connection rod (13) is connected to the thrust disc (12), and the other end of the connection rod (13) is connected with the ejector rod (16). A connection disc (23) is fixedly connected with the ejector rod (16), a sub-notch at one end of the connection disc (23) is connected with the front expanding body (15), and the other end of the connection disc (23) is connected with a rear expanding body (32). The piston rod of the hydraulic oil cylinder (7) penetrates through the thrust disc (12), then is sleeved with a shaft sleeve (34) and a second thrust disc (12) and finally is locked and fixed. The internal expanding type clamping mechanism of the large-caliber hot bend bevelling machine is convenient and fast to use, relieves labor intensity of workers and improves machining efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Lifting platform of construction vehicle

InactiveCN101812974AEasy to operateIncrease spaceDerricks/mastsAnchoring boltsMarine engineeringCoal

The invention provides a lifting platform of a construction vehicle, which comprises a lifting platform and a platform lifting device, and is characterized in that: the lifting platform has two stages of expansion plates, namely first-stage expansion plates and second-stage expansion plates; the first-stage expansion plates are positioned on two sides of the lifting platform and are hinged on the lifting platform, and overturning oil cylinders are arranged below the first-stage expansion plates and the lifting platform; the second-stage expansion plates are expansion plates with a draw type structure and are arranged in the first-stage expansion plates, namely the second-stage expansion plates are inserted into the first-stage expansion plates; and expansion cylinders are arranged between the first expansion plates and the second expansion plates. The lifting platform has the advantages of increasing the operation, activity and working space of construction operators, improving working safety conditions and environments, allowing constructors to work alternately at a high altitude, effectively reducing auxiliary work load, auxiliary work time and auxiliary workers and improving operation safety and production efficiency and is applicable to various construction vehicles for coal mine continuous mining, continuous excavation and comprehensive digging.

Owner:闫振东

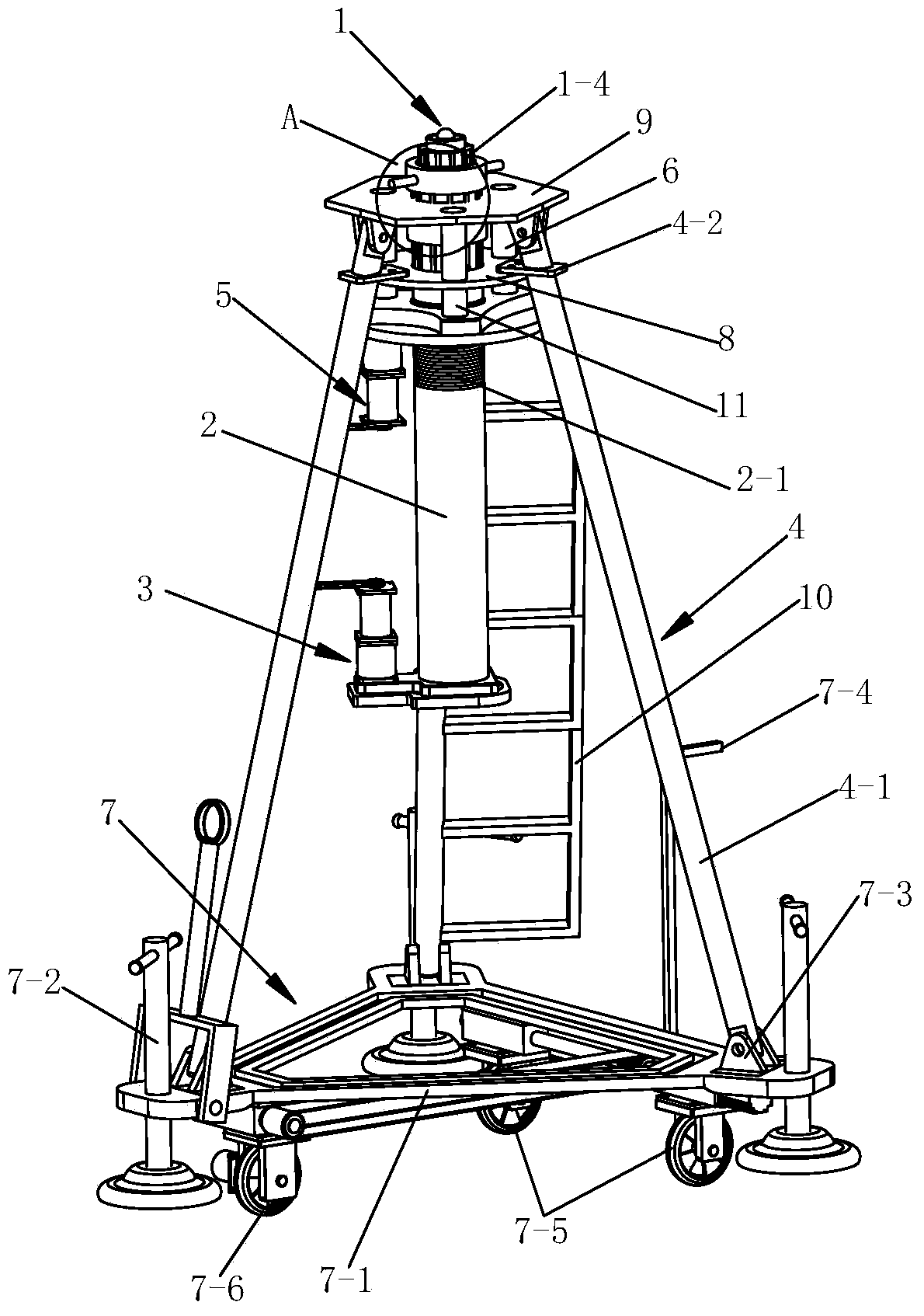

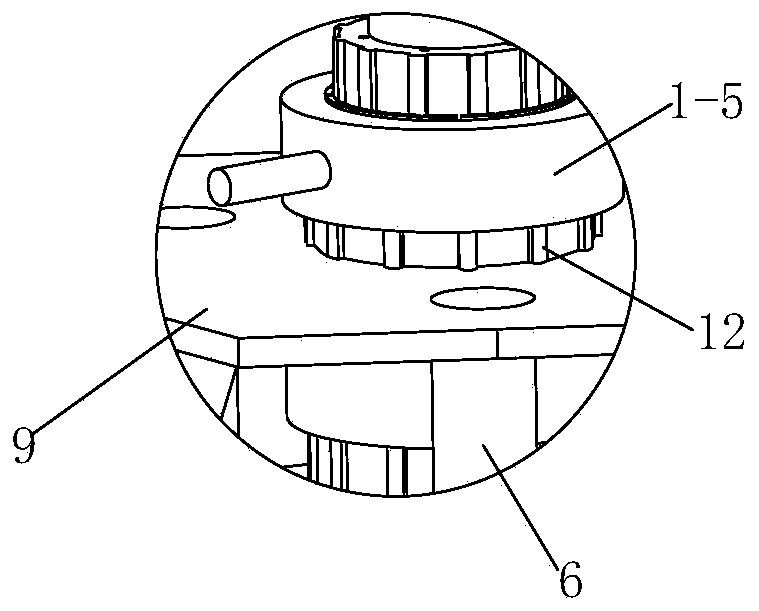

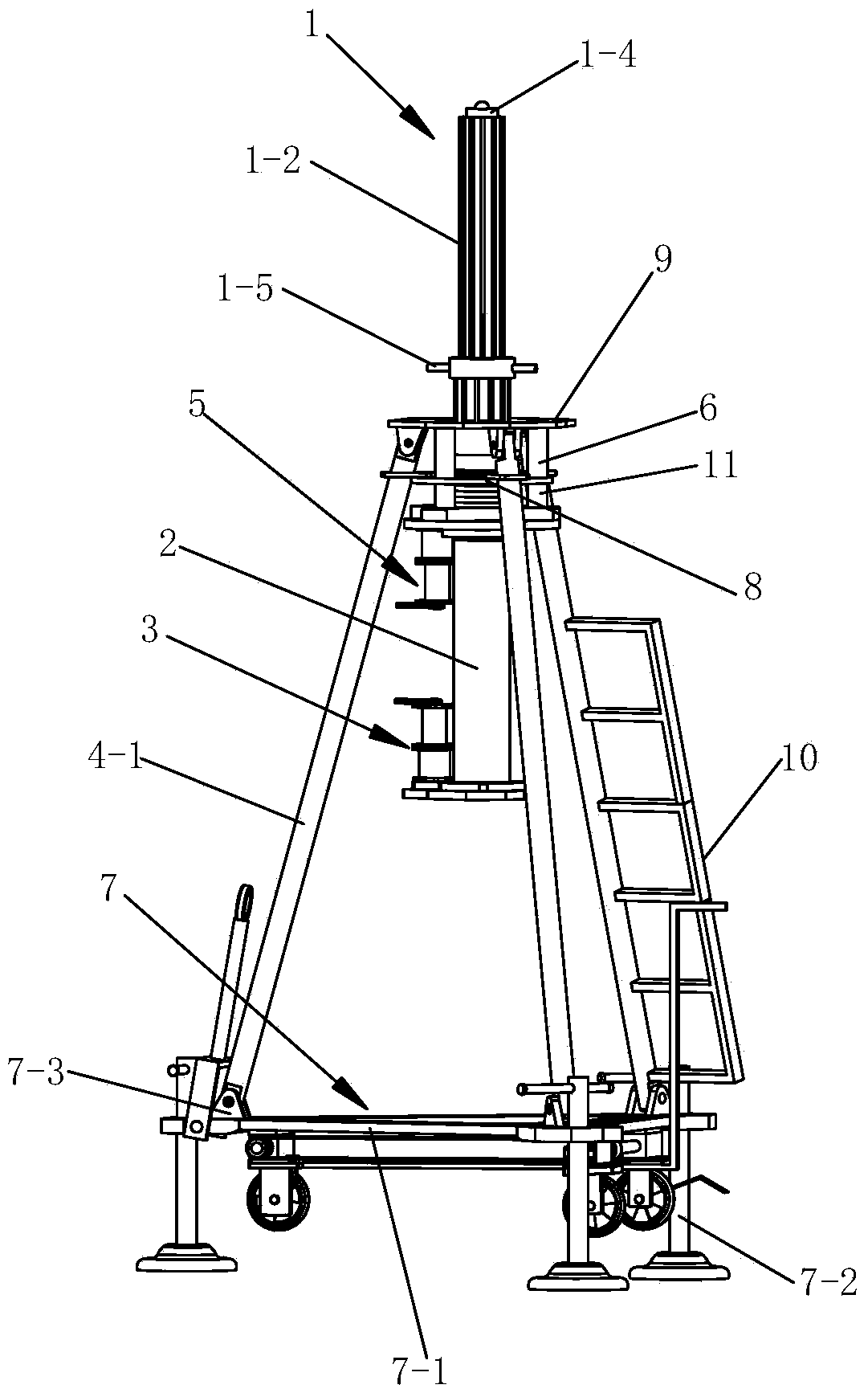

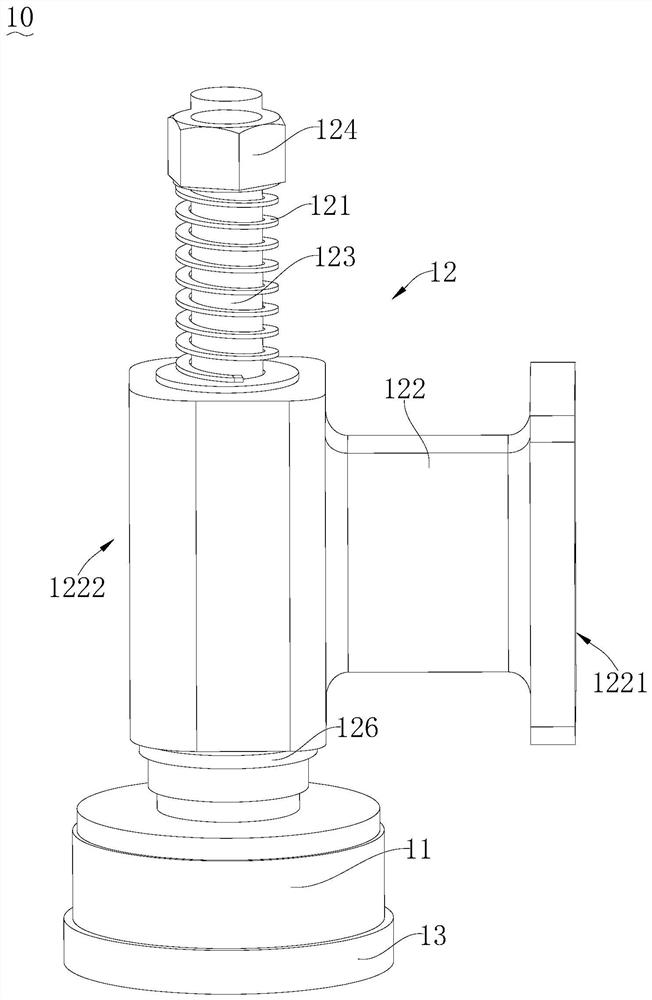

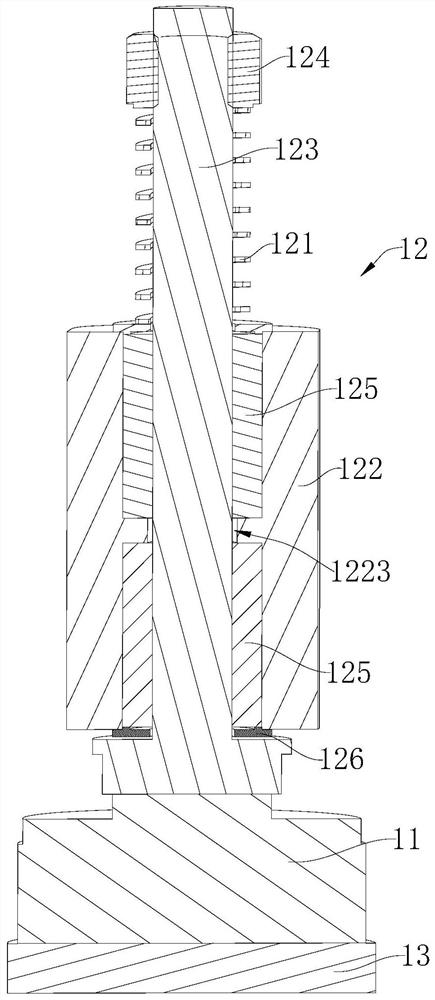

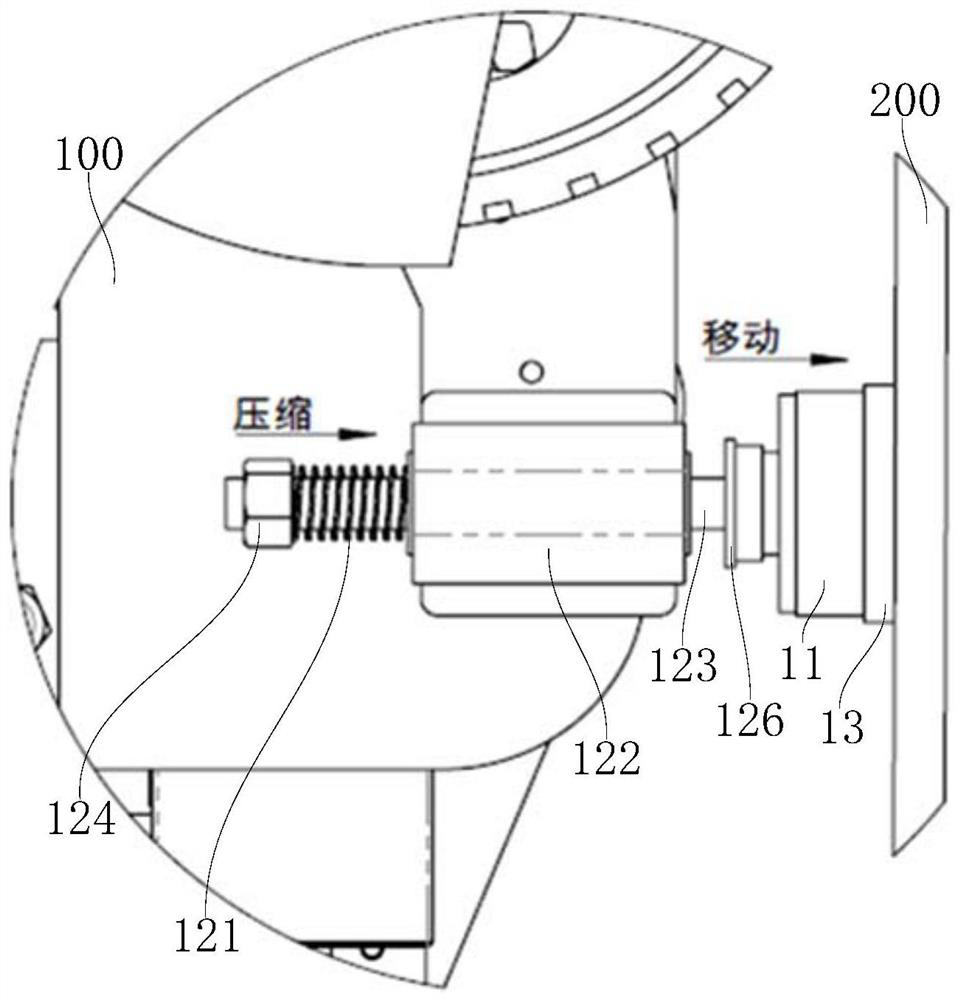

Mechanical airplane jack

InactiveCN104210983AReduce auxiliary work timeImprove efficiencyPortable framesLifting devicesJet aeroplaneHeavy load

The invention discloses a mechanical airplane jack. The mechanical airplane jack comprises a supporting frame, a rapid lifting mechanism, a rapid driving mechanism for driving the rapid lifting mechanism to move or position in a no-load stroke, a bearing sleeve and a heavy load driving mechanism for driving the bearing sleeve to move or position in a load stroke, wherein the rapid driving mechanism is mounted on the bearing sleeve; the lower end of the rapid lifting mechanism enters into the bearing sleeve and is in transmission match with the rapid driving mechanism; the heavy load driving mechanism is mounted on the supporting frame and is in transmission match with the bearing sleeve. According to the mechanical airplane jack, the rapid driving mechanism of the rapid lifting mechanism is separated from the heavy load driving mechanism of the bearing sleeve, so that the rapid lifting mechanism can rapidly achieve the target position, and the lifting time of the mechanical airplane jack can be sharply shortened.

Owner:XIAN UNIV OF SCI & TECH

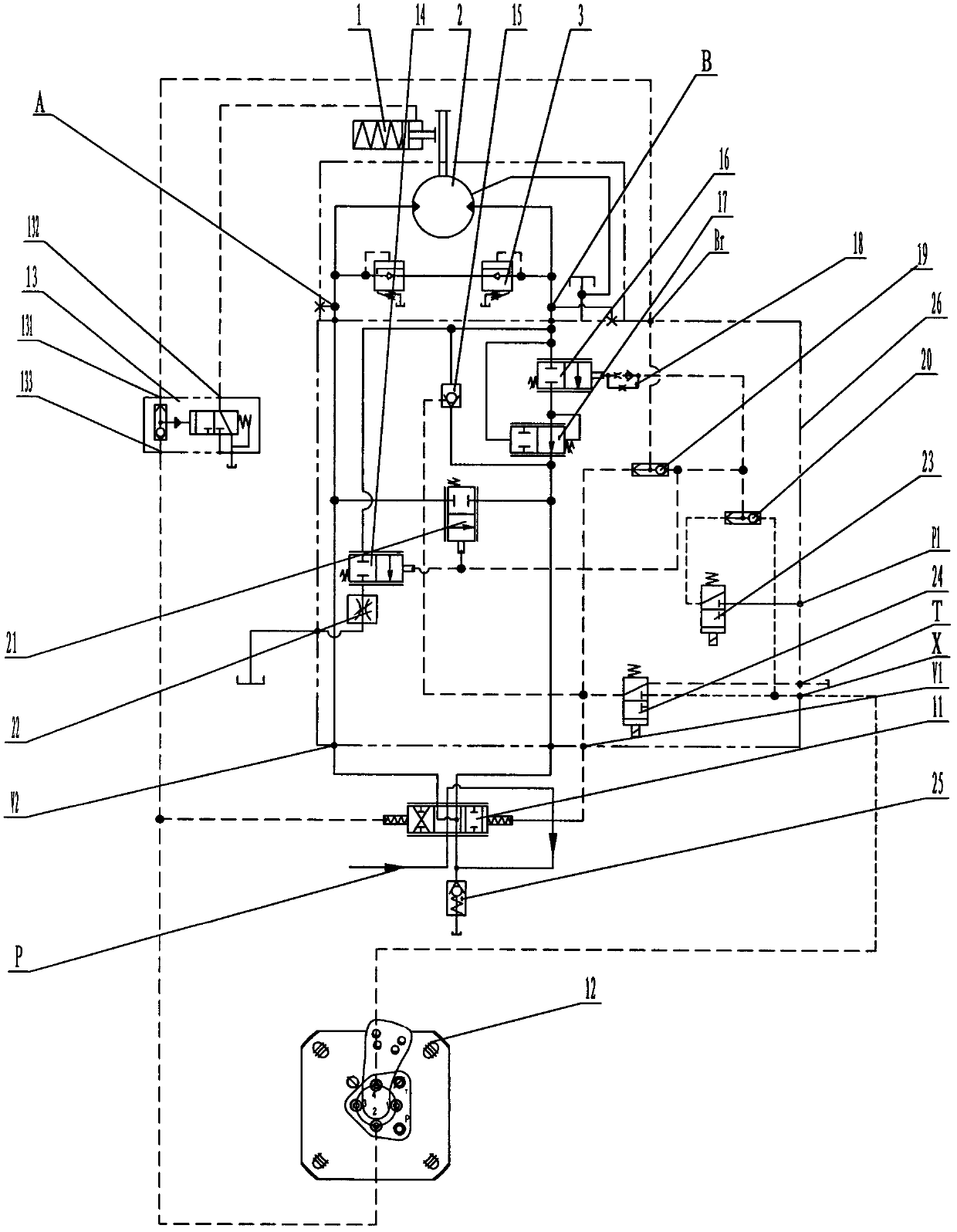

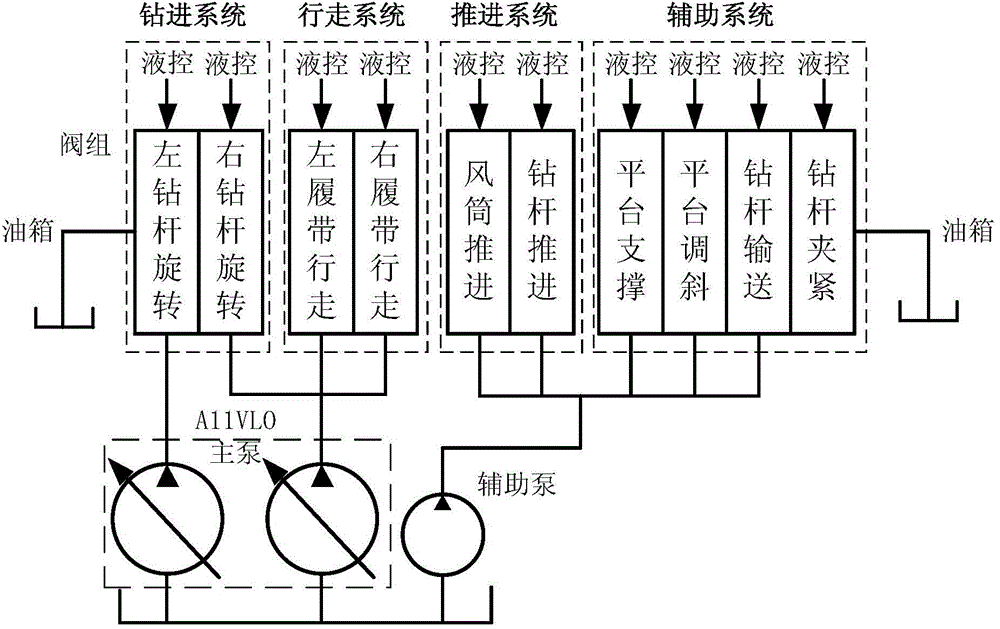

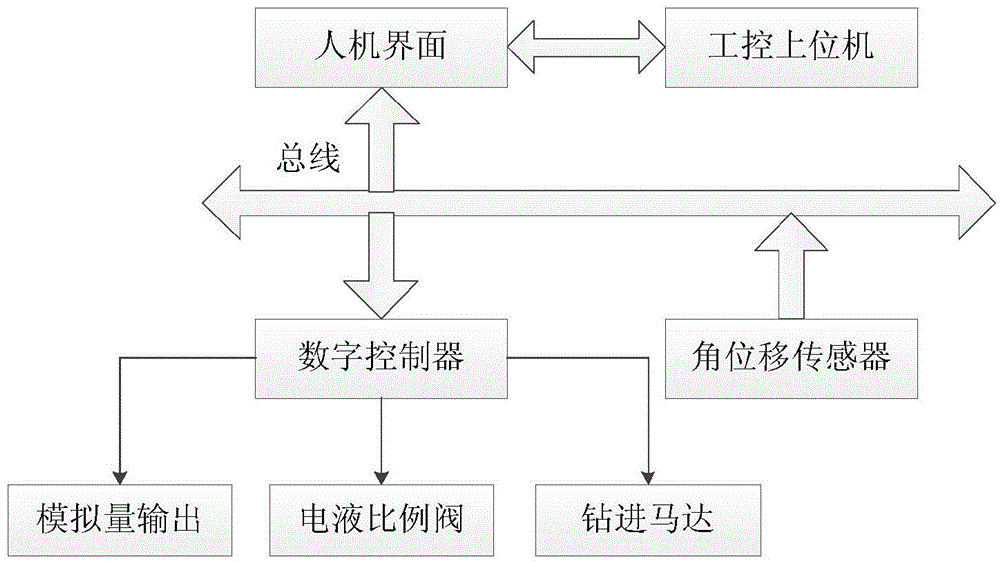

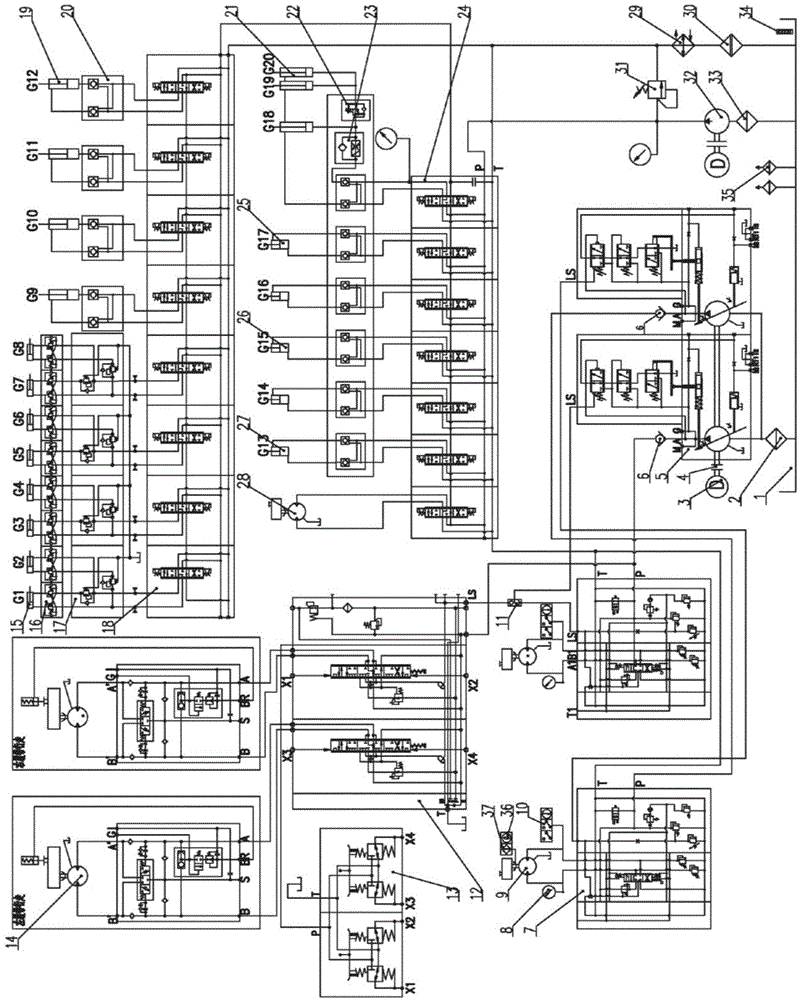

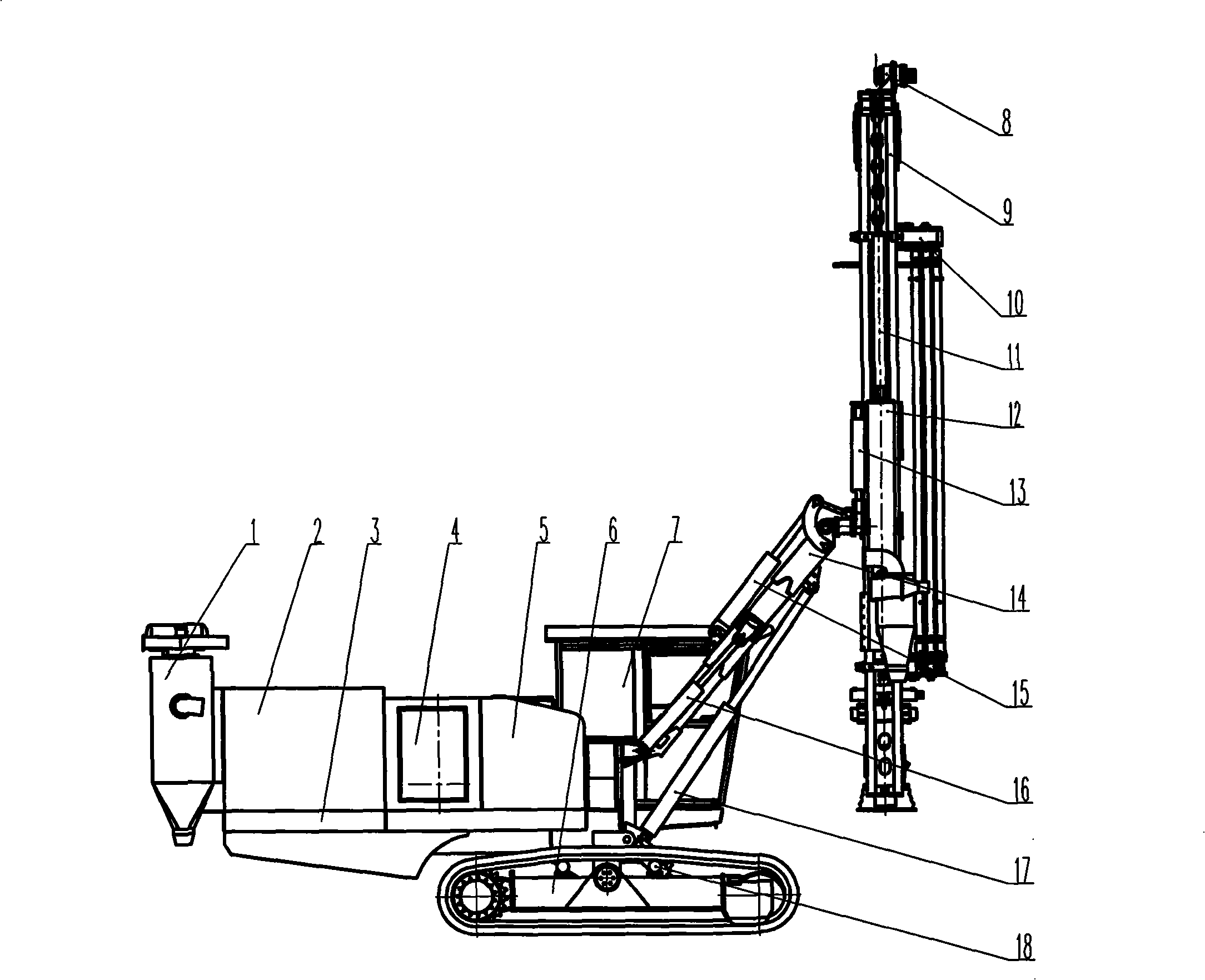

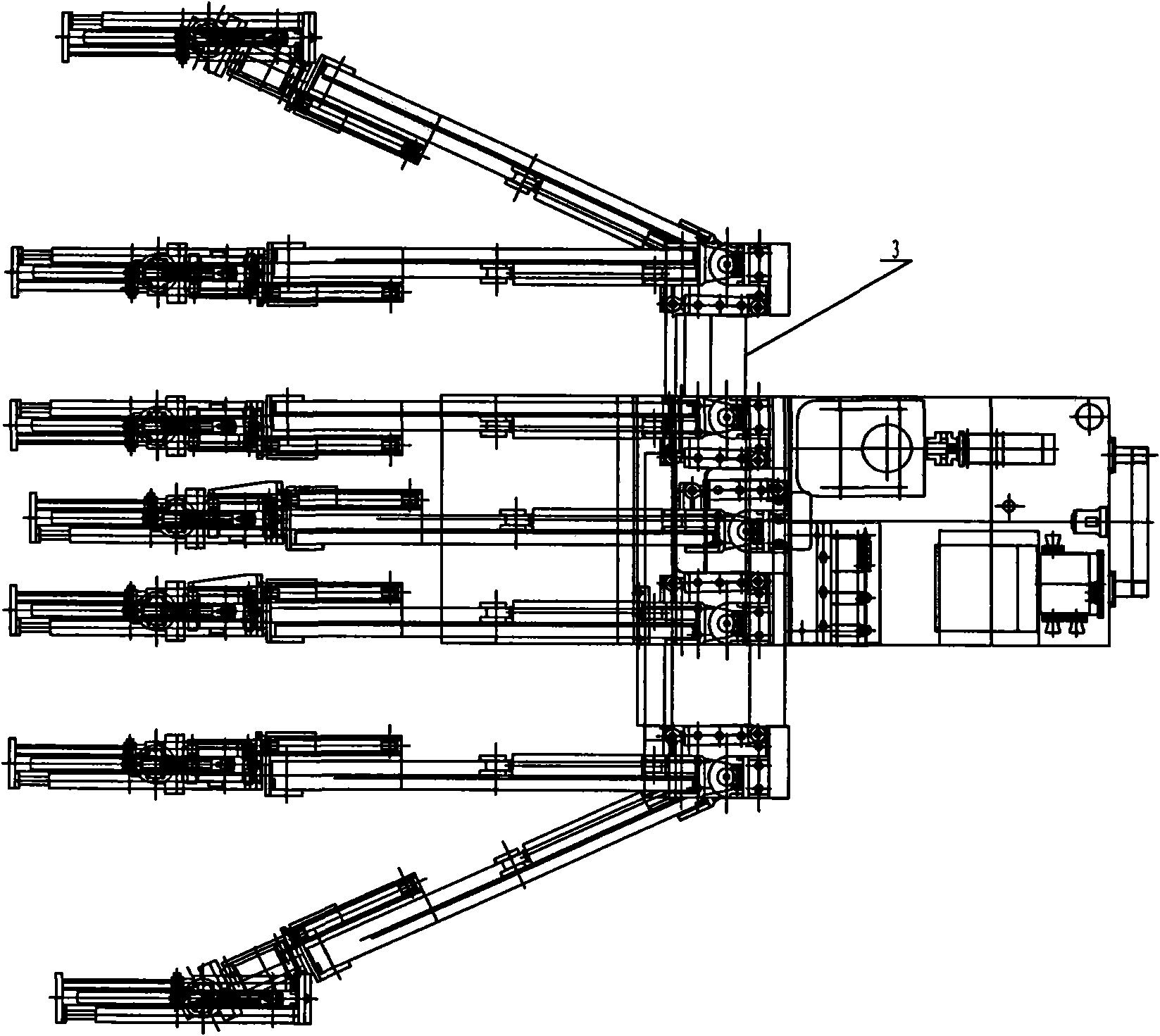

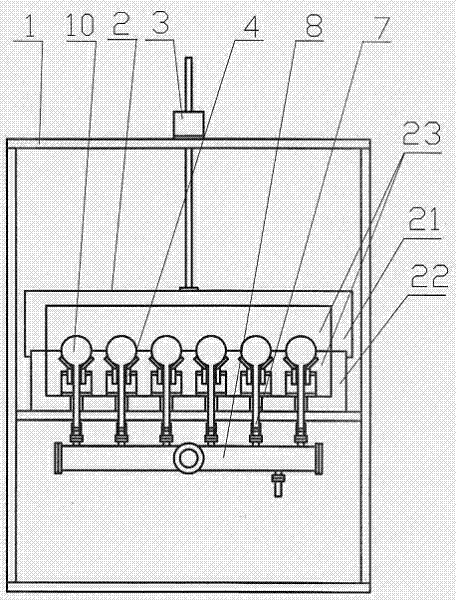

Hydraulic control system of full-hydraulic drill type coal miner

The invention discloses a hydraulic control system of a full-hydraulic drill type coal miner. The hydraulic control system comprises a drill system, a walking system, a propelling system and an auxiliary system. The drill system is controlled in a closed-loop manner by a load sensitive variable pump and an electro-hydraulic proportional valve, the pressure and the flow of the drill system can be automatically adjusted according to load changes; and the drilling speed and the position of a drill rod can be controlled in real time. The walking system and the drill system share one dual variable axial piston pump, and the complexity and space of the walking system can be effectively reduced; a speed regulating valve is adopted in the propelling system to adjust the speed, the propelling speed is adjusted according to the working condition, and cutting of a drill machine under the maximum power is achieved; and the auxiliary system can complete supporting and slope adjustment of a working platform of the drill machine, conveying and clamping of the drill rod and adjustment of the working angle of the drill machine, and positioning of the drill rod in the process of drill rod changing is completed. The problems that a hydraulic system of an existing hydraulic drill type coal miner is complex in oil way, the drill rod is difficultly controlled precisely, the system efficiency is low, and auxiliary work time and drill rod changing time are long are solved.

Owner:CHINA UNIV OF MINING & TECH

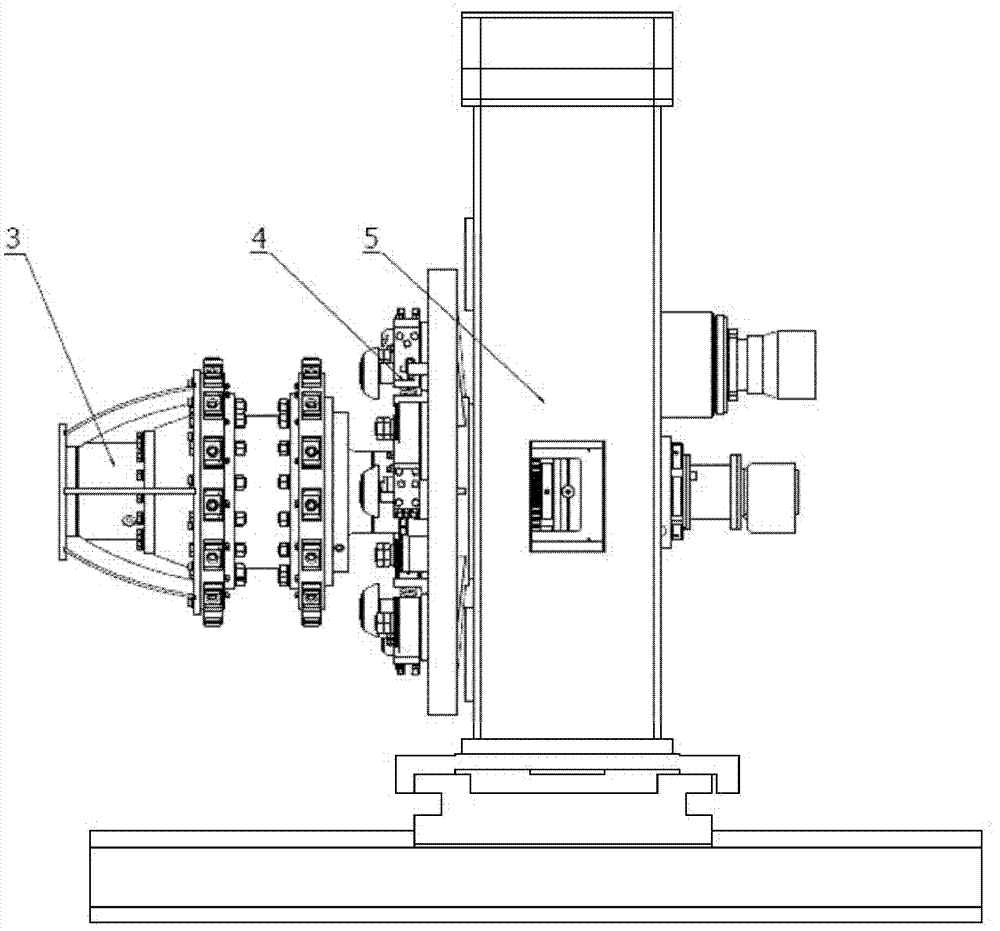

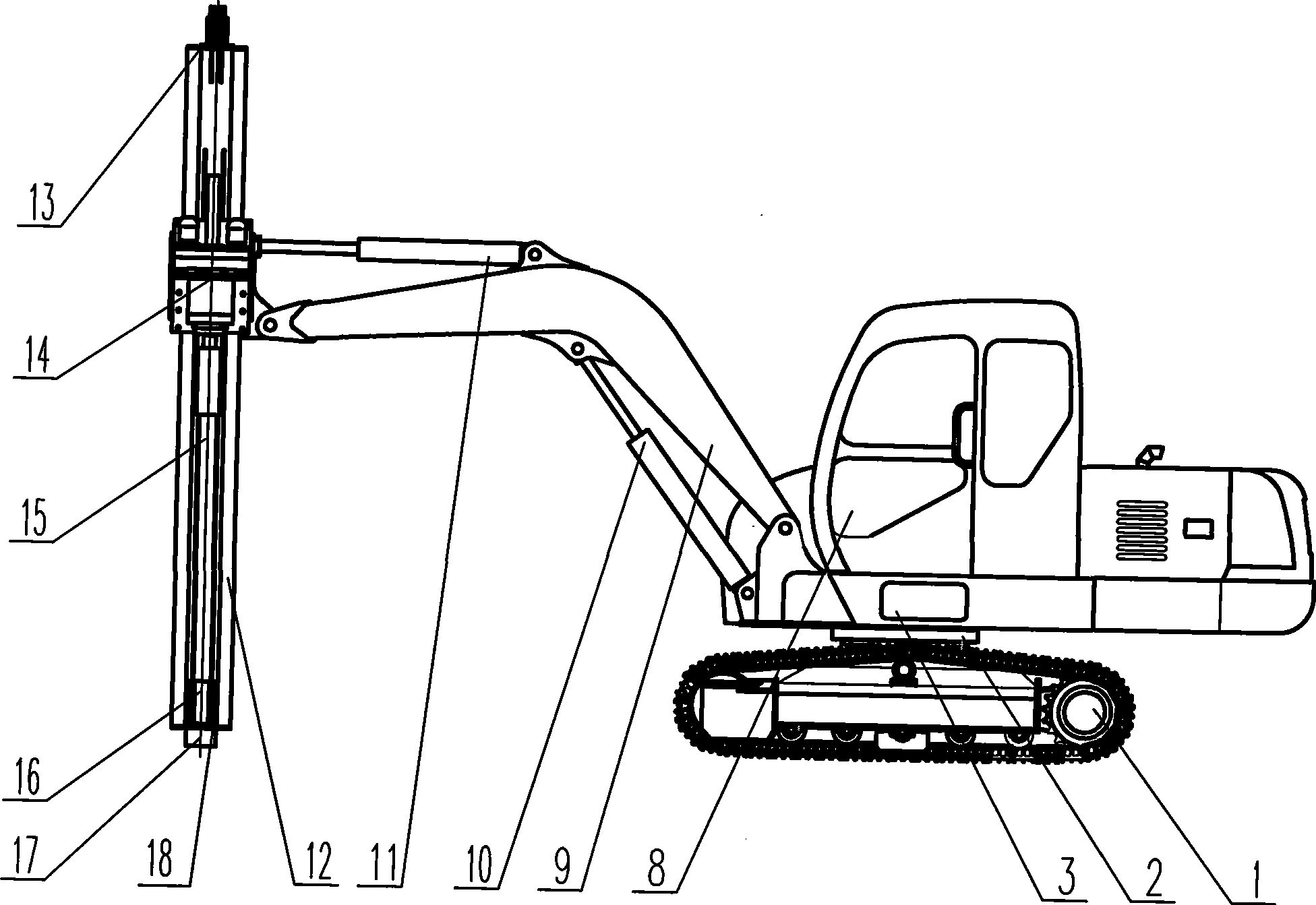

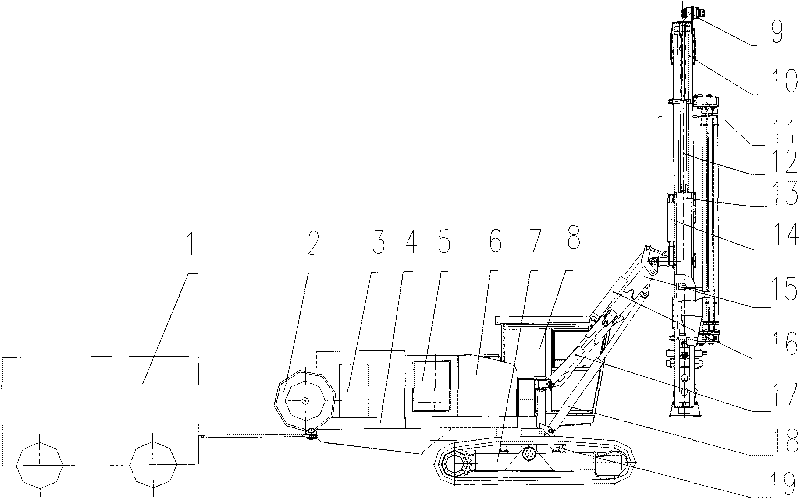

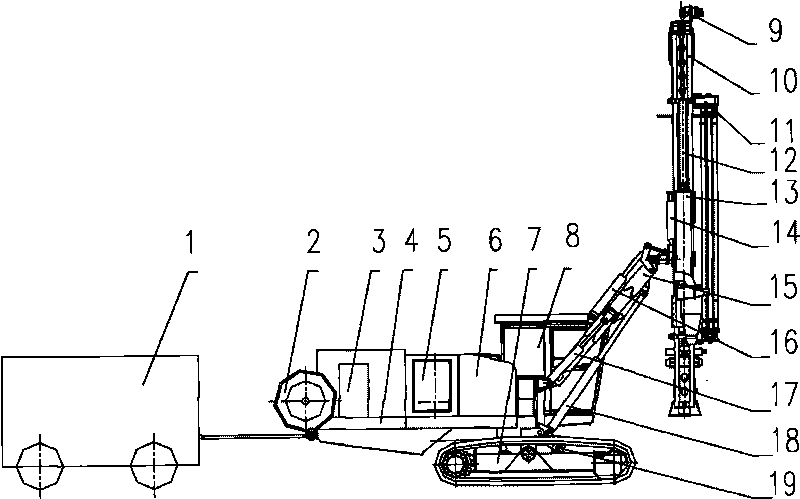

Integrated arm type in-hole perforator

InactiveCN101343979AWide range of operationsReduce auxiliary work timeDrilling machines and methodsControl systemEngineering

The invention discloses an integrated arm type down-the-hole drilling machine, which comprises a traveling chassis, a machine frame (3), a drill arm (14), a drill tower (9), a drilling system, a power system (4), a hydraulic system (5), a control system (19) and a cab (7), wherein, the traveling chassis which adopts a pedrail floating type traveling chassis (6) is arranged below the machine frame (3), an air compressor (2) and a dust removing system (1) are arranged on the machine frame (3), a drill arm lifting cylinder (17) and a drill arm deflecting cylinder (16) are installed between the drill arm (14) and the machine frame (3), and a drill tower lifting cylinder (15) and a drill tower deflecting cylinder (13) are arranged between the drill arm (14) and the drill tower (9). A compensation cylinder (11) is arranged between a sliding carriage (12) of the drilling system and the drill tower (9). The invention provides the integrated arm type down-the-hole drilling machine which has the advantages that the structure is compact, the maneuverability is good, the integrated arm type down-the-hole drilling machine can meet the requirements of multiple direction drilling, the operation range is wide, the energy consumption is low, the efficiency is high, the control is convenient and flexible, the maintenance is convenient, and the operation cost is low.

Owner:CENT SOUTH UNIV +1

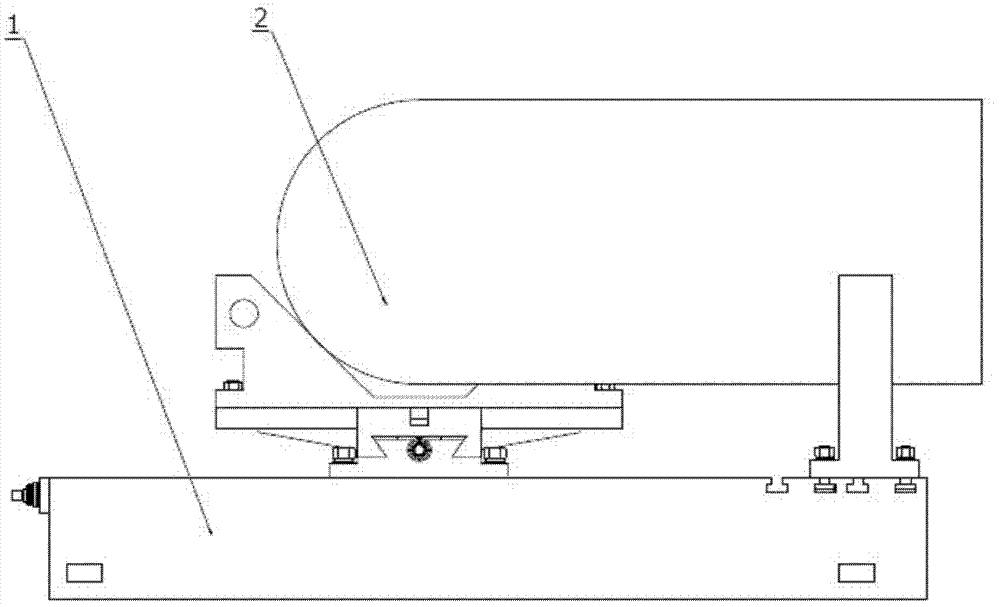

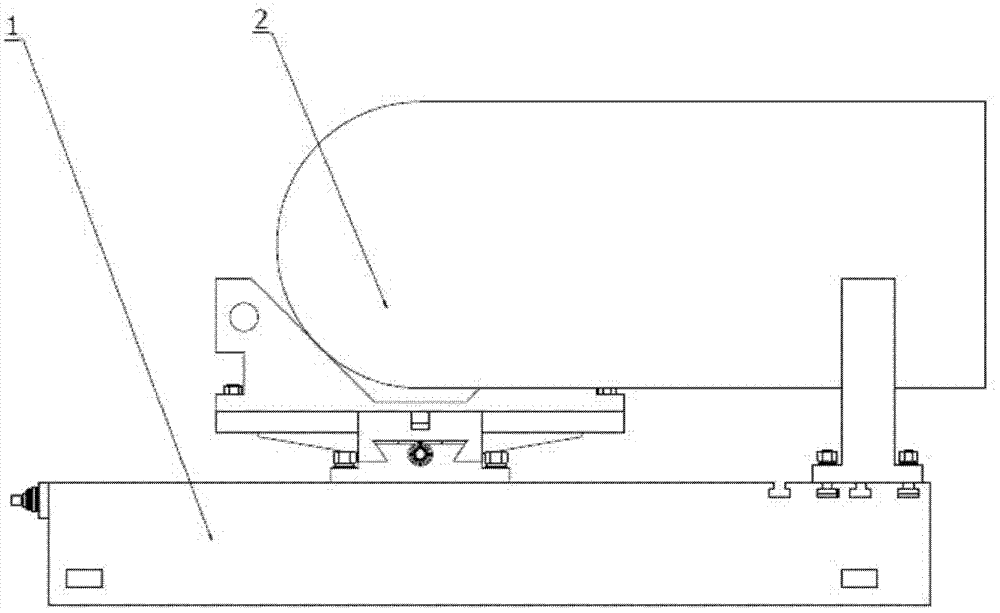

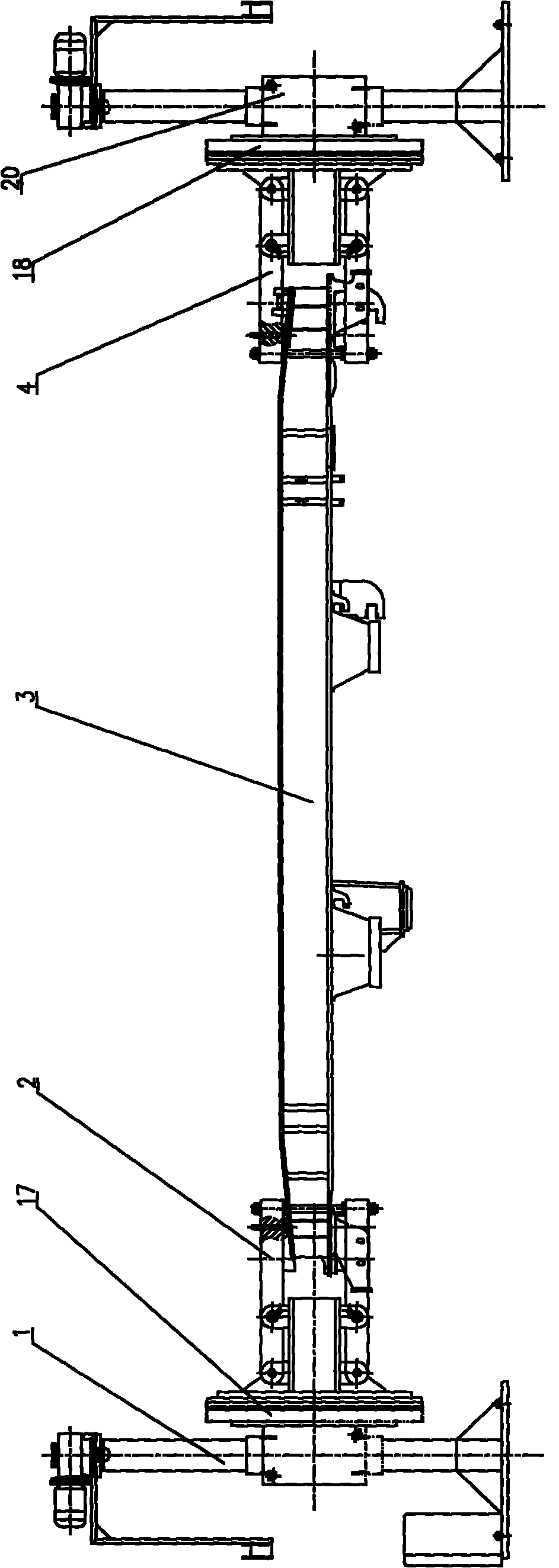

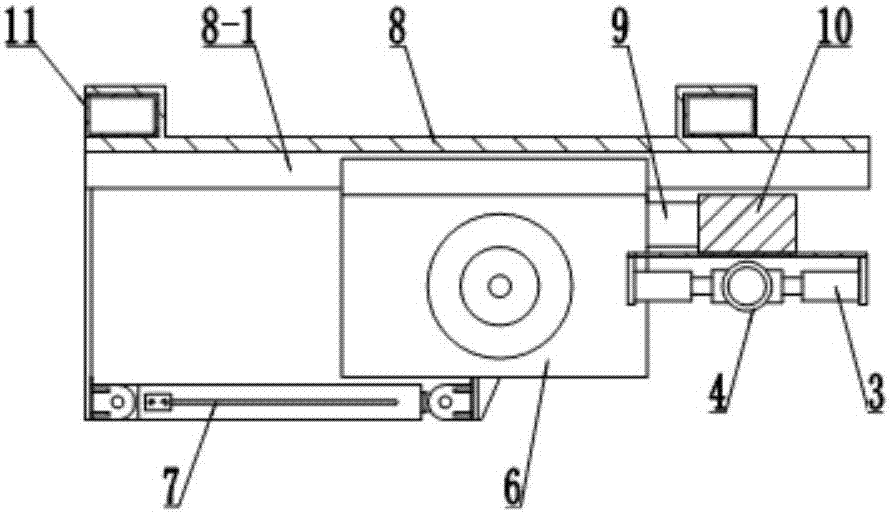

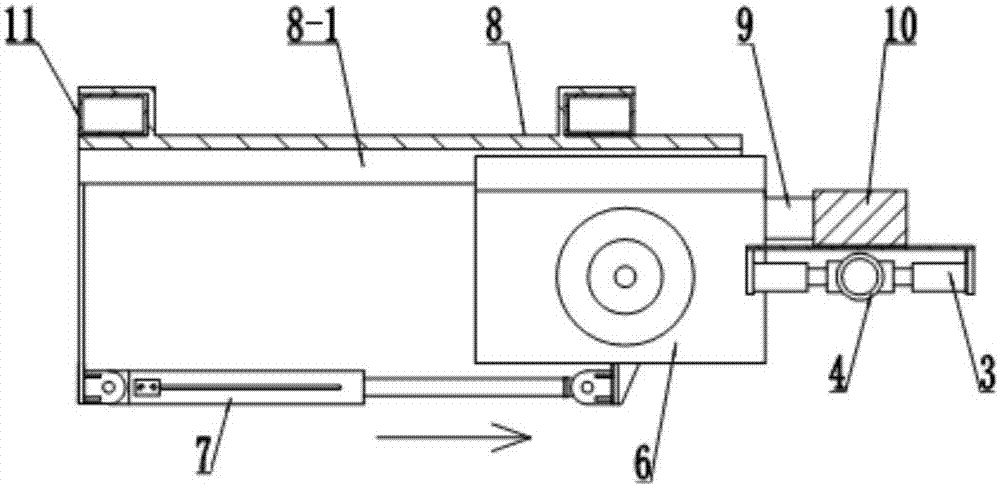

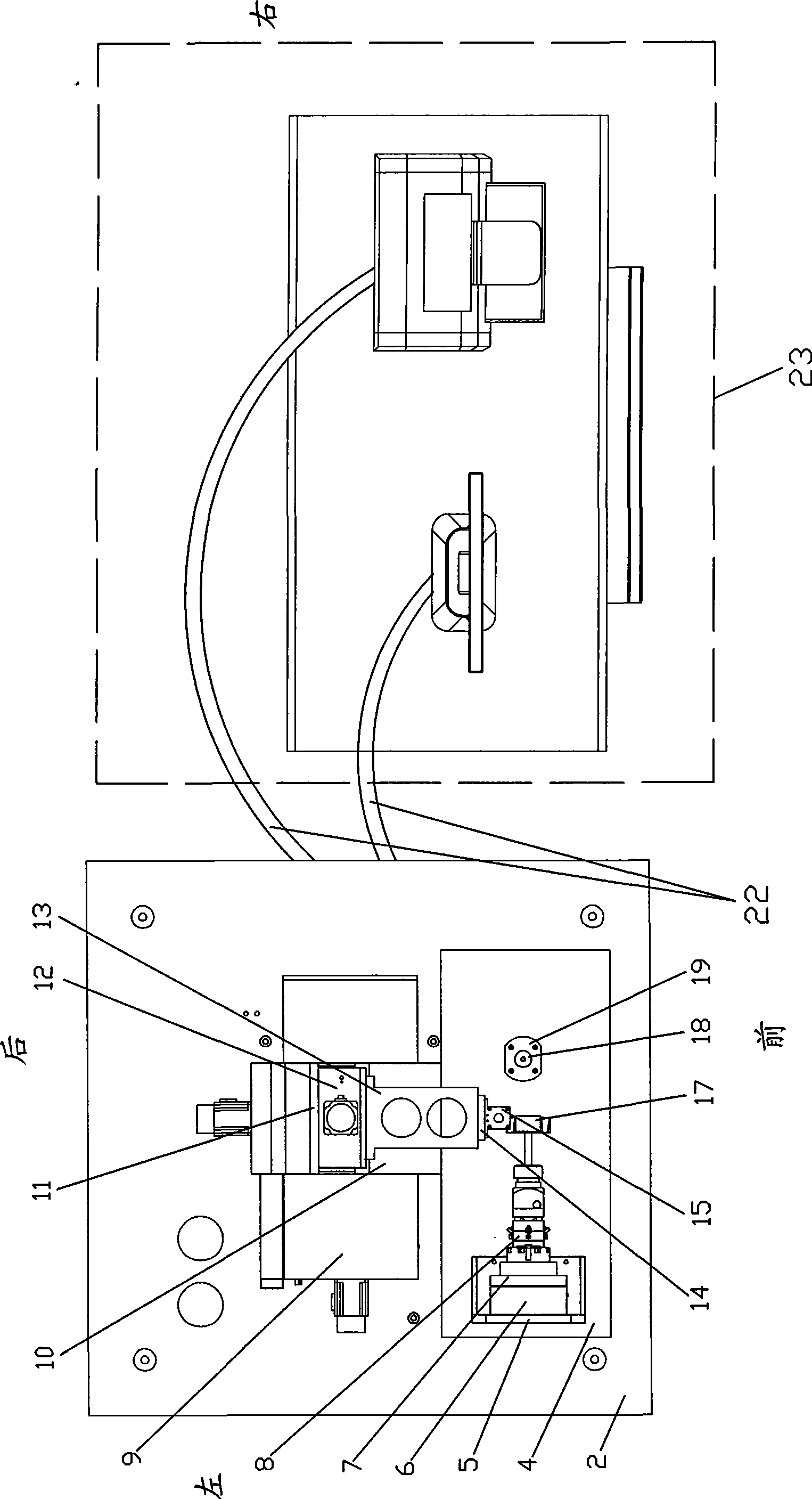

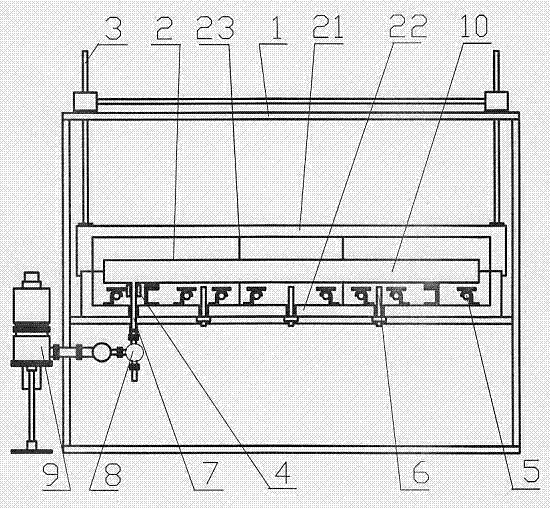

Workbench for groove machining of large-caliber hot bends

ActiveCN103358135AReduce occupancyReduce auxiliary work timeLarge fixed membersPositioning apparatusEngineeringCaliber

The invention discloses a workbench for groove machining of large-caliber hot bends. A fixed bottom board (9) provided with two thrust ball bearings (8) and a lower slide block lead screw (7) is fixed at the port communicated with a middle groove of a platform base (6). The threaded end of the lower slide block lead screw (7) is screwed into a threaded base of a transverse V-shaped slide block (15). A V-shaped groove of a fixed rotating disc base (14) is in sliding connection with a V-shaped protrusive block of the transverse V-shaped slide block (15). A movable V-shaped block (11) and the transverse V-shaped slide block (15) are fixed in the middle of the fixed rotating disc base (14) perpendicularly. A circular shaft matched with an upper hole of the fixed rotating disc base (14) is arranged at the lower end of the movable V-shaped block (11). A transverse slide board lead screw (20) is arranged in the center of one end of the transverse V-shaped slide block (15). A fixed V-shaped block (21) is arranged at the other end of the platform base (6) and is perpendicular to the movable V-shaped block (11) in direction. The workbench for groove machining of the large-caliber hot bends shortens the time for assisting in clamping, is rapid to locate and relieves labor intensity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

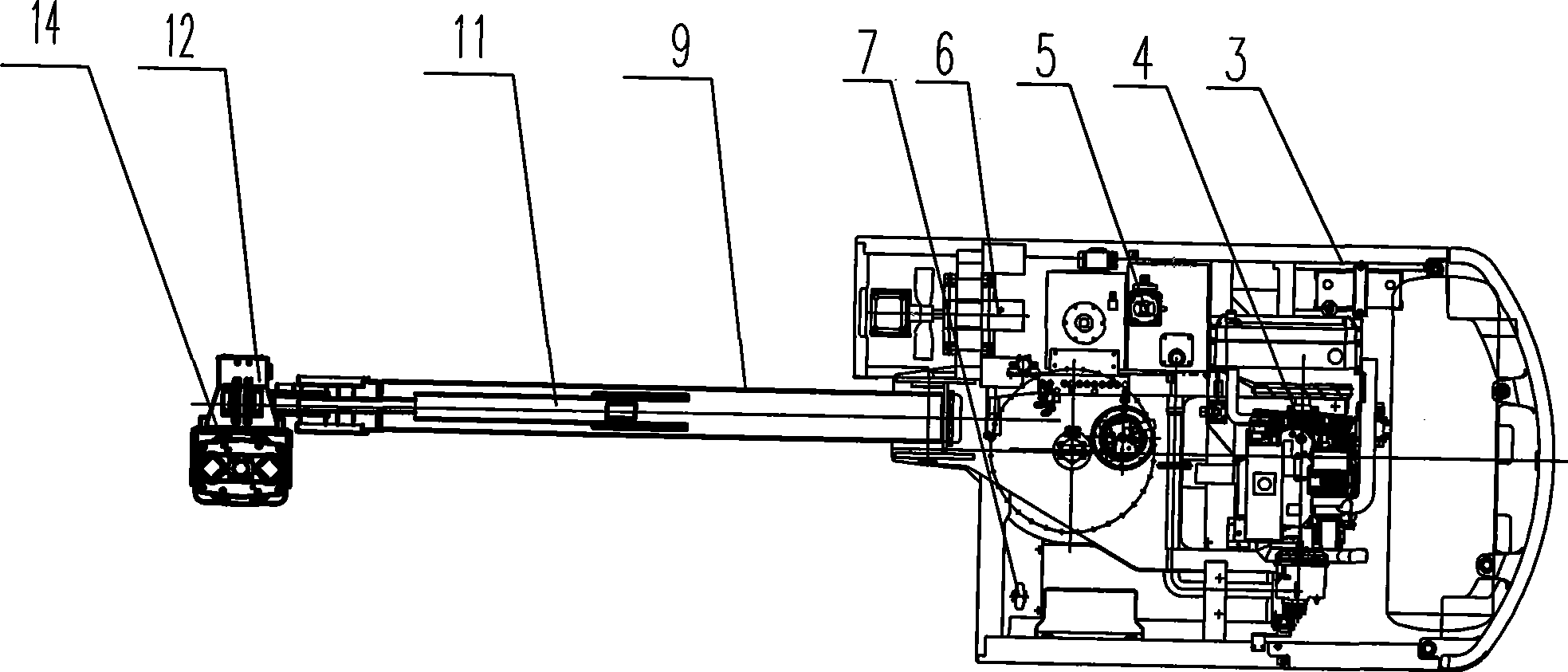

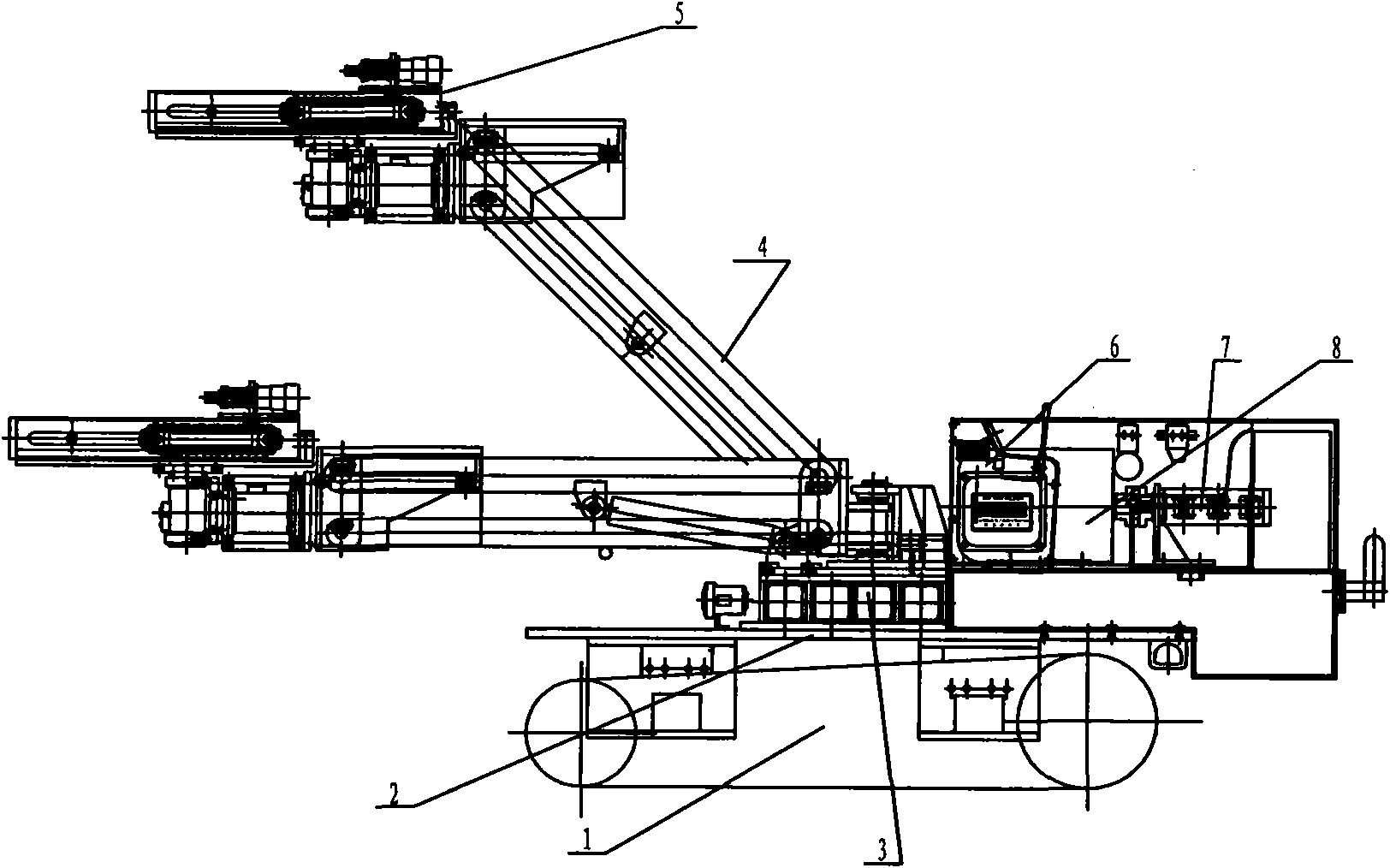

Dredger type drill

InactiveCN101382041AAvoid vibrationGreat driving forceConstructionsDerricks/mastsControl systemControl engineering

The invention discloses a digging machine type drill which comprises a walking chassis (1), a platform returning mechanism (2), a platform (3), a power system, a hydraulic system (5), a movable arm (9), a movable arm lifting cylinder (10) and an operating control system (7). A hydraulic drill is hinged with the front end of the movable arm (9), a drill tower tilting cylinder (11) hinged with the hydraulic drill is arranged on the movable arm (9), and the drill tower tilting cylinder (11) is hydraulically connected with a hydraulic part of the hydraulic drill and the hydraulic system (5). The digging machine type drill has a compact structure, good maneuverability, capability of meeting various drilling requirements, wide operating range, low energy consumption, high efficiency, convenient and flexible operation, simple maintenance, low use cost, and environmental friendliness.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

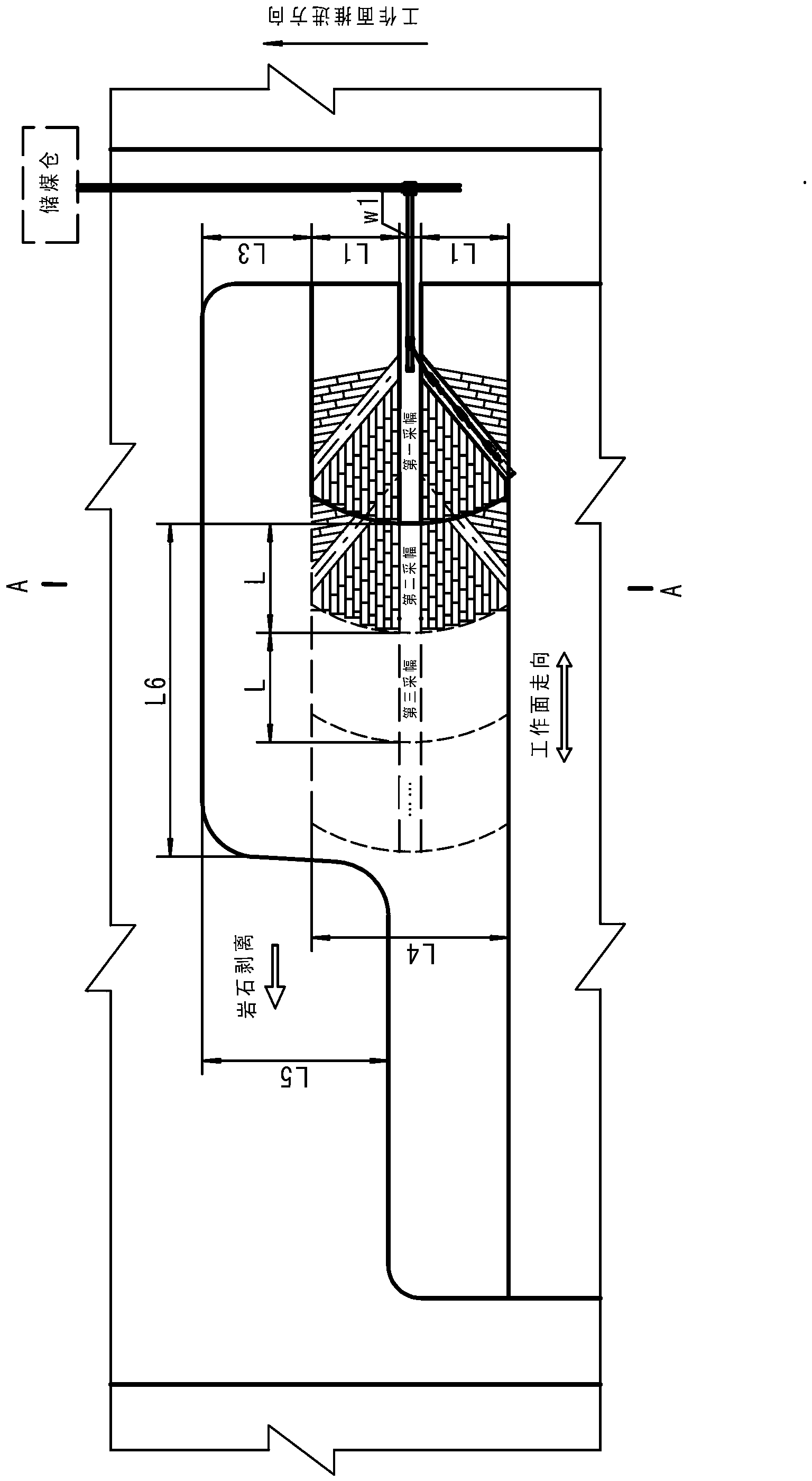

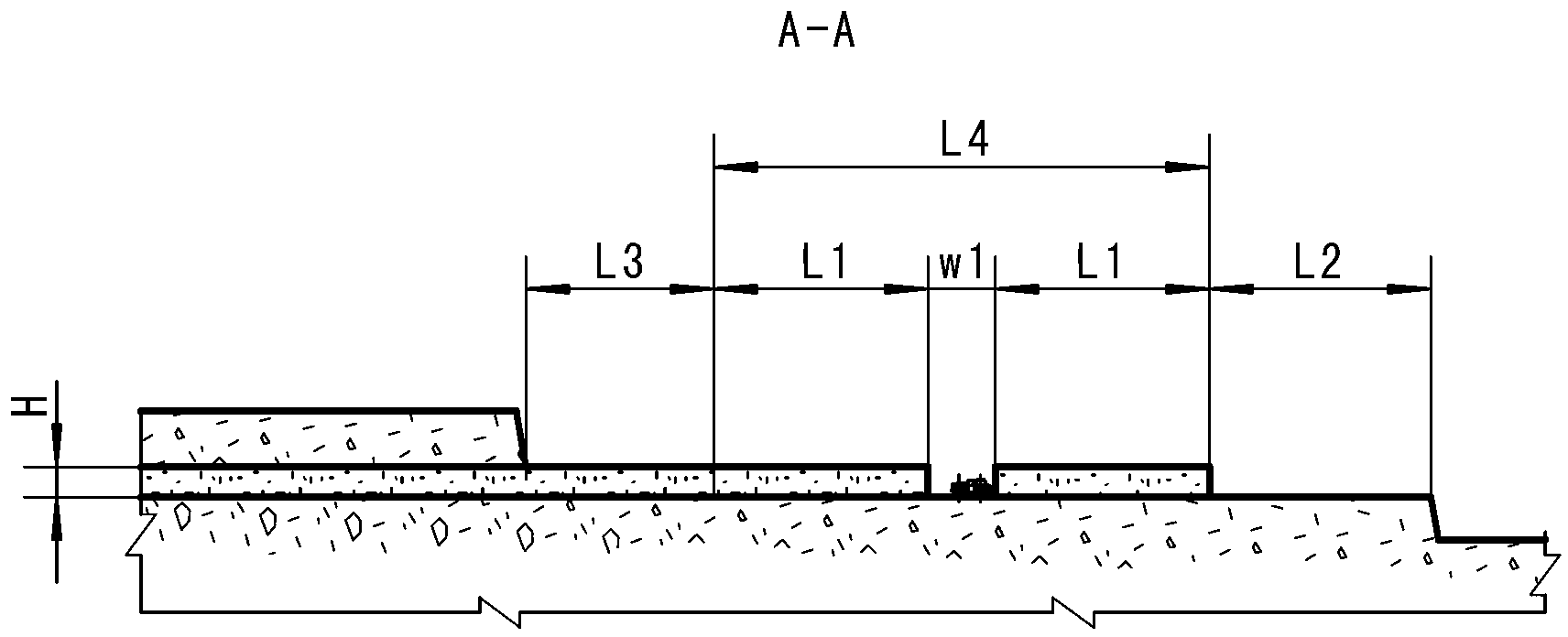

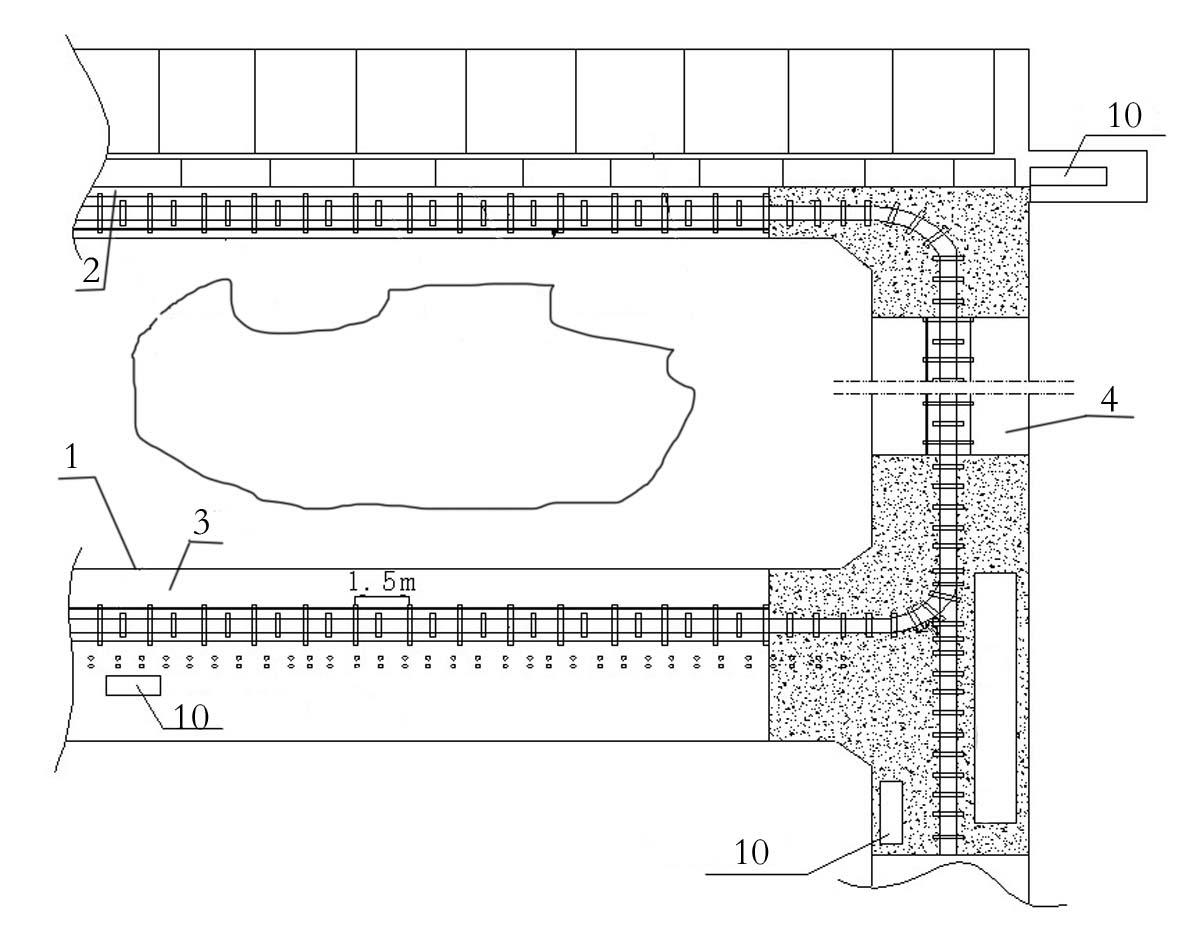

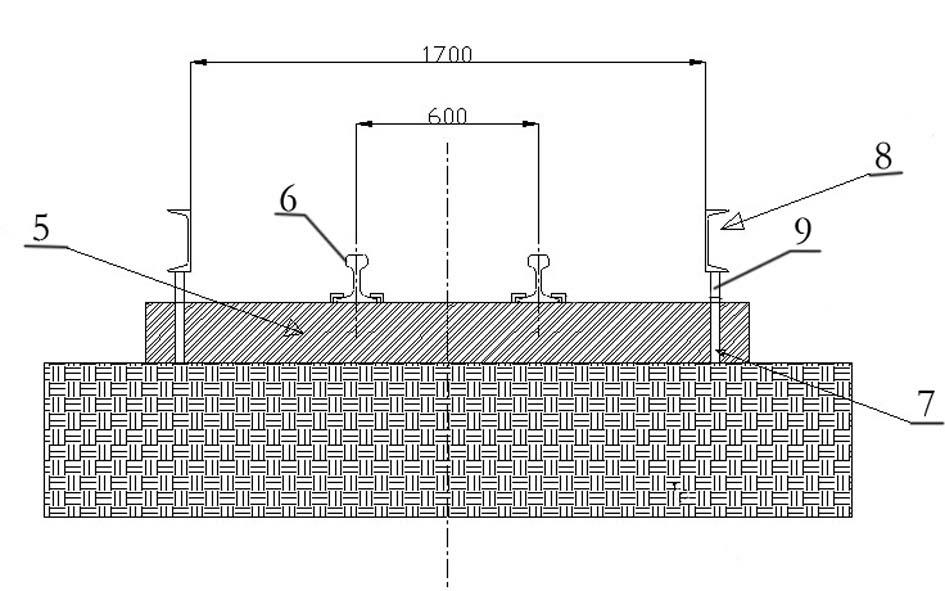

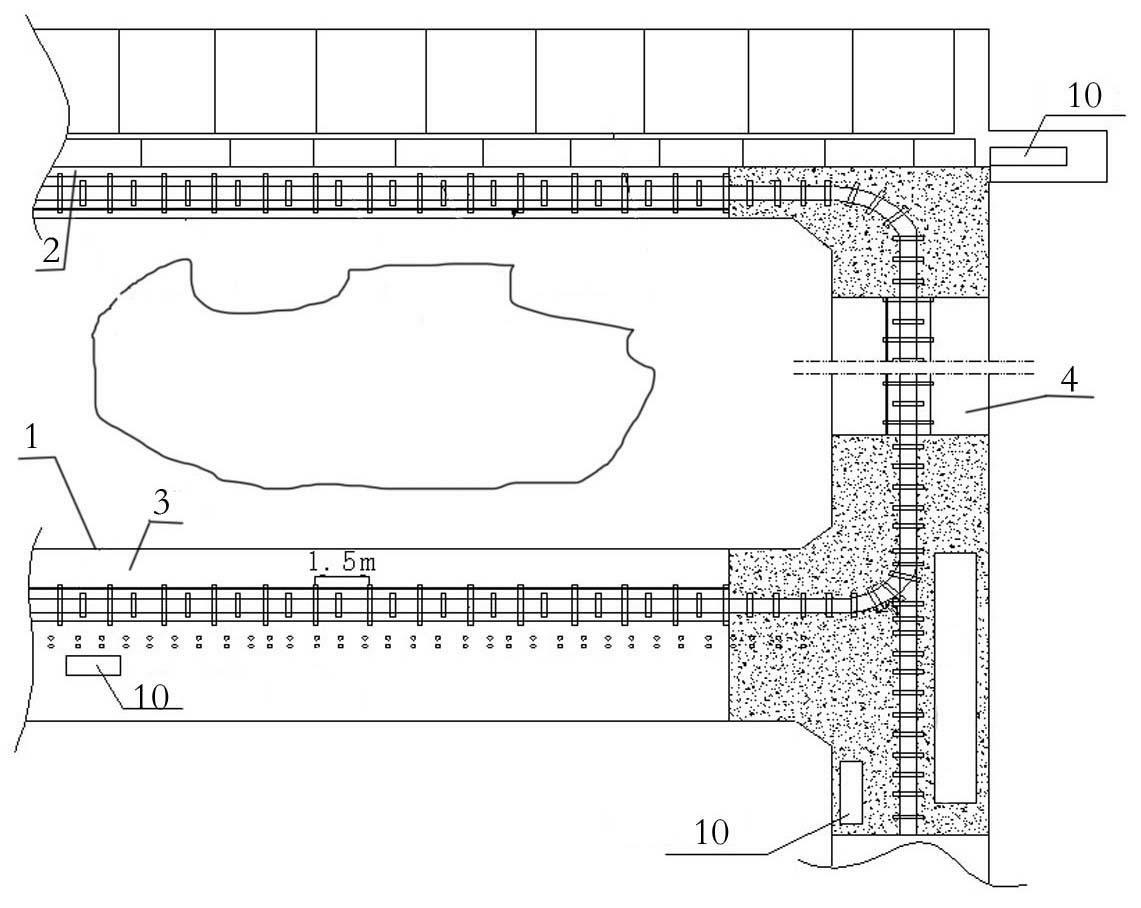

Double-wing continuous coal mining technique for open-pit coal mine

The invention relates to a double-wing continuous coal mining technique for an open-pit coal mine. According to the storage distribution and geological characteristics of the open-pit coal mine, firstly a plurality of mining areas being 2000*90m are designated, then a plurality of fan-shaped width mining areas are designated in the mining areas, and digging, crushing, transshipping and conveying equipment is laid in each width mining area according to a way of forward mining in a main lane and oblique fan-shaped mining in left and right wing lanes to form standardized cycle operation. According to the double-wing continuous coal mining technique, the process is advanced, the ancillary working time is shortened, the reciprocating motion times are reduced, the equipment working for cycle operation can be fully utilized, and the safety of coal mining is improved, so htat the double-wing continuous coal mining technique for the open-pit coal mine is very ideal.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

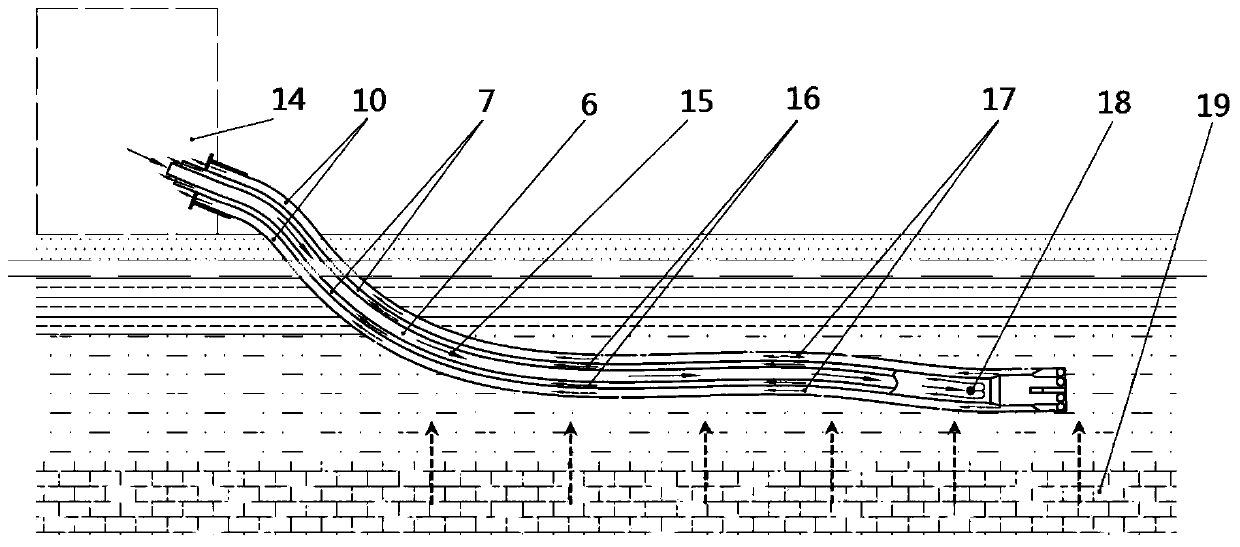

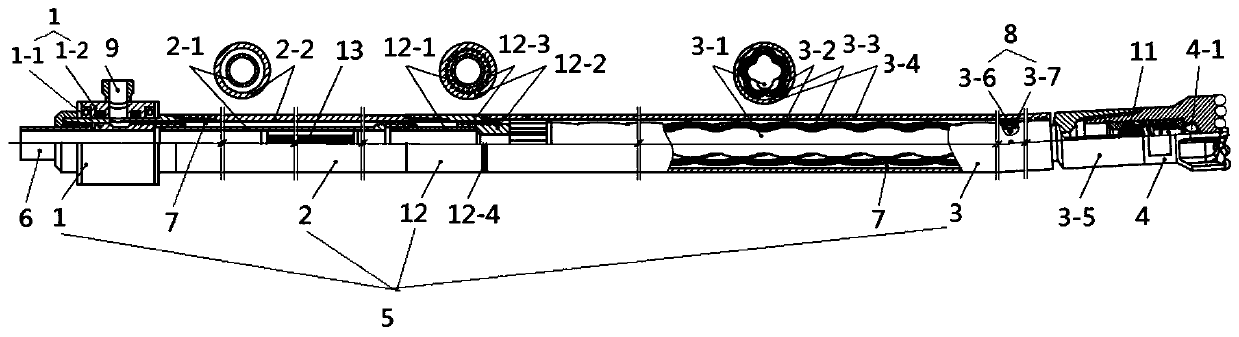

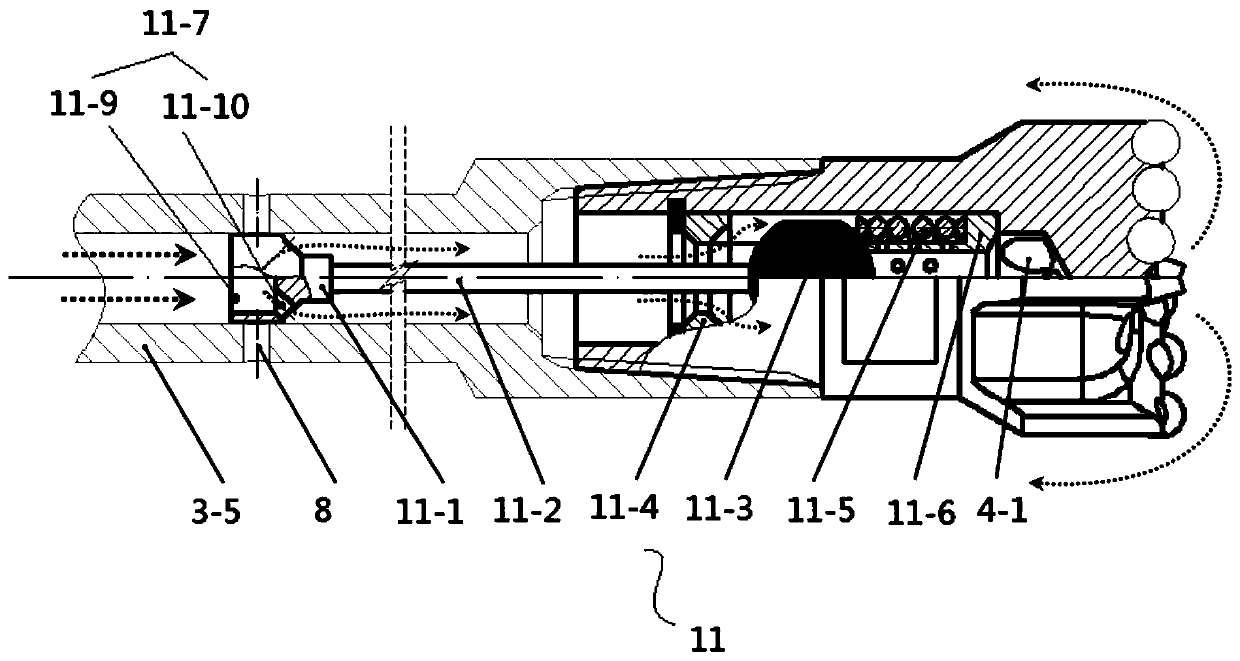

Underground coal mine water hole prevention and control high-water-pressure water jacking directional drilling tool and drilling method

The invention discloses an underground coal mine water hole prevention and control high-water-pressure water jacking directional drilling tool and drilling method. The directional drilling tool comprises a drill string body and a directional drill bit which are connected in sequence, and an inner annular hollow flow channel is arranged around the external of the drill string body; a ''Y-type'' structure flush fluid circulation flow channel consisting of a central flow channel and the inner annular hollow flow channel and an outer annular hollow flow channel formed between the drilling tool anda bore wall, the flush liquid is always flowing in the ''low back pressure'' state, the ''reactive'' load of a mud pump is substantially reduced, the effective utilization rate of the hydraulic energy can be improved by 15% or above, and it is ensured that the normal working and output torque parameters of the hole bottom power drilling tool do not change significantly under the working conditionof large water inrush of the high water pressure formation towards the inside of a hole. The drilling tool can normally directionally drill in the formation water outlet pressure condition of 6.0MPaor above, so that the downhole directional drilling water pressure resistance is improved by 50% or above, and the water jacking directional drilling hole-forming depth is 500m or above.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

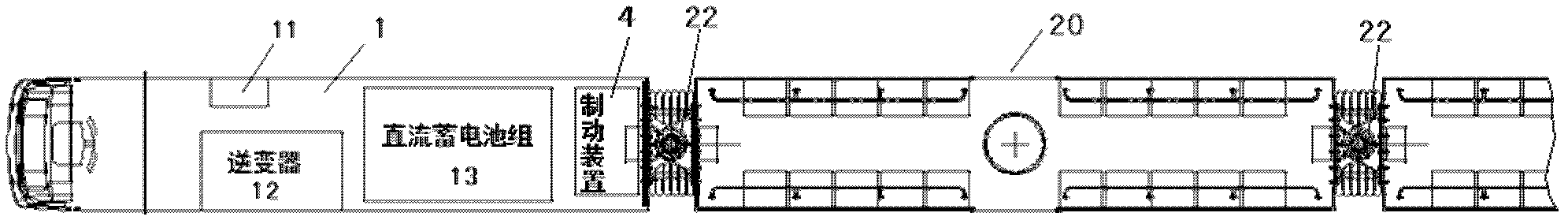

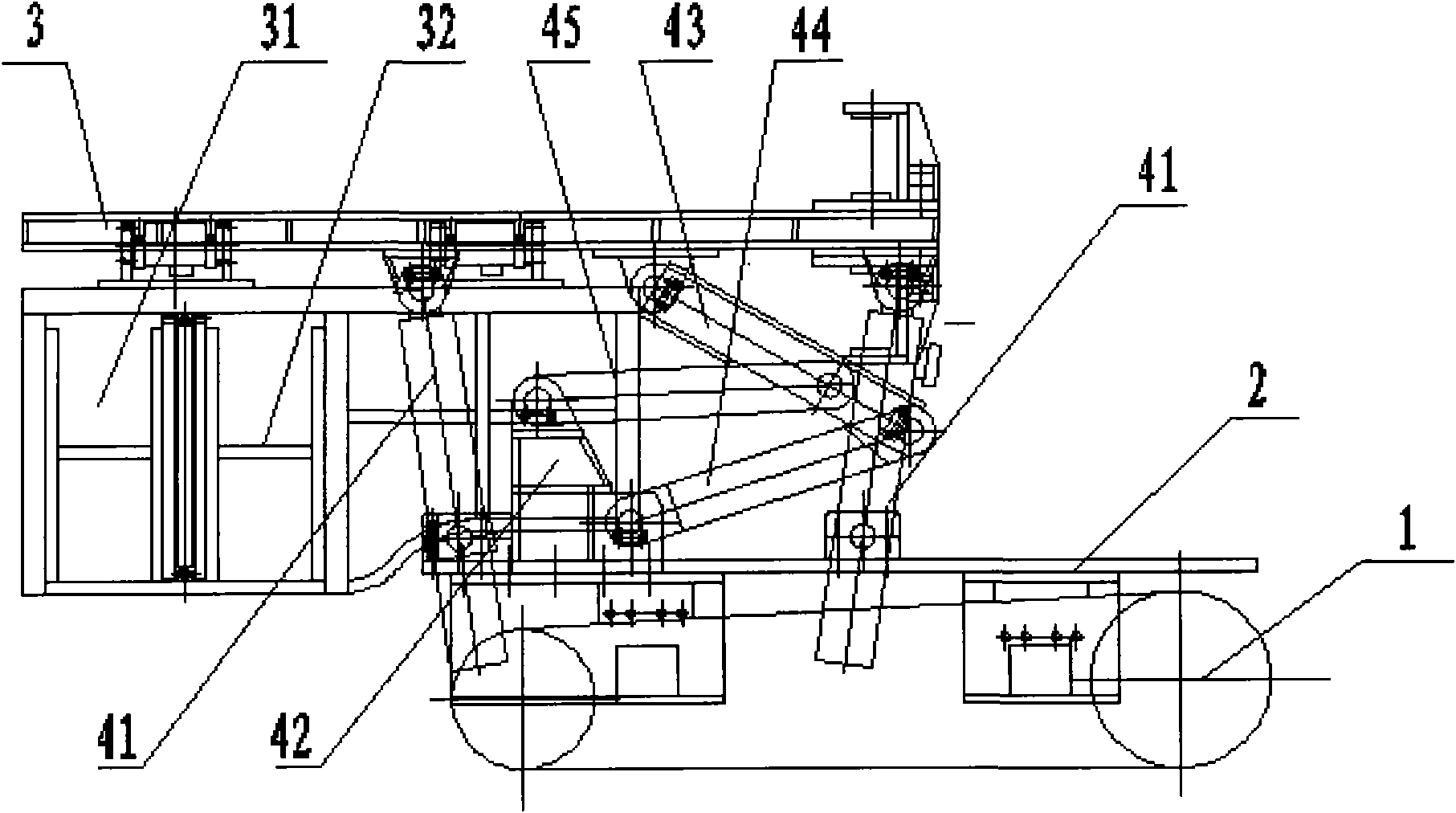

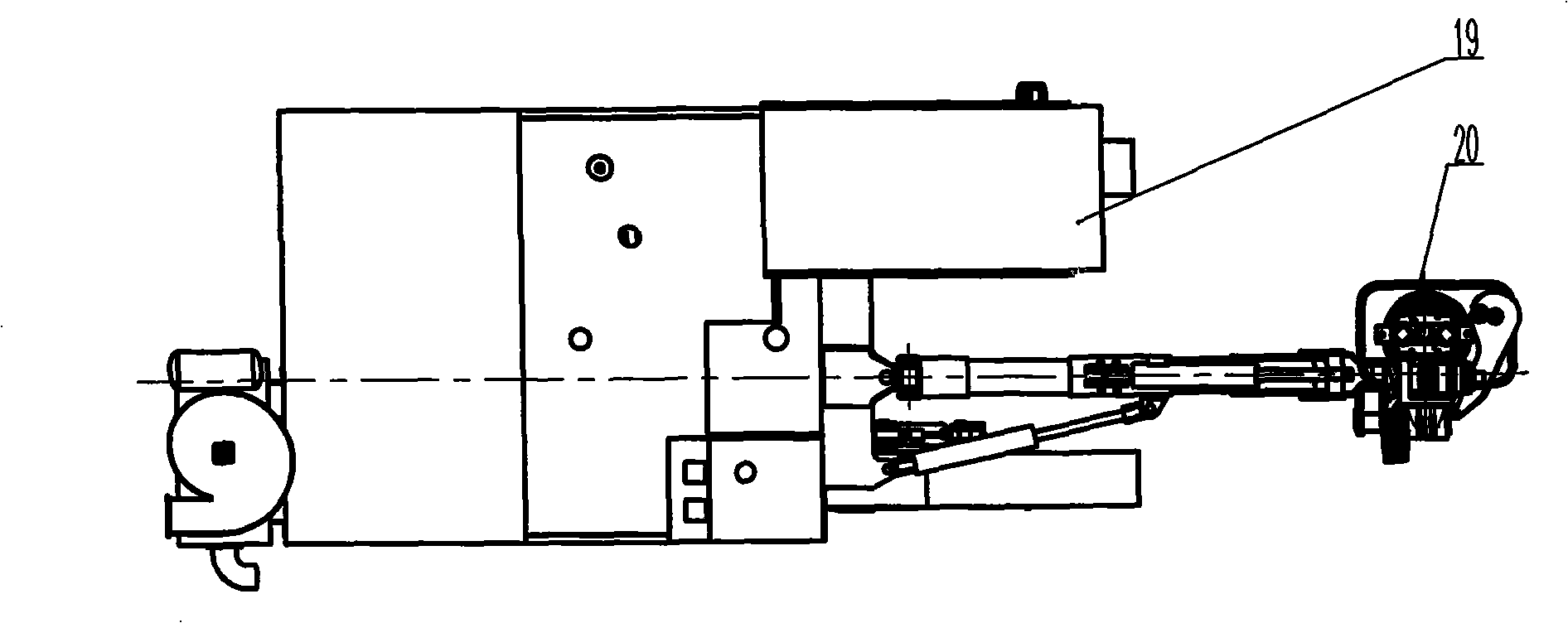

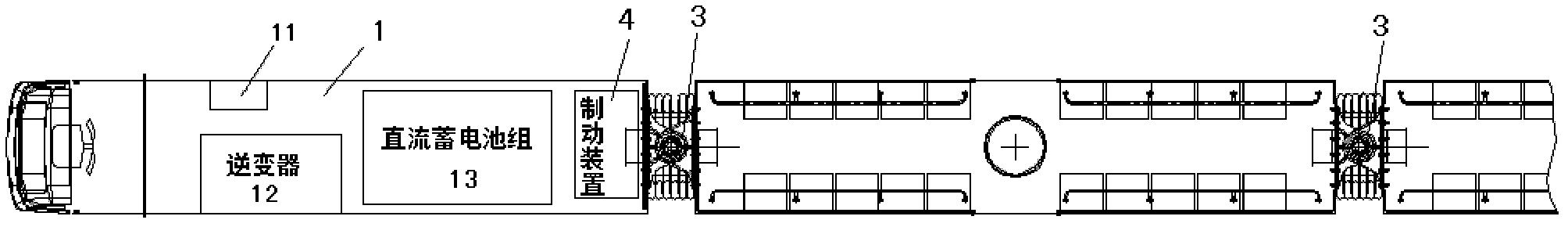

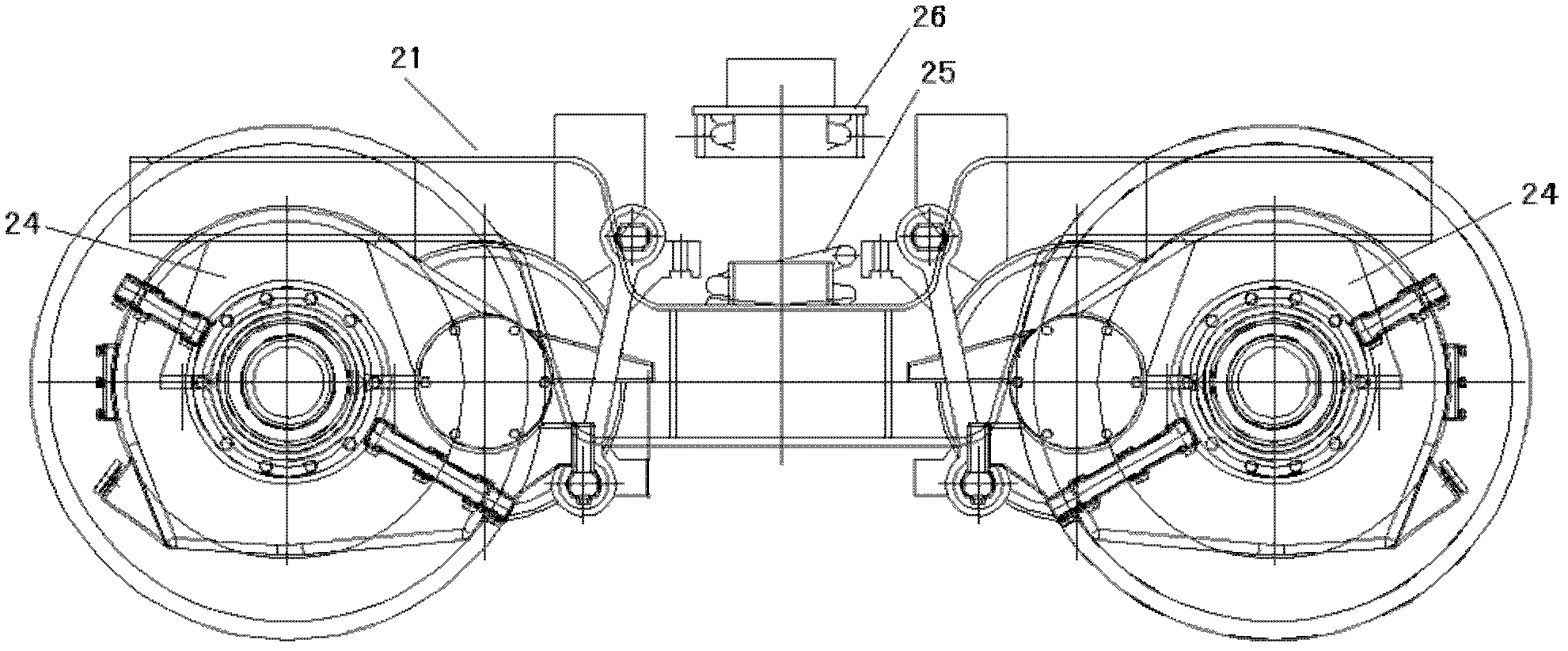

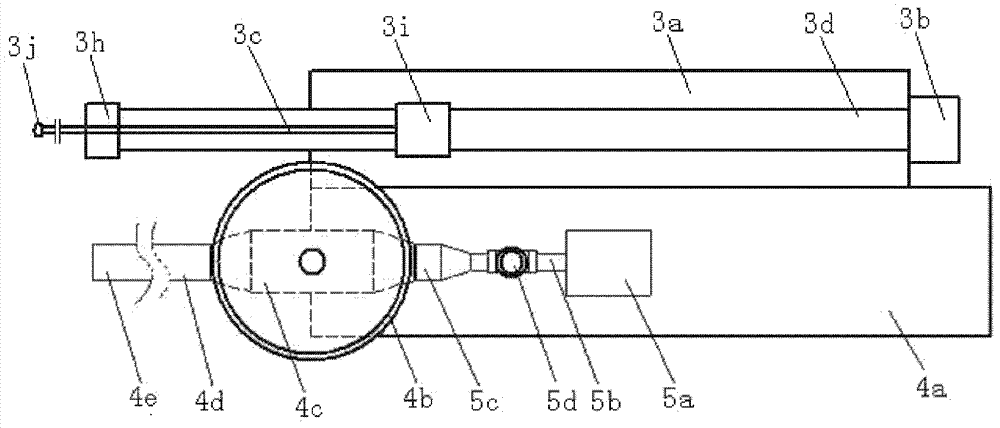

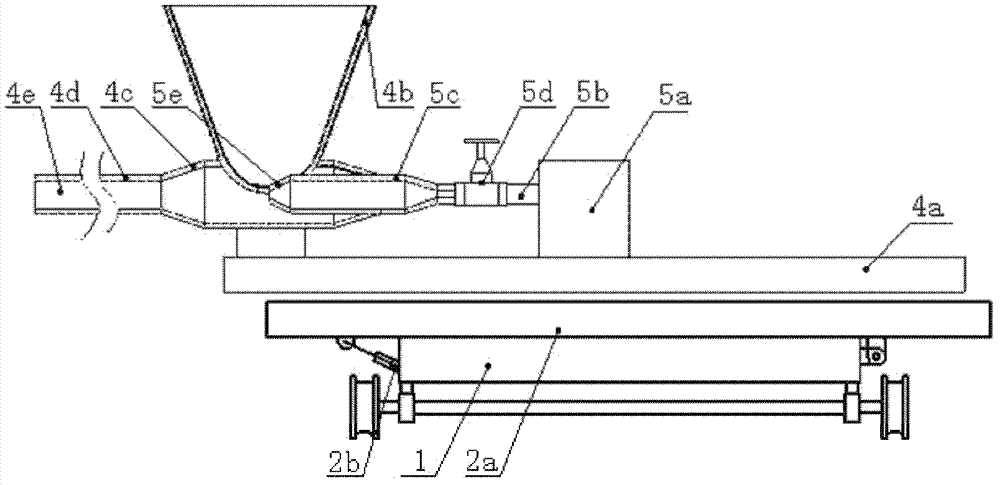

Power car for narrow gauge electric motor car

ActiveCN102501859AReduce volumeIncrease driving speedElectric locomotivesRailway transportBogieElectrical control

The invention relates to a power car for a narrow gauge electric motor car, which comprises a power car body, wherein, an electrical control system, a drive power supply and a braking device are arranged inside the car body; and two power steering frames are arranged at the bottom of the car body. The power car is characterized in that one of the power steering frames is arranged at the bottom of the car body under the drive power supply, and the other power steering frame is arranged between the bottom of the car body and the bottom of a carriage of an adjacent tow truck; the car body and the adjacent carriage are connected through an articulation device and a passing platform; the articulation device is arranged on a lower center plate of one of the power steering frames; the passing platform is arranged at the top of the articulation device; and the both sides between the car body and the adjacent carriage are connected with each other through a damper plate. The power car can be widely used in various occasions needing narrow gauge transportation, such as mine exploitation, tunnel excavation, light rails, subways, etc.

Owner:CHANGCHUN GUANGYIN GROUP

Calcium carbide submerged arc furnace hole punching and plugging device and method

The invention relates to the technical field of calcium carbide submerged arc furnaces, and discloses a calcium carbide submerged arc furnace hole punching and plugging device and method. The device comprises a frame, an inclination angle adjusting mechanism, a hole punching mechanism and a hole plugging mechanism, wherein the inclination angle adjusting mechanism is mounted on the frame; the hole plugging mechanism and the hole punching mechanism are mounted on the inclination angle adjusting mechanism respectively; the inclination angle adjusting mechanism is used for adjusting the inclination angle of the hole punching mechanism and the hole plugging mechanism; the hole punching mechanism is used for punching the furnace hole of the calcium carbide submerged arc furnace; and the hole plugging mechanism is used for plugging the furnace hole. According to the invention, the mechanization of the calcium carbide submerged arc furnace hole punching and plugging device is realized by the hole punching mechanism and the hole plugging mechanism, the hurt to an operator caused by manual operation is avoided, the working efficiency is improved, the auxiliary working time of the submerged arc furnace is shortened, and the energy is saved; and moreover, the hole is plugged by calcium carbide particles, the service life of the furnace mouth is long, and the output is increased.

Owner:内蒙古君正化工有限责任公司 +1

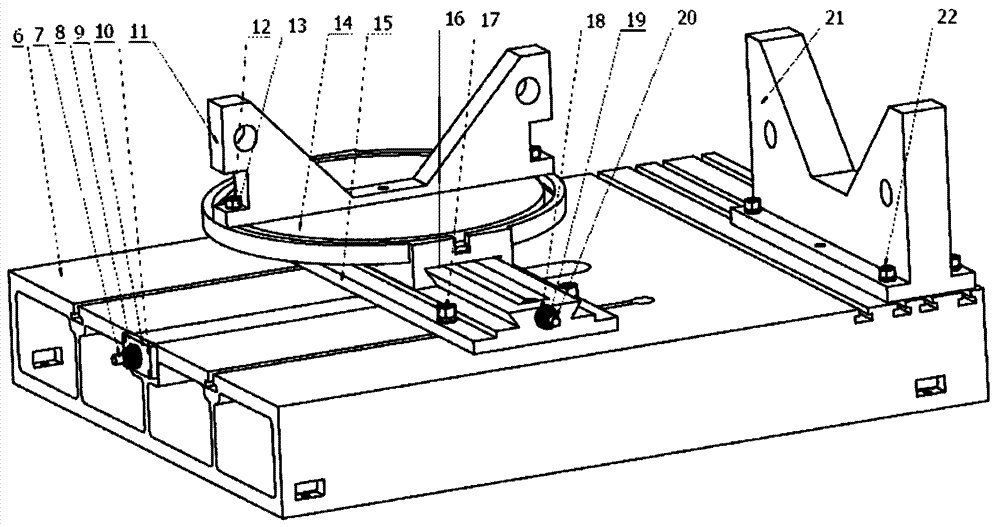

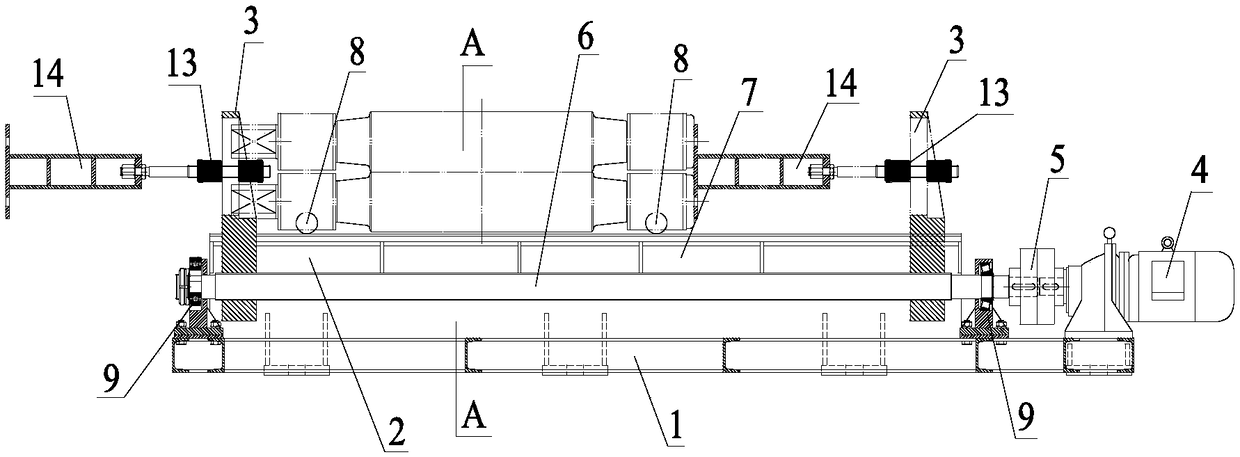

Framework turnover device and operation method thereof

ActiveCN101774103AFlanging after fast weldingConvenient for flanging after weldingWelding/cutting auxillary devicesAuxillary welding devicesWork periodEngineering

The invention discloses a framework turnover device of the locomotive field and an operation method thereof. The framework turnover device comprises a left and a right elevation rotation tires which are symmetrically arranged, a left clamp which is fixed on a left elevation rotation tire rotation disc and a right clamp which is fixed on a right elevation rotation tire rotation disc. A framework is arranged between the left and the right clamps, and the framework can be curled by adjusting the height of the left and the right elevation rotation tire rotation discs and rotating the left and the right elevation rotation tire rotation discs. The framework turnover device can rapidly, safely and conveniently turn over the framework of different locomotives and metro, not only saves a great amount of auxiliary working time and remarkably improves the production efficiency, but also reduces the labor intensity of the workers, and has simple operation, convenient loading and unloading, novel structure, safety and reliability.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

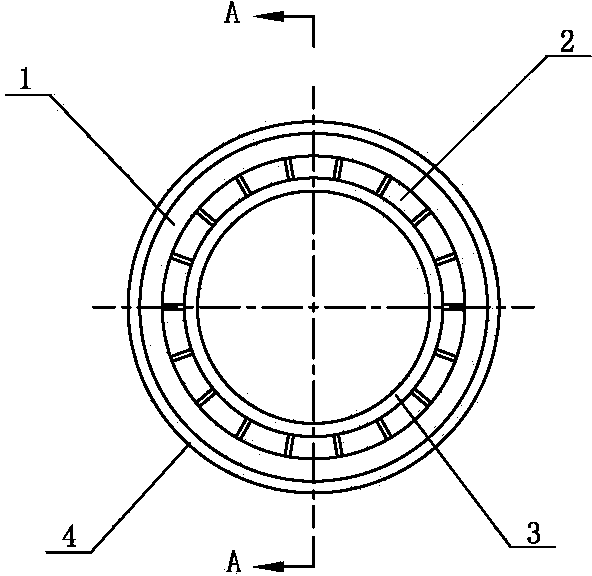

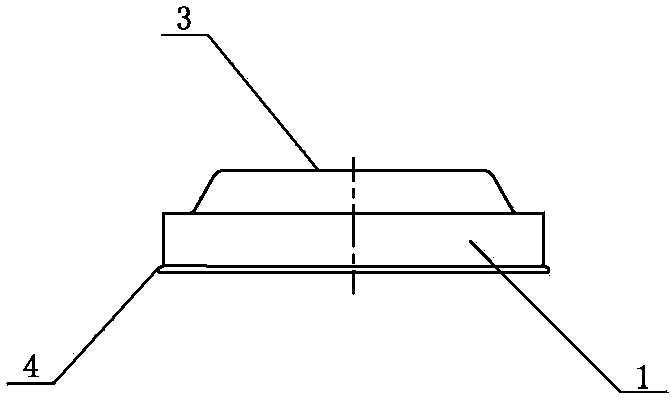

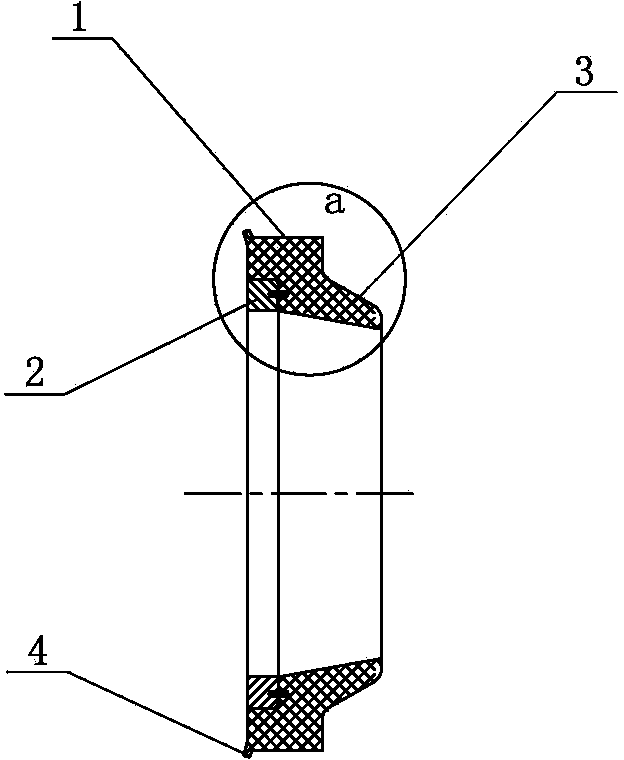

Steel tube end seal ring and sealing device

The invention discloses a steel tube end seal ring and a sealing device, and belongs to the technical field of sealing equipment. The steel tube end seal ring comprises a seal ring body and a supporting block arranged in an annular groove, and a steel tube seal peripheral edge and an end face seal peripheral edge are arranged on the end face of the seal ring body; an arc-shaped supporting groove is formed in the end face of one side of the seal ring body; a convex ring provided with a through groove is arranged on the outer circumferential face of the seal ring body. The sealing device comprises a sealing head and a locating sleeve which are mutually matched, and the steel tube end seal ring is arranged in the sealing device. A supporting ring of the locating sleeve is arranged in a supporting groove of the sealing head in a jacking mode and a gap is reserved. The steel tube end seal ring and the sealing device have the advantages that the pre-sealing link is omitted, the efficiency is improved, and cost is saved; the problem that the seal ring droops is solved, so that a pressure testing head can be designed smaller, and therefore a high-pressure test can be conducted on steel tubes with the diameter phi being larger than six hundred and thirty millimeters; the gap between the supporting groove and the supporting ring guarantees the effect that the seal ring body can be moved in place during pressure exertion, and after pressure is removed, the seal ring body can recover the original shape.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

Method for quickly moving fully mechanized mining face under special geological condition

InactiveCN102094673AReduce auxiliary work timeIncrease productivityRailway track constructionMovable tracksWork periodLow speed

The invention relates to a method for moving a fully mechanized mining face, in particular to a method for quickly moving the fully mechanized mining face under the special geological condition, and solves the problems of low speed and efficiency of the conventional method for moving the fully mechanized mining face under the special geological condition. A hydraulic bracket is directly dragged on a steel rail; in order to adapt to direct hauling, the structure of the rail is improved and optimized in modes of hardening the ground, adding a steel sleeper and a steel guardrail, and the like; and other fully mechanized mining equipment except the hydraulic bracket still adopts the conventional moving method. The hydraulic bracket is directly hauled, so that processes of feeding an empty vehicle, turning the vehicle, loading the vehicle, discharging the empty vehicle and the like in the conventional moving method are saved; therefore, the fully mechanized mining face is quickly moved under the special geological condition, a large amount of auxiliary work time is saved, and production efficiency is improved; meanwhile, vehicle deviating and rail separating accidents which possibly occur in the conventional moving method are avoided to a certain extent, and operation safety is effectively improved.

Owner:SHANXI JINCHENG ANTHRACITE COAL MINING GRP CO LTD

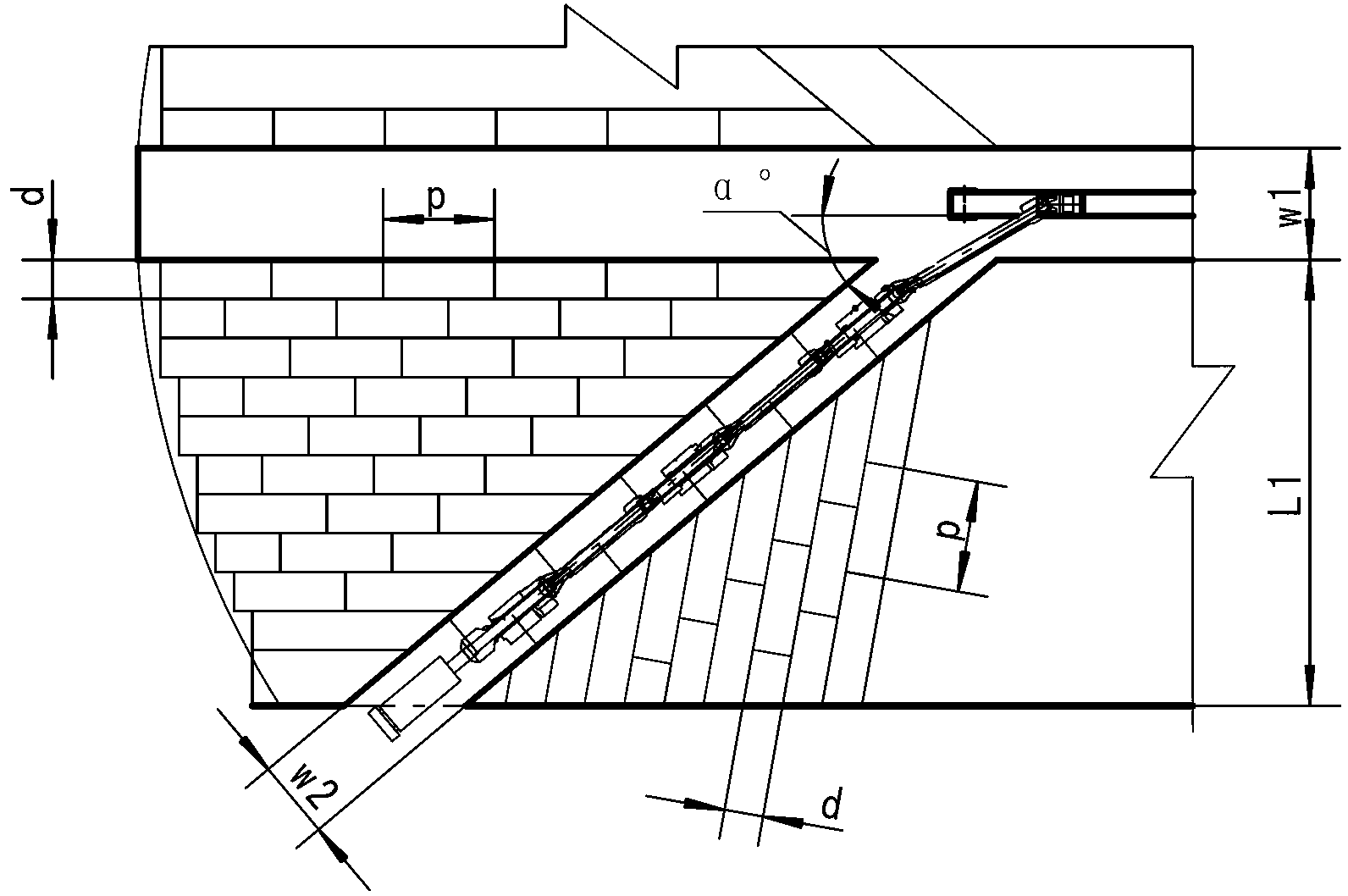

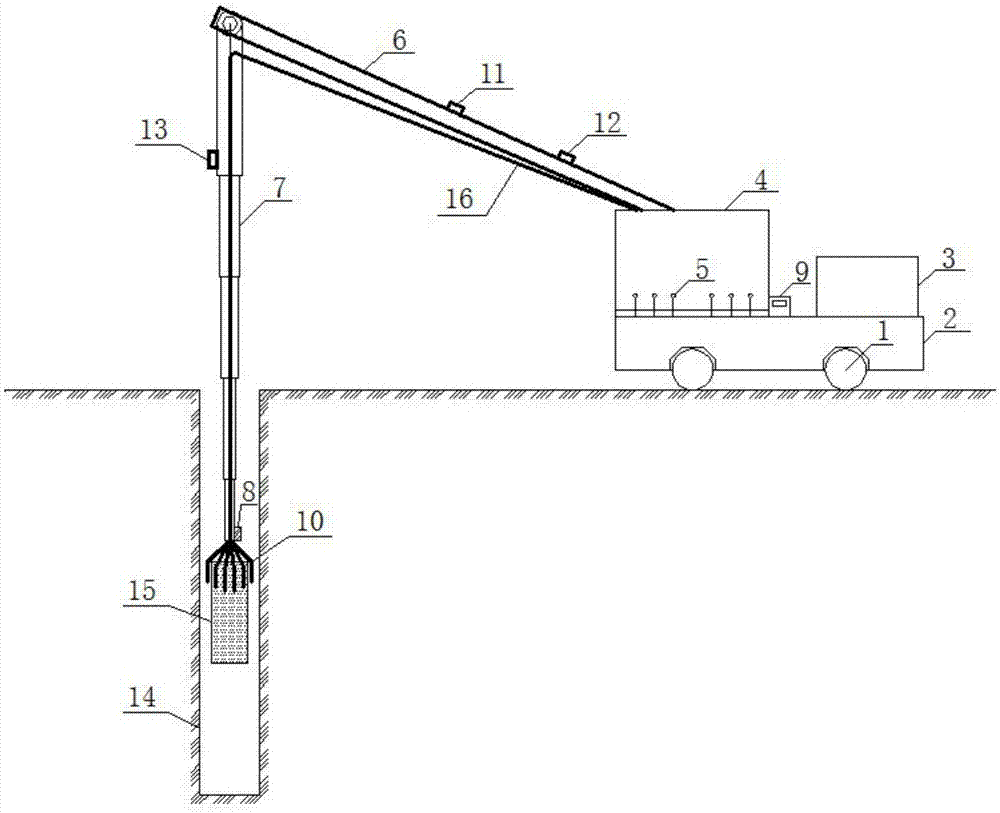

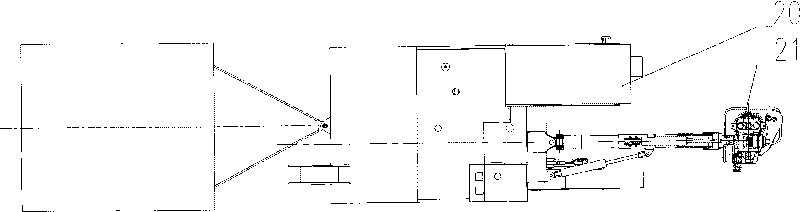

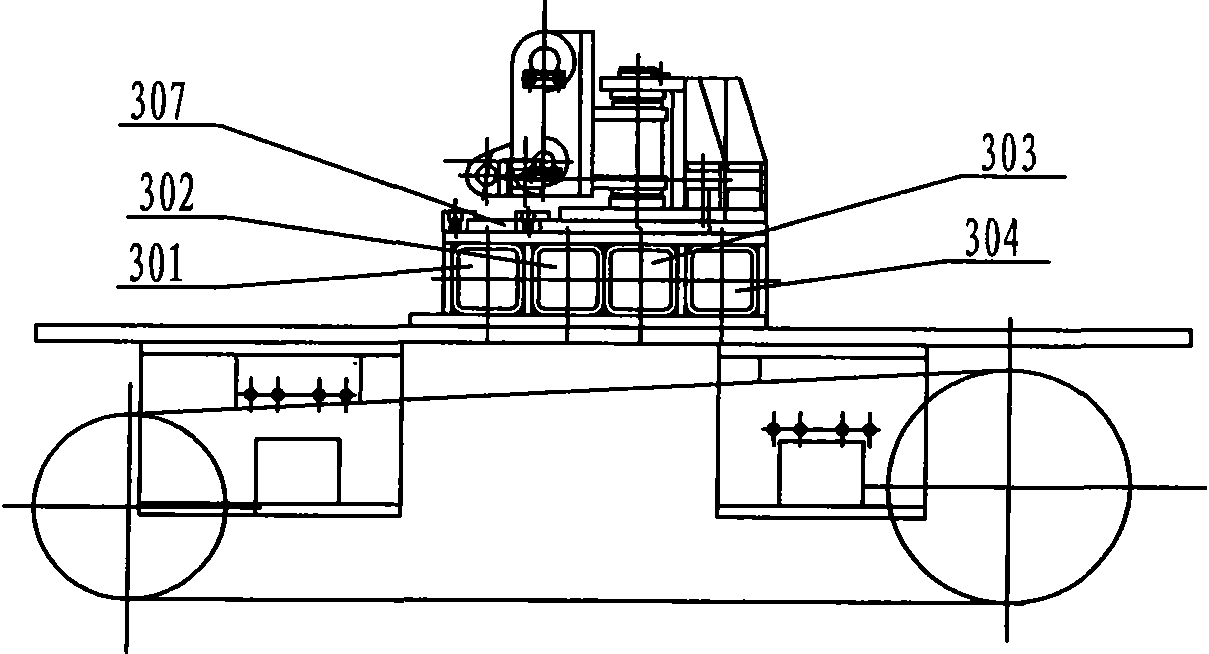

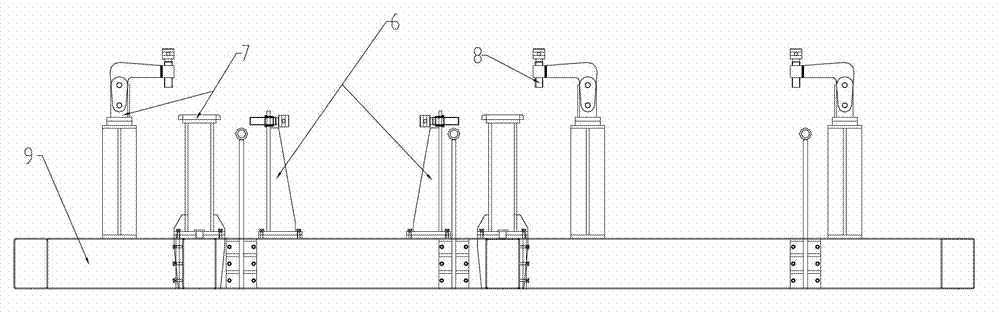

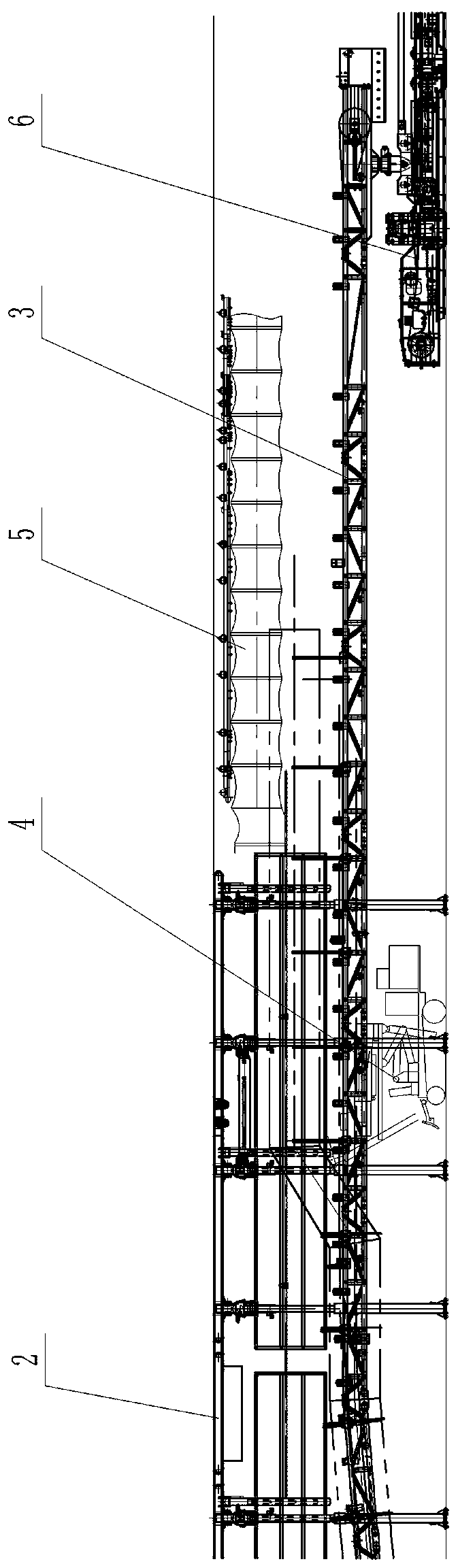

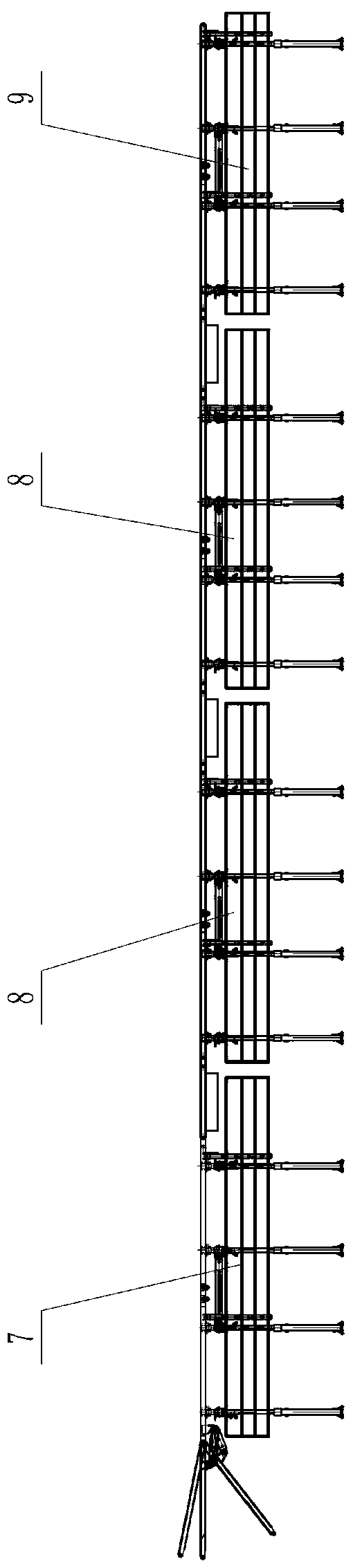

Surface blasting mechanization continuous powder charging system

ActiveCN107449333AEliminate premature explosion accidentsAvoid direct contactBlastingControl systemEngineering

The invention discloses a surface blasting mechanization continuous powder charging system. A rack (2) is supported on a travelling mechanism (1); a power system (3), a hydraulic system (4) and a control system (5) are mounted on the rack (2); one end of a support arm (6) is fixed on the travelling mechanism (1), and the other end of the support arm (6) is connected with a combined telescopic arm (7) downwards perpendicular; a hoisting oil cylinder (11) and a rotary oil cylinder (12) are arranged on the support arm (6); a telescopic oil cylinder (13) and a depth indicator (8) are arranged on the combined telescopic arm (7); the hydraulic system (4) communicates with the hoisting oil cylinder (11), the rotary oil cylinder (12) and the telescopic oil cylinder (13) through a hydraulic oil pipe (16); and the control system (5) controls operation of the support arm (6) and the combined telescopic arm (7) and controls open-close of a gripper (10) through the hydraulic system (4). The surface blasting mechanization continuous powder charging system can realize mechanization of the powder charging process, avoids the powder cut-off phenomenon, eliminates the misfire accident caused by discontinuous powder charging and improves the security of blasting operation.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Large-aperture split arm type downhole drill

InactiveCN101737008AAdjustable angleImprove performanceBorehole drivesDrilling machines and methodsAir compressorHigh pressure

The invention discloses a large-aperture split arm type downhole drill which comprises a stand (4), a drilling frame (10), a walking chassis and an air compressor, wherein the air compressor and the stand (4) are arranged in a split type; the air compressor and a drilling machine are connected by using a high-pressure air pipe; one end of a drilling arm (15) is articulated with the stand (4), while the other end is articulated with the drilling frame (10); a drilling frame hoisting oil cylinder (16) and a drilling frame deflection oil cylinder (14) are arranged between the drilling frame (10) and the drilling arm (15); and a drilling arm hoisting oil cylinder (18) and a drilling arm deflection oil cylinder (17) are arranged between the drilling arm (15) and the stand (4). The large-aperture split arm type downhole drill has convenient movement, good maneuverability, small influence on the drilling machine and the air compressor by dust generated by drilling, difficult machine abrasion, convenient maintenance, long service life and wide drilling operation range.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD +1

Movable three-arm top-assisting anchor rod and anchor cable construction drill carriage

ActiveCN101845952AShorten working timeImprove support efficiencyAnchoring boltsCutting machinesEngineeringSafe operation

The invention relates to a movable three-arm top-assisting anchor rod and anchor cable construction drill carriage which comprises a caterpillar travelling part, an engine body platform, a base seat, drilling arm parts, hydraulic drill rig devices, an operating system, a pump station part and an electric motor, wherein the hydraulic drill rig devices are arranged on the tops of the drilling arm parts; the operating system, the pump station part, the electric motor and the like are installed at the rear on the engine body platform; the construction drill carriage is characterized in that the construction drill carriage is provided with three sets of independent drilling arm parts and hydraulic drill rig devices which are respectively arranged at the left, the middle and the right of the base and are installed on the base; the base is fixedly arranged on the engine body platform; and the drilling parts and the hydraulic drill rig devices which are arranged at the left and the right sides can slide outwards. The construction drill carriage lightens the labor intensity of constructors, reduces the number of the constructors, improves the advancing speed and the operation efficiency, creates safe operation environment, and has the functions of automatically moving, lifting, double platforms, synchronous construction of top-assisting anchor rod and anchor cable, ultrahigh laneway supporting and protecting, etc.

Owner:闫振东

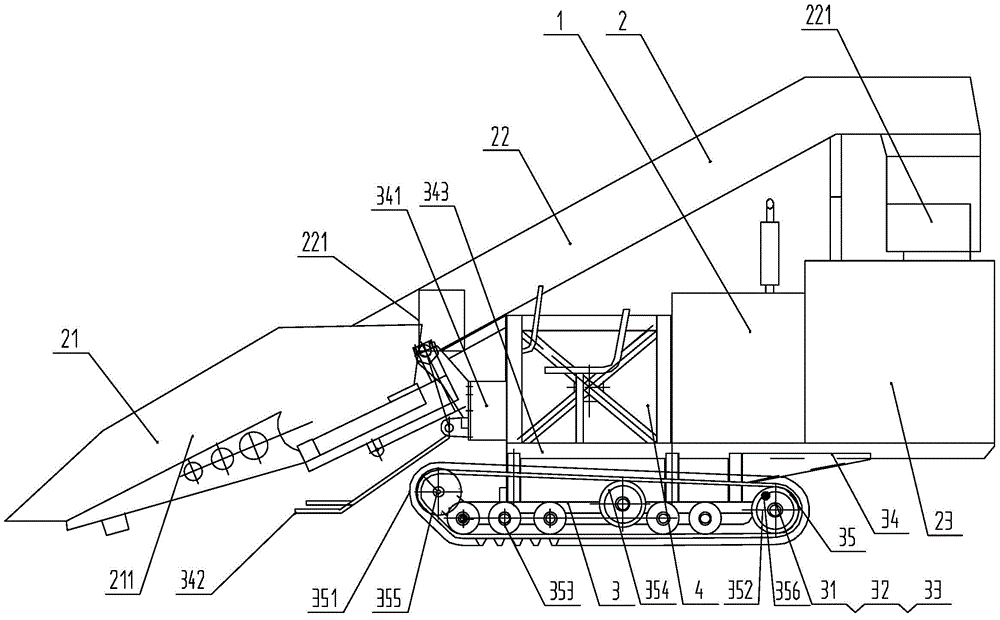

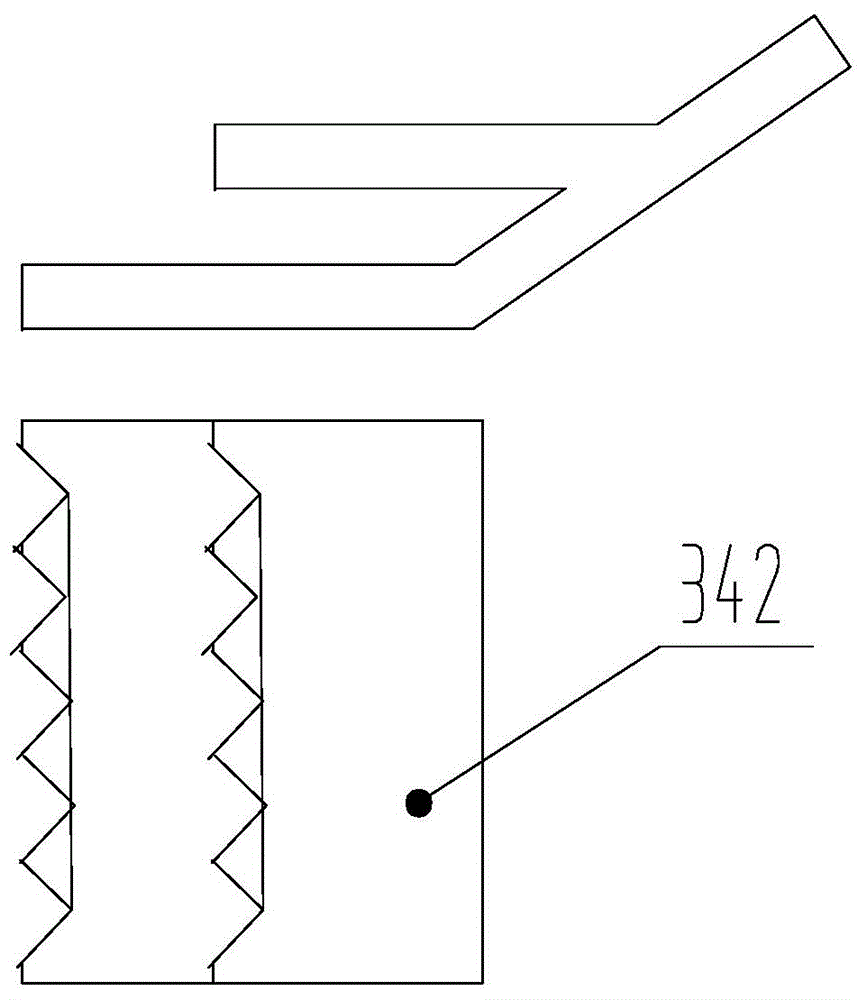

Track maize harvesting machine

The invention provides a track maize harvesting machine. The machine comprises an engine, a working device, a chassis assembly, an operation chamber and a hydraulic system; the working device comprises cutting platform systems, a cluster bin, and a fruit cluster conveyor arranged between the cutting platform systems and the cluster bin; the cutting system comprises a spike cutting device; the chassis assembly comprises a transmission device, a turning braking device and a track travelling system; the track travelling system comprises a frame and a travelling device; a cutting platform bracket for mounting the cutting platform systems is arranged at the front part of the frame; a straightening mechanism is arranged at the lower end of the cutting platform bracket; the working device and the operation chamber are fixed to the left and right on a connecting plate at the front part of the frame; the cluster bin is arranged at the tail part of the frame; the hydraulic system comprises a hydraulic valve, a hydraulic oil tank, a turning oil cylinder, a cutting platform oil cylinder, a hydraulic pump, a radiator and a travelling motor. The machine is under full-hydraulic transmission and high in working adaptability; a plurality of rows of cutting platform systems can be combined in different forms according to the actual working conditions, so that the working efficiency is high.

Owner:天津萨克赛斯机械技术开发有限公司

Tool for welding side bearing air duct beam

InactiveCN102962620AImprove working conditionsSave human effortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding-efficient tool for welding a side bearing air duct beam. The tool comprises brackets and positioning seats supported by the brackets; every mutually connected brackets and positioning seats are a group; the positioning seats are fixedly connected with the brackets; the brackets are fixed on a base; at least two groups of brackets and positioning seats are fixed on the base; and the upper surface of each positioning seat is a positioning surface and matched with the side bearing air duct beam. With the adoption of the tool, each weld joint of the side bearing air duct beam is positioned in an appropriate place, so that the weld joint quality is improved, the assembly precision is ensured, the deformation is controlled, the labor intensity is reduced, the processing efficiency is improved, and the tool is applicable to the welding work of the side bearing air duct beam.

Owner:CRRC DALIAN CO LTD

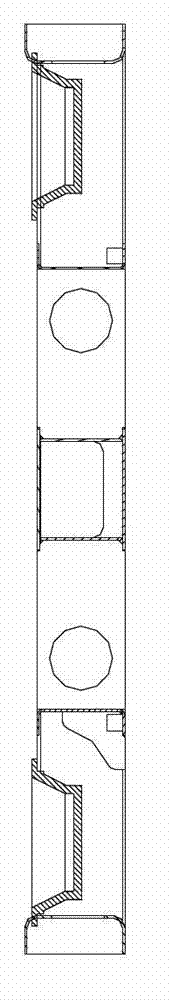

Switching device of submarine drill machine power head and wire line coring system

InactiveCN107269261ARealize automatic switchingQuality improvementConstructionsUnderwater drillingRock coreWell drilling

The invention provides a switching device of a submarine drill machine power head and a wire line coring system, and belongs to the technical field of well drilling equipment. The switching device of the submarine drill machine power head and the wire line coring system comprises a power head, a wire line coring system, a sliding frame and a sliding oil cylinder. The sliding frame is fixed to a mast of a drill machine, and a slide rail arranged horizontally is arranged on the sliding frame; the power head is mounted on the slide rail, and the power head forms an integrated structure through a connecting plate and the wire line coring system; the sliding oil cylinder is fixedly mounted on the sliding frame, the tail end of a telescopic arm of the sliding oil cylinder is connected with the power head, the power head moves horizontally along the slide rail under driving of the sliding oil cylinder, and switching of the power head and the wire line coring system at the well opening position is achieved. By adopting the switching device, automatic switching of the power head and the wire line coring system and automatic operation of breaking away from clamping of a core barrel and a fisher are achieved, therefore the wire line coring technology can be applied to submarine deep-hole drill machines, and the purposes that auxiliary operation time is shortened, and the working efficiency and the quality of cores are improved are achieved.

Owner:EXPLORATION TECH RES INST OF CHINESE ACADEMY OF GEOLOGICAL SCI

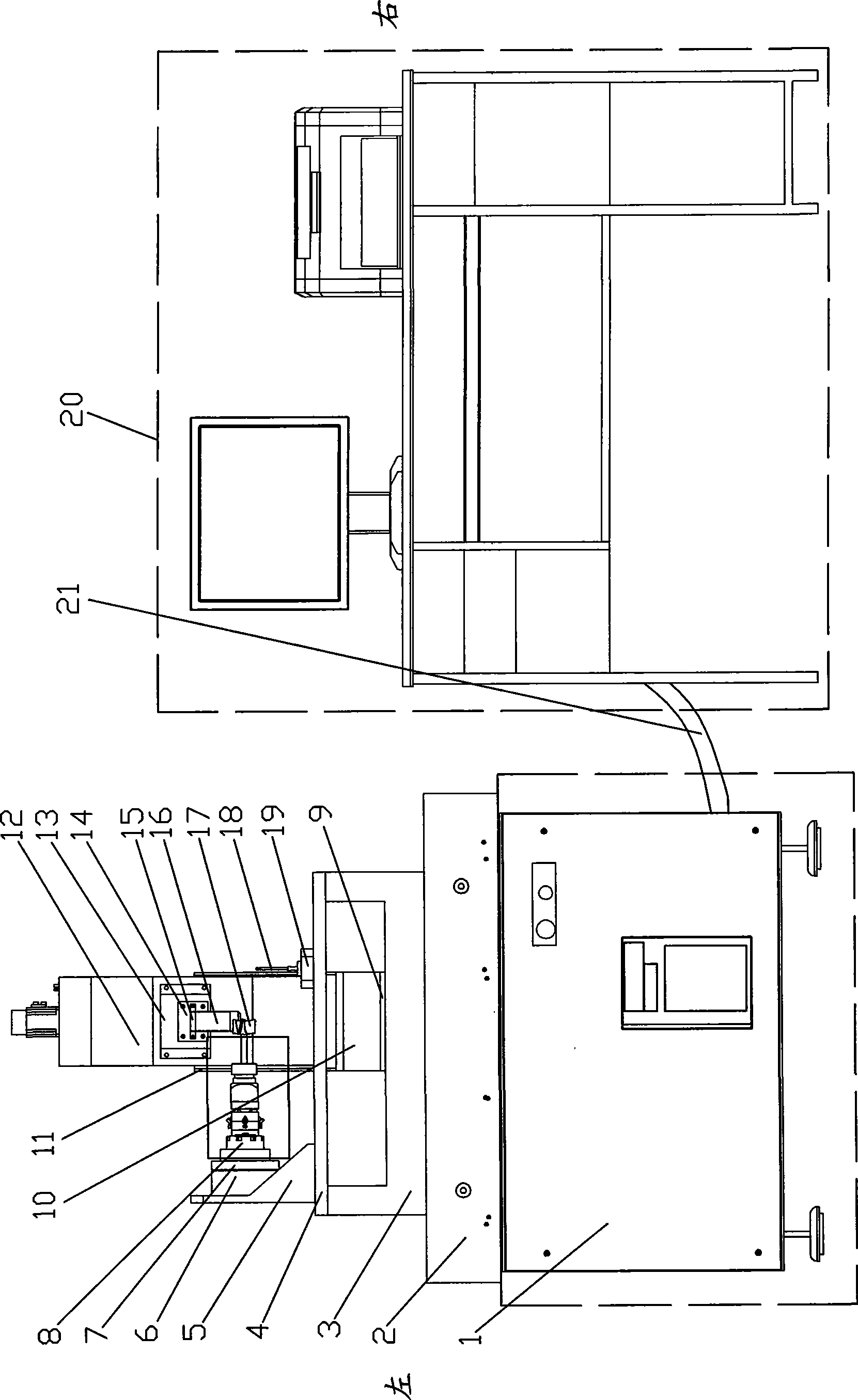

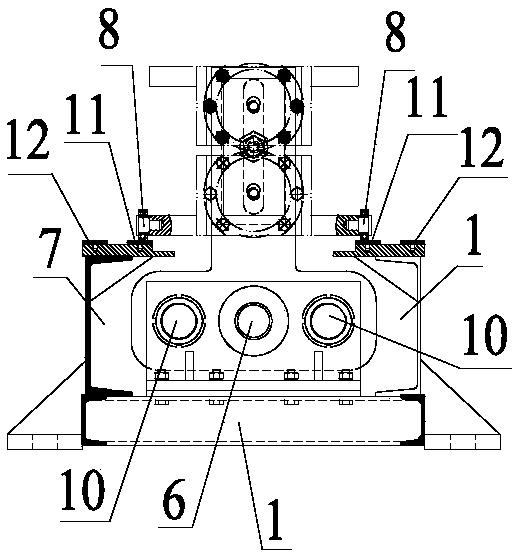

Complicate electrode pose pre-adjustment device

InactiveCN101508046AImprove pre-adjustment accuracyReduce auxiliary work timeInteraction deviceEngineering

The invention relates to an electrode pose pre-adjusting device, which aims to solve the problems that the prior electrode pose adjustment is mainly performed in the place of an electric spark machine tool, the adjustment time is long by observing pointer jump of a dial indicator, and the adjustment accuracy is difficultly guaranteed. A first bottom plate is arranged on the table top of a big platform; a second bottom plate is arranged on a first slide block; a support plate is connected with a second slide block on a front and back moving mechanism; an extension support is arranged on the lateral end face of a third slide block; an insulating board is arranged on the front of the extension support; a measuring head mounting seat is arranged on the front of the insulating board; a measuring head is arranged on the front of the measuring head mounting seat; a master ball is fixedly arranged on the upper end face of a small platform; and a human-computer interaction device is connected with an electric control cabinet through a cable. In the process of processing rimed turbine blisks by the electric spark machine tool, the electrode pose pre-adjusting device can synchronously complete adjustment of the electrode pose, so that the processing and the adjustment are performed simultaneously, service working time of the electric spark machine tool is reduced and the processing efficiency of the electric spark machine tool is improved.

Owner:HARBIN INST OF TECH

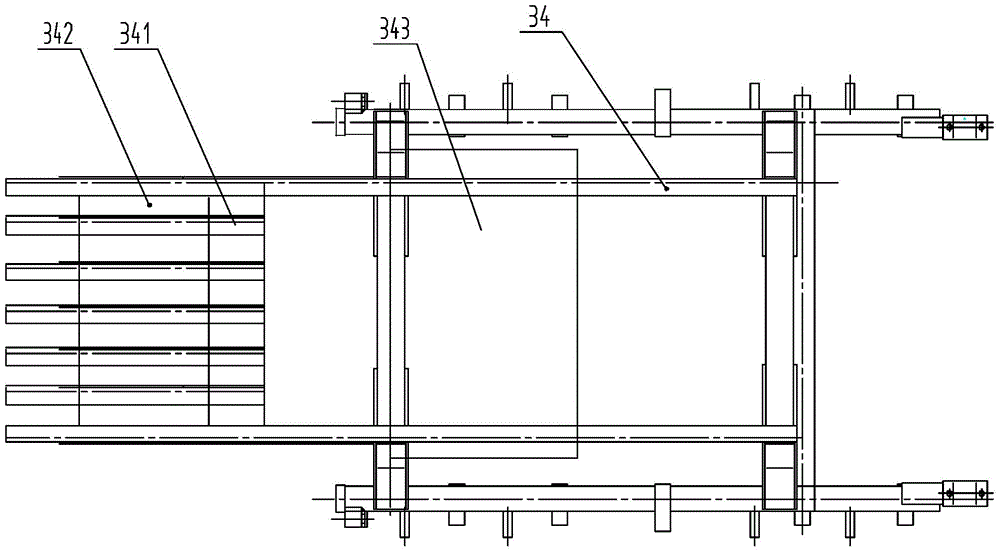

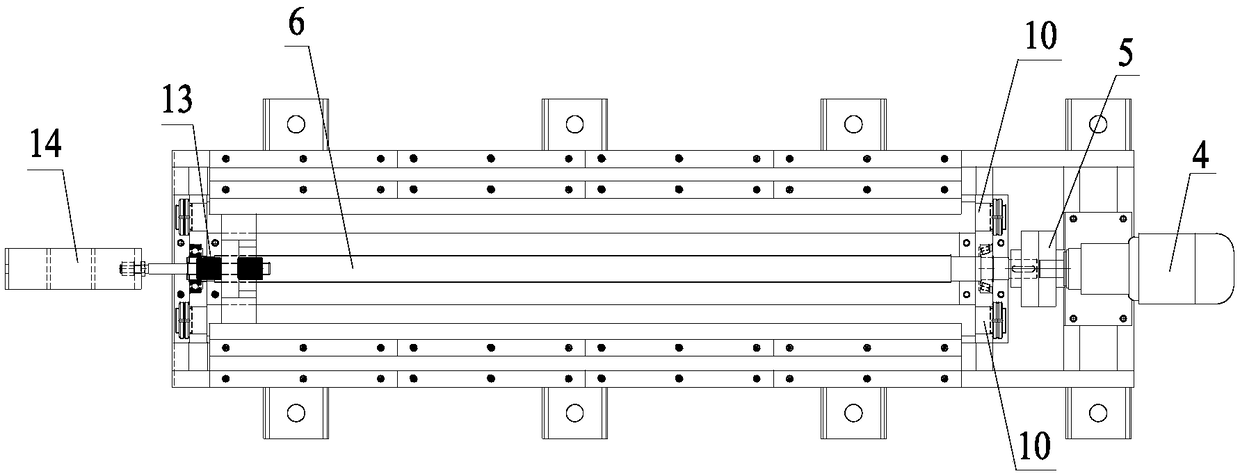

Quick roll changing device for working roll or supporting roll of hot rolling production line, and changing method

InactiveCN108994084AImprove efficiencyReduce site occupancyMetal rolling stand detailsMetal rolling arrangementsProduction lineWork roll

The invention relates to the field of hot rolling, and discloses a quick roll changing device for a working roll or a supporting roll of a hot rolling production line. The quick roll changing device for the working roll or the supporting roll of the hot rolling production line comprises a rack, wherein a sliding frame is arranged on the rack and comprises two sliding baffle plates symmetrical leftand right; a cycloidal pin wheel speed reducer is fixedly arranged on the rack and is connected with a screw rod through a pin coupler; the screw rod sequentially penetrates through the lower parts of the two sliding baffle plates through threaded connection; the sliding frame further comprises two roll changing platforms parallel to the screw rod; the two roll changing platforms are located on two sides of the screw rod; and two rows of rollers of the working roller or the support roller are located on the two roll changing platforms. The invention further discloses a changing method of thequick roll changing device for the working roll or the supporting roll of the hot rolling production line. The quick roll changing device for the working roll or the supporting roll of the hot rollingproduction line, and the changing method provided by the invention support the changing of the working roll or the supporting roll, and is accurate in control, fast in roll changing speed and low inworking intensity; and the device is simple in design and low in cost.

Owner:武汉钢铁有限公司

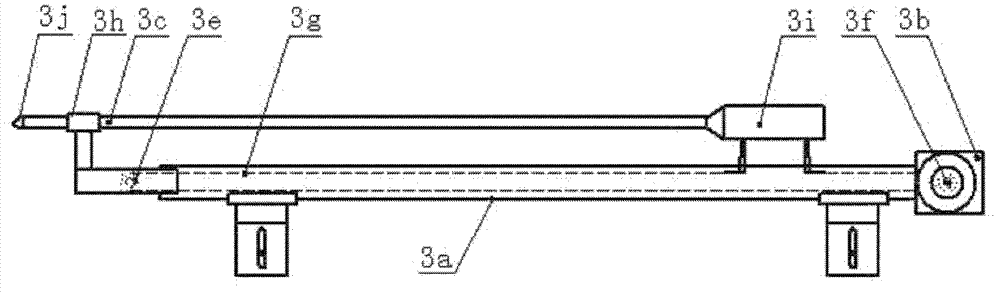

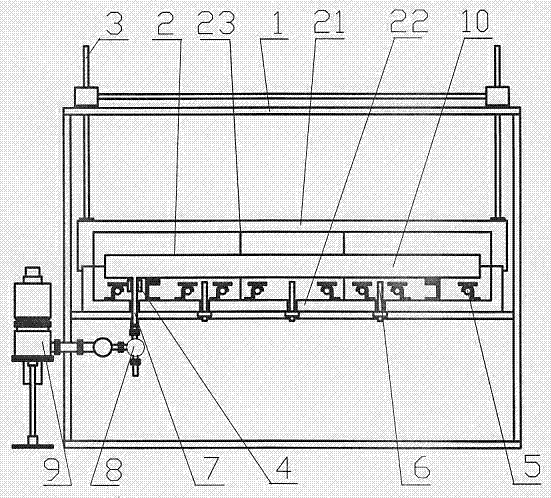

Solar energy high-temperature heat collecting pipe exhaust method used for generating electricity and horizontal-type exhaust platform

InactiveCN102162689ASolve the difficult problem of loading and unloadingEasy to openSolar heat devicesGlass reforming apparatusTemperature controlVacuum pumping

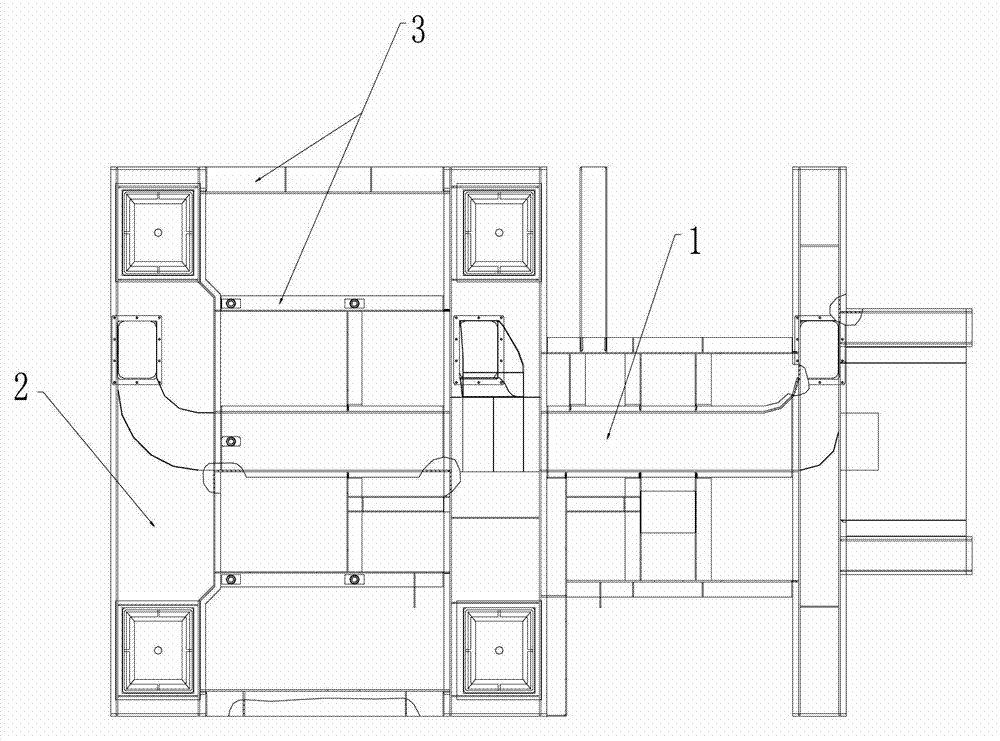

The invention discloses a solar energy high-temperature heat collecting pipe horizontal-type exhaust platform, comprising a rack (1), a heat preservation box (2), a lifting mechanism (3), an electric heating sealing furnace (4), an electric heating pipe (5), a thermocouple (6), a vacuum plastic tube (7), an exhaust header pipe (8) and a molecular pump vacuum air suction system (9), wherein, a horizontal-type square box body structure is adopted for the heat preservation box (2) which is divided into an upper box body (21) and a lower box body (22); the box body is separated into three temperature control areas by a clapboard (23); the electric heating sealing furnace (4) and a stainless steel vertical-tube electric heating pipe (5) are arranged on the base plate of the lower box body (22); an armoured thermocouple (6) is arranged in the heat preservation box (2) for detecting the temperature in the box; the molecular pump vacuum air suction system (9) is connected with the tail end of a high-temperature heat collecting pipe (10) through the exhaust header pipe (8) and the vacuum plastic tube (7), so as to carry out roasting and exhausting. In the invention, the existing heat collecting pipe exhaust platform vertical structure is changed into a horizontal-type structure, thus the difficulties that the equipment and the workshop are ultrahigh, as well as the use, the maintenance, the assembling and the disassembling of the workpieces are difficult caused by exhausting by a ultralong pipe are solved, thus creating condition for automation implementing.

Owner:衡阳市真空机电设备有限公司

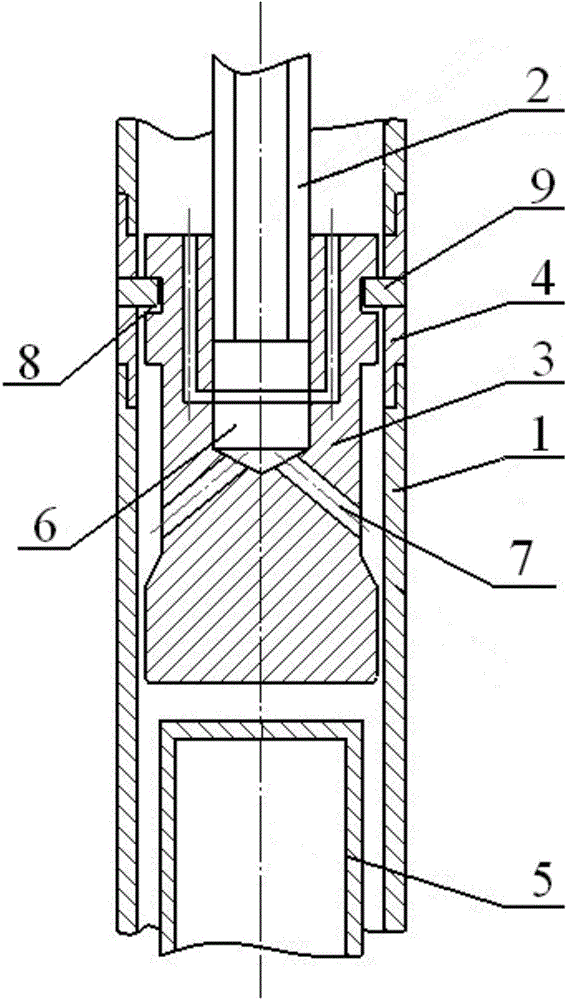

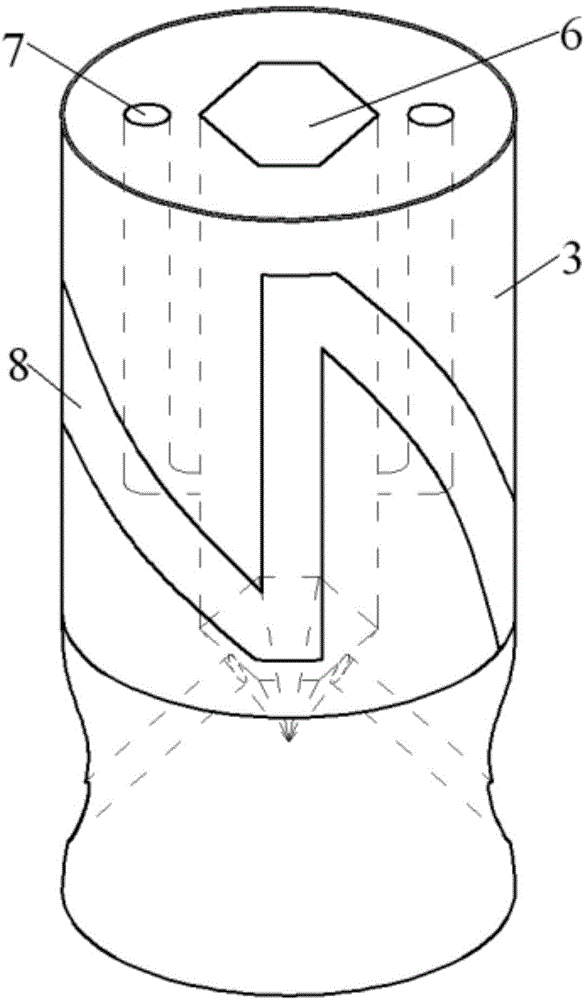

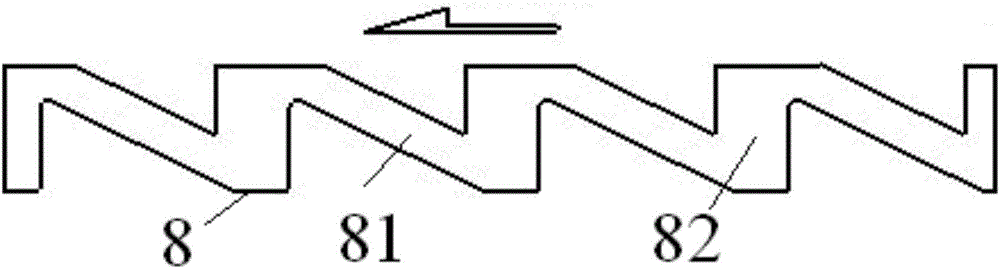

Drilling bit spiral impact device

InactiveCN104863497AImprove rock breaking abilityEasy to disassembleBorehole drivesEngineeringCoring

The invention provides a drilling bit spiral impact device which comprises an outer casing pipe, an impact hammer and a lower connector which are mounted in the outer casing pipe in sequence in the vertical direction; a power input shaft is arranged at the center of the impact hammer; the power input shaft is movably connected with the impact hammer and drives the impact hammer to rotate; the impact hammer is connected with the outer casing pipe through a guide mechanism; the impact hammer moves up and down along the power input shaft under the action of the guide mechanism; the guide mechanism comprises a saw-toothed ring groove which is formed by spiral line grooves and vertical grooves which are alternatively formed and two or more guide blocks positioned in the saw-toothed ring groove; the spiral line grooves and the vertical grooves are identical in number and are mutually communicated; the guide blocks are uniformly distributed on the inner wall of the outer casing pipe and the saw-toothed ring groove is formed in the side surface of the impact hammer. The drilling bit spiral impact device does not need quick-wear parts like springs, is simple in structure, convenient to maintain, low in cost, suitable for coring of hole sections of various depths and not influenced by hole depth and pressure change of a water column, and can improve the rock breaking effect and improve the roundtrip meterage length.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Novel tunneling process

ActiveCN110410118AReduce labor intensityAlleviate deformation damageProps/chocksAnchoring boltsEngineering

The invention provides a novel tunneling process in order to solve the problems that a tunneling machine in the prior art needs to be halted and retreated after tunneling a distance and then conductsnet laying, anchor rod driving operation and other permanent supporting operation, the roadway tunneling efficiency is low and mine excavation is hard to follow. According to the novel tunneling process, a temporary supporting device is separated from the tunneling machine, the tunneling temporary supporting device is independently arranged on the outer portion of the tunneling machine in a covering mode and can move forwards along with tunneling of the tunneling machine to support a roof exposed during tunneling in time. Meanwhile, operation personnel can implement anchor rod driving or shederecting and other permanent supporting operation inside the tunneling temporary supporting device behind the tunneling machine. Through the novel tunneling process, noninterference and parallel operation between tunneling of the tunneling machine and roadway permanent supporting are realized, the operating ratio and tunneling efficiency of the tunneling machine can be improved, the safety of theroadway tunneling operation environment is improved, the labor intensity of net laying and permanent supporting by workers is reduced, and the condition that mine excavation is hard to follow is effectively relieved.

Owner:SHENYANG TIAN AN TECH CO LTD

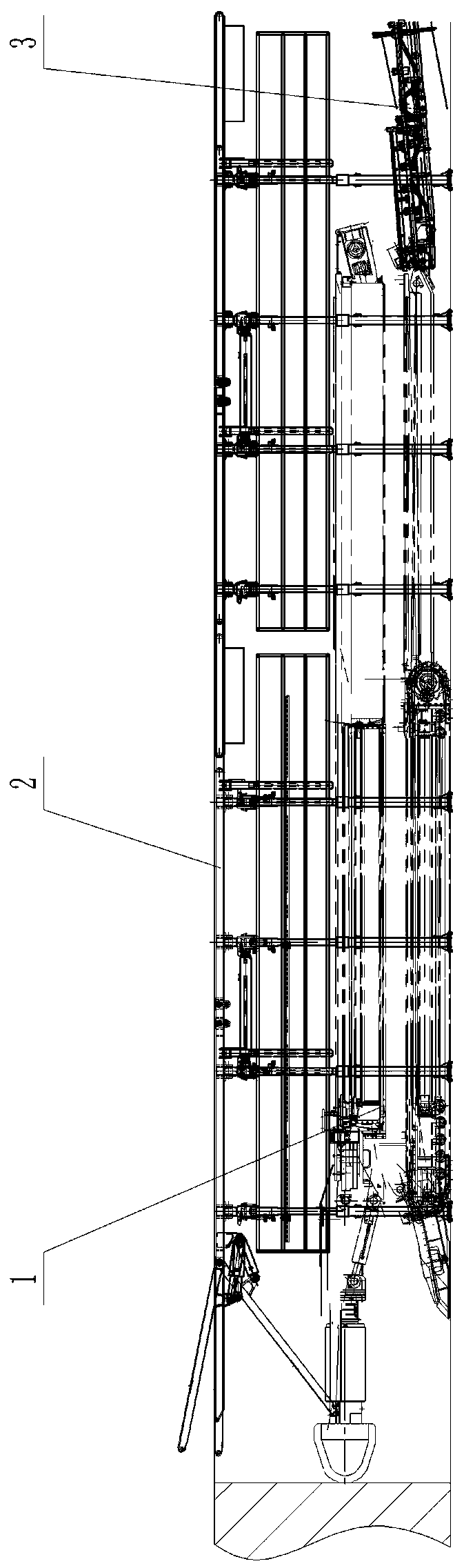

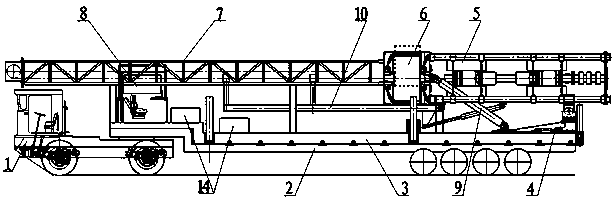

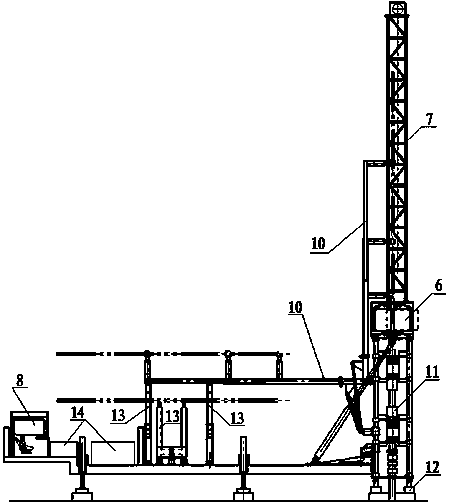

Integrated high-temperature pressure balance workover rig

InactiveCN103939013AHighly integratedEasy to transportDrilling rodsSealing/packingMarine engineeringPressure balance

The invention discloses an integrated high-temperature pressure balance workover rig which has the advantages of being high in integrity and work efficiency and convenient to operate. The integrated high-temperature pressure balance workover rig comprises a traction vehicle, a trailer, a work platform, a derrick translation system, a framewok type derrick system, a forced lifting system, a hydraulic system, manipulator systems and the like. The work platform is arranged on the trailer, a control chamber and a hydraulic work station are sequentially arranged on the front portion of the work platform, the derrick translation system is arranged on the tail portion of the work platform, the framework type derrick system provided with an anti-blowout system and bases is hinged to the tail portion of the work platform, one end of each of two derrick turning oil cylinders is arranged on the framework type derrick system, the other end of each of the two derrick turning oil cylinders is installed on the work platform, the forced lifting system provided with a guide supporting frame on the upper portion is arranged on the framework type derrick system, and the two sets of the manipulators are connected with the framework type derrick system and the work platform respectively. All the systems are integrated on a vehicle body system, devices are convenient to transport and use, work cost is low, auxiliary work time is little, and the safety degree is high.

Owner:SHENYANG POLYTECHNIC UNIV

Facade operation wall-climbing robot and anti-falling and anti-sliding device thereof

The invention belongs to the technical field of robots, and particularly relates to a facade operation wall-climbing robot and an anti-falling and anti-sliding device thereof. The anti-falling and anti-sliding device comprises an anti-falling protection mechanism and an anti-falling control module, the anti-falling protection mechanism comprises an electromagnetic attraction piece, an exciting coil is arranged in the electromagnetic attraction piece, and the anti-falling control module comprises a gravity acceleration sensor and an exciting circuit. The gravity acceleration sensor is used for collecting the acceleration value of the robot body and judging whether the robot body is in a normal operation state or a falling state, the exciting circuit is electrically connected with the gravity acceleration sensor and the exciting coil, and the gravity acceleration sensor controls the exciting circuit to be electrically connected with the exciting coil. Therefore, quick response of falling and sliding prevention of the robot body can be achieved, the anti-falling and anti-sliding device is integrated on the robot body and can be transferred along with transferring of the robot body, and use is more flexible and convenient.

Owner:SHENZHEN XINGZHIXING ROBOT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com