Full-automatic picking and hanging pin-chain system and method for rail transportation

A rail transportation, fully automatic technology, applied in the field of fully automatic pin-chain removal system, can solve the problems of laborious and heavy lifting, and achieve the effect of reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

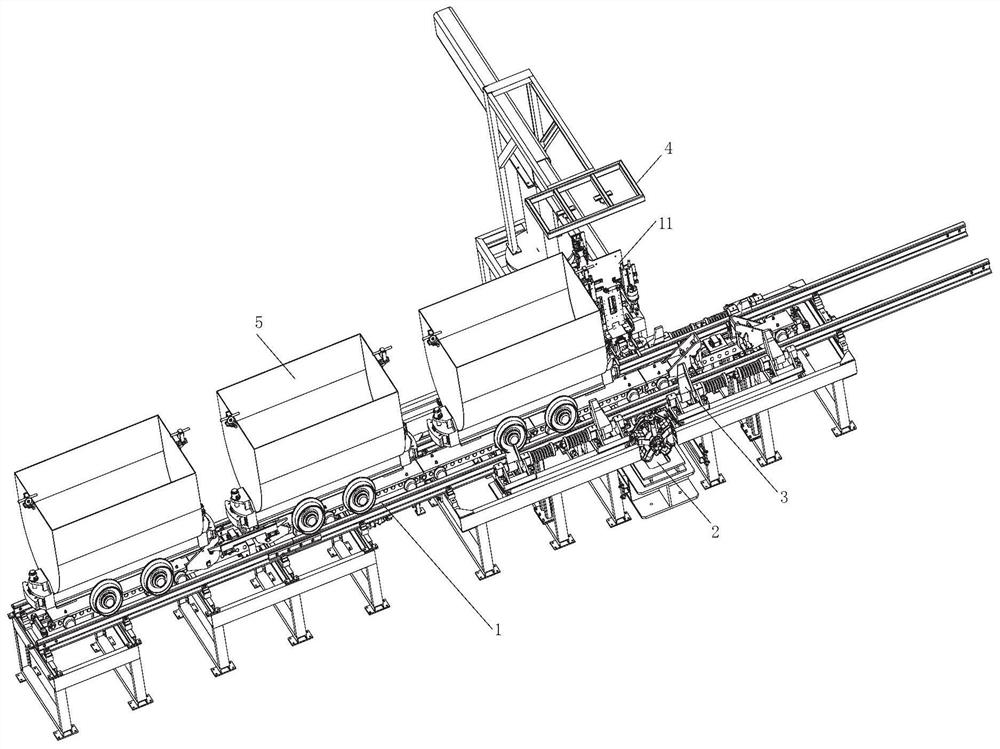

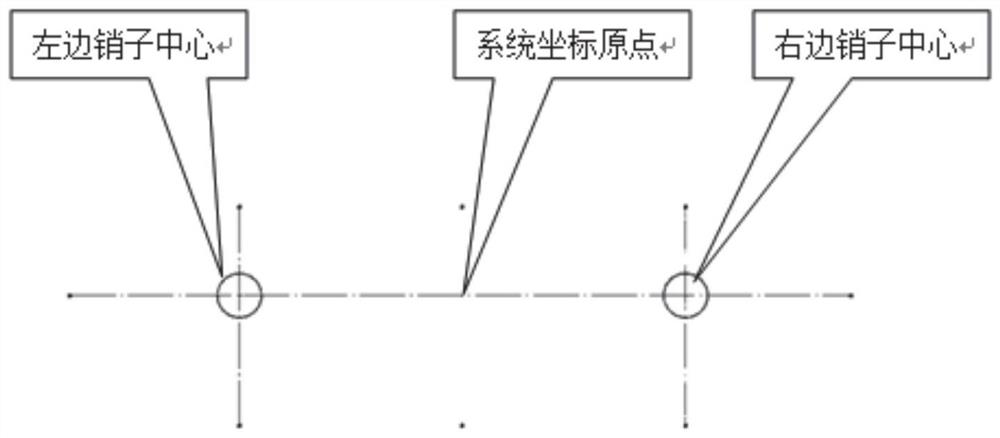

[0075] refer to figure 1 , image 3 , Figure 4 and Figure 5 , an embodiment of the present invention provides a vehicle precision positioning system for rail transport, which includes a track 1, a two-way trailer mechanism 2, two two-way vehicle arrestors 3 installed on the track, an intelligent visual inspection system 4 and Unhanging pin-chain device 11, two two-way car stoppers 3 are arranged at intervals along the length direction of track 1, and two-way trailer mechanism 2 is used for initial positioning of mine cars, and is arranged between two two-way car stoppers 3.

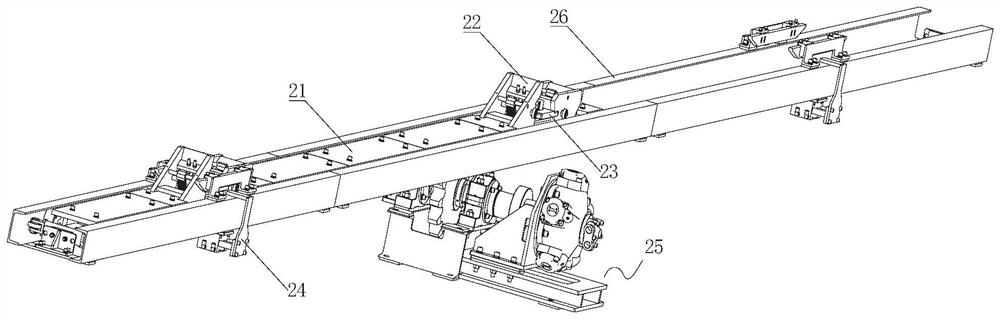

[0076] The two-way trailer mechanism 2 is at least used to make the vehicle move along the first direction or the second direction on the track 1 until it reaches the position of one of the two-way vehicle arrestors 3; wherein, the specific structure of the two-way trailer mechanism 2 is as follows: image 3As shown, it includes a pin tooth chain row 21 fixedly connected with the guide rail 26 and tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com