Automatic wire collecting and arranging machine

A technology of wire arranging machine and wire take-up machine, which is applied in the direction of thin material processing, delivery of filamentous materials, transportation and packaging, etc., which can solve the problems of irregular wire rewinding, difficult control of wire spacing, and surface quality of finished enameled wires. Poor problems, achieve scientific and reasonable structure, improve work efficiency, and avoid surface scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in combination with specific embodiments.

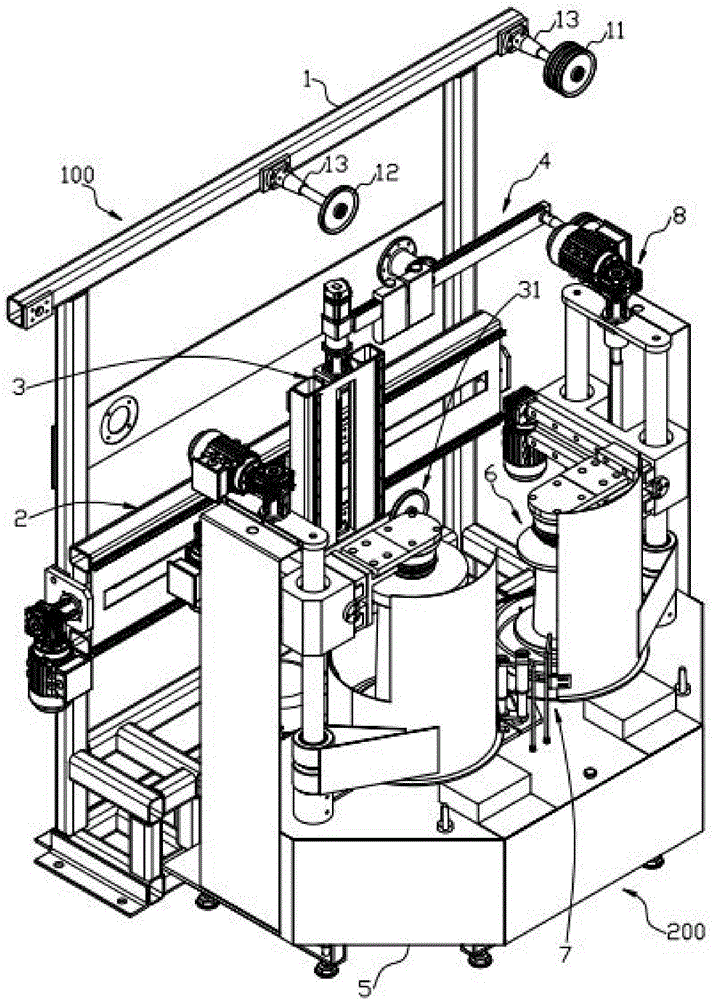

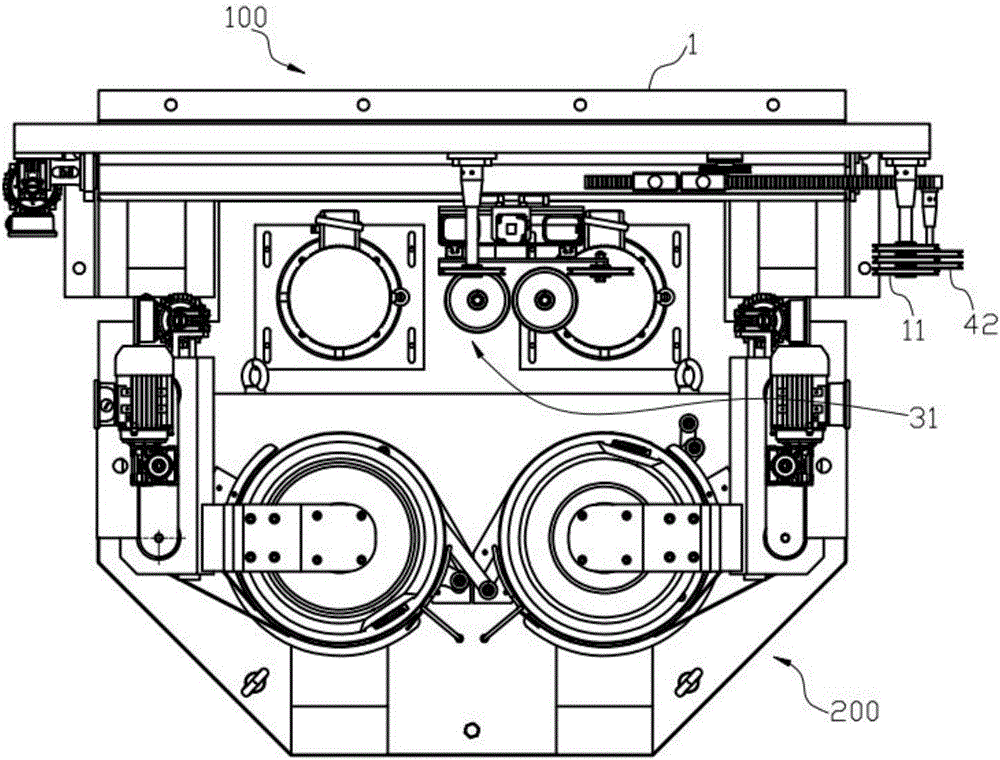

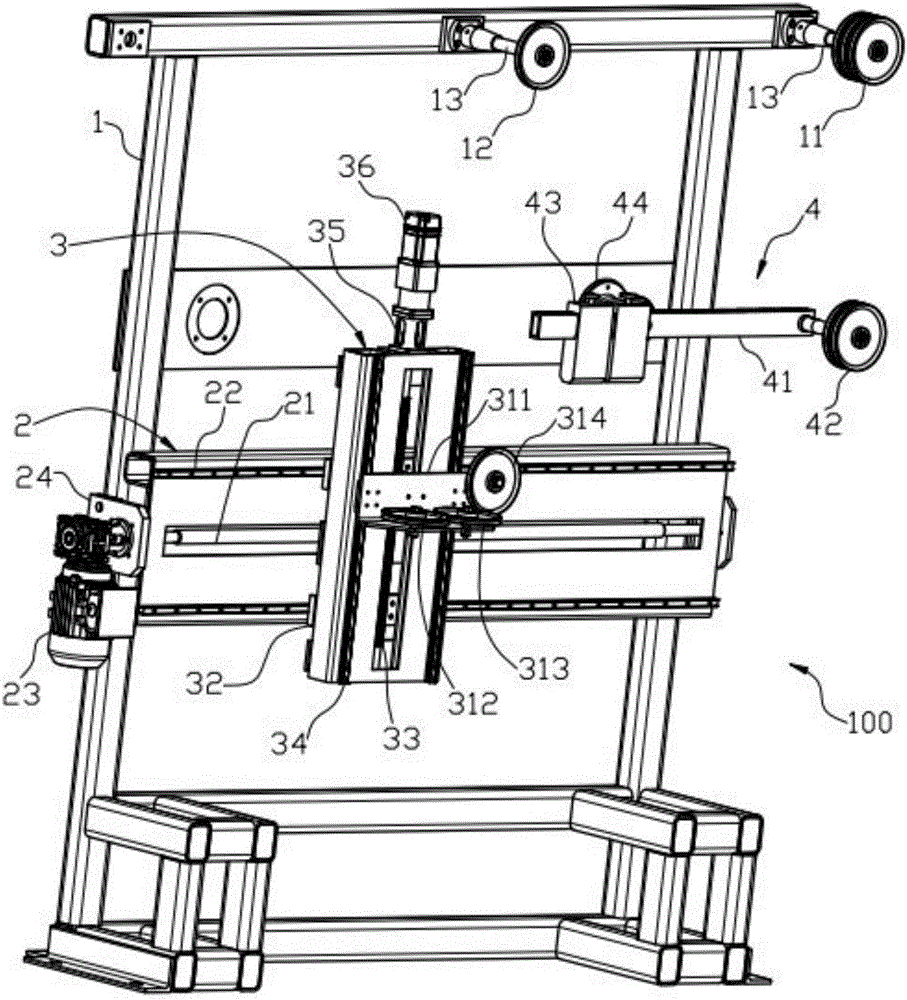

[0036] Such as figure 1 , 2 As shown in and 3 , the automatic wire take-up and winding machine according to an embodiment of the present invention includes an XY type wire winding device 100 and a wire taking-up device 200 . The XY type cable arrangement device 100 includes a cable arrangement frame 1 , a horizontal cable arrangement frame 2 , a longitudinal cable arrangement frame 3 , a first line passing guide wheel 11 , a second line passing guide wheel 12 and a take-up tension system 4 . The horizontal cable rack 2 is installed on the cable rack 1 , the vertical cable rack 3 is movably installed on the horizontal cable rack 2 , and the vertical cable rack 3 can move left and right relative to the horizontal cable rack 2 . The first wire passing guide wheel 11 and the second wire passing guide wheel 12 are all vertically installed on the top of the cable rack 1 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com