Axle hung retarder

A vehicle blocker and axle-type technology, applied in the direction of mandatory railway blocker, railway car body parts, transportation and packaging, etc., can solve the problems of hindering the transportation of large items, complicated installation of overspeed hoisting beams, affecting the work of mine carts, etc. Small space limitation, simple structure, easy to make effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

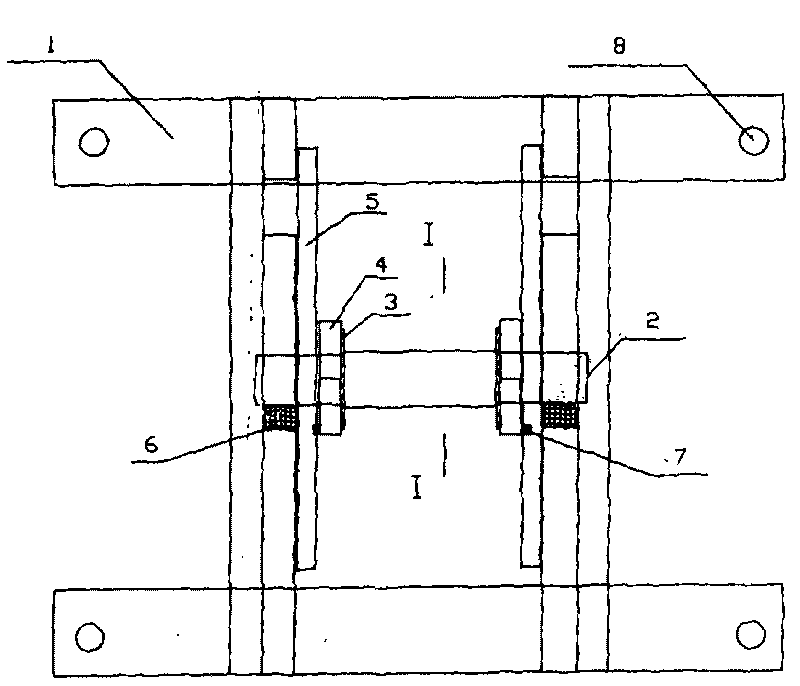

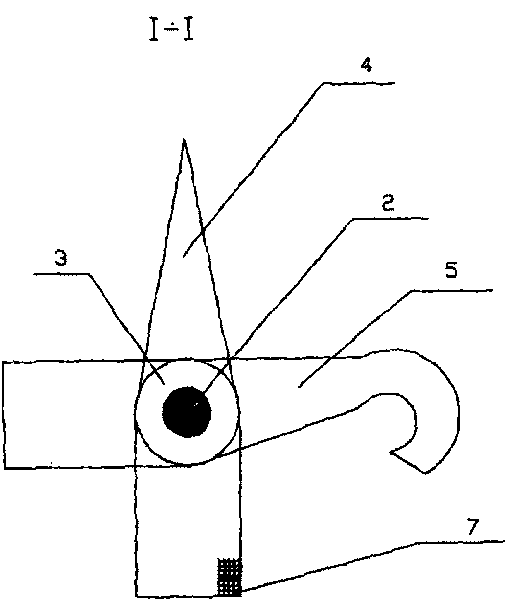

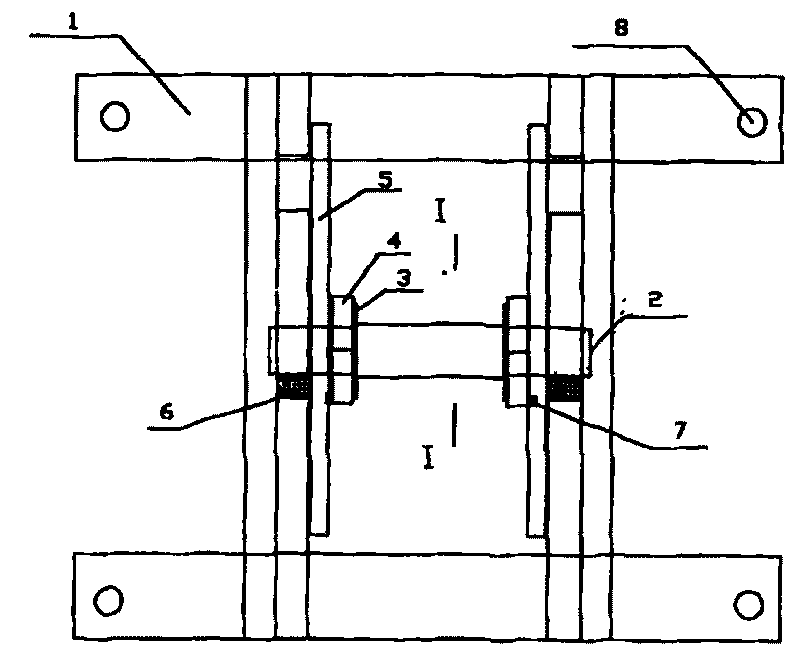

[0015] exist figure 1 or figure 2 Among them, the hook block chassis 1, the hook block main shaft 2, the hook block retaining ring 3, the hook block ram 4, the hook block hook plate 5, the shaft block plate 6, the ram bump 7, the chassis fixed eye 8.

[0016] As shown in the figure: its specific implementation is as follows:

[0017] 1. Hook block main shaft 2, hook block retaining rings on both sides 3, then assemble the hook block striker 4, hook block hook plate 5 in sequence, and then install the above seven small pieces into the inner channel steel of the hook block chassis 1 as a whole, and Place the shaft head of the hook blocking main shaft 2 in front of the shaft blocking plate 6 , and the shaft blocking plate 6 is arranged on the upper middle part of the channel steel of the hook blocking chassis 1 .

[0018] 2. The hook block bumper 4 of the shaft-holding type car stopper is a long triangle, with a round hole in the middle, and the bumper 7 is set on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com