Pneumatic-electric braking system for goods train

A technology for freight trains and braking systems, applied in the directions of brakes, pneumatic brakes, brake transmission devices, etc., can solve the problems that cannot be completely overcome, the development of brake control technology is limited, and there are no freight cars, and achieves simple structure and low maintenance costs. , the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

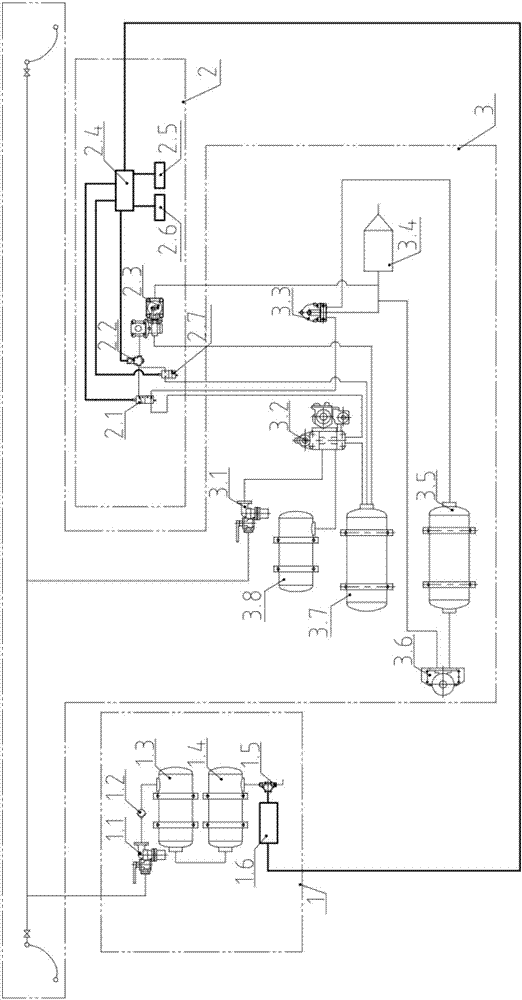

[0029] An air-electric brake system for freight trains, the structure of which is as follows figure 1As shown, it includes a first combined dust collector 3.1, a 120-type distribution valve 3.2, an auxiliary air cylinder 3.7, an acceleration relief air cylinder 3.8, a brake cylinder 3.4, a mechanical proportional valve 3.3, a weighing mechanism 3.6 and a pressure-reducing air cylinder 3.5 Connect the air brake system module 3, the air brake system also includes the electric brake adjustment module 2, and the pneumatic power generation module 1 that supplies power to the electric brake adjustment module 2, the electric brake adjustment module 2 includes Switching solenoid valve 2.1, proportional solenoid valve 2.2, relay valve 2.3 and brake electronic control unit 2.4, wherein, switching solenoid valve 2.1 is connected to the pipeline between 120 type distribution valve 3.2 and mechanical proportional valve 3.3, from switching solenoid valve 2.1 The electronic control brake air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com