Patents

Literature

36results about How to "Prevent derailment accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wheeltrack magnetic levitation universal technology

InactiveCN101481893AReduce construction landReduce engineering costsRailway tracksCommunications systemTrackway

The invention relates to a general technology of wheeltrack magnetic suspension, belonging to the technical field of earthbased track traffic. The general technology of wheeltrack magnetic suspension mainly comprises a wheeltrack magnetic suspension dualpurpose trackway, an electromagnetic trackway, an electromagnetic switching turnout, a suspension-oriented technology and a matched train, and is characterized in that the wheeltrack magnetic suspension dualpurpose trackway can be mutually connected with a pure suspension trackway and a common wheeltrack trackway to form a trafficable trackway communication system; the corresponding position relationship of a long stator winding and a suspension trackway which are arranged in the pure magnetic suspension trackway is consistent with the position relationship of the long stator winding and the suspension trackway which are arranged in the wheeltrack magnetic suspension dualpurpose trackway; and the track space of two steel rails in a common wheeltrack trackway is equal to the track space of two steel rails in the wheeltrack magnetic suspension dualpurpose trackway. The general technology of wheeltrack magnetic suspension combines the wheeltrack technology with the magnetic suspension technology, is used for meeting the requirement of the long-distance high-speed transportation, and has the advantages of low construction cost, high versatility, energy saving, and environmental protection, etc.

Owner:李葛亮

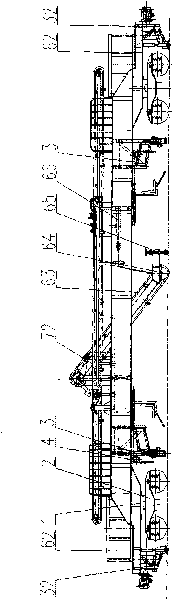

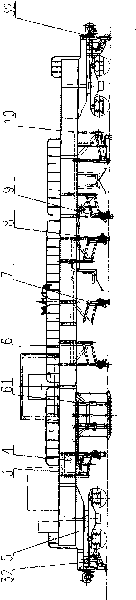

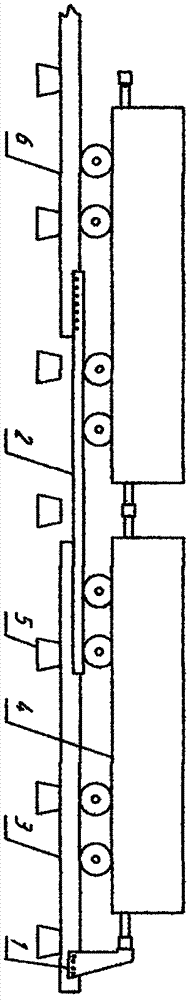

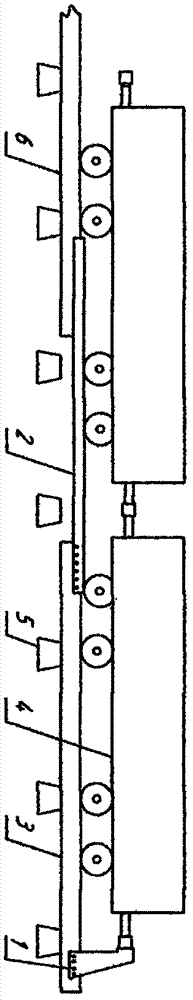

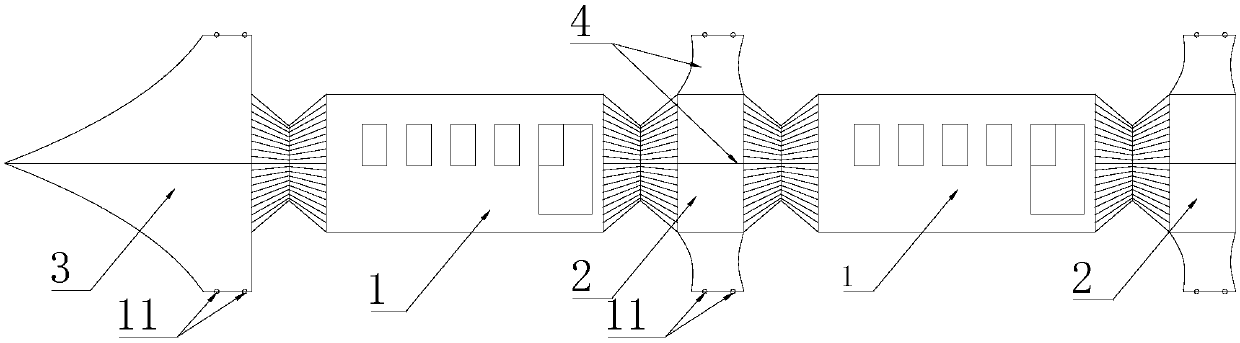

Fast rail-exchanging vehicle for jointless track and rail-exchanging method

InactiveCN101718066AReduce forcePrevent falling offRailway track constructionBogieFront and back ends

The invention relates to a fast rail-exchanging vehicle for a jointless track and a rail-exchanging method. The front and back ends of a travel mechanism of a fast rail-exchanging vehicle for a railway are provided with a guardrail recovering device; a crosstie-pressing device, a steel rail retraction device for clamping and moving a new steel rail and an old steel rail, a steel rail clincher and an operating position are arranged at intervals below the vehicle body between two bogies of the travel mechanism, the operating position is arranged according to the need; and the crosstie-pressing device and the steel rail clincher are arranged respectively close to the bogies at the two ends; and the vehicle can perform the marshalling operation together with the auxiliary vehicles, such as a fastener recovered vehicle, and the like. When the fast rail-exchanging vehicle for the railway is adopted for construction, the operation is divided into two parts of the old steel rail retraction operation and the new steel rail retraction operation which are synchronously carried out. The vehicle can reach the rail-exchanging speed of more than 2km / h, can be applied to the fast rail-exchanging need of the jointless track, complete the rail exchanging within 50 meters and is suitable for the construction needs of the section with less curve radius. The invention has the advantages of safety and high degree of automation.

Owner:株洲新通铁路装备有限公司

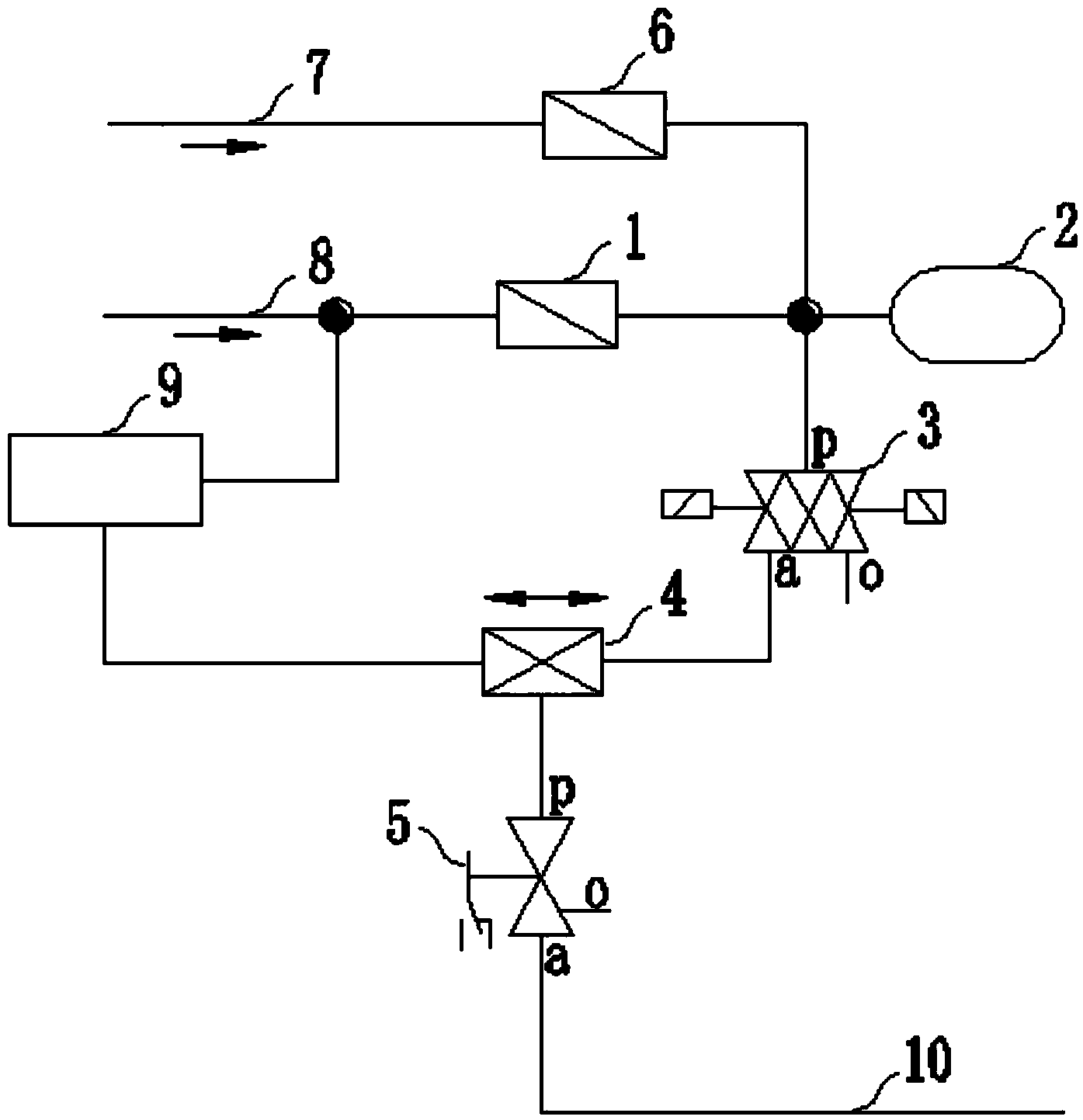

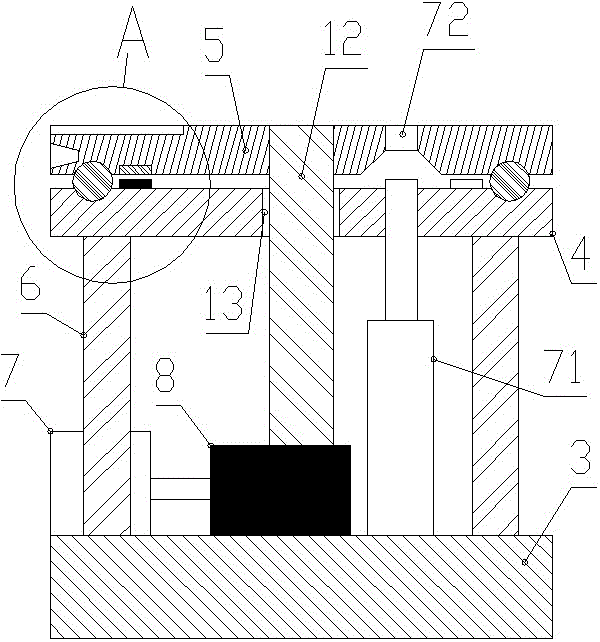

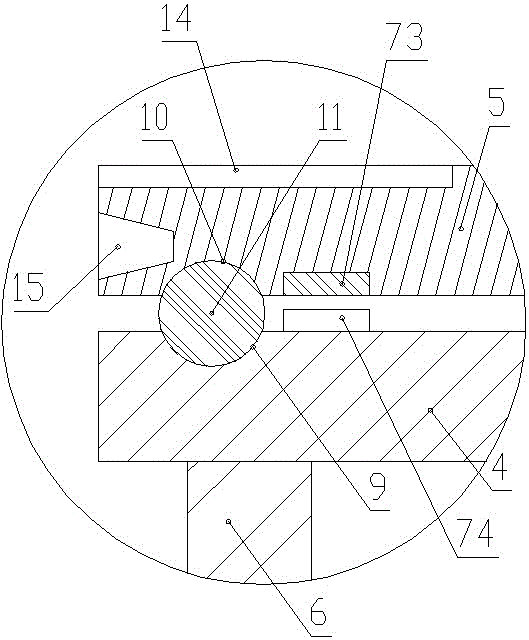

Rapid brake and relieve device and method of parking brake cylinder of fireless loopback locomotive

The invention discloses a rapid brake and relieve device and method of a parking brake cylinder of a fireless loopback locomotive. The parking brake cylinder 10 is connected with one end of a reverse valve 4 through a cock 5 of the parking brake cylinder 10. The other two ends of the reverse valve 4 are connected with a brake 9 and the end a of a bidirectional solenoid valve 3 respectively. The end p of the bidirectional solenoid valve 3 is connected with an air storage cylinder 2 and is further connected with a check valve 1 of a main air cylinder 8. A train pipe 7 is connected with the end p of the bidirectional solenoid valve 3 through a check valve 6 of the train pipe 7. The method includes the step of parking braking, wherein a parking braking action button of a fireless locomotive cab is operated, a port a of the bidirectional solenoid valve 3 is controlled to be communicated with a port 0, compressed air of the parking brake cylinder 10 is exhausted to the atmosphere, and then the parking brake cylinder 10 is at the action state; the step of fireless loopback, wherein the train pipe 7 is communicated with the fireless locomotive, a parking braking relieve button of the fireless locomotive cab is operated, a port p of the bidirectional solenoid valve 3 is controlled to be communicated with the port a, sustained pressure of the train pipe 7 is injected into the parking brake cylinder 10, and then the parking brake cylinder is relieved.

Owner:CRRC DALIAN CO LTD

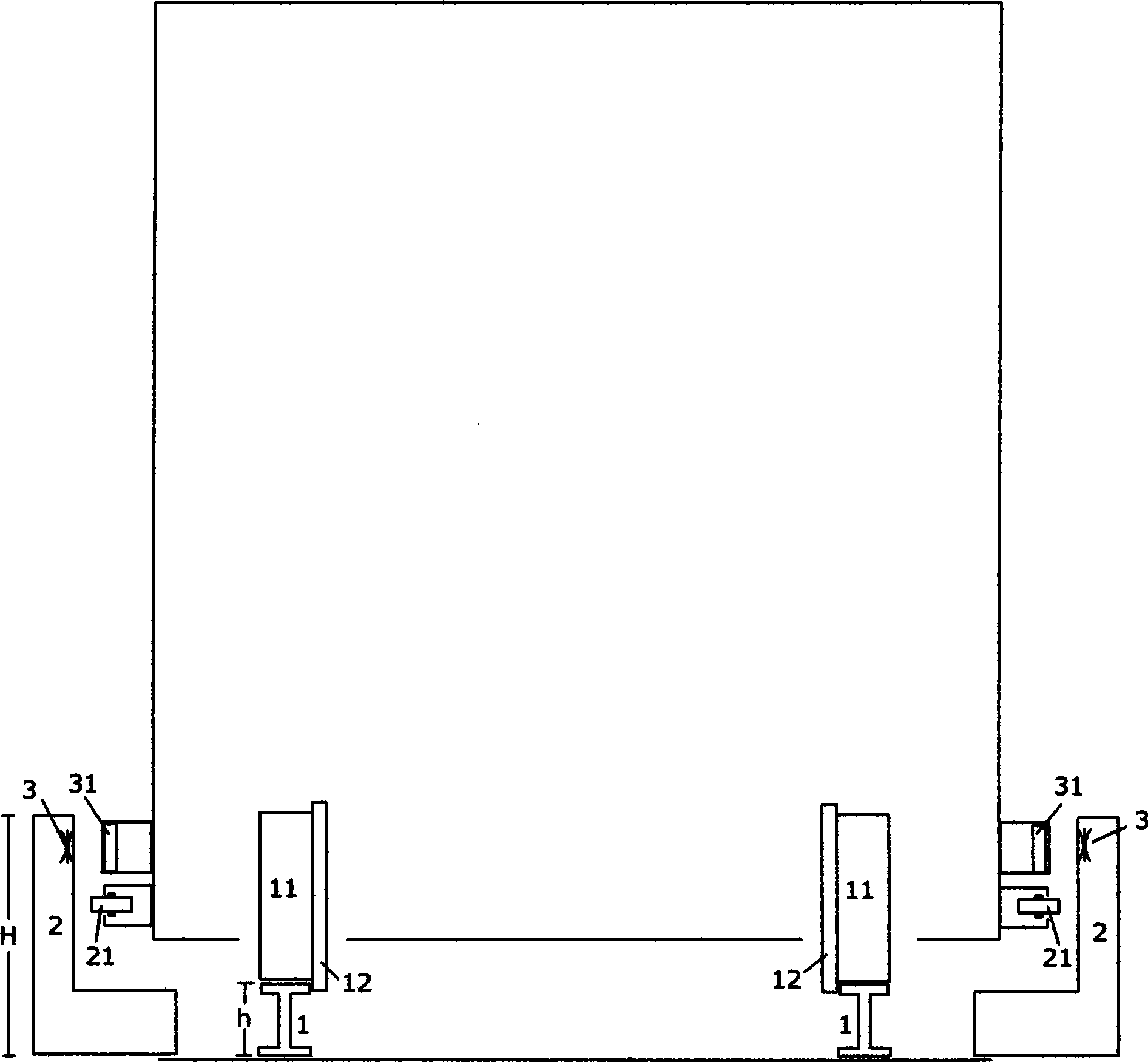

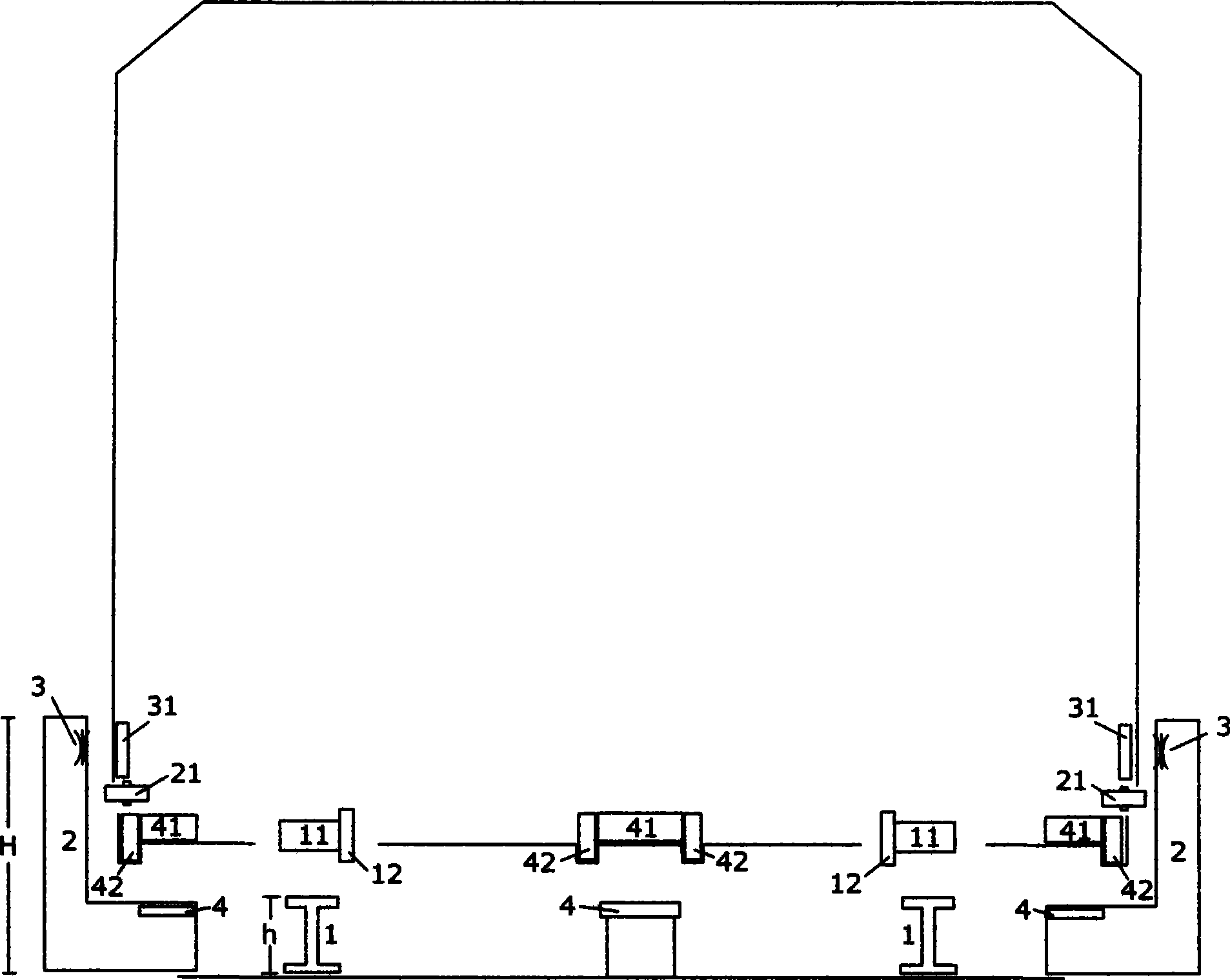

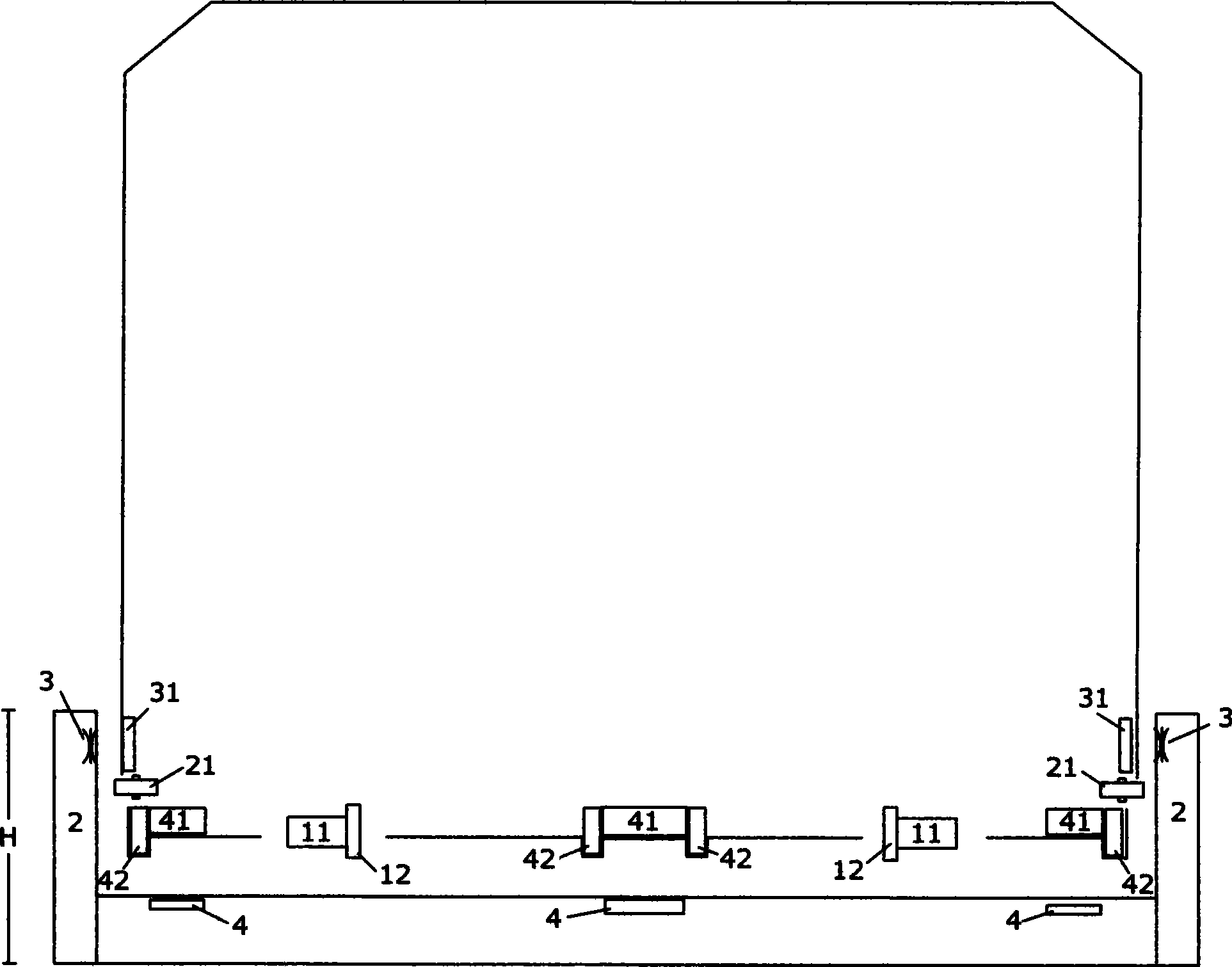

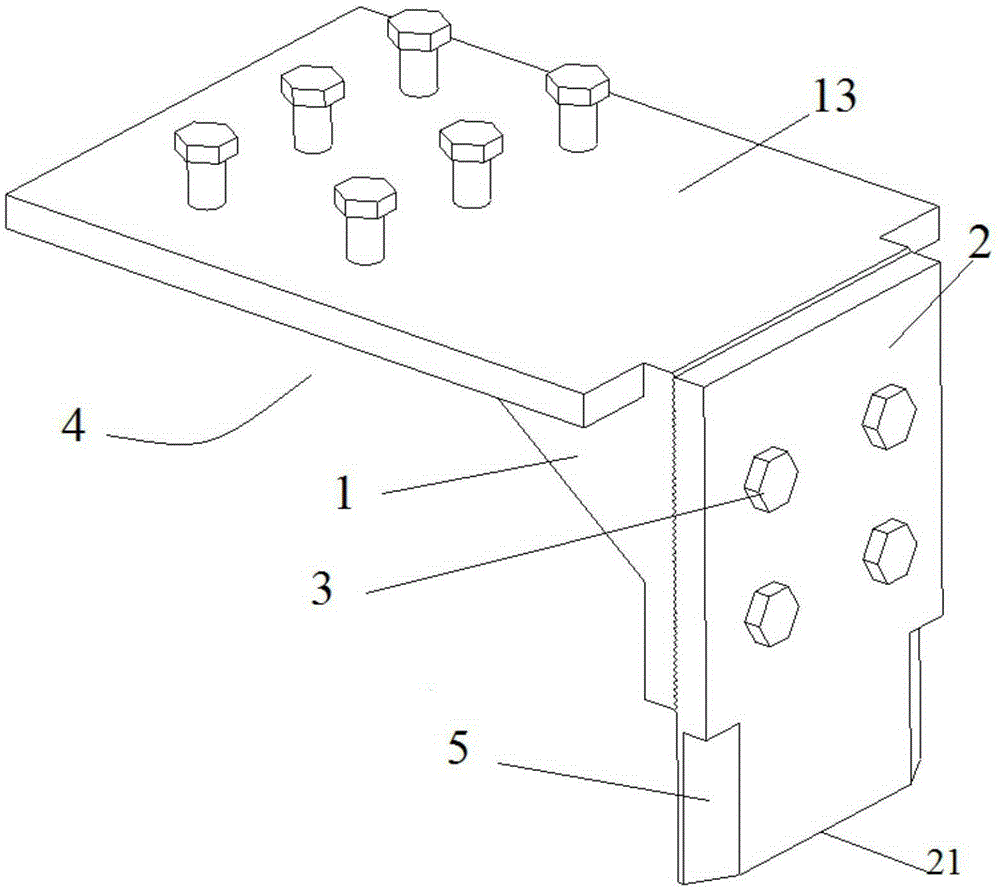

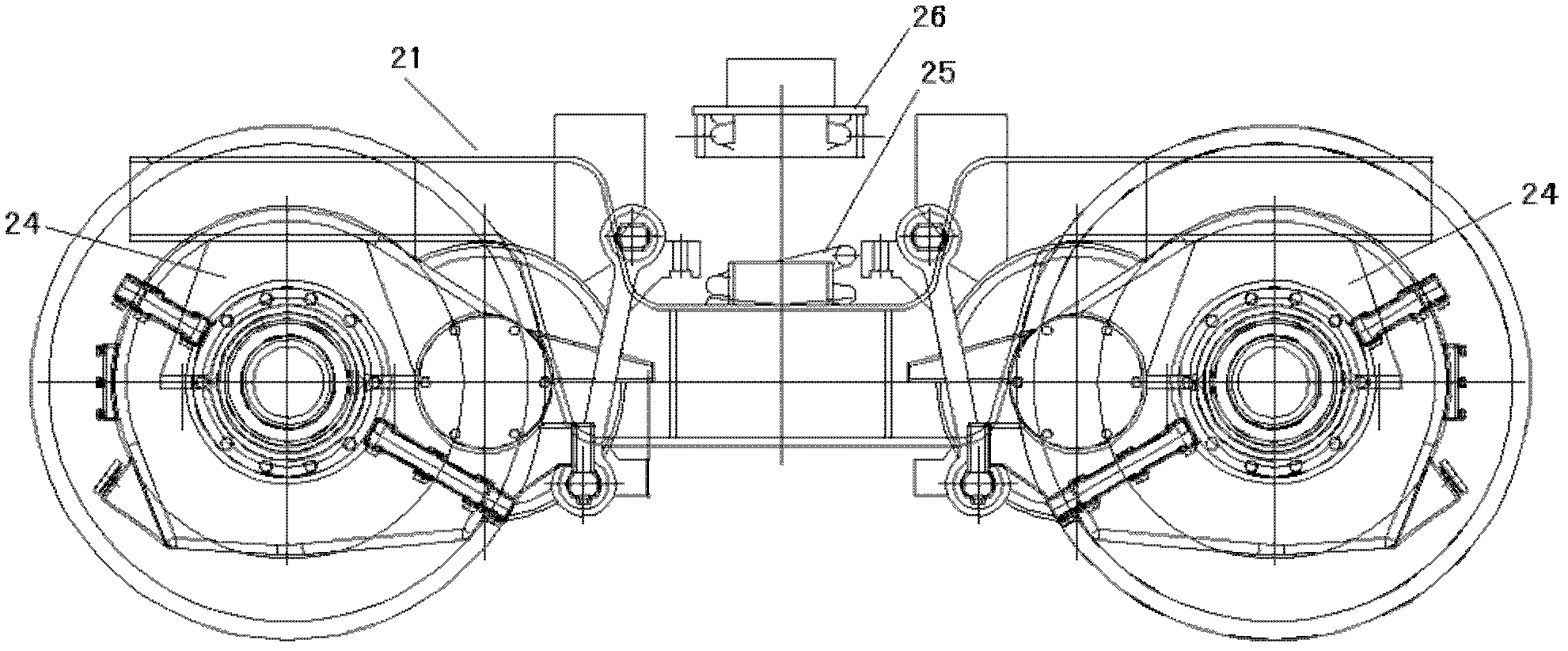

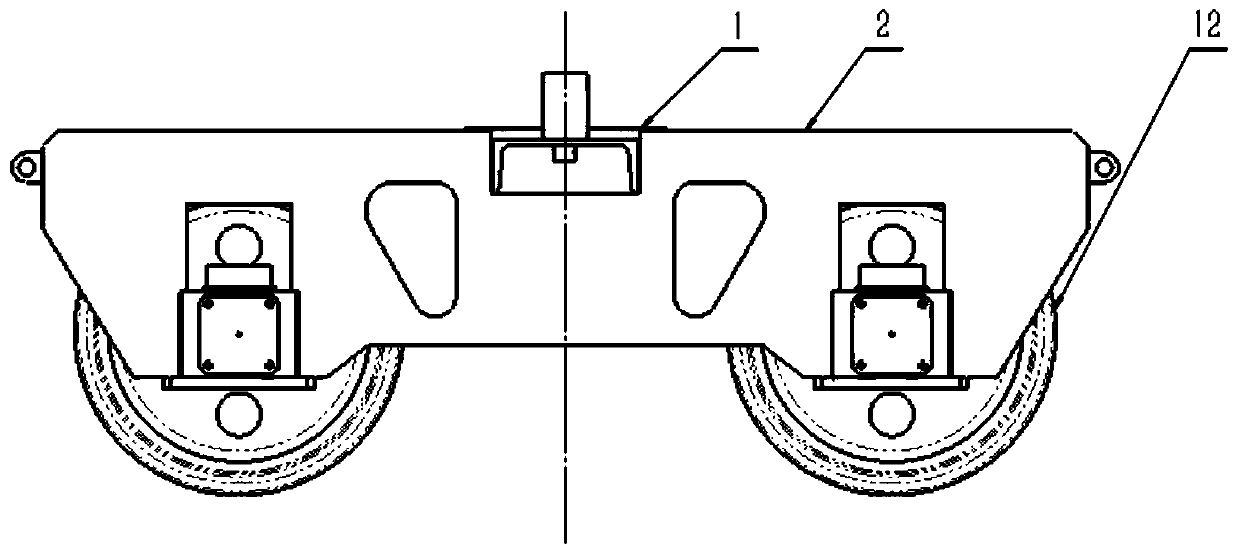

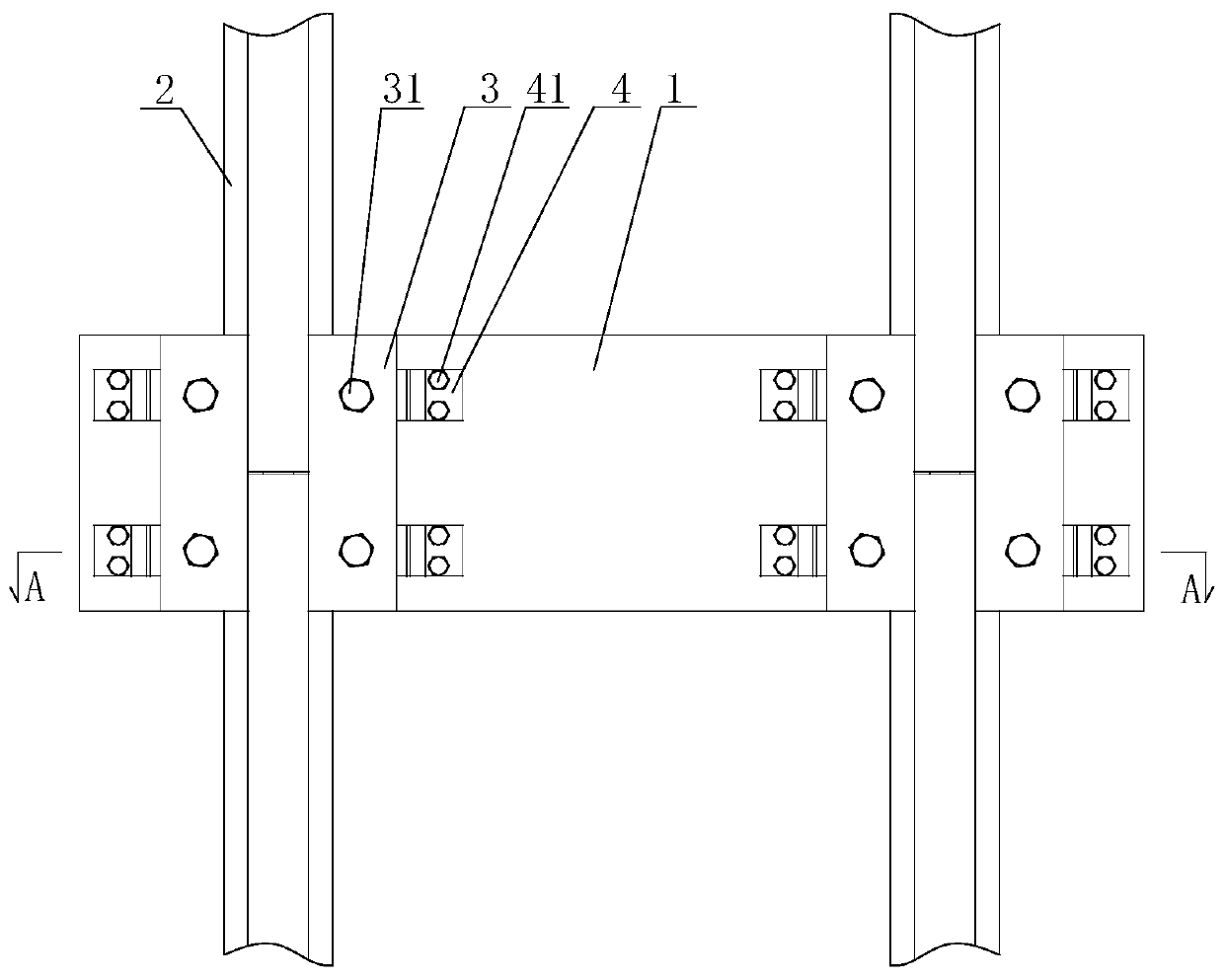

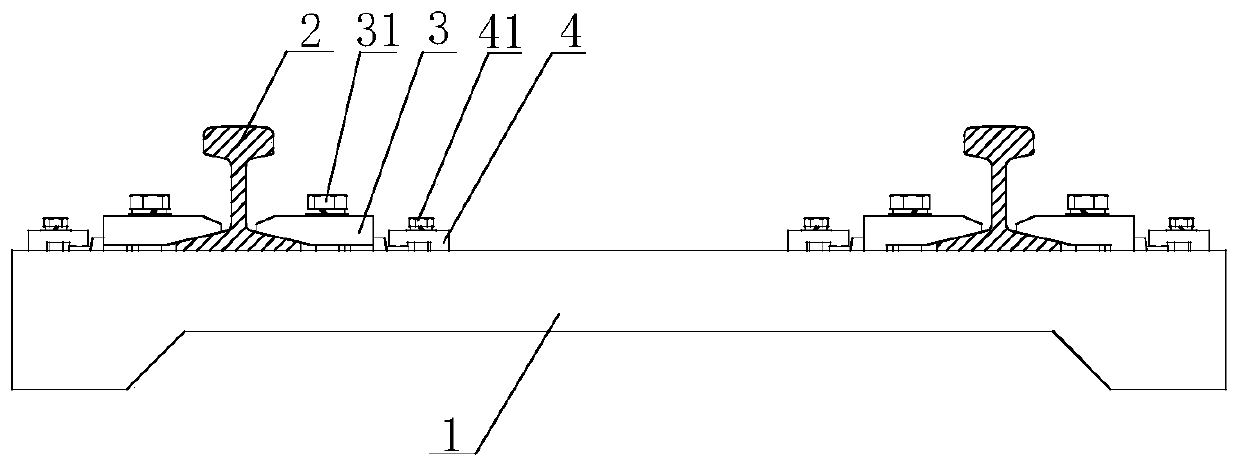

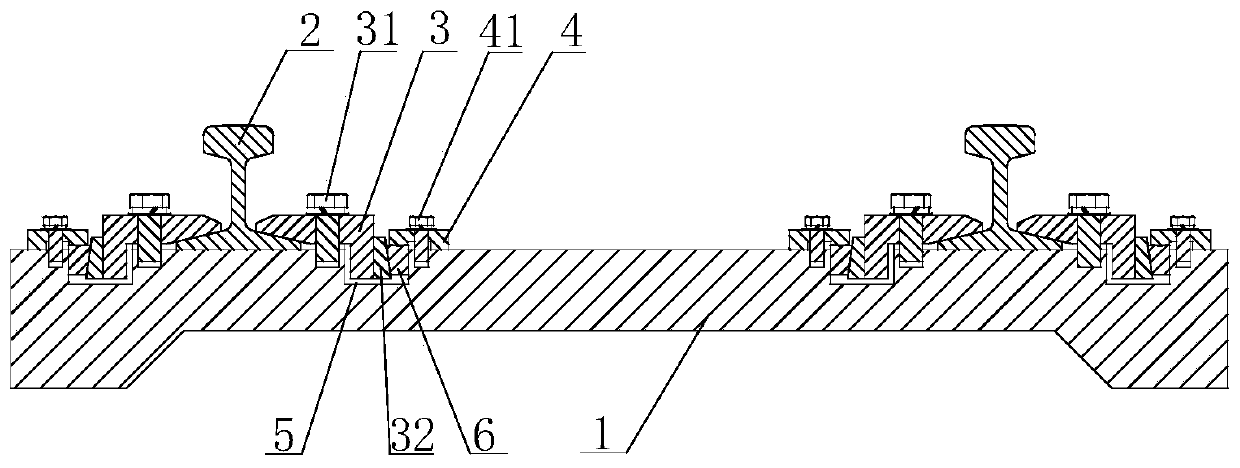

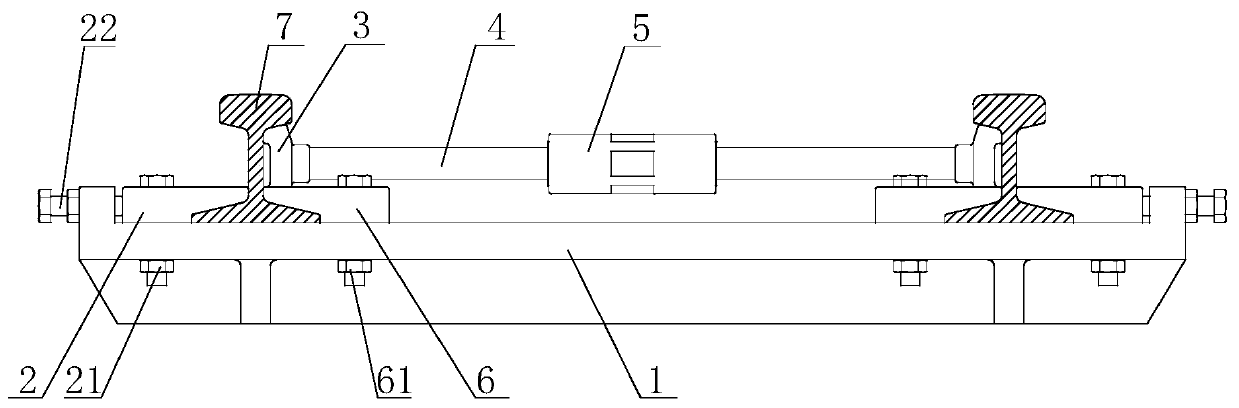

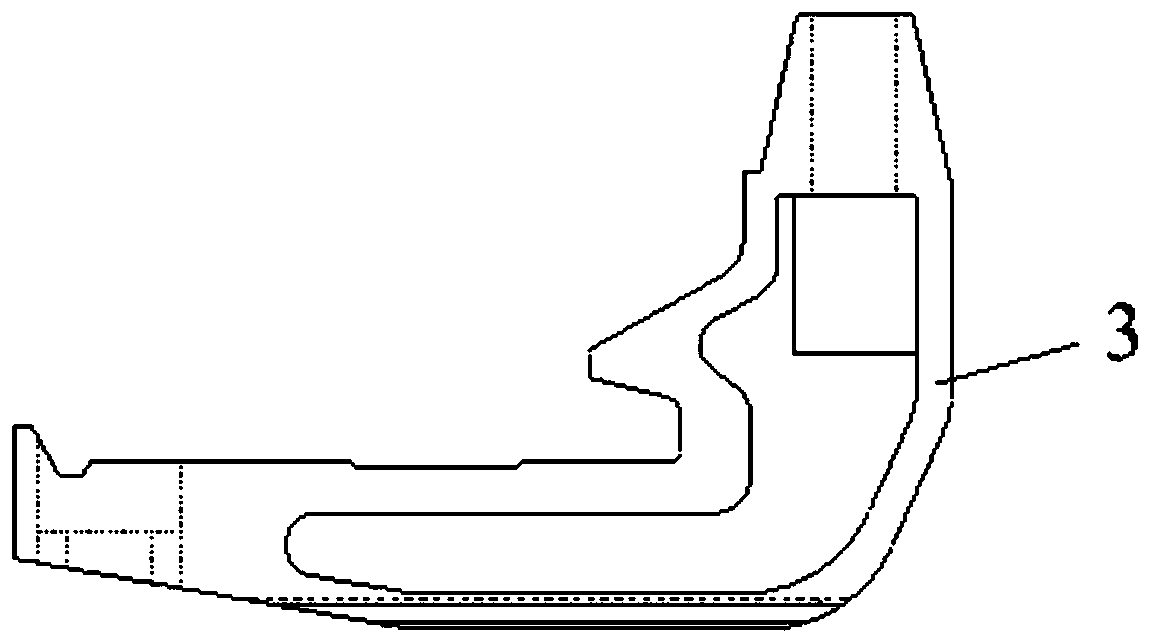

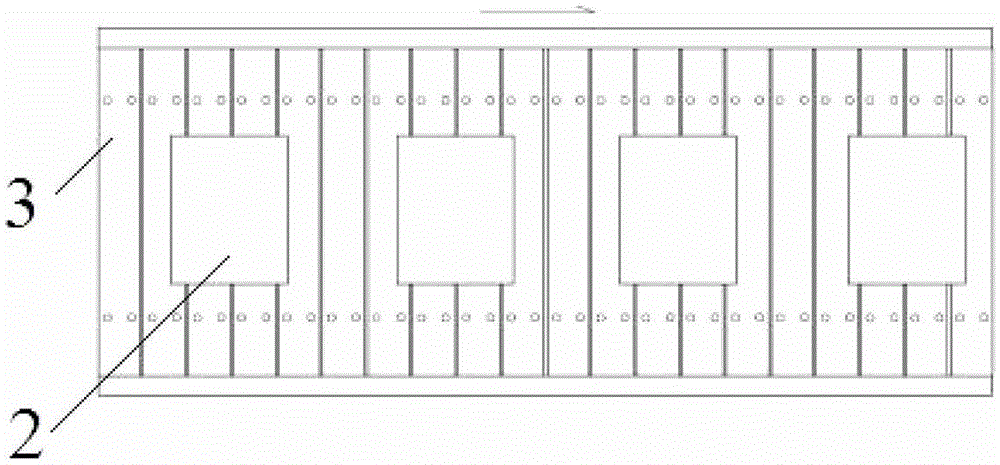

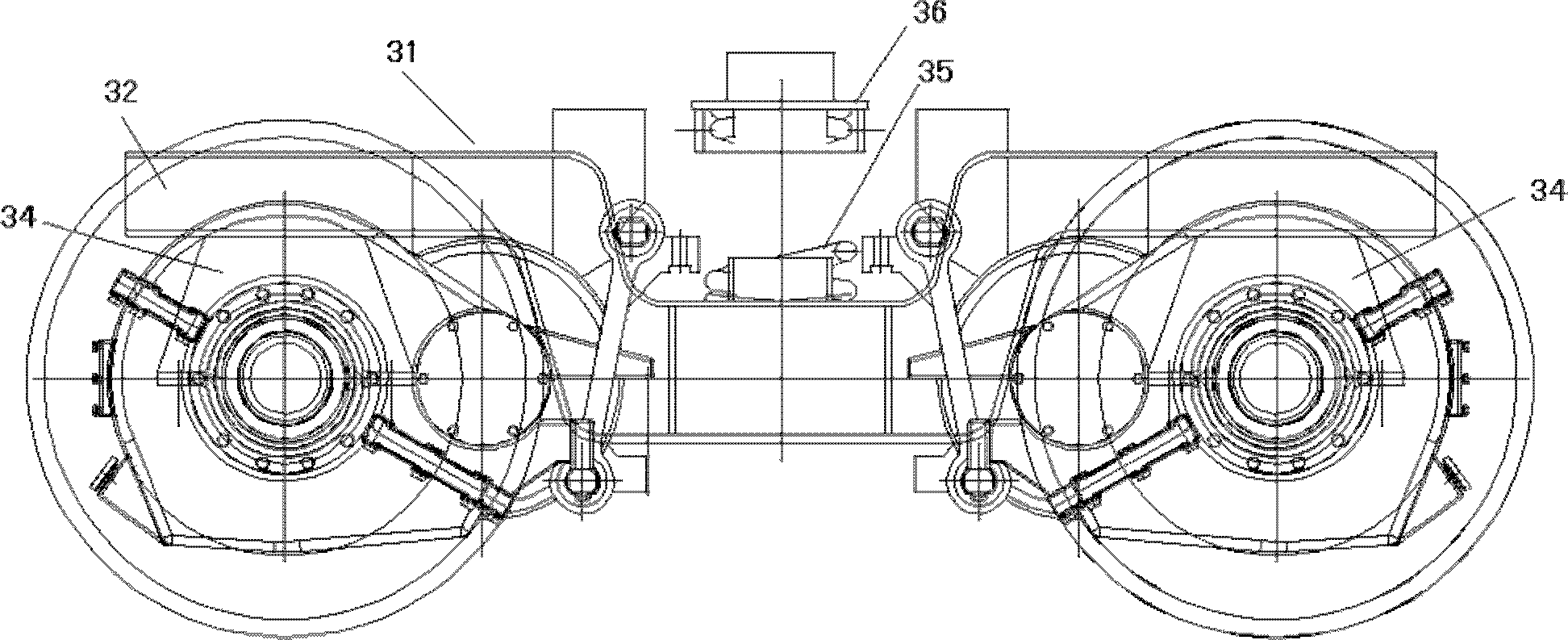

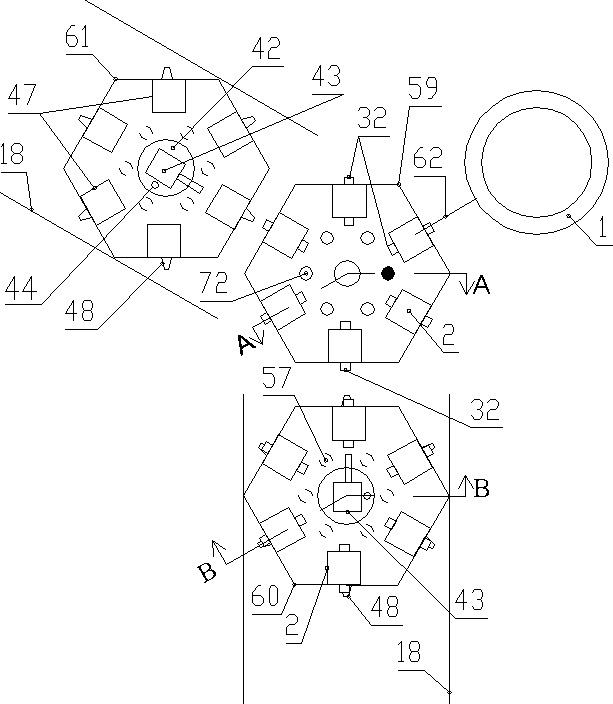

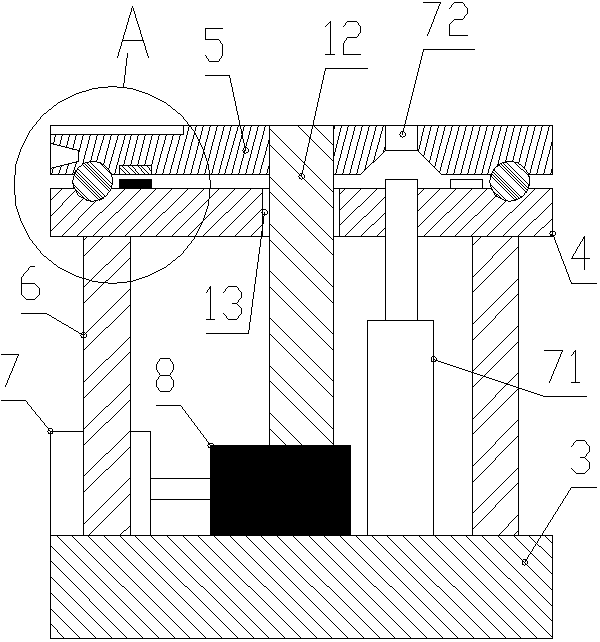

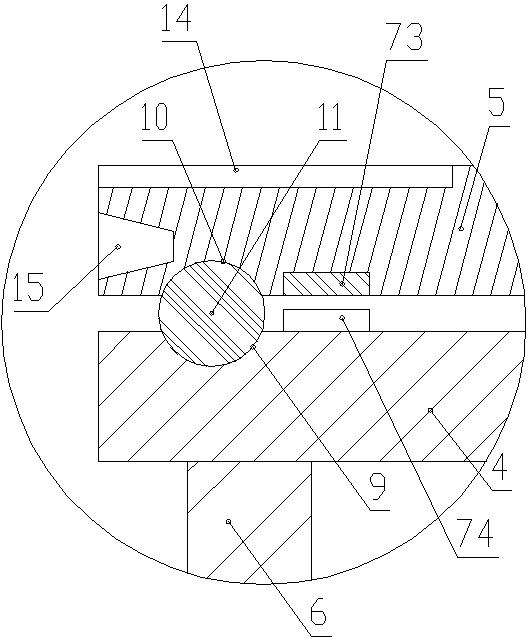

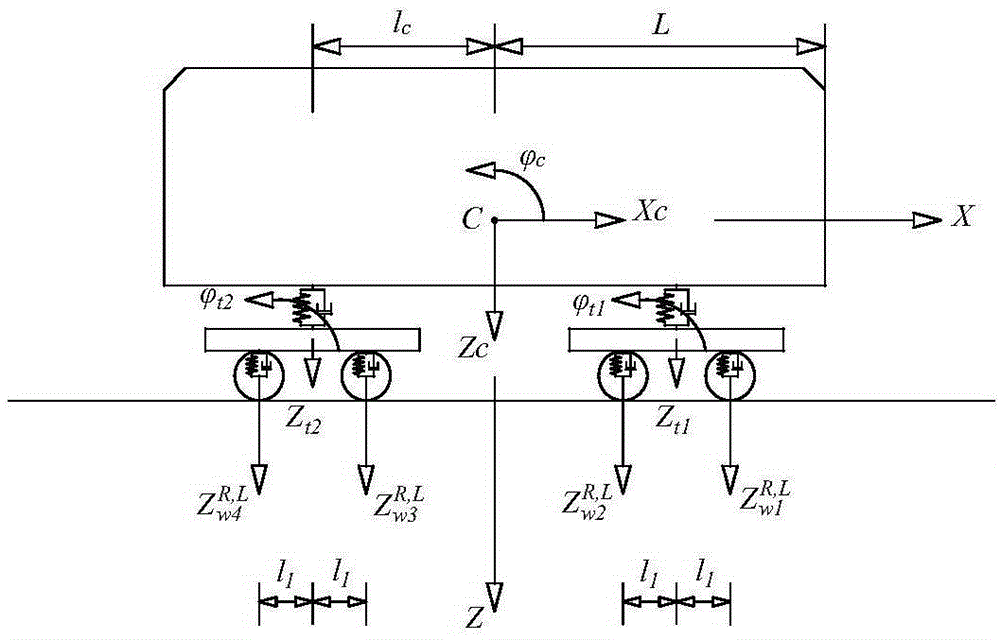

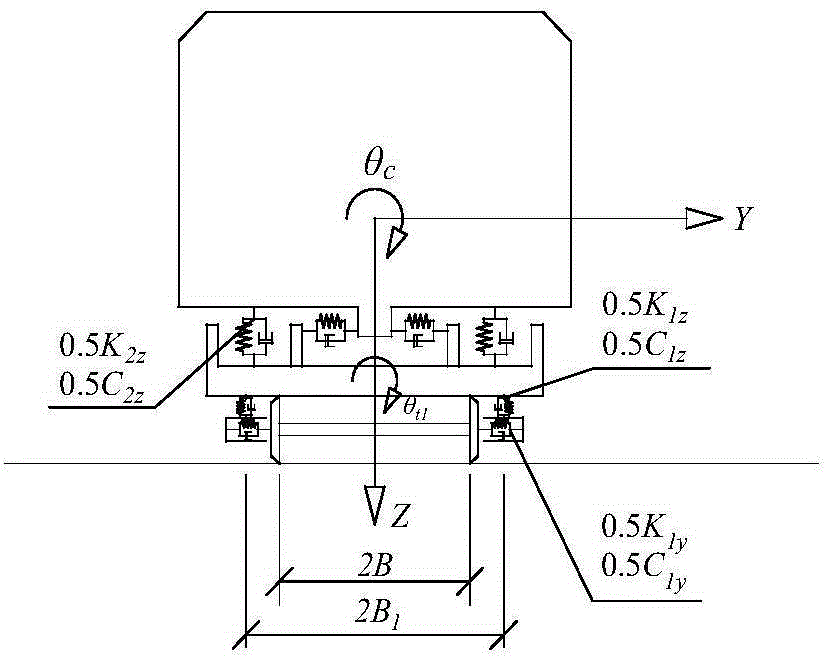

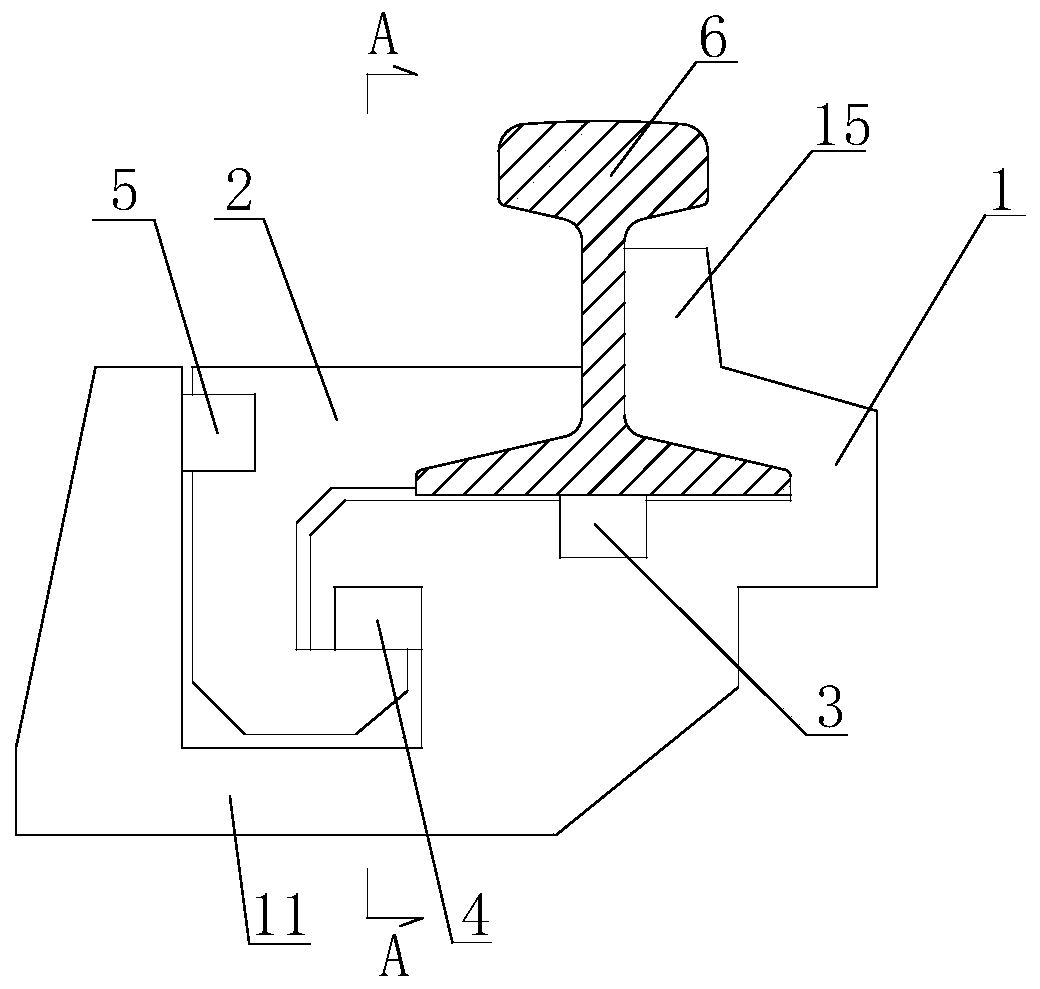

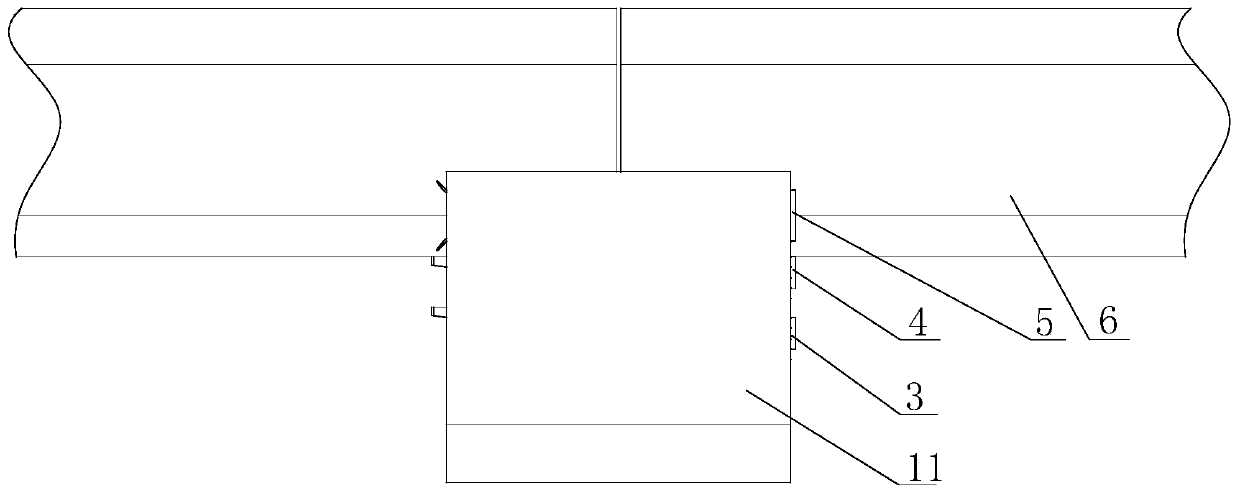

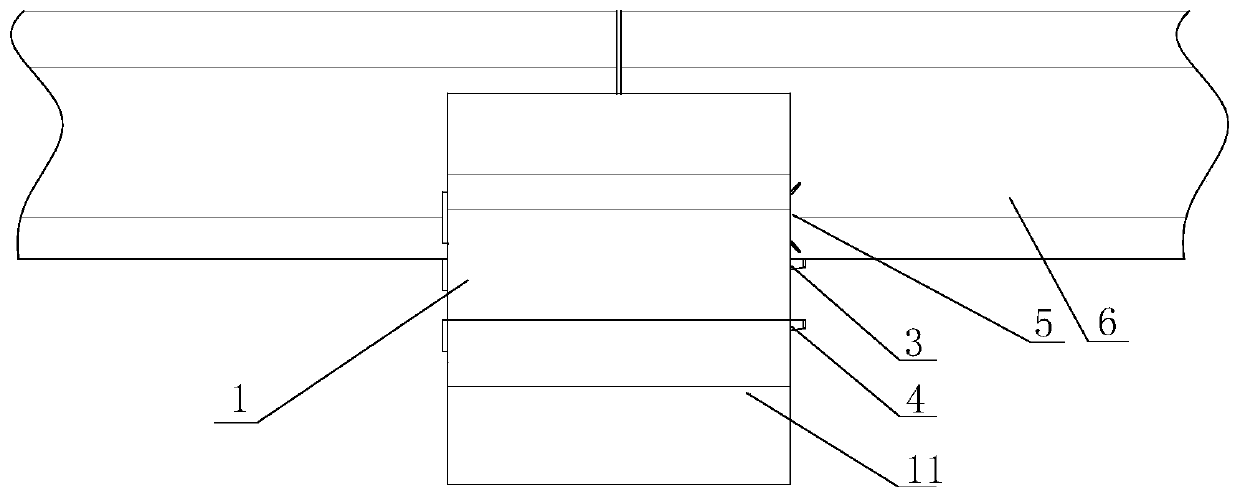

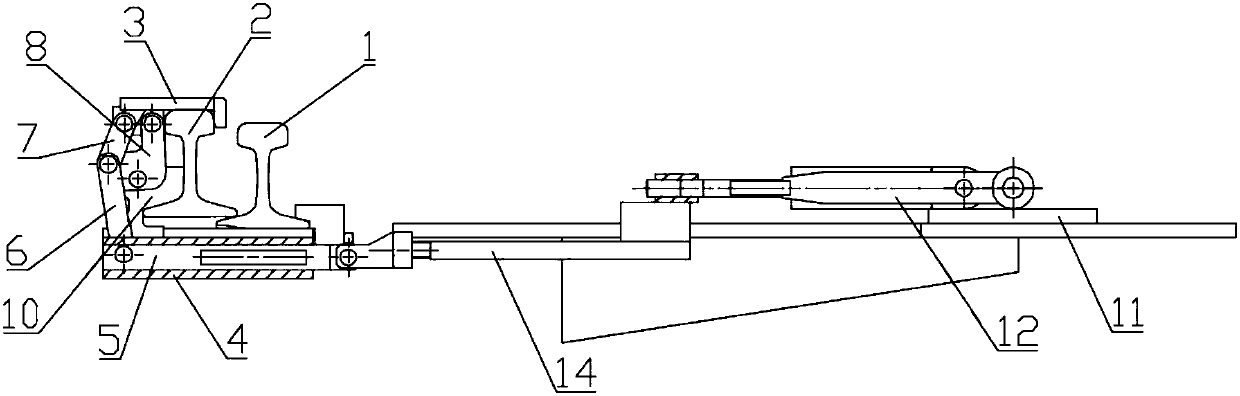

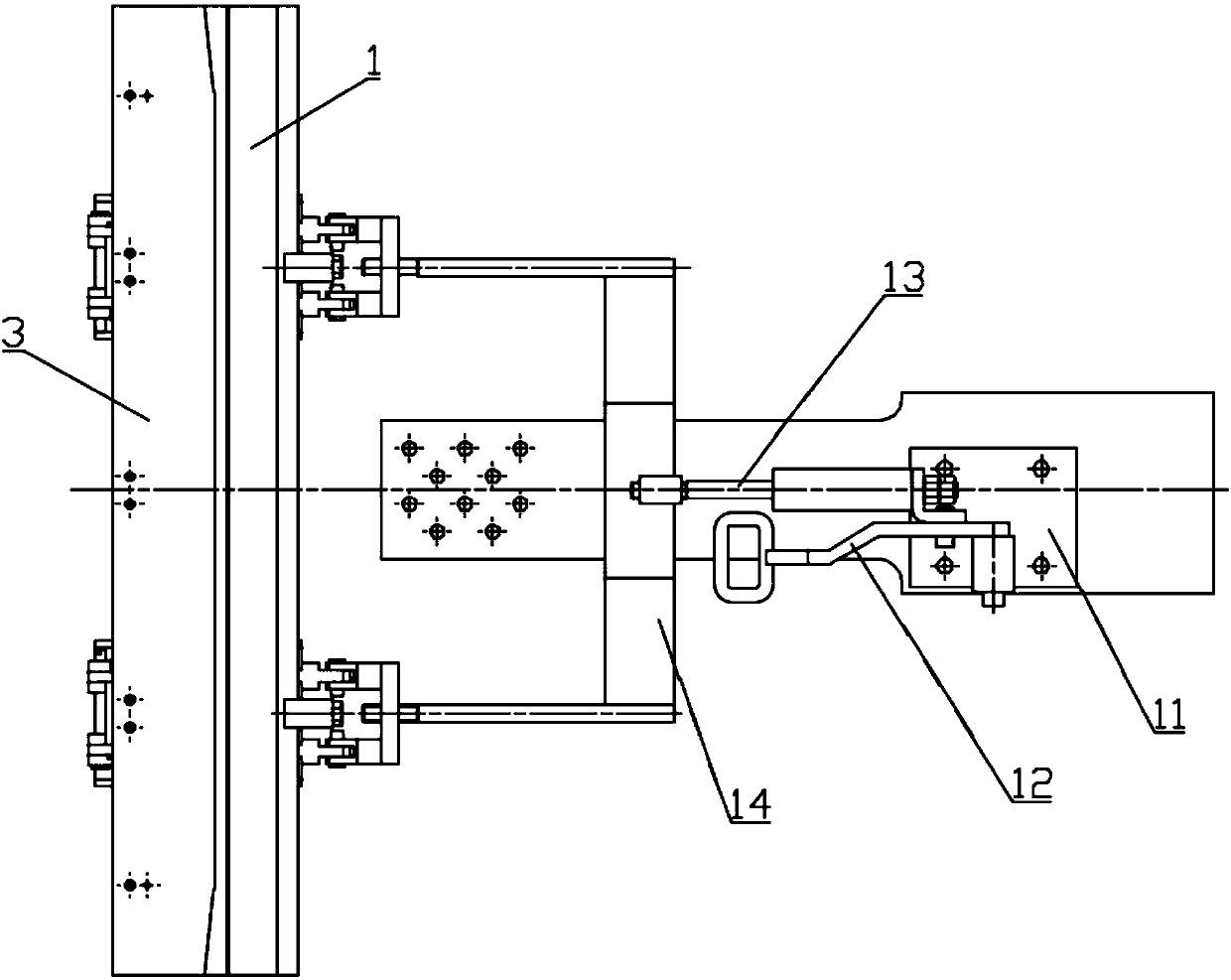

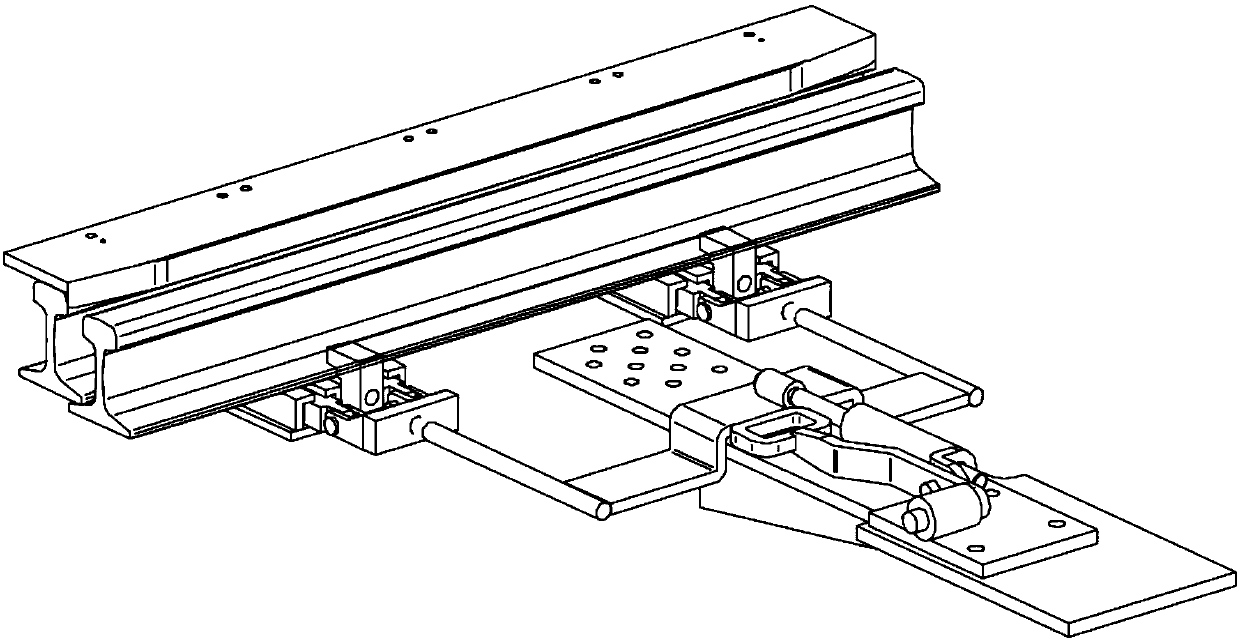

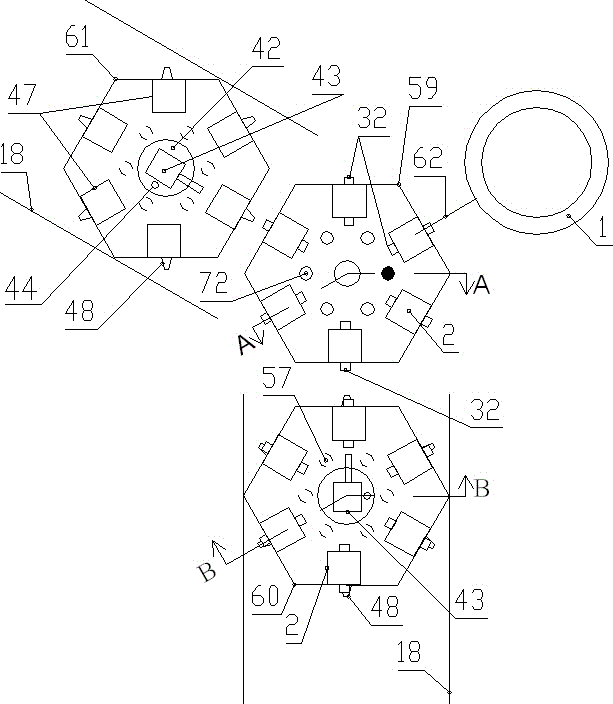

Anti-derailing device for rail vehicle bogie and rail vehicle bogie

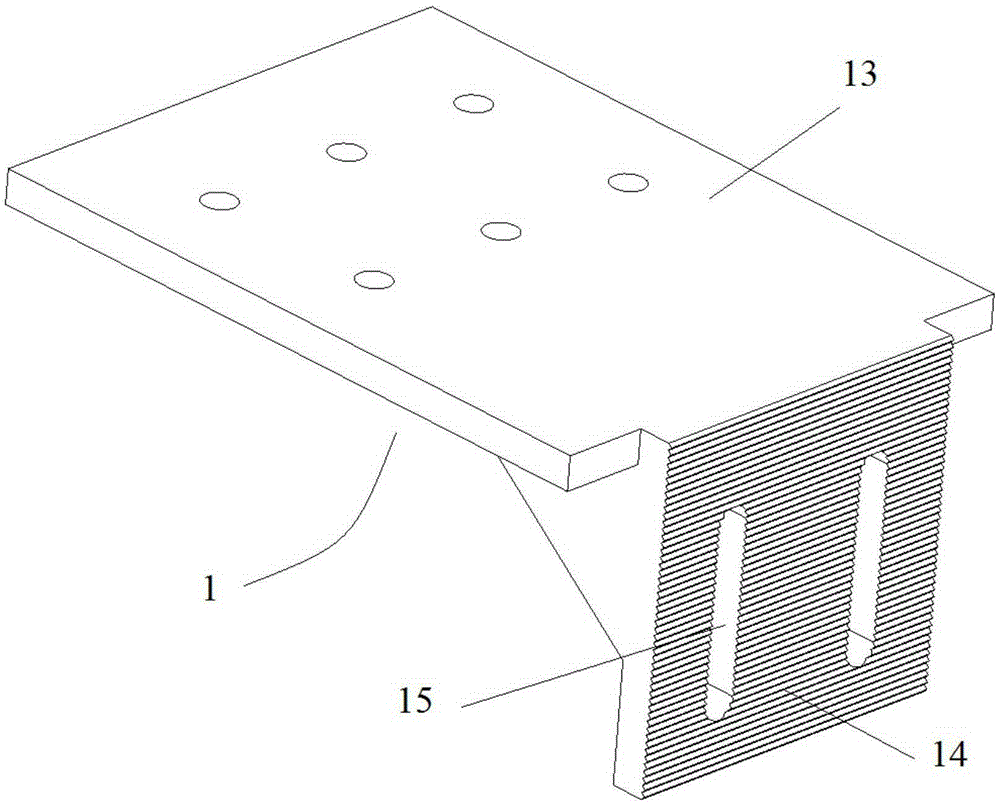

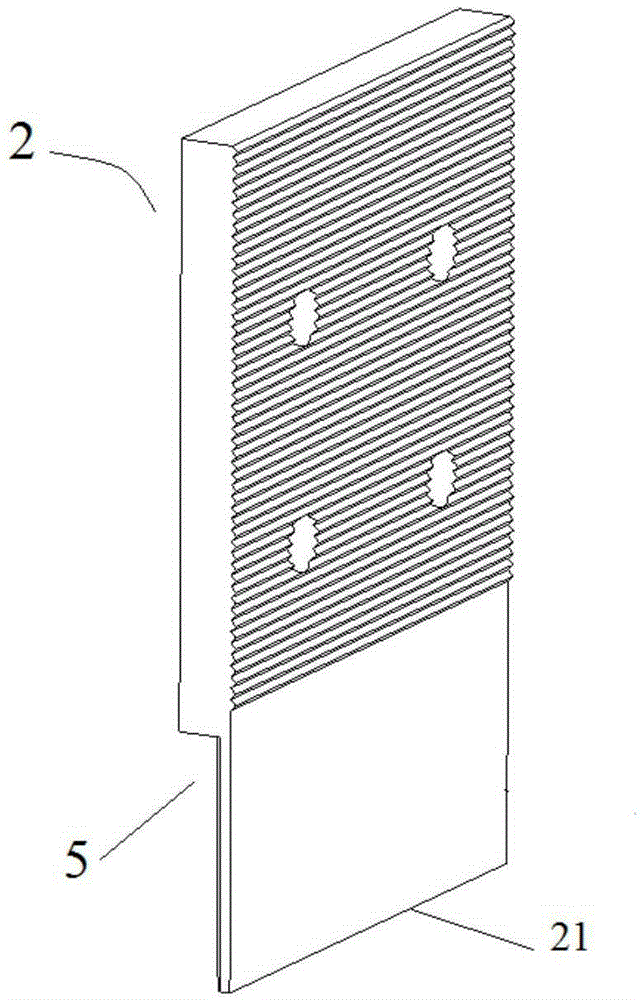

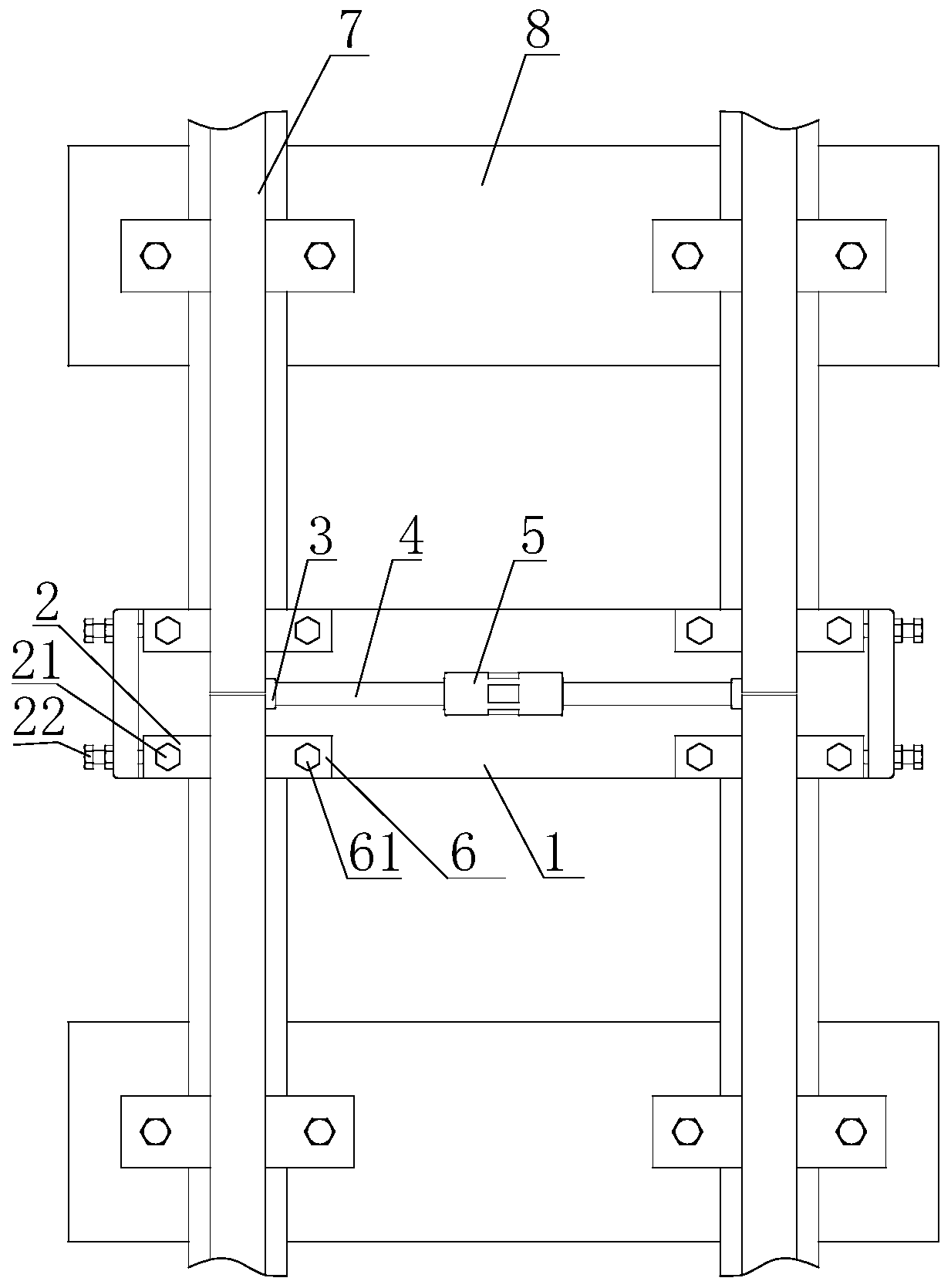

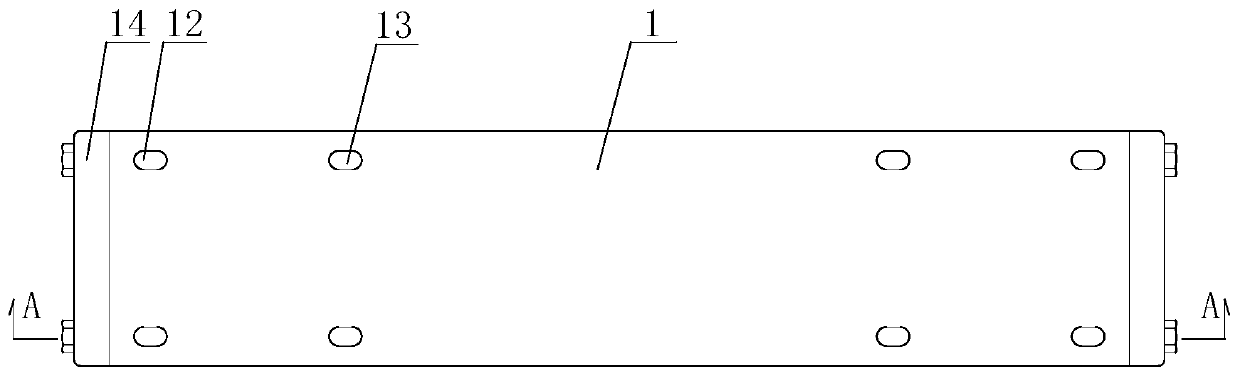

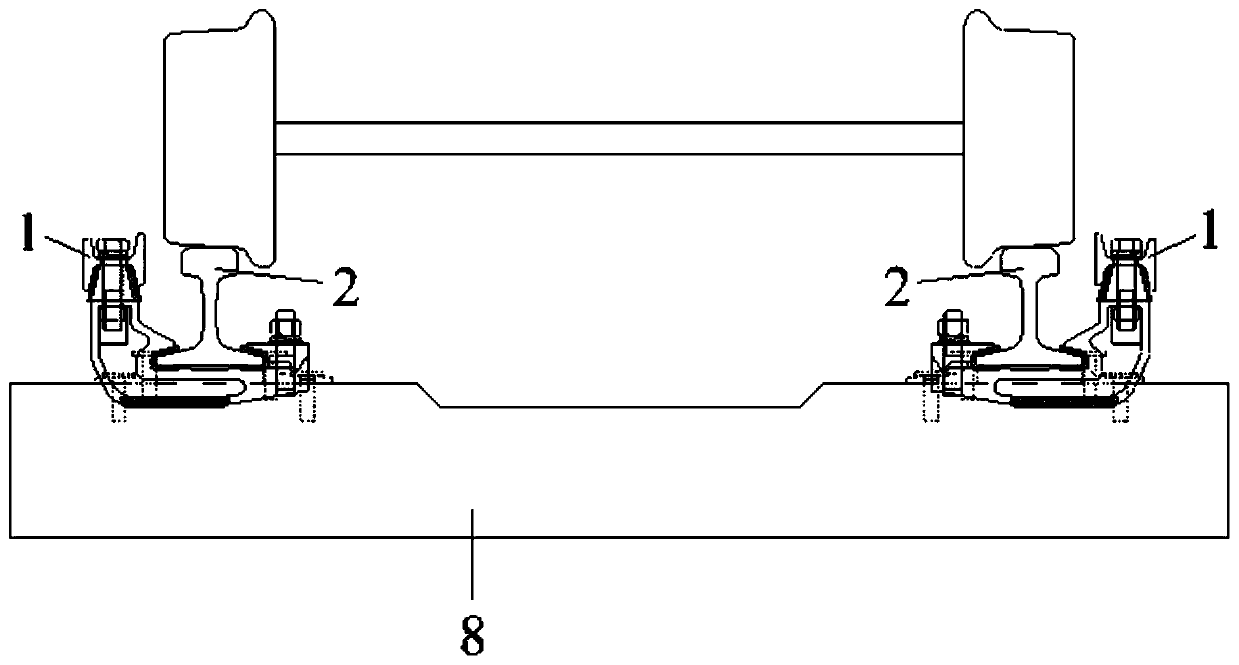

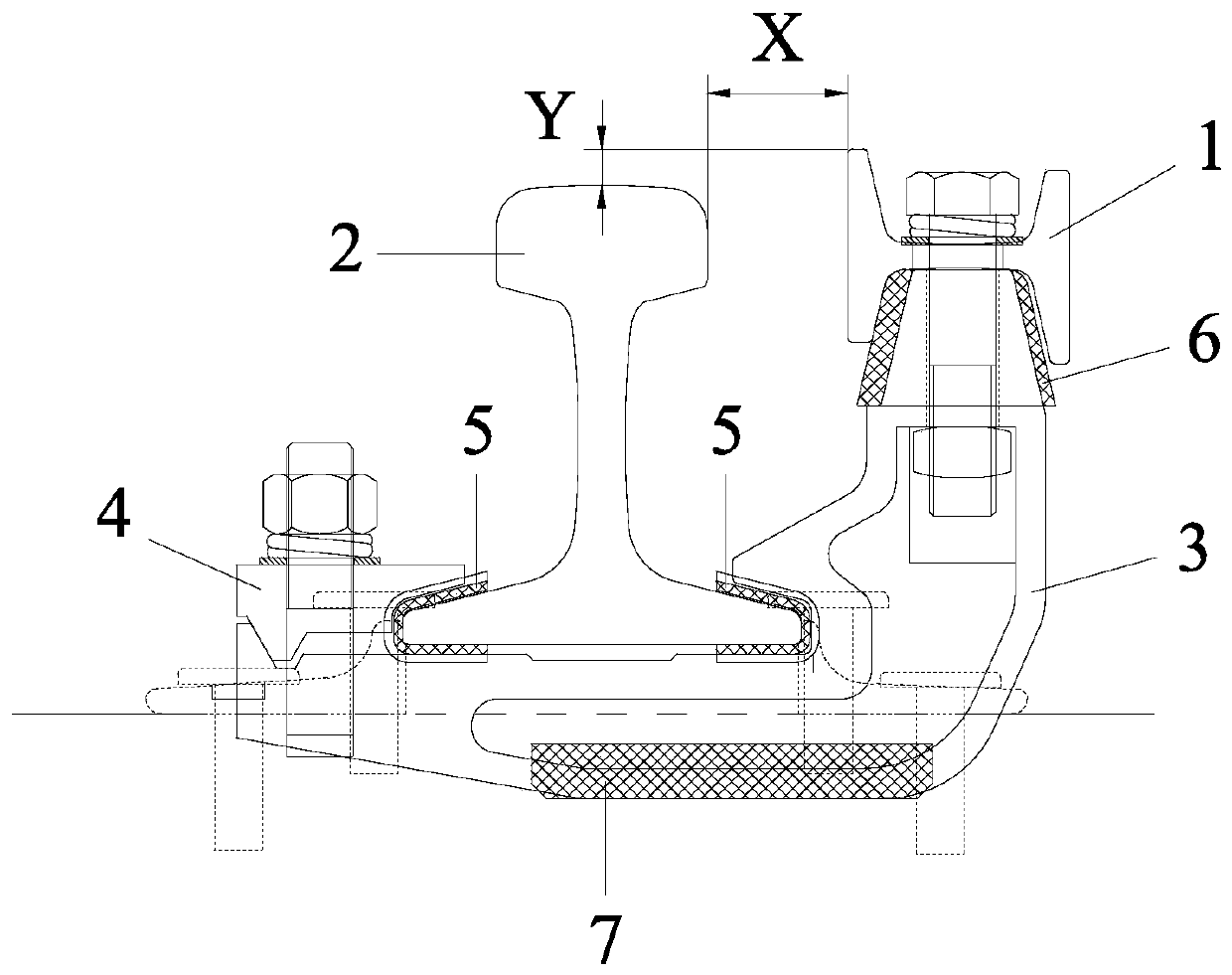

ActiveCN105383511APrevent derailment accidentsPrevent derailmentRail derailment preventionBogiesBogieSlide plate

The invention provides an anti-derailing device for a rail vehicle bogie. The anti-derailing device comprises at least one installing seat (1) installed at the bottom of the rail vehicle bogie (9). The installing seat (1) is provided with an anti-derailing sliding plate (2) stretching to ground rails (8). Transverse positioning and vertical-direction stretching length of the anti-derailing sliding plate (2) on the installing seat (1) simultaneously meet the following requirements that 1, the anti-derailing sliding plate (2) is located on the inner side of the ground rails (8) when a rail vehicle runs normally; 2, when at least one wheel set (6) of the rail vehicle climbs on the rails, the anti-derailing sliding plate (2) can act on the ground rails (8) to form transverse limiting junctures to limit the freedom degree of the rail vehicle, and then the rail vehicle is still restrained by the ground rails (8). According to the anti-derailing device, the rail vehicle bogie can be prevented from derailing during operation, especially derailing probably occurring after the wheel sets climb on the rails can be avoided, and therefore train safety and transporting efficiency are improved.

Owner:CENT SOUTH UNIV

Centrifugal force safety braking device of active track-locking type tramcar

InactiveCN101580070APrevent derailment accidentsAvoid loss of life and propertyTrack-braking member co-operationVehicle frameEngineering

The invention relates to a braking device of a tramcar, in particular to a centrifugal-type safety braking device of an active track-locking tramcar. The invention solves the problems that the existing passive anti-skid device is prone to insensitive response and long braking response time, the maintenance thereof is easily ignored, and the reliability thereof is low. In the invention, two groups of centrifugal speed sensors are arranged on two tramcar wheel bodies; the two ends of a rotary connecting rod are fixedly connected with two gears on the outer side of the tramcar frame by passing through the tramcar frame; two racks are mounted on the tramcar frame and engaged with the gears; one end of each rack, which is hook-shaped, is matched with the other end of a telescopic rod; two frameworks are arranged below the rotary connecting rod and connected with the tramcar frame via a suspender switch; two locking dogs are rotatablely mounted at the ends of the two frameworks, which are connected via a fixed connecting rod. The invention has the advantages of sensitive response, short braking response time, convenient maintenance and high reliability.

Owner:吴强 +3

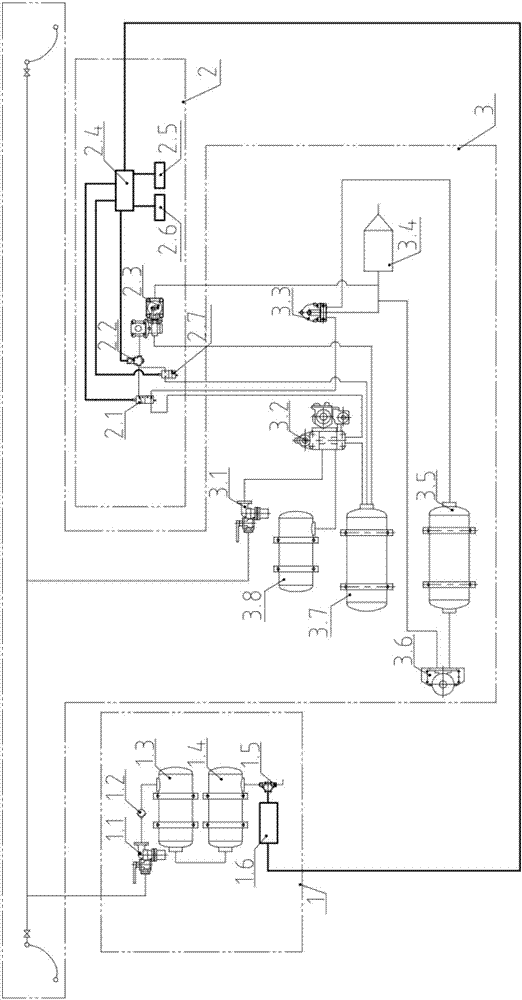

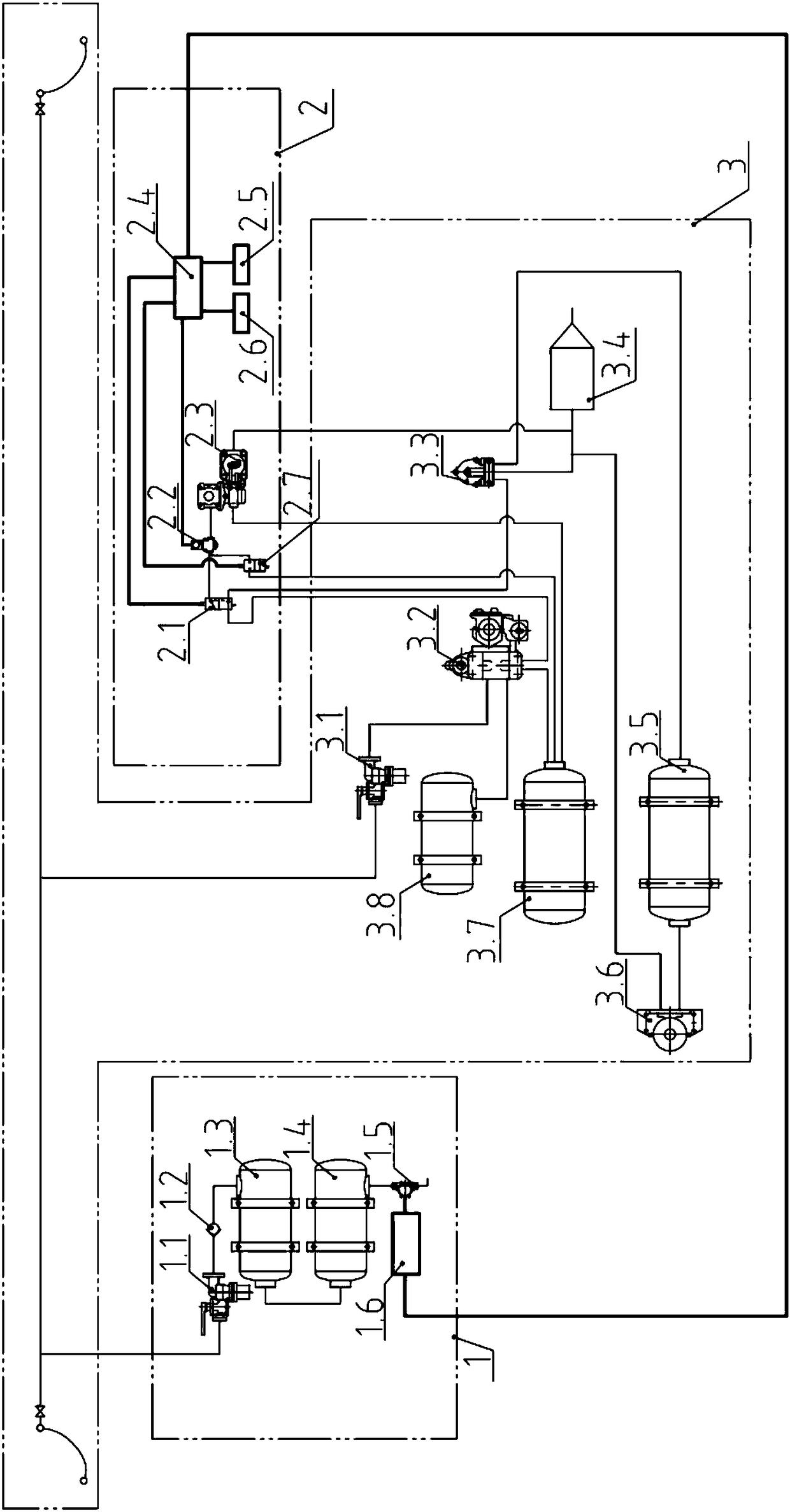

Pneumatic-electric braking system for goods train

InactiveCN107298111AImprove adaptabilitySimple structureRailway hydrostatic brakesRailway hydrodynamic brakesElectronic control unitElectricity

The invention relates to a pneumatic-electric braking system for a goods train. An air brake system is additionally provided with a pneumatic power generating module and an electric control dynamic adjustment module, wherein the air brake system is suitable for conventional goods trains and is composed of a train pipe, a 120# distribution valve, a braking cylinder, an auxiliary air cylinder, an acceleration relief air cylinder and a mechanical empty and heavy vehicle adjusting assembly, and the mechanical empty and heavy vehicle adjusting assembly is composed of a mechanical proportional valve, a weight measuring mechanism and a pressure reduction air cylinder; the pneumatic power generating module is composed of an air storage cylinder assembly, a pneumatic power generator and a storage battery unit, and the storage battery unit comprises a storage battery and a management system; the electric control dynamic adjustment module is composed of a brake electronic control unit, a switching electromagnetic valve, a proportional electromagnetic valve, a relay valve and sensors; and the pneumatic power generating module is used for supplying power to the electric control dynamic adjustment module, and pneumatic-electric braking is finally achieved. Compared with the prior art, the pneumatic-electric braking system for the goods train can meet the requirement for precise control over braking under no-load or heavy-load conditions and has the advantages of skid resistance and high sensitivity.

Owner:TONGJI UNIV

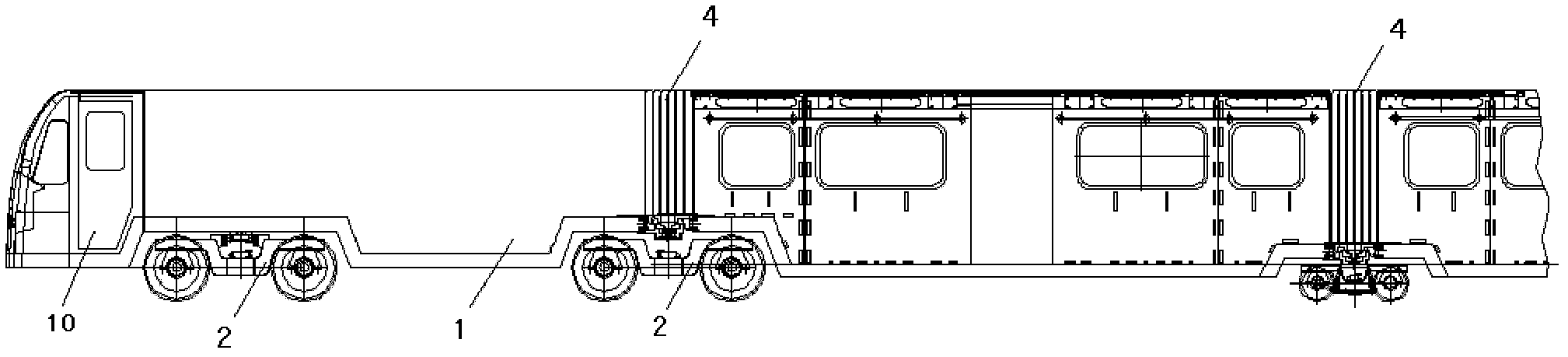

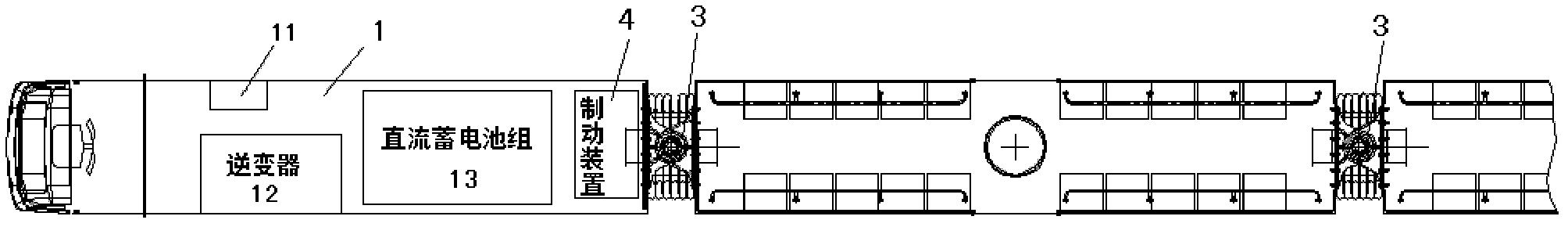

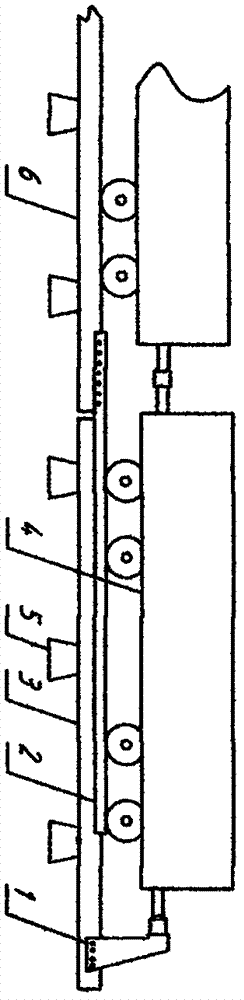

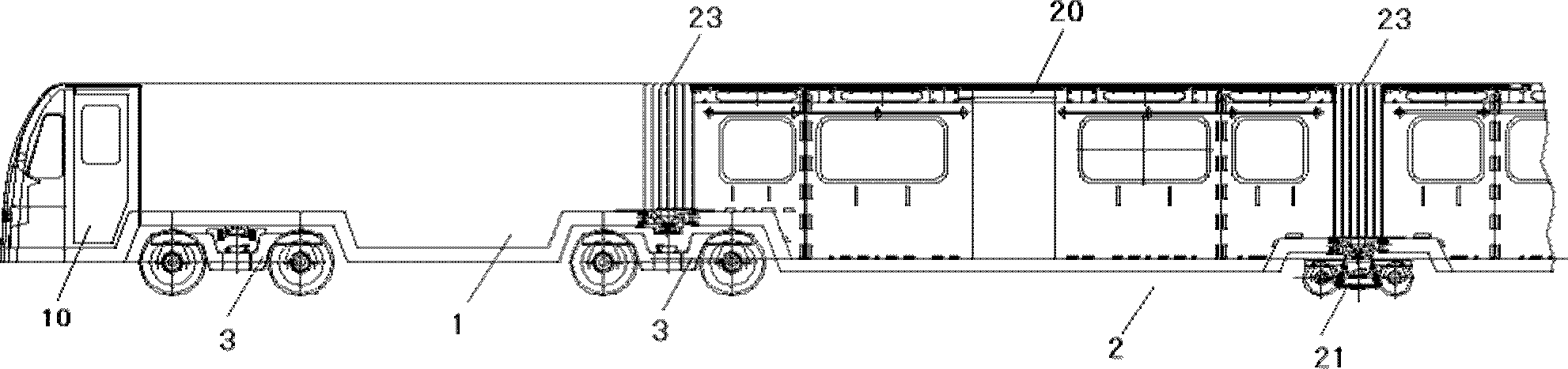

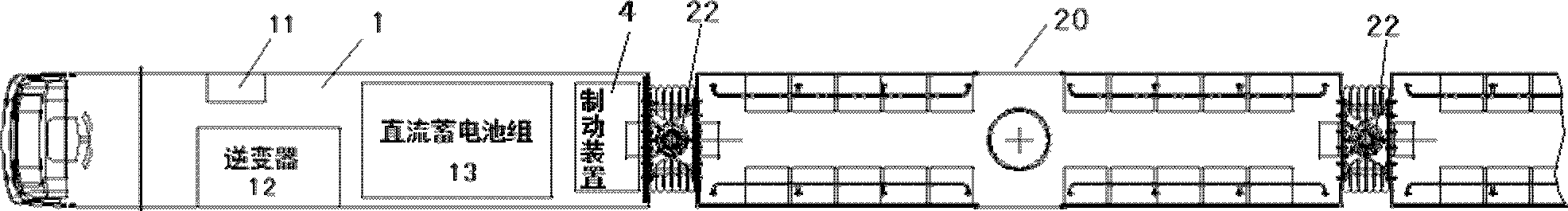

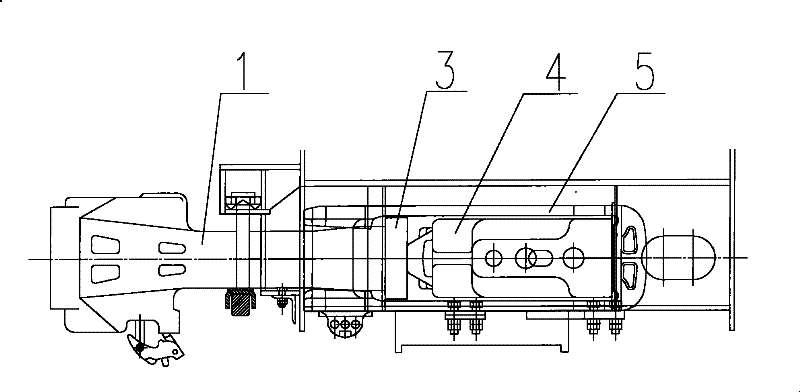

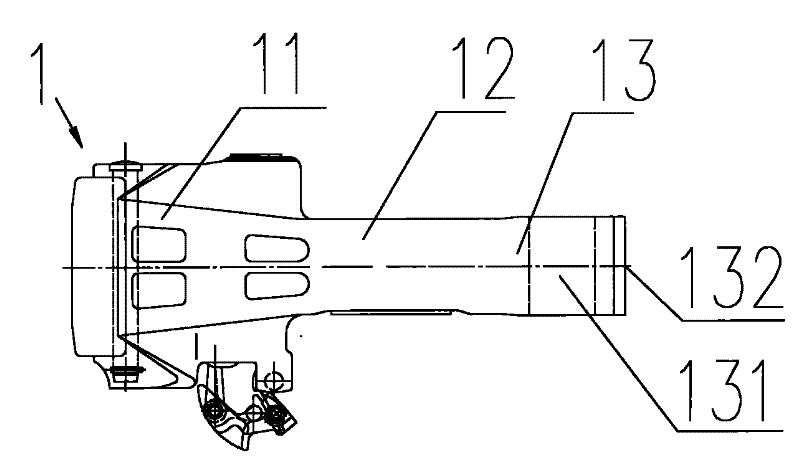

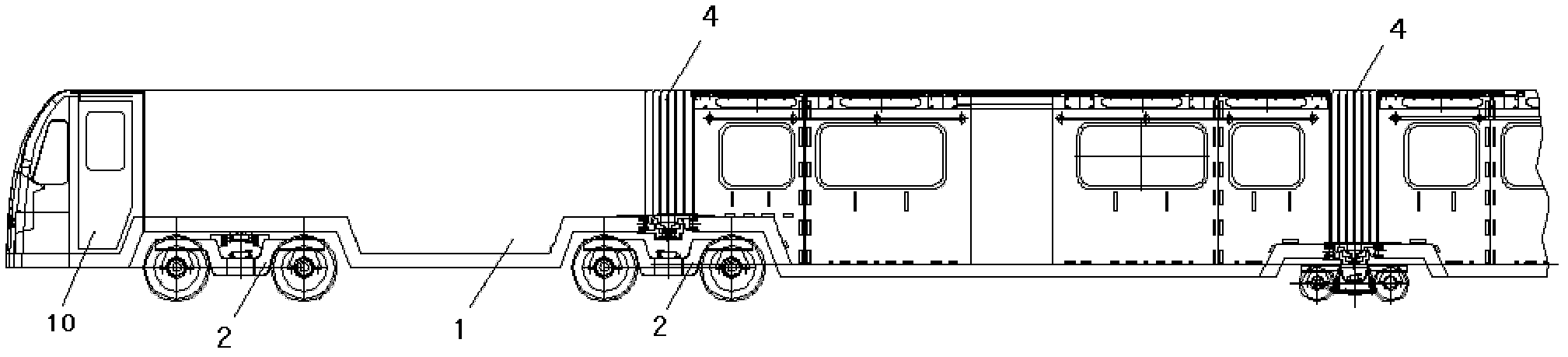

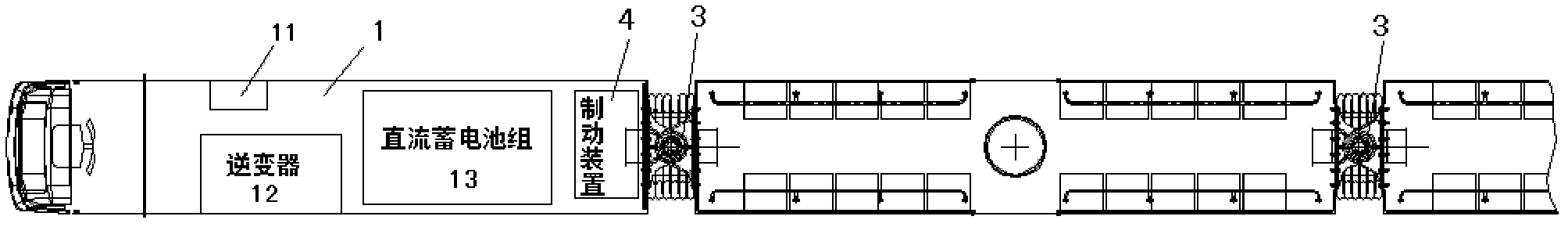

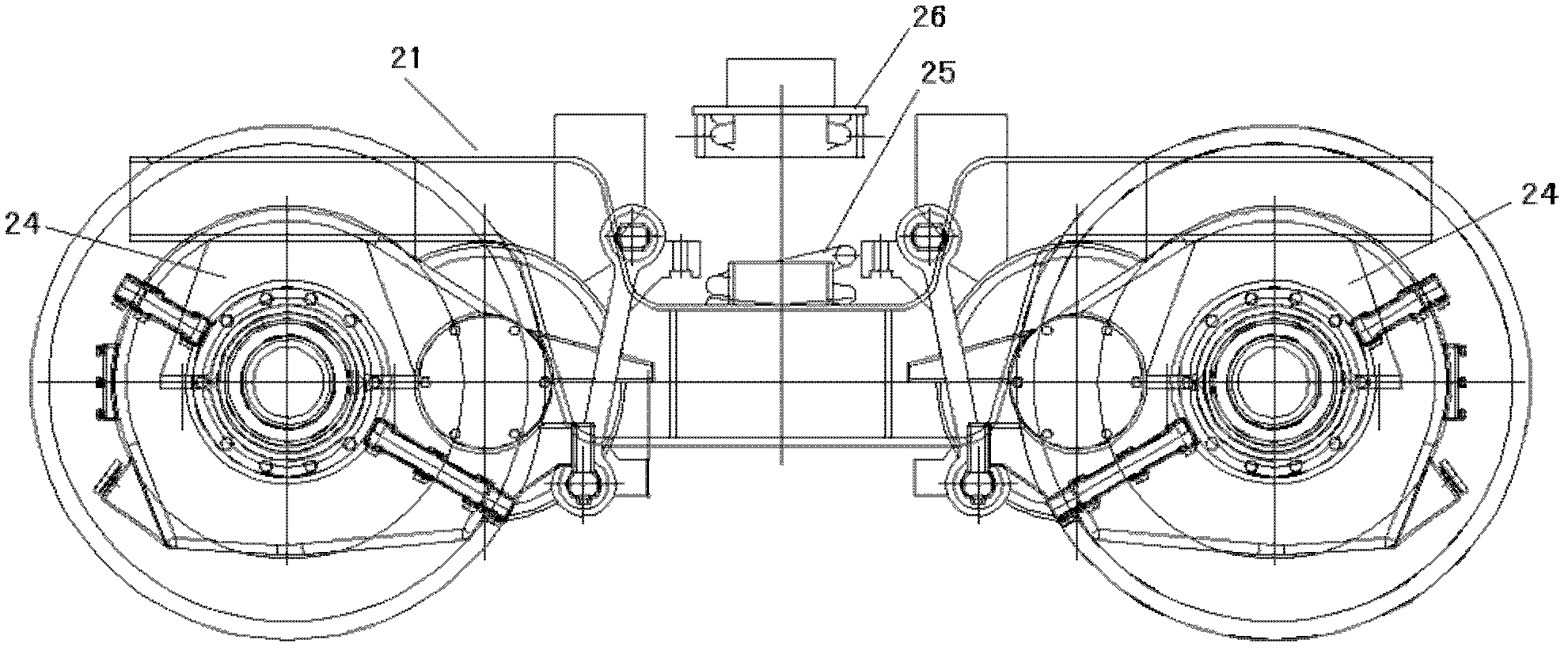

Power car for narrow gauge electric motor car

ActiveCN102501859AReduce volumeIncrease driving speedElectric locomotivesRailway transportBogieElectrical control

The invention relates to a power car for a narrow gauge electric motor car, which comprises a power car body, wherein, an electrical control system, a drive power supply and a braking device are arranged inside the car body; and two power steering frames are arranged at the bottom of the car body. The power car is characterized in that one of the power steering frames is arranged at the bottom of the car body under the drive power supply, and the other power steering frame is arranged between the bottom of the car body and the bottom of a carriage of an adjacent tow truck; the car body and the adjacent carriage are connected through an articulation device and a passing platform; the articulation device is arranged on a lower center plate of one of the power steering frames; the passing platform is arranged at the top of the articulation device; and the both sides between the car body and the adjacent carriage are connected with each other through a damper plate. The power car can be widely used in various occasions needing narrow gauge transportation, such as mine exploitation, tunnel excavation, light rails, subways, etc.

Owner:CHANGCHUN GUANGYIN GROUP

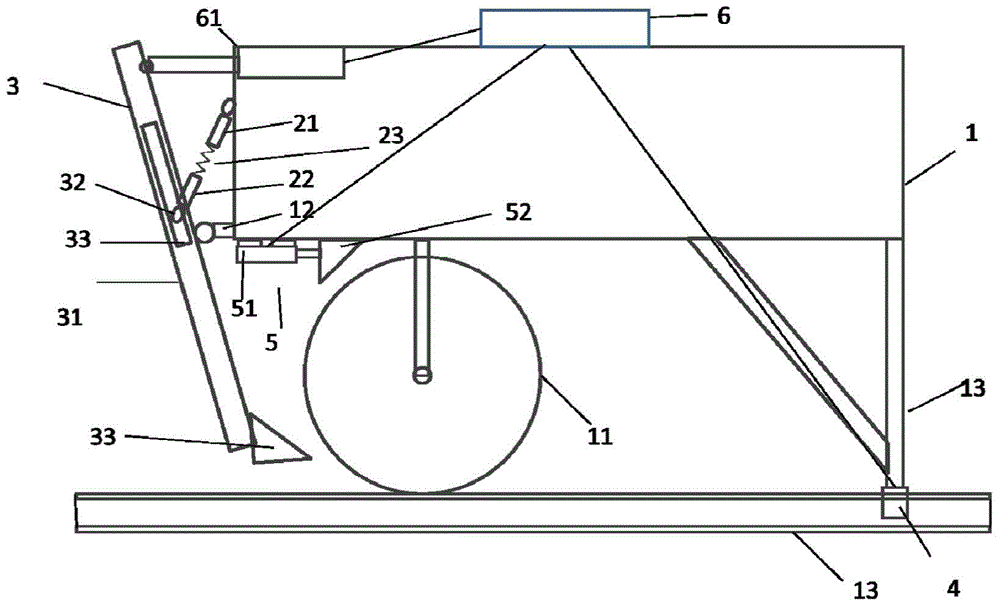

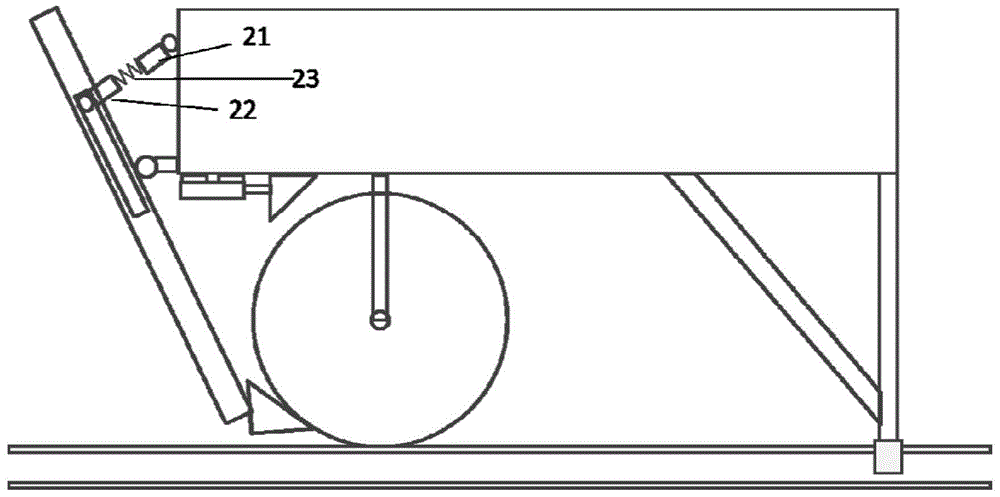

Braking device on tracks

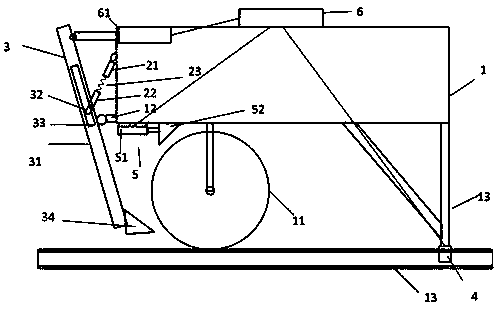

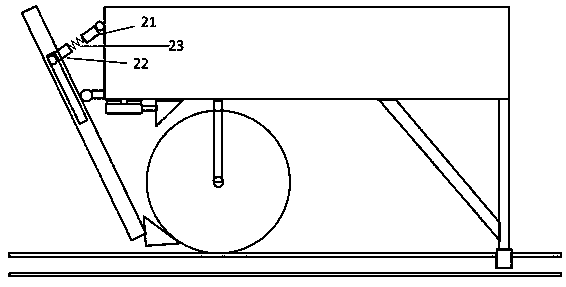

ActiveCN106585659APrevent derailment accidentsSmooth rideTrack-braking member co-operationHydraulic cylinderTurning frames

The invention relates to a baking device on tracks. The braking device comprises hydraulic pincers (4), brakes (5), and wheel bottom brakes (3), wherein the hydraulic pincers (4) are arranged at the tail end of a frame (1), are hydraulically driven, and are connected with the tail end of the frame (1) through a tripod; each of the brakes (5) is arranged at the top end of a corresponding wheel (11), is fixed on the corresponding wheel (11), and comprises a hydraulic cylinder (51); a push rod of each hydraulic cylinder (51) faces the corresponding wheel, and the front end of each of the push rods is connected with a first braking block (52); each of the wheel bottom brakes (3) comprises a connecting rod (31); each connecting rod (31) is hinged to a supporting seat (12) fixed on the frame, and a sliding groove (33) is formed in a position, at the upper end of the supporting seat (12), of each connecting rod (31), and is in sliding connection with a sliding block (32); each sliding block (32) is connected with a second connecting rod (22), and the other end of each second connecting rod (22) is fixedly connected with a spring (23); each spring (23) is fixedly connected with a third connecting rod (21); each third connecting rod (21) is hinged to the frame (1); and a second braking block (33) is fixed to the bottom end of each connecting rod (31).

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

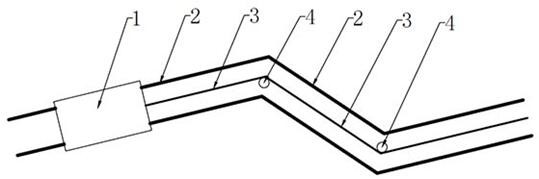

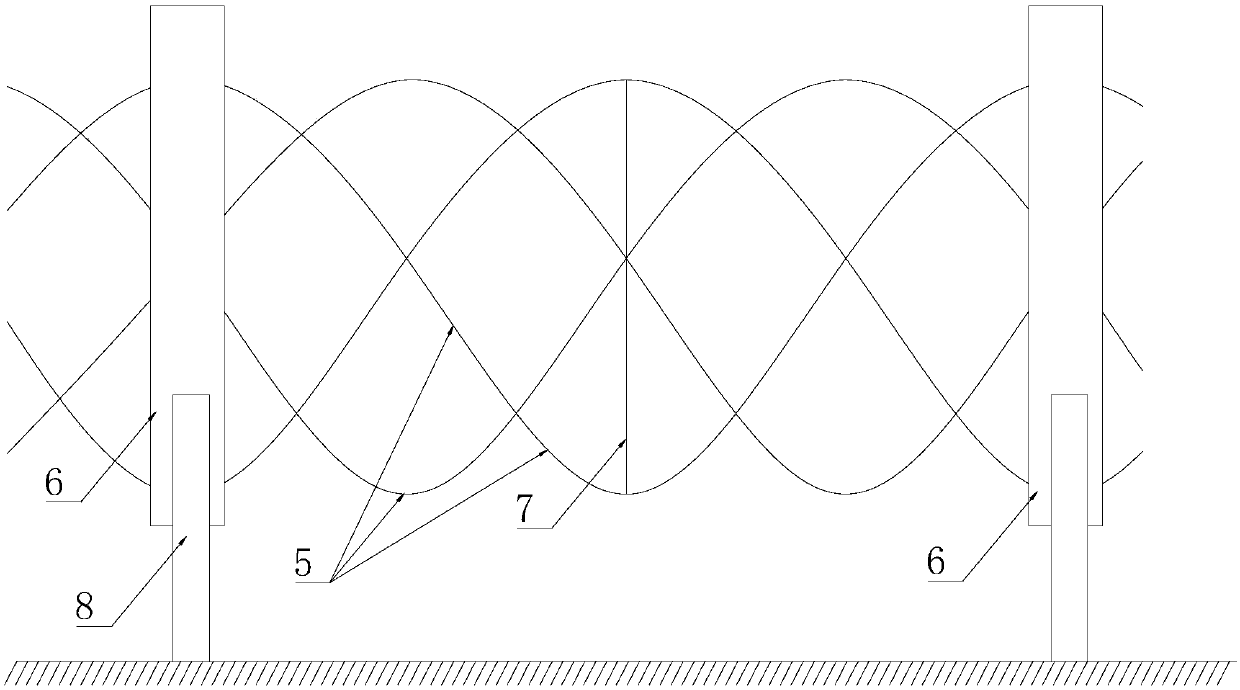

New-concept railway safety dead end

InactiveCN107187462APrevent derailment accidentsAdaptableRailway braking systemsPositive railway stopsDerailmentEngineering

The invention relates to a dead end track in a railway line, in particular to a dead end of a dead end track, and discloses a new-concept railway safety dead end which can prevent a vehicle from rushing out of a dead end track and avoid a derailing accident. According to the technical scheme and principle, a stop pile (1) is connected with a movable rail (3); when a vehicle (4) collides with the stop pile (1), the movable rail (3) can be driven to move together with the vehicle (4), a rail bridge (2) can bear loads between the movable rail (3) and a static rail (6), frictional resistance borne by the movable rail (3) when the movable rail (3) slides on sleepers (5) can make the vehicle (4) decelerate and stop quickly, and thus a derailing accident is avoided.

Owner:徐玉林

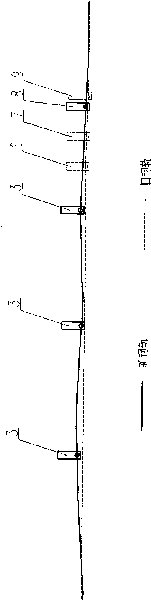

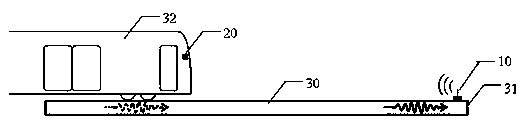

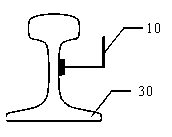

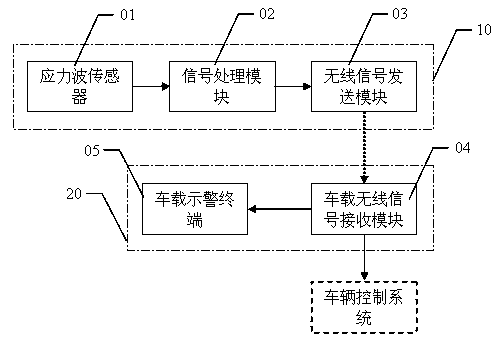

System and method for preventing vehicles from derailing at endpoints of rail transit line

ActiveCN104290774APrevent derailment accidentsGood anti-derailment effectRailway signalling and safetyDevice MonitorEngineering

The invention relates to the technical field of rail transit, in particular to a system and method for preventing vehicles from derailing at the endpoints of a rail transit line. The system and method aim to solve the technical problem that an existing method is poor in derailing preventing effect. The system comprises vehicle-mounted warning units installed in cabs of vehicles, and a plurality of stress wave sensing devices installed at the line endpoints on a rail respectively. A stress wave sensor, a signal processing module and a wireless signal transmitting module are arranged in each stress wave sensing device. Each vehicle-mounted warning unit comprises a vehicle-mounted warning terminal and a vehicle-mounted wireless signal receiving module. All the stress wave sensing devices monitor rail stress signals through the stress wave sensors, evaluate the risk grade of derailing of the vehicles according to the monitored signals, and then transmit corresponding wireless warning signals to the vehicle-mounted wireless signal receiving modules in the cabs of the vehicles through the wireless signal transmitting modules. According to the system and method, derailing of the vehicles can be prevented, and the implementation cost is low.

Owner:SHANGHAI SHENTONG RAIL TRANSIT RES & CONSULTANCY +2

An air-electric braking system for freight trains

InactiveCN107298111BImprove securityImprove adaptabilityRailway hydrostatic brakesRailway hydrodynamic brakesFreight trainsElectric control

The invention relates to a pneumatic-electric braking system for a goods train. An air brake system is additionally provided with a pneumatic power generating module and an electric control dynamic adjustment module, wherein the air brake system is suitable for conventional goods trains and is composed of a train pipe, a 120# distribution valve, a braking cylinder, an auxiliary air cylinder, an acceleration relief air cylinder and a mechanical empty and heavy vehicle adjusting assembly, and the mechanical empty and heavy vehicle adjusting assembly is composed of a mechanical proportional valve, a weight measuring mechanism and a pressure reduction air cylinder; the pneumatic power generating module is composed of an air storage cylinder assembly, a pneumatic power generator and a storage battery unit, and the storage battery unit comprises a storage battery and a management system; the electric control dynamic adjustment module is composed of a brake electronic control unit, a switching electromagnetic valve, a proportional electromagnetic valve, a relay valve and sensors; and the pneumatic power generating module is used for supplying power to the electric control dynamic adjustment module, and pneumatic-electric braking is finally achieved. Compared with the prior art, the pneumatic-electric braking system for the goods train can meet the requirement for precise control over braking under no-load or heavy-load conditions and has the advantages of skid resistance and high sensitivity.

Owner:TONGJI UNIV

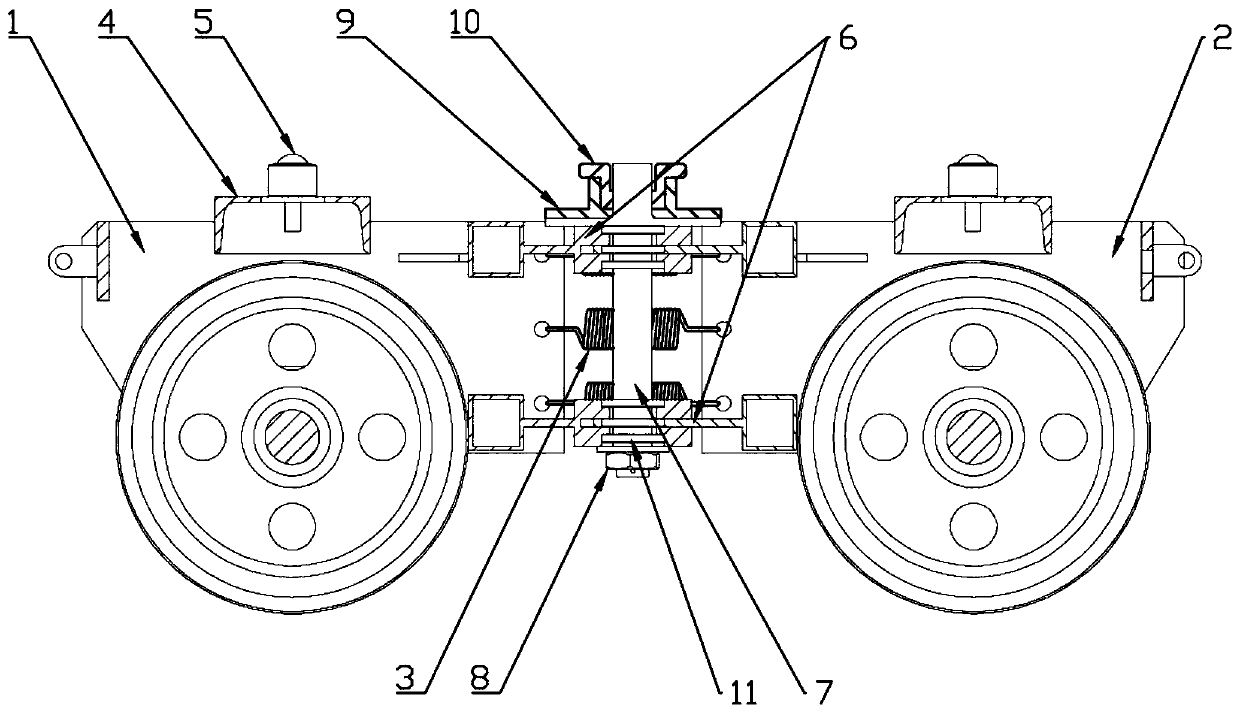

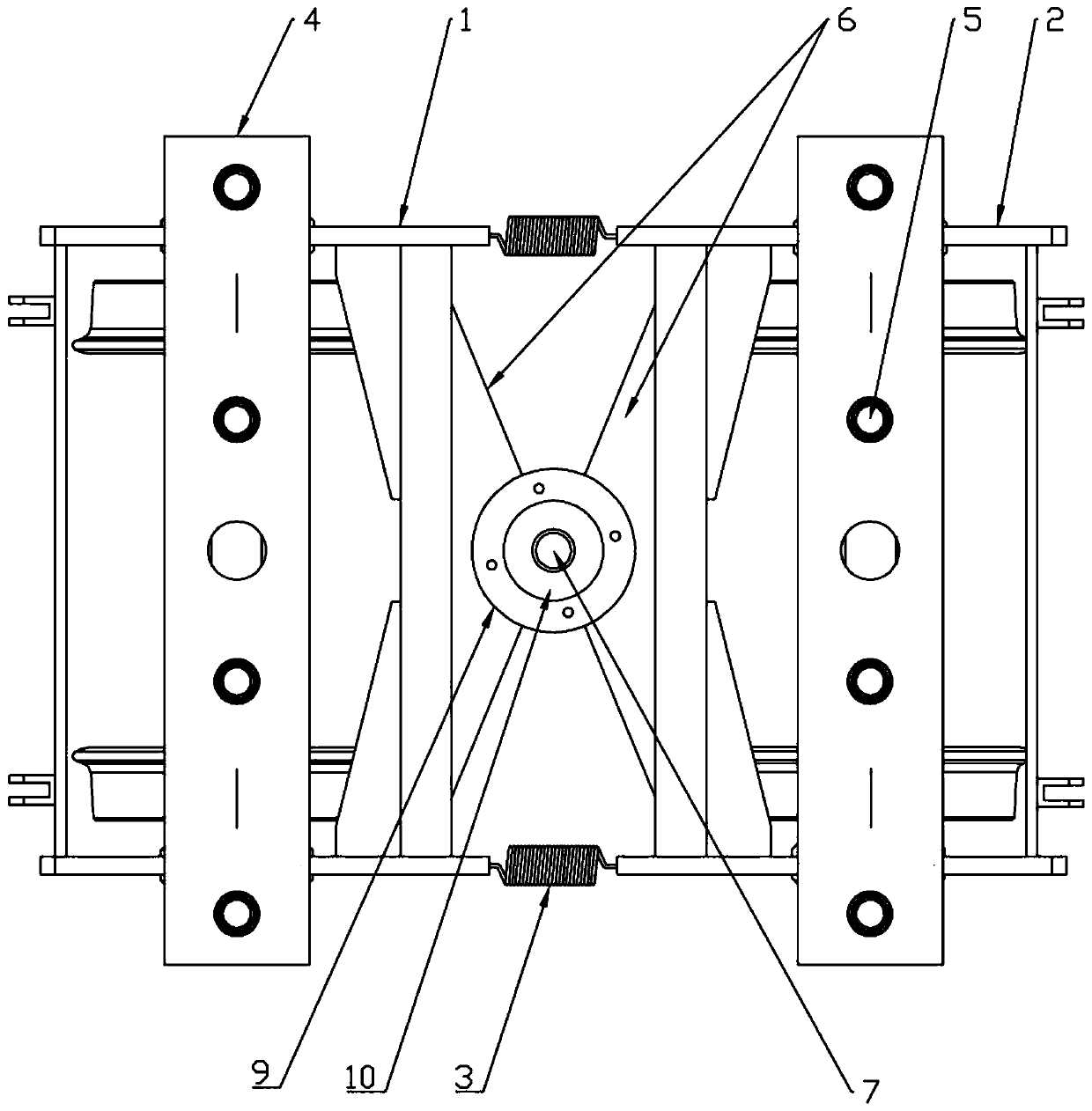

Articulated bogie

The invention discloses an articulated bogie. The vehicle comprises a front vehicle frame and a rear vehicle frame, a hinge mechanism is arranged between the front vehicle frame and the rear vehicle frame, the front vehicle frame and the rear vehicle frame are connected through the hinge mechanism, and the front vehicle frame and the rear vehicle frame can horizontally rotate with the hinge mechanism as a fulcrum; the top of the hinge mechanism is provided with an installation base used for being connected with a carriage. Elastic connecting parts are arranged between the two sides of the front frame and the two sides of the rear frame, and the two ends of each elastic connecting part are connected with the front frame and the rear frame respectively. According to the technical scheme, thesightseeing train is divided into the front frame and the rear frame, the front frame and the rear frame are connected through the hinge mechanism, the front frame and the rear frame horizontally rotate with the hinge mechanism as a fulcrum during turning, the included angle between the steel wheels on the front frame and the rear frame is changed, turning of the train is achieved advantageously,and derailment accidents of the sightseeing train are prevented.

Owner:重庆艾博瑞威轨道交通设备有限公司

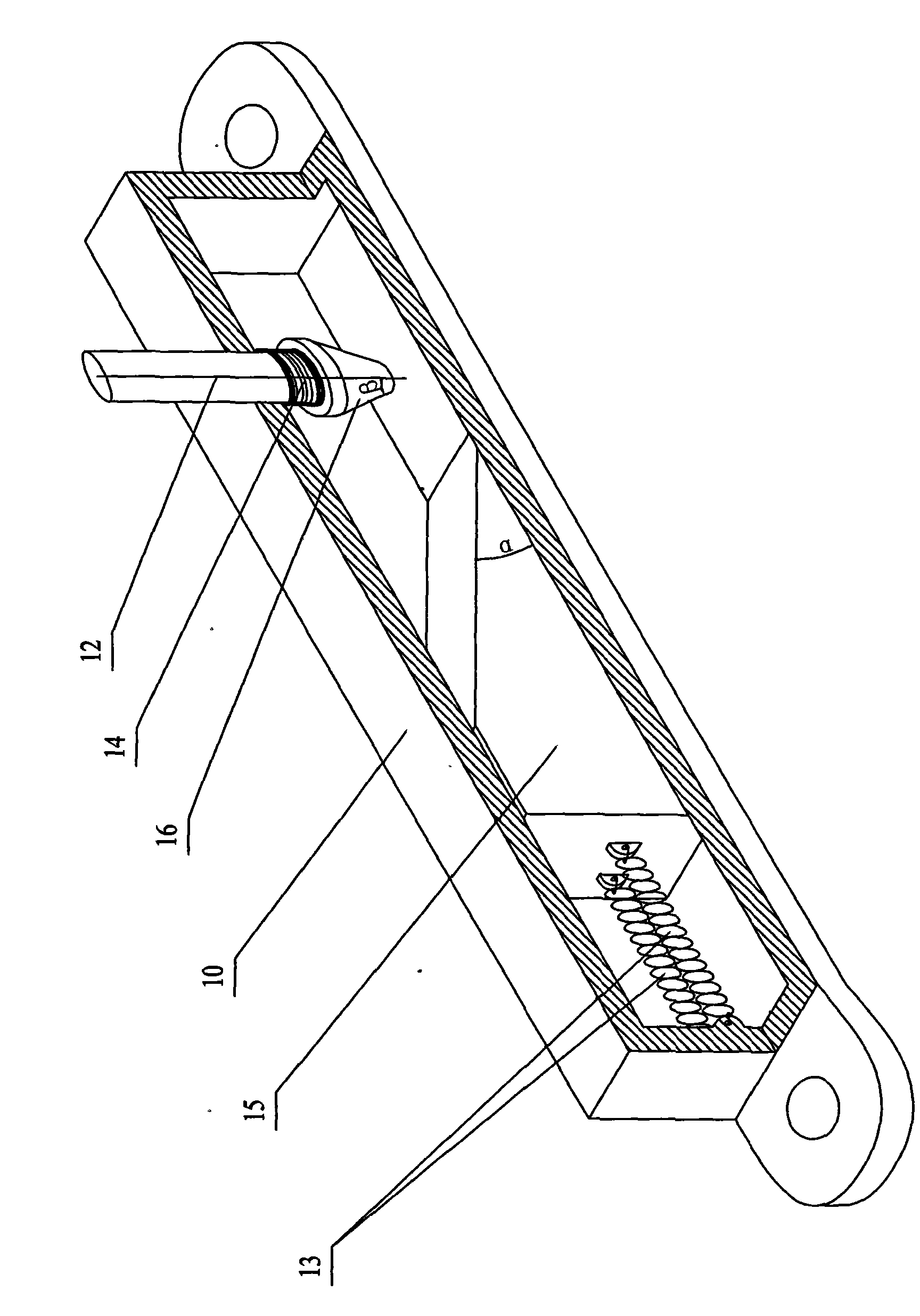

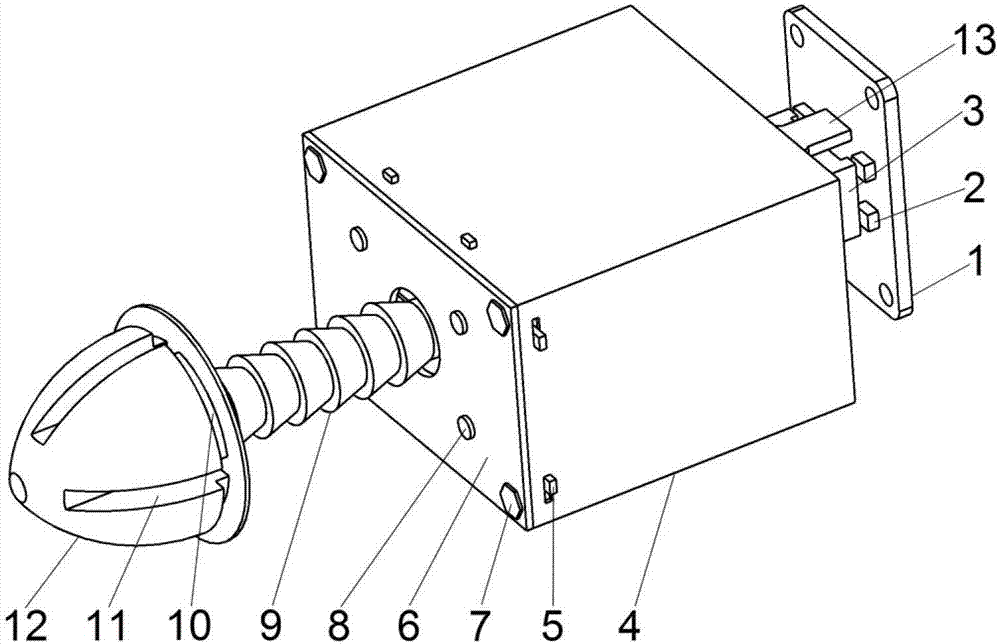

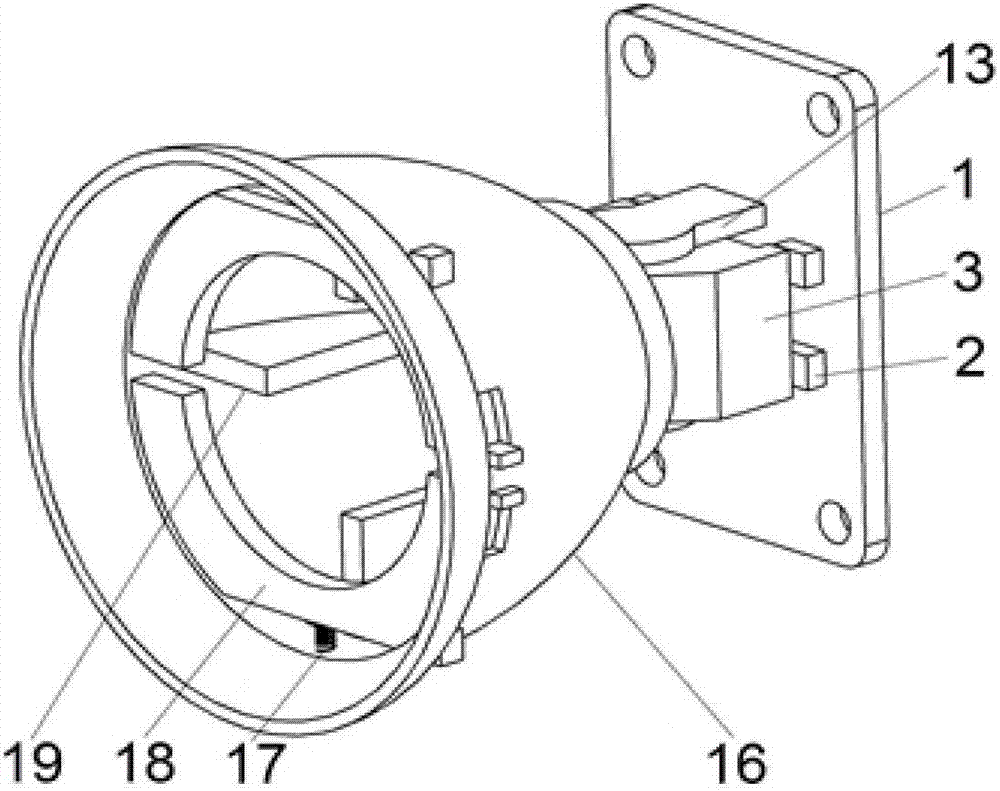

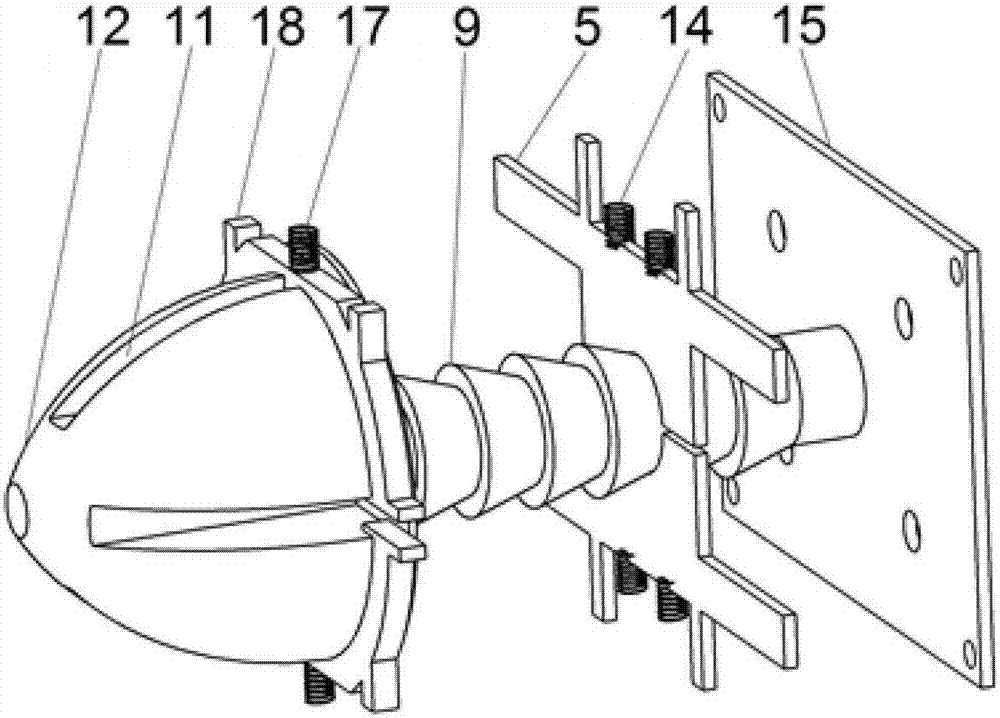

Deviation prevention energy absorption locking device

ActiveCN107176180APrevents lateral buckling behaviorPrevent derailment accidentsRailway wheel guards/bumpersEnergy absorptionSlide plate

The invention provides a deviation prevention energy absorption locking device and relates to the technical field of passive safety of rail vehicles. The top end of a rotator of a male locking structure is fixedly connected with the outer side of the bottom of a square box; energy absorption pipes are fixed to the inner side of the bottom of the square box; one ends of guiding rods are fixed to the inner side of the bottom of the square box; four through holes with the spaces being equal to those of the guiding rods are uniformly formed in a square plate connected with a cover plate through breaking bolts; the cover plate is fixedly connected with the opening end of the square box; the four protruding ends of a combined sliding plate in a shape like the Chinese character 'jing' are stored in sliding grooves of the side face of the square box and make contact with the inner wall of the square box through second reset springs; one end of a connecting rod is fixed to the square plate, and the other end of the connecting rod is fixedly connected with the flat end of a conical head; square groves and annular grooves are formed in the conical head; the top end of a rotator of a female locking structure is fixedly connected with the outer side of the bottom of a variable-diameter cylinder; a trapezoidal plate is fixed to the inner wall of the variable-diameter cylinder; and an arc-shaped sliding plate is stored in a sliding groove of the variable-diameter cylinder and connected with the inner wall of the variable-diameter cylinder through first reset springs.

Owner:SOUTHWEST JIAOTONG UNIV

Rail butt joint fixing device

The invention discloses a rail butt joint fixing device. A sleeper is arranged at a rail butt joint; positioning grooves are formed in the two sides of the rail on the sleeper. A rail fixing pressingplate screw hole is formed in one side of the positioning groove; a positioning block is arranged on one side of the track fixing pressing plate, the positioning block of the track fixing pressing plate is inserted into the positioning groove, the track fixing pressing plate is pressed on the base on the two sides of the joint of the track, the track fixing pressing plate is fixed through a trackfixing pressing plate bolt, and the track fixing pressing plate bolt is connected into a track fixing pressing plate screw hole of the sleeper. The rail butt joint has the following technical effectsthat fixation of the rail butt joint is strengthened, when a mine car or a shuttle car brakes at the rail butt joint, passing of the holding claws is not affected, rail deformation and dislocation arenot likely to happen at the rail butt joint, and derailment accidents are prevented.

Owner:XIANGTAN HENGXIN IND

Rail butt joint clamping base

The invention discloses a rail butt joint clamping base. The rail butt joint clamping base comprises a rail clamping base body, a pair of rail outer side pressing blocks and a pair of inner side railweb top blocks. A pair of outer side pressing block waist-shaped bolt holes is formed in the rail bottom side on the outer side of a rail on the rail clamping base body. Outer side pressing block boltholes are formed in the rail outer side pressing blocks respectively. An outer side pressing block fastener penetrates through one outer side pressing block bolt hole and the corresponding outer sidepressing block waist-shaped bolt hole to fasten the corresponding rail outer side pressing block. An ejector rod is arranged on each inner side rail web top block. The ejector rods of the pair of inner side top blocks are connected through a left and right threaded nut. The rail butt joint clamping base has the following technical effects that because fixation on a rail butt joint is strengthened, when a mine car or a shuttle car or other conveying equipment brakes on the rail, on one hand, passage of holding claws is not affected, and on the other hand, rail deformation or dislocation is notprone to happening to the rail butt joint, and then derailment accidents are avoided; and because the ejector rods are connected to the top blocks, and the ejector rods of the pair of rail inner sidetop blocks are connected through the left and right threaded nut, the rail outer side clamping base body is tightly clamped from the inner sides to prevent the rail outer side clamping base body fromgetting loose, and the strength of the rail webs can be improved.

Owner:XIANGTAN HENGXIN IND

Design method of a railway flexible guard rail device

ActiveCN109868692BPrevent derailmentAccurately calculate the size of the design valueRailsTrackwayStructural engineering

The invention discloses a design method of a railway flexible guardrail device. A guardrail is arranged on the outer side of a steel rail, the design method is initiated, equipment mounted on the inner side of the steel rail is avoided, the interval between the guardrail and the steel rail is X is the average value of the distance between the guardrail and the steel rail, and the average value iscalculated according to the wheel rail parameter rim width D, the steel rail head width L, and the wheel edge thickness d under the different rail areas and the different conditions; meanwhile, the mean square error of the principle of statistics is adopted for analyzing out deviation, a specific flexible guardrail device is used for laying a section, different guarantee coefficients N are selected for precisely calculating the design value of the V value, and derail of wheels of the D-series high-speed train can be effectively prevented.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

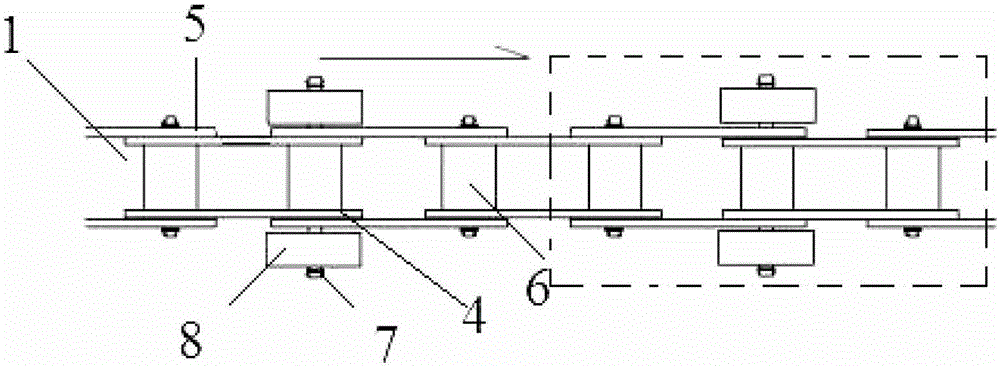

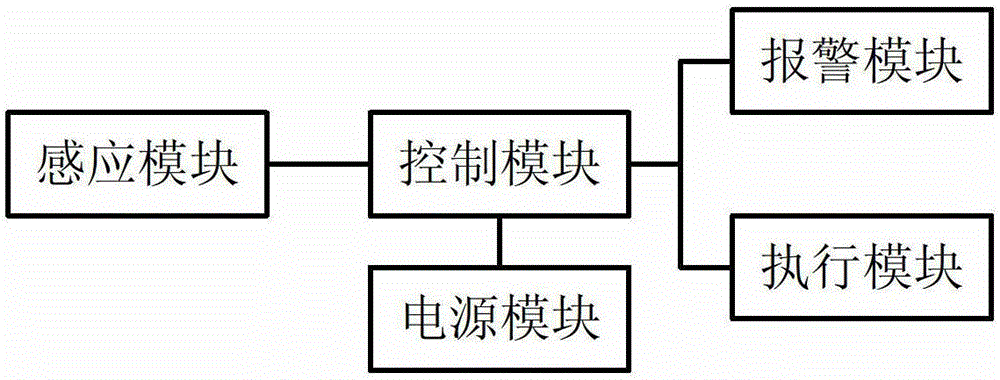

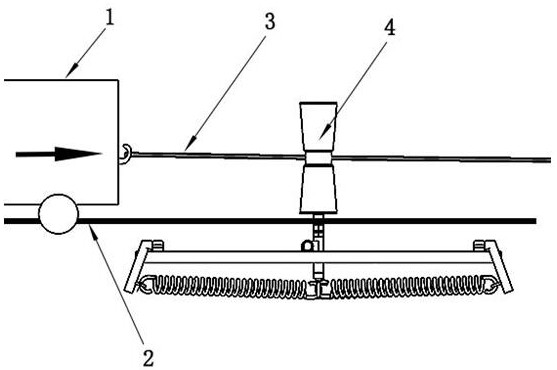

Conveyor chain drop detection device and method

ActiveCN103662730BPrevent derailment accidentsImprove production safetyControl devices for conveyorsDerailmentFall detection

The invention discloses a wheel-falling detection device and method for a conveying chain, and relates to the technical field of production line workpiece conveying. The device comprises a control module, an execution module and at least one induction module. The induction module is connected with the control module and used for sending an induction signal to the control module in real time when the conveying chain passes through the induction module. The control module is connected with the induction module and the execution module and sends a command signal to the execution module according to the induction signal sent by the induction module. The execution module is connected with the control module and stops operation of the conveying chain according to the command signal. According to the wheel-falling detection device and method, due to the induction module arranged nearby the conveying chain, the wheel-falling phenomenon can be timely and accurately found, the derailment accident is effectively prevented from happening, and production safety is improved.

Owner:BEIQI FOTON MOTOR CO LTD

A rail brake device

ActiveCN106585659BPrevent derailment accidentsSmooth rideTrack-braking member co-operationHydraulic cylinderAgricultural engineering

The invention relates to a baking device on tracks. The braking device comprises hydraulic pincers (4), brakes (5), and wheel bottom brakes (3), wherein the hydraulic pincers (4) are arranged at the tail end of a frame (1), are hydraulically driven, and are connected with the tail end of the frame (1) through a tripod; each of the brakes (5) is arranged at the top end of a corresponding wheel (11), is fixed on the corresponding wheel (11), and comprises a hydraulic cylinder (51); a push rod of each hydraulic cylinder (51) faces the corresponding wheel, and the front end of each of the push rods is connected with a first braking block (52); each of the wheel bottom brakes (3) comprises a connecting rod (31); each connecting rod (31) is hinged to a supporting seat (12) fixed on the frame, and a sliding groove (33) is formed in a position, at the upper end of the supporting seat (12), of each connecting rod (31), and is in sliding connection with a sliding block (32); each sliding block (32) is connected with a second connecting rod (22), and the other end of each second connecting rod (22) is fixedly connected with a spring (23); each spring (23) is fixedly connected with a third connecting rod (21); each third connecting rod (21) is hinged to the frame (1); and a second braking block (33) is fixed to the bottom end of each connecting rod (31).

Owner:XUZHOU LIEQI COMMERCE & TRADE CO LTD

Narrow-gauge electric motor car

ActiveCN102501858BLower center of gravityIncrease net heightElectric locomotivesRailway couplingsBogieCoupling

Owner:CHANGCHUN GUANGYIN GROUP

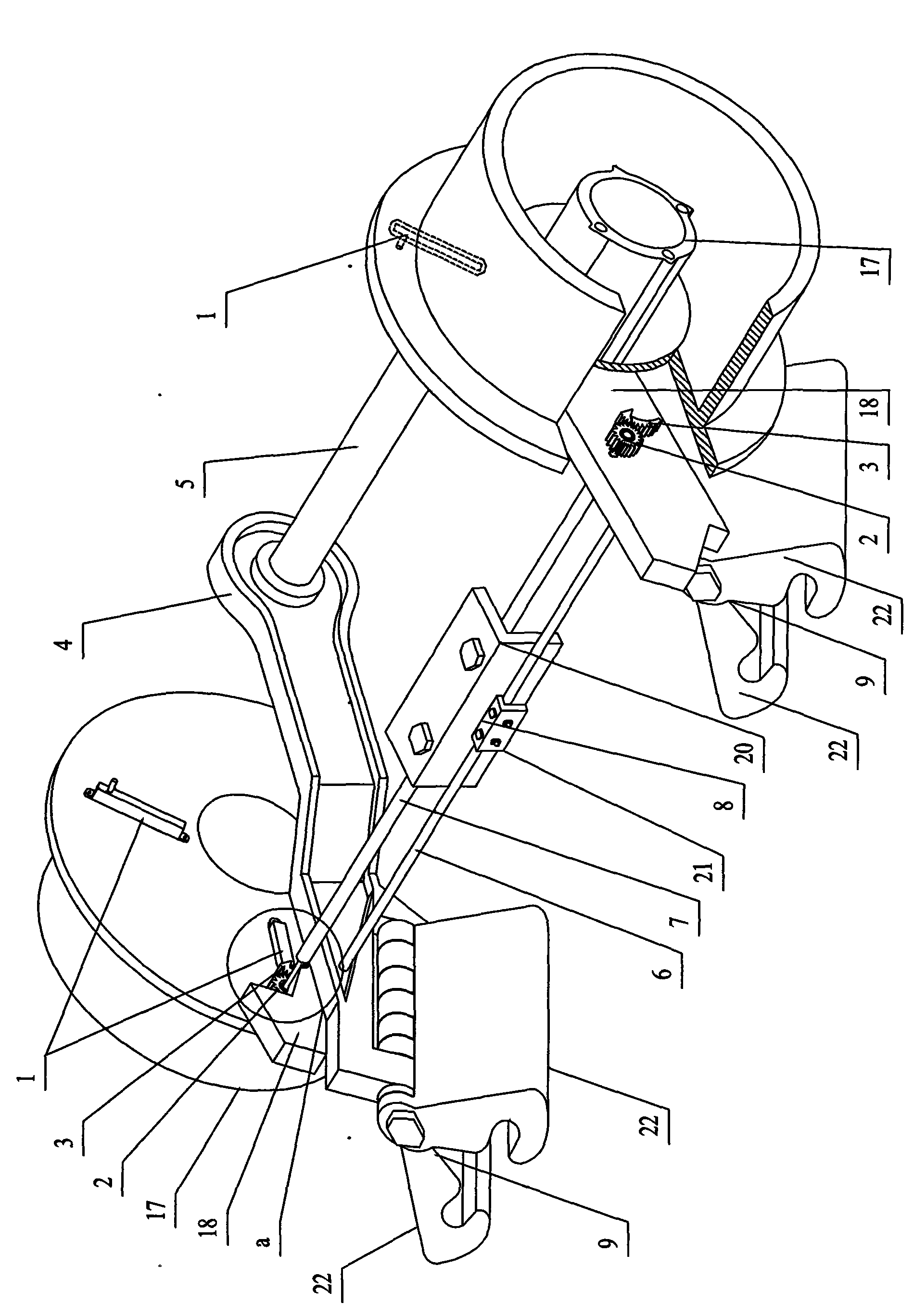

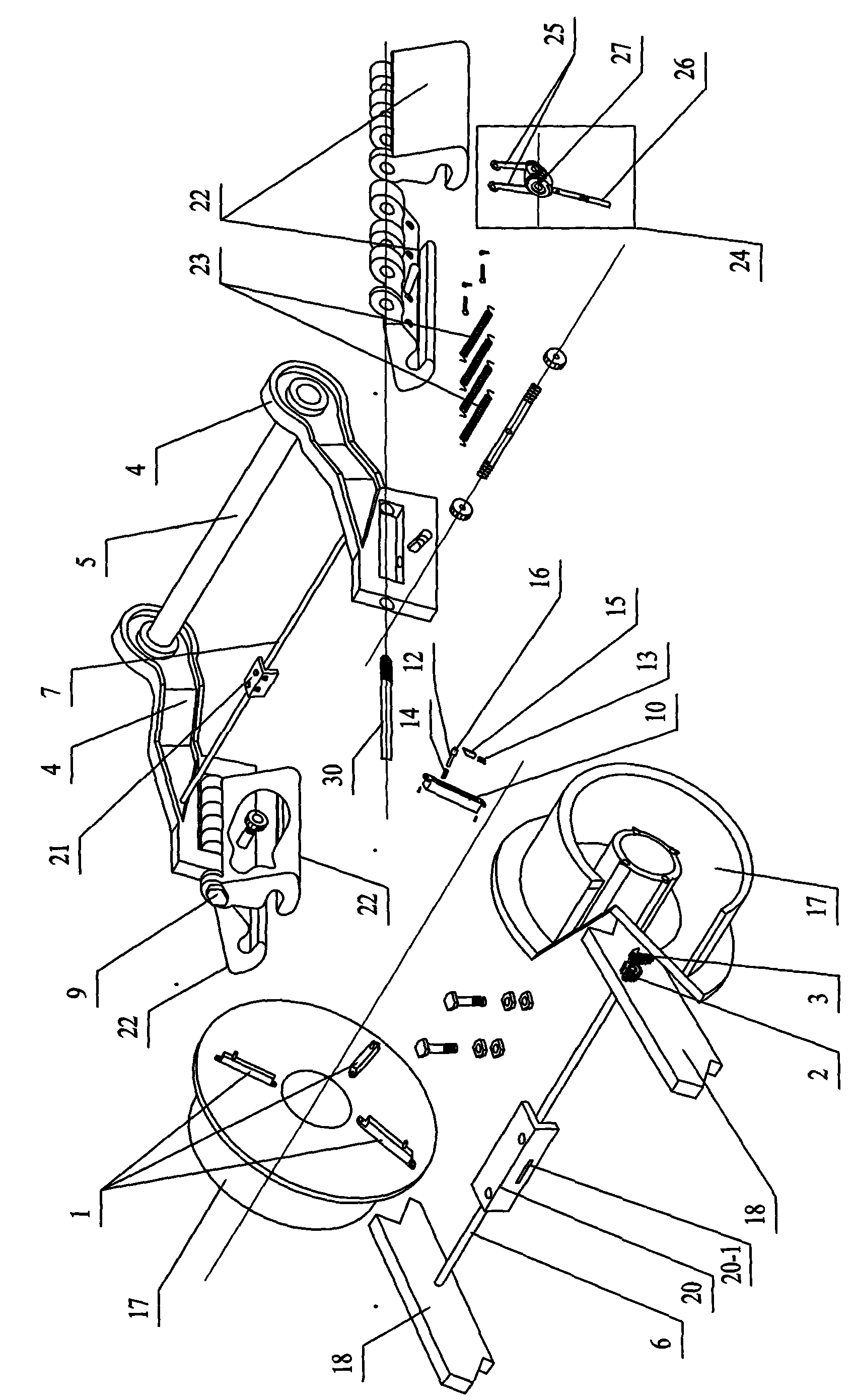

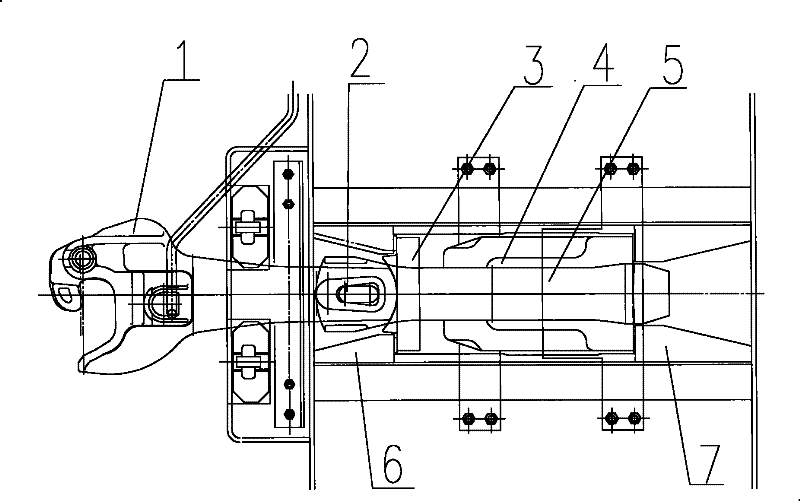

Coupler buffering mechanism

ActiveCN101475012BStrong automatic centering functionImproved Kinetic Stabilization EffectsDraw-gearRailway coupling accessoriesMechanical engineeringKnuckle

The invention discloses a coupler buffer device including a coupler, a coupler tail frame, a coupler tail pin and slave plates. A coupler head of the coupler comprises a coupler knuckle, a coupler knuckle pin, a coupler knuckle thrower, a coupler lock, a lower lockpin assembly, and a lower lockpin rotating shaft, wherein when the lower lockpin rotating shaft rotates, the lower lockpin assembly actuates to ensure that the coupler lock moves up and down along an inner cavity of the couplerhead of the coupler to drive the rotation of the coupler knuckle thrower to push the coupler knuckle to rotate around the coupler knuckle pin; the middle part of the end surface of a coupler tail of the coupler has a cylindrical surface, and convex shoulders are symmetrically arranged at both sides. A head part width size of the coupler tail frame is near the distance between opposite surfaces of blocks in a base of two front slave plates, so that the distance enables the gap between the coupler tail frame and the blocks in the base of the front slave plates to decrease. Under the drag and compression states, the blocks in the base of the front slave plates can limit the landscape swing of the coupler tail frame so as to lead the coupler buffer device to have guiding and position correction functions.

Owner:CRRC QIQIHAR ROLLING CO LTD

Continuous production system for molten injection refractories

ActiveCN106113225BShorten heating timeRealize continuous production operationAuxillary shaping apparatusHydraulic cylinderElectric arc furnace

The invention discloses a continuous production system for a cast refractory material. The continuous production system comprises an electric arc furnace, casting boxes, a rotating casting device, a rotating box feeding mechanism and a rotating box discharging mechanism. Each casting box comprises a box body with an opened top end, wherein the two opposite side walls of the box body are fixedly connected with box moving stress blocks correspondingly. The rotating casting device comprises a casting base, a casting supporting plate and a casting rotating bearing plate. The rotating box feeding mechanism and the rotating box discharging mechanism are of the same structure, and each of the rotating box feeding mechanism and the rotating box discharging mechanism comprises an outer frame, an upper positioning hydraulic cylinder arranged on the top of the outer frame downwards, a rotating box moving device arranged in the outer frame and located below the upper positioning hydraulic cylinder, and two guide rails arranged on the ground. According to the continuous production system, due to the cooperative work of the rotating casting device, the rotating box feeding mechanism and the rotating box discharging mechanism and the continuous and synchronous cooperative operation of the continuous box feeding substep, the rotating casting substep and the continuous box discharging substep, people do not need to wait for a crane or a forklift truck in the production process, continuous production work is achieved, and the production efficiency is greatly improved.

Owner:郑州东方安彩耐火材料有限公司

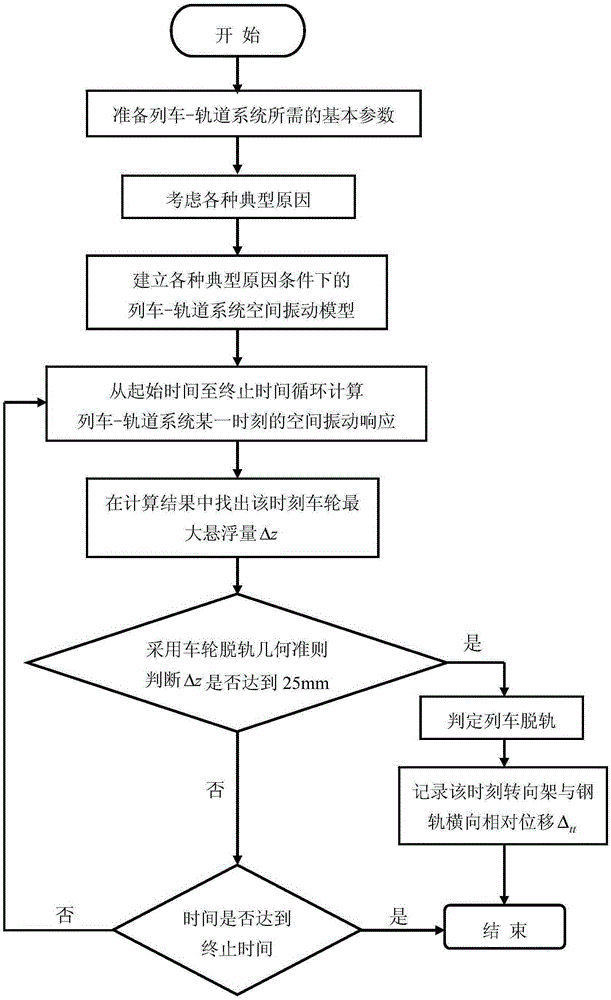

Real-time and reliable parking control method for freight train derailment

InactiveCN104228880BEnsure safetyGuaranteed uptimeRailway braking systemsRailway signalling and safetyRelative displacementFreight trains

The invention discloses a control method for real-time and reliable parking of a derailed freight train. According to the method, based on the train derailment energy stochastic analysis theory, various typical derailment conditions for explicit reasons are simulated, and calculation models on all kinds of typical reason conditions are established; calculation of the whole derailment process of the freight train on all kinds of explicit reason conditions is realized, the wheel-rail contact state, wheel-rail relative positions, dimensional relations and the like at the moment of derailment of the freight train on the explicit reason conditions are summarized comprehensively, and key data such as wheel suspension capacity and transverse relative displacement of steel rails are obtained; as a result, the minimum size and the installation position of a wheel derailment detection device of the freight train are determined, it is ensured that the device can overcome the influence caused by a narrow space of the bottom of the train and can also accurately make contact with the steel rails immediately when the train derails, a braking system of the train is controlled to work in real time, and timely parking is achieved. The method can provide an important theoretical basis and reasonable basic data for research and development of mechanical and electronic train wheel derailment detection devices.

Owner:CENT SOUTH UNIV

Track butt joint connector fixing clamp

PendingCN110872795APrevent looseningNot easy to deform and misplaceMovable tracksRailway fasteningButt jointTrackway

The invention discloses a track butt joint connector fixing clamp. The track butt joint connector fixing clamp comprises a fixing clamp, wherein the fixing clamp comprises a track inner side clamp, afixed pressing plate clamping groove is arranged at the bottom of the track inner side clamp outwards, a through groove matched with the track bottom on one side of the track is formed in the inner side of the track inner side clamp, the track bottom at one side of the track is sleeved in the through groove, the fixed pressing plate is embedded into a fixed pressing hook clamping groove from one end of the fixing clamp, and is fixed on the track bottom of the track from the outer side of the track. The track butt joint connector fixing clamp has the technical effects that the fixation at the position of the track butt joint connector is reinforced, when the transportation equipment such as a mine car or a shuttle car is braked at the track, firstly, the passing of a holding claw is not affected, secondly, the position of the track butt joint connector is not prone to deformation and dislocation, the derailing accident is prevented, an inclined wedge can prevent the track and the fixedpressing plate from loosening, and a track waist protection plate can increase the strength of a track waist.

Owner:XIANGTAN HENGXIN IND

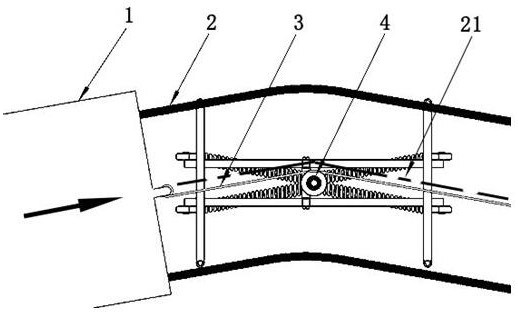

A traction steering method and steering equipment for mountain rail transport machinery

ActiveCN111115135BPrevent derailment accidentsEasy to buildMechanical conveyorsTraction cordEngineering

The invention relates to a traction and steering method and steering equipment for a mountain track transport machine, comprising: a track, a track transport machine, a traction rope and a guide sleeve vertically arranged at the bend of the track, and the traction rope changes direction after bypassing the guide sleeve , keeping the tow rope in the same direction as the track. The roller can swing along the direction of the track, and can be pushed down by the track transport machine without affecting the operation of the track transport machine. The traction steering method and the steering equipment of the present invention can build the track of the mountain rail transport machinery in the most convenient and quick way according to the terrain, greatly improving the work efficiency.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Gap adjusting device for main rail and guard rail

ActiveCN107805979AReduce gapPrevent derailment accidentsRailsTrack superstructureRail trafficMechanical engineering

The invention discloses a gap adjusting device for a main rail and a guard rail. The gap adjusting device comprises the main rail, the guard rail on the inner side of the main rail, and a gap adjusting plate with an L-shaped cross section; the gap adjusting plate can be in a closed or opened state through a transmission component, and when the gap adjusting plate is in the opened state, the gap adjusting plate is located on the inner side of the guard rail, and a rail traffic vehicle with the standard wheel pair inner side distance can normally pass through a railway switch; when the gap adjusting plate is in the closed state, the gap adjusting plate covers the top surface of the guard rail and the side surface, opposite to the main rail, of the guard rail, and the gap between the main rail and the guard rail is reduced so that a rail traffic vehicle with the large wheel pair inner side distance can safely pass through the railway switch. The gap adjusting device is low in cost and construction difficulty, the vehicle producing manufacturing enterprise and the maintenance enterprise can sufficiently use an existing rail device and do not need to redesign or transform the structureof the railway switch, the function is achieved that rail traffic vehicles with different wheel pair inner side distances share the railway switch, and the railway track construction and transformation cost of the enterprise is greatly lowered.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Power car for narrow gauge electric motor car

ActiveCN102501859BReduce volumeIncrease driving speedElectric locomotivesRailway transportBogieElectrical control

The invention relates to a power car for a narrow gauge electric motor car, which comprises a power car body, wherein, an electrical control system, a drive power supply and a braking device are arranged inside the car body; and two power steering frames are arranged at the bottom of the car body. The power car is characterized in that one of the power steering frames is arranged at the bottom of the car body under the drive power supply, and the other power steering frame is arranged between the bottom of the car body and the bottom of a carriage of an adjacent tow truck; the car body and the adjacent carriage are connected through an articulation device and a passing platform; the articulation device is arranged on a lower center plate of one of the power steering frames; the passing platform is arranged at the top of the articulation device; and the both sides between the car body and the adjacent carriage are connected with each other through a damper plate. The power car can be widely used in various occasions needing narrow gauge transportation, such as mine exploitation, tunnel excavation, light rails, subways, etc.

Owner:CHANGCHUN GUANGYIN GROUP

Method for preventing empty weight misloading of container

PendingCN114394531APrevent derailment accidentsReduce labor intensityWagons/vansLoad-engaging elementsStructural engineeringMachine

The invention discloses a method for preventing empty and heavy misloading of containers, which comprises the following steps of: calibrating the position of a vehicle array through a container loading and unloading machine, particularly the delivery position of each batch of vehicles and the loading position of the containers, and reading the weight of the loaded containers through the container loading and unloading machine; whether any two containers are loaded on the same vehicle or not is judged, and then weight information is compared; if the weight information comparison does not exceed the set value, the container loading and unloading machine does not give an alarm prompt, normal loading is not affected, and if the weight information comparison exceeds the set value, an alarm prompt is given, and the container cannot continue to fall or the lifting appliance cannot be unlocked and disengaged after falling. By means of the method, the accident that an empty container and a heavy container are loaded on the same vehicle, and consequently the train vehicle is loaded seriously and heavily can be prevented, possible driving accidents are avoided, safety is guaranteed, and meanwhile the labor intensity of operators is relieved.

Owner:单人煌

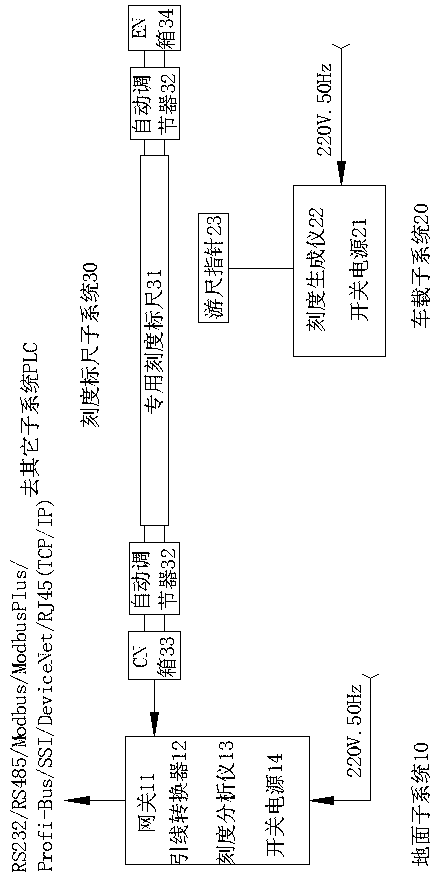

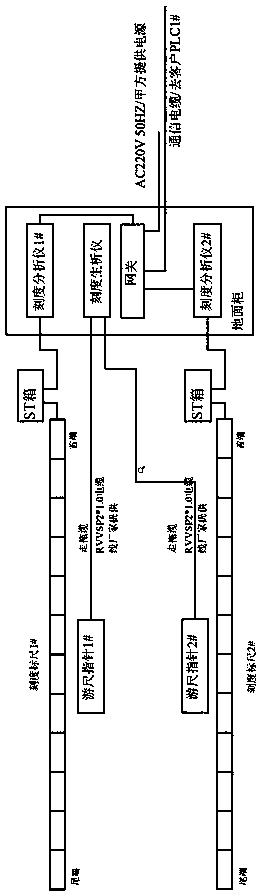

Displacement recognition system of belt conveyor telescopic head

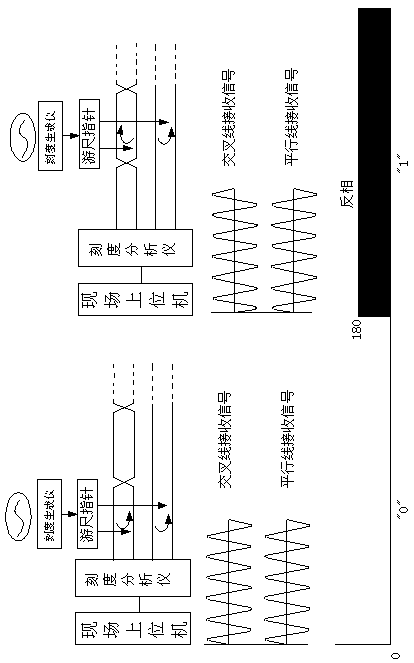

InactiveCN109051623APrecise workSimple processControl devices for conveyorsElectromagnetic couplingReciprocating motion

The invention relates to a displacement recognition system of a belt conveyor telescopic head. The displacement recognition system of the belt conveyor telescopic head comprises a ground subsystem, avehicle-mounted subsystem and a scale subsystem. The ground subsystem is provided with a scale analysis meter connected with a site upper machine and receives an electromagnetic signal of a scale in the scale subsystem; the vehicle-mounted subsystem is provided with a scale generating meter which is connected with a vernier pointer and gives the vernier pointer to generate the electromagnetic signal, the vernier pointer is arranged outside a vehicle body and in parallel to the scale in a non-contact installation mode, and a pointed position value at present is determined through the electromagnetic coupling mode with the scale; and the scale is installed on a single side edge of a moving track of a telescopic device of the belt conveyor head, or the scale is laid on the ground along the moving trajectory of the telescopic device of the belt conveyor head, or the scale is installed through a fence beside the track. The displacement recognition system of the belt conveyor telescopic headsends out instructs of moving, stopping and discharging to the vehicle-mounted subsystem according to the present position of the belt conveyor telescopic head, and coordinated transposition feedingto multipath transmission is achieved through the reciprocating movement of the belt conveyor telescopic head in the track direction.

Owner:河北华电曹妃甸储运有限公司

Continuous production system for cast refractory material

ActiveCN106113225AContinuous productionIncrease productivityAuxillary shaping apparatusContinuous productionForklift truck

The invention discloses a continuous production system for a cast refractory material. The continuous production system comprises an electric arc furnace, casting boxes, a rotating casting device, a rotating box feeding mechanism and a rotating box discharging mechanism. Each casting box comprises a box body with an opened top end, wherein the two opposite side walls of the box body are fixedly connected with box moving stress blocks correspondingly. The rotating casting device comprises a casting base, a casting supporting plate and a casting rotating bearing plate. The rotating box feeding mechanism and the rotating box discharging mechanism are of the same structure, and each of the rotating box feeding mechanism and the rotating box discharging mechanism comprises an outer frame, an upper positioning hydraulic cylinder arranged on the top of the outer frame downwards, a rotating box moving device arranged in the outer frame and located below the upper positioning hydraulic cylinder, and two guide rails arranged on the ground. According to the continuous production system, due to the cooperative work of the rotating casting device, the rotating box feeding mechanism and the rotating box discharging mechanism and the continuous and synchronous cooperative operation of the continuous box feeding substep, the rotating casting substep and the continuous box discharging substep, people do not need to wait for a crane or a forklift truck in the production process, continuous production work is achieved, and the production efficiency is greatly improved.

Owner:郑州东方安彩耐火材料有限公司

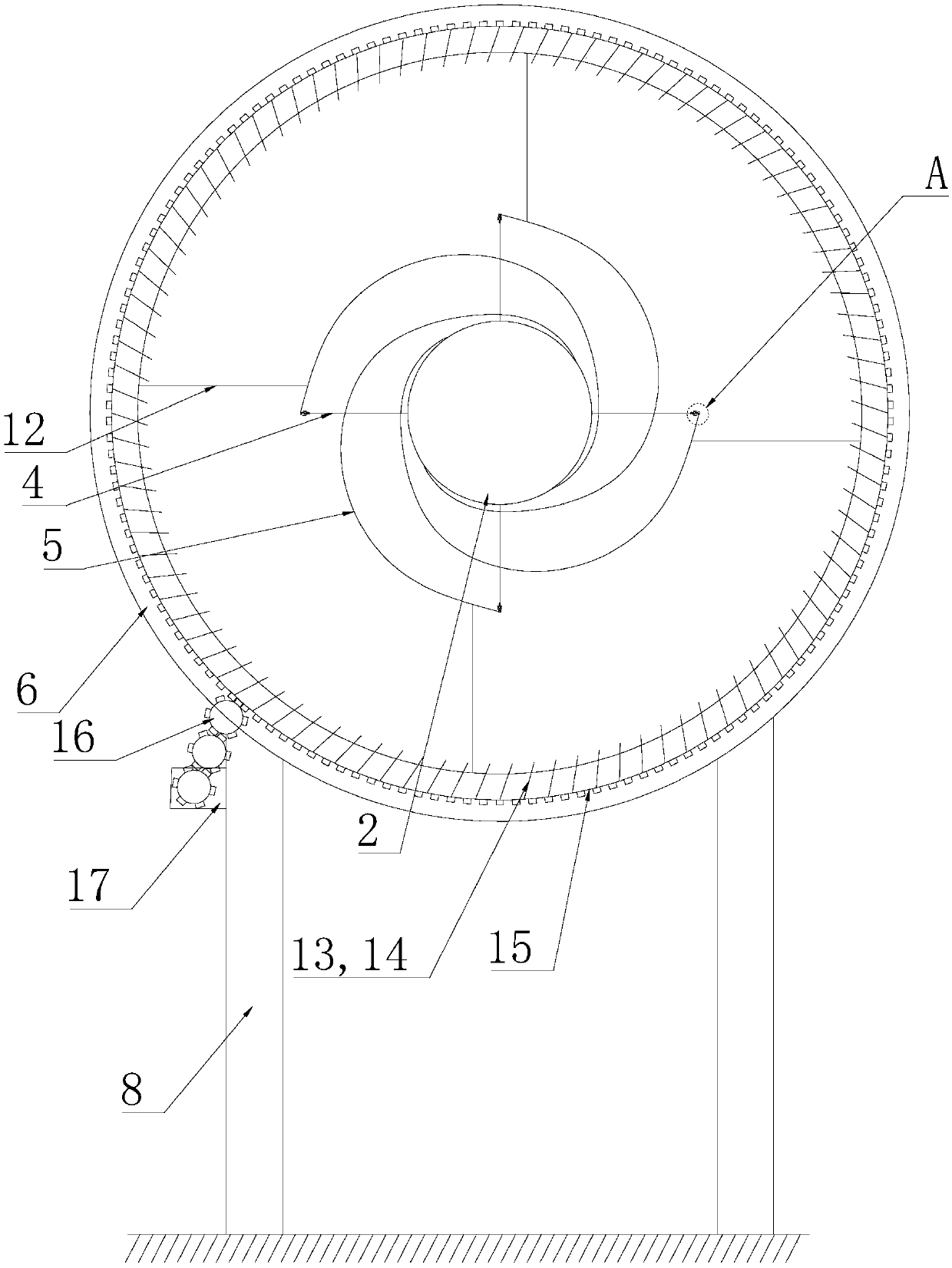

Vehicle structure

ActiveCN109532880AReduce air resistanceImprove balanceRailway tracksAxle-box lubricationMechanical engineeringSpiral line

The invention discloses a vehicle structure. The vehicle structure comprises a compartment, a rotating part and wheels, wherein the compartment allows passengers to take and / or loads goods; the rotating part can rotate around the movement direction of a vehicle and rotate relative to the compartment; the wheels are arranged at the periphery of the rotating part and correspondingly located in a guide rail to rotate around a spiral line of a cylinder for driving the vehicle to move forward. The vehicle structure has the advantages that the rotating part capable of rotating around the compartmentis arranged on the vehicle, so that the wheels at the periphery of the rotating part travel along a spiral line track, thereby driving the rotating part to rotate around the axis continuously to travel forward, and therefore the air resistance during running of the vehicle is reduced; the compartment is rotationally hinged relative to the rotating part, so that the compartment is kept in a parallel state relative to the ground, thereby ensuring the comfort of the passengers and the safety of the loaded goods.

Owner:CRRC QINGDAO SIFANG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com