Dynamic front roll-over protection method and system of stacking machine and stacking machine with system

A technology of protection system and stacker, which is applied in the field of stacker, can solve the problem of danger warning that the stacker cannot tip over forward, and achieve the effect of avoiding the influence of human and operational factors and preventing forward tipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

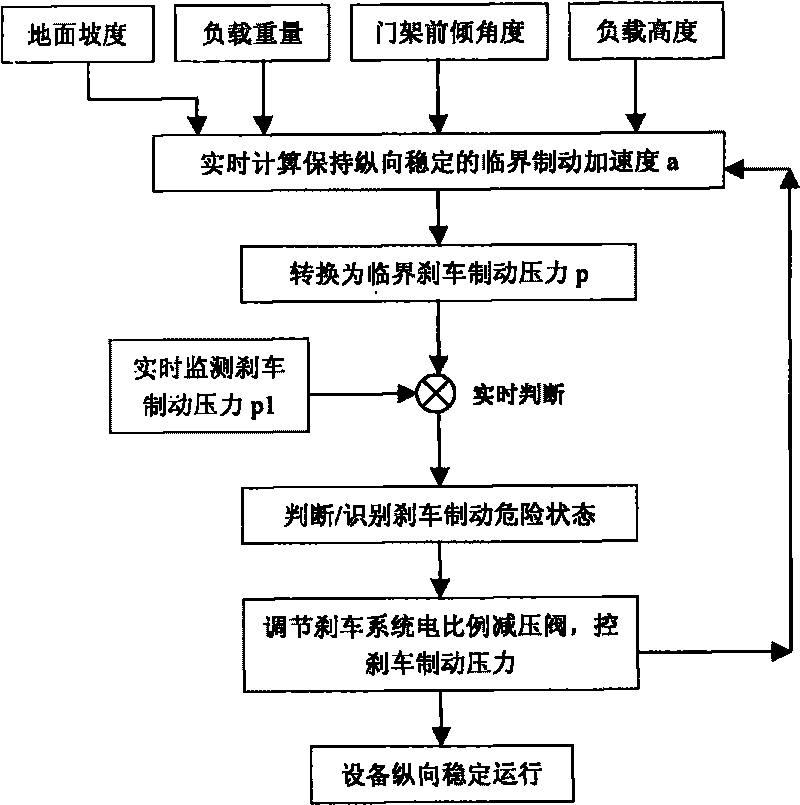

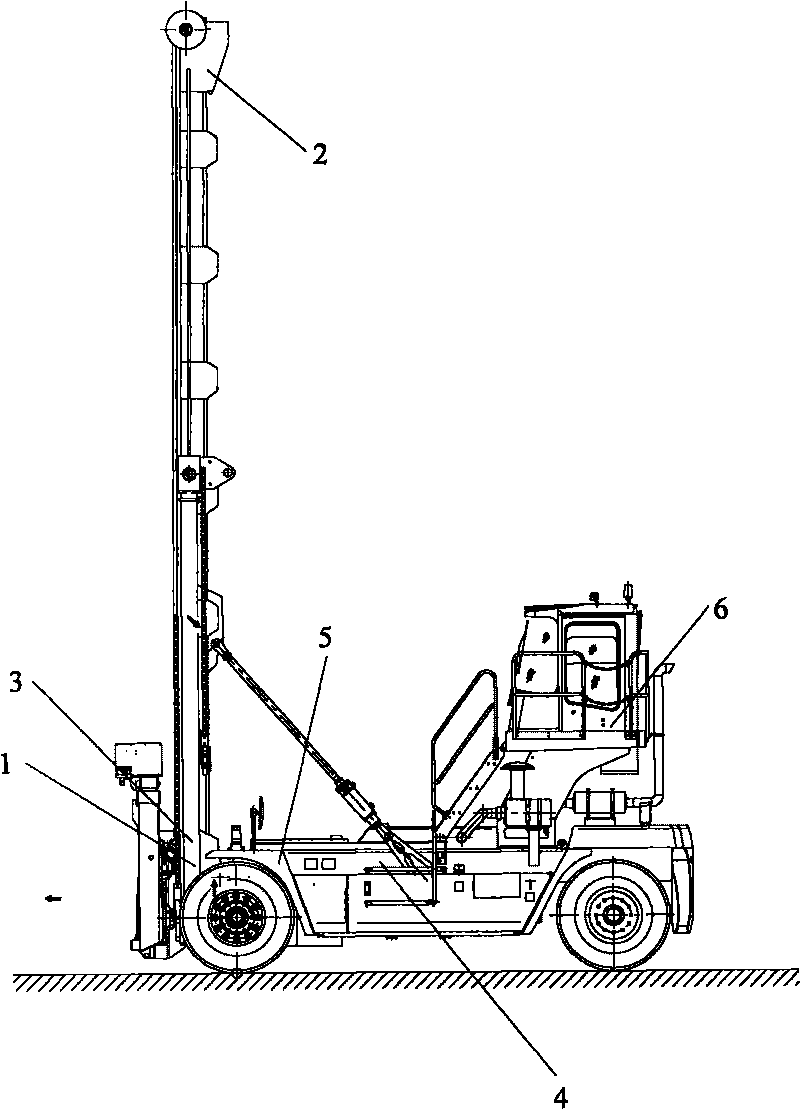

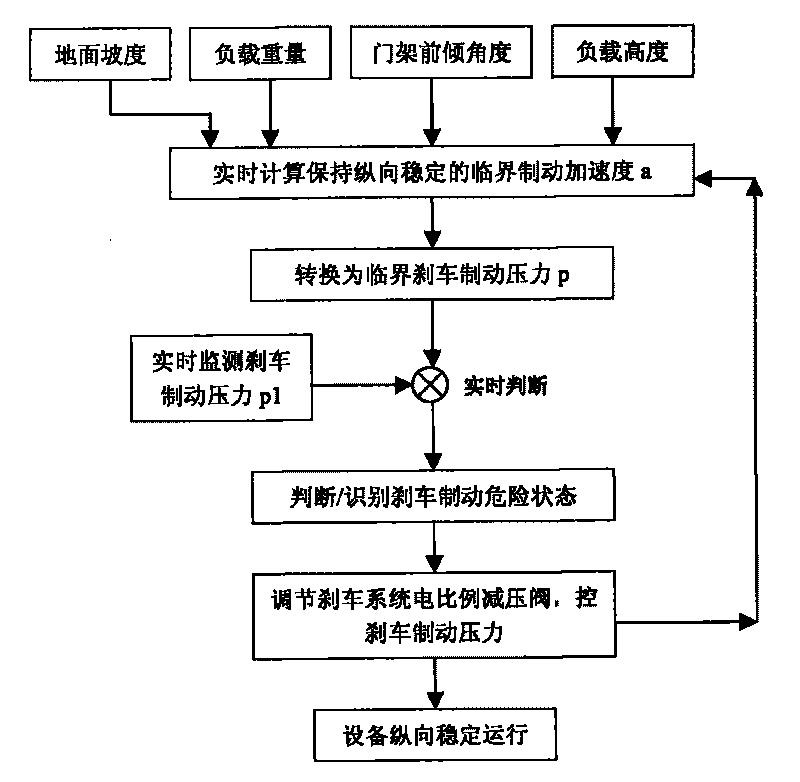

[0016] exist figure 1 Fig. 1 schematically shows a flow chart of a method for dynamic front rollover protection of a forklift according to the present invention. exist figure 1 In the process, the load weight m of the forklift, the lifting height L of the mast of the forklift, the inclination angle θ of the mast of the forklift and the slope of the ground α are firstly detected.

[0017] However, the critical braking acceleration a is calculated from the detected load weight m, lift height L, inclination angle θ and said ground gradient α. Finally, the critical braking force p is calculated from the calculated critical braking acceleration a.

[0018] In the next step, compare the current braking force p1 with the critical braking force p, if the current braking force p1 is greater than or equal to the critical braking force p, an alarm will be issued and the braking device of the stacker will be controlled to Reduce the current braking force p1.

[0019] In the method acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com