Inclined shaft safe door device preventing equipment sliding

A technology for preventing sports cars and safety doors, which is used in transportation and packaging, railway car body parts, and mandatory railway stoppers, etc. It can solve the problems of high risk of manual operation, inability to prevent sports cars in advance, and inability to prevent the danger of manual operation of sports cars in advance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

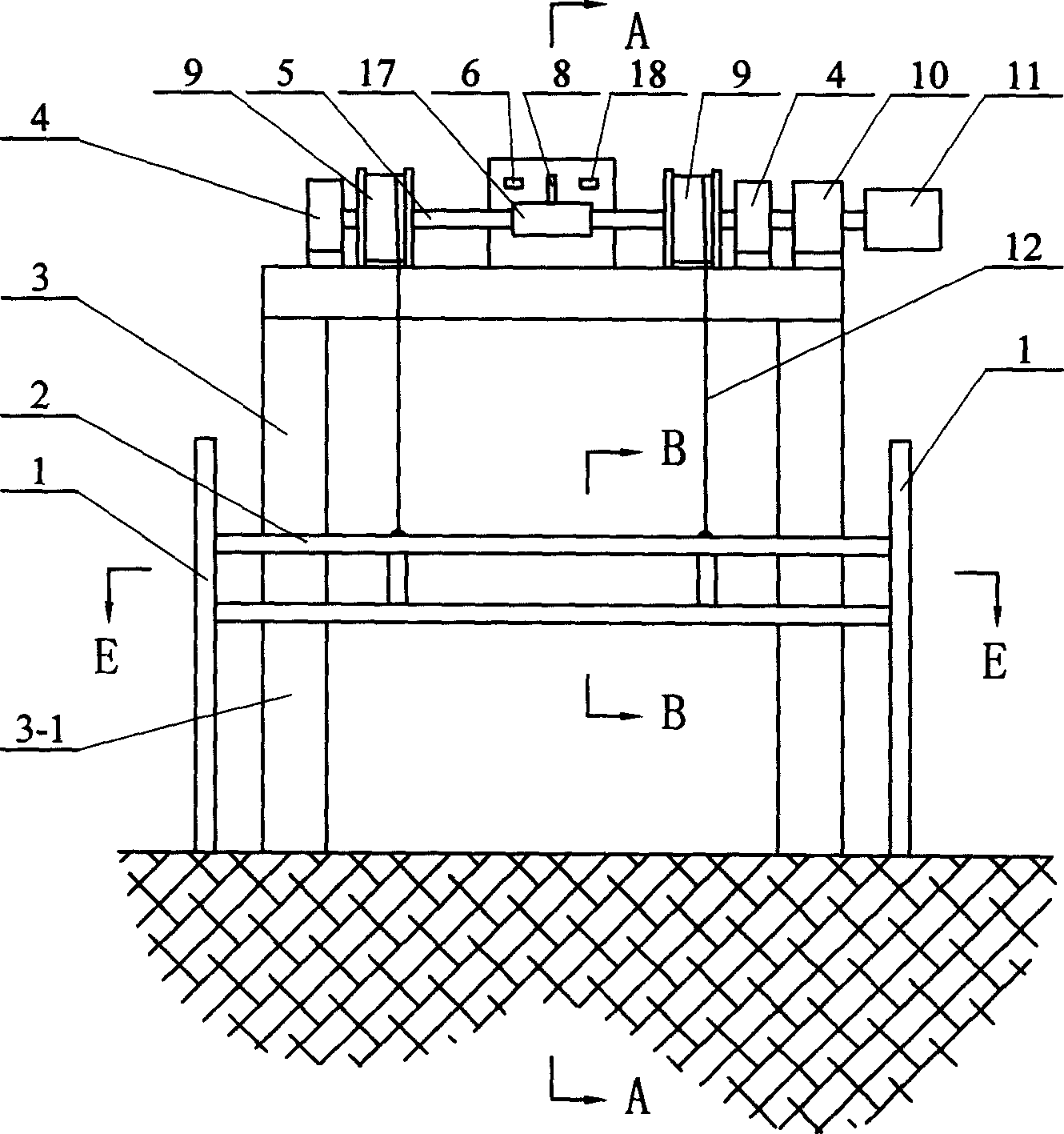

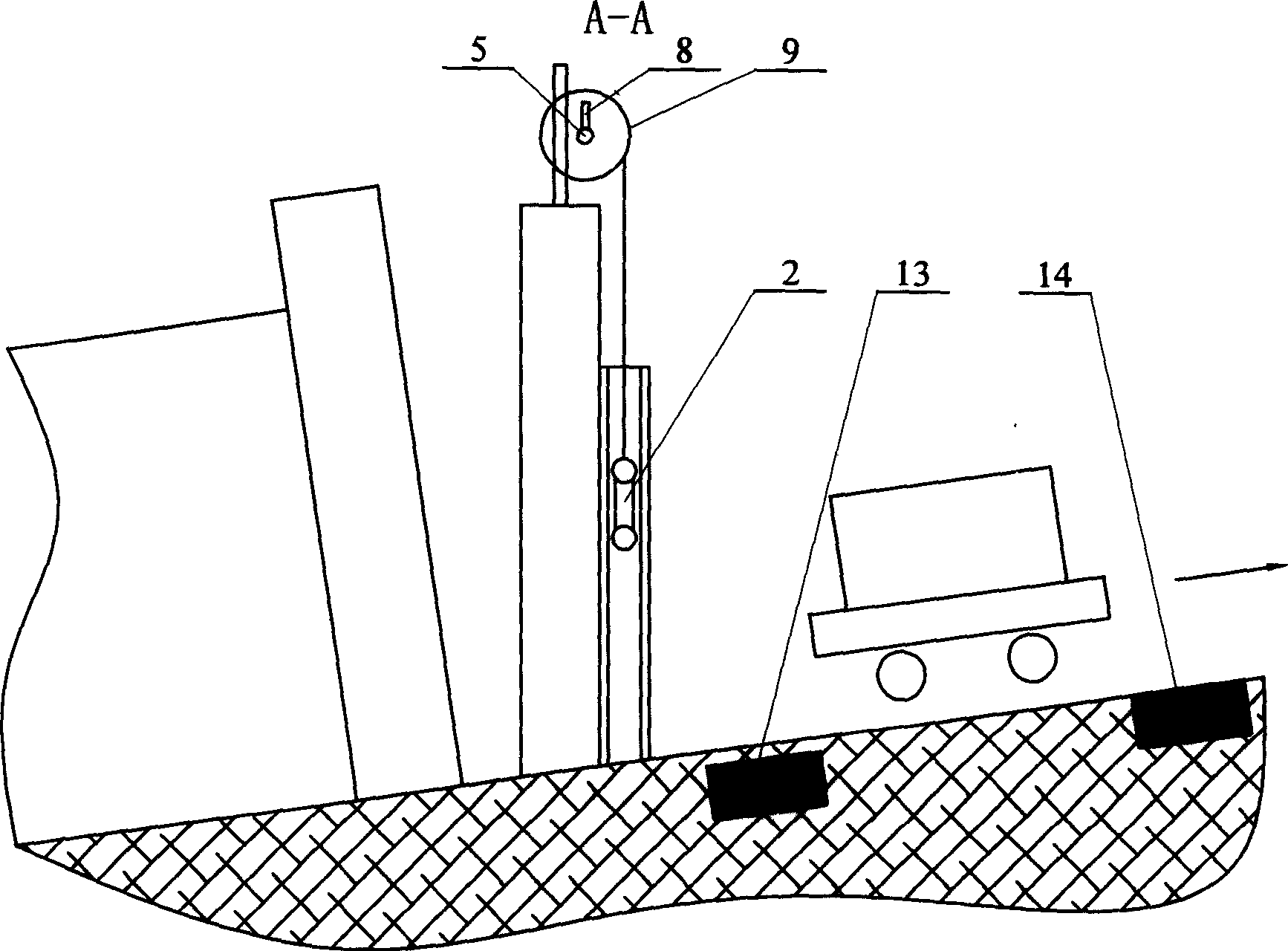

[0005] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. This embodiment consists of a frame-shaped main frame 3, two slideways 1, safety railings 2, bearing housings 4, through shafts 5, screw nuts 17, levers 8, left travel switches 6, right travel switches 18, and rollers 9. , reducer 10, motor 11 and steel wire rope 12, the through shaft 5 is set horizontally on the upper top of the main frame 3 through the bearing seat 4, the roller 9 is fixed on the through shaft 5 and rotates coaxially with the through shaft 5, and the lead screw Nut 17 is screwed in the lead screw that is opened in the middle section of through shaft 5 length direction, and driving rod 8 is fixed on the leading screw nut 17, and left travel switch 6 and right travel switch 18 are respectively arranged on the left and right sides of driving rod 8. At the two cut-off positions, one end of the through shaft 5 is connected to...

specific Embodiment approach 2

[0006] Specific implementation mode two: the following combination figure 2 , Figure 4 and Figure 5 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes the moving contact ZC of the upwell contactor, the moving contact FC of the downhole contactor, the on-board sensor 13, the off-board sensor 14, the program controller 20, the forward rotation The contactor 21 and the reverse contactor 22, one end of the moving contact ZC of the upper well contactor and the moving closing contact FC of the lower well contactor are connected to the power supply VCC, and the other end of the moving closing contact ZC of the upper well contactor is connected to the vehicle sensor 13 One connection terminal of the left travel switch 6 and the moving contact of the left travel switch 6, the other end of the downhole contactor moving contact FC is connected with a connection terminal of the alighting sensor 14 and the m...

specific Embodiment approach 3

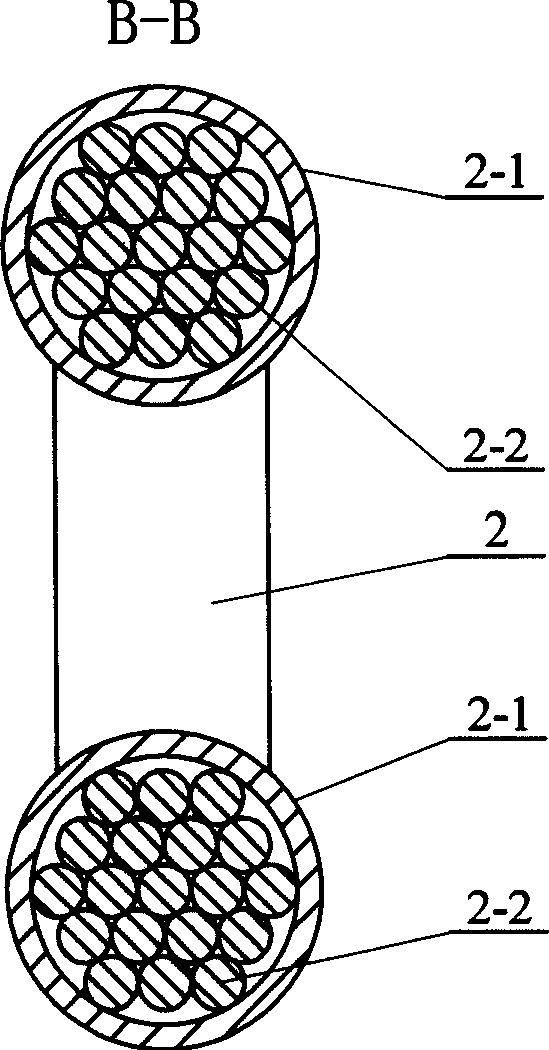

[0007] Specific implementation mode three: the following combination image 3 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the rod body 2-1 of the safety railing 2 is a steel pipe, and a steel wire rope 2-2 is passed through the inner cavity of the rod body 2-1. So set, the anti-collision strength of safety railing 2 is big.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com