Vehicle structure

A vehicle and vehicle movement technology, applied in the field of rail vehicles, can solve the problems of high operating costs of high-speed rail, and achieve the effects of improving vehicle balance, ensuring comfort, and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

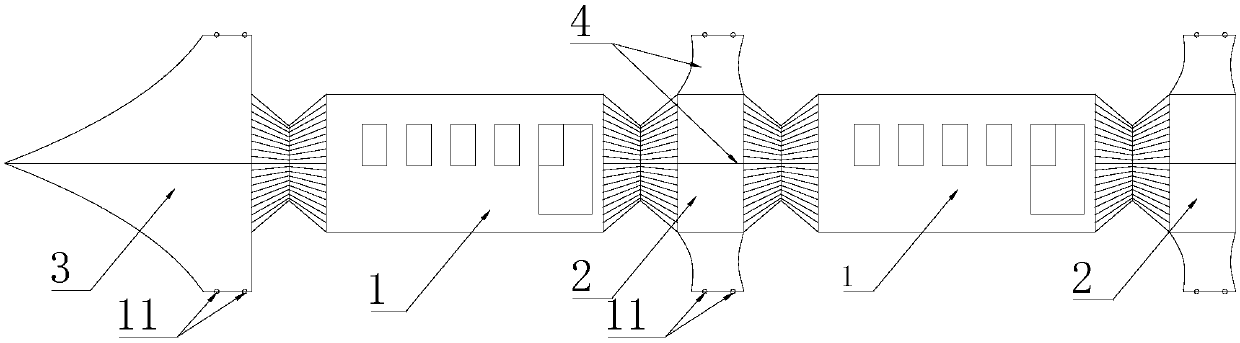

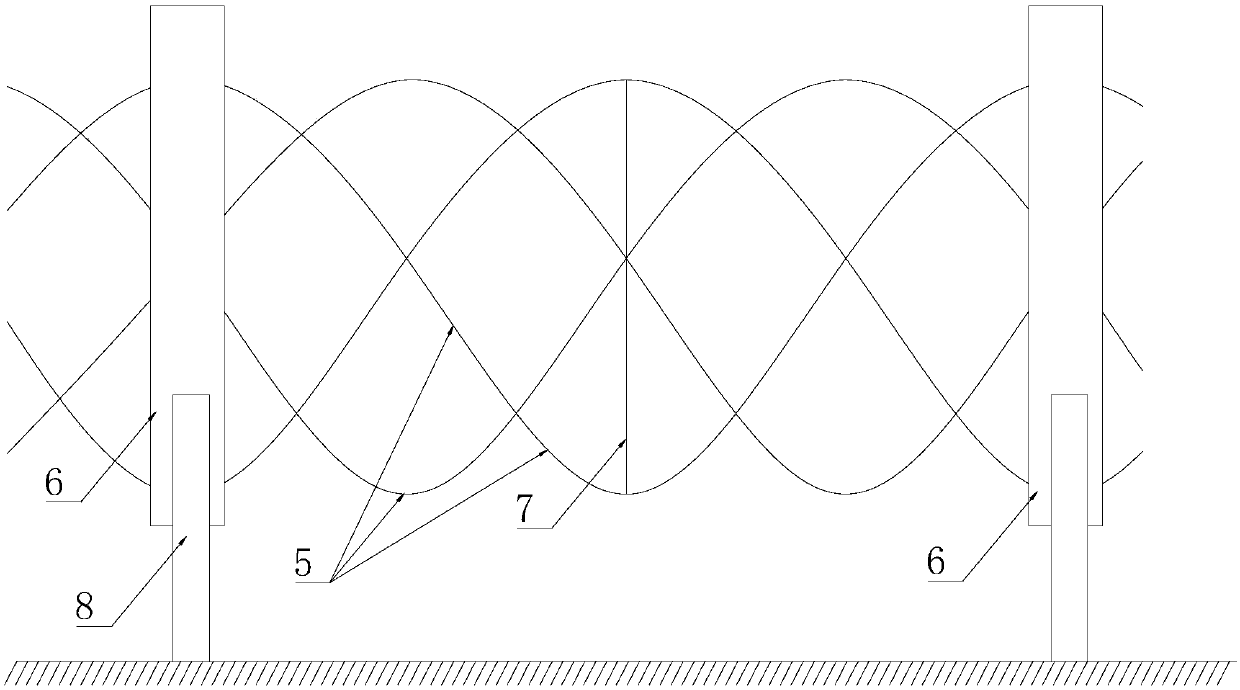

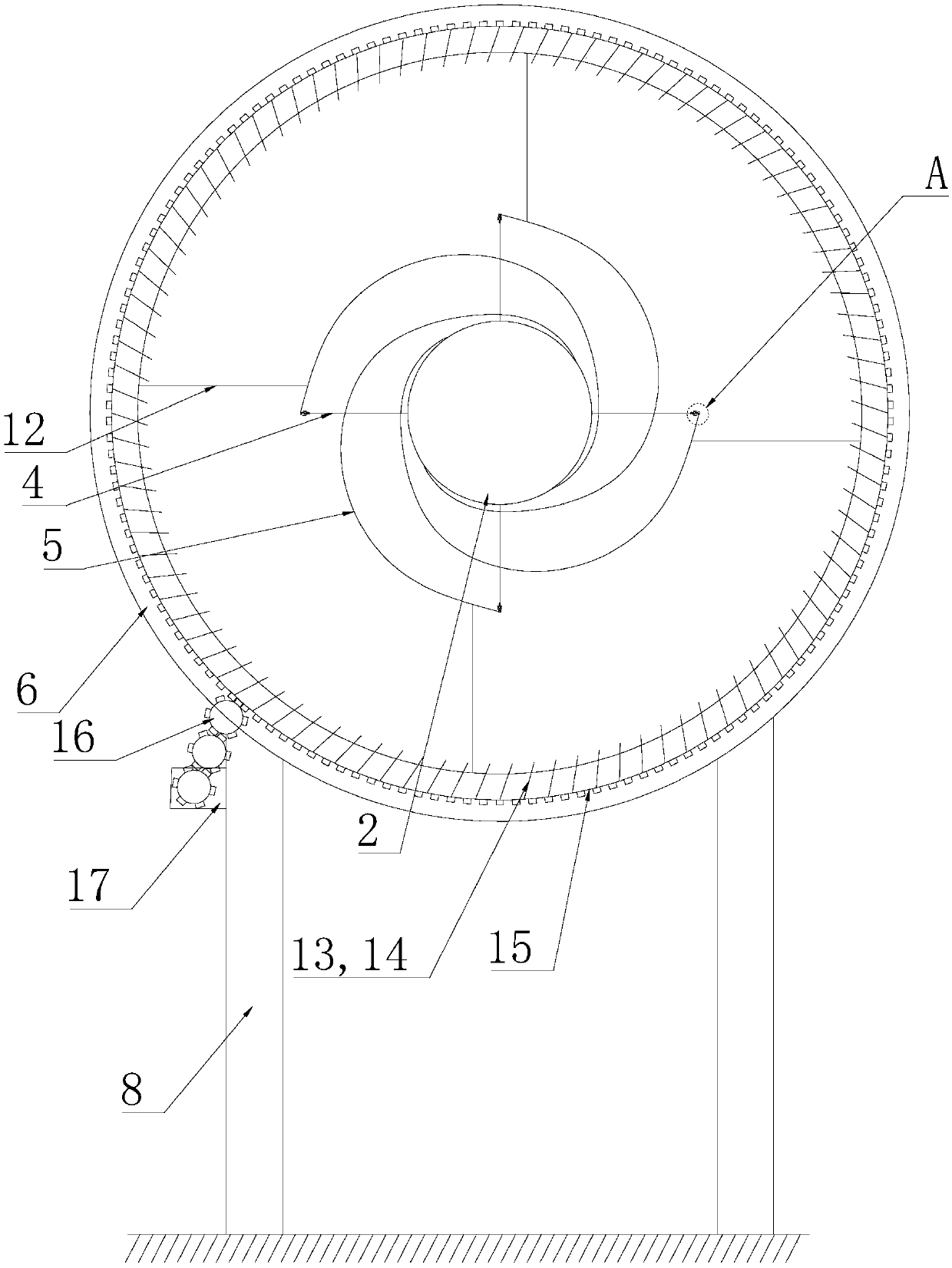

[0035] Such as Figure 1 to Figure 6 As shown, the present embodiment provides a vehicle structure, which includes: a compartment 1 for passengers to ride and / or load goods; a rotating part 2 that can rotate around the moving direction of the vehicle and relative to the compartment 1; The outer periphery of the part 2 is correspondingly located in the guide rail 5, so as to drive the vehicle to move forward by rotating along the cylindrical helical line.

[0036] By setting a rotating part on the vehicle that can rotate around the carriage, the wheels on the outer periphery of the rotating part travel along the helical track, and the rotating part is driven to move forward continuously around the axis, so as to reduce the air resistance during the operation of the vehicle. At the same time, the carriage is rotatably hinged relative to the rotating part, so that the carriage remains parallel to the ground, thereby ensuring the comfort of passengers and the safety of loaded good...

Embodiment 2

[0043] This embodiment introduces a vehicle structure based on the first embodiment above, and also has the following characteristics: the vehicle structure also includes a headstock 3 located at the front end of the vehicle moving direction, the headstock 3 is in the shape of a cone whose center line extends along the vehicle moving direction, and the cone The large end of the headstock 3 is connected with the corresponding end of the rear side compartment 1, and the tapered front end 3 is hinged with the compartment 1 that can rotate around the vehicle moving direction.

[0044] In this embodiment, the conical headstock 3 includes a plurality of sheet-like structures protruding radially from the center, and the extended side of the sheet-like structures is an inclined plane parallel to the moving direction of the vehicle, so that the sheet-like structures are connected to the compartment 1. The length of one side is greater than that of the opposite side; each sheet-like stru...

Embodiment 3

[0047] This embodiment introduces a vehicle structure based on the above embodiments, and also has the following features:

[0048] In this embodiment, the carriage 1 is always in a balanced state under the action of its own gravity and / or the balance device, so that the carriage does not rotate around the axis with the rotating part, but always maintains a relatively fixed position relative to the moving direction of the carriage.

[0049] In this embodiment, the self-weight of the carriage 1 is more than ten times that of the rotating part 2 .

[0050] In this embodiment, the balancing device includes a counterweight arranged at the bottom of the compartment 1, so that the center of gravity of the compartment 1 is at the bottom of the compartment;

[0051] In this embodiment, the balance device includes a first electromagnet arranged on one side of the outer circumference of the carriage 1, and a limit rail fixedly installed on the ground. The limit rail extends along the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com