Centrifugal force safety braking device of active track-locking type tramcar

A technology of safe braking and centrifugal force, which is applied in the field of mining vehicle components, can solve problems such as long braking response time, low reliability performance, and insensitive response, so as to avoid loss of life and property, high reliability performance, and fast braking response time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

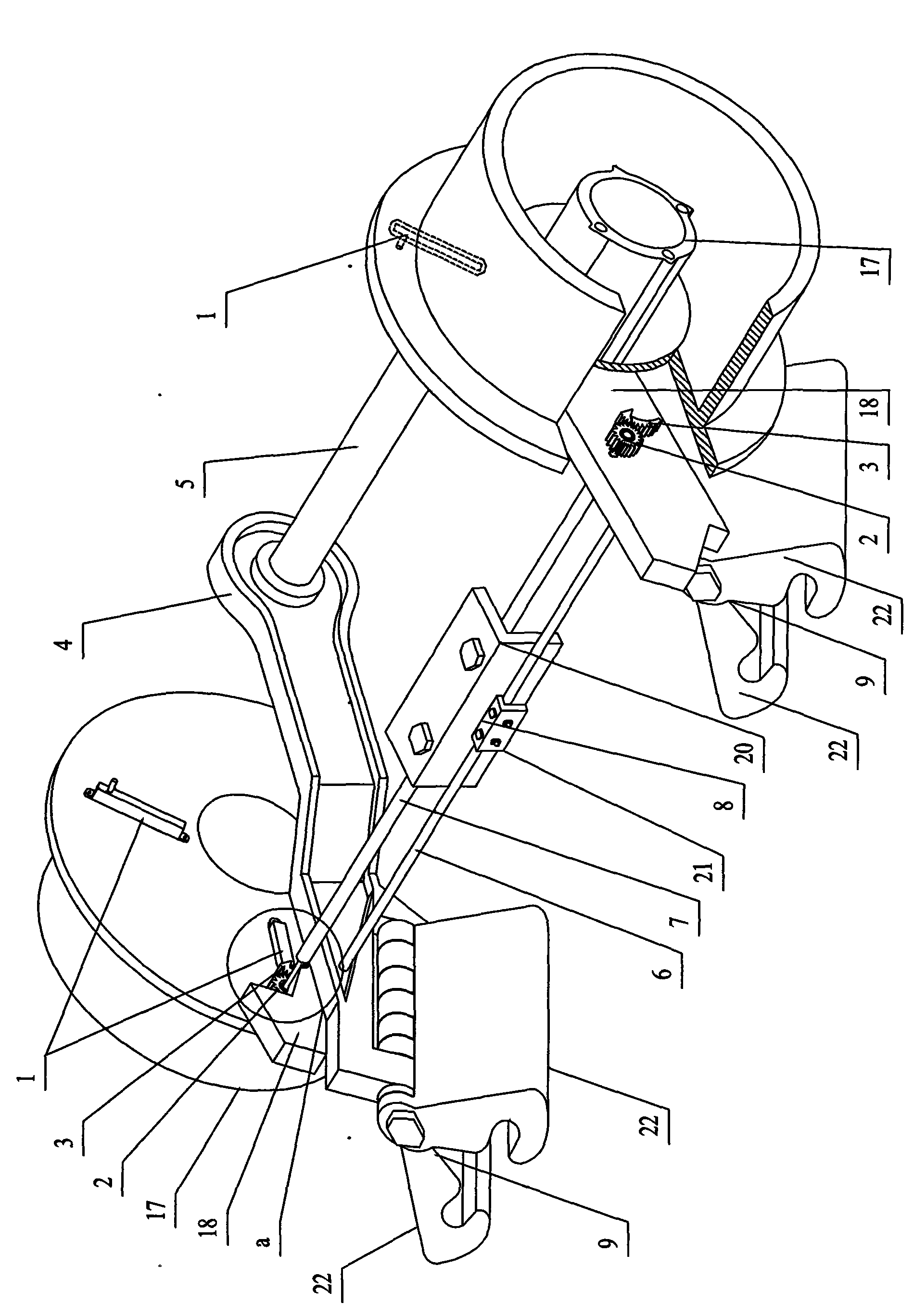

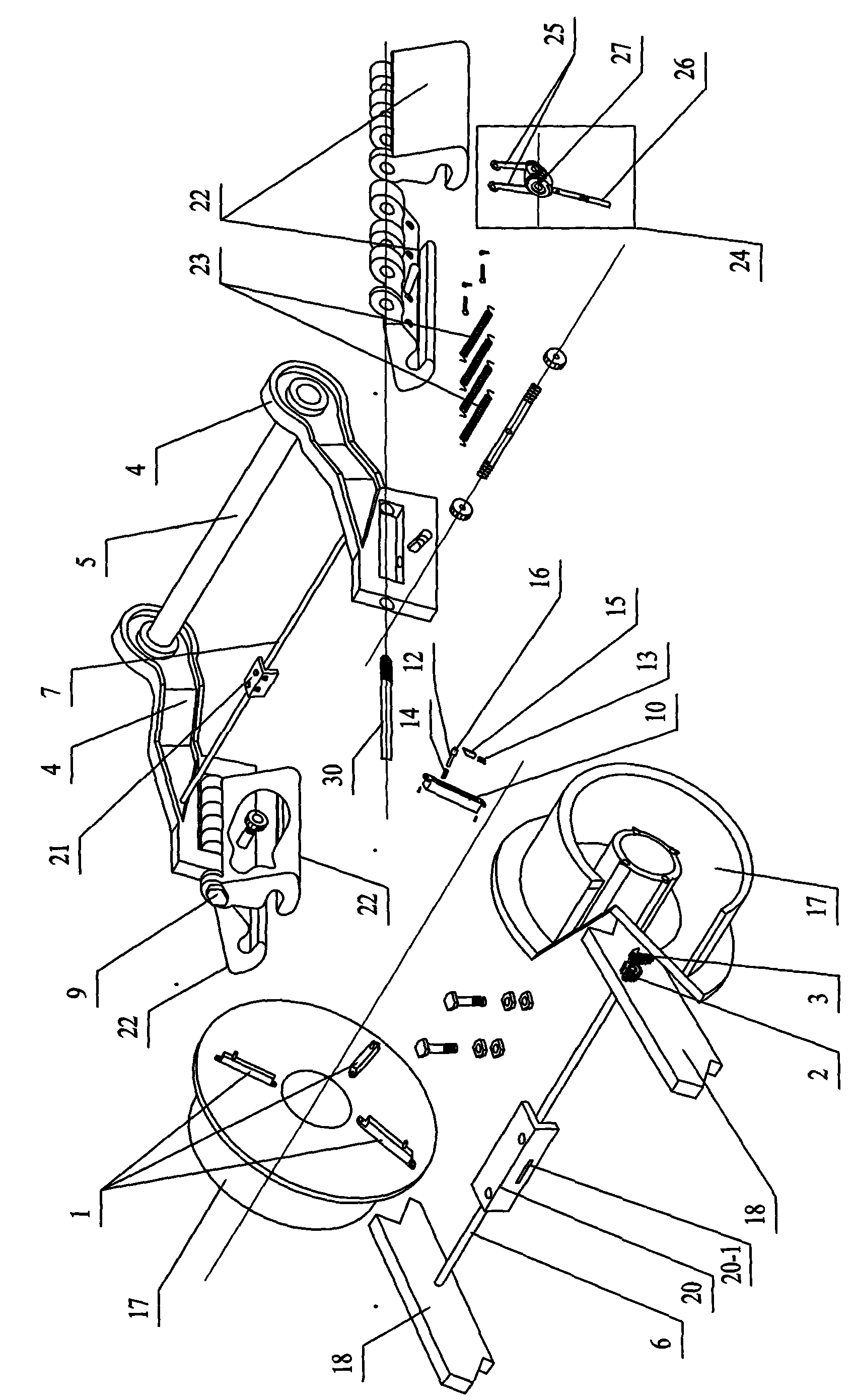

[0007] Specific implementation mode 1: Combination Figure 1~Figure 9 To illustrate this embodiment, the active rail-locking type mining car centrifugal force safety brake device of this embodiment consists of two sets of centrifugal force sensors, two gears 2, two racks 3, two main frames 4, a connecting shaft 5, and a fixed The connecting rod 6, the rotating connecting rod 7, the suspension switch 8, the two brake claws 9, the mine wheel body 17 and the mine cart frame 18, each group of centrifugal force sensors is composed of multiple centrifugal force sensors 1, The two sets of centrifugal force sensors are arranged on the two mine wheel bodies 17 opposite to each other. The multiple centrifugal force sensors 1 on each mine wheel body 17 are evenly arranged along the circumferential direction of the mine wheel body 17, and each centrifugal force The speed sensor 1 is arranged along the normal direction of the mine wheel body 17. Each centrifugal force sensor 1 consists of a sli...

specific Embodiment approach 2

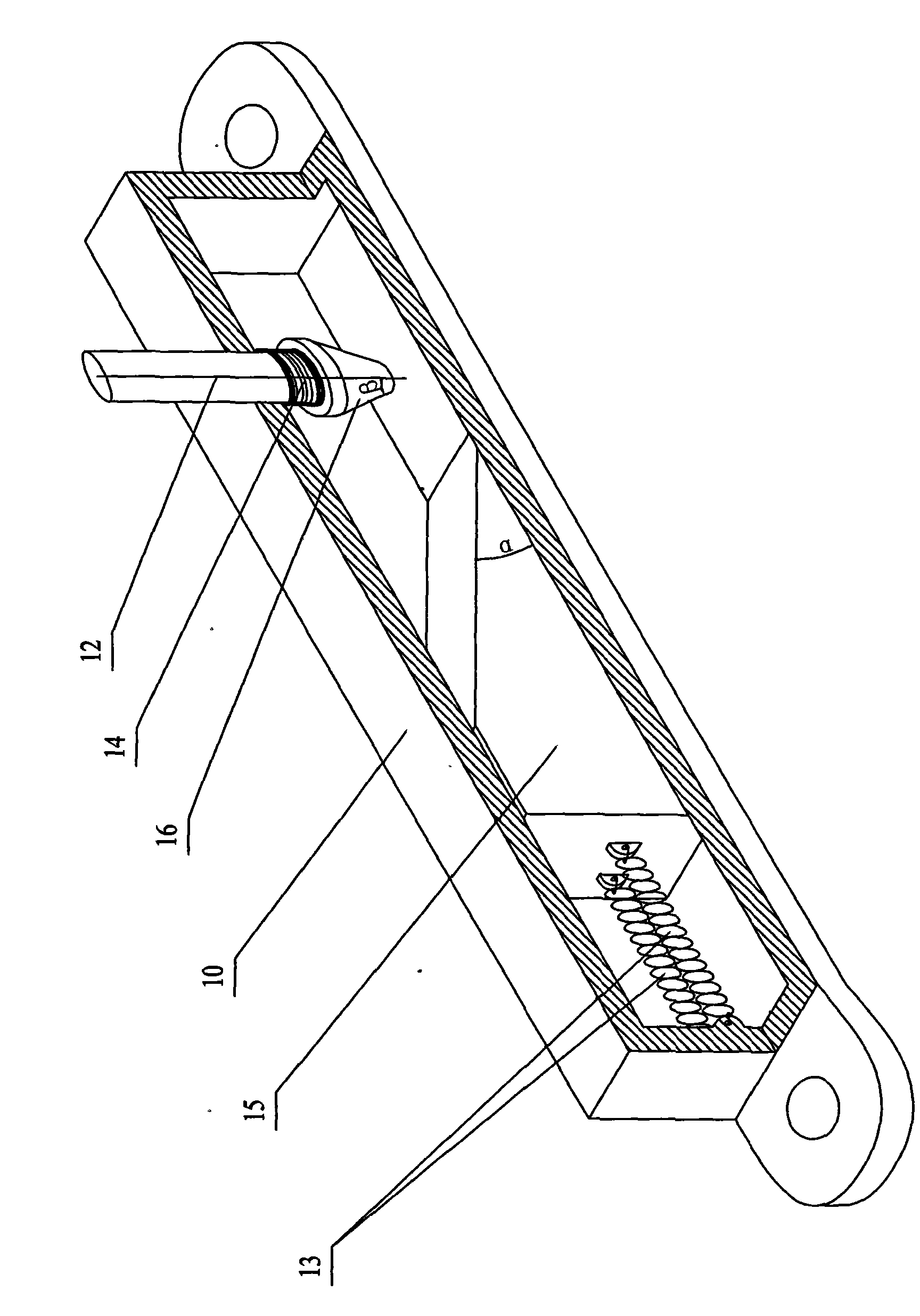

[0008] Specific implementation manner two: combination image 3 To describe the present embodiment, the sum of the wedge angle α of the wedge slider 15 and the taper angle β of the truncated cone body 16 of the present embodiment is less than 90°. With this arrangement, the contact area between the wedge-shaped slider 15 and the circular table body 16 is small, and the relative friction is small, so that the centrifugal force sensor is more sensitive and the braking time is shorter. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with figure 2 To explain this embodiment, each group of centrifugal force sensors in this embodiment is composed of two to five centrifugal force sensors 1. With this setting, when a certain centrifugal force sensor fails and stops working, other centrifugal force sensors can act as a timely brake, so that the safety factor of the braking device is improved. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com