Framework turnover device and operation method thereof

An operation method and framework technology, applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as hidden dangers in operation, achieve the effects of improving production efficiency, convenient loading and unloading, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

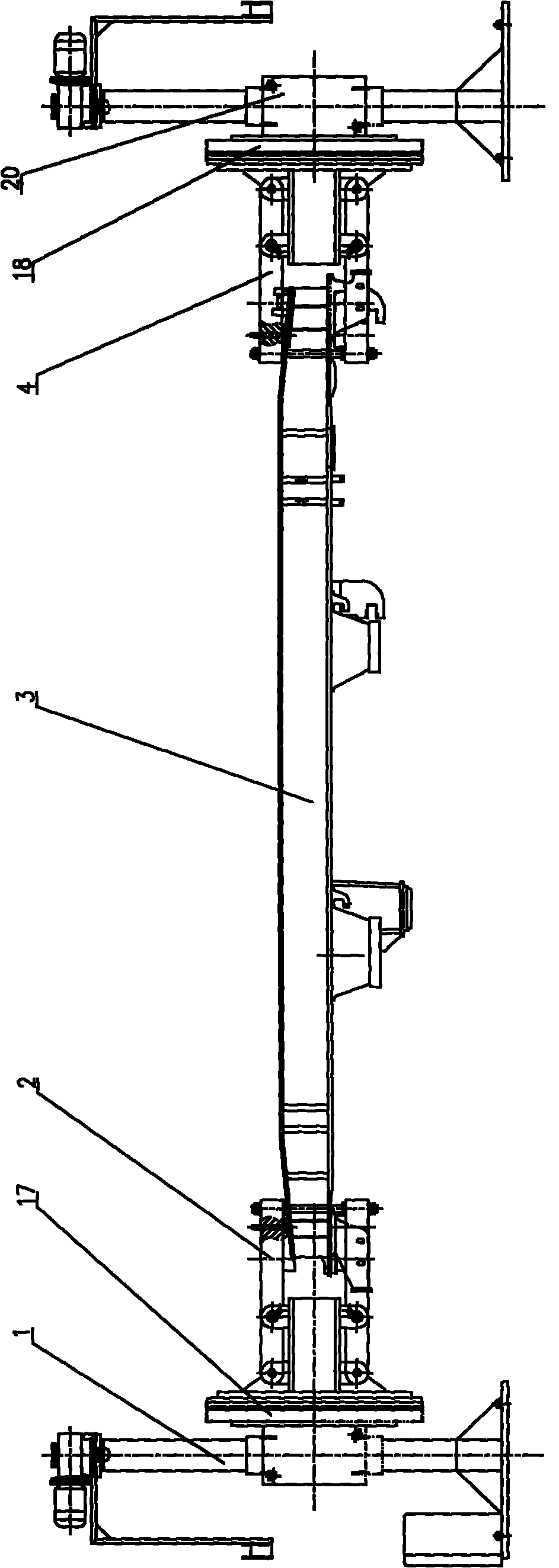

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

[0030] A frame turning device, such as figure 1 Shown, it comprises the left and right lift rotary tire 1 of symmetrical arrangement, 20, the left clamp 2 that is fixed on the left lift rotary tire turntable 17 and the right clamp 4 on the fixed right lift rotary tire turntable 18. By adjusting the height of the left and right lifting and rotating tire turntables 17 and 18, the end beams of the frame 3 are placed in the left and right clamps 2 and 4 for positioning and clamping, and then the left and right lifting and rotating tire rotating disks 17 and 18 can be started to align the frame 3 Flanging.

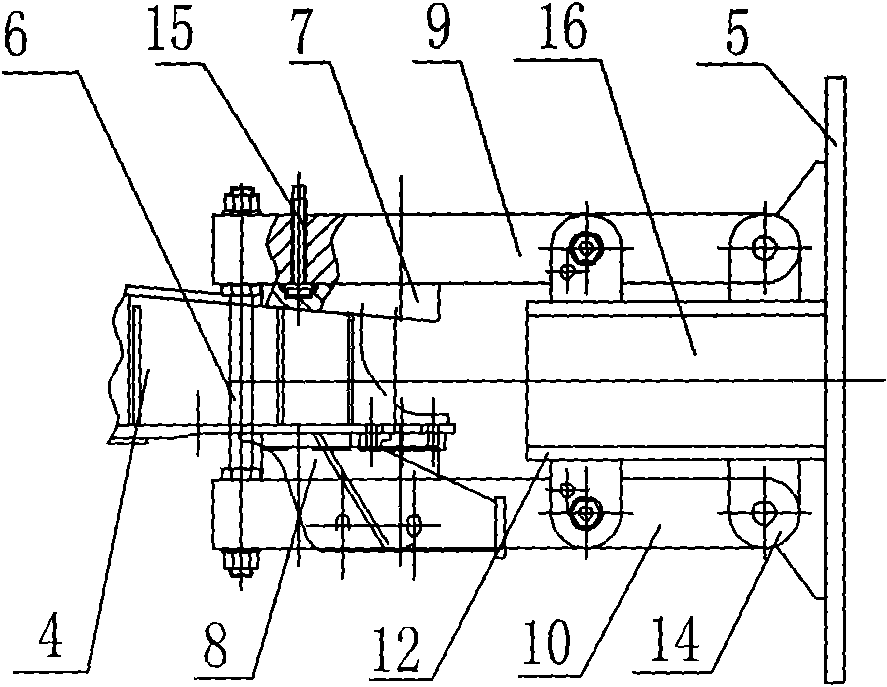

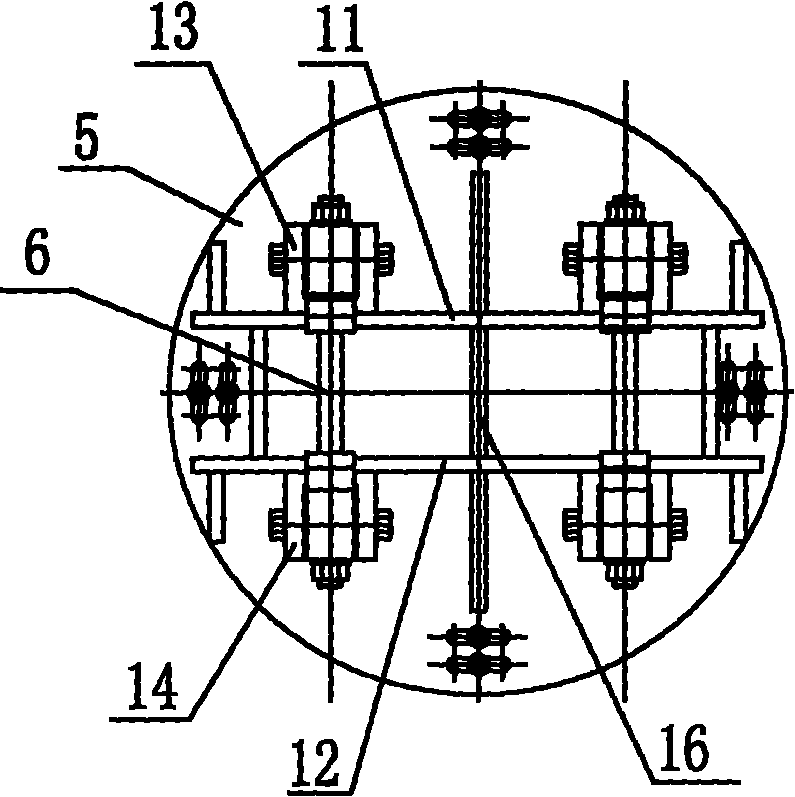

[0031] The structural components of the left clamp 2 and the right clamp 4 are the same.

[0032] Such as Figure 2~4 As shown, the right clamp 2 includes a connecting plate 5 fixed to the right lifting rotary tire turntable 18 by bolts, and an upper supporting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com