Tool for welding side bearing air duct beam

A technology of side bearing air channel beams and tooling, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the requirements of mass production of locomotives, high labor intensity of employees, and difficulty in guaranteeing welding quality, etc. problems, to achieve the effect of shortening the production cycle, saving manpower and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

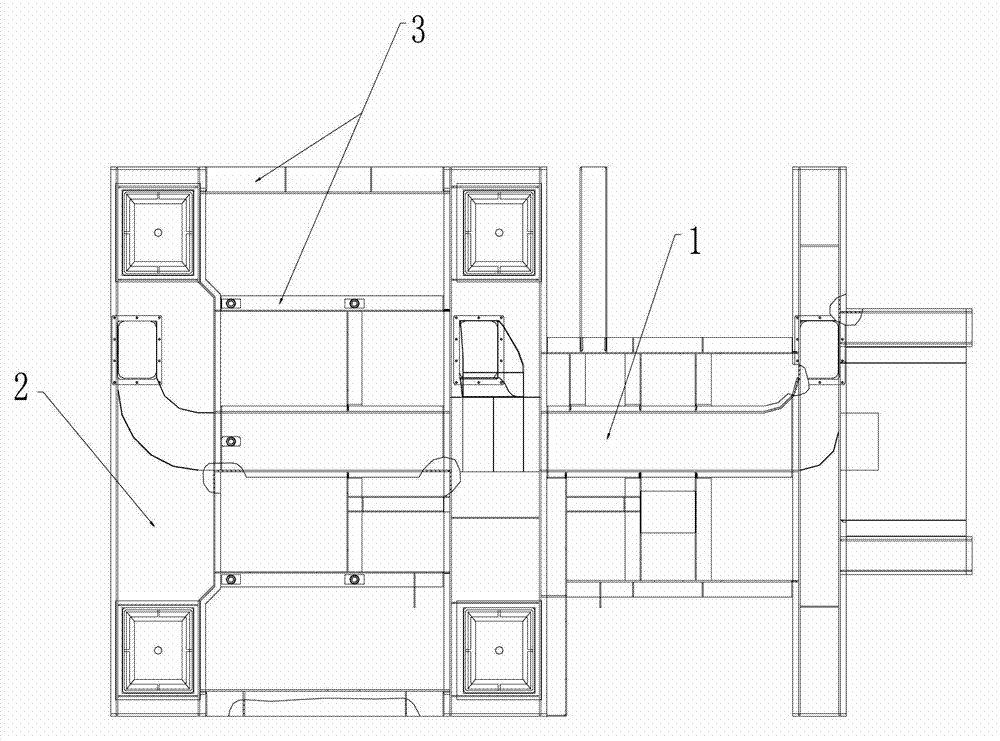

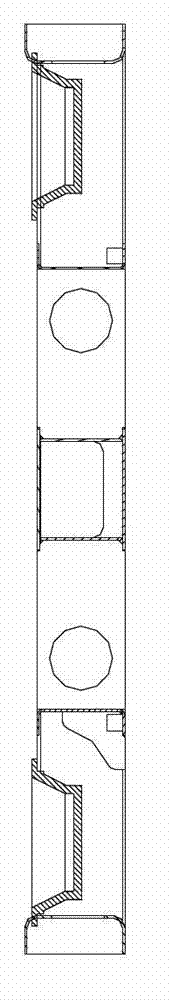

[0022] The present invention will be further described below in conjunction with accompanying drawing.

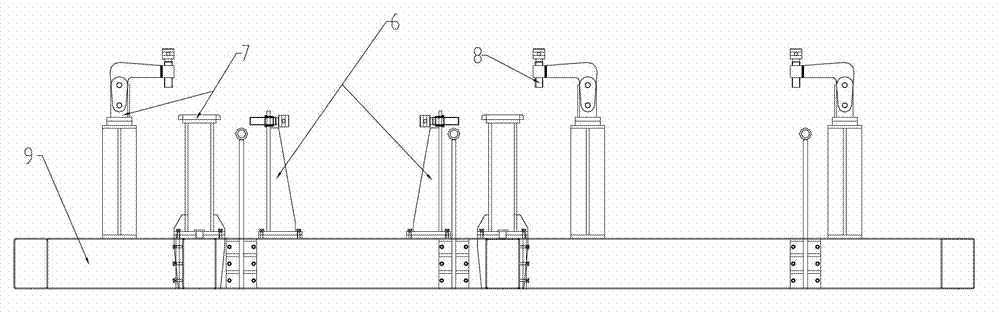

[0023] According to the structural characteristics of the side bearing air duct beam, the tooling of the present invention uses the three elements of "support, positioning, and clamping" of the welding tool and the principle of six-point support, positioning, and clamping of objects in space to position the side bearing air duct beam. In the appropriate position, it is welded to ensure the manufacture of qualified products. Such as figure 2 As shown, the bracket 6 is used as the supporting reference, and the side bolster assembly and the like are assembled to one place through it and the positioning seat 7 on it, and then each positioning clamping device is installed on the corresponding position on the upper plane of the positioning seat 7 Above, clamp the components of the side bearing duct beam.

[0024] Bracket 6 is bent into channel steel by plate, and is combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com