Patents

Literature

543results about "Positive railway stops" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

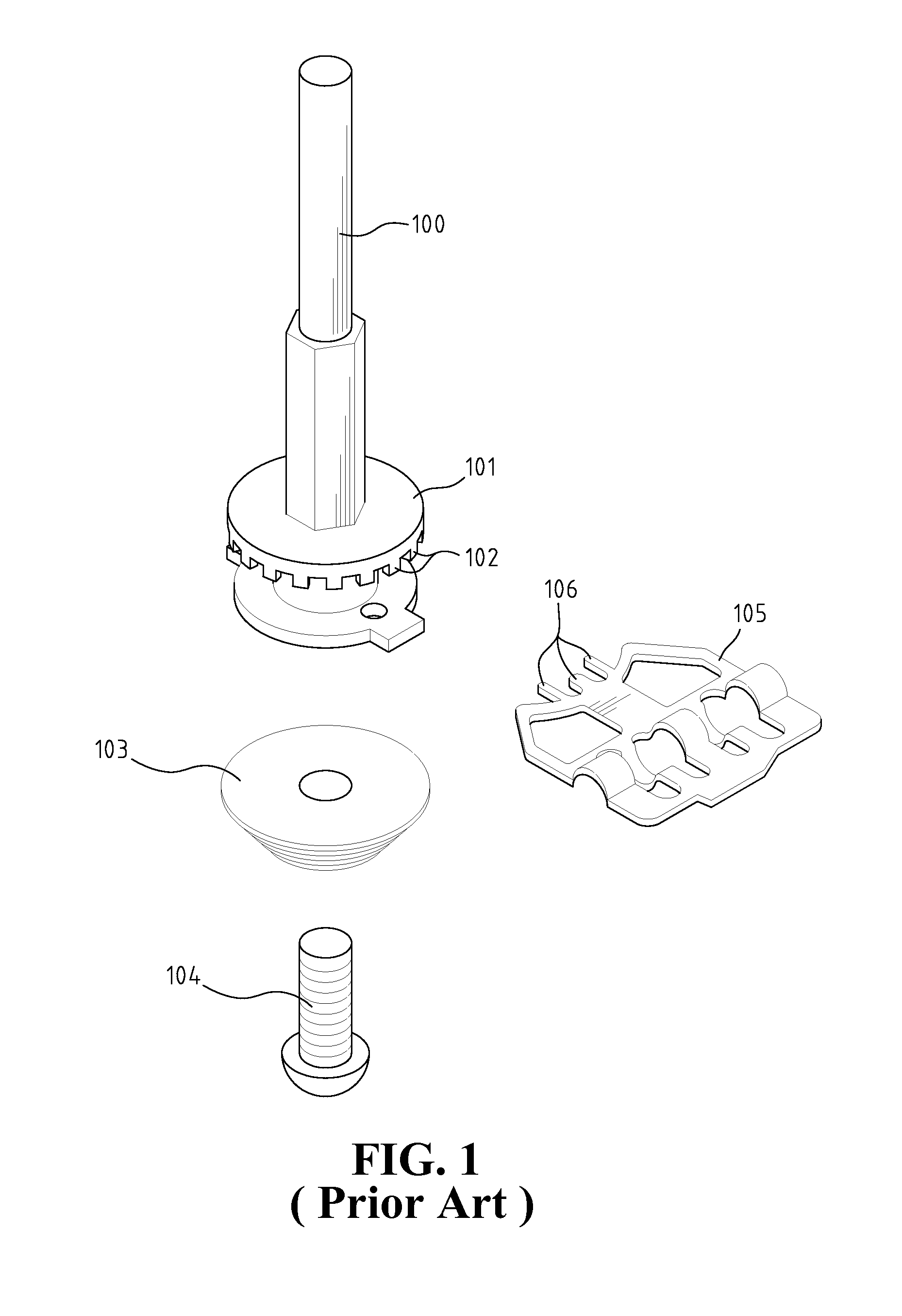

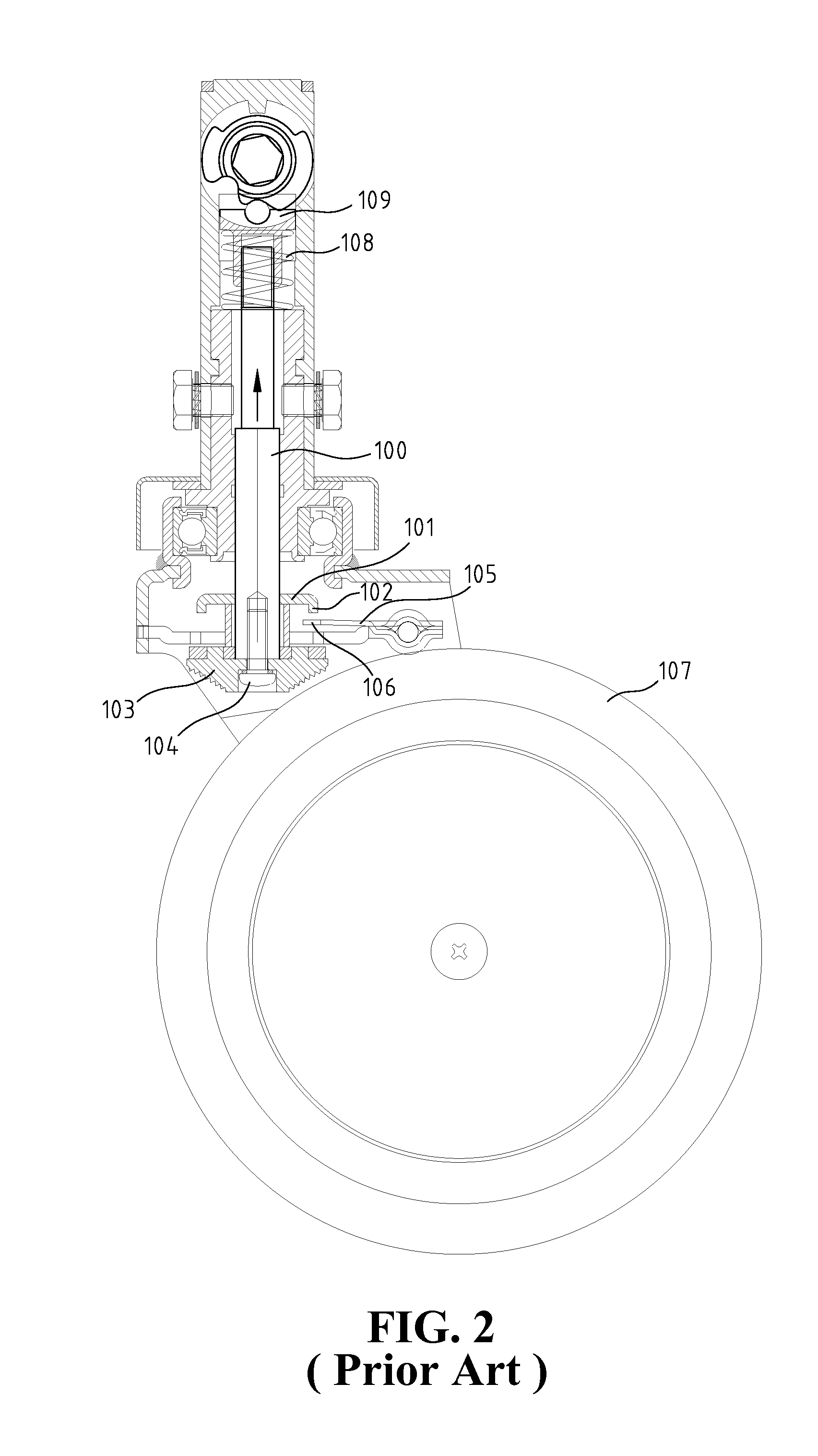

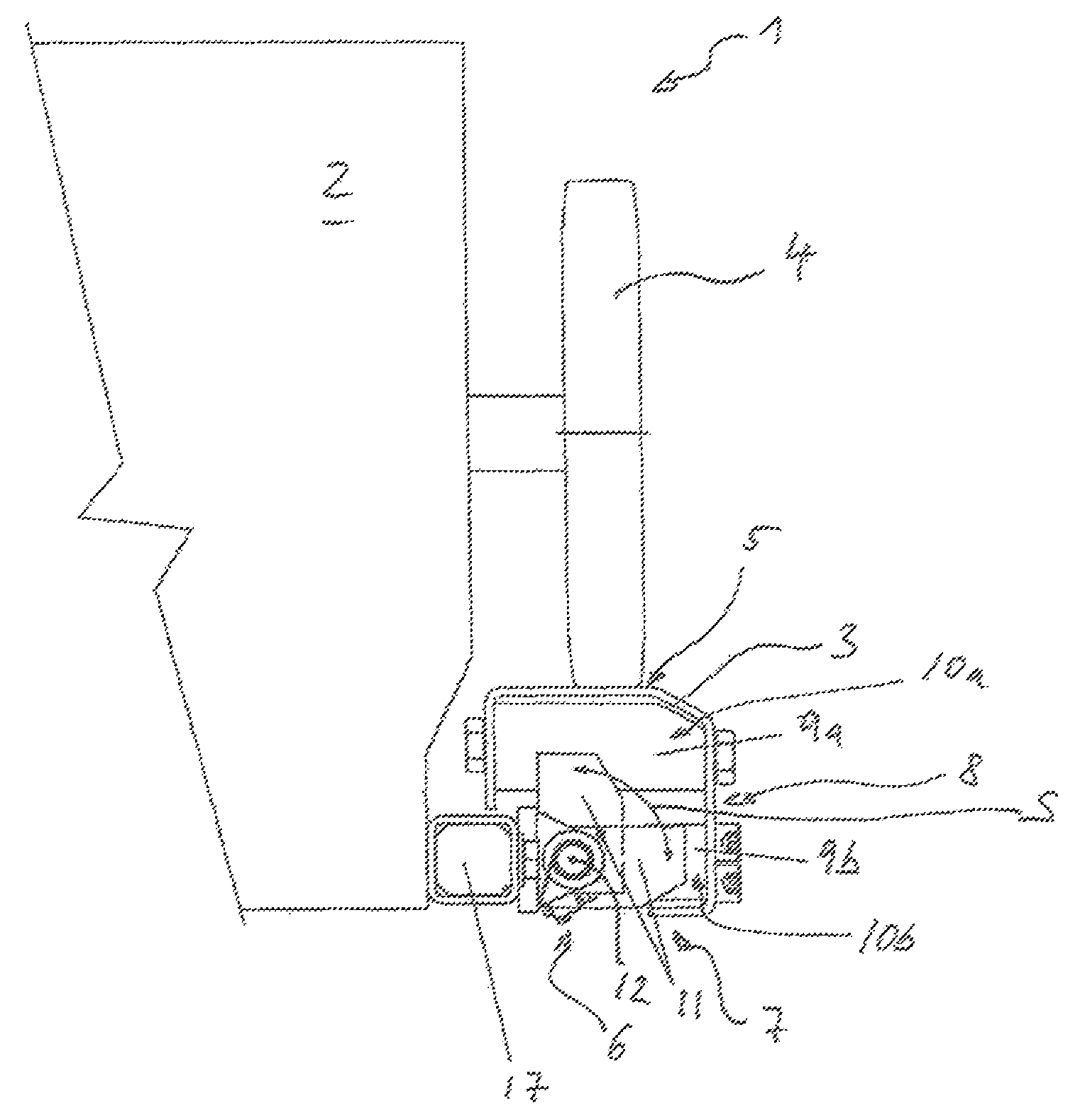

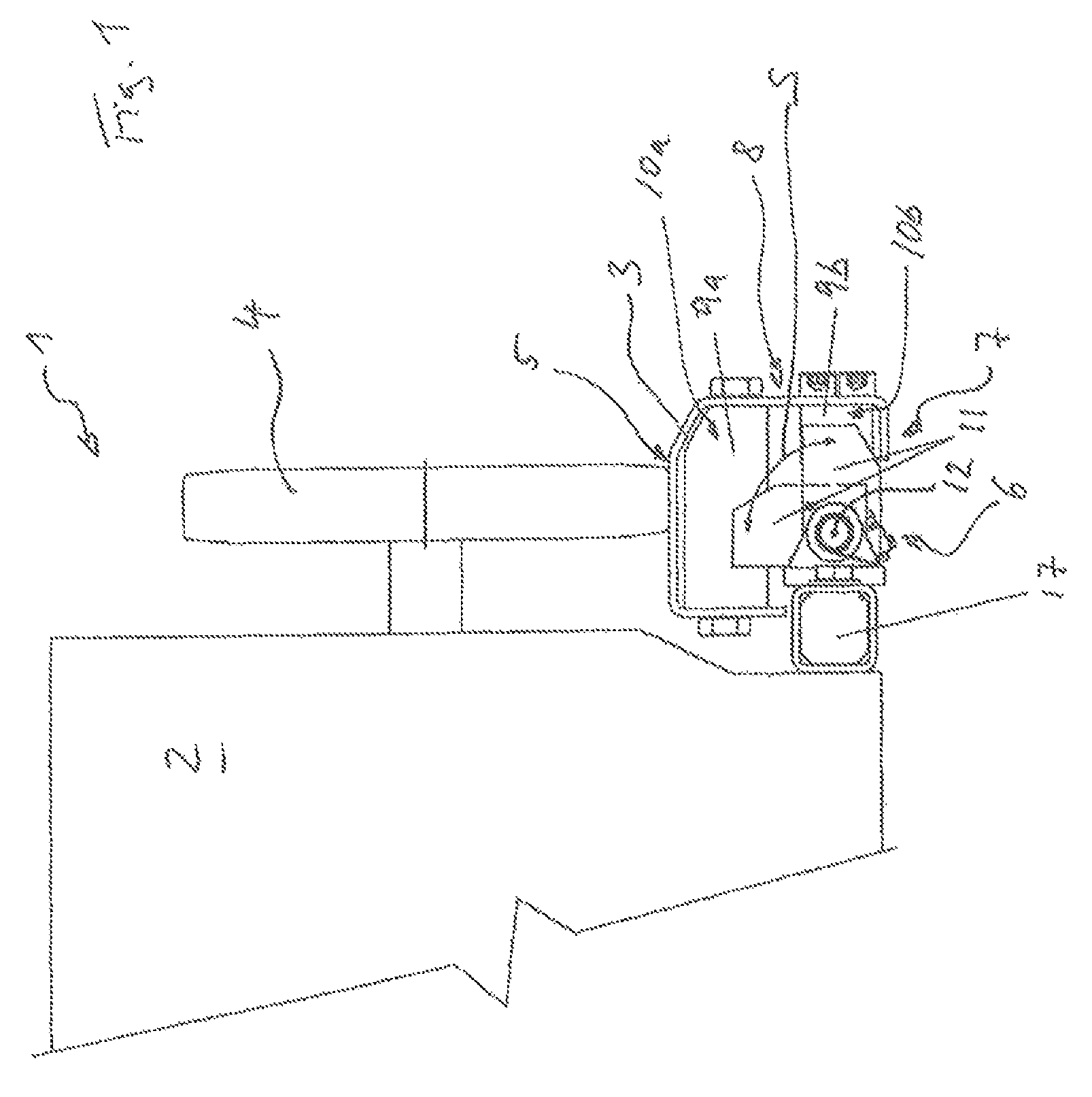

Cart braking device

InactiveUS7810613B2Reduce harmStop rotatingBraking element arrangementsCastorsEngineeringMechanical engineering

A cart braking device includes a swivel unit, a shaft unit and a braking unit which has a central shaft, an orientation member, a braking member and a base. The central shaft is coupled with the orientation member and has an elastic piece for moving the central shaft upward. A bottom of the orientation member has an orientation gear and a top of the braking member has a fixation gear corresponding to the orientation gear. The braking member is disposed in the base and includes two braking pads. An elastic member is disposed between the base and the braking member, and can move the braking member away from the base. When the braking pads are pressed against the wheel, the cart braking device stops the rotation of the wheel. When the orientation gear is engaged with the fixation gear, the cart braking device prevents the wheel from changing direction.

Owner:LIN CHING SUNG

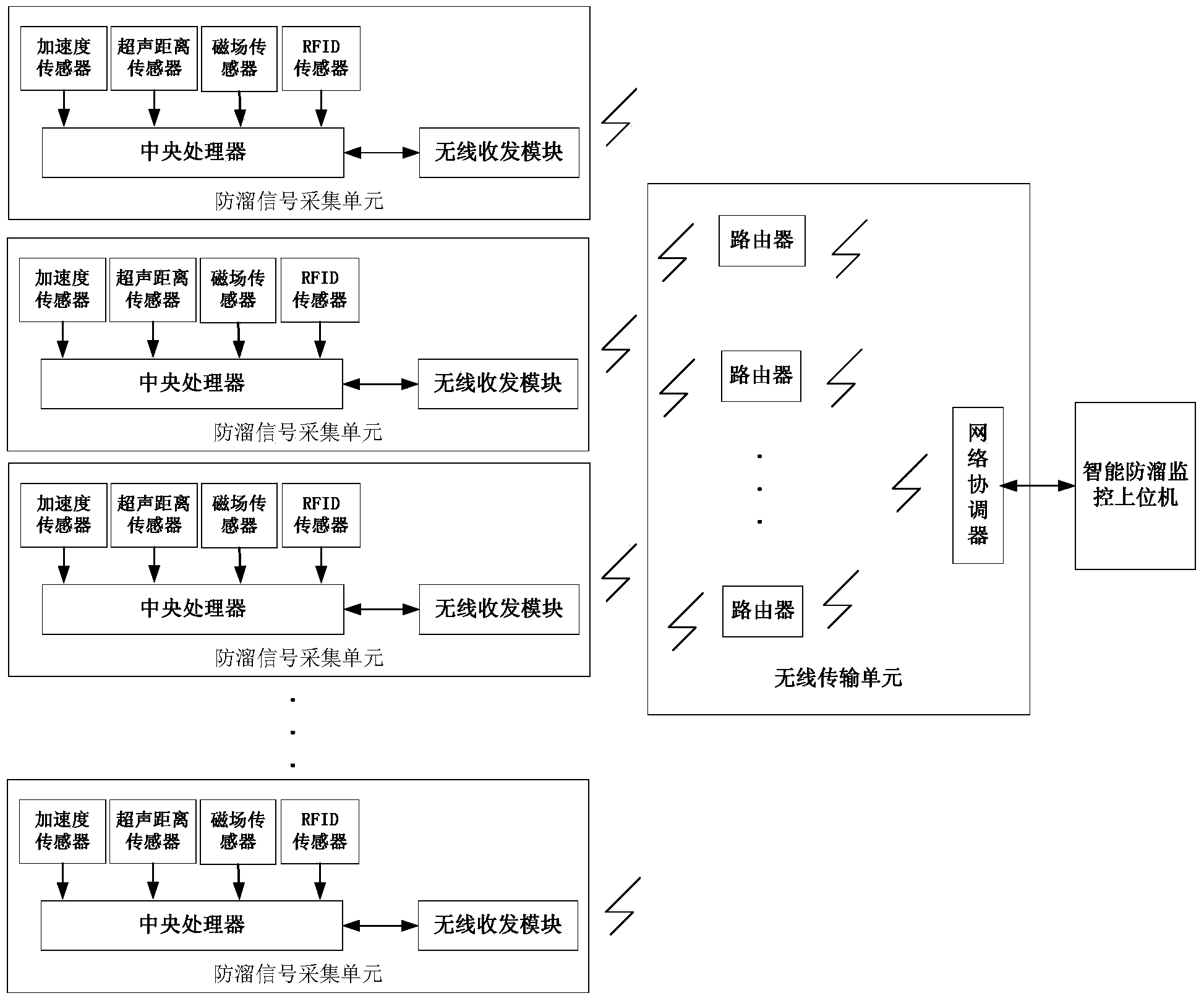

Intelligent anti-sliding system and method for stopping of railway vehicles

ActiveCN104240477AImprove reliabilityEasy to operateTransmission systemsAlarmsWireless transceiverWireless transmission

The invention discloses an intelligent anti-sliding system and method for stopping of railway vehicles. The system comprises multiple groups of anti-siding signal acquisition units, a wireless transmission unit and an intelligent anti-sliding monitoring upper computer, wherein the wireless transmission unit consists of a plurality of routers and a network coordinator; each anti-siding signal acquisition unit comprises an acceleration sensor, an ultrasonic range sensor, a magnetic field sensor, a temperature sensor, an RFID (radio frequency identification) sensor, a central processing unit and a wireless transceiver, the sensors are used for acquiring corresponding parameter information of stopping of the vehicles, signal output ends of the sensors are connected with corresponding signal input ends of the central processing units, the central processing units are connected with the routers through the wireless transceivers, all the routers are in wireless connection with the network coordinator, and the network coordinator is connected with the intelligent anti-sliding monitoring upper computer. The system is a monitoring system which is efficient, easy to operate and high in reliability, real-time monitoring and management on anti-sliding devices can be realized, and the system has very important significance and practical values in guaranteeing the safe running of railways.

Owner:南京富岛信息工程有限公司

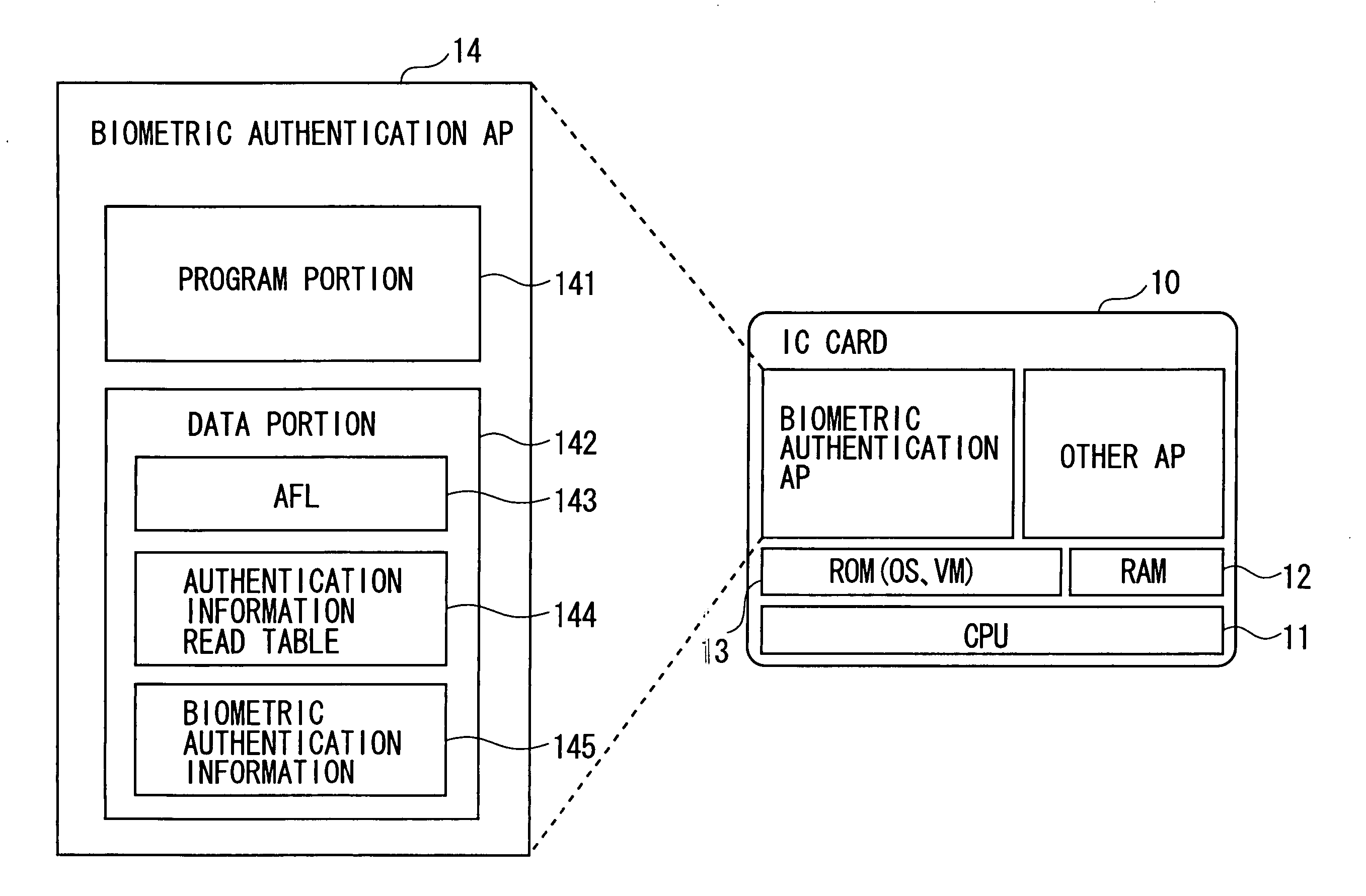

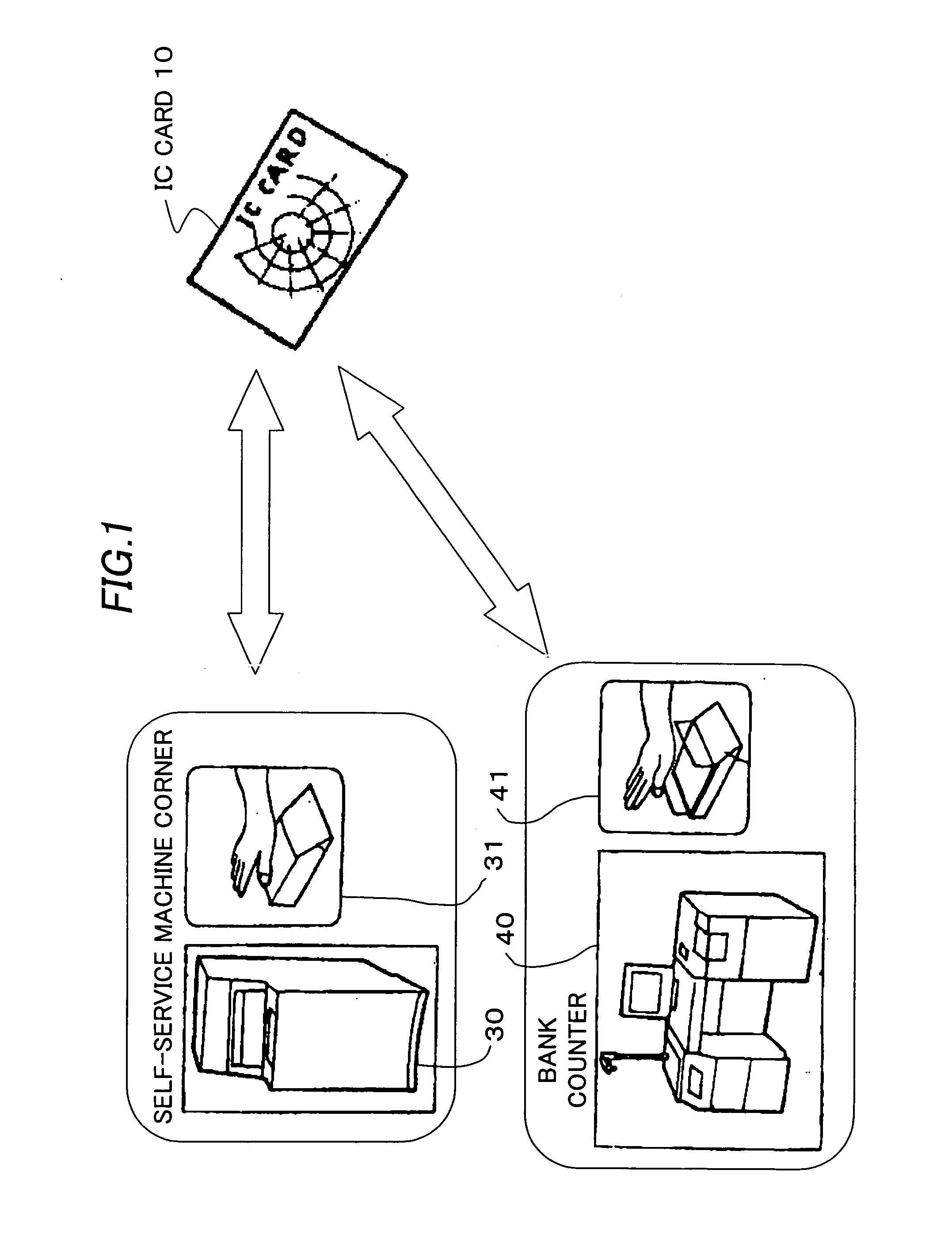

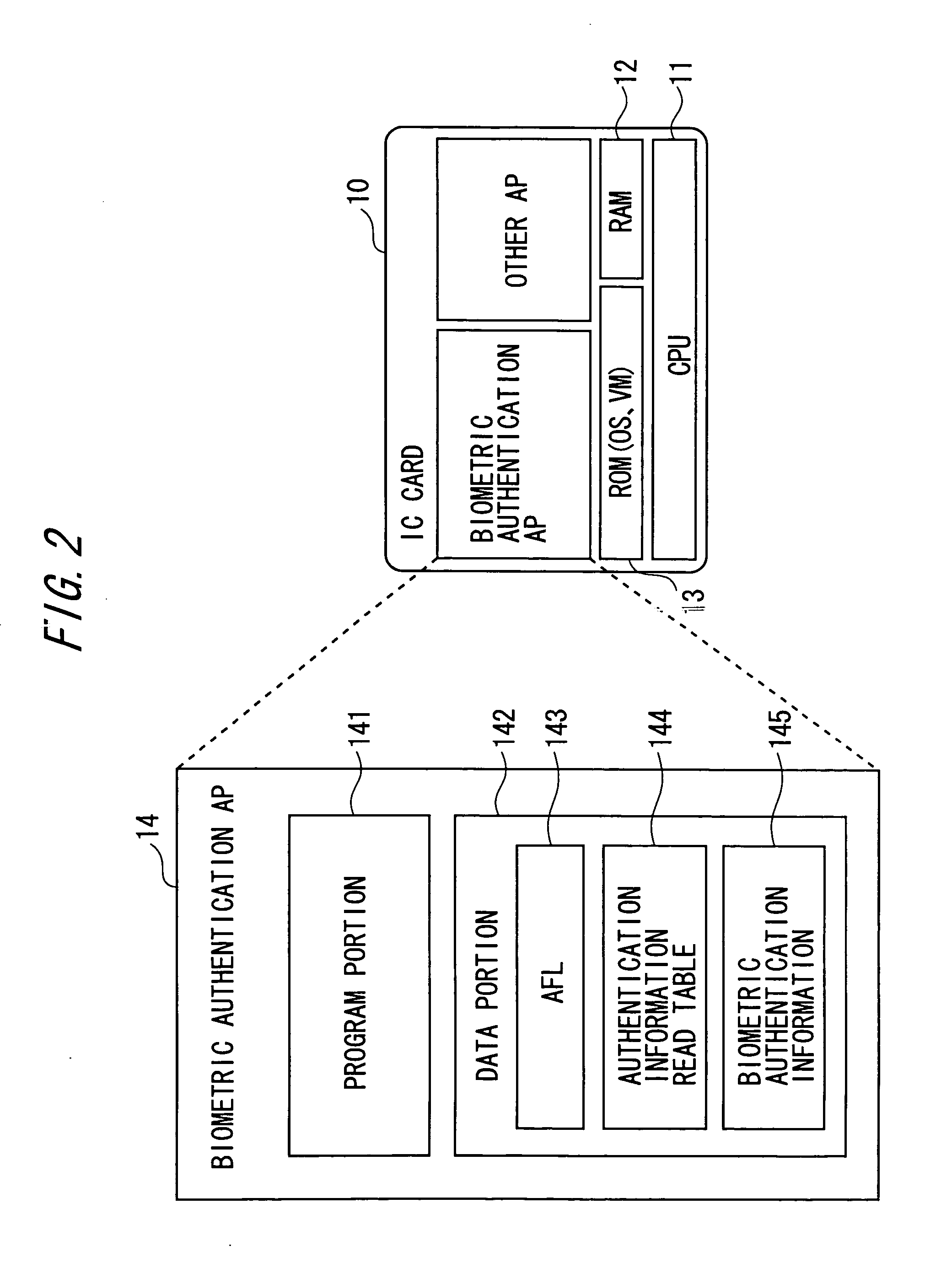

User authentication apparatus, electronic equipment, and a storage medium embodying a user authentication program

InactiveUS20060080548A1Efficient biometric authenticationEffective informationHigh internal friction springsSheet joiningComputer hardwareUser authentication

A user authentication apparatus includes: means for storing biometric authentication information obtained from a user; means for communicating with a electronic equipment, which authenticates the user with the user's biometric authentication information; means for sending, in response to a first inquiry from the electronic equipment, store location definition information, which defines store locations of various output information; and output means for outputting, in response to a read request sent from the electronic equipment to designate a store location defined by the store location definition information, the output information along with identification information which indicates the type of the output information. The output means outputs, to an external device, as one of the output information, along with identification information, authentication information store location information, which describes in a given format where authentication information including the biometric authentication information is stored.

Owner:FUJITSU LTD +1

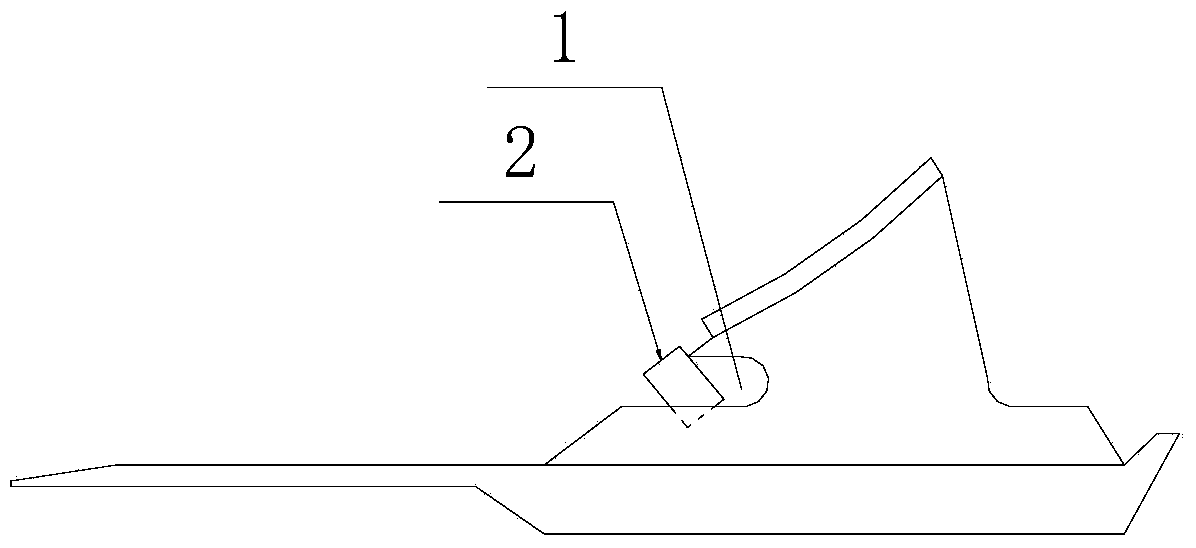

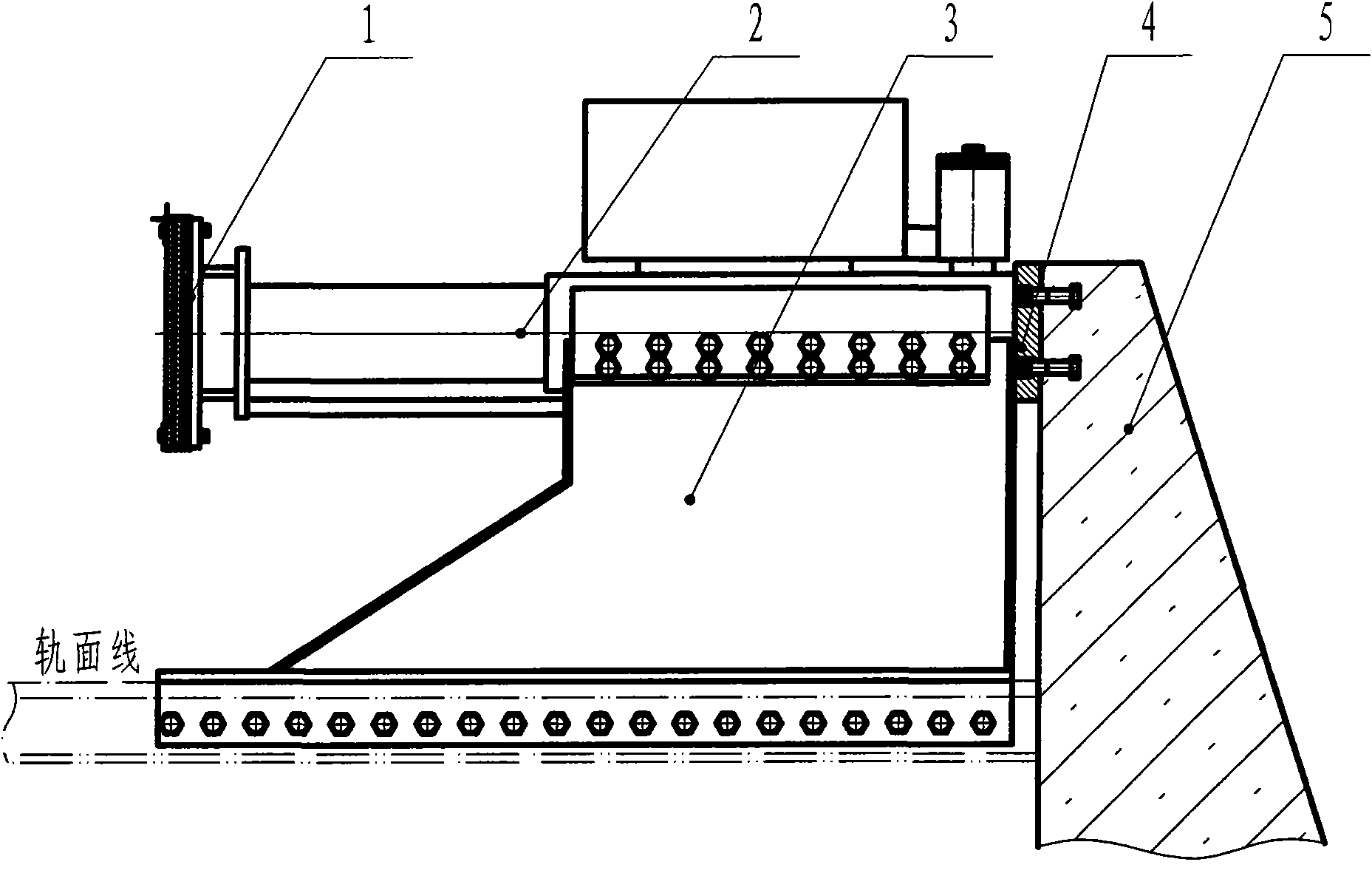

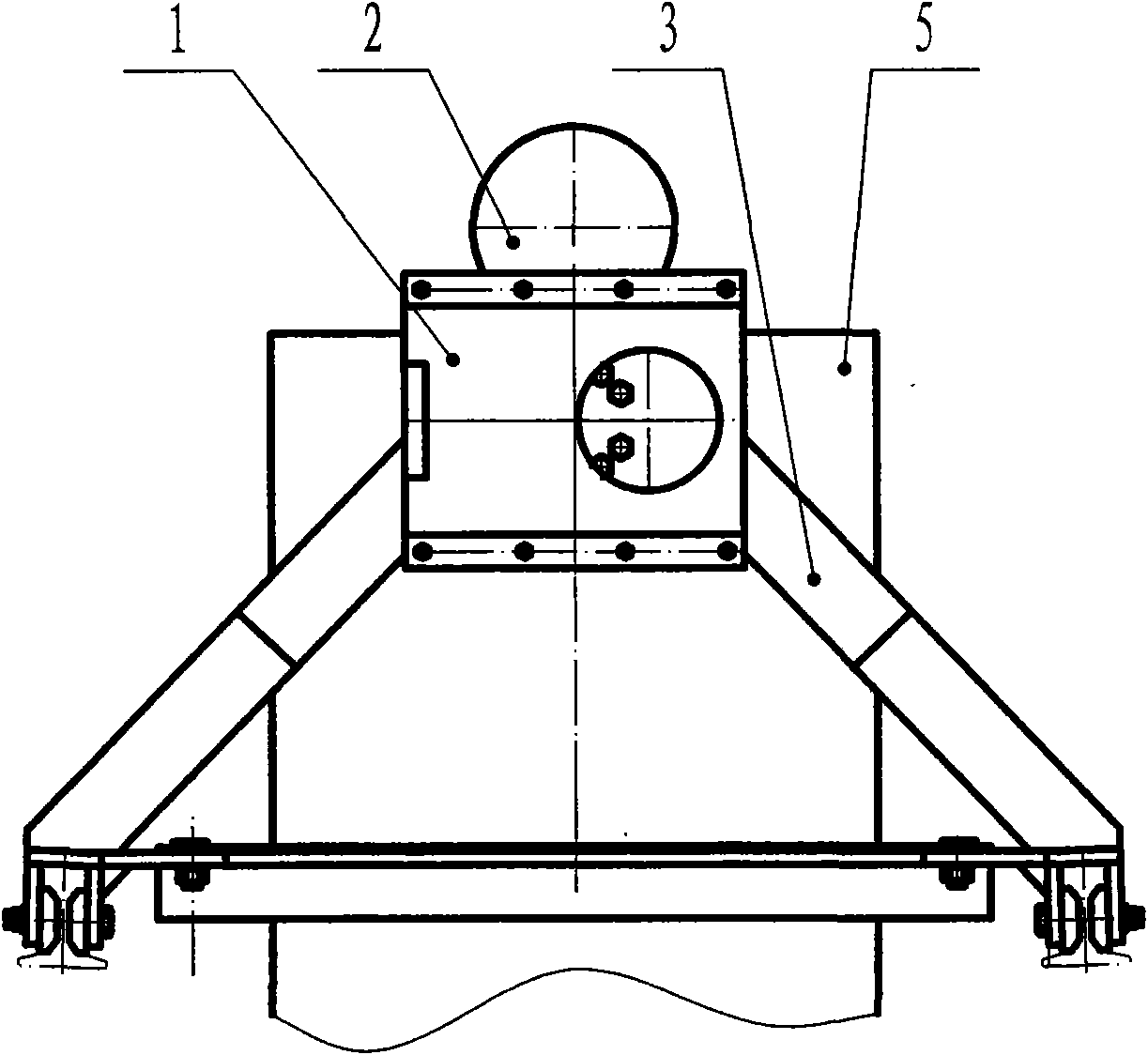

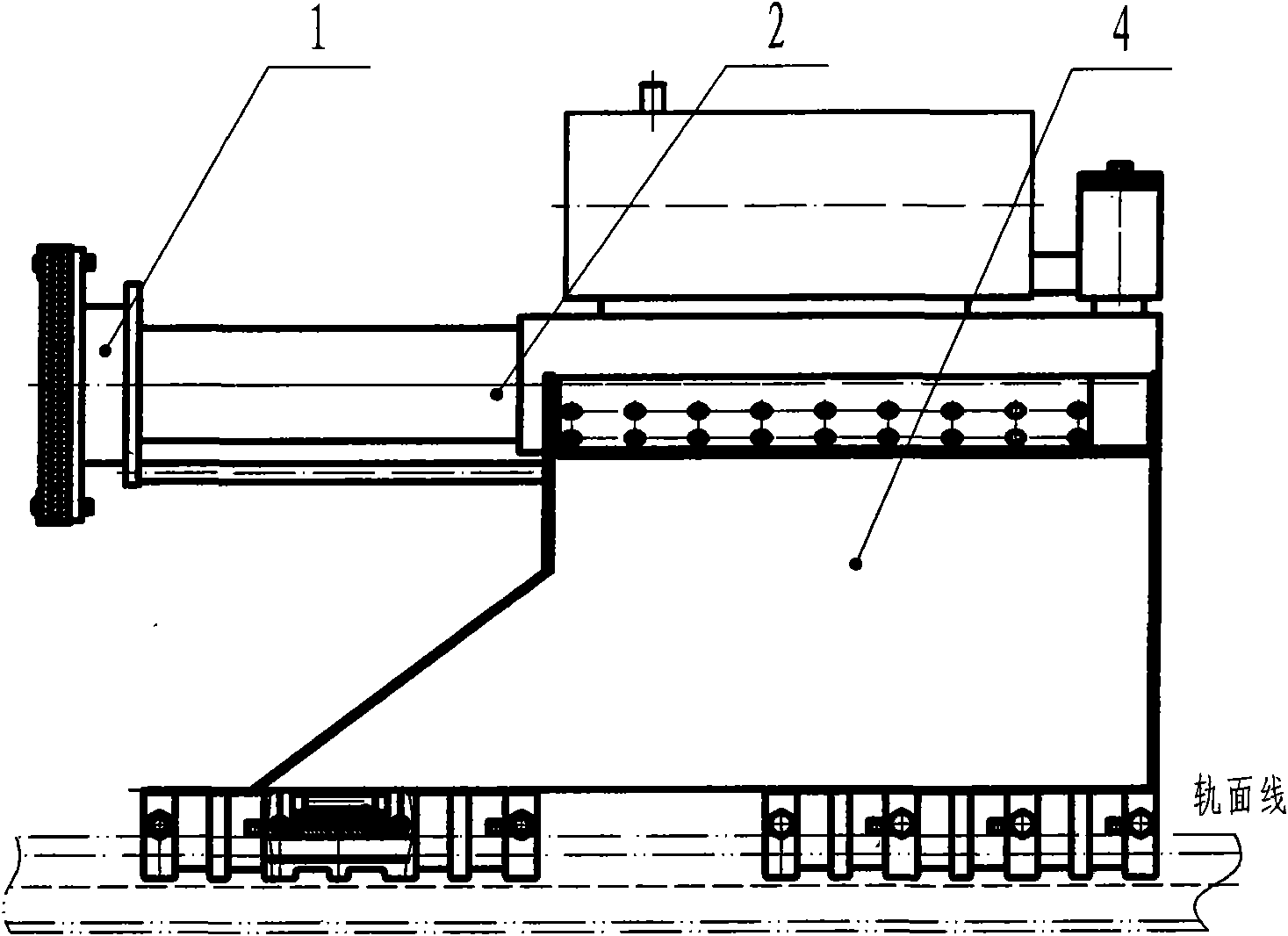

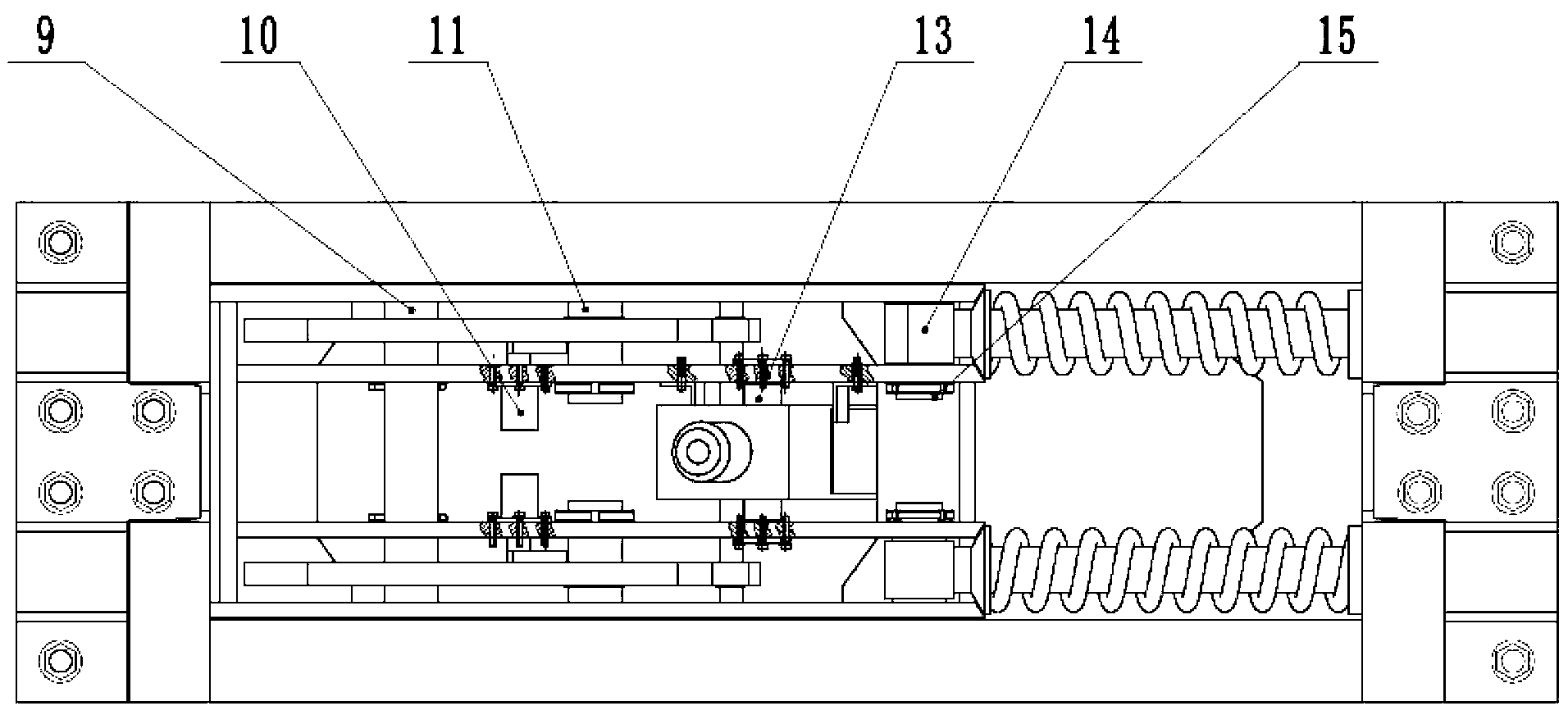

Hydraulic buffer stopper

InactiveCN101804821APrevent crashShunting operation safetyPositive railway stopsRetaining wallBolt connection

The invention discloses a hydraulic buffer stopper, which is a safety device for preventing vehicles from rushing out of line terminal. A buffer head of a fixed hydraulic buffer stopper is tightly and fixedly connected with a plunger bolt of a hydraulic buffer assembly, connecting plates at two sides of an oil cylinder of the hydraulic buffer assembly are connected with supporting arms at the left and right of a fixed bracket via bolts, the rear end of the hydraulic buffer assembly is connected with a retaining wall via a bolt for buffer seat, the retaining wall can be left out in case of low vehicle speed, lower portions of the supporting arms at the left and right of the fixed bracket are connected with a basic rail of the line via bolts, a buffer head of a sliding hydraulic buffer stopper is tightly and fixedly connected with the plunger bolt of the hydraulic buffer assembly, the connecting plates at two sides of the oil cylinder of the hydraulic buffer assembly are connected with supporting arms at the left and right of a sliding bracket, a damper at the lower portion of the sliding bracket is tightly and fixedly clamped on the head of the basic rail of the line via the bolt and is tightly inserted between a spring plate and a friction base via a taper. Such a stopper plays the role of buffering and absorption of impact energy for humping vehicles, thereby guaranteeing shunting safety.

Owner:沈阳中铁安全设备有限责任公司

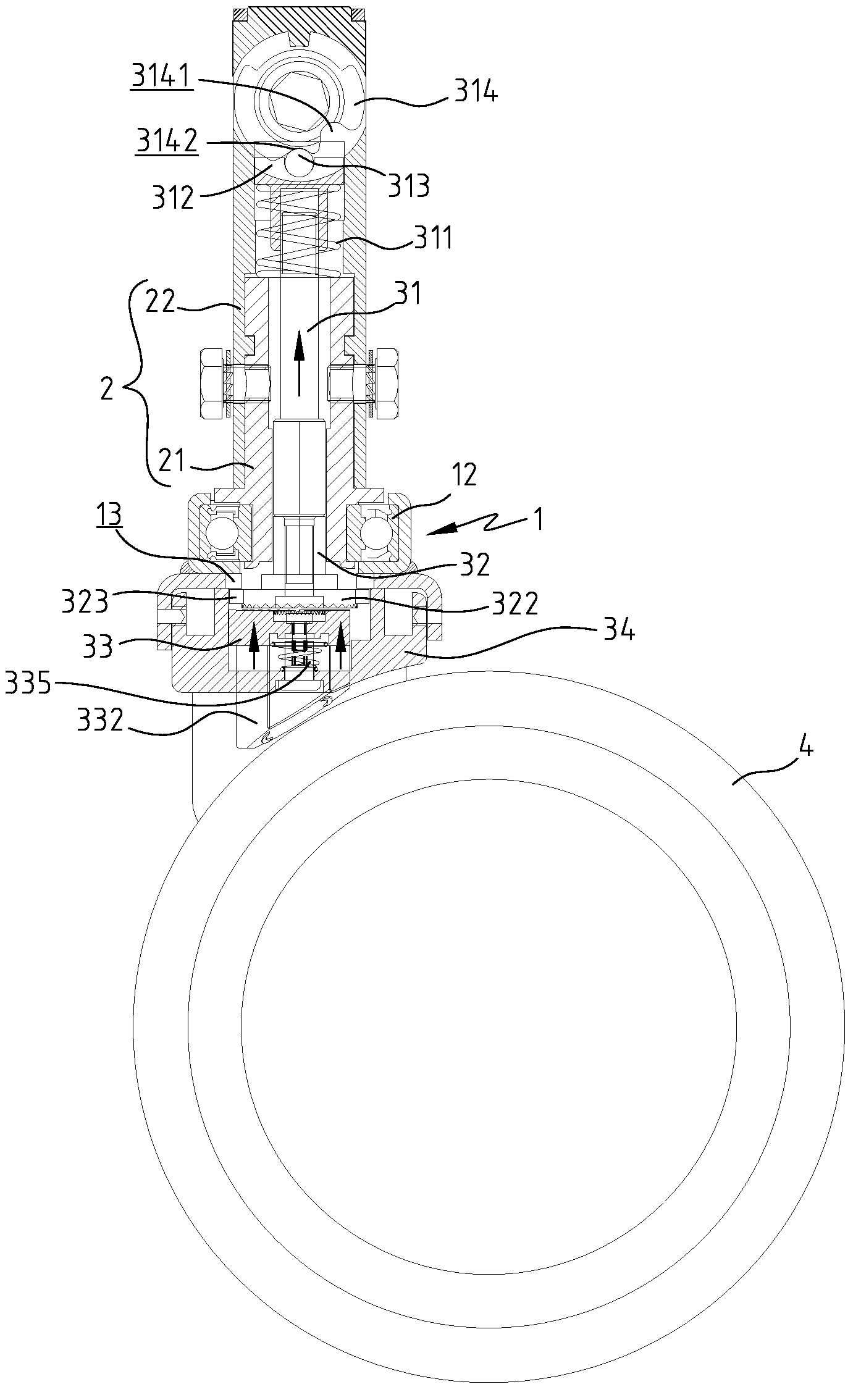

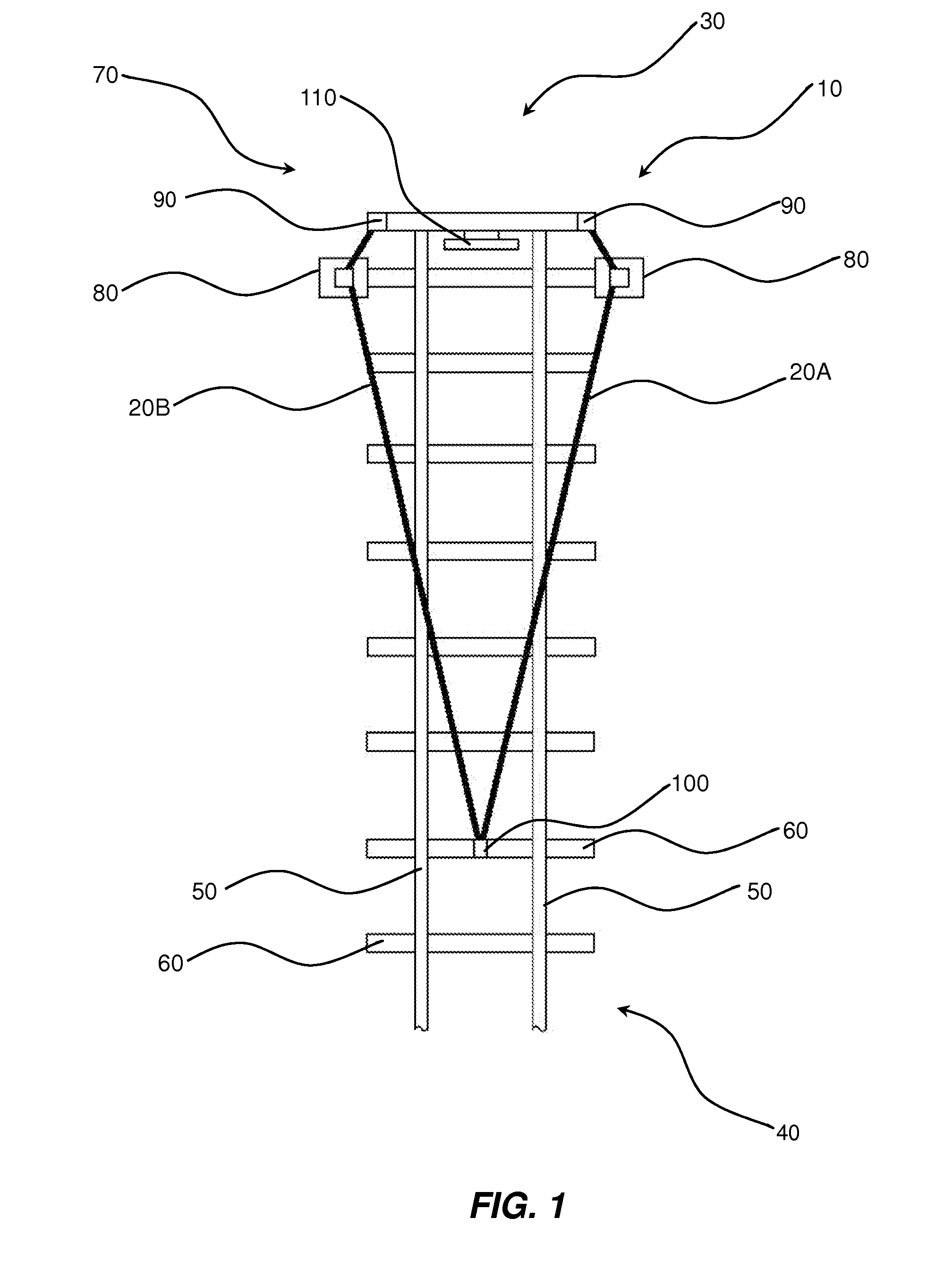

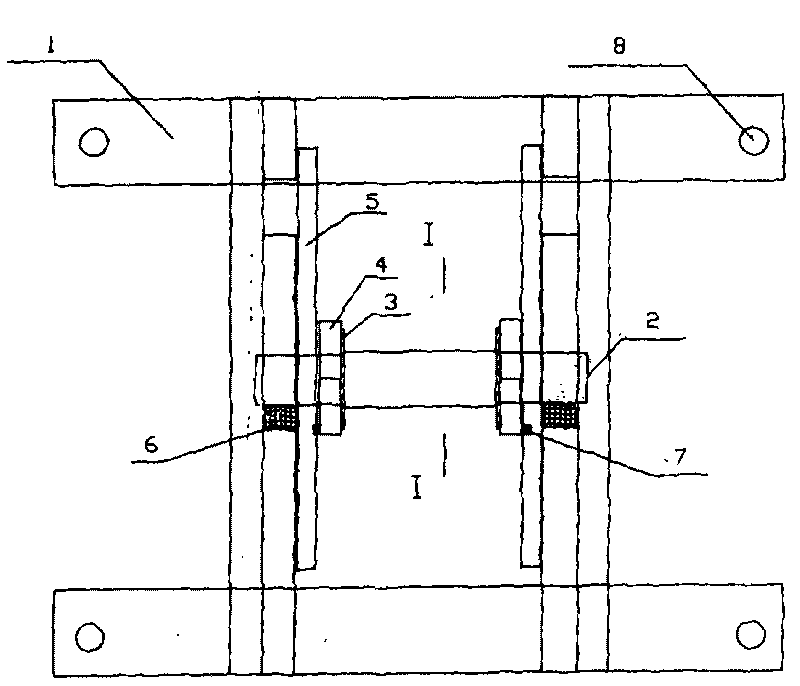

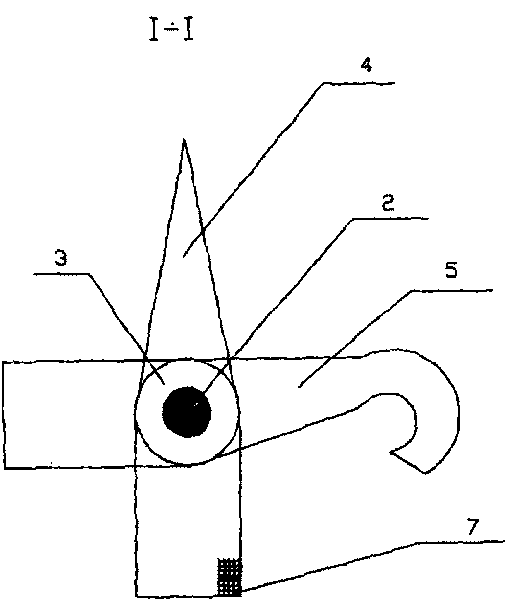

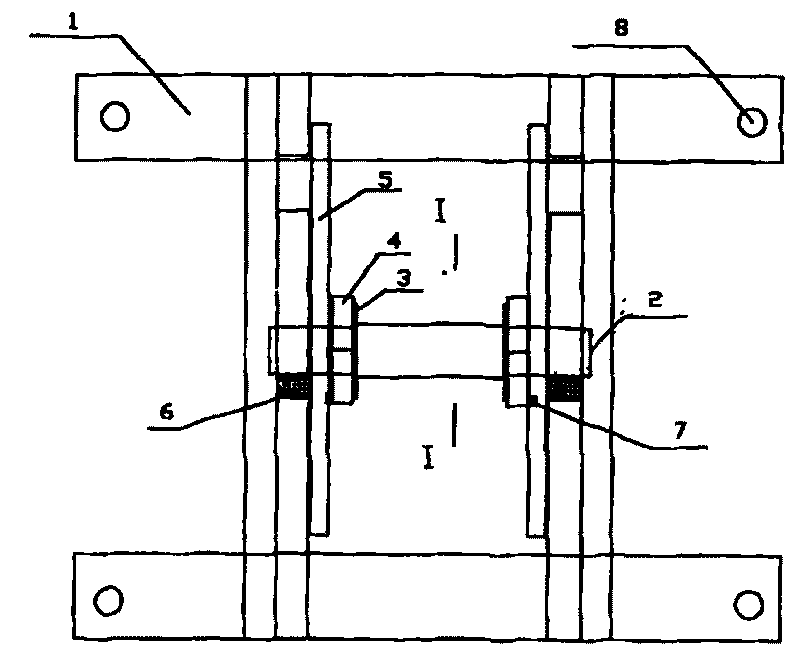

Bottom lifting type arrester

InactiveCN101289091AExpand the scope of protectionReduce turn-on timePositive railway stopsStart up timeEngineering

A vehicle hurdle of a bottom raised type is provided, which comprises a buffer, a wire rope and a baffle screen; two ends of the baffle screen are connected with the buffer fixed at two sides of tramroad by the wire rope; a baffle screen holding room is arranged at the lower part of the tramroad of mine working, the upper part of which is provide with a rail bridge which can be started and stopped; the side part of the baffle screen holding room is provided with a baffle screen lifting mechanism. The rail bridge can be started by a starting and stopping mechanism arranged at the side of the baffle screen holding room and can also connect the baffle screen and can be lifted with the baffle screen. The baffle screen can adopt a rotation starting method or a vertical lifting method. The wire rope of the buffer screen is arranged on the ground of two sides of laneway; the buffer screen moves under the rail and the height of the moving is lower than the height of tramcar, which takes no space at the top and two sides of the laneway; as the baffle screen is not started to place and the material of the mine vehicle is too wide, the baffle screen can not cause mine vehicle to scrap the screen. furthermore, as the starting and stopping travel of a bottom raised type buffer screen is shorter than a top raised type buffer screen, the start-up time is shortened, dead work space is effectively reduced and protection scope for running vehicle is increased.

Owner:靳慧民

Emergency stopping system for track mounted movable bullet targets and target trolleys

An emergency stopping system for track mounted movable targets used divergent cables to stop a target trolley which has not been otherwise stopped before coming to the end of a track. As the trolley passes over the diverging cables, the cables are forced together, causing the trolley to dissipate kinetic energy.

Owner:ACTION TARGET

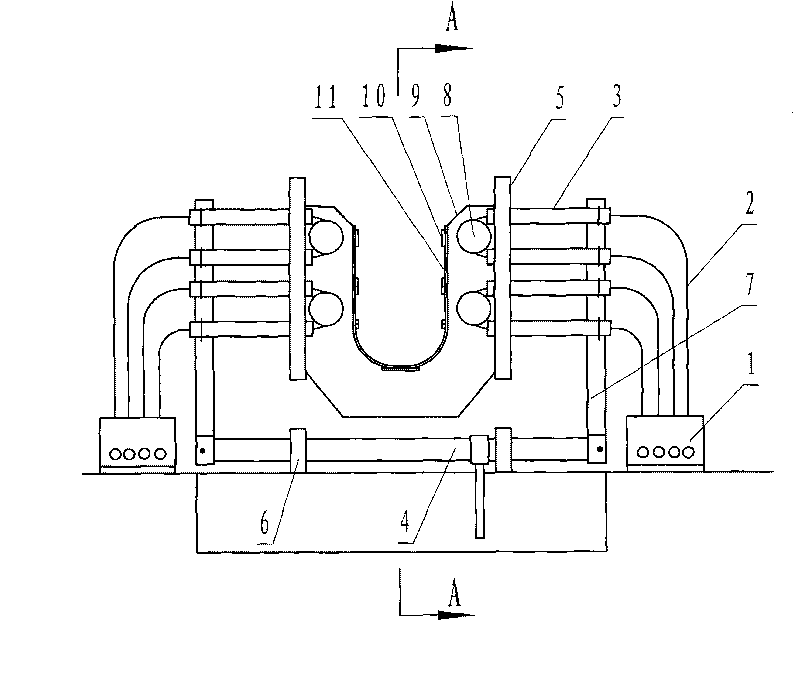

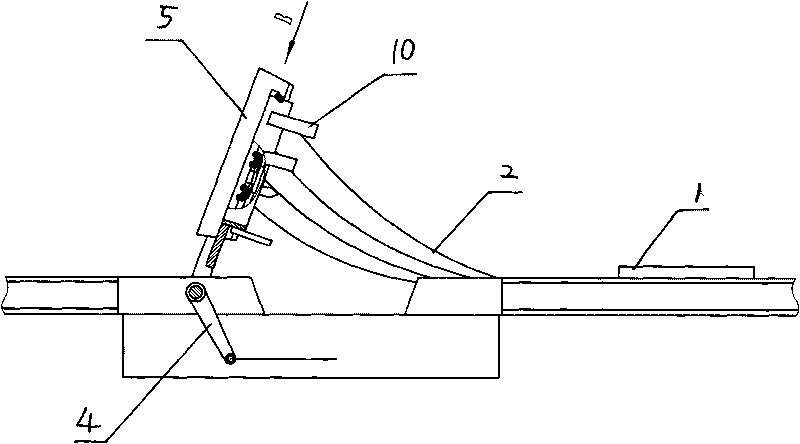

Normally closed type intelligent catcher

InactiveCN101913366AImprove speed measurement accuracyEffective interceptionPositive railway stopsLower limitWinch

The invention discloses a normally closed type intelligent catcher belonging to the technical field of mine hoisting equipment protection. The catcher is provided with a car blocking column with a buffer action on a well wall. A performing structure for lifting and descending the car blocking column is arranged on the car blocking column. Two buffers are symmetrically arranged on a track in front of the car blocking column and are connected with the car blocking column. The catcher also comprises a speed sensor for detecting the speed of a mining car, a controller connected with the speed sensor, a monitoring case having the functions of displaying the state of the car blocking column and alarming and connected with the controller, a power supply and a switch which are connected with the controller, wherein the power supply is connected with the performing structure; the speed sensor is arranged on a depth indicator for indicating the lifting / descending depth of a mining car by a winch; an upper limit sensor and a lower limit sensor for detecting the state of the car blocking column are arranged on the performing structure and are connected with the controller. The invention has the advantages of improving the safety in the transportation process of an inclined shaft.

Owner:CHINA COAL NO 5 CONSTR

Transporting system

ActiveUS8973506B2Travel path can be limitedPrevent crashStorage devicesPositive railway stopsTransport systemTransit system

The invention relates to an in-house track-bound transporting system with self-propelling carriages that move on rails. The system has stoppers to prevent said carriages from crossing over open rail ends or track borders, and the system is provided with stops. The stoppers collide with the stops in order to prevent a crossing-over, said stops having first and second fixed stop elements. The stoppers can be moved between a first crossing-over position and a second crossing-over position such that the first stop elements can be crossed over in the first crossing-over position of the stoppers, and the second stop elements can be crossed over in the second crossing-over position of the stoppers, wherein the first stop elements cannot be crossed over in the second crossing-over position of the stoppers, and the second stop elements cannot be crossed over in the first crossing-over position of the stoppers.

Owner:DEMATIC

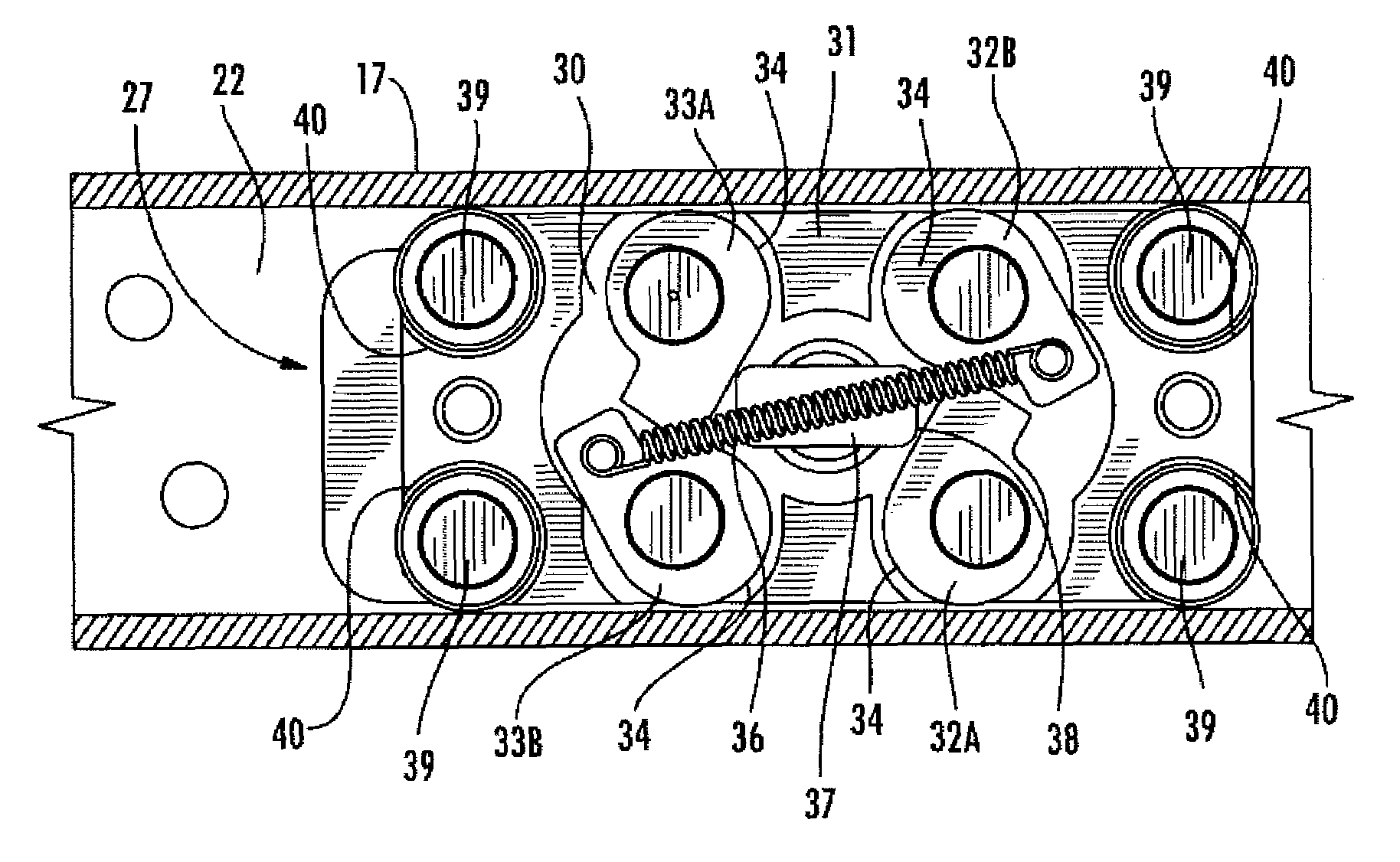

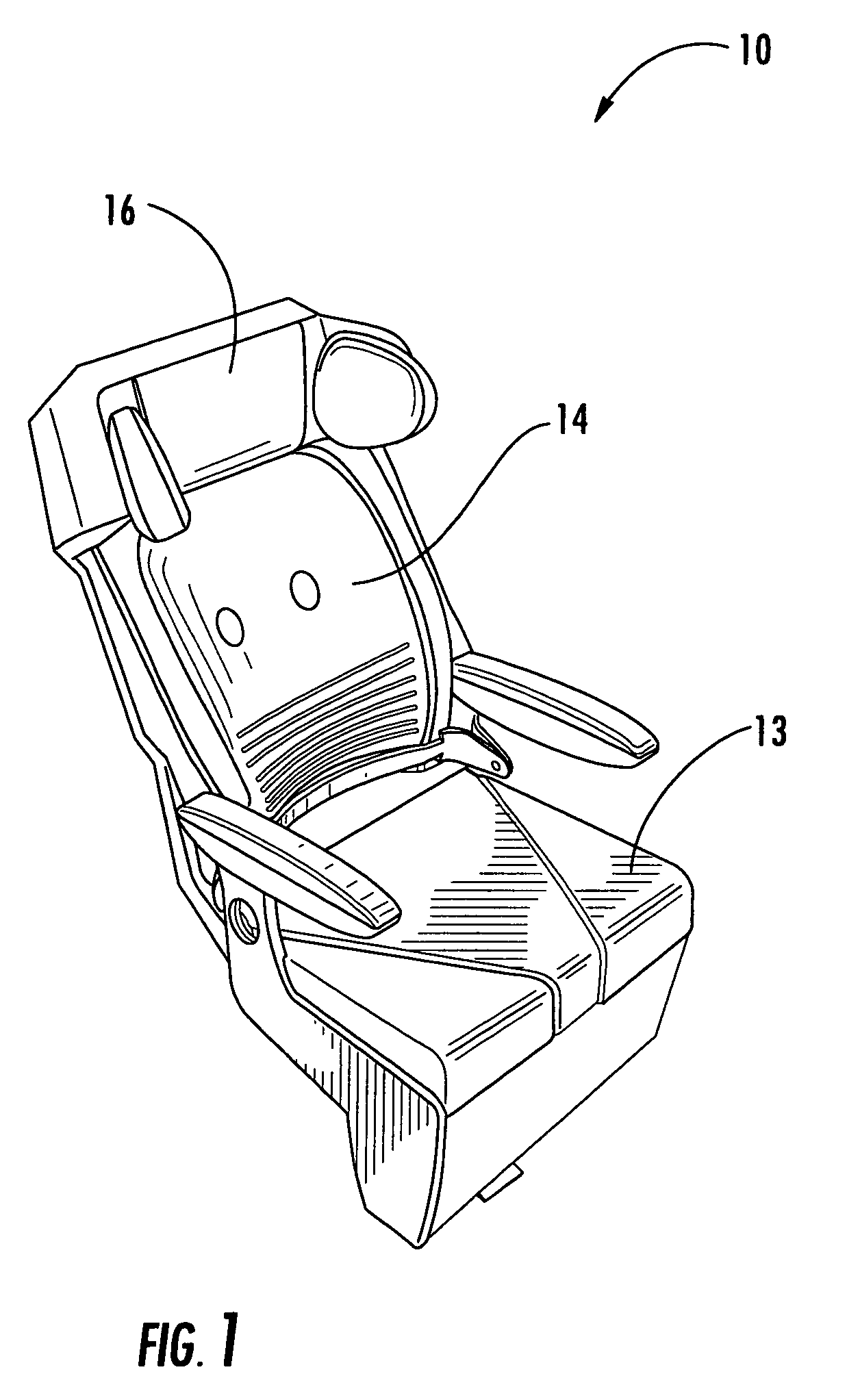

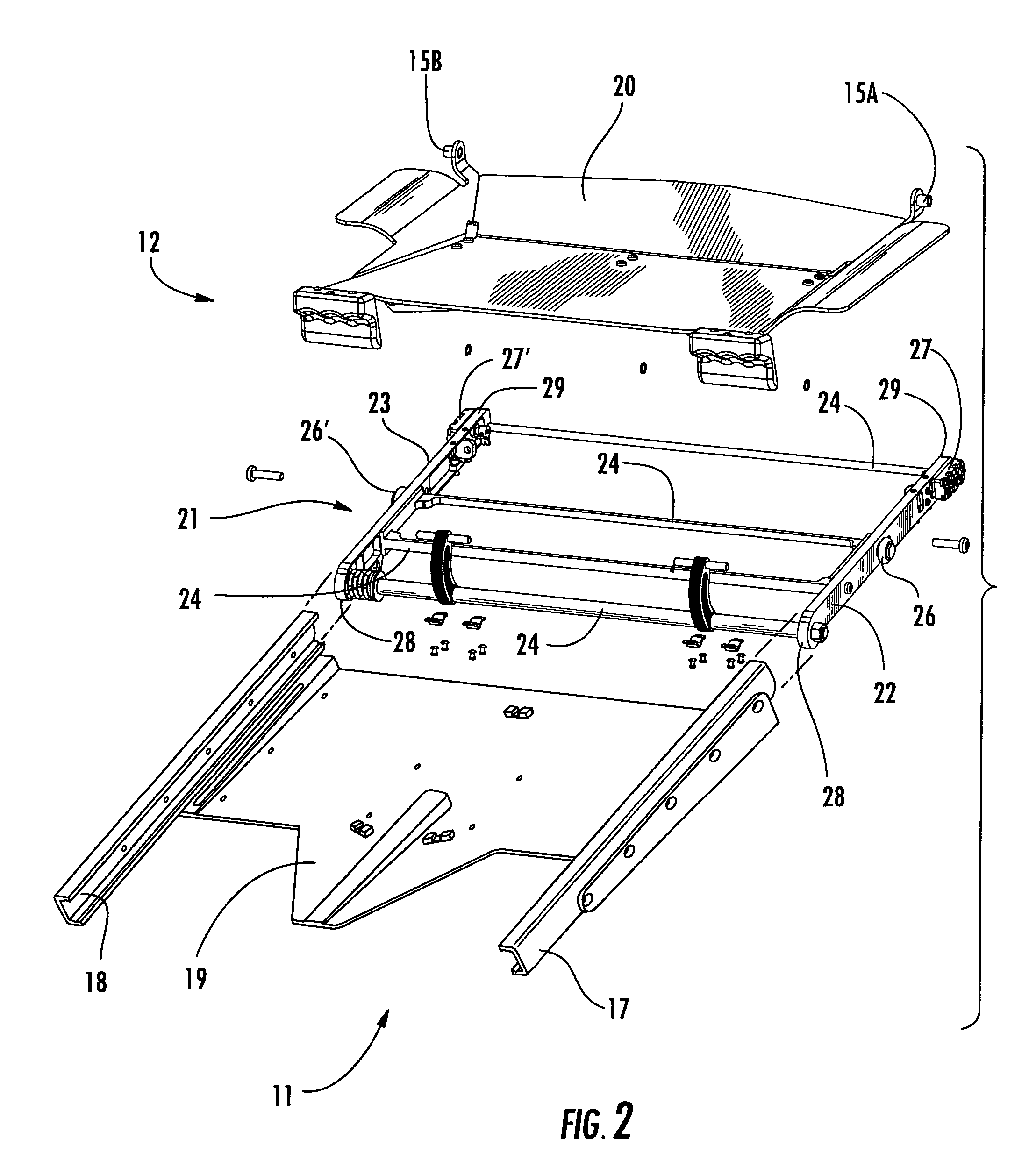

Cam lock for vehicle seating

ActiveUS7261378B2Reduce manufacturing costPrevent slidingOperating chairsDental chairsEngineeringCam

Owner:BE AEROSPACE INCORPORATED

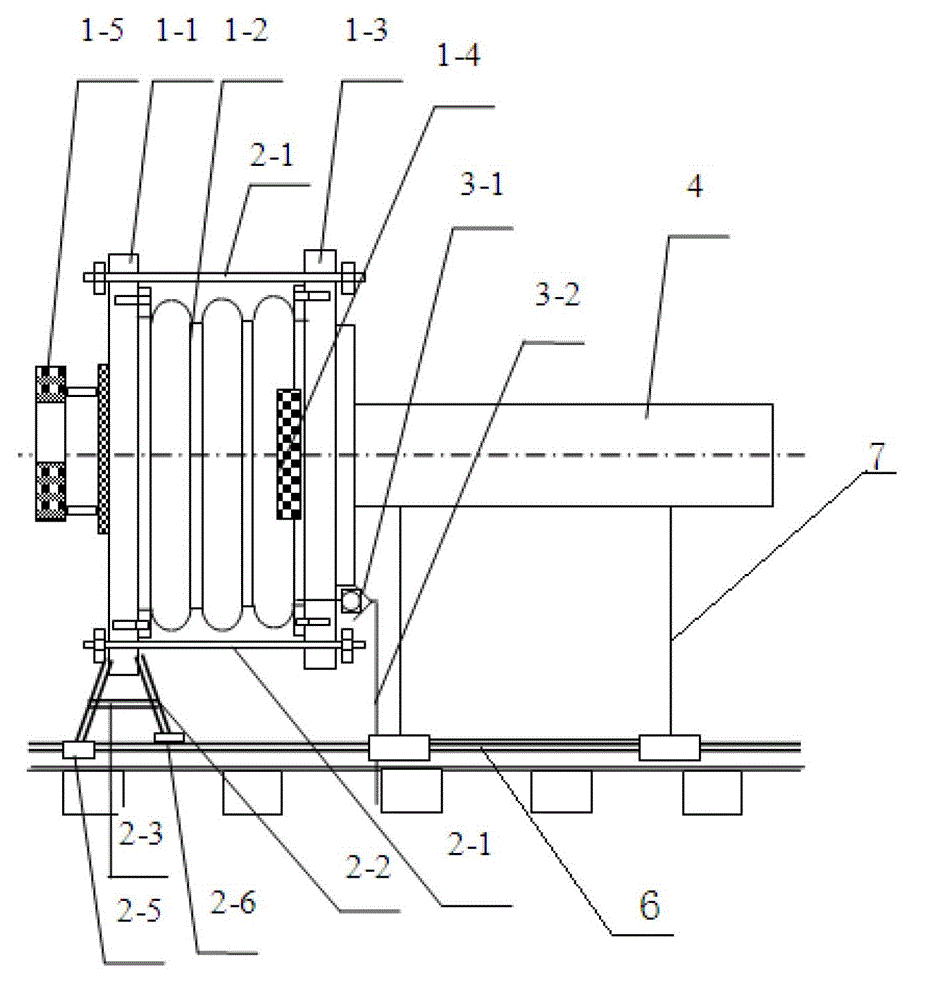

Air spring buffer car stop

The invention discloses an air spring buffer car stop which comprises an air spring buffer and a fixed track, wherein the air spring buffer is connected with the fixed track through a guide support device in a sliding manner, the rear end of the air spring buffer is fixedly connected with a transmission drum, the transmission drum is fixedly connected with a car stop frame which is connected to the fixed track in a sliding manner, and the air spring buffer is also connected with an air supplement device. In necessity, a hydraulic buffer is fixedly connected between the air spring buffer and the transmission cylinder. The air spring buffer car stop solves the faults of buffer hydraulic seal abrasion, response interruption and the like easily caused by the traditional hydraulic buffer car stop in the car stop conditions of high speed, big quantity of motion and impact force eccentricity, solves the technical problem that a huge impact force is instantly generated to damage a buffer system to cause that the buffer is disabled, and ensures the car stop safety in the car stop conditions of high speed, big quantity of motion and impact force eccentricity.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP +1

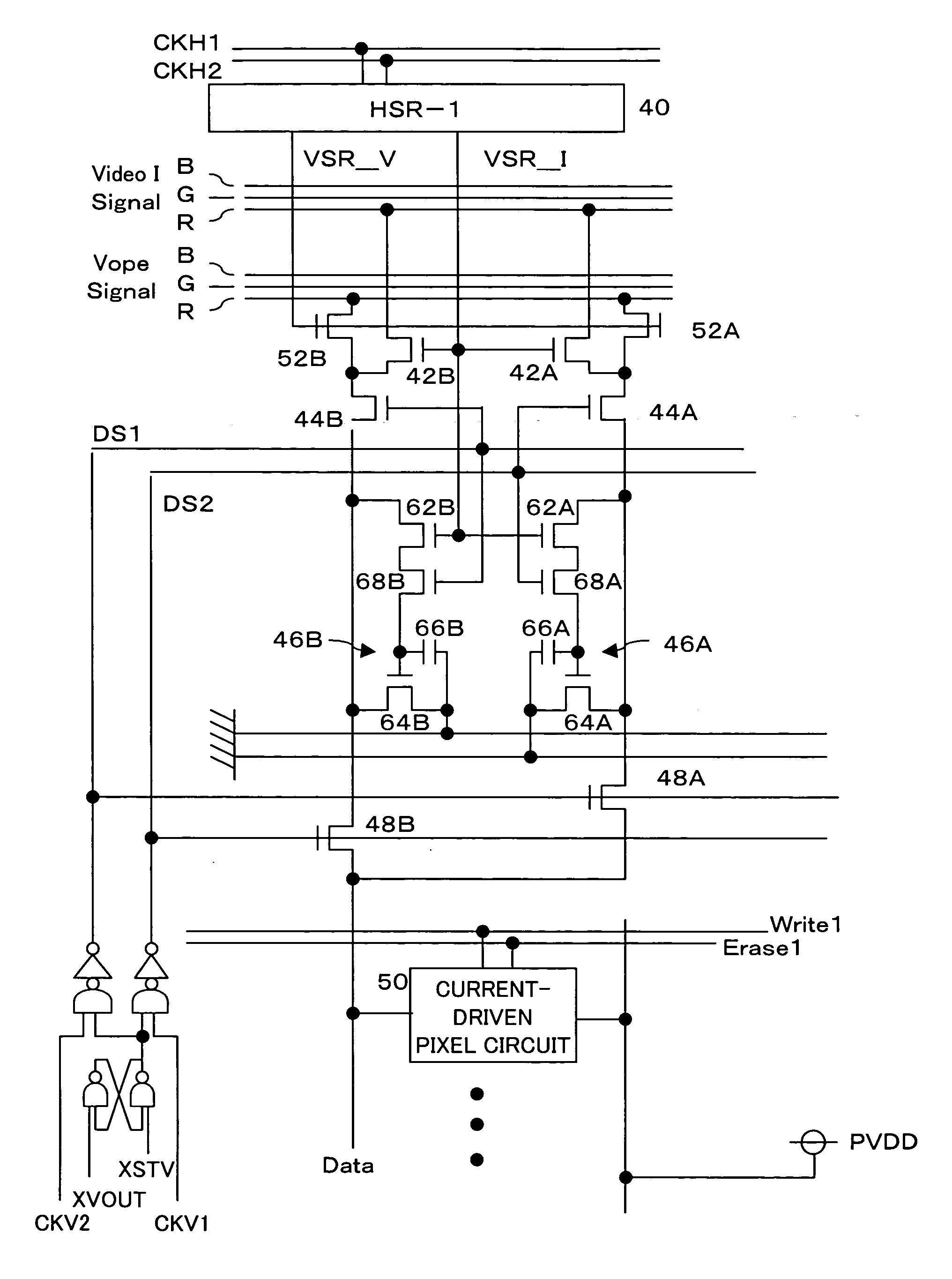

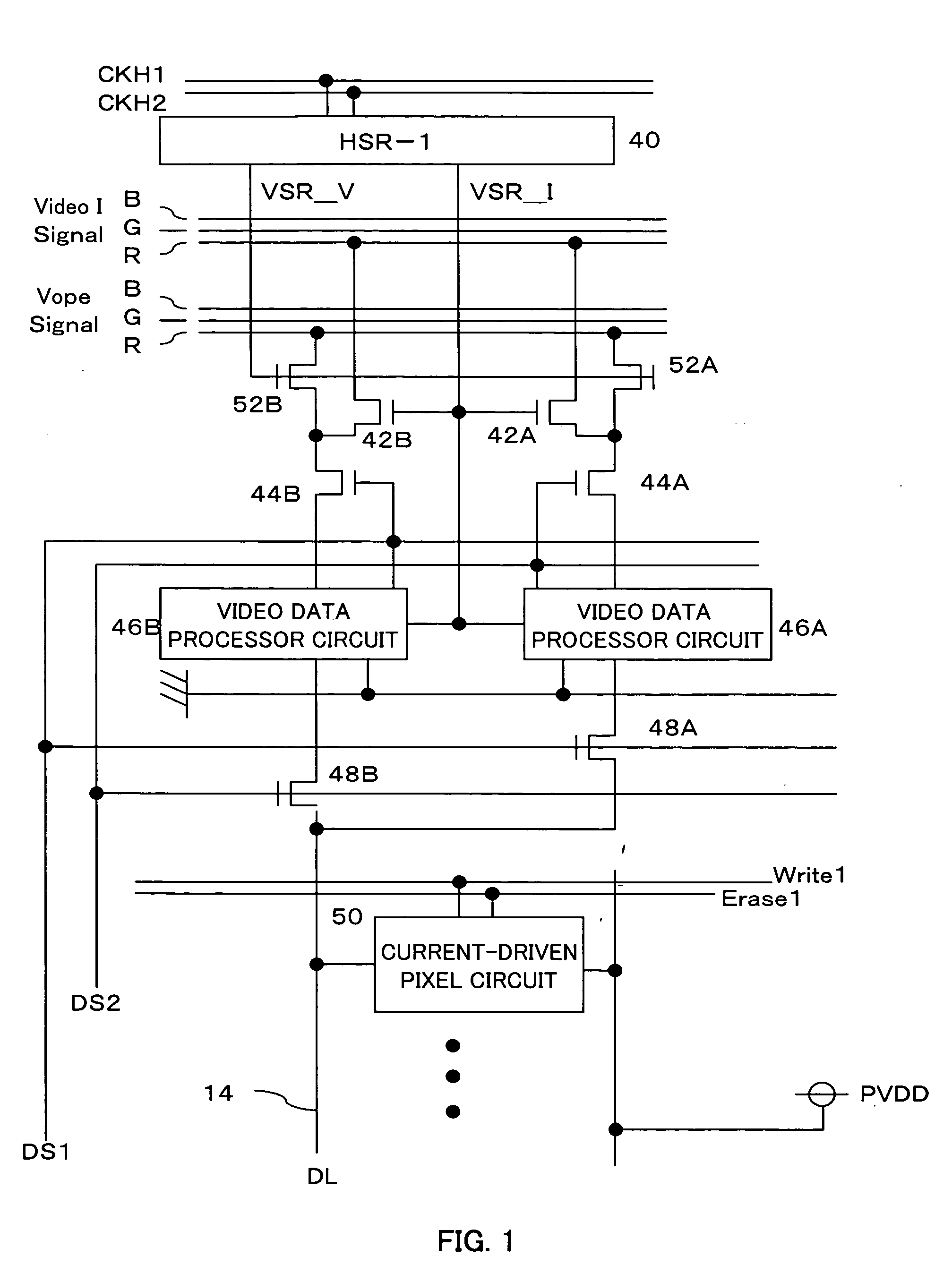

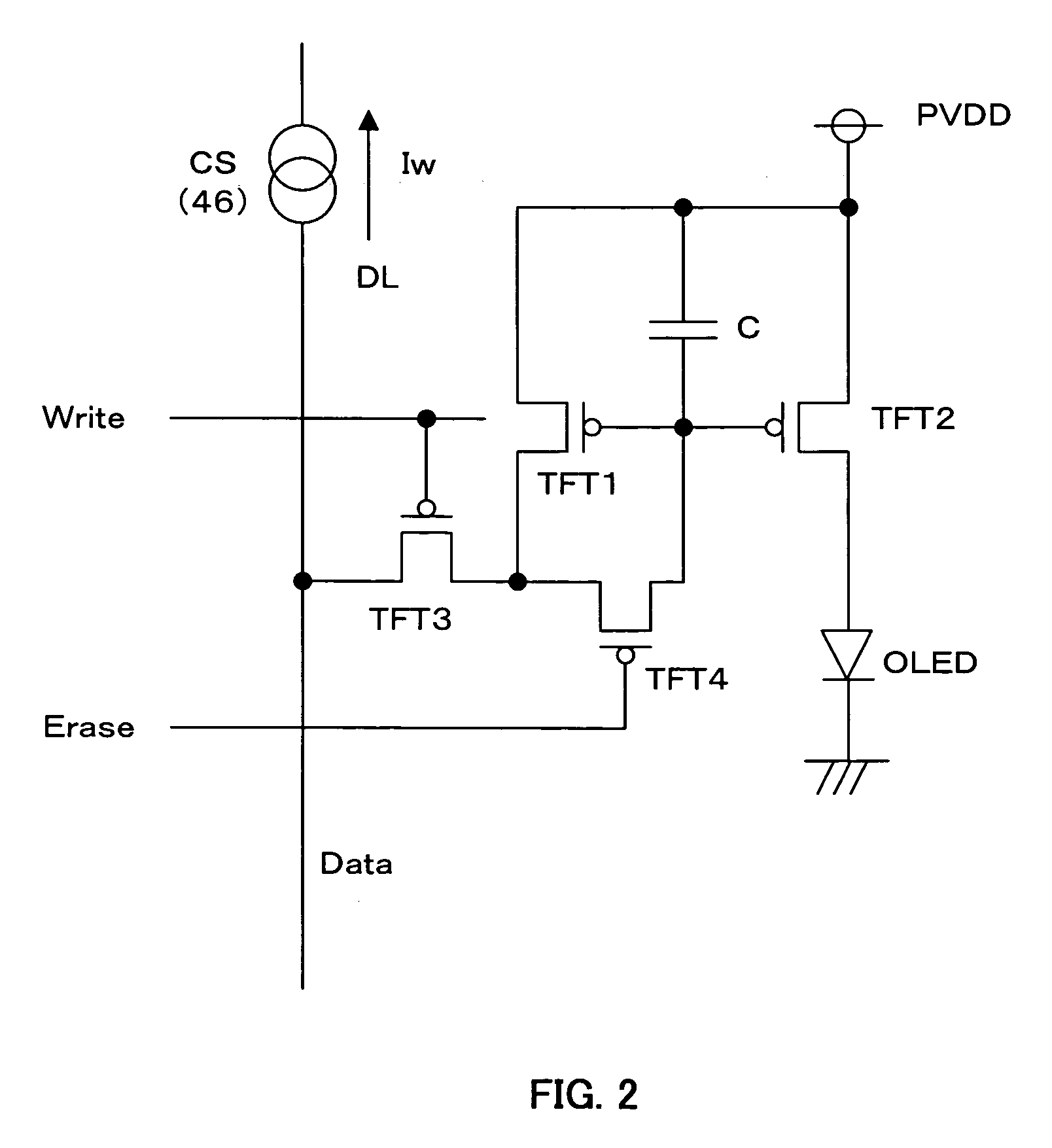

Display device

InactiveUS20040233142A1Fast dataEasy to controlElectroluminescent light sourcesSolid-state devicesDisplay deviceOperation point

An operation point voltage signal and a current video signal are received and stored in a video data processor circuit and a current signal is output onto a data line for a period of one horizontal line. A current-driven pixel circuit can be driven by an operation point voltage signal and a current video signal.

Owner:SANYO ELECTRIC CO LTD

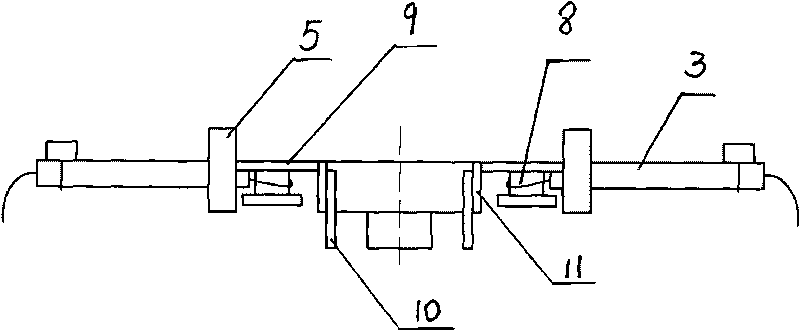

Axle hung retarder

The invention discloses a run-away tramcar protecting device, in particular an axle hung kick-up block suitable for traveling crane protecting devices of mine inclined shafts (drifts) construction. The axle hung kick-up block consists of a hook stop chassis, a hook stop main axle, a hook stop check ring, a hook stop collision bar, a hook stop hook plate, an axle stop plate, a collision bar joint and a chassis fixing hole, wherein the hook stop collision bar of the axle hung kick-up block is in a long triangle; the middle of the collision bar is provided with a circular hole, and the collision bar joint is arranged below the collision bar near one side of the hook stop collision bar; and the closed angle end of the hook stop collision bar is always in an upward posture to be collided. The hook strop plate of the axle hung kick-up block is oblong, and the middle of the hook stop plate is provided with a circular hole, one end of the hook stop plate is provided with a hook, the diameter of the inner side of the hook is equal to that of the axle of a tramcar and the hook horizontally clings on the channel steel of the hook stop chassis. The axle hung kick-up block has simple manufacture, simple structure and convenient overhauling; the mounting quantity is not limited and the space limitation is small; and the kick-up block is installed in the middle of a rail, thereby not influencing the traveling of any tramcar.

Owner:中煤第一建设有限公司第三十一工程处

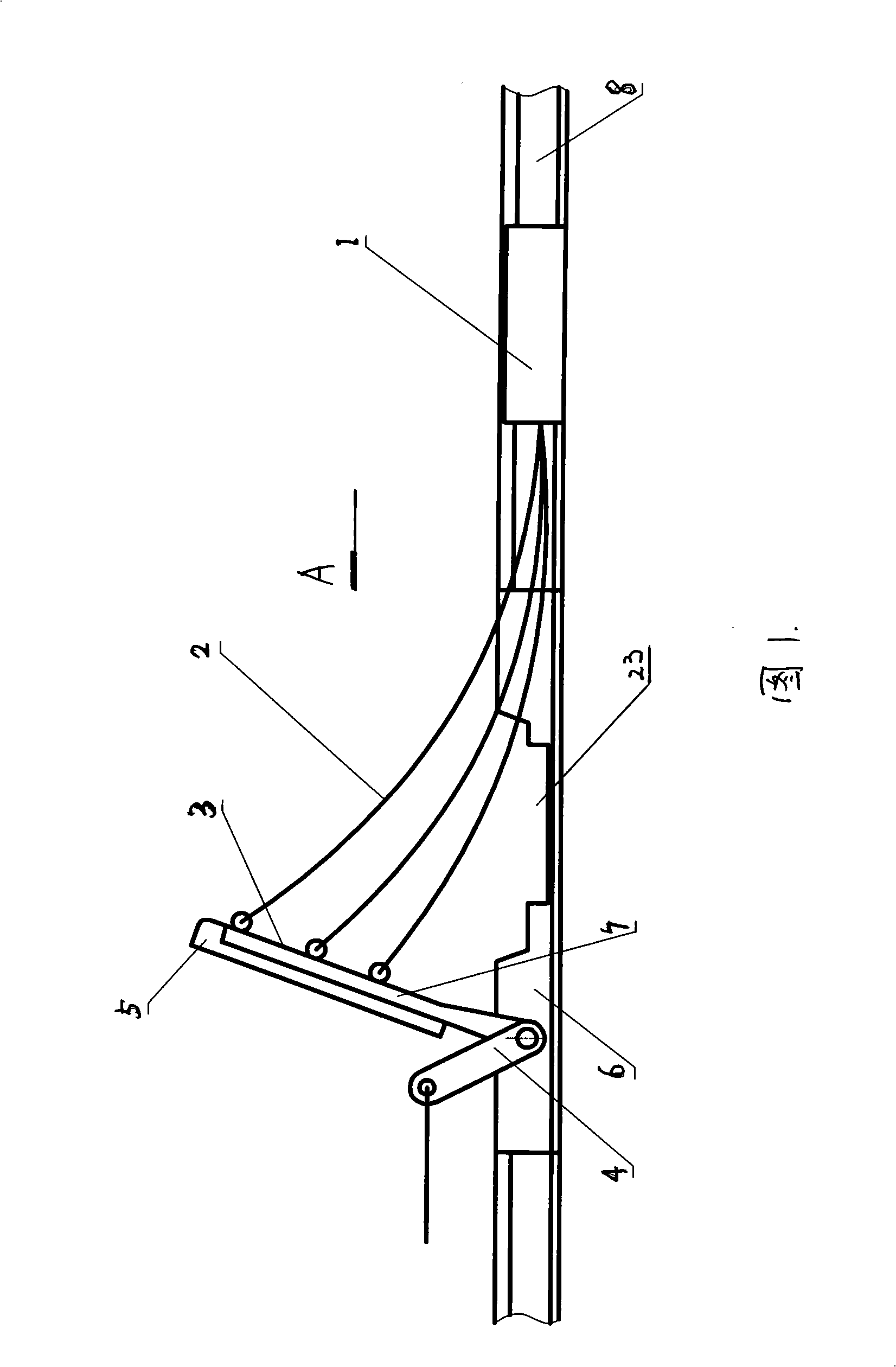

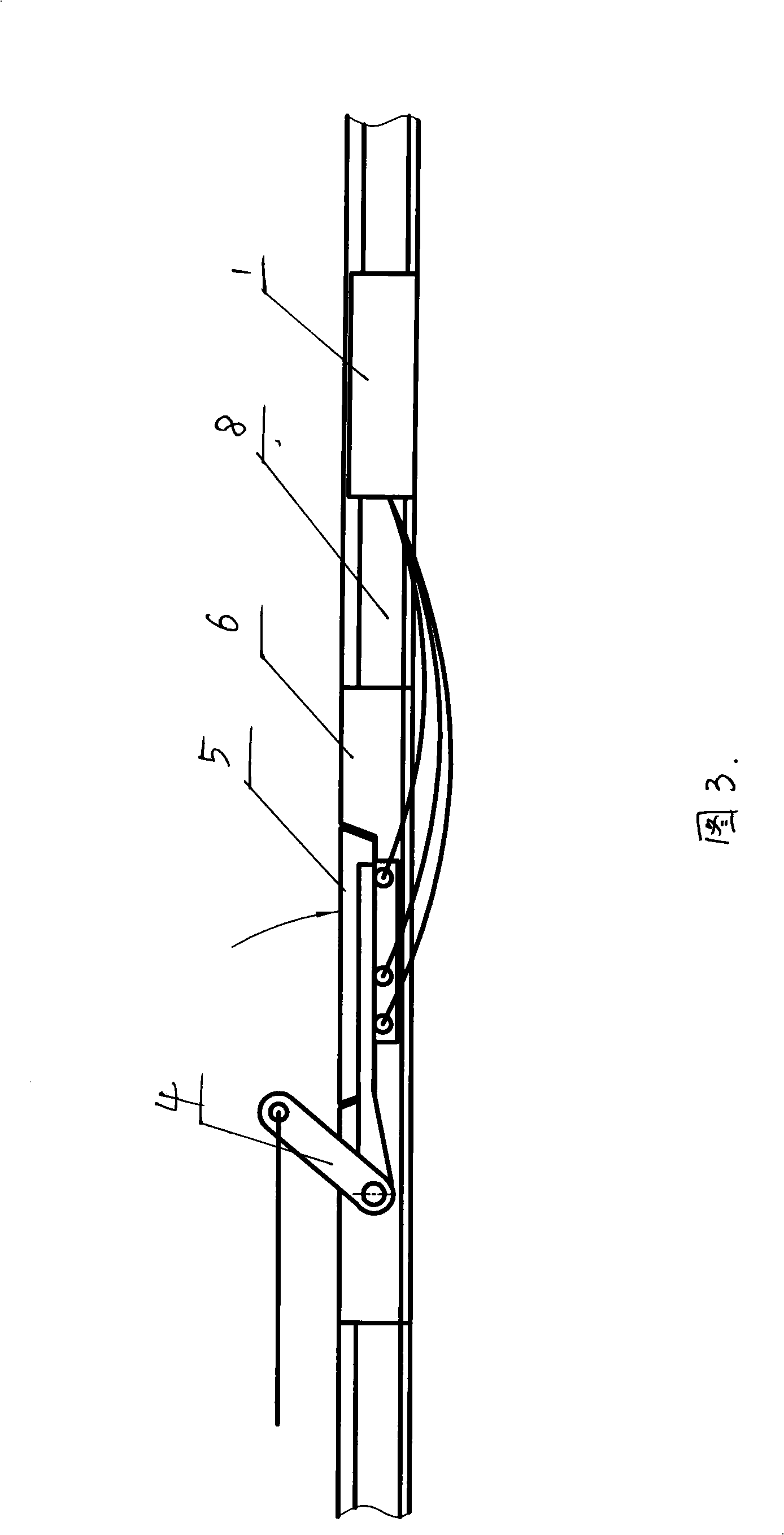

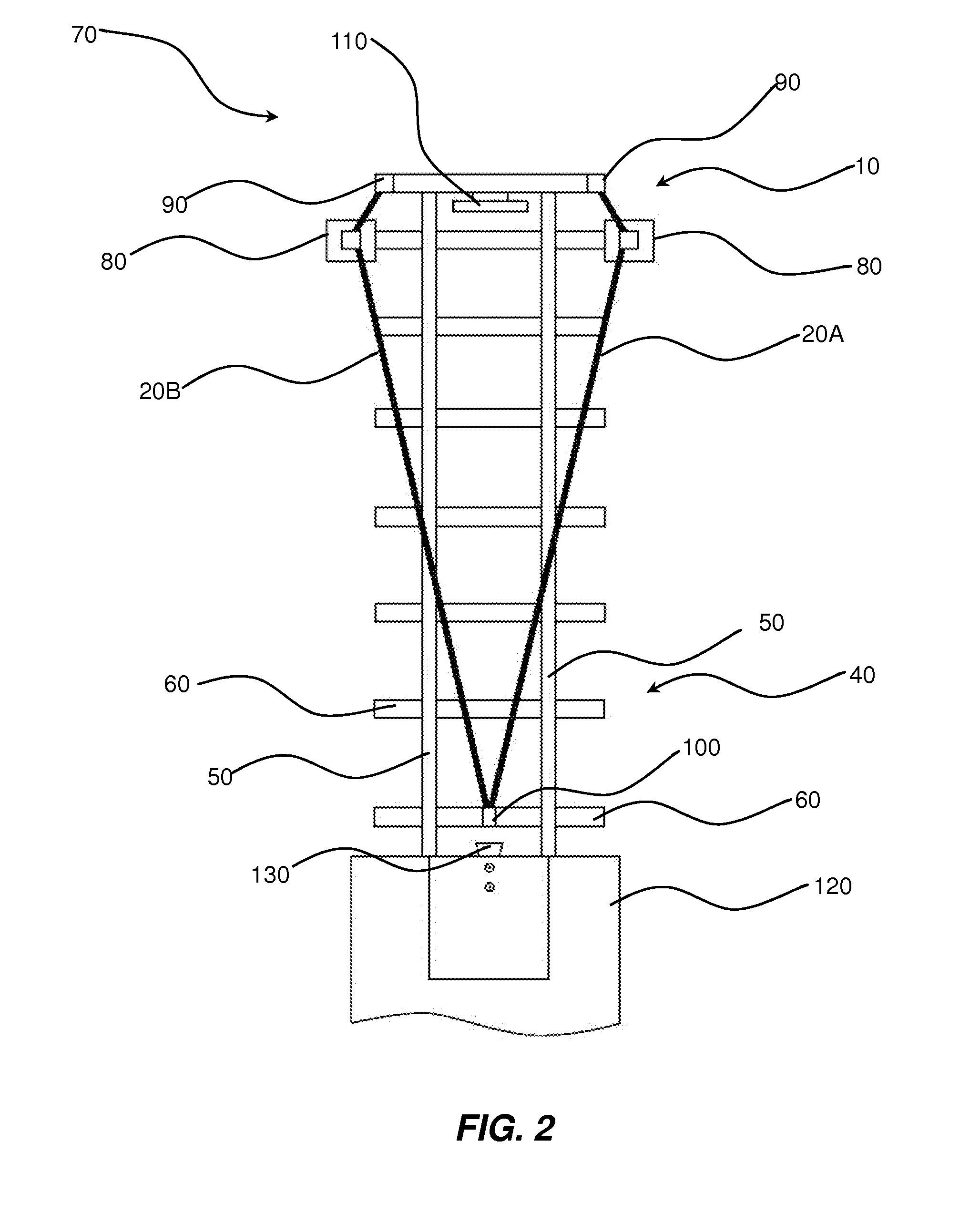

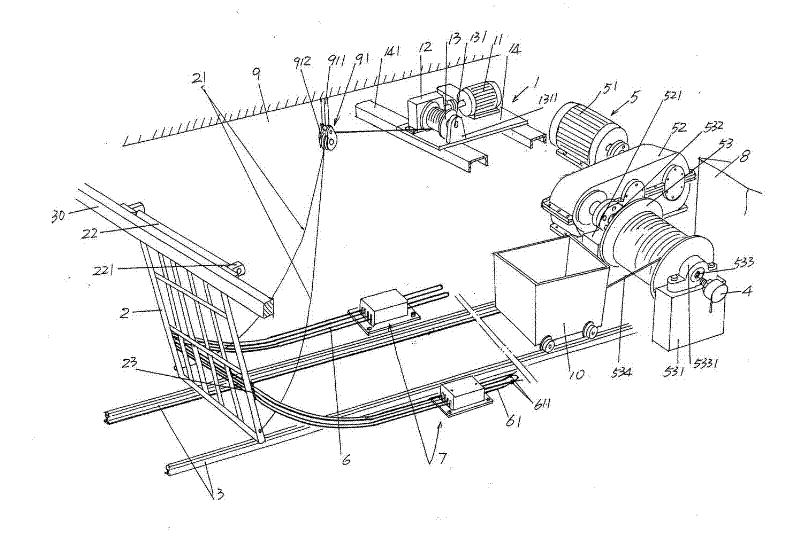

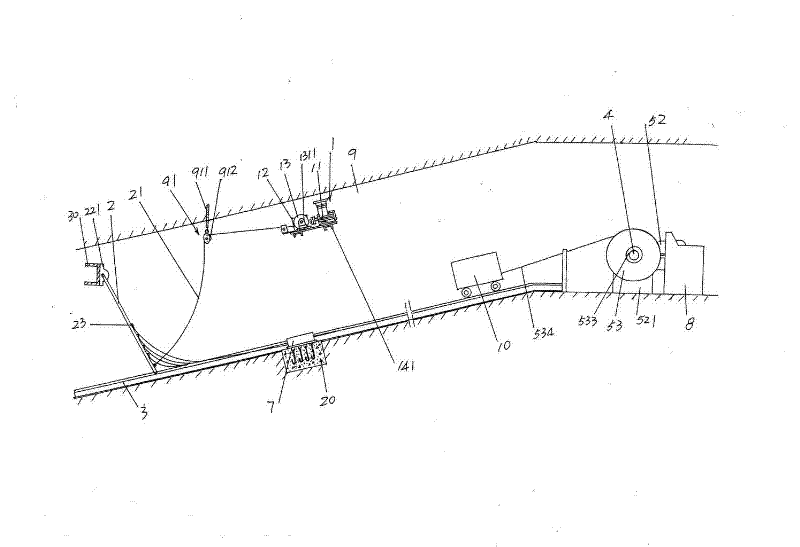

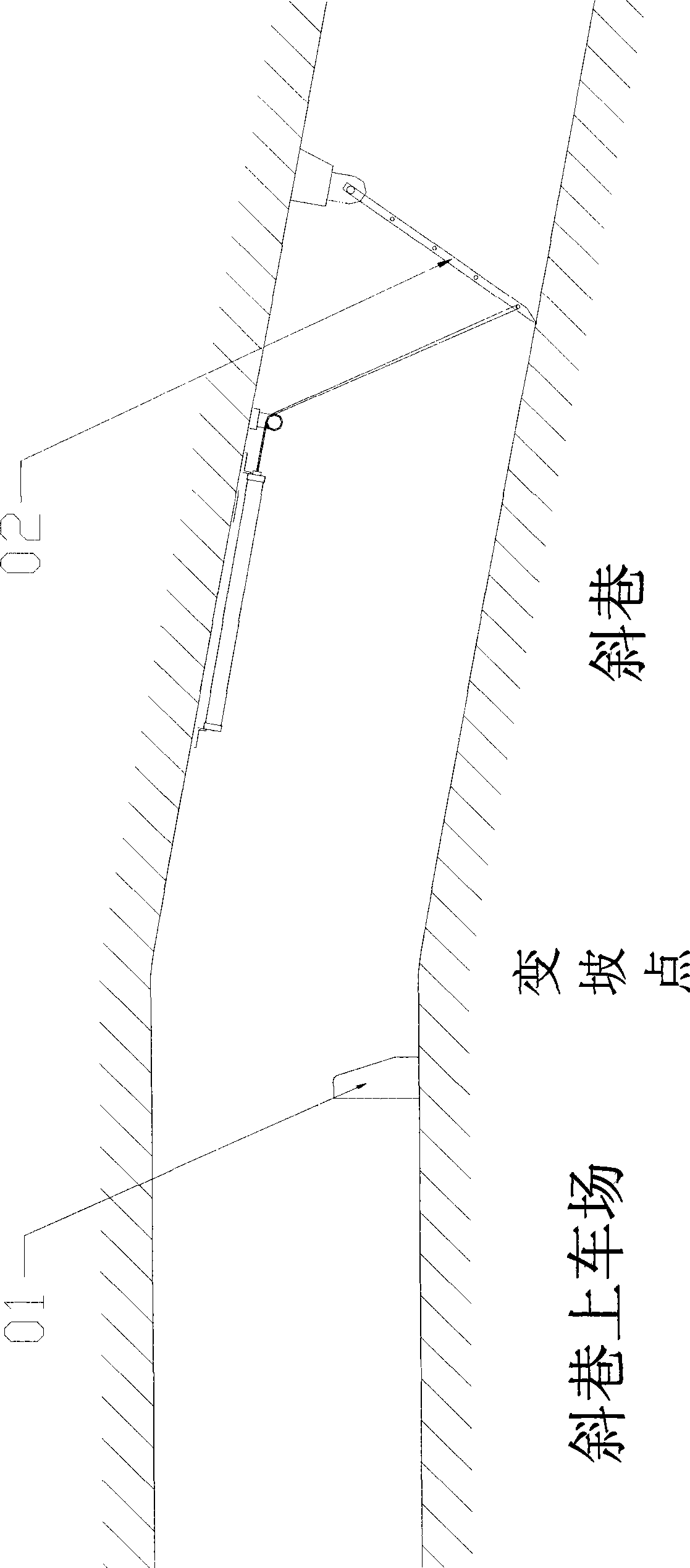

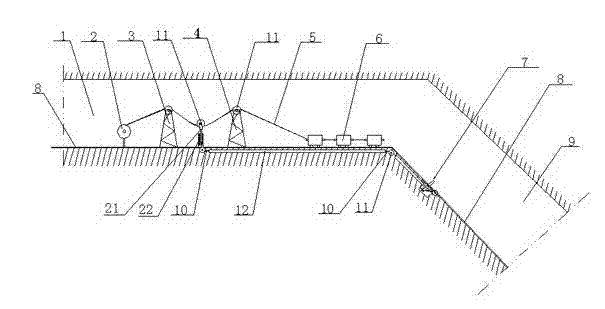

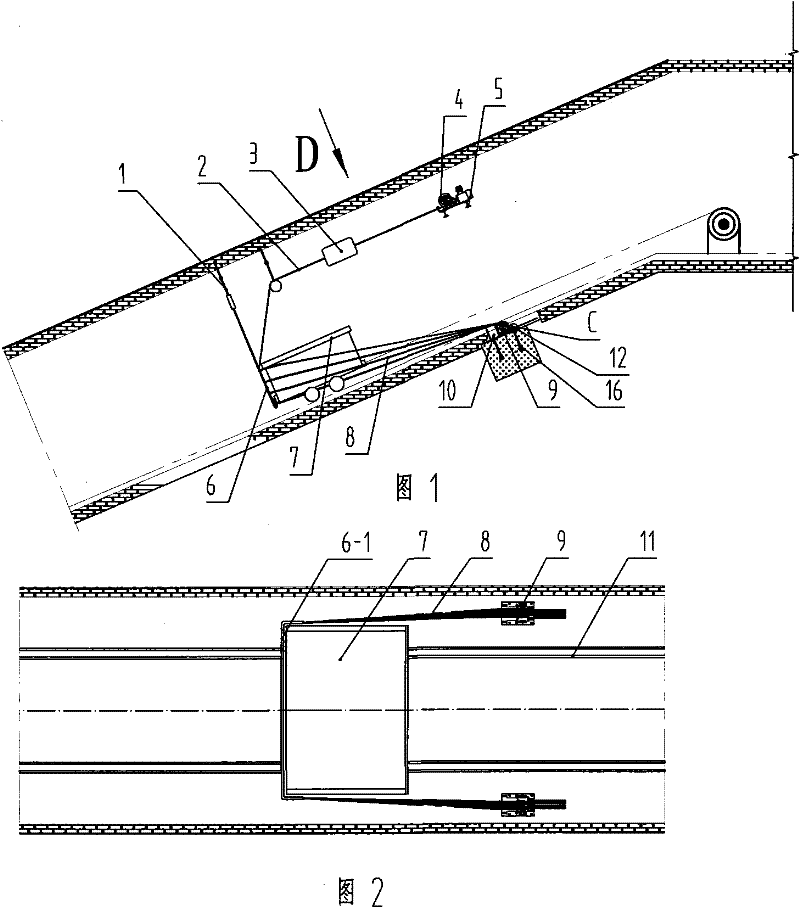

Inclined drift anti-run-off mechanism for mine

InactiveCN102229342ARise and fall in timeEasy to fixPositive railway stopsProgrammable logic controllerElectrical control

The invention discloses an inclined drift anti-run-off mechanism for a mine and belongs to the technical field of safety facilities for mines. The mechanism comprises a pulling rope retracting and releasing device, a vehicle retaining column, a rotary encoder and a group of buffer ropes, wherein the pulling rope retracting and releasing device is arranged on the top of a mine roadway; the vehicle retaining column is connected with a wall of the mine roadway; one end of at least one pair of pulling ropes is connected to the vehicle retaining column, and the other end of the pair of pulling ropes is connected with the pulling rope retracting and releasing device; the rotary encoder is arranged on a winch device; the middle of the group of buffer ropes is sleeved on the vehicle retaining column; and one end of the group of buffer ropes is connected with a buffer, and the other end of the group of buffer ropes is connected with another buffer. The mechanism is characterized in that: the pulling rope retracting and releasing device, the winch device and the rotary encoder are in electrical control connection with an electrical control box provided with a programmable logic controller; and the buffer comprises a bottom plate, a group of foundation piles, a group of pressing plates and a protective cover. The invention has the advantages that: a fixing effect between the mechanism and a foundation pit can be improved, and the safety is ensured; and a good action matching effect can be guaranteed, so that the vehicle retaining column rises and falls timely.

Owner:JIANGSU HUAKAI MINING TECH

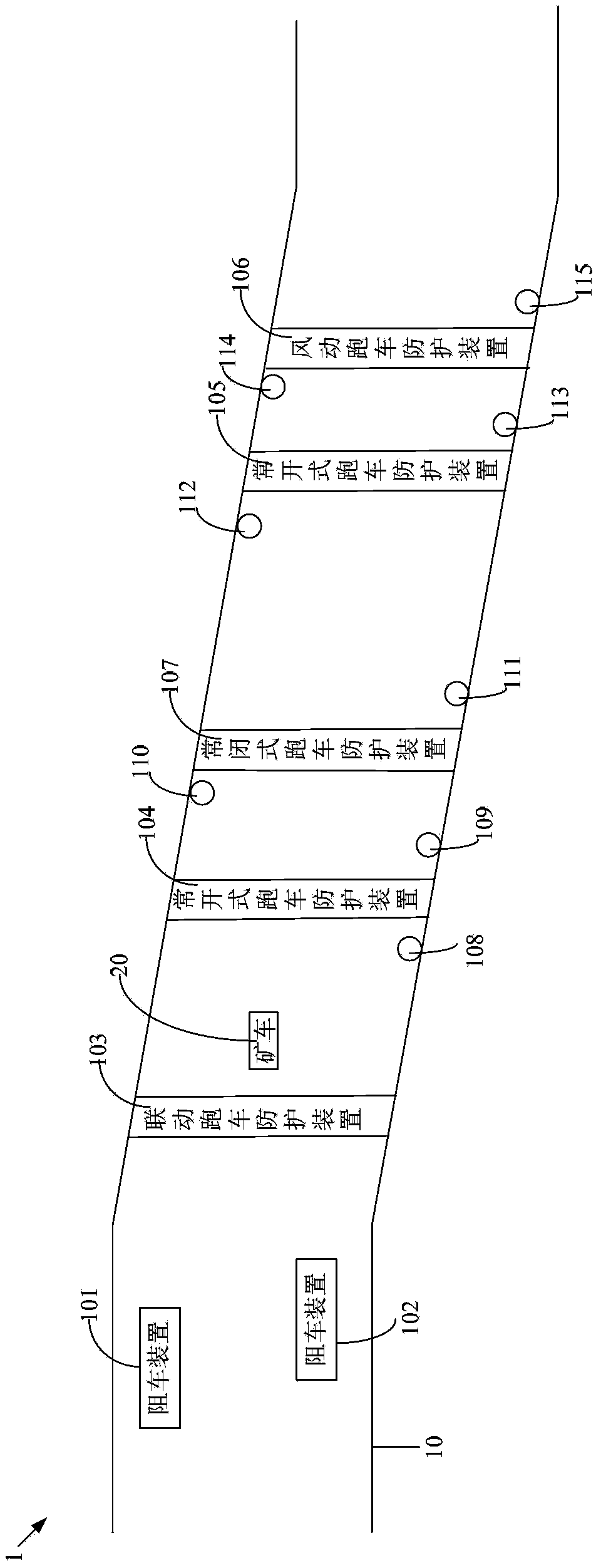

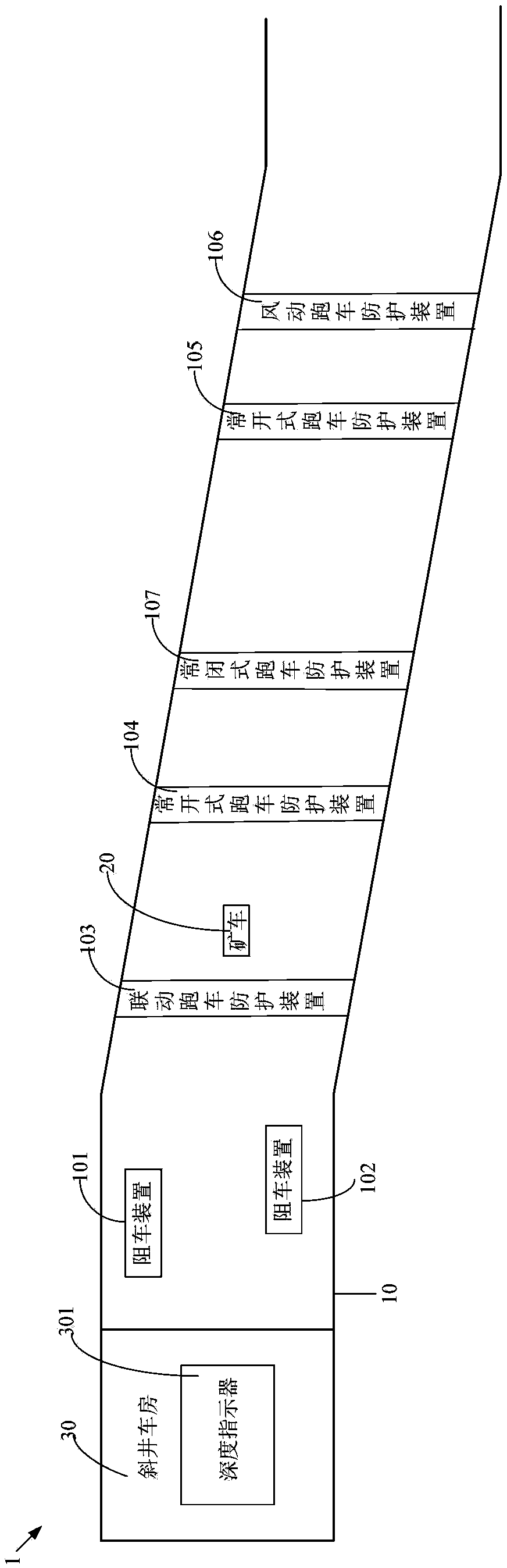

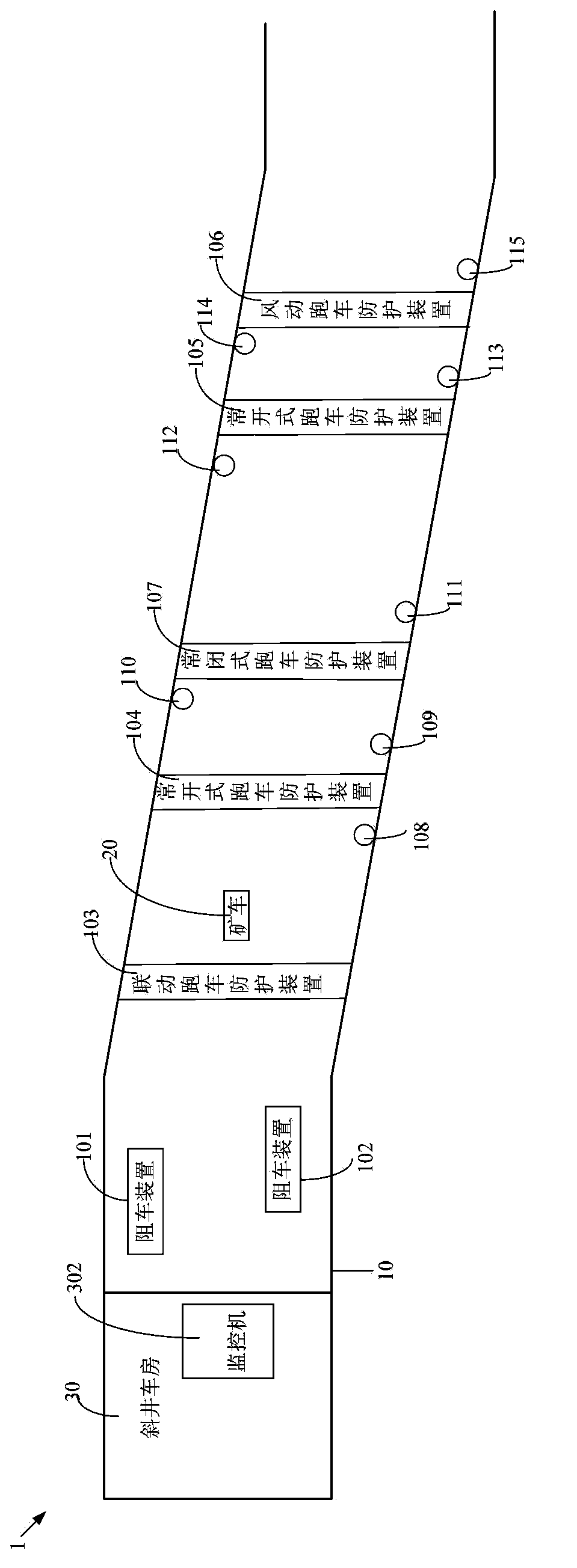

Inclined drift rail transport protection system

The invention provides an inclined drift rail transport protection system which comprises at least one device of a cart stopping device, a linkage cart running protection device, a normally-open cart running protection device and a pneumatic cart running protection device which are arranged along an inclined drift rail. The system further comprises a normally-closed cart running protection device arranged along the inclined drift rail, sensors corresponding to the devices are arranged on the inclined drift rail and / or a depth indicator, and the sensors are used for transmitting sensed mine cart running speed to corresponding devices to enable the devices to block and protect a cart when the running speed of the cart exceeds the normal range. The inclined drift rail transport protection system is used for improving transport safety of the inclined drift rail.

Owner:HUAINAN MINING IND GRP

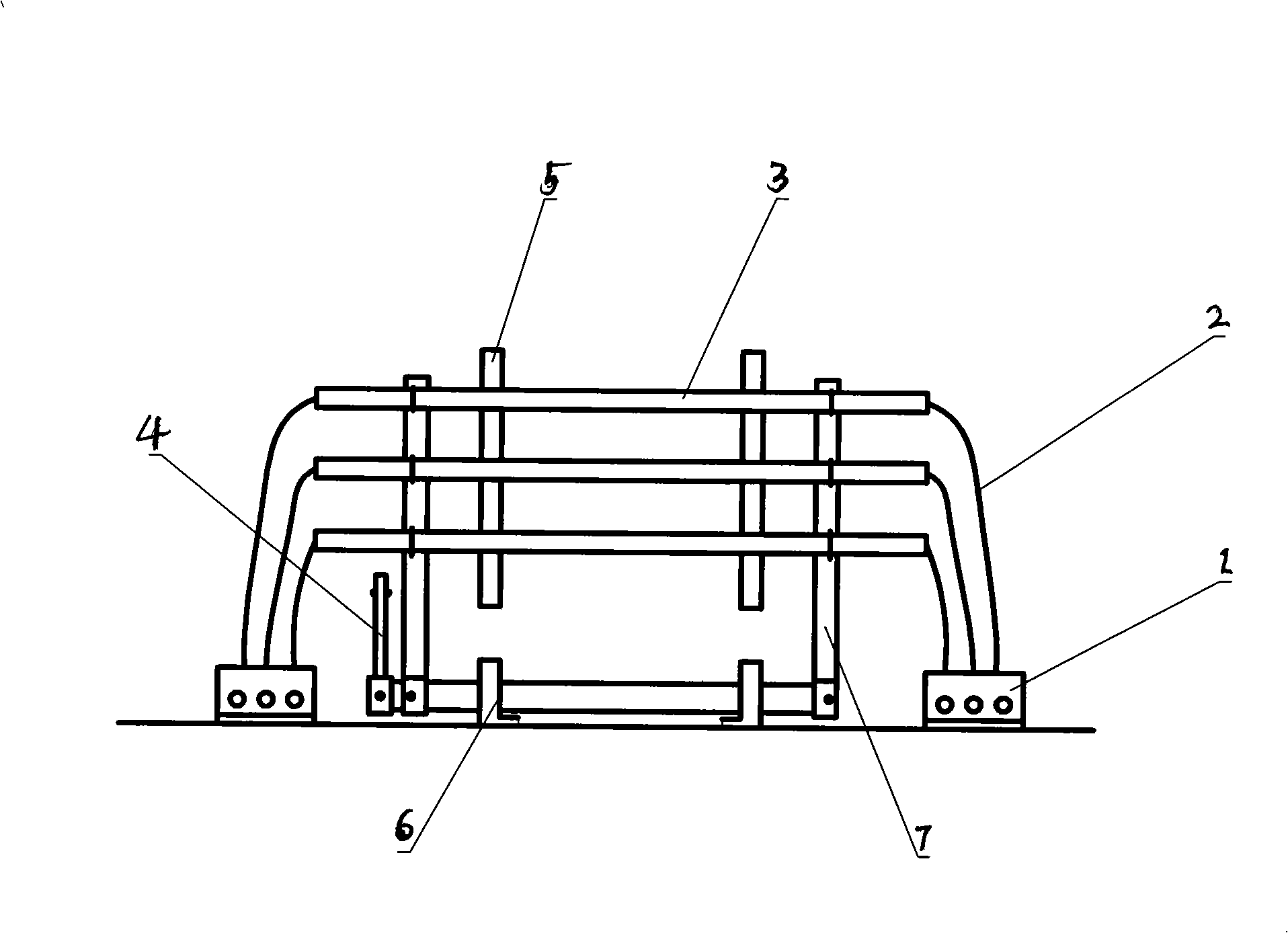

Bottom lifting type U-shaped tram guard

InactiveCN101704374AGuaranteed to open in placePositive railway stopsArchitectural engineeringWire rope

A bottom lifting type U-shaped tram guard comprises a buffer, a steel cable, and a baffle screen which comprises a baffle screen framework and a connecting support; a baffle screen receiving chamber is arranged below a tram road of a well lane; a track bridge which can be opened and closed is arranged above the baffle screen receiving chamber; a baffle screen lifting mechanism is arranged on a side part of the baffle screen receiving chamber; the baffle screen is provided with a left part, a right part and a middle connecting trough plate; the connecting trough plate is provided with a notch through which the tramcar lifting wire cable passes when the baffle screen lifts; a reinforcing plate is arranged on the edge of the notch of the connecting trough plate; and the connecting trough plate is provided with anti-slip teeth which are vertical to the connecting trough plate and prevents the baffle screen from slipping from a locked tramcar. A robe pile is arranged on a connecting position between both sides of the connecting trough plate and the baffle screen framework. In the situation that the lifting wire cable presses the tram guard, the tram guard is guaranteed to open in place, and the application range of the bottom lifting type U-shaped tram guard is expanded; and the bottom lifting type U-shaped tram guard can be applied in an endless rope, a shuttle tram or double-rail hoist, and has good application prospect.

Owner:靳慧民 +1

Normally closed type inclined alley stopping device

InactiveCN101397018AReduce investmentEliminate the potential for injuryPositive railway stopsStops deviceEngineering

The invention discloses a car lug of a normally-closed inclined tunnel used for the safe transporting measure of the inclined tunnel of a coal mine, which comprises a normally-closed duplex car lug, a car lug bar of the normally-closed inclined tunnel, an interlocking pneumatic control box and a connection pipeline. The car lug has simple structure and is convenient to be maintained; interlocking control is adopted, therefore, devices are mutually closed and locked, thus being capable of preventing the running-way of the inclined tunnel reliably or stopping the running-way reliably and timely once the running-way happens; the original compressed air on the spot under a well is used as power, therefore, the car lug of the invention is safe and reliable, and the capital investment is reduced.

Owner:无锡市锡湖液压气动机械有限公司

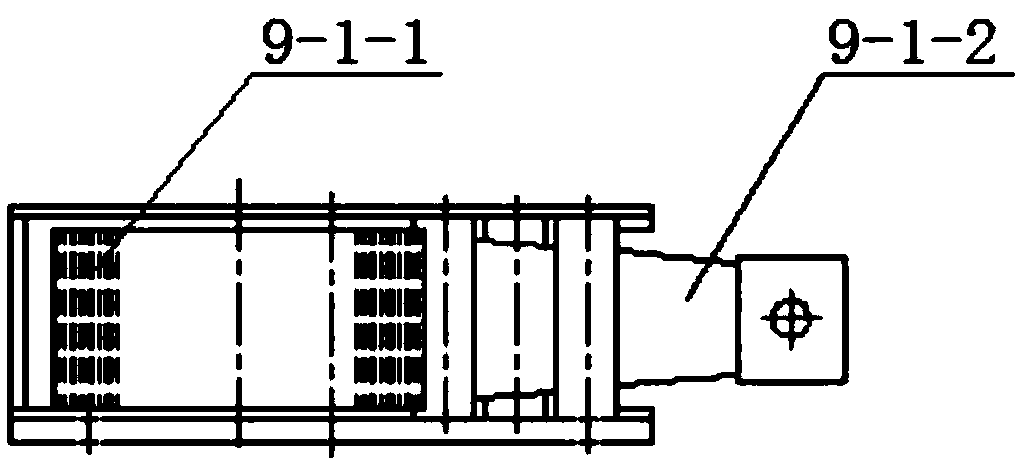

Torque-changeable buffer power absorber

InactiveCN103273943APrevent easy rope breakageDisadvantages of preventing fallPositive railway stopsCopperElectrical and Electronics engineering

Disclosed is a torque-changeable buffer power absorber. The torque-changeable buffer power absorber comprises a rope mechanism and a buffer power absorber. The rope mechanism is installed on one side of an installing seat; the buffer power absorber is installed on the other side of the installing seat; a rotating disc of the rope mechanism is connected with the buffer power absorber through a rotary shaft; an extrusion plate of the buffer power absorber is installed on the rotary shaft through threads; a threaded shaft section, matched with the extrusion plate, of the rotary shaft is located between the tail end position when a spring is in an original state and the position where the extrusion plate is located when the spring reaches a maximum compressing state. The torque-changeable buffer power absorber has the advantages of overcoming the defects that the rope of the prior power absorber is easy to break and off the road because the spring is dynamically compressed, bringing positive effect for reducing mine accident losses and guaranteeing personal safety and production safety, being easy to assemble and maintain, and overcoming the defects that being matched with a friction plate, the power absorber is easy to rust and is fixedly combined with the friction plate because a non-asbestos material based on copper and 65 Mn are adopted as matched friction materials.

Owner:DALIAN JIAOTONG UNIVERSITY

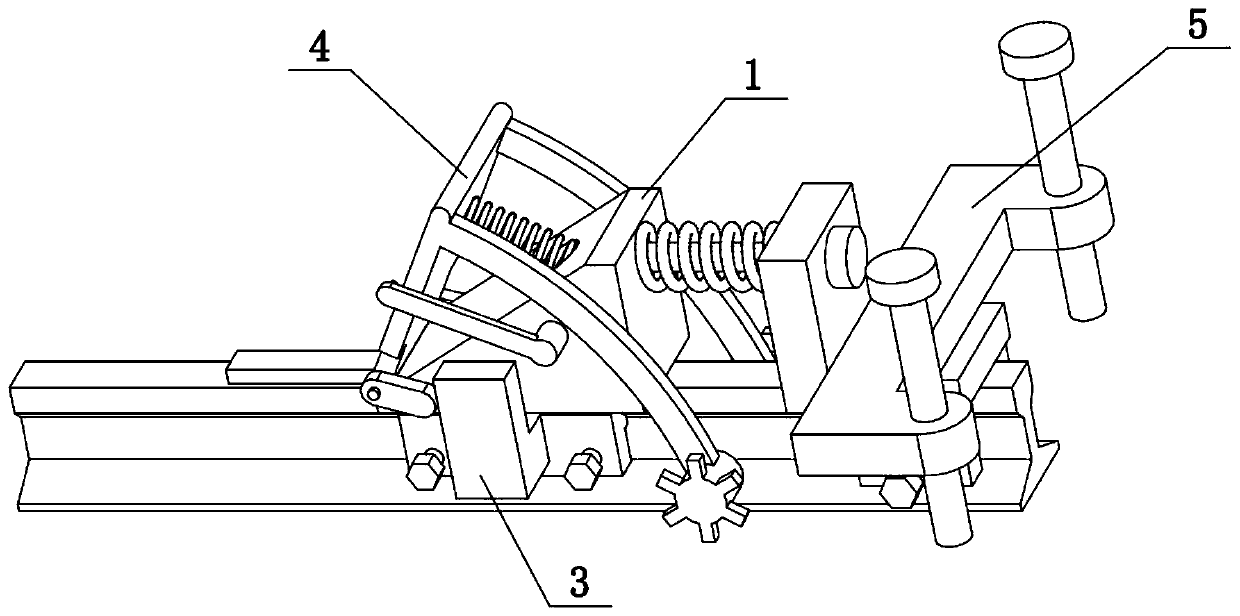

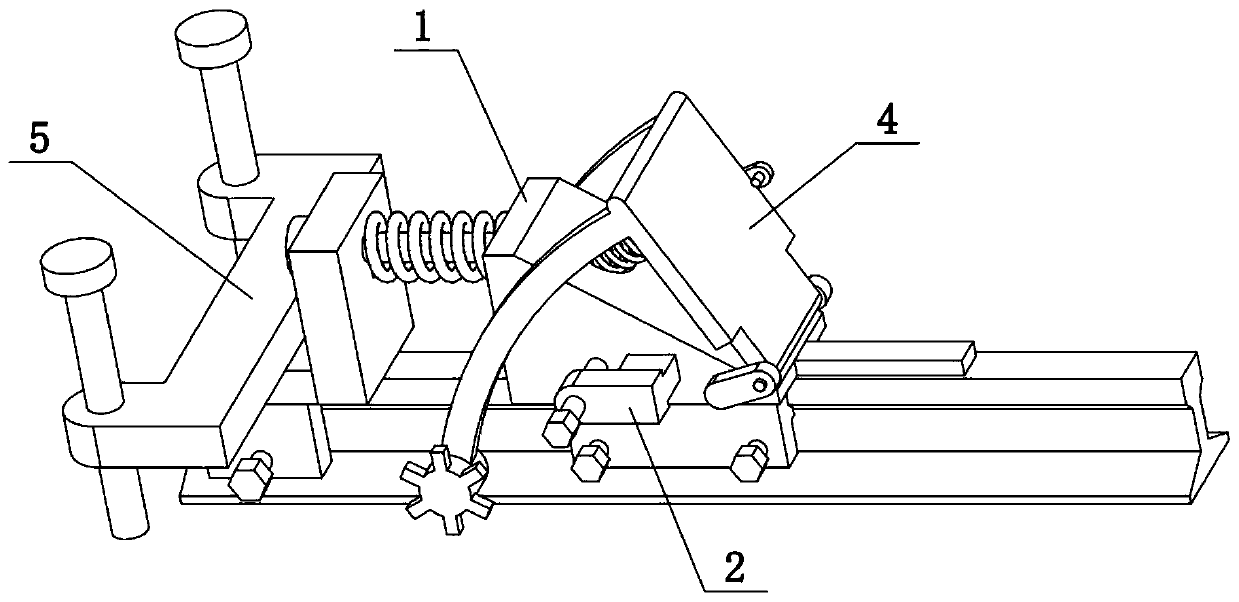

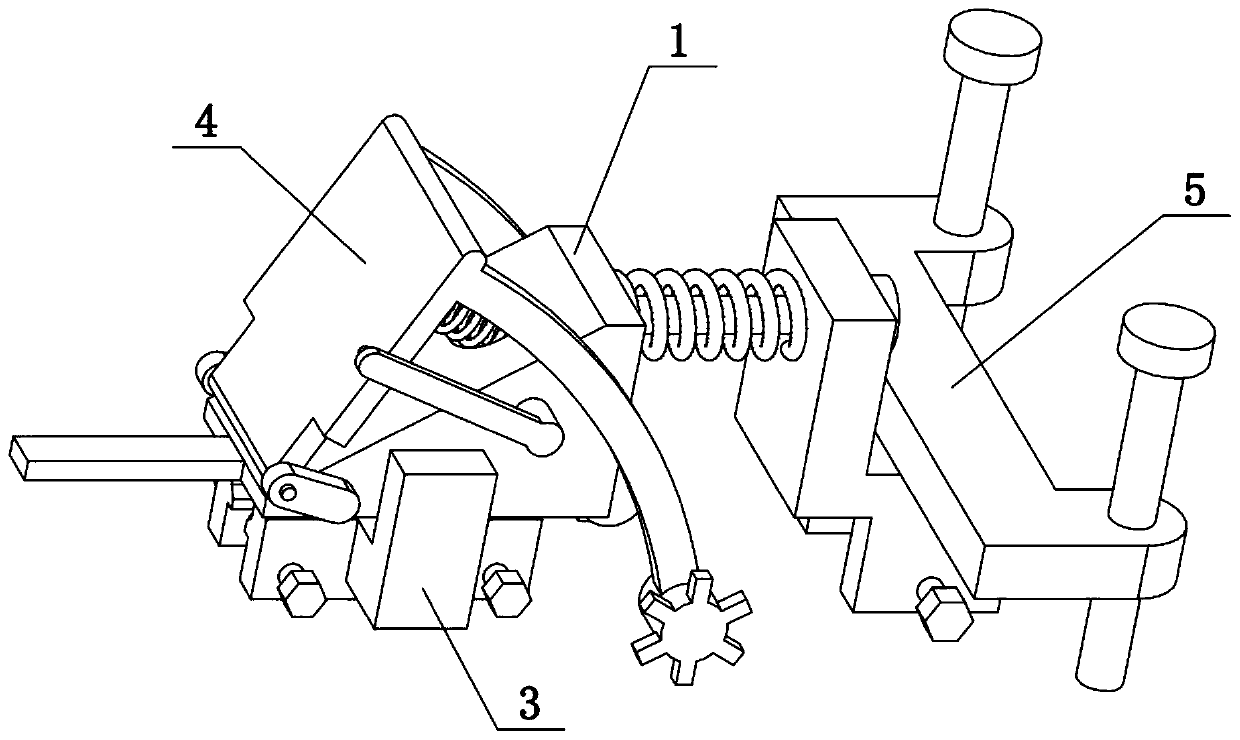

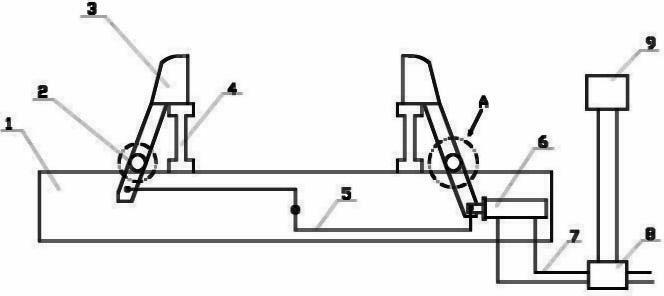

Locomotive vehicle anti-running device

ActiveCN107054403APlace automatic intelligenceAvoid operabilityPositive railway stopsAutomotive engineeringMotive power

The invention relates to a locomotive vehicle anti-running device which comprises a touch mechanism, a transmission mechanism, a power output mechanism and an iron shoe mechanism. The touch mechanism comprises a collision structure and a base, wherein the collision structure collides with a locomotive when the locomotive runs; the transmission mechanism comprises a transmission shaft which is fixedly connected with the base, and the transmission shaft transmits power to the power output mechanism; the power output mechanism comprises a pull rod and a gear rack mechanism for adjusting the transmission ratio; and the iron shoe mechanism comprises a mounting seat for mounting an iron shoe and a rack for allowing the mounting seat to move in accordance with a set track, and a track groove matched with the mounting seat is formed in the rack, so that the iron shoe is placed above the track and breaks away from the track, and the pull rod is in transmission connection with the mounting seat. Automatic intelligent placement of the iron shoe can be realized, the locomotive vehicle anti-running device is clamped between wheels, thus friction force of the locomotive with the track is increased to achieve parking, the problems of worker misoperation or forgetting and high labor strength in the prior art can be solved, in addition, the locomotive vehicle anti-running device only adopts the pure mechanical mechanisms, and the structure is also simple.

Owner:ZHENGZHOU ZHILIANG ELECTRONICS SCI & TECH CO LTD

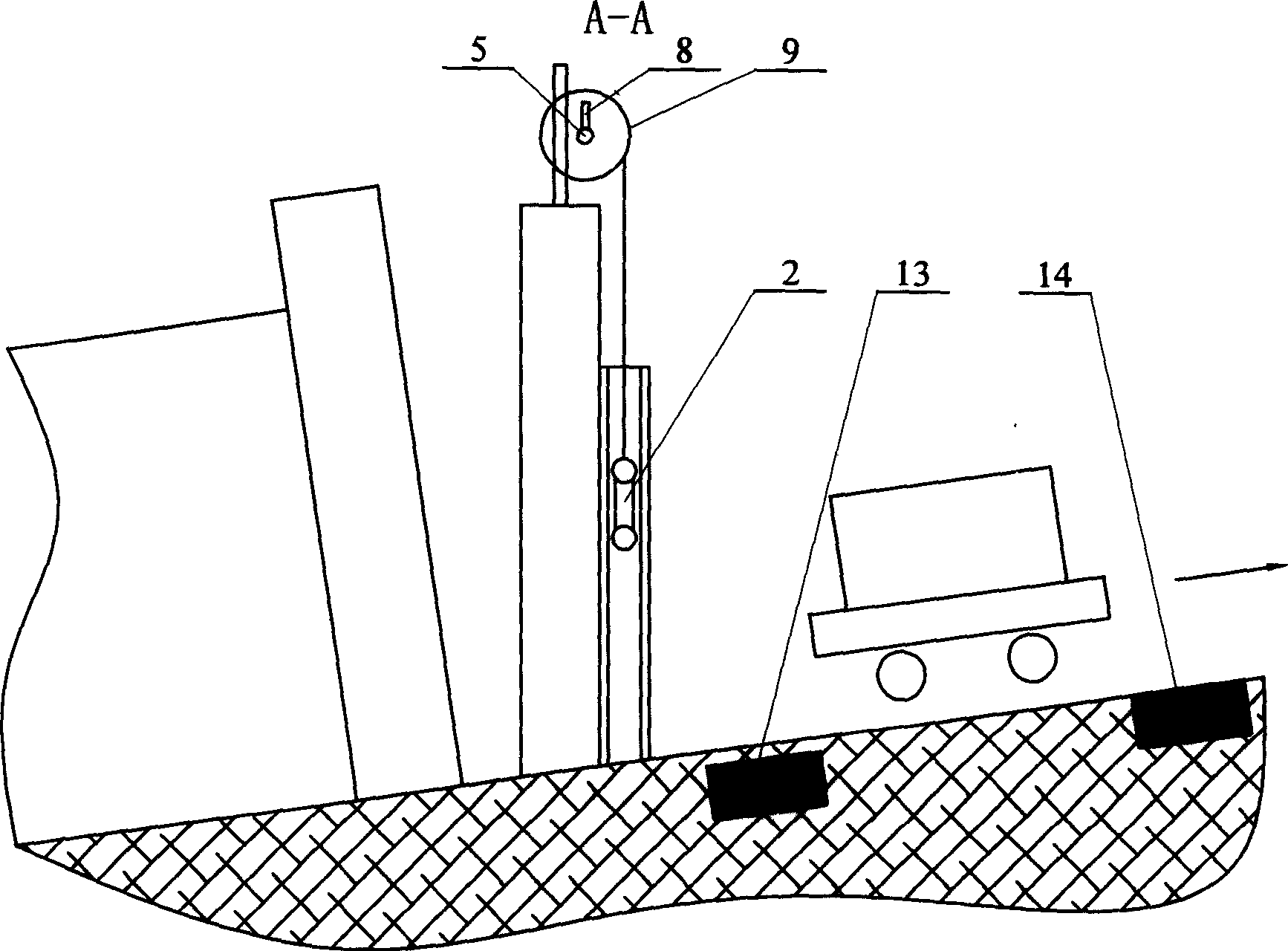

Inclined shaft safe door device preventing equipment sliding

InactiveCN1603187AWork reliablyReasonable designPositive railway stopsReduction driveElectric machine

The invention relates to an inclined shaft sports car prevention safety door device, concretely relates to an mine inclined shaft safety device prevented mine car from automatically sliding back to the inclined shaft. Feed-through shaft is set at the top of the main frame. Roller is fixed at the feed-through shaft and did coaxial rotation with it. Its one end is connected to the output shaft of the electric machine by the speed reducer. The up end of the wire rope is twined at the roller, and the down is fixed at the top of the insurance balustrade. It is set in the vertical two slide ways. The plane with the two slide ways is paralleled with the plane with the main frame. After the mine car is ran in the inclined shaft and passed through the main frame, the electric machine is rotated along the clockwise, and drove the feed-through shaft to rotate, the insurance balustrade is put down. When the mine car is run away, the insurance balustrade is rose up. The insurance balustrade is put down at once when the mine car is run. This can avoid that the protective measures can not be brought into effect in time after the accident happened. And the operation of rising up and putting down the protective device are not need handwork.

Owner:周荣刚

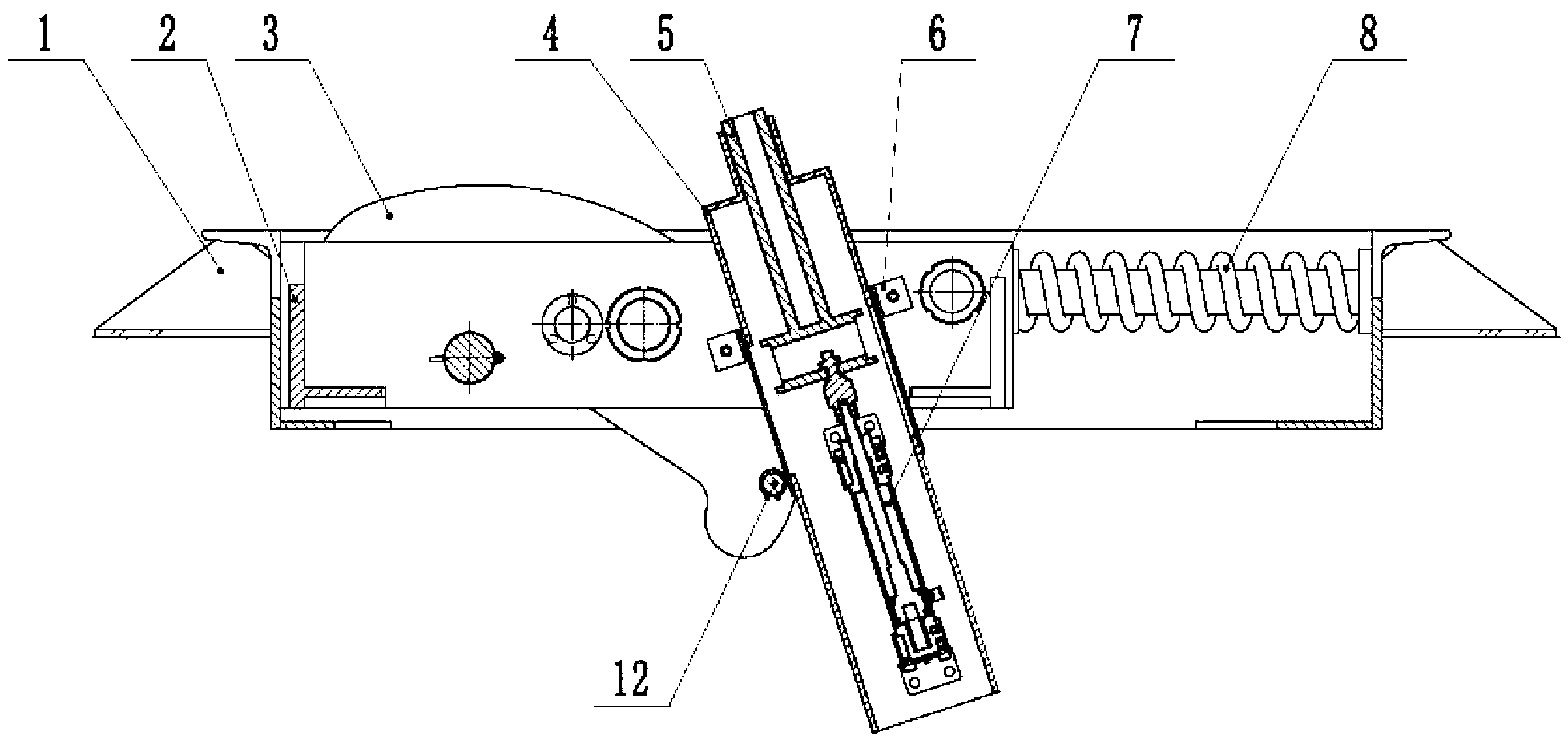

Normally-closed type buffer tramcar retarder

Provided is a normally-closed type buffer tramcar retarder. The normally-closed type buffer tramcar retarder comprises a mounting base, a movable frame, a journal sticking mechanism, a trigger mechanism and a buffer mechanism, wherein the movable frame is installed inside the mounting base through stopping shafts and guiding base shafts, the movable frame can move forward and backward in the mounting base, one end of the movable frame abuts against the mounting base through buffer springs, the journal sticking mechanism is composed of journal sticking hooks, journal sticking hook rotary shafts and self-locking devices, and the trigger mechanism is composed of a trigger base, a trigger, an air cylinder and trigger base rotary shafts. The normally-closed type buffer tramcar retarder has the advantages that the structure is simple and compact, and compared with a tramcar blocking column, the occupied space is reduced and cost is low. Due to the fact that the movable frame and a fixed frame are connected through springs, buffer tramcar retard is achieved. Due to the fact that the normally-closed type buffer tramcar retarder is in a closed state all the time when in a normal condition, the requirement that a tramcar blocking device needs to be in a normally-closed state is met. Due to the fact that the normally-closed type buffer tramcar retarder can retard a rear axle of a tramcar, the tramcar is prevented from tipping.

Owner:DALIAN JIAOTONG UNIVERSITY

Anti-slipping device of freight train

The invention relates to the field of freight, in particular to an anti-slipping device of a freight train. The device comprises an anti-slipping seat, a tensioning rod, a clamping mechanism, a ground inserting mechanism and an additional stabilizer; when freight train wheels are pressed on a wheel press plate, an inclined face seat is fixed, and the inclined face seat is used for preventing the freight train from slipping; when the freight train wheels are pressed on an inclined plate and press down the inclined plate, two bottom cylinders and a plurality of ground inserting teeth are inserted into the space among gravel around a rail, the inclined face seat is further prevented from moving, and thus the stability of the inclined face seat is improved; if the inertia of the freight train wheels is large so as to cause the movement of the inclined face seat, the additional stabilizer can carry out tertiary protecting to prevent the inclined face seat from moving too much; and the device can be applied to the rails with different width specifications. According to the device, the tensioning rod is connected to the anti-slipping seat in a slipping mode in the front and back direction, the clamping mechanism is fixedly connected to the front end of the tensioning rod, and the ground inserting mechanism is hinged to the left end of the anti-slipping seat.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

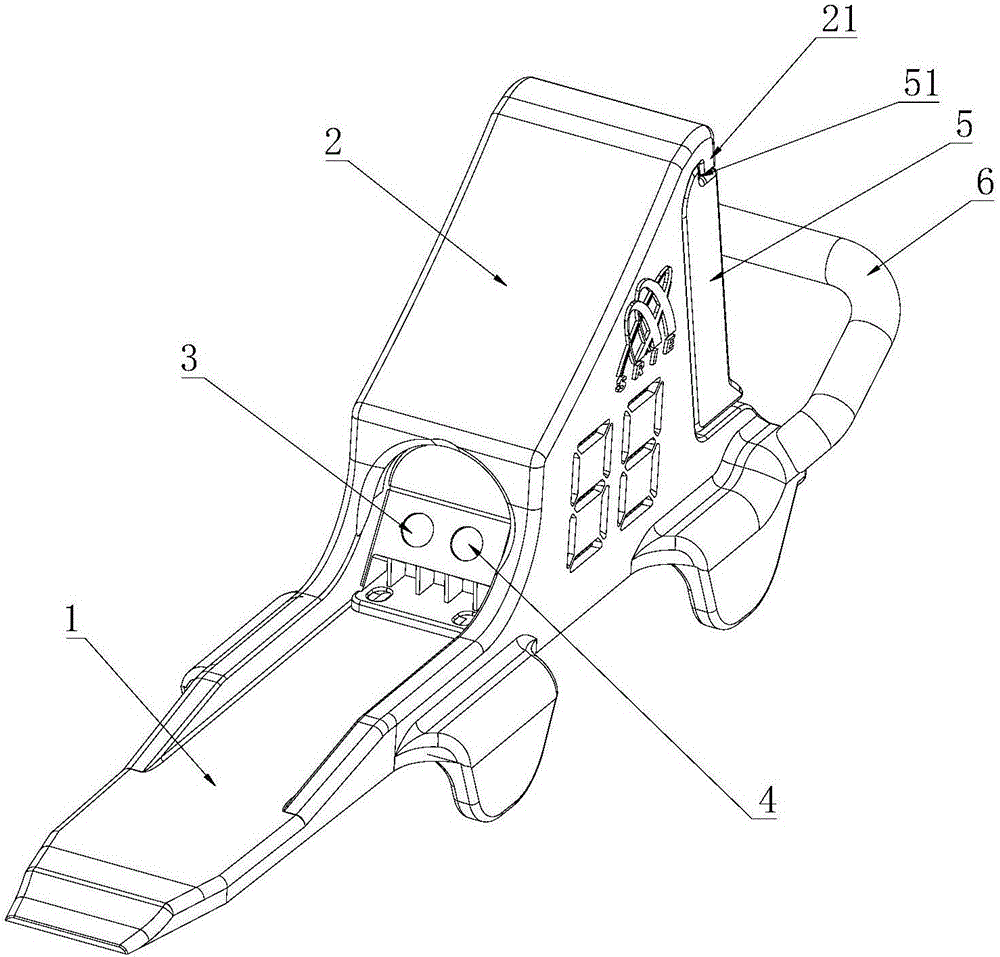

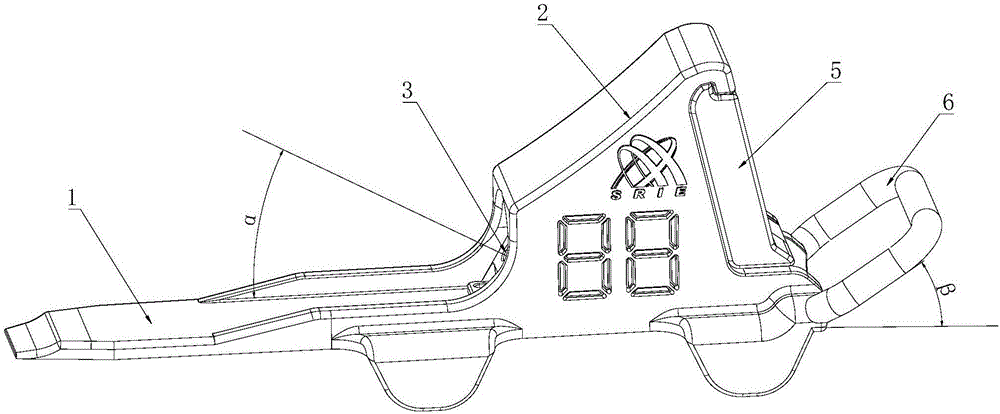

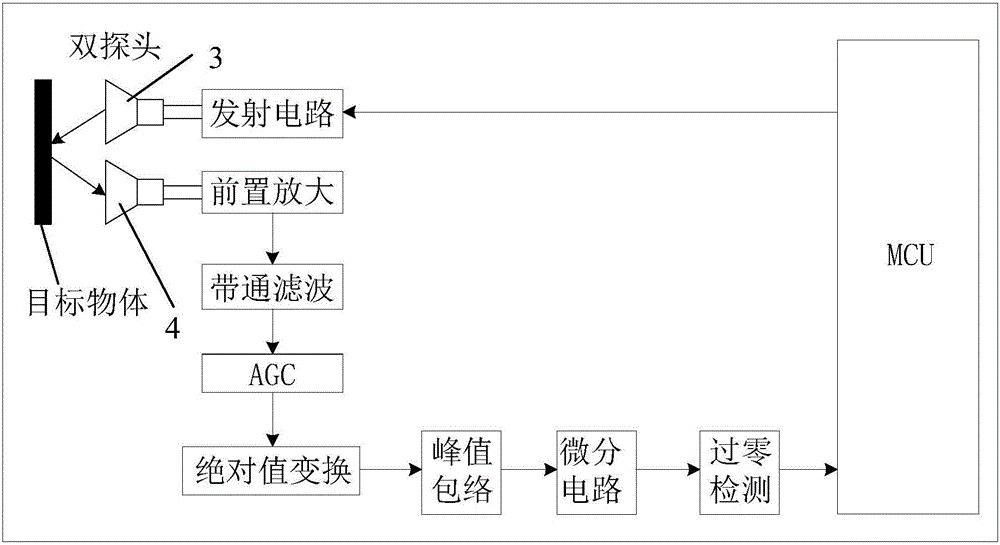

Intelligent dual-probe iron shoe with precise detection function

ActiveCN106218667AAnti-slipAvoid issues such as labor intensity of inspectionsPositive railway stopsAcoustic wave reradiationComputer moduleEngineering

The invention discloses an intelligent dual-probe iron shoe with a precise detection function. The intelligent dual-probe iron shoe with the precise detection function comprises a shoe body, a detection module, a wireless communication module, a control module and a battery, wherein the detection module, the wireless communication module, the control module and the battery are arranged on the shoe body. The shoe body comprises a bottom part and a head part; and the detection module comprises an emitting probe and a receiving probe. The emitting probe is used for emitting a detecting signal used for detecting a target object; the receiving probe is used for receiving the detecting signal reflected by the target object; and the detecting signal is sent to a monitoring terminal through the wireless communication module after being processed by the control module. According to the intelligent dual-probe iron shoe with the precise detection function, the emitting probe and the receiving probe are arranged, detecting signals are sent out by the emitting probe continuously and reflected to the receiving probe by a train, the emitting probe is not affected by aftershock, detecting dead zones are greatly decreased, the detecting precision is improved, the position of the train can be better detected, the purpose of preventing slip of the train is achieved, and the problem that the labor intensity of workers is intensified due to false detection of the intelligent iron shoe is avoided.

Owner:GUANGZHOU SINORAIL INFORMATION ENG

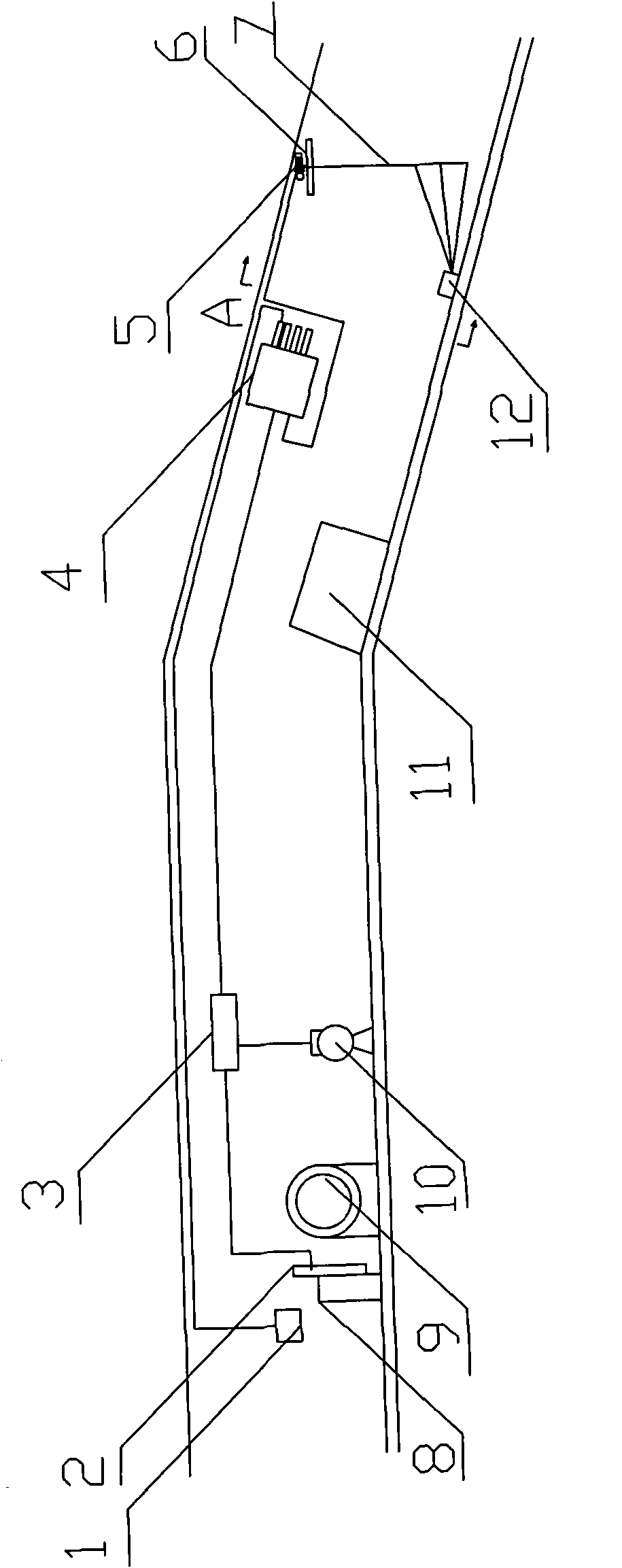

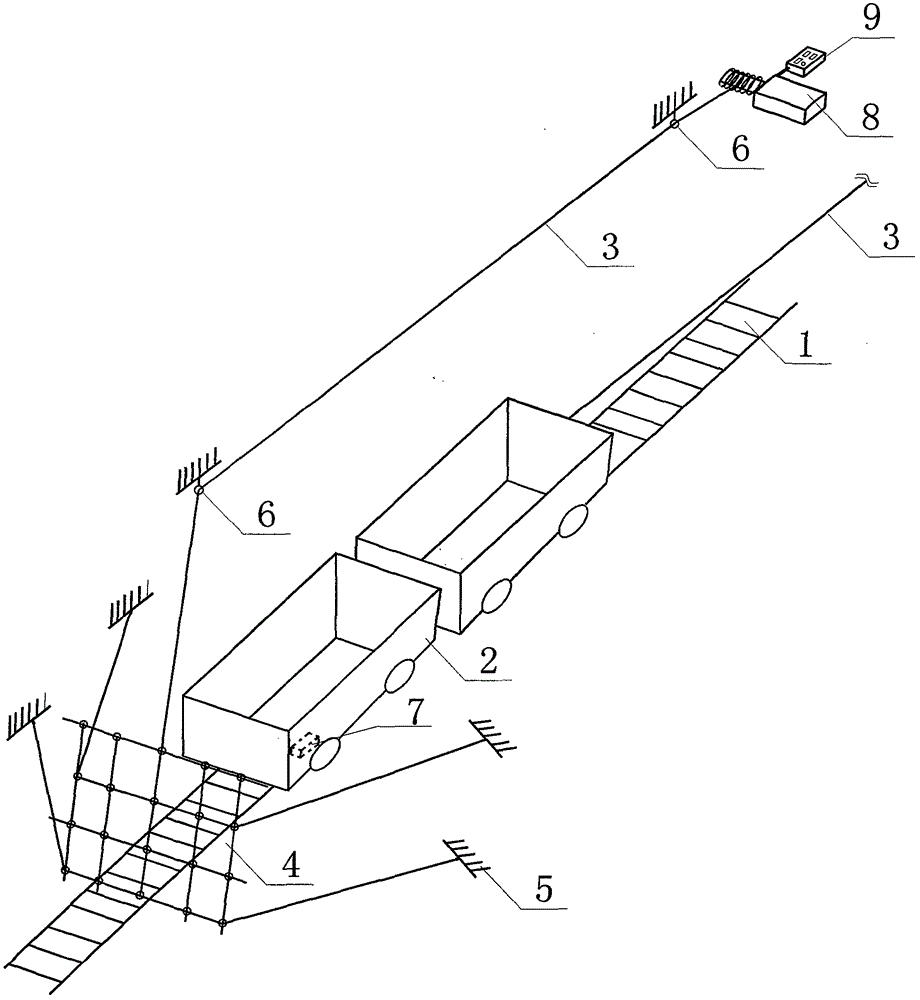

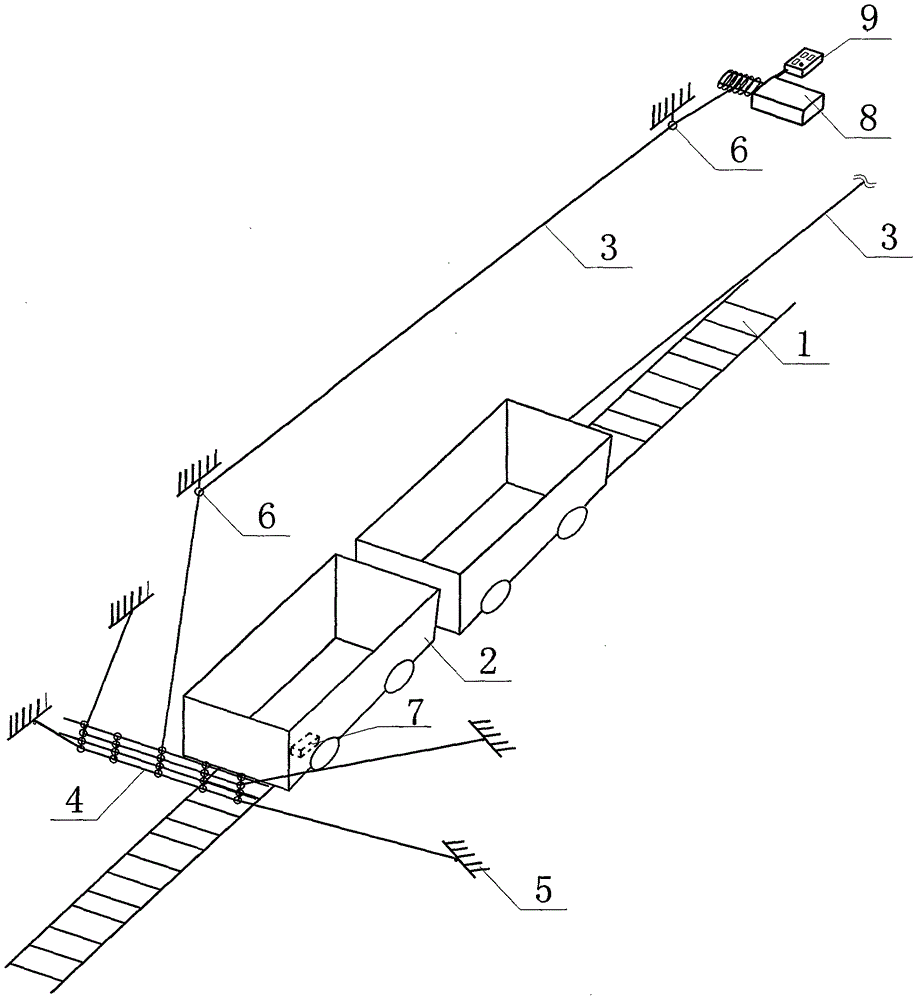

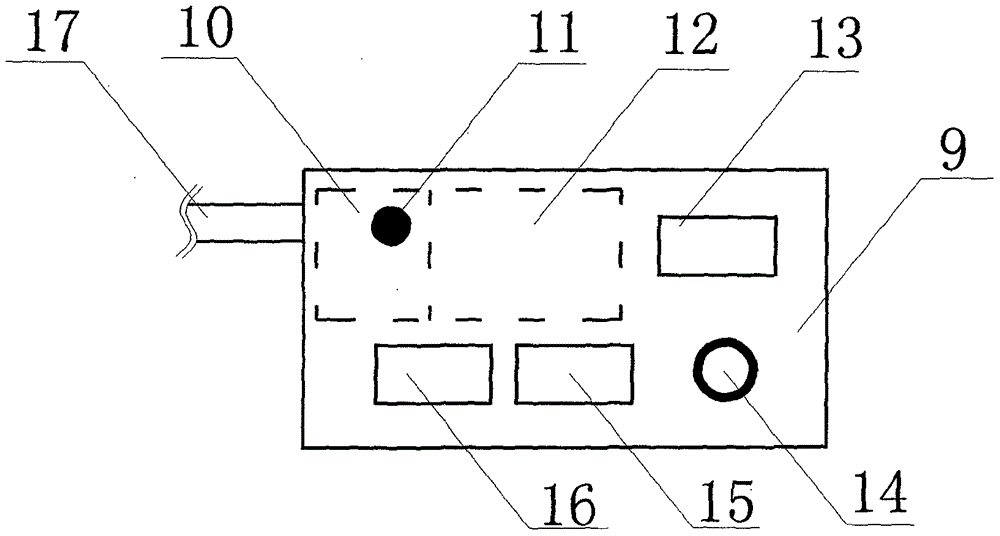

Anti-car-sliding system of inclined roadway in coal mine shaft

InactiveCN107176181AAchieve blockingRealization can be achieved by manual and automatic blockingPositive railway stopsAutomatic controlMotor controller

The invention relates to an anti-sports car system for an inclined lane in a coal mine, which is mainly applicable to the technical field of underground transportation safety facilities in a coal mine. , a speed sensor, a small mining winch, and an inclined road anti-car system console; its characteristics are: a speed sensor is installed on the wheel shaft of the first mine car, and the left and right sides of the car-blocking wire mesh are respectively anchored in the surrounding rock of the inclined road. The two ends of the wire rope are respectively connected to the car-stop wire mesh and the small mining winch. The console includes a speed signal receiver, an automatic control button, a manual control button (up, down), an emergency stop button, a main control circuit board and a motor controller. Its advantages: this system can realize the blocking of the accident mine car manually and automatically. Once the down speed of the accident mine car exceeds the preset threshold value, the system will start the motor and automatically lower the car wire mesh. This system is safe and effective, simple in structure and easy to install , Strong adaptability and high promotional significance.

Owner:LIUPANSHUI NORMAL UNIV

Steel belt type buffer variable force energy-absorbing device for preventing cart from running out for inclined shaft

InactiveCN102582655AImprove buffering effectEasy to interceptPositive railway stopsSheet steelEngineering

The invention discloses a steel belt type buffer variable force energy-absorbing device for preventing a cart from running out for an inclined shaft, belonging to the field of mining equipment. The device comprises a cart baffling fence, a variable force energy-absorbing device and a connecting device. The cart baffling fence comprises a plurality of buffer steel wire ropes, C-shaped casing pipes and suspending chains. The variable force energy-absorbing device comprises a bottom plate combined part, a lateral plate, an upper supporting rod, a mandrel, idler wheels, a screw rod, a nut, a sliding block, a lower supporting rod, a top plate, a top cover and a steel belt. The screw rod is meshed with the nut and connected with the sliding block by bolts and the pressing pins. The nut is arranged between the two lateral mandrels close to the top plate and connected with the lateral plate and the top plate by bolts. The screw rod is meshed with the nut and connected with the sliding block by bolts and pressing pins. The sliding block is semicircular and tightly glued on the steel belt. The steel plate passes through the middle parts of the two idler wheels, and the left end of the steel plate is connected with the steel wire ropes by the connecting device. The steel belt type buffer variable force energy-absorbing device is adjustable in buffering power and reliable in property, and the potential safety hazards caused by cart running out can be further reduced when the steel wire ropes are broken in inclined drifts of coal mines in the conveying process.

Owner:徐州泰荣煤矿设备有限公司

Pneumatic car arrester

InactiveCN102180186AOvercome defectsEasy to troubleshootPositive railway stopsElectric controlElectromagnetic valve

The invention discloses a pneumatic car arrester which comprises a mounting bracket, fixed axes, car arresters, a reverse connecting rod, a cylinder, an electromagnetic valve and an electric control box, wherein the mounting bracket is arranged below a track, the fixed axes are arranged on the mounting bracket at two sides of the track, respectively provided with one car arrester, and movably connected with the car arresters, one end of one car arrester is connected with the cylinder, one end of the other car arrester is connected with the cylinder by virtue of the reverse connecting rod, andthe electromagnetic valve is arranged on a pipeline between the cylinder and the electric control box. The pneumatic car arrester can be used for overcoming the defects of the prior art, is convenient to maintain, low in cost, convenient to operate and manage and reliable for running, and has good industrial application prospects.

Owner:焦作煤业(集团)新乡能源有限公司

Mine safety device

InactiveCN102229341AAvoid causing "flying car" phenomenonSafe and reliable workWinding mechanismsPositive railway stopsPull forceVehicle frame

The invention discloses a mine safety device. A horizontal traffic lane is provided with a winch, a first support and a second support; one end of a steel wire rope is connected with the winch, and the other end of the steel wire rope is used for connecting a mine vehicle; the steel wire rope between the first support and the second support is connected with a tension force induction rope; the other end of the tension force induction rope is conneced with the rotary arm of a kick-up block arranged on an inclined shaft; a return spring is installed between the vehicle blocking plate and a vehicle blocking frame of the kick-up block; and when the steel wire rope is not connected with the mine vehicle, the steel wire rope is not stressed, the return spring on the vehicle blocking plate enables the vehicle blocking plate to be in a vehicle blocking state, only when the mine vehicle and the steel wire rope are connected well, the steel wire rope is stressed, and the vehicle blocking state can be released for the vehicle blocking plate. The device does not need manual operation and proffesional motive power, and the mine vehicle which is not connected with the steel wire rope can be prevented from sliding downward along the inclinded shaft to further hurt people below the inclined shaft, and the vehicle sliding problem which puzzles people in the mine well over the years is solved easily.

Owner:单玉川

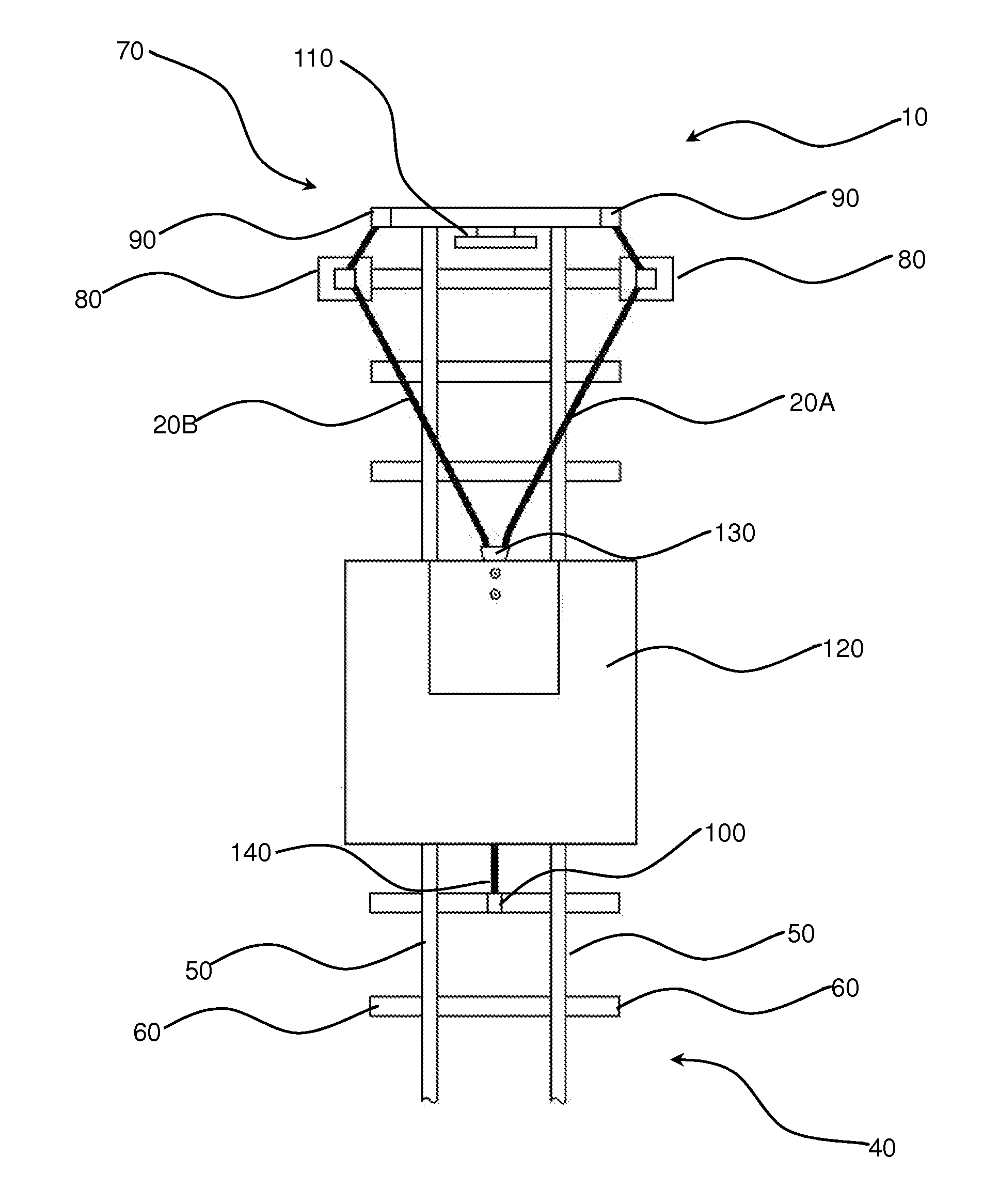

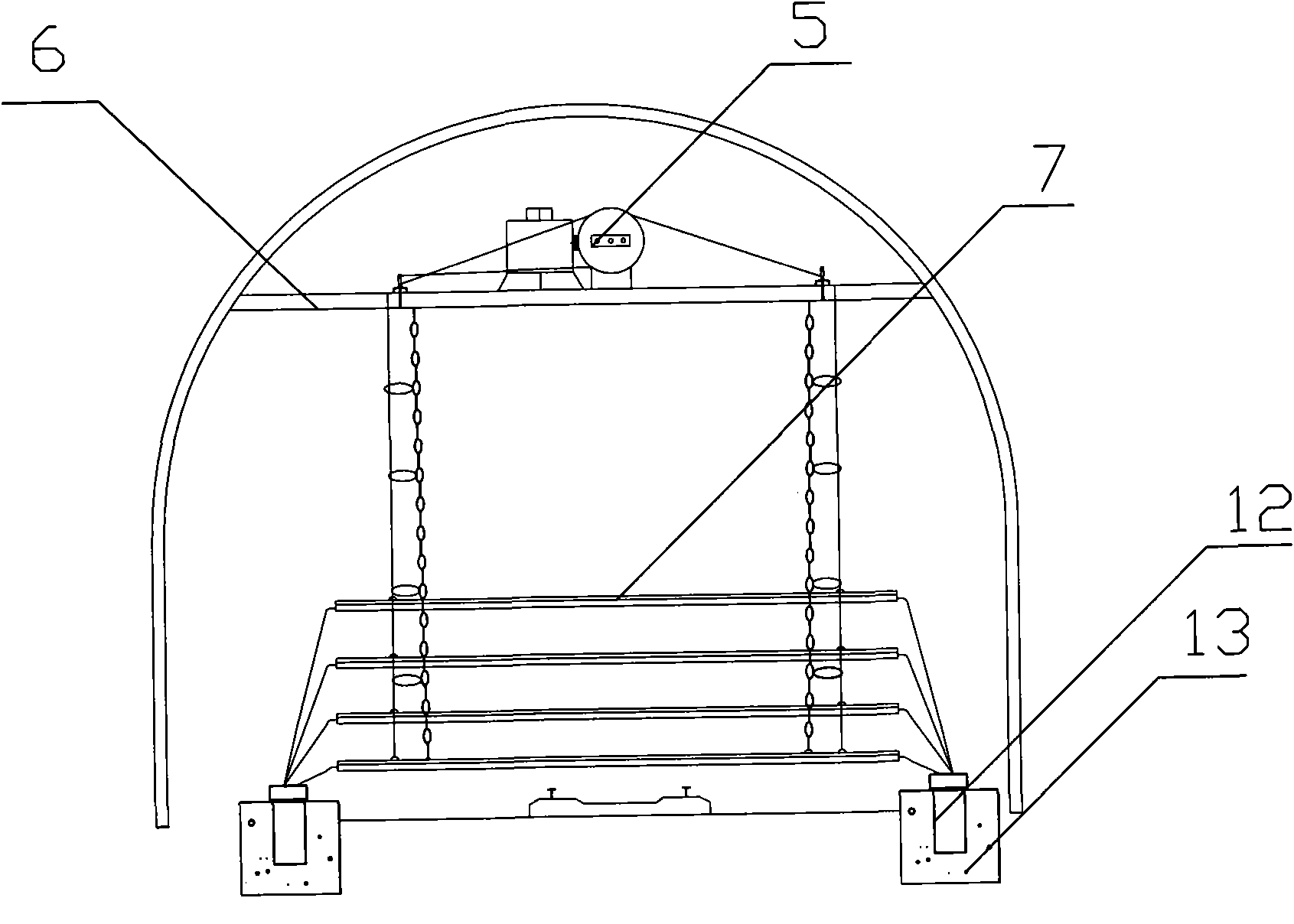

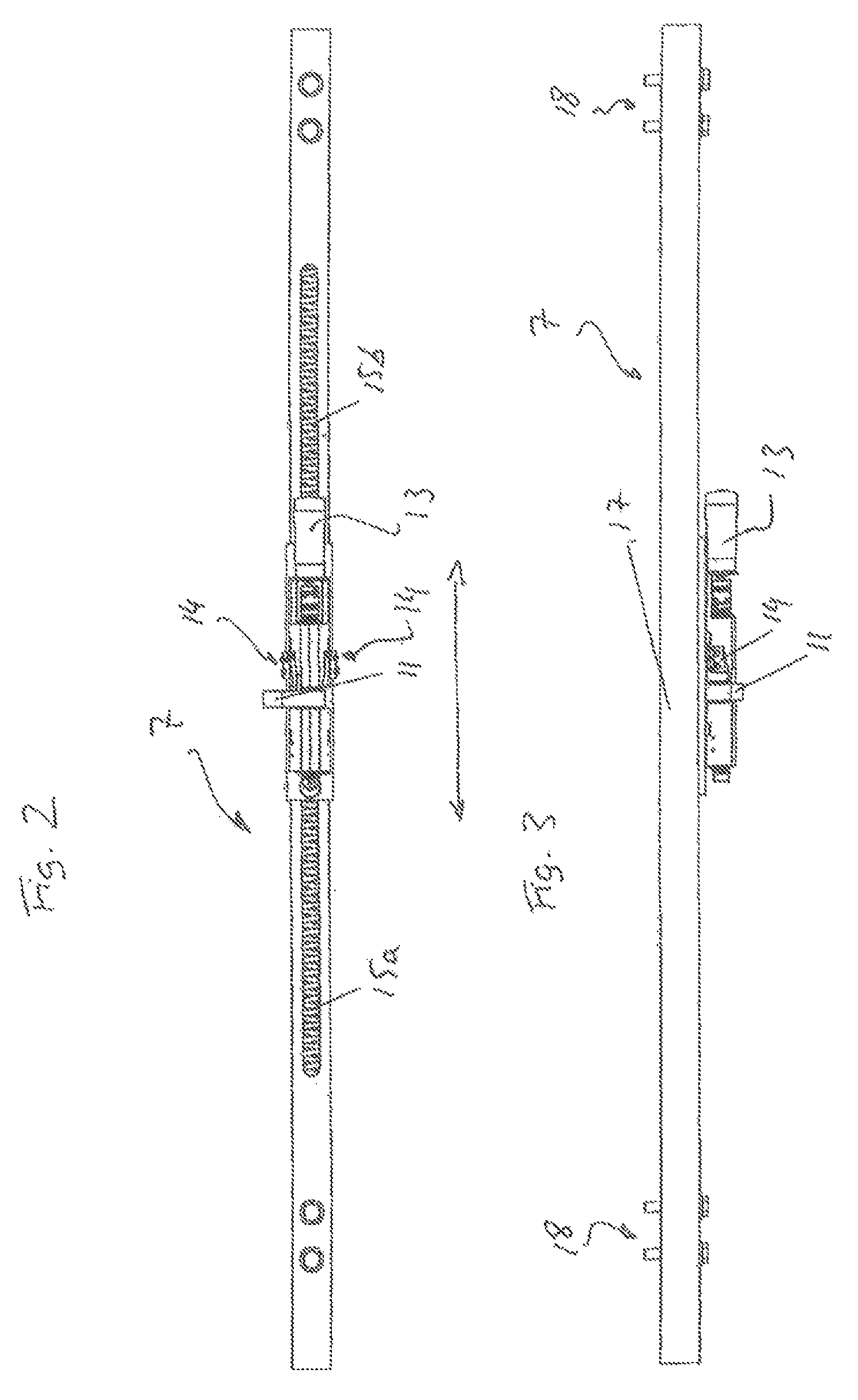

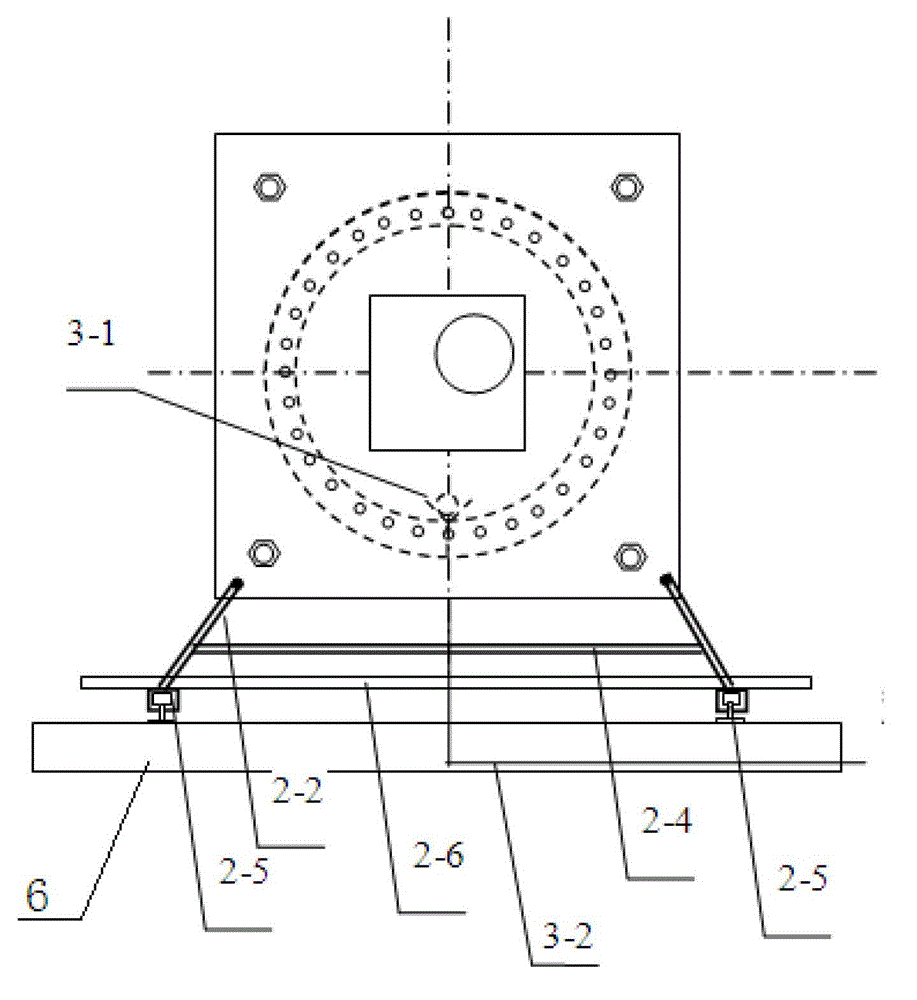

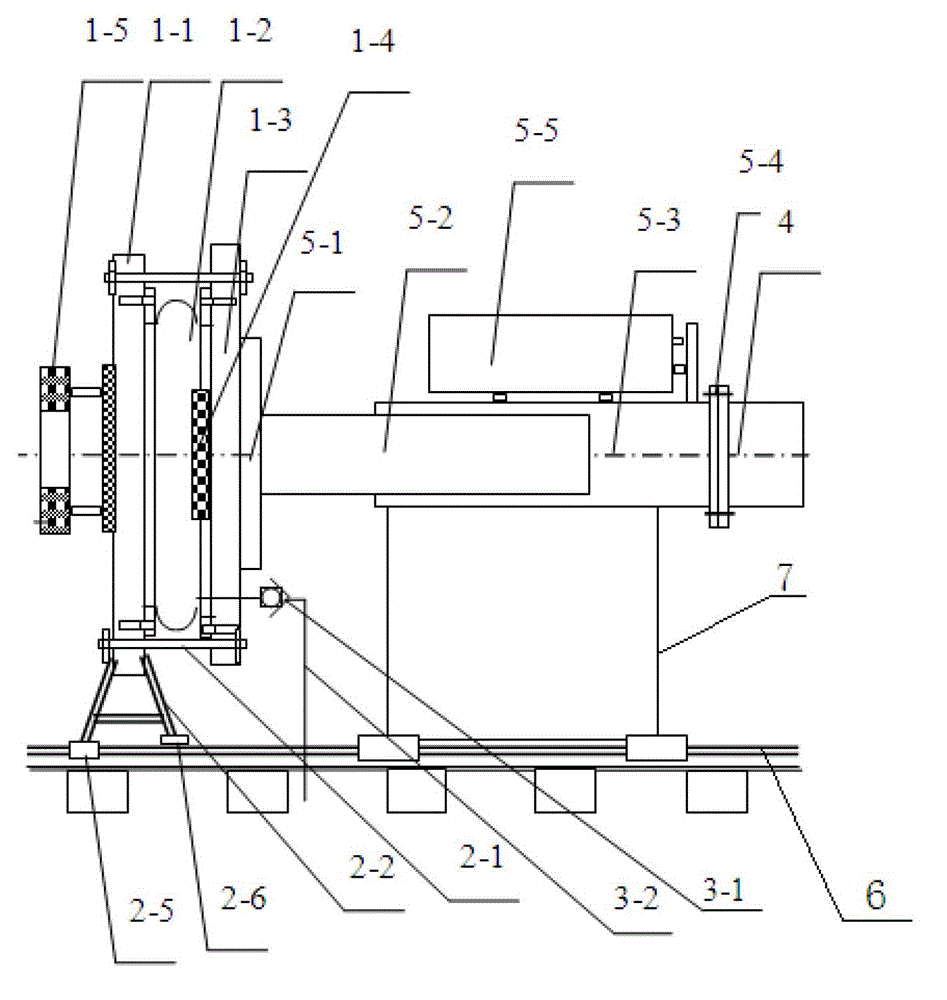

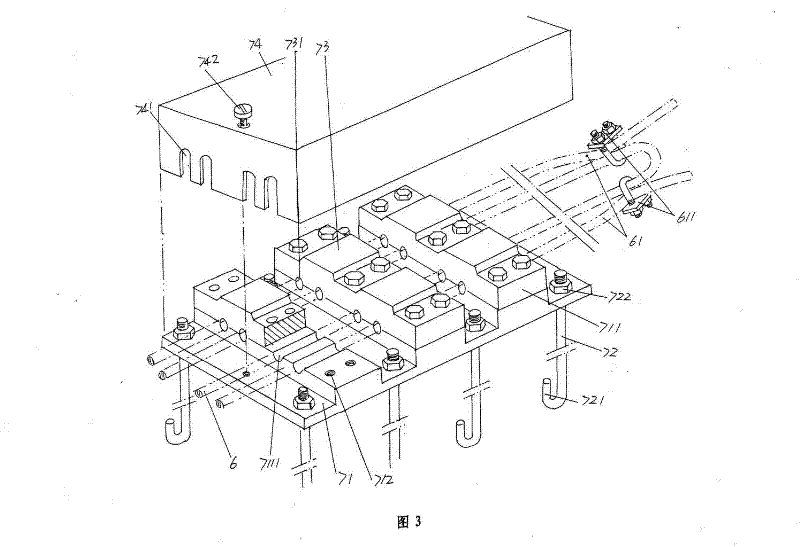

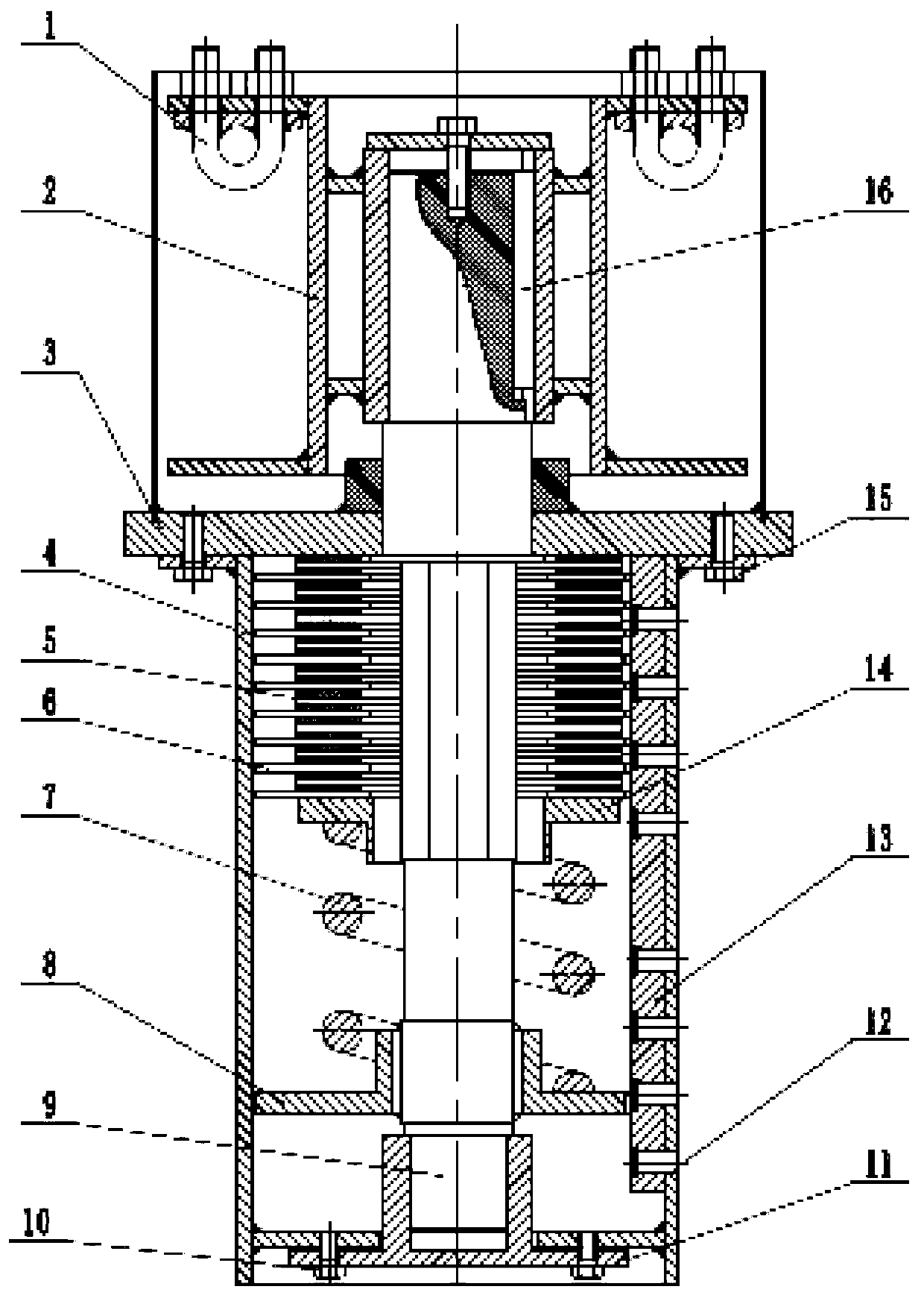

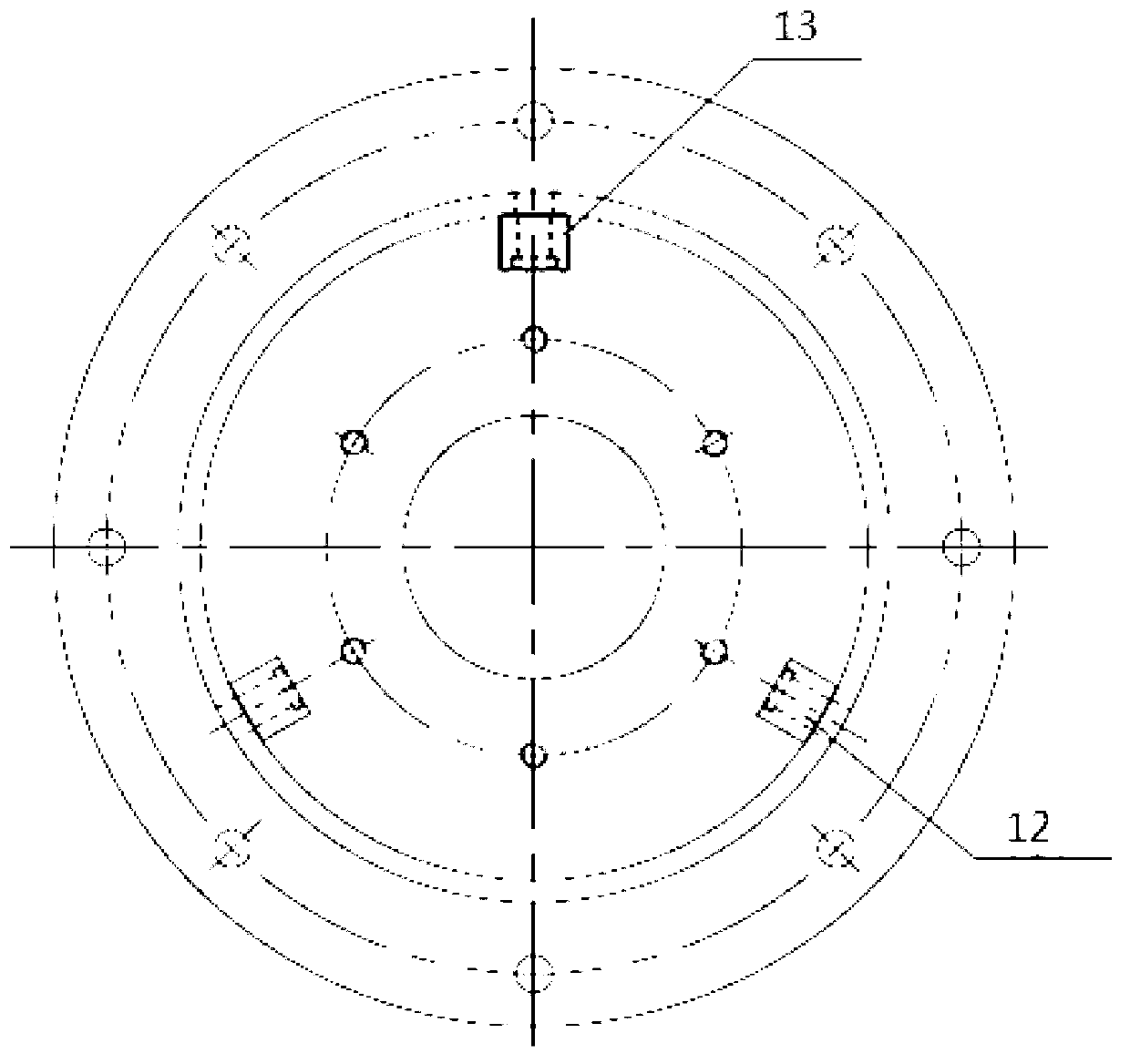

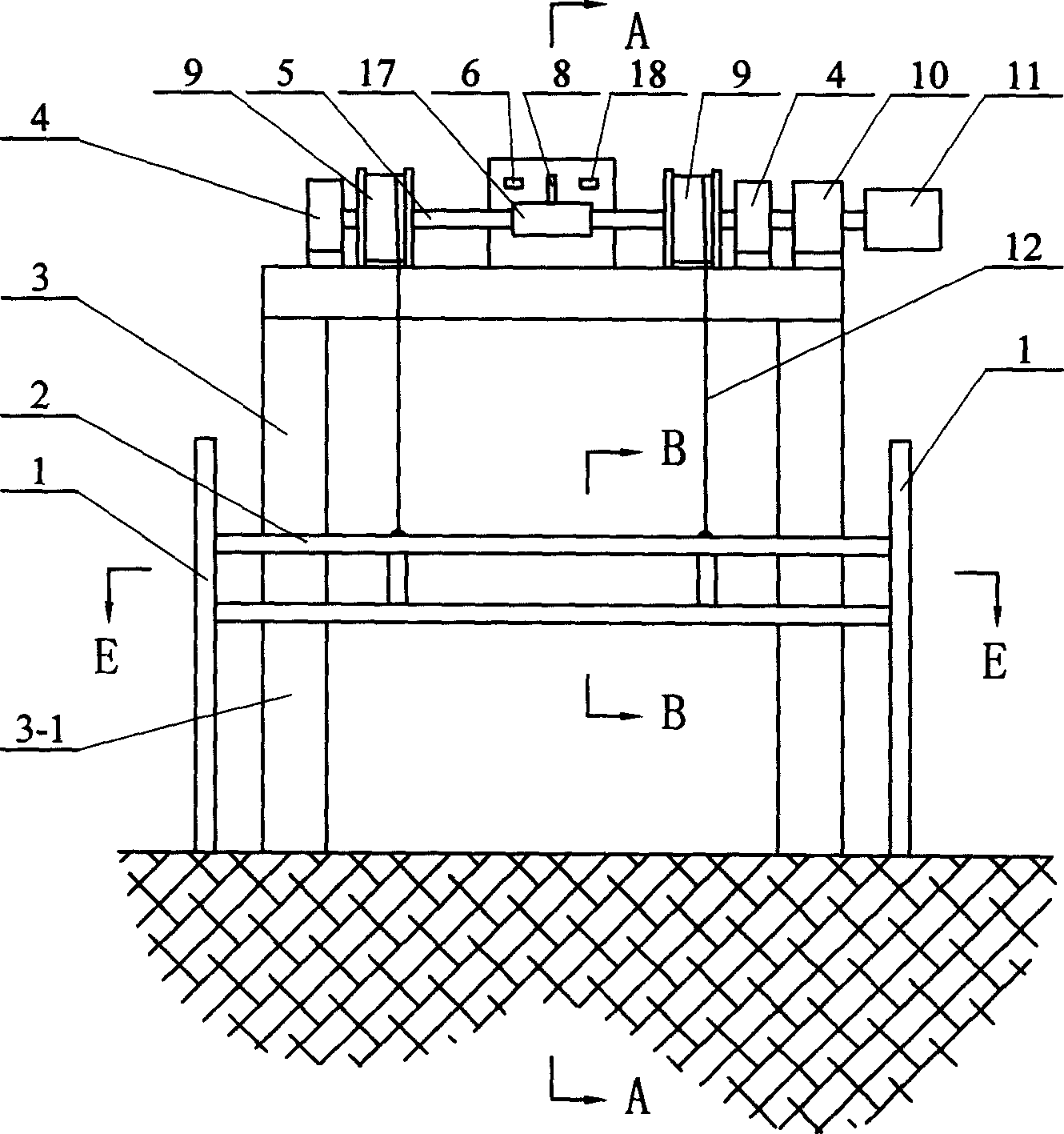

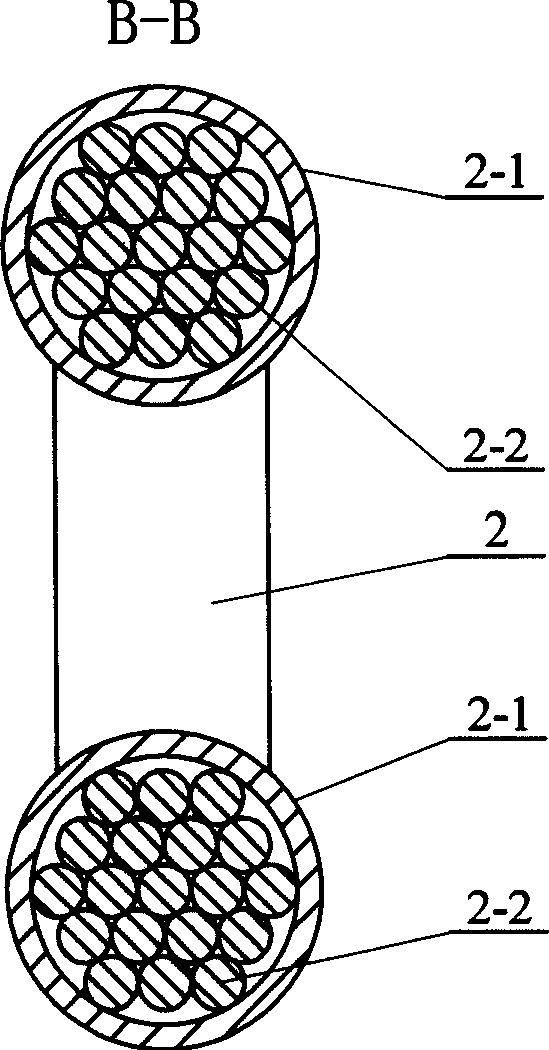

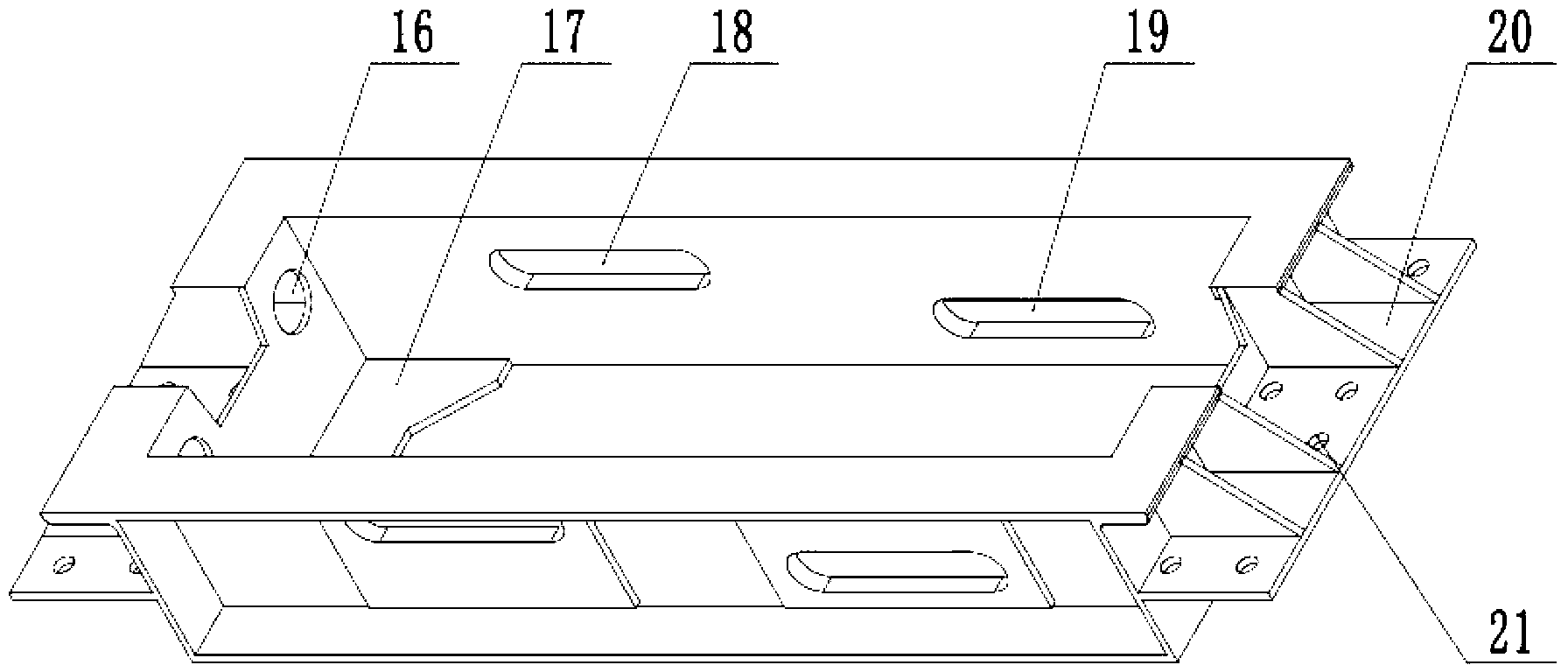

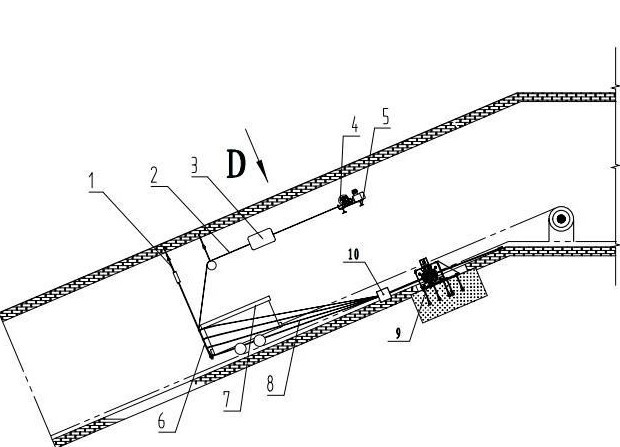

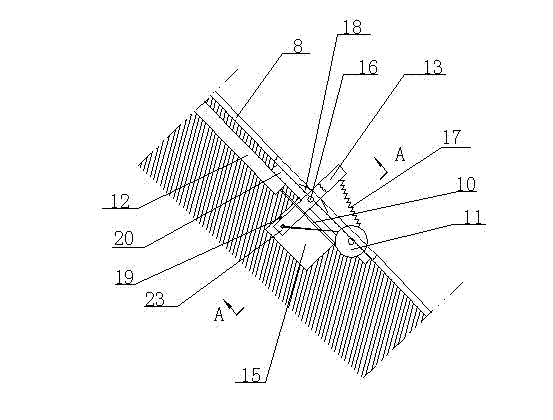

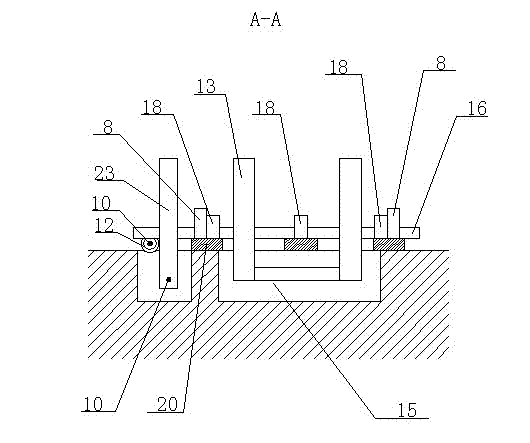

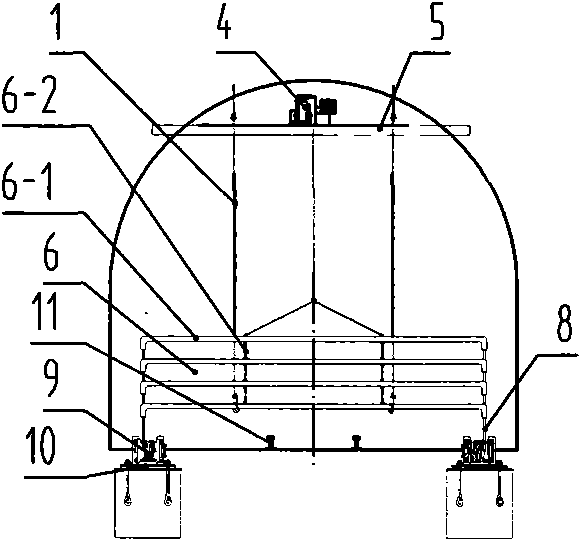

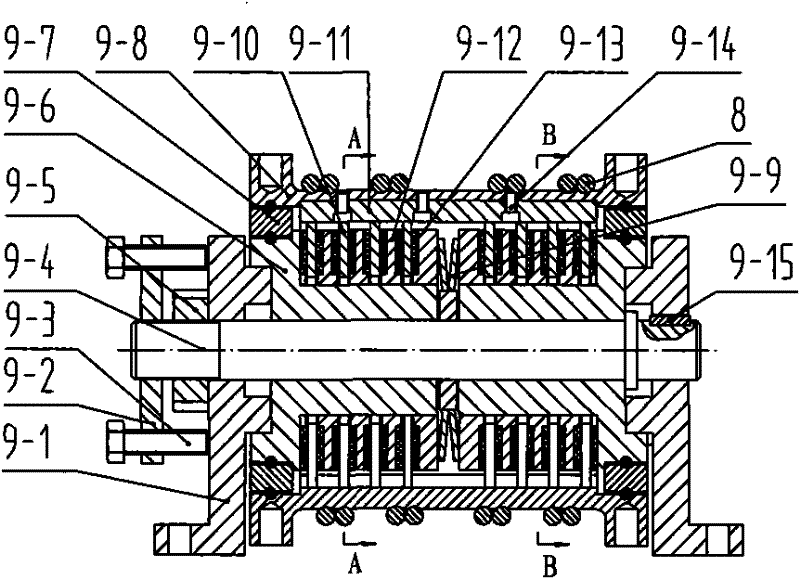

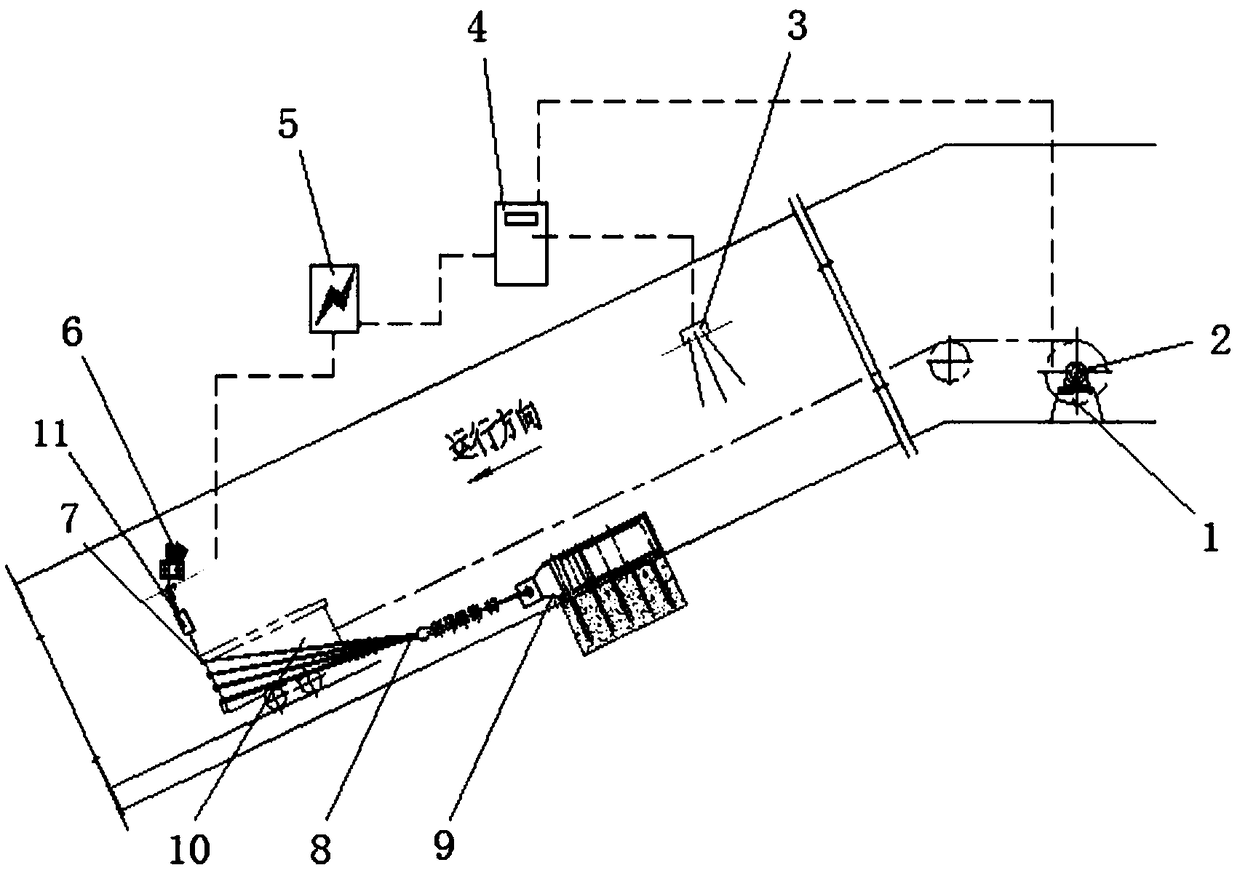

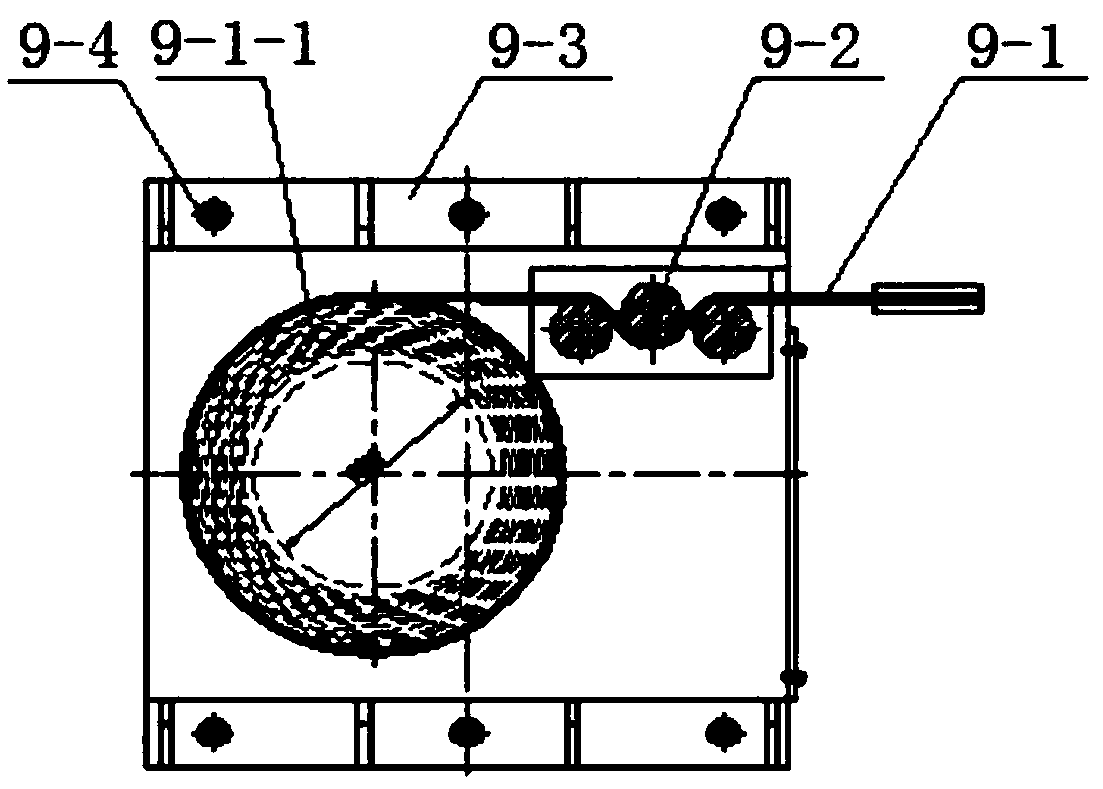

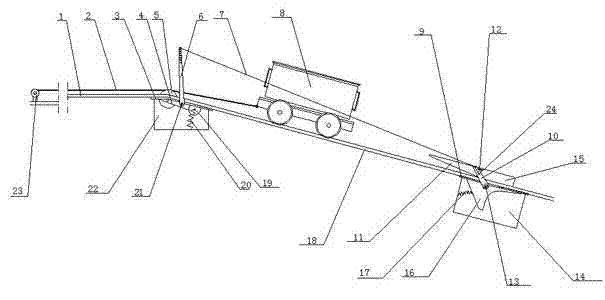

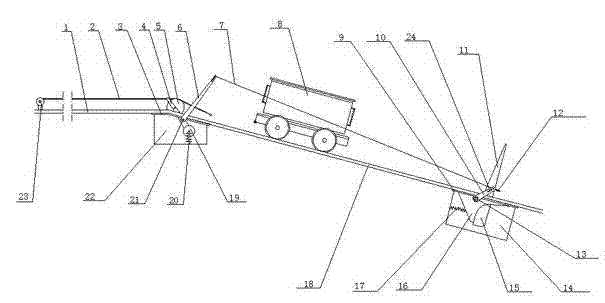

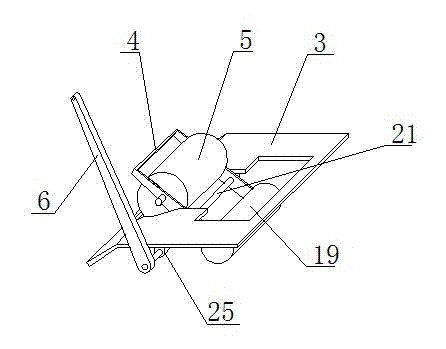

Buffer variable force energy adsorption adjustable device for preventing vehicle from running in inclined shaft

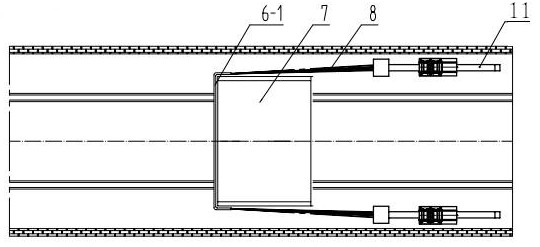

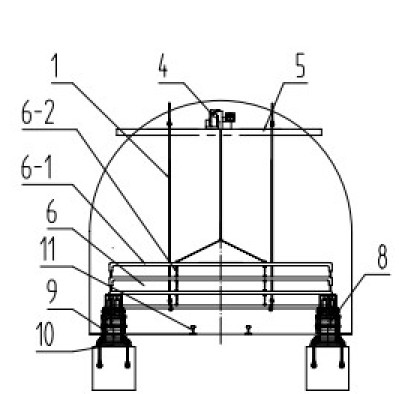

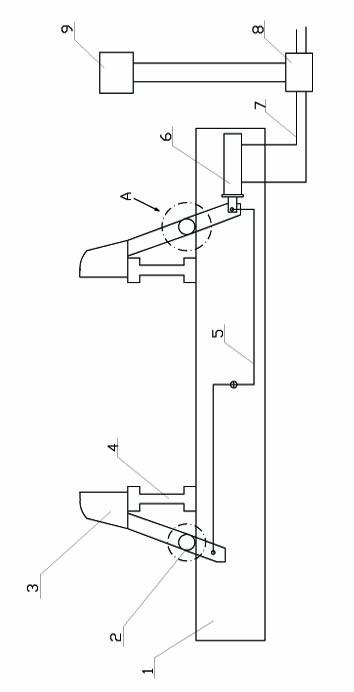

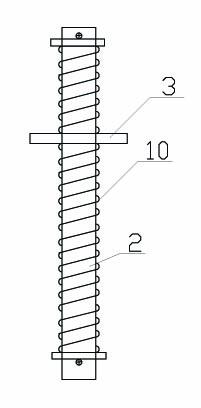

InactiveCN102233884AImprove reliabilityImprove safety and reliabilityPositive railway stopsWinchAutomotive engineering

The invention discloses a buffer variable force energy adsorption adjustable device for preventing a vehicle from running in an inclined shaft and relates to mining equipment. The device consists of a vehicle stopping column 6 for preventing a mining vehicle from running, and a variable force energy adsorption device 9. The vehicle stopping column 6 comprises a plurality of buffer steel wire ropes 8, C-shaped sleeve pipes 6-1, and hanging chains 6-2; two ends of each buffer steel wire rope 8 are connected with the viable force energy adsorption device 9; the C-shaped sleeve pipes are connected through the hanging chains 6-2 to form a grating guardrail; and the hanging chains 6-2 are connected with a lifting winch 4. The variable force energy adsorption device 9 is arranged on an inclined shaft basis through foundations 10 and foundation bolts 16 and comprises a support 9-1, a shaft 9-4, a shaft sleeve 9-6, a winding drum 9-8, an external brake plate 9-10, an inner brake plate 9-12, and a friction sheet 9-13. The device performs adjustment timely and buffers energy according to parameters of each inclined shaft, so that the device can effectively stop the vehicle optimally when the rope is broken and then the vehicle runs in the inclined shaft; therefore, the deformation of the mine vehicle under impact is reduced.

Owner:徐州泰荣煤矿设备有限公司

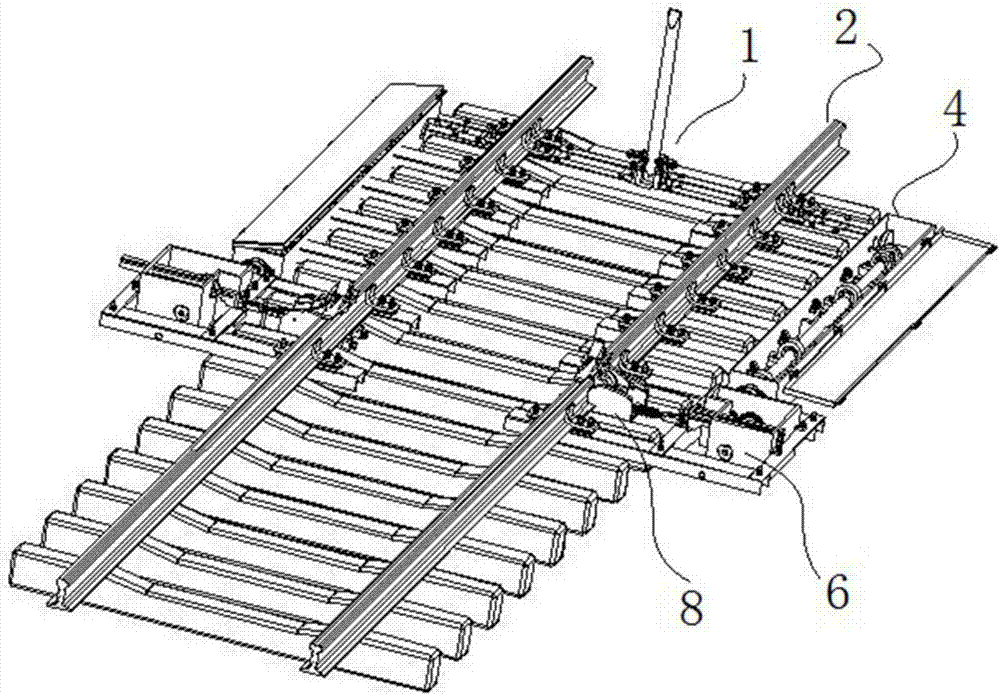

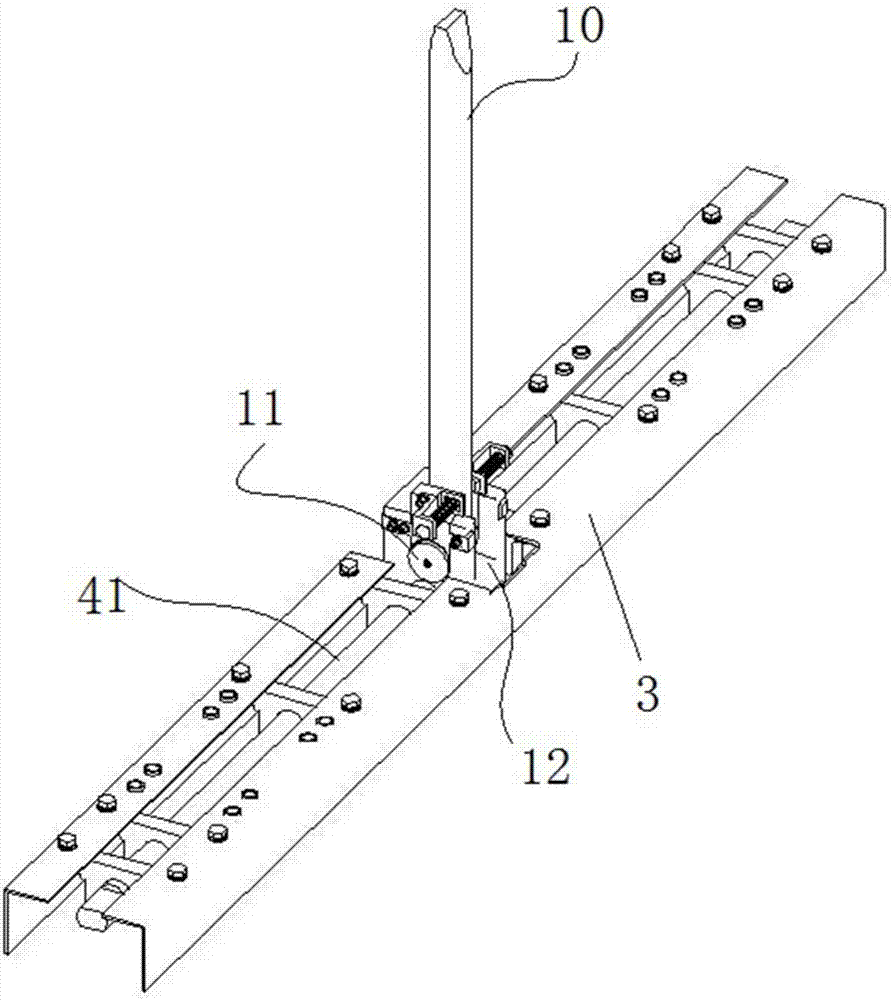

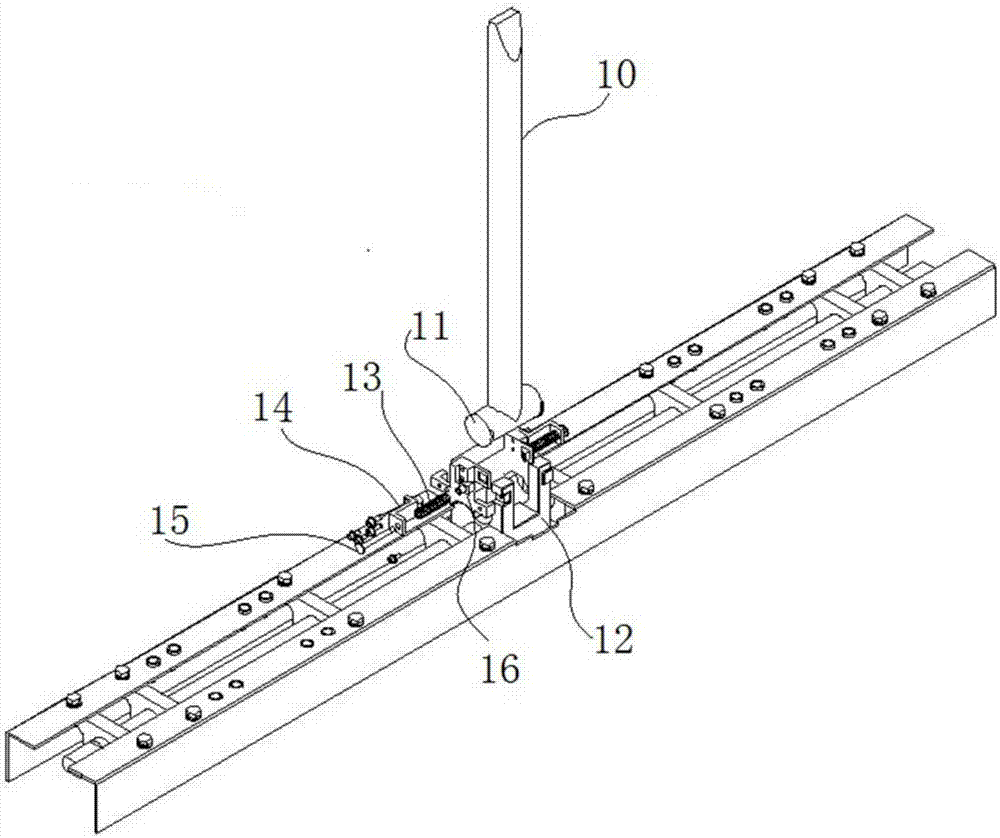

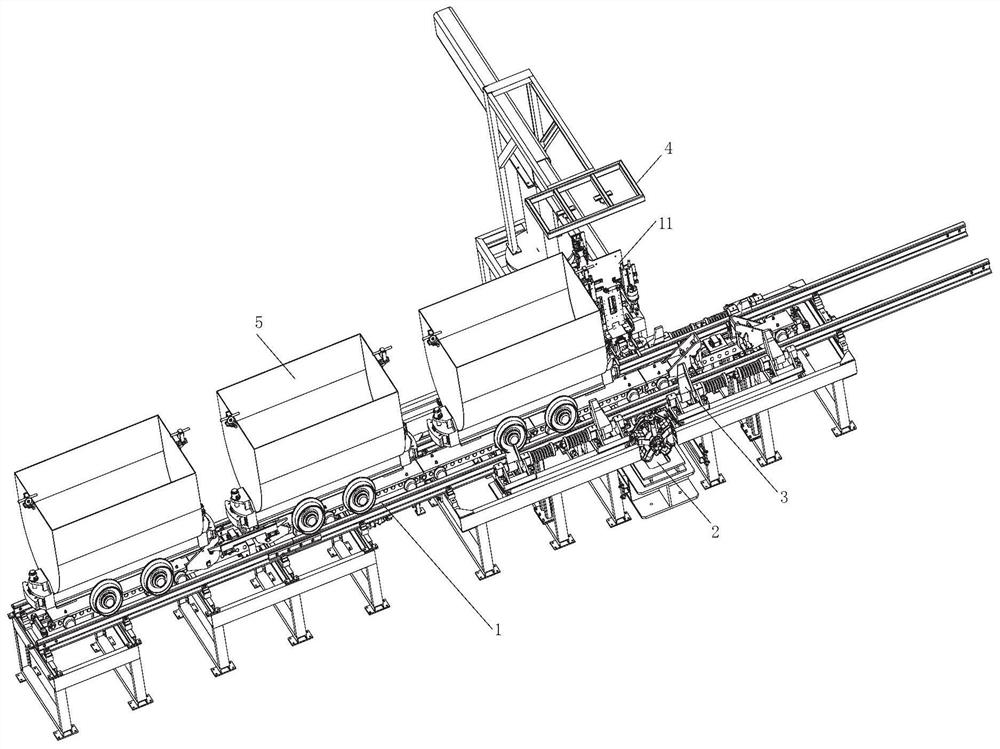

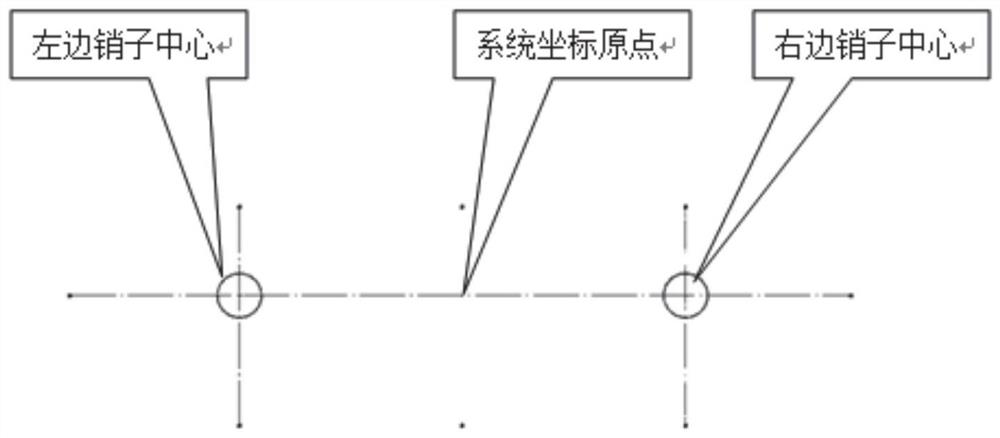

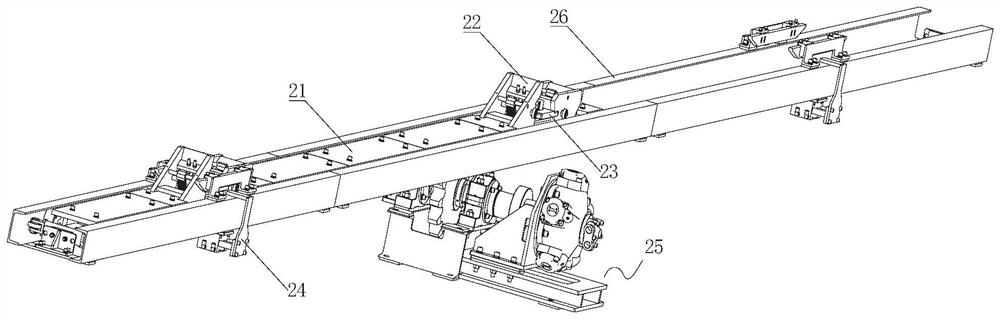

Full-automatic picking and hanging pin-chain system and method for rail transportation

ActiveCN111674421ASuccessful realization of unhooking automationRealize work state transitionRailway coupling accessoriesPositive railway stopsMobile vehicleControl theory

The invention discloses a full-automatic picking and hanging pin-chain system and method for rail transportation. The full-automatic picking and hanging pin-chain system comprises two two-way car arresters installed on a rail, wherein the two two-way car arresters are used for locking a car and can move along the rail together with the car until the car reaches an ideal position. The two-way trailer mechanism is used for initial positioning of a mine car, arranged between the two two-way car stoppers and used for enabling the car to move on the rail in the first direction or the second direction till the car reaches the position where one of the two-way car stoppers is located. An intelligent visual detection system is used for detecting the actual position of the specified bolt position in real time and comparing the actual position with the ideal position, and then controlling the bidirectional car arrester to move the car until the specified bolt position reaches the ideal position;and a picking and hanging pin-chain device is used for picking off or hanging a loop chain connected between adjacent carriages of the vehicle. According to the full-automatic picking and hanging pin-chain system and method for rail transportation, automatic picking and hanging of the stringing loop chain are smoothly achieved, and the number of operators is reduced.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

Derail-preventiondisc type steel belt plastic deformation cushion brake device for inclined shaft

PendingCN109263682AImprove buffering effectConstant and calibratable braking forcePositive railway stopsControl systemEngineering

The invention discloses a derail-preventiondisc-type steel strip plastic deformation cushioning brake device for inclined shaft, which comprises a signal system, a control system, a vehicle stopping system and a cushioning brake system. The signal system is arranged in the running direction of the running container in the inclined shaft roadway and is used for acquiring the speed signal. The control system is arranged in the vicinity of the signaling system for receiving signals of the signaling system and controlling the operation of the vehicle stopping system; the baffle system is arrangedat the top of the inclined shaft roadway, and is used for receiving the command from the signal system and blocking the running container in time. A cushion brake system is arranged at that bottom ofthe inclined shaft roadway for cushion braking aft the vehicle retaining system blocks the running vessel. The invention avoids the generation of the non-safe space in the roadway, and prevents the safety hidden trouble and safety accident of the personnel equipment and the roadway caused by the steel belt shaking when braking. At that same time, the device has the advantage of simple structure, convenient installation, stable performance, safety and reliability.

Owner:武汉云竹科技有限公司

Automatic anti-slipping device for slope running of mine car

InactiveCN102785678ASmooth slidingProtection securityLocomotivesPositive railway stopsPull forceEngineering

An automatic anti-slipping device for slope running of a mine car is characterized in that a tension sensing device is arranged at the junction of a horizontal rail and a slope rail, and a protector in linkage with the tension sensing device is arranged on the slope rail. When a steel wire rope is disconnected with the mine car, the protector is automatically in the car blocking state, and the mine car can be retained by a braking retaining plate when slipping down along the slope rail, so that safety of operators at the bottom of the slope rail is guaranteed. When the mine car is connected with a traction rope, the tension sensing device is capable of sensing tension of the traction rope when the mine car slips down along the slope rail, and the tension sensing device transfers the sensed tension to the protector through a tension transfer part, so that the protector is changed to the car running state, and the mine car is guaranteed to slip down to the bottom of the slope rail smoothly. The automatic anti-slipping device for slope running of the mine car needs no manual operation and is safe and reliable to operate, capable of avoiding 'running away' due to the fact that the mine car slips down along the slope rail to injure people when the mine car is disconnected with the traction rope, and the problem of 'running away' in mine shafts troubling people all the time is solved.

Owner:向正国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com