Automatic anti-slipping device for slope running of mine car

A technology of anti-slip and protective devices, applied in the field of mining machinery, can solve the problems of mining enterprises and mine workers' losses, and achieve the effect of safe and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

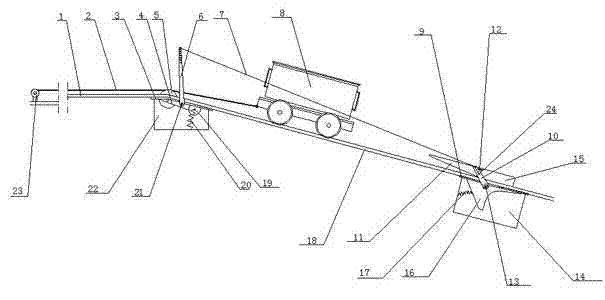

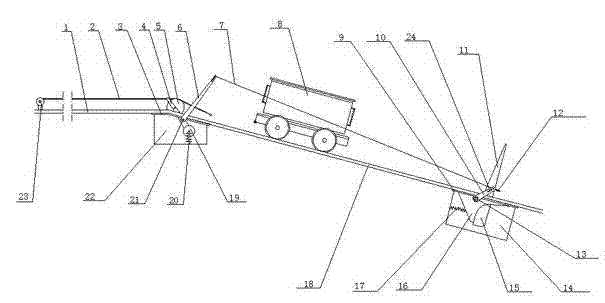

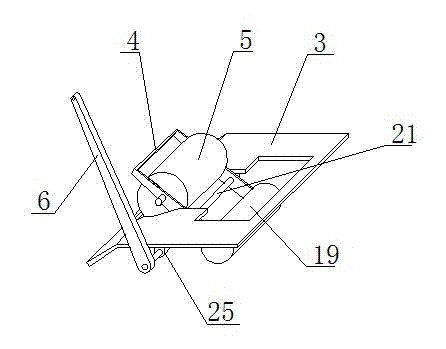

[0024] Such as Figure 1 to Figure 7 As shown, a mine car slope running automatic anti-slip device includes a winch 23, a mine car 8, a horizontal track 1, a ramp track 18 and a traction rope 2 connected to the winch 23, and is set at a position where the ramp track 18 is close to the horizontal track 1 There is an induction pit 22, an induction bottom plate 3 is installed above the induction pit 22, a rotating support 25 is arranged on the induction bottom plate 3, and the induction rotating shaft 21 is rotatably installed in the rotating support 25, and the end of the induction rotating shaft 21 is connected with Execute the rocker arm 6, the induction shaft 21 is fixedly connected with the turret 4, the upper end of the turret 4 is equipped with a rotatable ground wheel 5, and the ground wheel 5 is located at the junction of the horizontal track 1 and the slope track 18; the lower end of the turret 4 is installed Balance iron 19 is arranged, and the effect of balance iron 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com