Switching device of submarine drill machine power head and wire line coring system

A drilling rig power head and system switching technology, which is applied in the direction of undisturbed core extraction device, drilling automatic control system, rotary drilling rig, etc., can solve problems such as poor reliability, reduce auxiliary operation time, and difficult design, so as to improve work efficiency , reduce auxiliary operation time, improve the effect of core quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

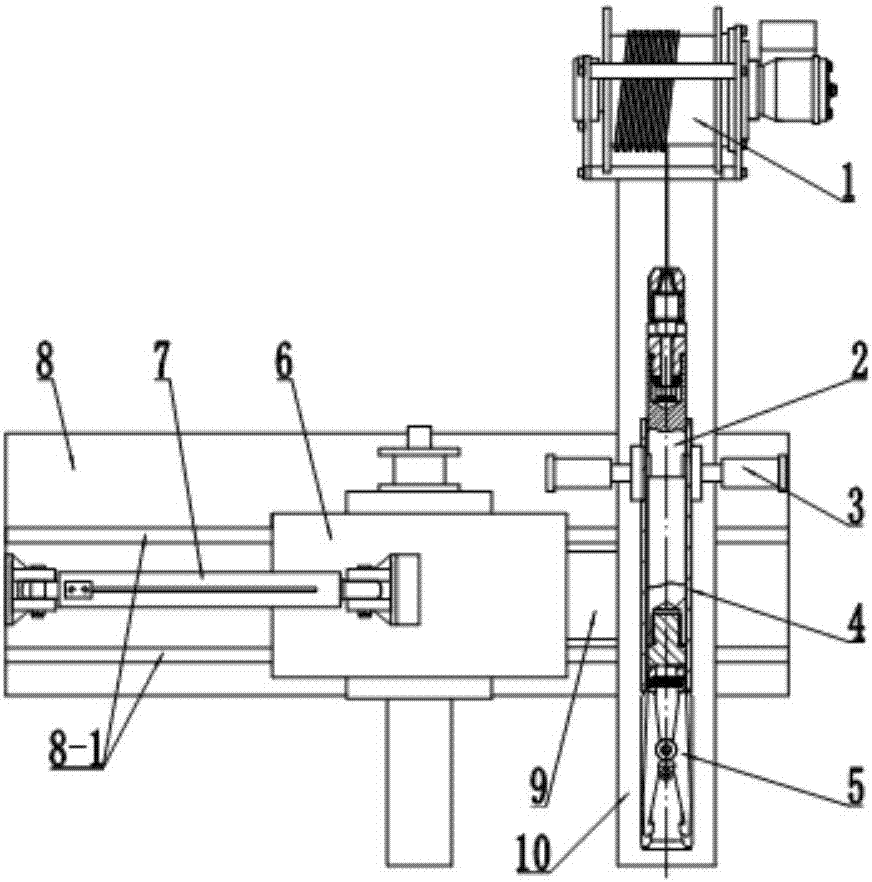

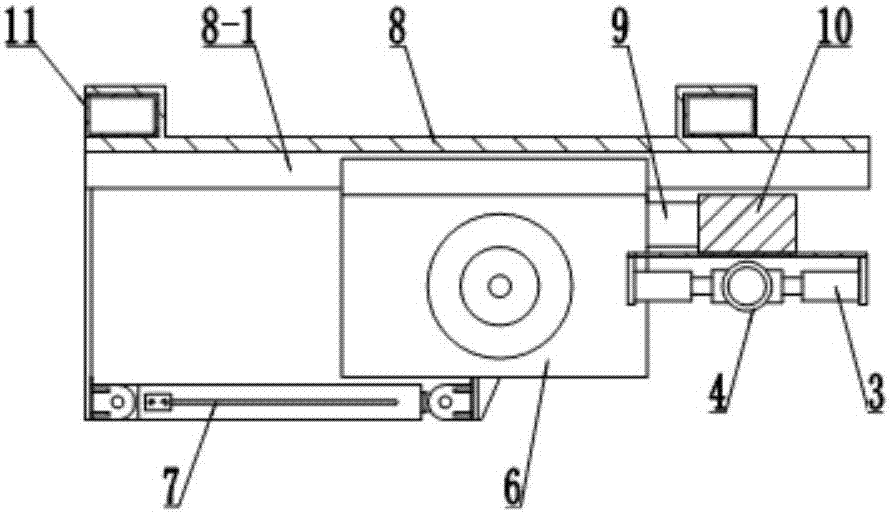

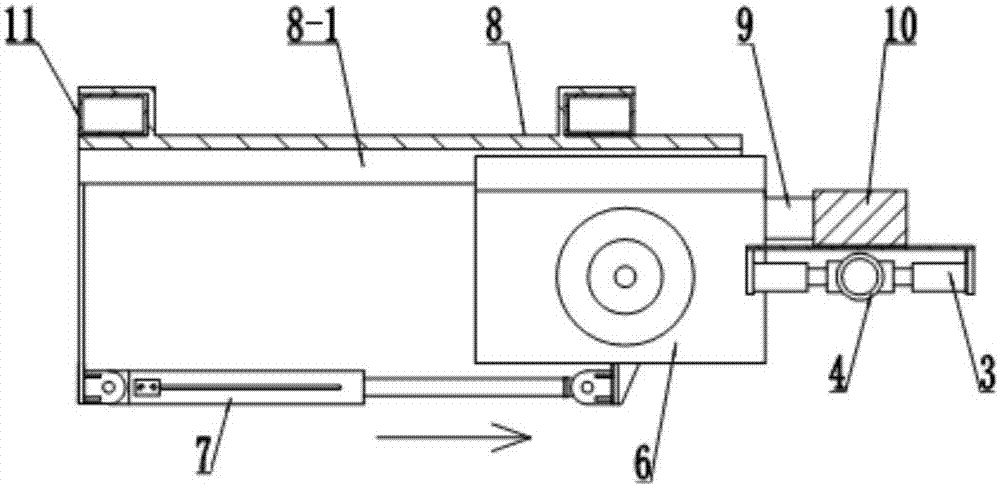

[0022] see figure 1 , figure 2 , the present invention provides a switching device between the power head and the cable coring system of a subsea drilling rig, which includes a power head 6, a rope coring system, a sliding frame 8 and a sliding oil cylinder 7; the sliding frame 8 is fixed on the drilling rig mast 11 On the sliding frame 8, at least two sets of horizontally arranged slide rails 8-1 are set; the power head 6 is installed on the slide rails 8-1, and the power head 6 is also integrated with the rope coring system through the connecting plate 9 type structure; the rope coring system includes a support frame 10, a hoist 1, a fishing device 2, a card release pipe 4 and a card release holder 3, and the support frame 10 is connected to the power head 6 through a connecting plate 9, The winch 1 is installed at the upper end of the support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com