Mine safety device

A safety device and mine technology, applied in hoisting devices, transportation and packaging, railway car body parts, etc., can solve problems such as loss of mining enterprises and mine workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

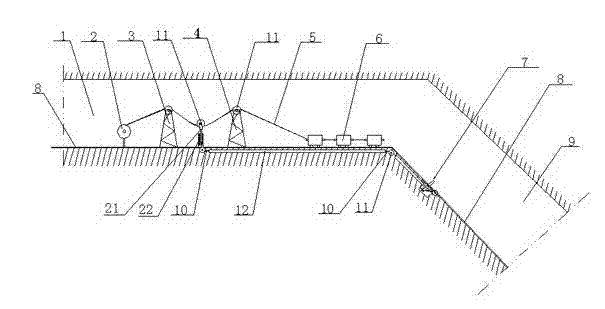

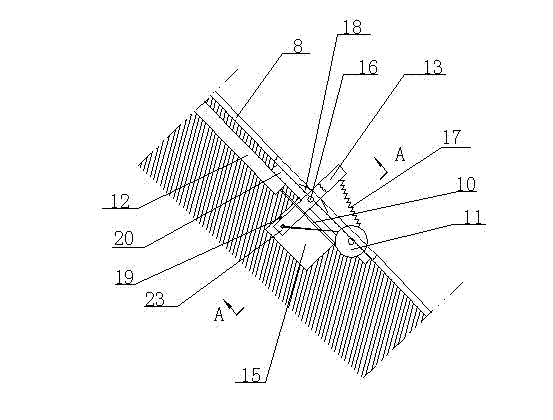

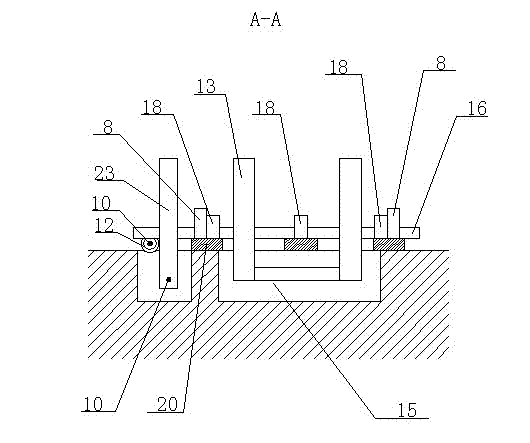

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an electric winch 2, a first bracket 3 and a second bracket 4 are installed on the horizontal carriageway 1 in the mine. One end of the wire rope 5 is connected to the electric winch 2, and the other end is used to connect the mine car 6. The wire rope 5 between the first bracket 3 and the second bracket 4 is connected with a tension sensing rope 10, a roller 11 is provided at the connection, a guide tube 22 is installed on the ground below the roller 11, and a telescopic rod 21 is connected to the roller 11 , The lower end of the telescopic rod 21 is connected to the top end of the tension sensing rope 10, and the telescopic rod 21 is placed in the guide tube 22; a vehicle blocking pit 15 is provided below the track 8 of the inclined shaft 9 in the mine, and the pit 15 is installed above the The car stop frame 20, the rotating shaft 16 is installed on the car stop frame 20 through the fixed seat 18, the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com