Anti-slipping device of freight train

A technology of anti-rolling cars and trains, which is applied in the field of freight transportation, can solve the problems of low stability and unsuitability for freight trains, and achieve the effects of improving stability, preventing the movement of inclined seats, and preventing excessive movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

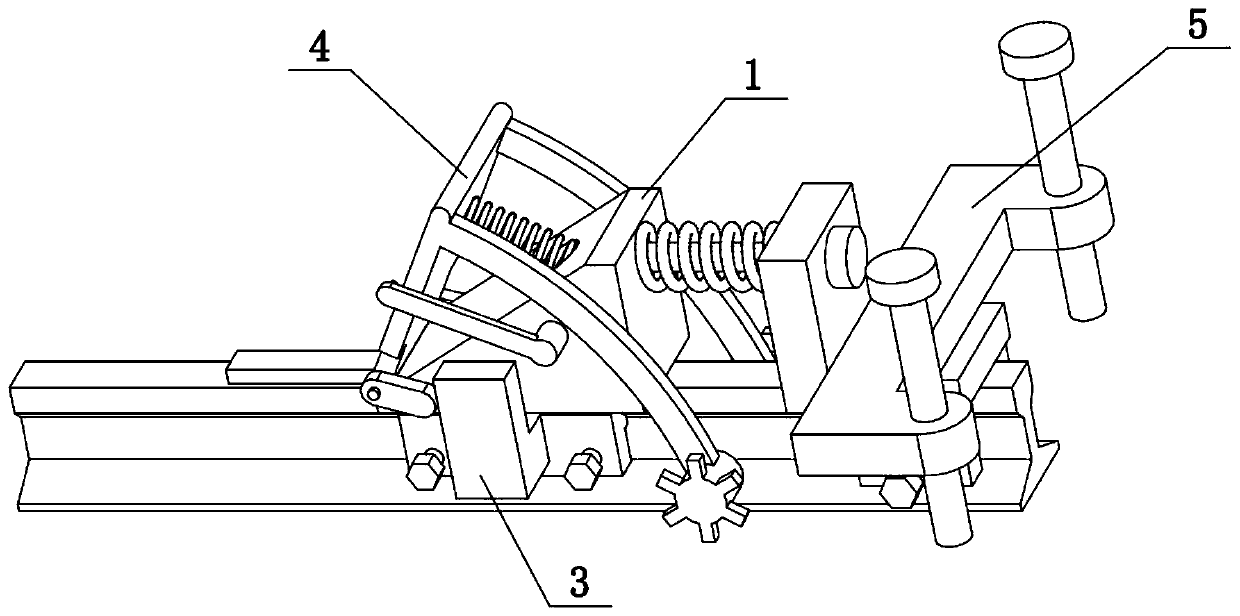

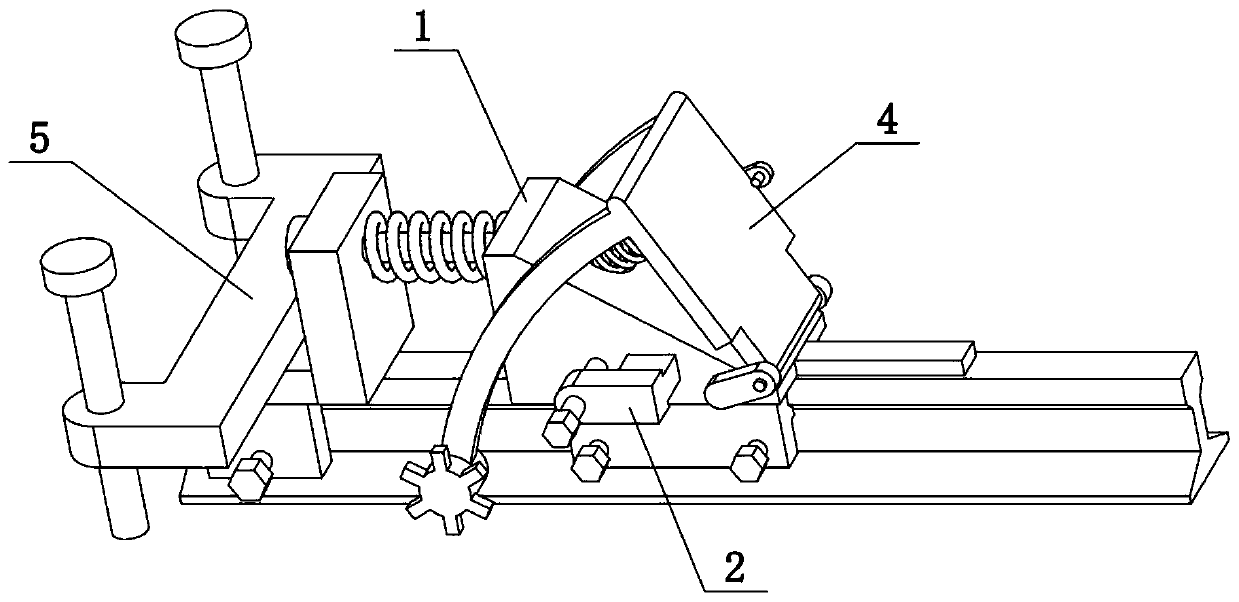

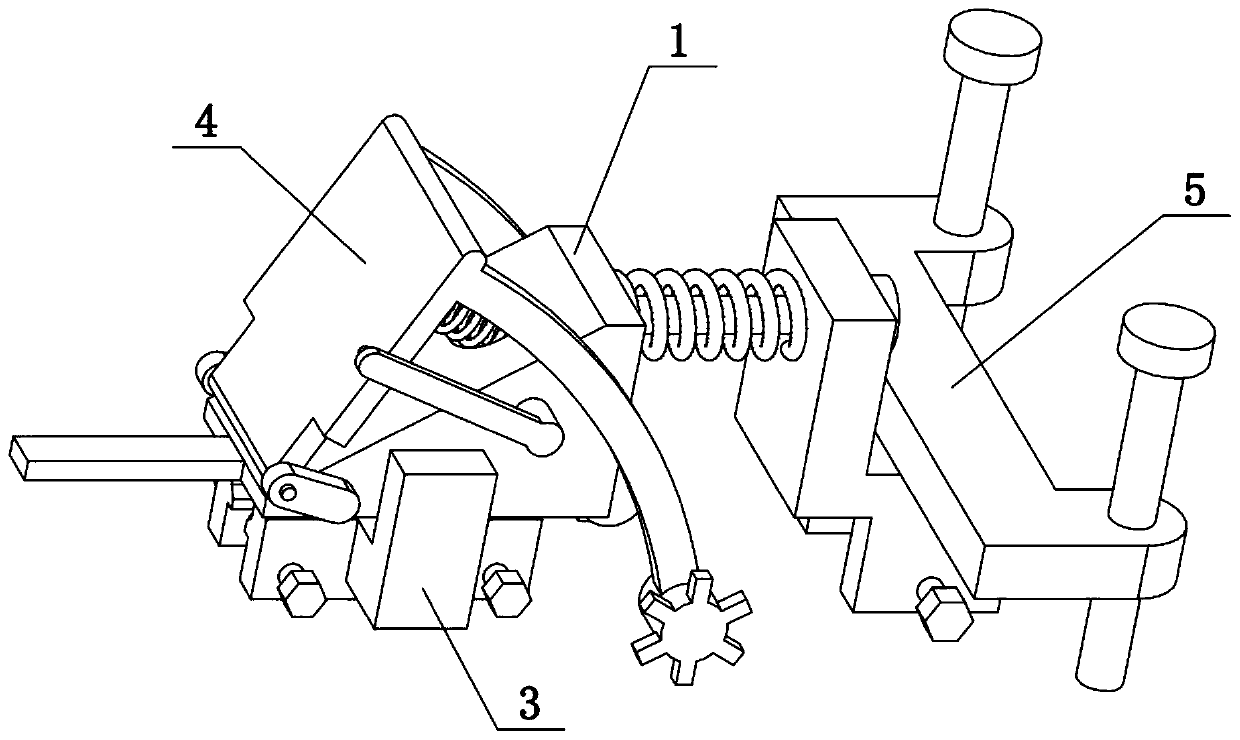

[0036] Combine below Figure 1-15 Description of this embodiment, the present invention relates to the field of freight transport, more specifically an anti-rolling device for freight trains, including an anti-rolling seat 1, a tension rod 2, a clamping mechanism 3, a ground insertion mechanism 4 and additional stabilizing Device 5, when the freight train wheel is pressed on the wheel pressing plate 1-9, the inclined plane seat 1-1 is fixed immediately, and the inclined plane seat 1-1 prevents the freight train from slipping; when the freight train wheel is pressed on the inclined plate 4-1, the inclined plane When the plate 4-1 is pressed down, two bottom cylinders 4-3 and a plurality of ground teeth 4-4 are inserted into the gravel around the rail, further preventing the slope seat 1-1 from moving, and improving the stability of the slope seat 1-1 property; if the freight train wheel inertia is large when the inclined plane seat 1-1 is moved, the additional stabilizer 5 can ...

specific Embodiment approach 2

[0039] Combine below Figure 1-15 To illustrate this embodiment, the anti-slip vehicle seat 1 includes an inclined plane seat 1-1, a spring socket 1-2, an extension column 1-5, a diagonal rod 1-6, a rectangular through hole 1-7, and a hinged seat 1- 8. Wheel pressure plate 1-9, limit pin 1-10, rear splint 1-11, rear card edge 1-12 and rear screw 1-13, the left side of the inclined plane seat 1-1 is an inclined plane, and the inclined plane seat 1-1 A spring jack 1-2 is arranged on the upper end slope of the upper end, and one end of the compression spring 1 is fixedly connected in the spring jack 1-2, and the other end of the compression spring 1 stretches out of the spring jack 1-2, and the inclined plane seat 1-1 is set There are rectangular through holes 1-7 that run through the front and back, the front and rear ends of the left end of the inclined plane seat 1-1 are fixedly connected with the hinged seat 1-8, the left end of the inclined plane seat 1-1 is fixedly connecte...

specific Embodiment approach 3

[0041] Combine below Figure 1-15 To illustrate this embodiment, the tension rod 2 includes a slide bar 2-1, a top screw seat 2-2 and a top screw 2-3, the slide bar 2-1 is slidably connected to the rectangular through hole 1-7, and the slide bar 2 The rear end of -1 is fixedly connected with a top screw seat 2-2, and the top screw seat 2-2 is threadedly connected with a top screw 2-3, and the front end of the top screw 2-3 is pushed on the rear side of the inclined plane seat 1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com