Locomotive vehicle anti-running device

A technology for locomotives and vehicles, applied in the field of anti-slip devices for locomotives and vehicles, can solve the problems of high cost, easy misoperation, high labor intensity, etc., and achieve the effects of simple structure, increased friction, and energy saving in manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

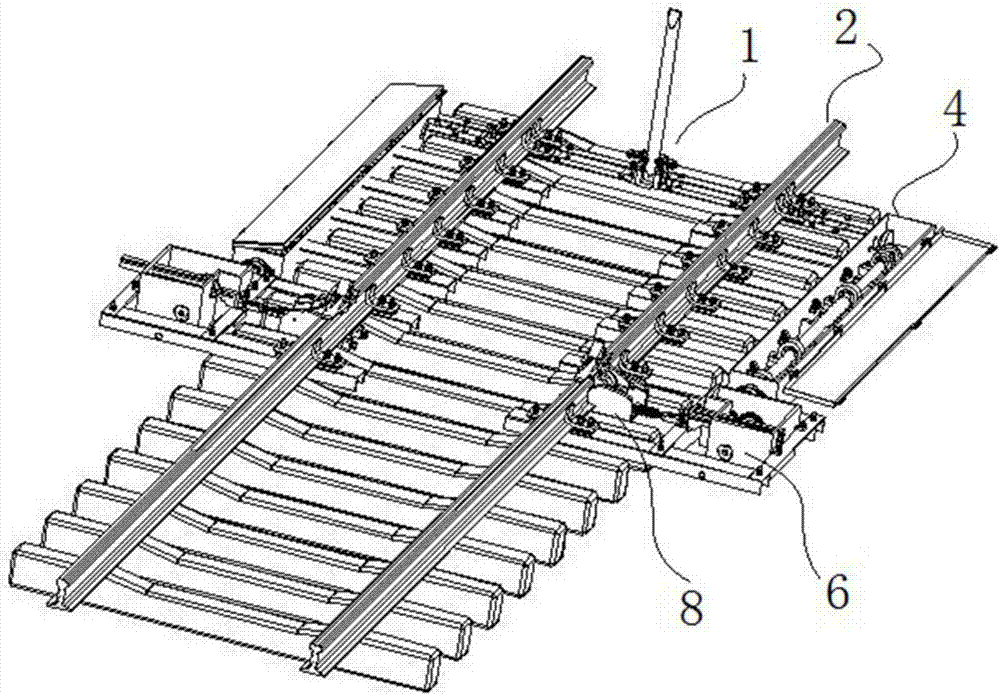

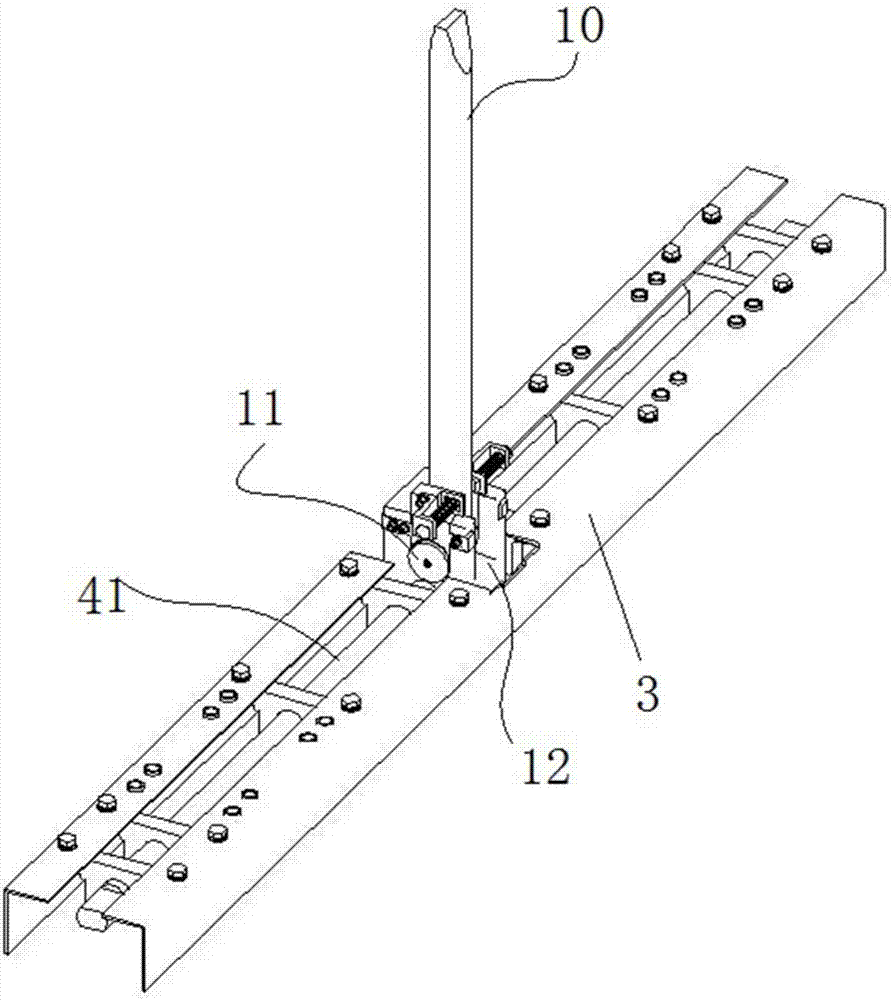

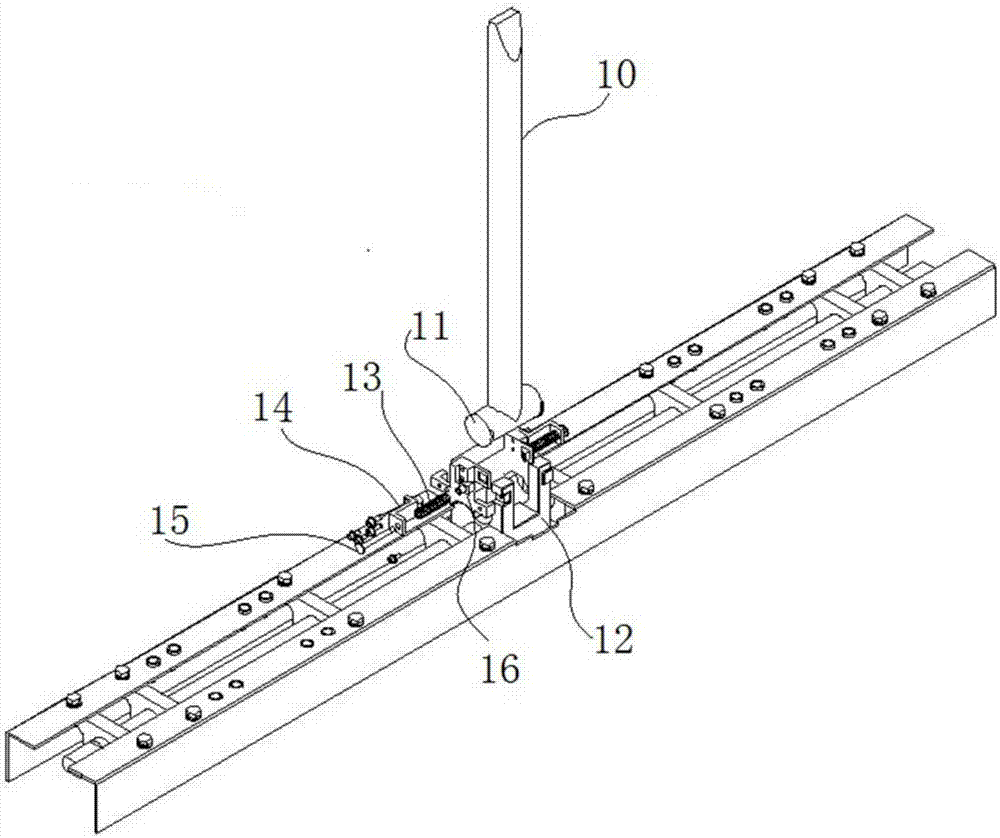

[0030] The embodiment of rolling stock anti-slip device of the present invention, as Figure 1-Figure 13 As shown, it includes a touch mechanism 1, a transmission mechanism 4, a power output mechanism 6, and an iron shoe mechanism 7. The touch mechanism 1 includes a collision structure and a base 12 that collide with the locomotive when the locomotive rolls. 12 fixedly connected transmission shaft, the transmission shaft transmits power to the power output mechanism, the power output mechanism 6 includes a pull rod and a rack and pinion mechanism for adjusting the transmission ratio, and the iron shoe mechanism 7 includes a mounting seat for installing the iron shoe 9 and a mounting seat for installation The frame 81 that the seat moves according to the set track, the frame 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com