Bottom lifting type U-shaped tram guard

A vehicle barrier and U-shaped technology, which is applied in the field of bottom-lifting U-shaped vehicle barrier, can solve the problem that the vehicle barrier cannot be opened well, and achieves the effect of good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

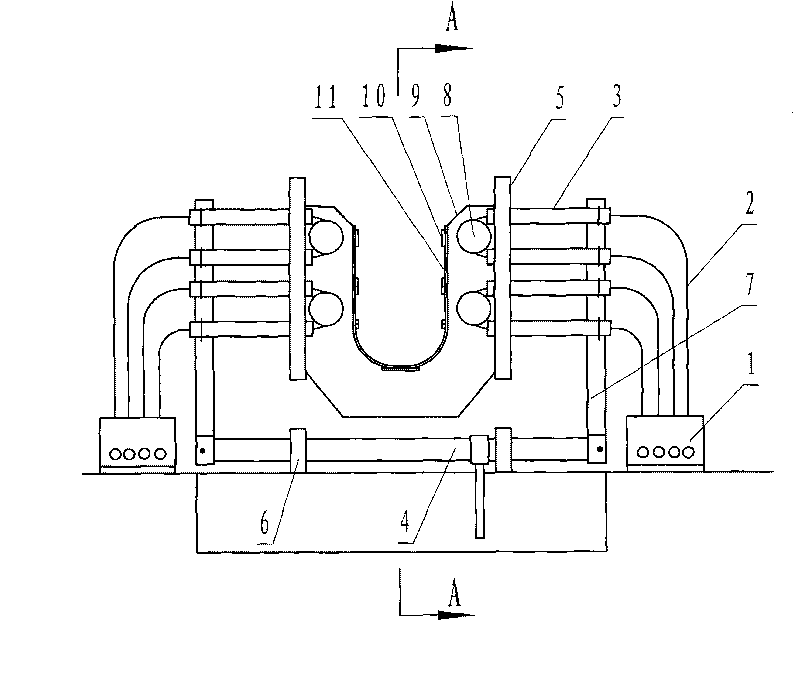

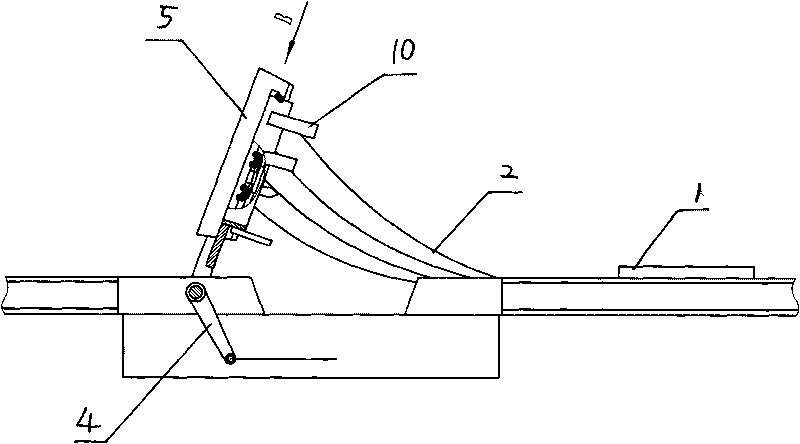

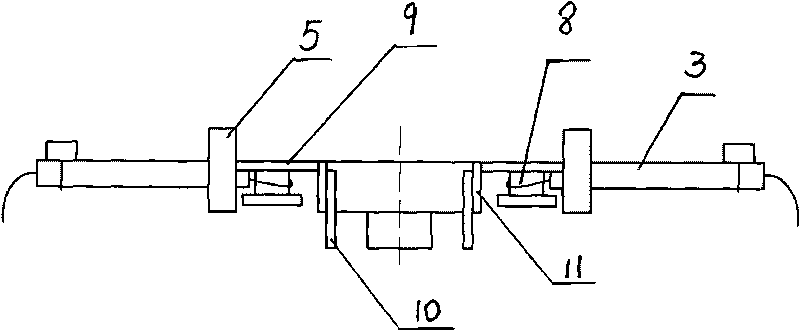

[0017] A bottom-lifting U-shaped car barrier includes a buffer 1, a steel wire rope 2, and a retaining net. The retaining net includes a retaining net skeleton 3 and a connecting support 7. Connected with the device, there is a net storage room under the mine car track in the shaft, an openable track bridge 5 is arranged above the net storage room, and a net lifting mechanism 4 is provided on the side of the net storage room. , the retaining net is provided with left and right two parts and the middle connecting groove plate 9, and the connecting groove plate is provided with a notch through which the mine car lifts the steel wire rope after the retaining net rises, and the notch edge of the connecting groove plate is provided with a reinforcing plate 11, The anti-slip teeth 10 that prevent the retaining net from slipping off from the quilt cover mine car perpendicular to the connecting groove plate are provided on the connecting groove plate. The anti-skid teeth 10 are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com