Torque-changeable buffer power absorber

An energy absorber and rope technology, applied in the field of mining machinery, can solve problems such as difficulty in meeting requirements, long braking distance of sports cars, broken ropes, etc., and achieve the effects of easy assembly and maintenance, reduction of mine accident losses, and efficient energy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

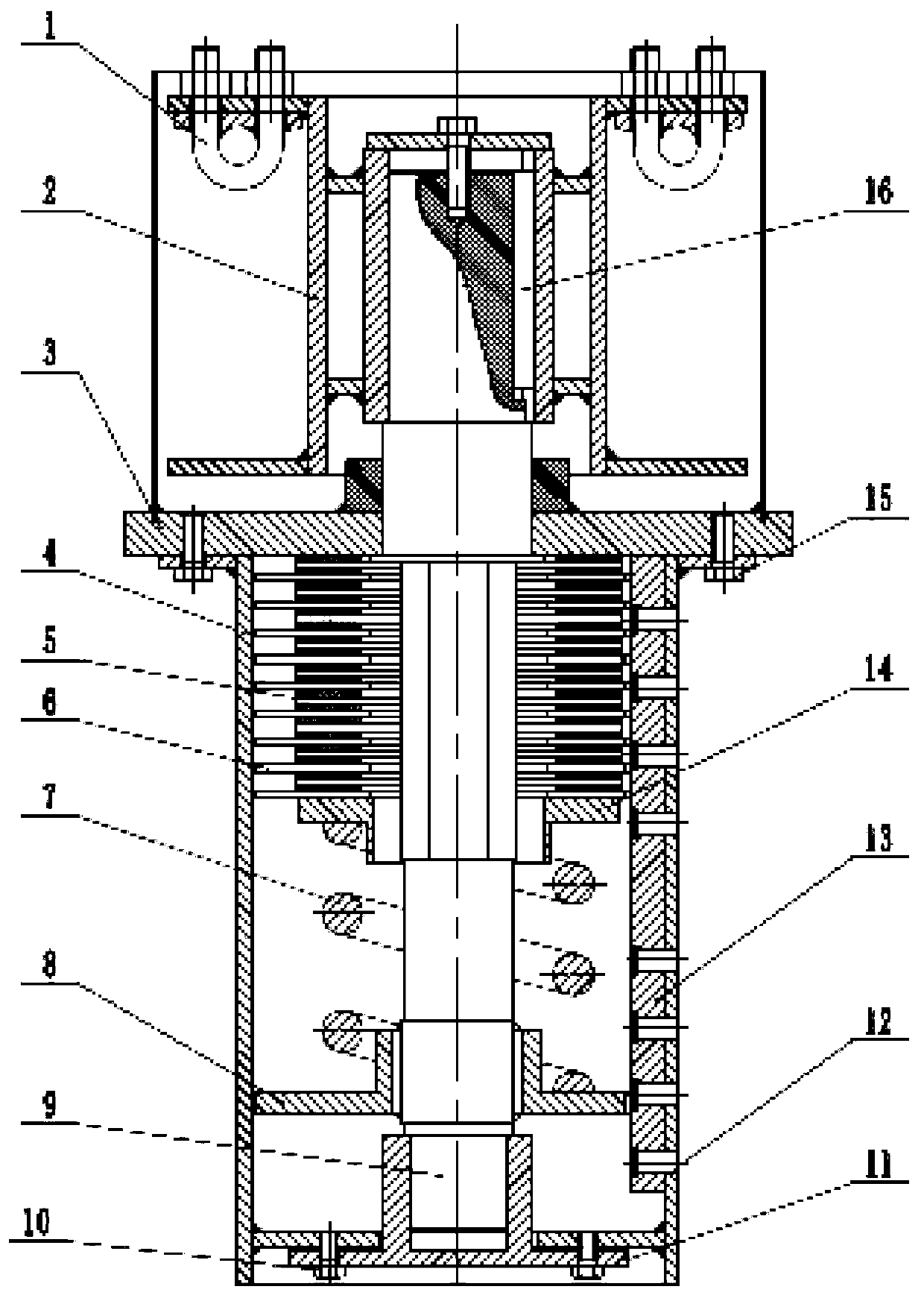

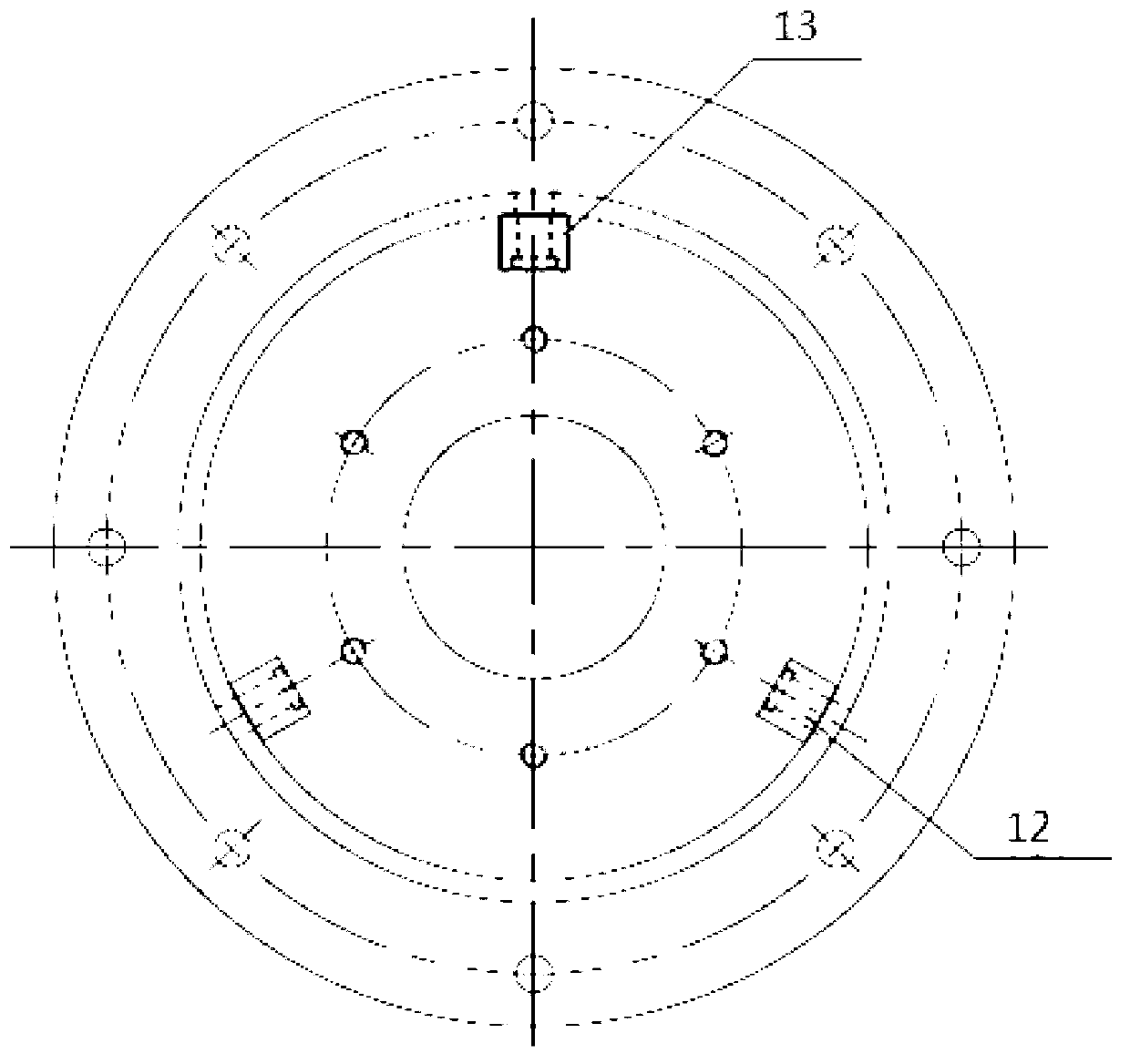

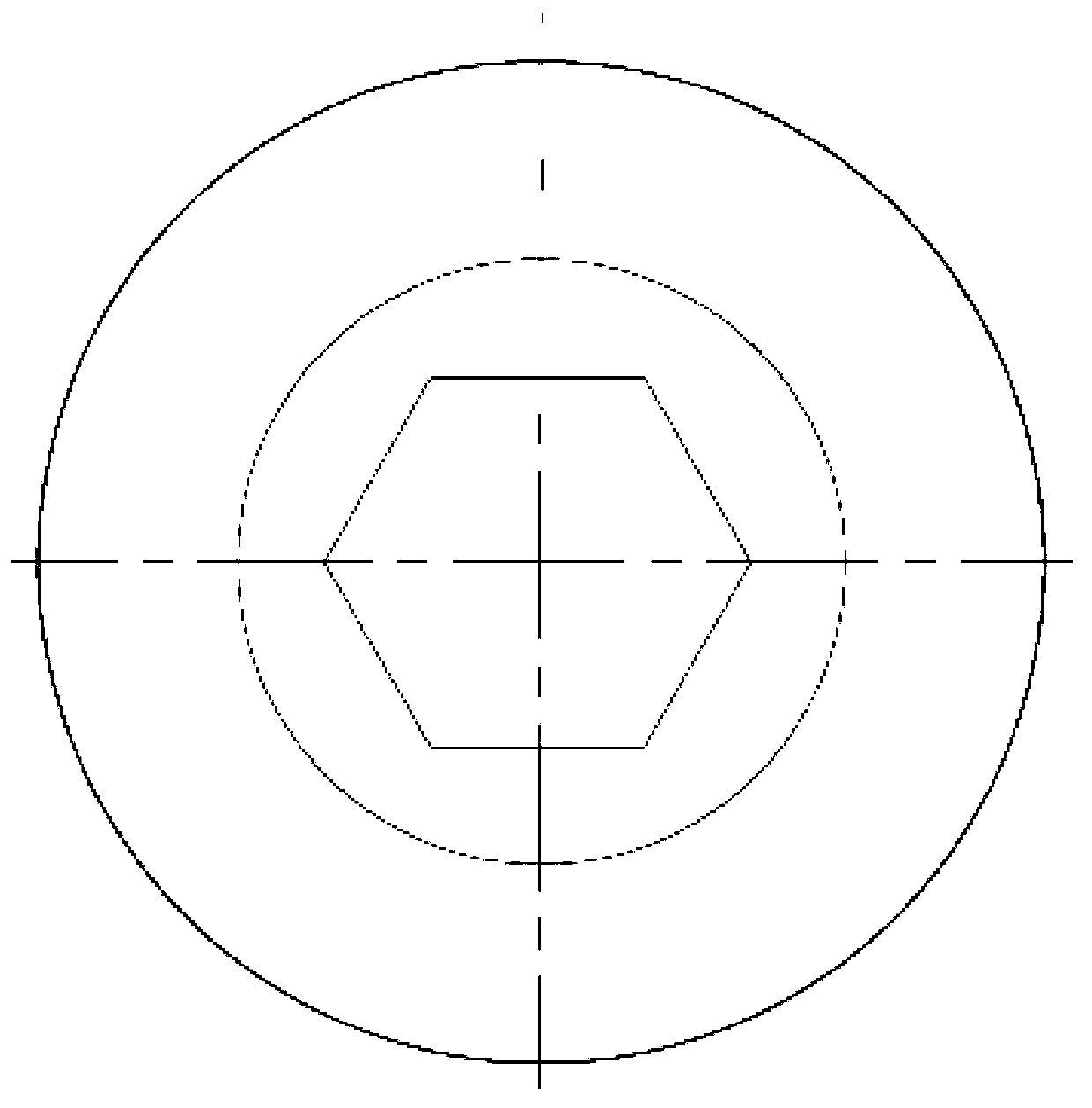

[0026] As shown in the accompanying drawings, the present invention includes a rope mechanism and a buffer energy absorber. The rope mechanism includes a rope, a mounting base 3, a shaft 9, a rope clamp 1 and a turntable 2, and the shaft 9 passes through the mounting base 3 and is supported on the mounting base 3. , one side becomes the installation shaft section of the turntable, and the other side becomes the installation shaft section of the buffer energy absorber. The turntable 2 is assembled on the turntable installation shaft section on the side of the mounting seat 3 through the key 16, and the rope is wound on the turntable 2 through the rope clamp 1. Above, the buffer energy absorber includes the friction plate cover 4, the dynamic friction plate 5, the static friction plate 6, the spring 7, the end cover 11, the push seat 14, the squeeze plate 8 and the stop block 13, and the friction plate cover 4 is installed on the mounting seat 3 On the other side, the three stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com