Displacement recognition system of belt conveyor telescopic head

A technology of identification system and telescopic head, which is applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of affecting workers' occupational health, increasing workers' labor intensity, and poor reliability, so as to protect workers' health Health and personal safety, improve work efficiency and production management level, reduce the effect of manual error probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

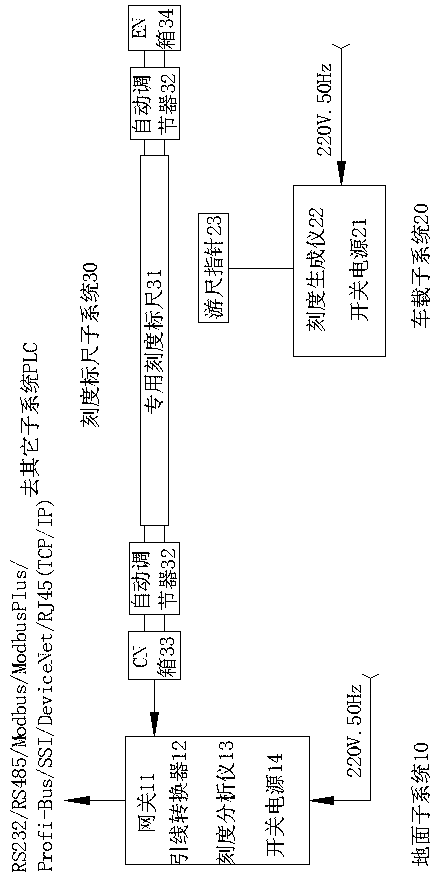

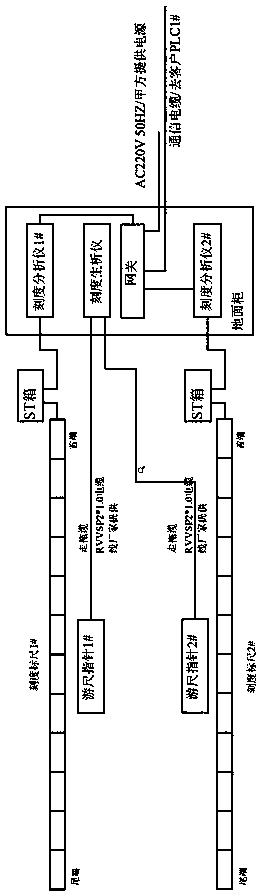

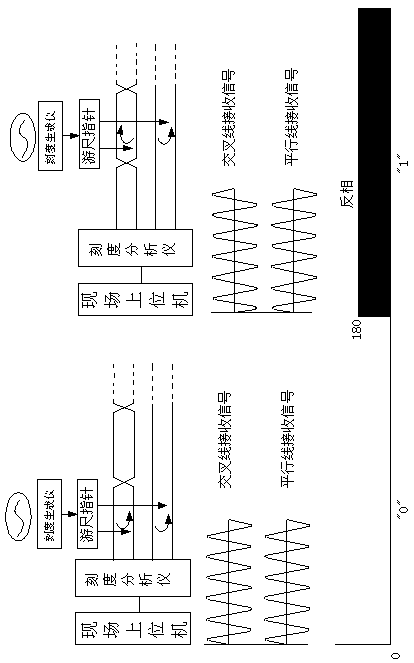

[0033] see figure 1 , a belt conveyor telescopic head displacement identification system, composed of a ground subsystem 10, a vehicle subsystem 20, and a scale subsystem 30. The ground subsystem 10 includes a ground subsystem switching power supply 14, a scale analyzer 13, a lead converter 12, and a gateway 11. The signal input terminal of the scale analyzer 13 is connected with the scale scale 31 in the scale scale subsystem 30, and receives the scale scale 31 electromagnetic signal, the signal output terminal of the scale analyzer 13 is connected with the on-site host computer, and the signal obtained by comparison is transmitted to the on-site host computer through the gateway 11; the vehicle-mounted subsystem 20 is arranged on the belt conveyor head telescopic device, including The scale generator 22 and the vernier pointer 23, the scale generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com