Patents

Literature

40results about How to "Reduce the chance of human error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

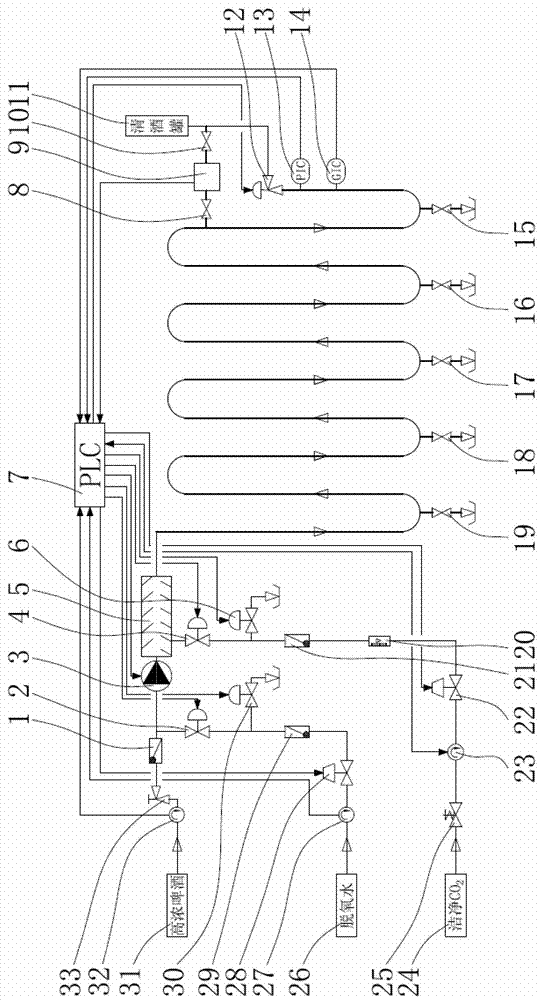

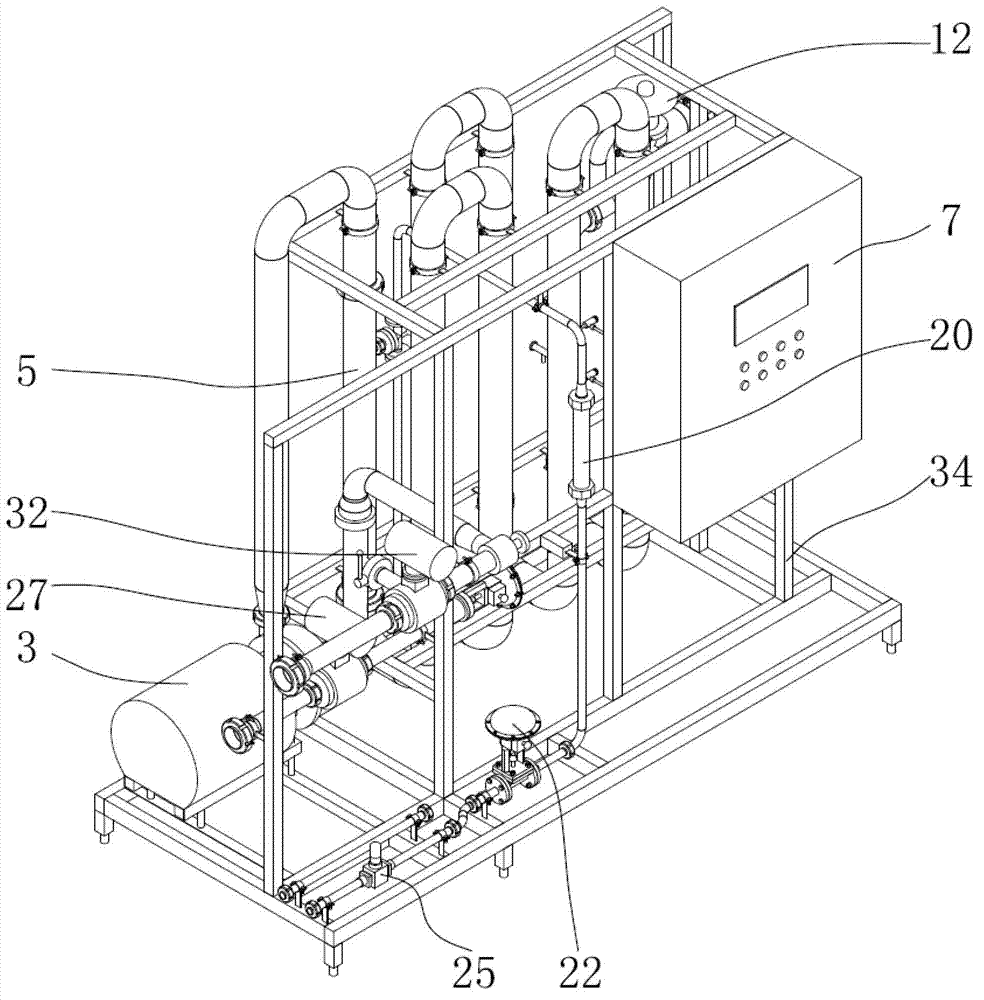

Full-automatic high-concentration beer dilution ratio mixing machine and mixing method thereof

InactiveCN102827717AReduce the impactAvoiding problems with feedback regulation hysteresisBeer brewingHysteresisHigh concentration

The invention discloses a full-automatic high-concentration beer dilution ratio mixing machine and a mixing method thereof, relating to the technical field of multi-material mixing processes such as biology and wine fermentation engineering, food beverage engineering, bio-pharmaceuticals, fine chemistry industry and chemical engineering. The full-automatic high-concentration beer dilution ratio mixing machine comprises a frame, a PLC (Programmable Logic Controller) control cabinet, a static mixer and a diluting pump, wherein the PLC control cabinet is arranged on the outer side of the frame; the static mixer is arranged above the frame; the diluting pump is arranged at the lower end of the static mixer; and the full-automatic high-concentration beer dilution ratio mixing machine is externally connected with high-concentration beer, deoxygenated water, clean CO2 and a finished beer tank. The mixing method comprises the following steps of: mixing high-concentration beer with deoxygenated water in the diluting pump; and mixing with clean CO2 in the static mixer, and feeding into the finished wine tank. The method is practicable; a mass flow meter is applied, so that a reliable precondition is provided for accurate adding of CO2 into diluted beer; a mathematical model is established, so that reliable basis is provided for accurate adding of deoxygenated water and CO2 into high-concentration beer; an open-ring control principle is applied, so that the phenomenon of incorrect mixture ratio caused by hysteresis of feedback adjustment and detection data distortion in closed-ring control is avoided; and automation control in an entire process is realized, so that the labor strength is greatly lowered, the possibility of human errors is lowered, and the product quality and uniformity are improved.

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

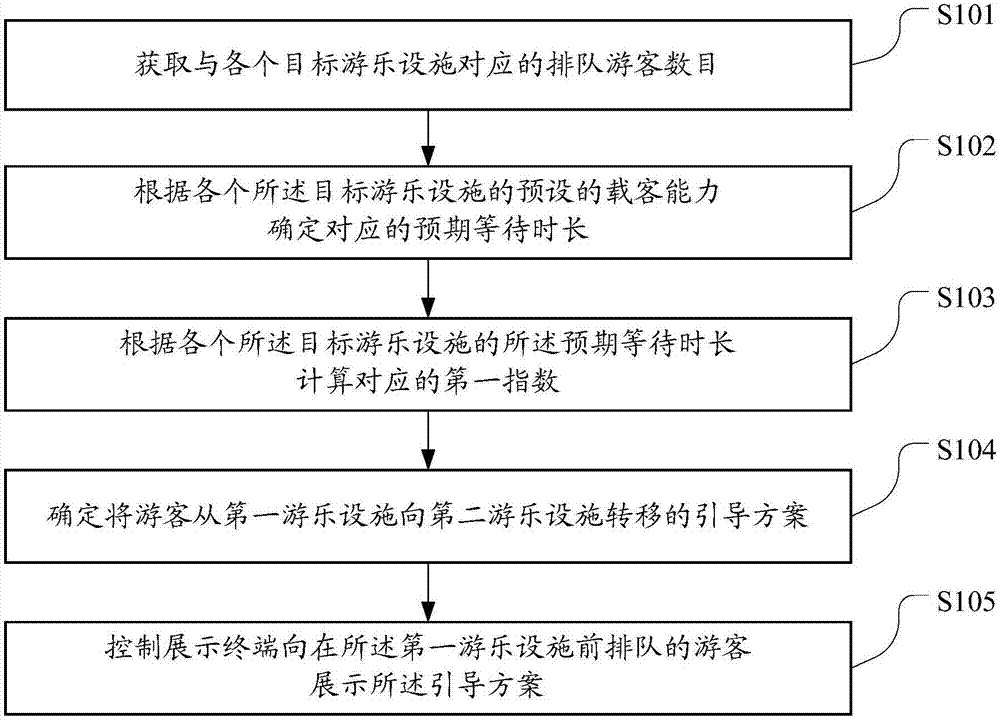

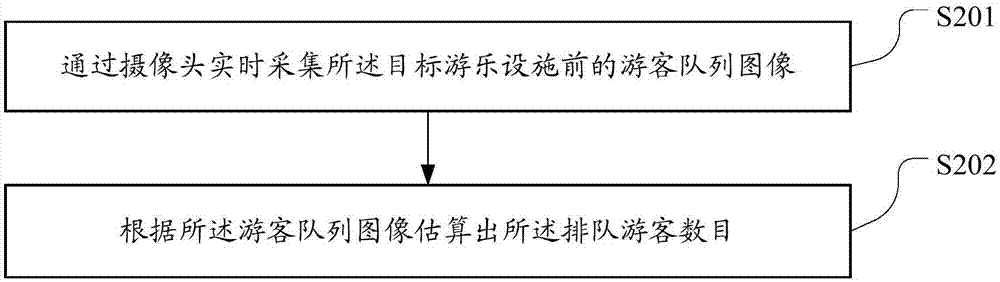

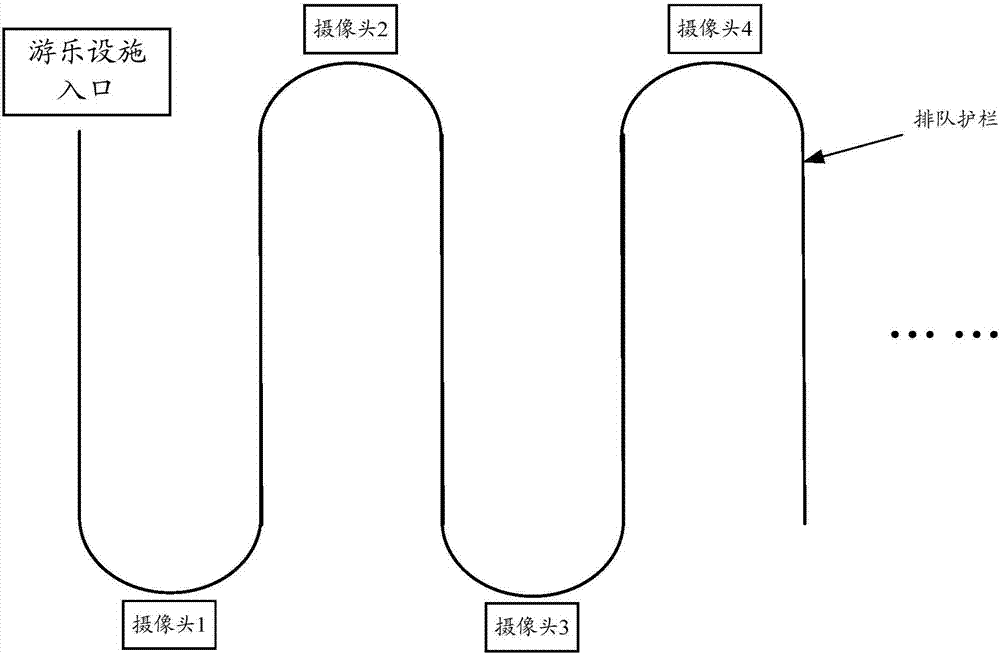

Amusement park management method and device

InactiveCN107368947AGuaranteed normal operationReduce human inputCharacter and pattern recognitionResourcesRecreationThe Internet

The invention is suitable for the technical field of the Internet of Things, and provides an amusement park management method and device. The method includes obtaining the number of queuing tourists corresponding to each target recreation facility; determining corresponding expected waiting duration according to a preset carrying capability of each target recreating facility, wherein the expected waiting duration is duration required by the target recreation facility for completing carrying of the corresponding number of the queuing tourists; calculating a corresponding first index according to the expected waiting duration of each target recreating facility; determining a guidance scheme of transferring tourists from a first recreation facility to a second recreation facility; and controlling a display terminal to display the guidance scheme to tourists queuing in front of the first recreation facility, so that the tourists transfer from the first recreation facility to the second recreation facility according to the guidance scheme. Through the amusement park management method provided by the embodiment of the invention, the tourist guidance scheme can be automatically determined and the tourists are guided to transfer, thereby reducing management cost, and improving overall efficiency.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

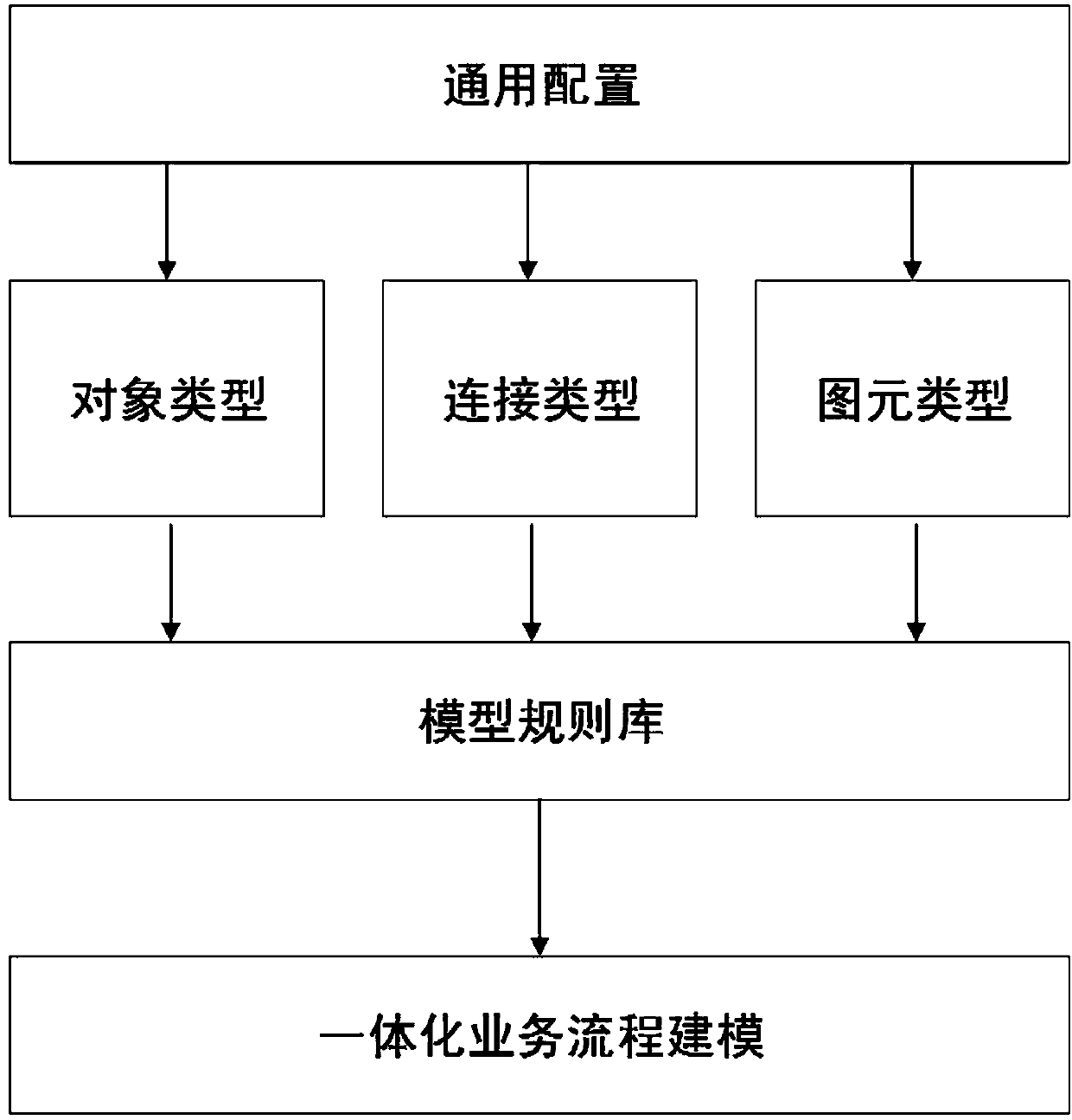

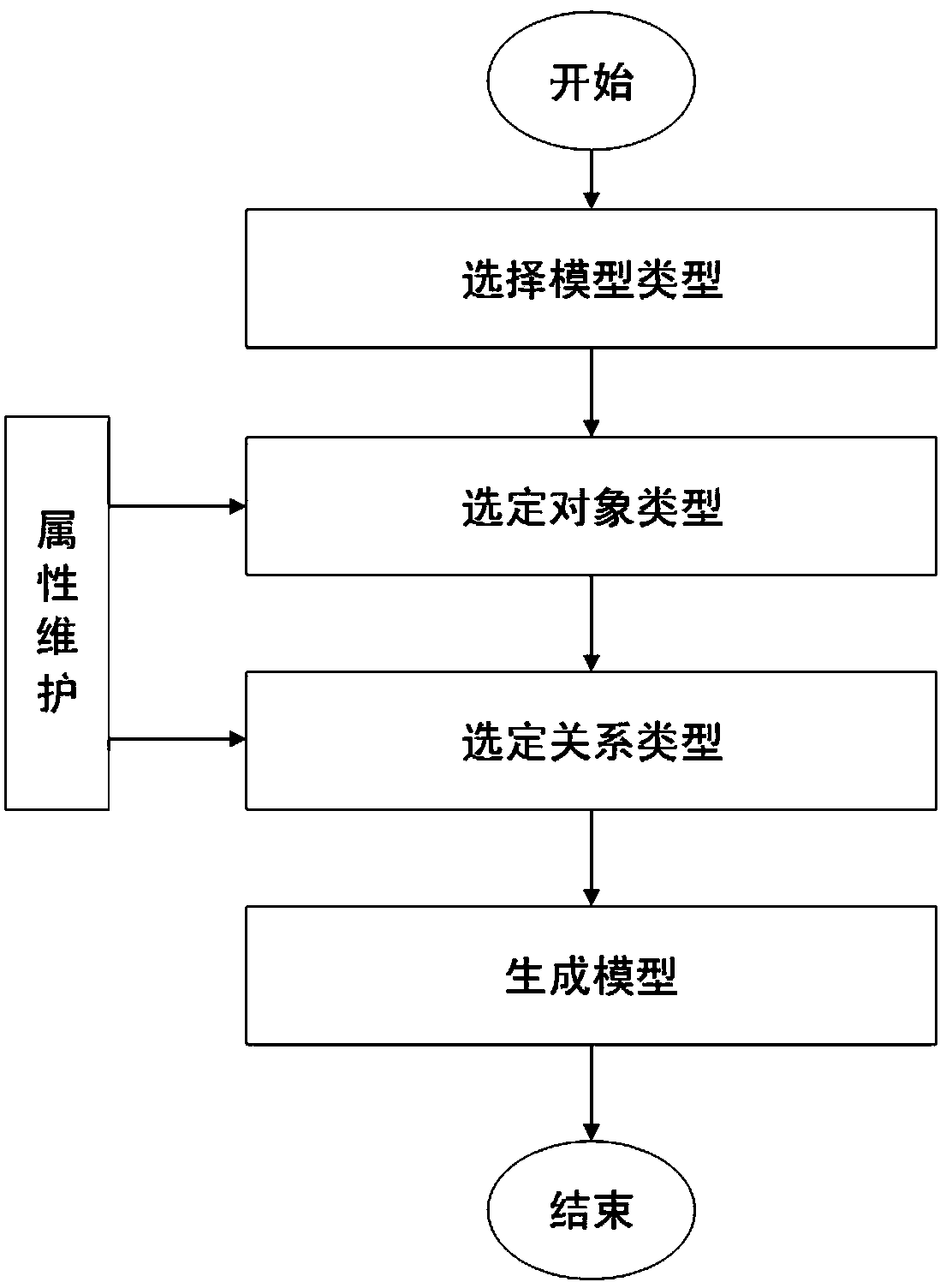

Computer modeling method of full operation flow based on structuralization

InactiveCN104217306ASolve the problem of structured managementEnsure complianceResourcesStructured modelModel method

The invention provides a computer modeling method of a full operation flow based on structuralization. The computer modeling method comprises the first step of establishing a modeling basic library comprising such structured modeling basic elements as primitives, object elements and connecting line types, the second step of establishing a model rule library, namely selecting elements needed for modeling from a basic object library and a basic connection library, and according to different modeling requirements, establishing different model rules including an operation flow model rule, a risk model rule and an organizational structure model rule, the third step of performing integrated operation flow modeling based on a model rule library, and the four step of performing version control and release management on the built mode, wherein the model objects and the connecting line types usable for model examples are appointed in the model rule library; the model cannot be put into use before being released; only the released model can be used in practical production. The computer modeling method of the full operation flow based on structuralization has the characteristics of convenient operations and convenient for use, and meanwhile, is capable of well supporting integrated modeling of the operation flow.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

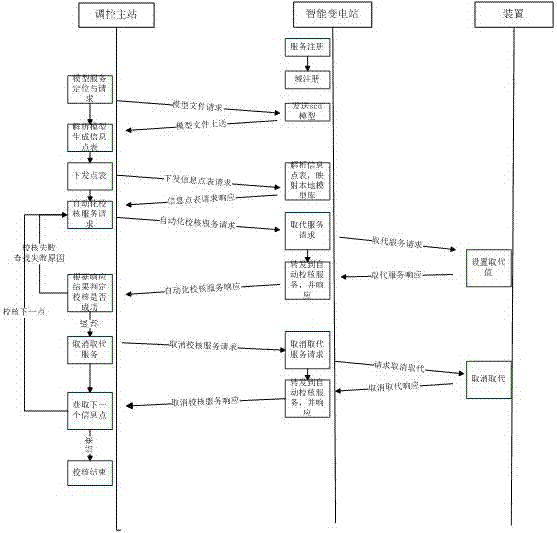

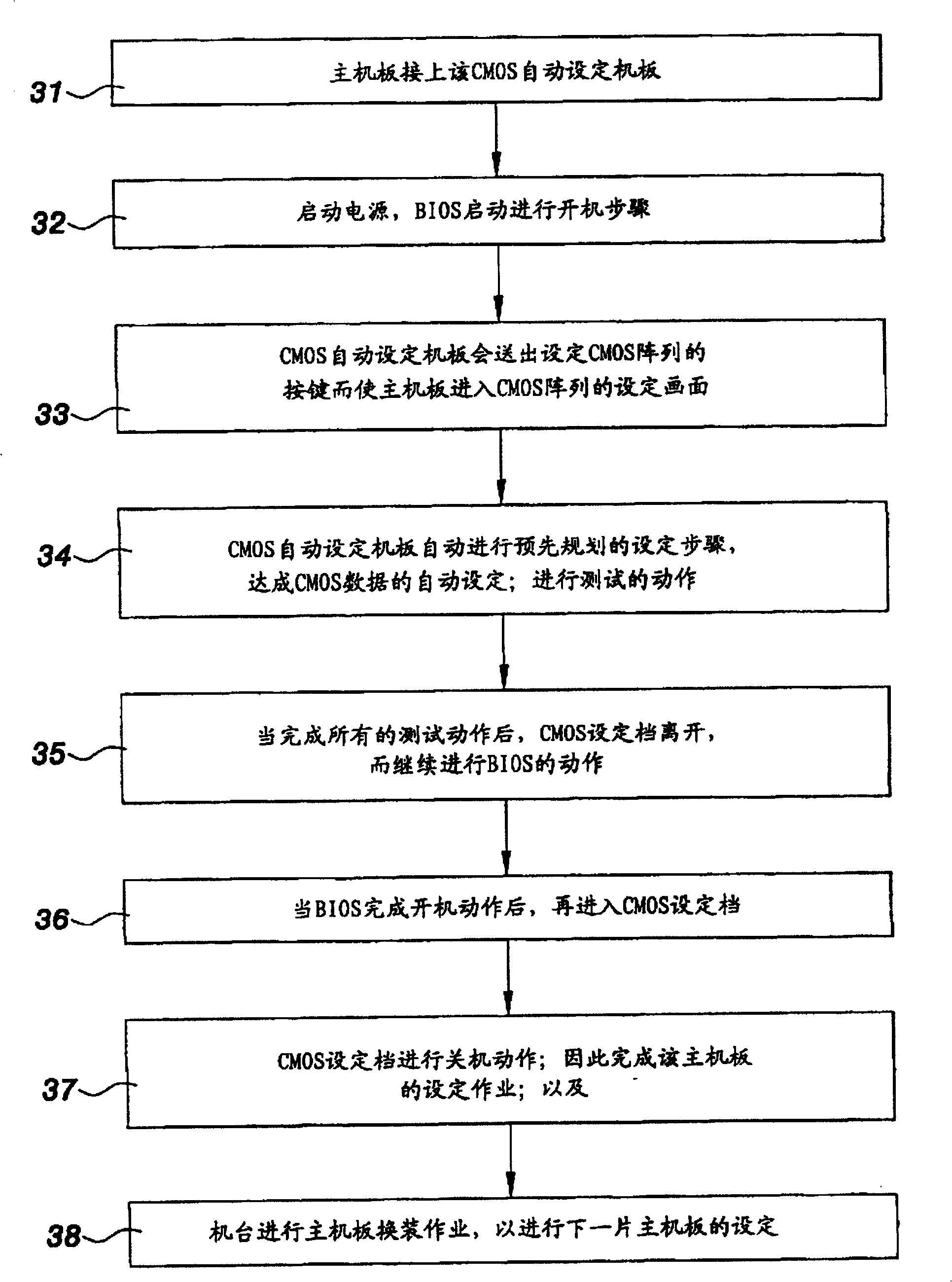

Implementation system and method for automatic check of POI table in intelligent power grid

ActiveCN107067161AReduce the chance of human errorImprove efficiency and accuracyResourcesService providerPlug and play

The invention aims to provide an implementation system and method for automatic check of a POI (Point of Information) table in an intelligent power grid. According to the invention, a server / consumer mode is adopted and a function of a service provider is implemented in an intelligent communication gateway machine. The service provider includes a model service producer and an automatic check service producer. Through a plug-and-play technical system and an IEC61850 substitution service of an intelligent substation, automatic check of point table between a regulation main station and the intelligent substation and automatic check technique for POI between the main and sub stations and An IED device. Manual error rate is reduced; efficiency and accuracy of POI interaction between the regulation main station and the intelligent substation are improved. Manual point check work load is reduced; automatic maintenance of the POI table is facilitated; and automation degree of interaction between the regulation main station and the intelligent substation is improved.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

A method for directly importing BOM into a production system

InactiveCN109325730AImprove efficiencyReduce the chance of human errorOffice automationManufacturing computing systemsModularityDevice type

The invention discloses a method for directly importing BOM into a production system. The method comprises the following steps of S100, setting PCB design software, inputting material key informationinto a schematic diagram, and deriving an initial BOM; step S200, automatically merging, counting, classifying and sorting the material information in the initial BOM to generate a final BOM, whereinthe material information comprises a device type, a material code, an encapsulation and a value; step S300, directly importing the final BOM into the production system. The method of the invention adopts a script program to realize automatic classification, merging and sorting, which can effectively improve the efficiency of outputting final BOM. By reducing the comparison of complicated information of materials, and only inputting useful information, the probability of manual error can be reduced, and by the operation of PCB schematic diagram, the reuse of circuit module or unit can be realized and the labor cost is reduced.

Owner:SICHUAN JIUZHOU ELECTRONICS TECH

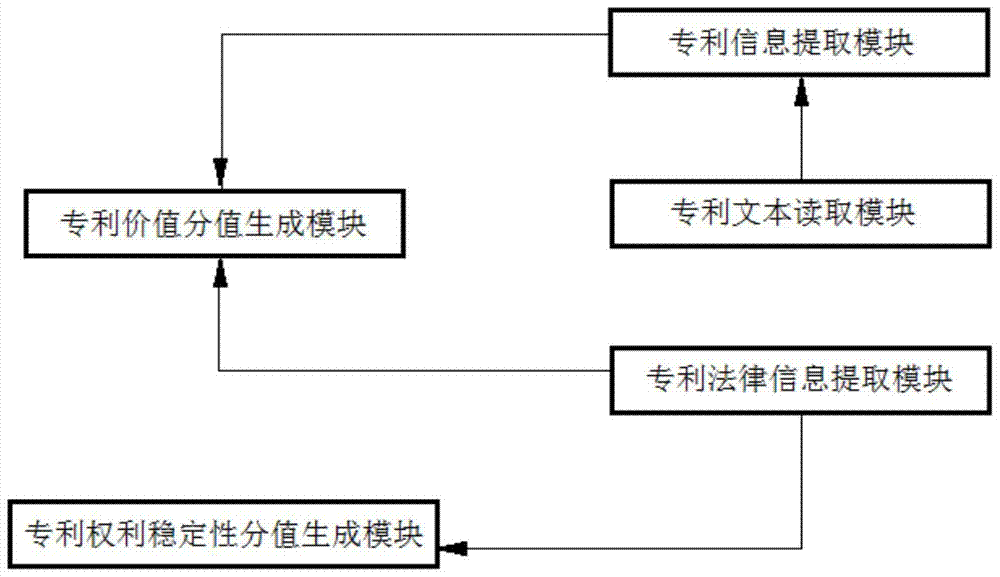

Patent operation risk control and evaluation system

InactiveCN107015981AShorten the timeReduce the chance of human errorData processing applicationsSpecial data processing applicationsRisk ControlData mining

The invention discloses a patent operation risk control and evaluation system. The system comprises a patent law information extraction module, a patent text reading module, a patent information extraction module, a patent value score generation module, and a patent right stability score generation module. The patent value score generation module reads in patent application date, claim items, patent cited times, patent number of a patent family, and generates patent residual effective year number. The patent value score generation module reads in times and results that a patent is requested in an invalid manner, and times and results of patent related patent lawsuit, and assign each extracted parameter, so as to obtain a total score of patent value of the patent. The patent right stability score generation module reads in times and results that the patent is requested in an invalid manner, and times and results of patent lawsuit, and assigns each parameter to obtain the total score of patent right stability. The system greatly reduces time consumed by retrieval and evaluation by evaluators, and evaluation is more objective, and probability of man-made errors is reduced.

Owner:广州知商互联网科技有限公司

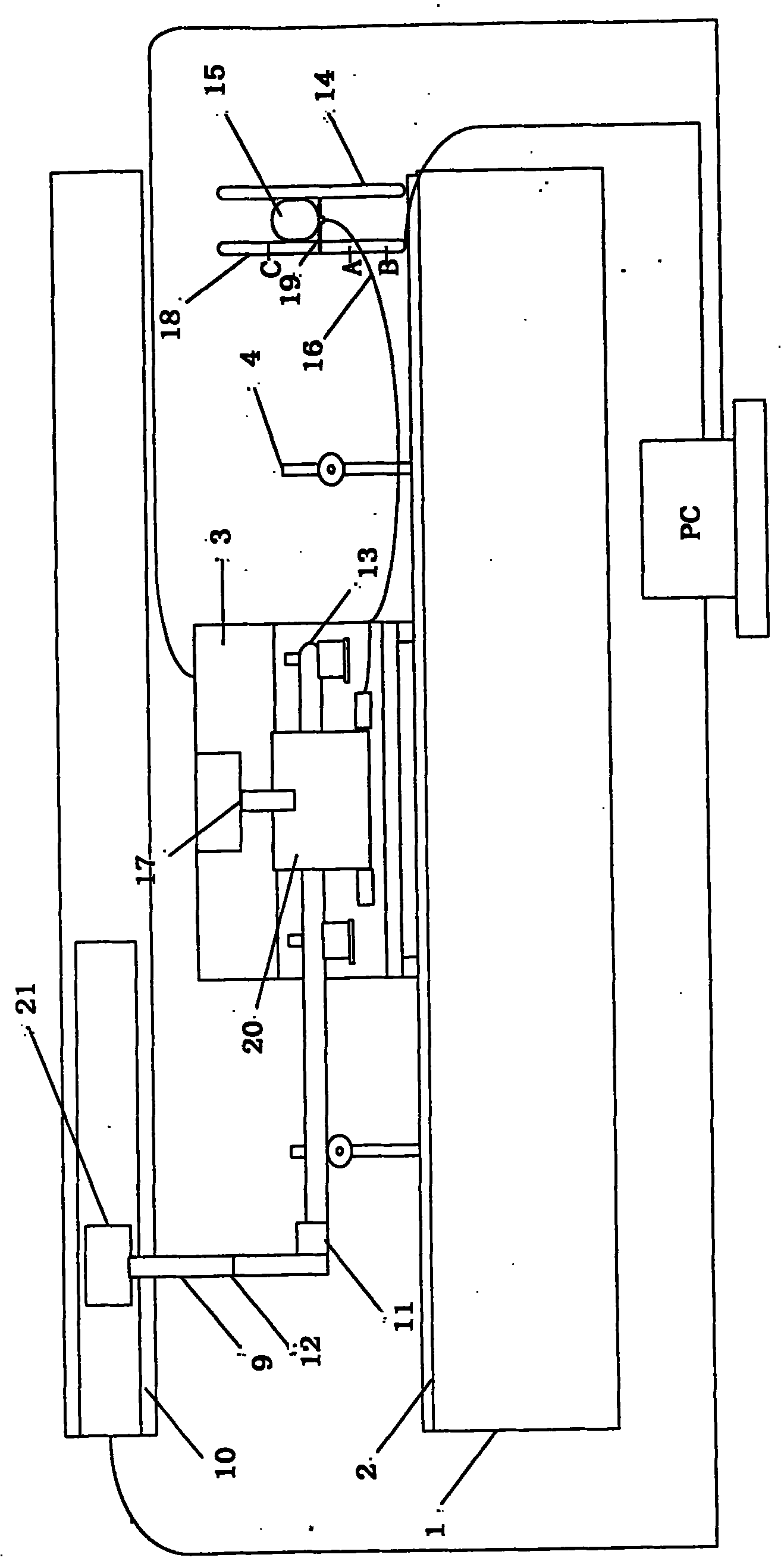

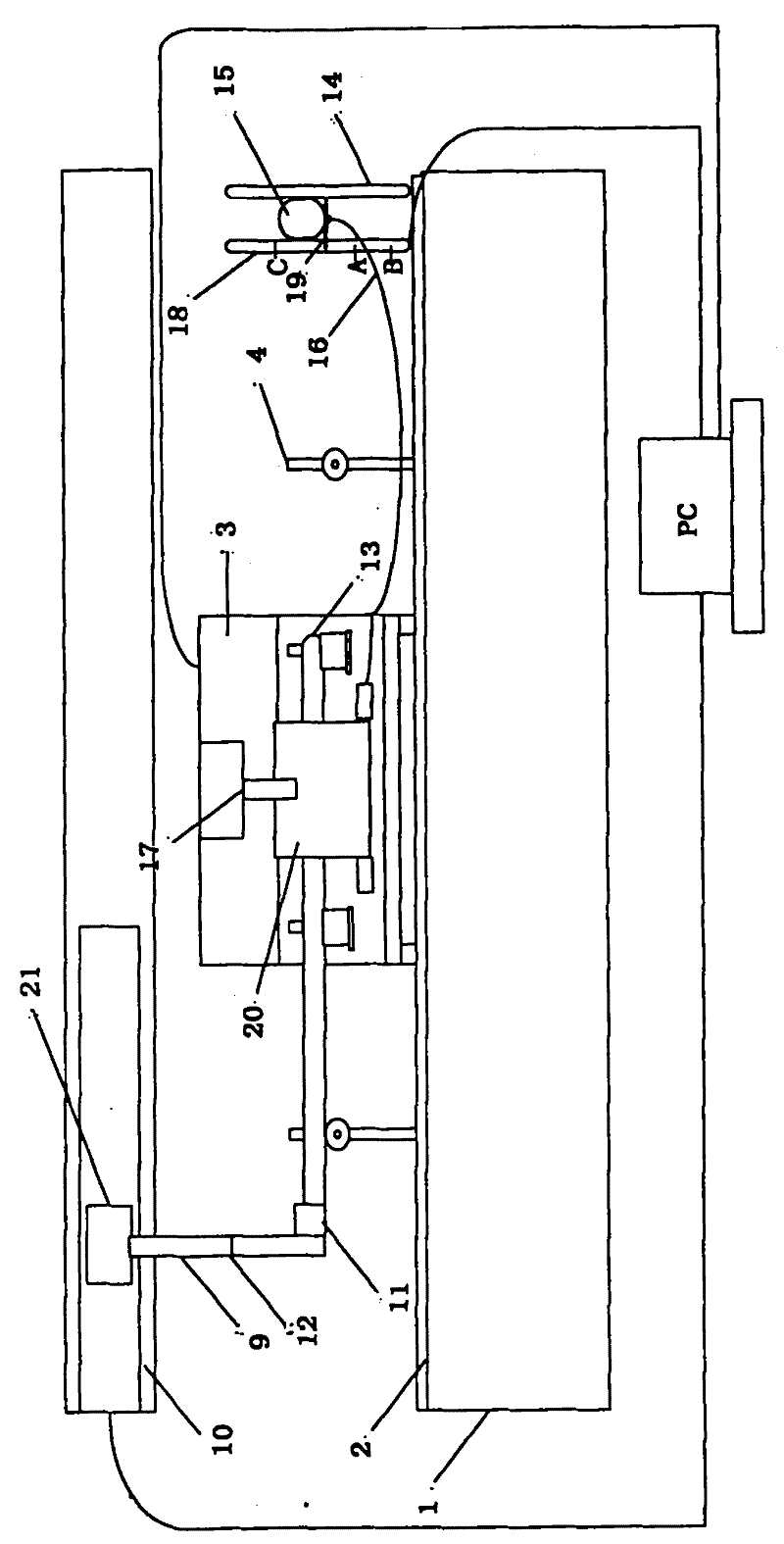

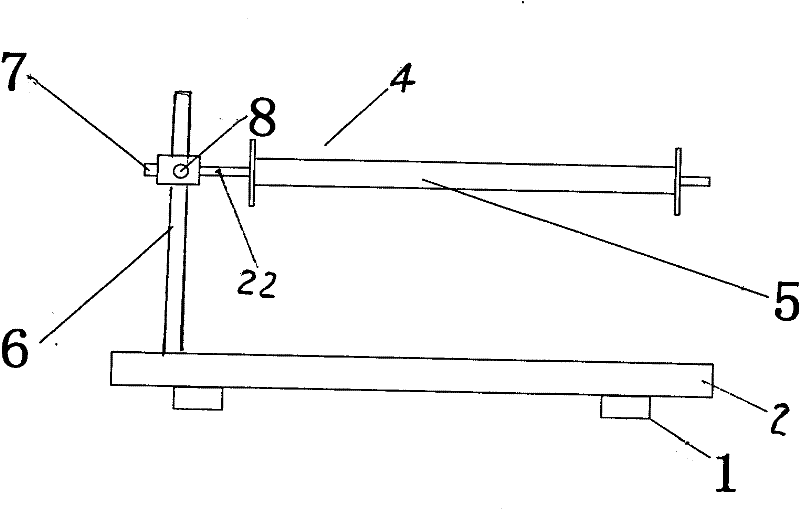

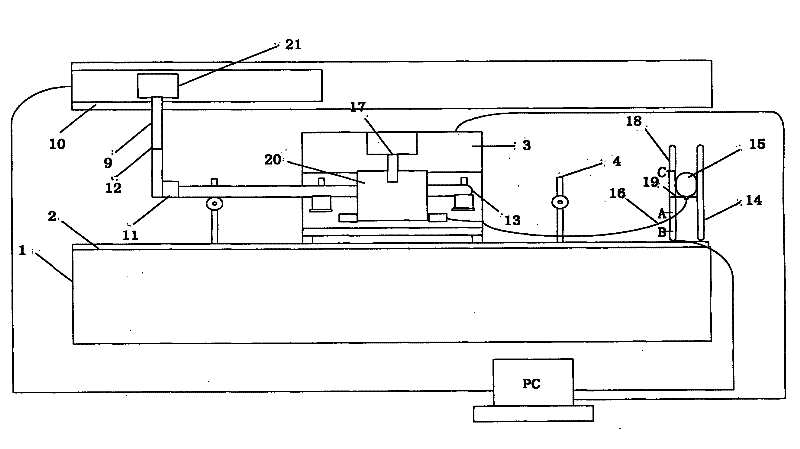

System and method for automatically measuring optical fiber preform

ActiveCN101788471AFully automatedFast production process feedbackPhase-affecting property measurementsTester deviceEngineering

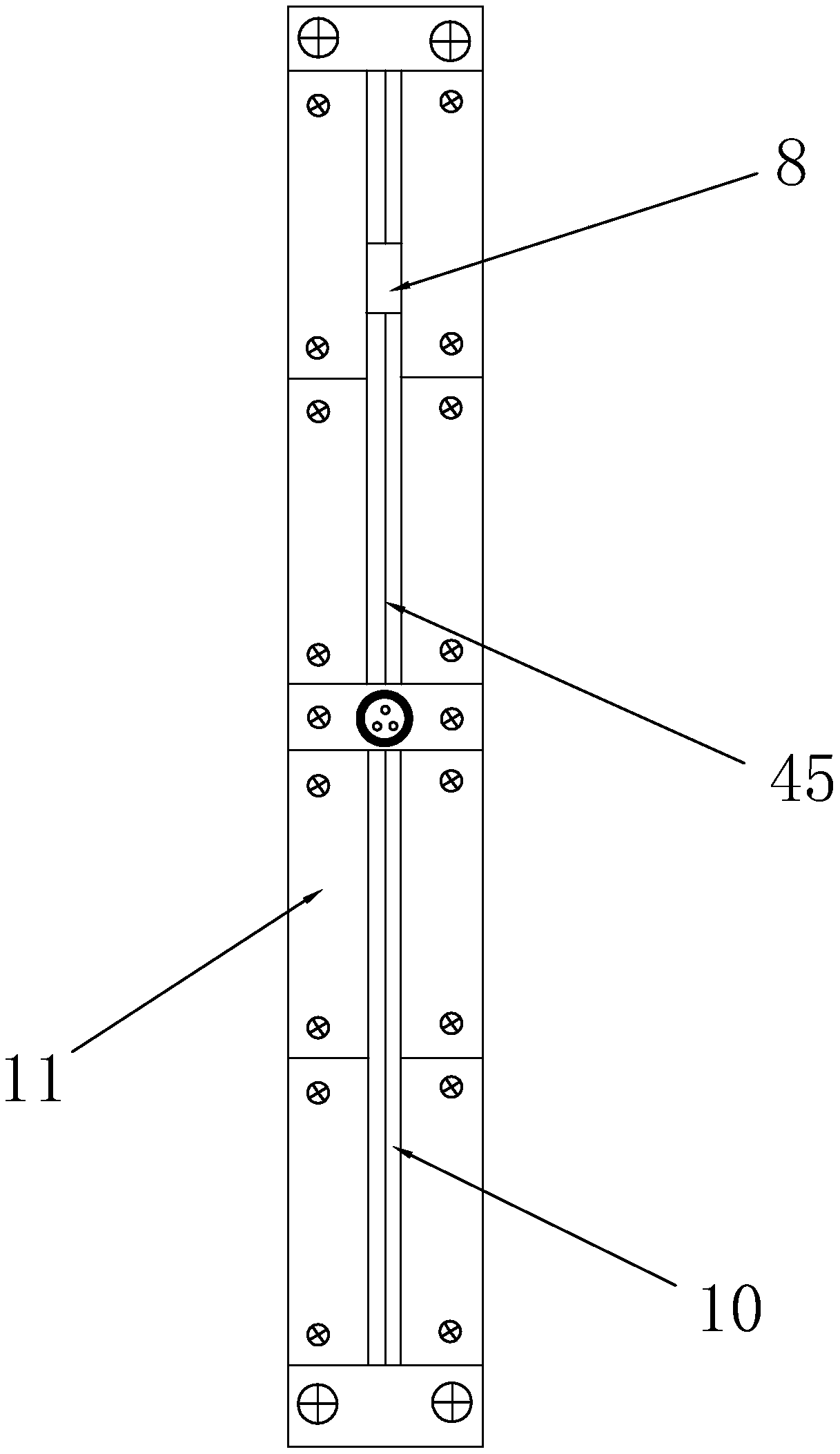

The invention relates to the technical improvement of optical fiber preforms production, in particluar to a system and a method for automatically measuring an optical fiber preform. The system consists of an automatic rod-pushing device, an automatic matched oil charging and discharging device and an preform tester, wherein the automatic rod-pushing device comprises a testboard, a carriage, a servo motor and a pushing arm, a guide rail is arranged on the testboard, the carriage and the tester are fixed on the guide rail, the carriage can slide along the guide rail, the upper part of the testboard is provided with a pushing arm track through a support, the servo motor is arranged in the pushing arm track and is connected with the pushing arm which is hinged with a push rod, the push rod is provided with a push rod head which moves forward and props against one end of the preform, the carriage is provided with a rolling shaft arranged on a central shaft, and the central shaft is fixed at the vertical axis of the carriage; and the automatic matched oil charging and discharging device comprises a measuring cavity, a lifting screw, a scaleplate, a motor and a matched oil bottle, and the measuring cavity is arranged in the preform tester.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

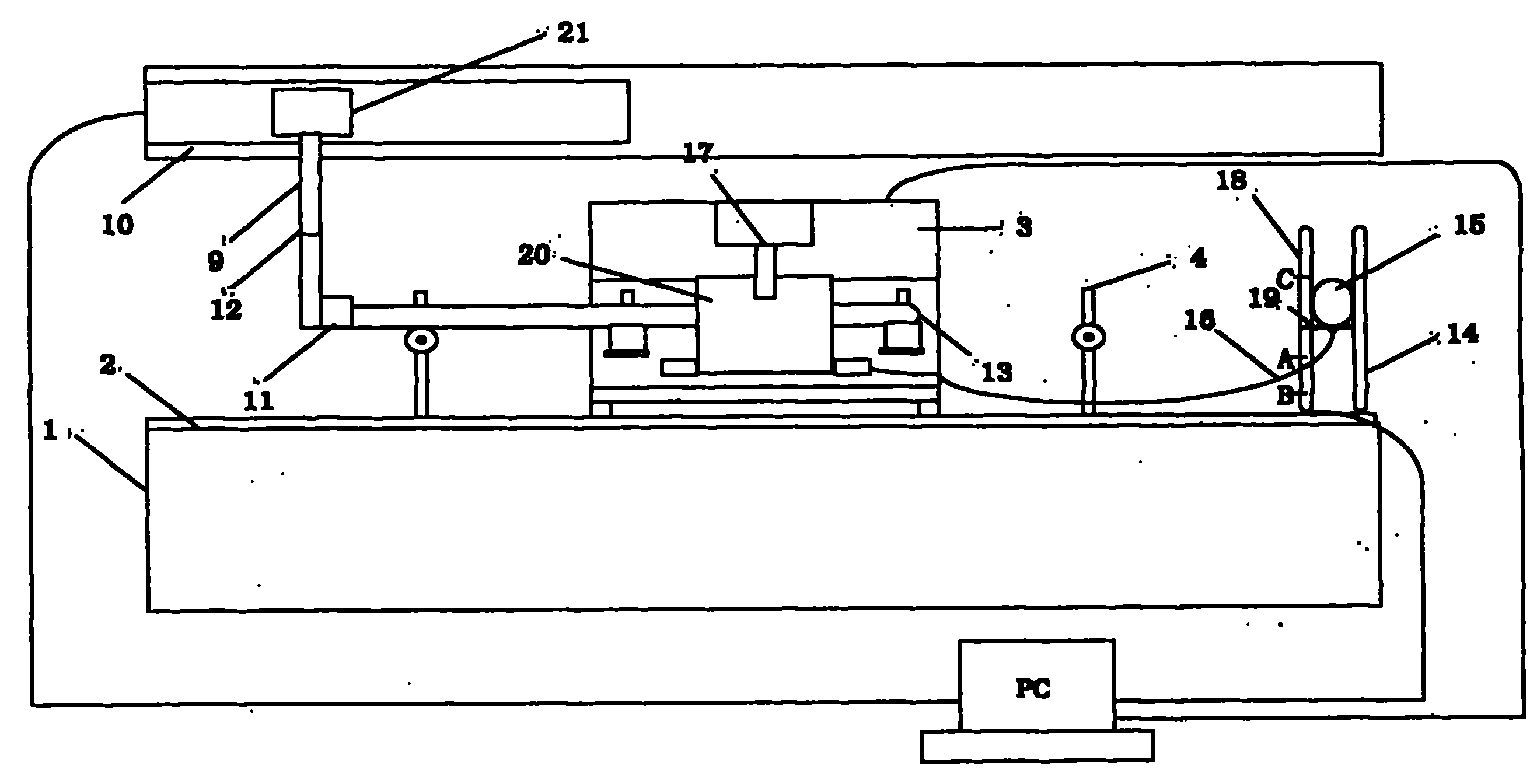

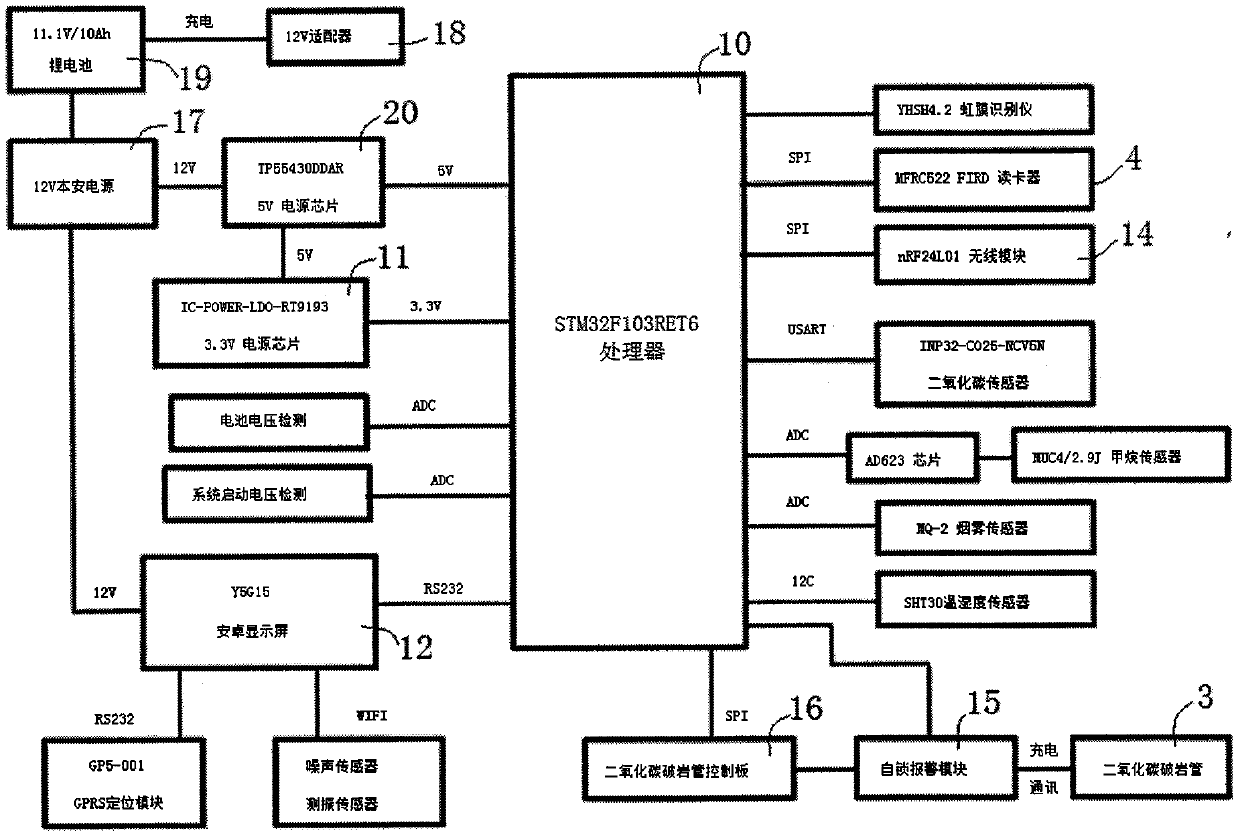

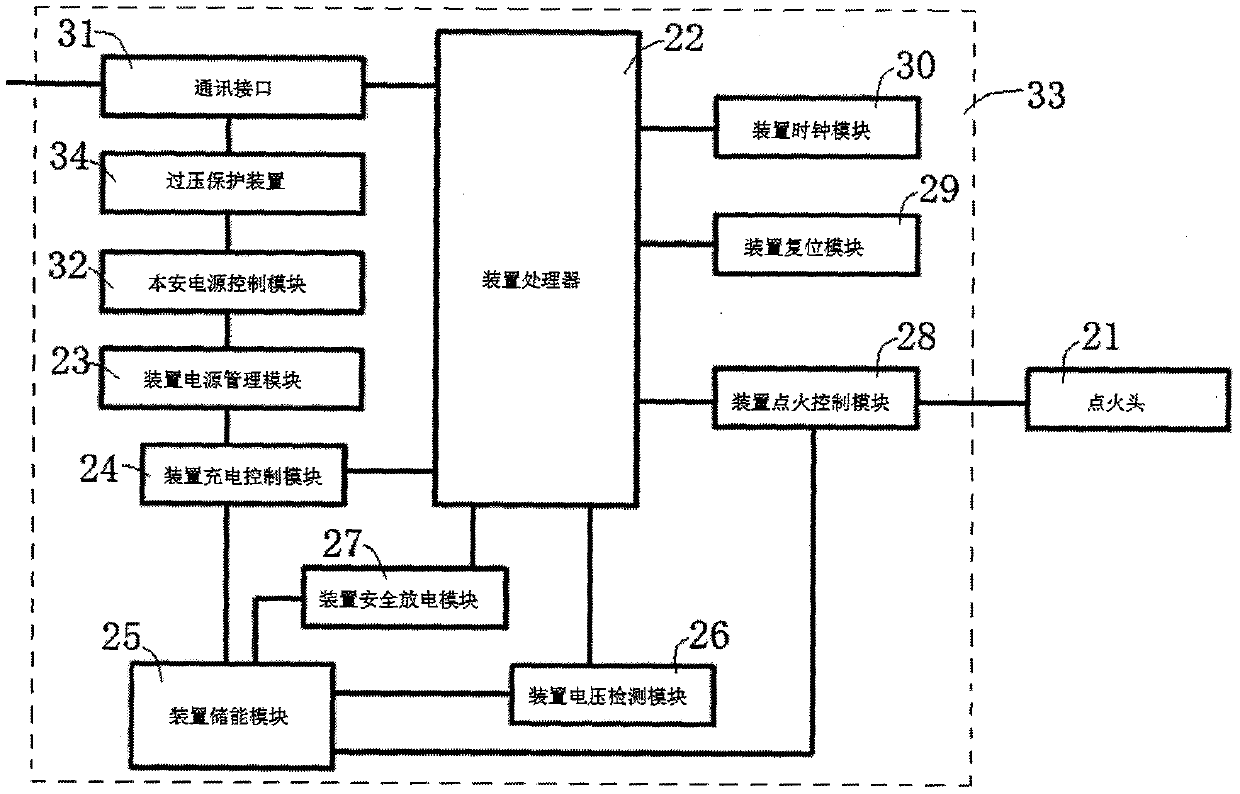

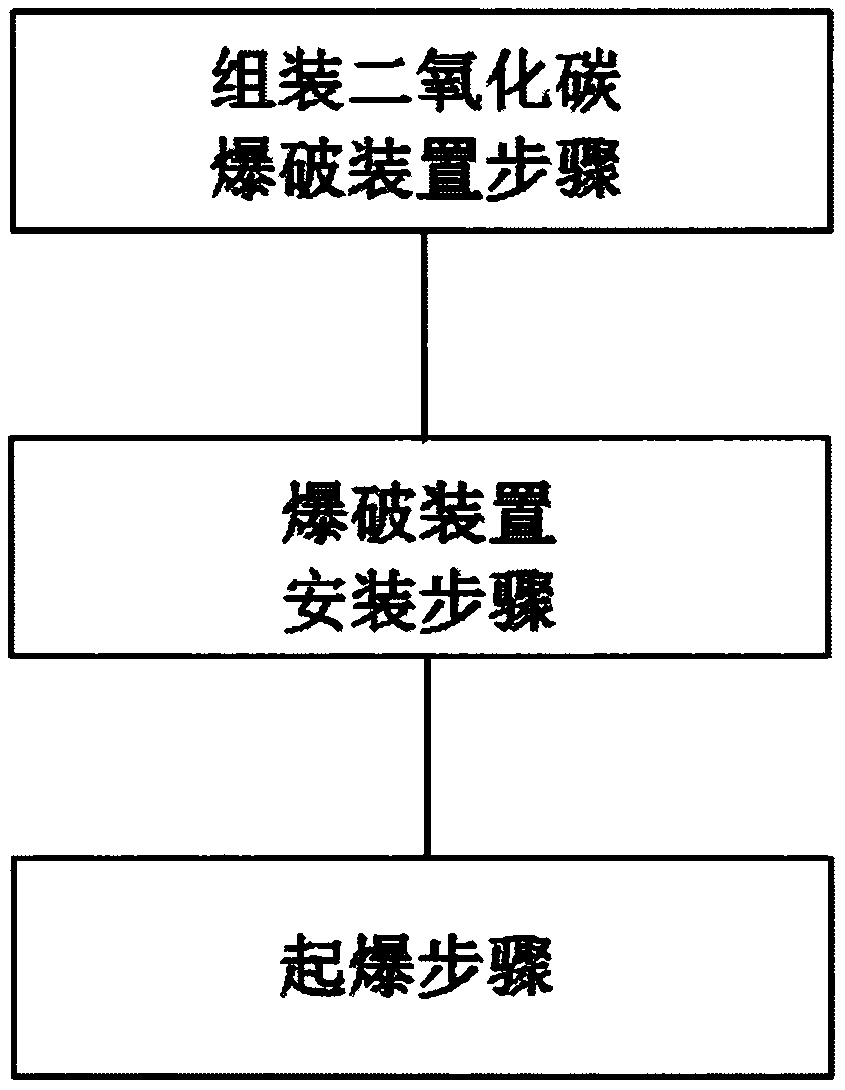

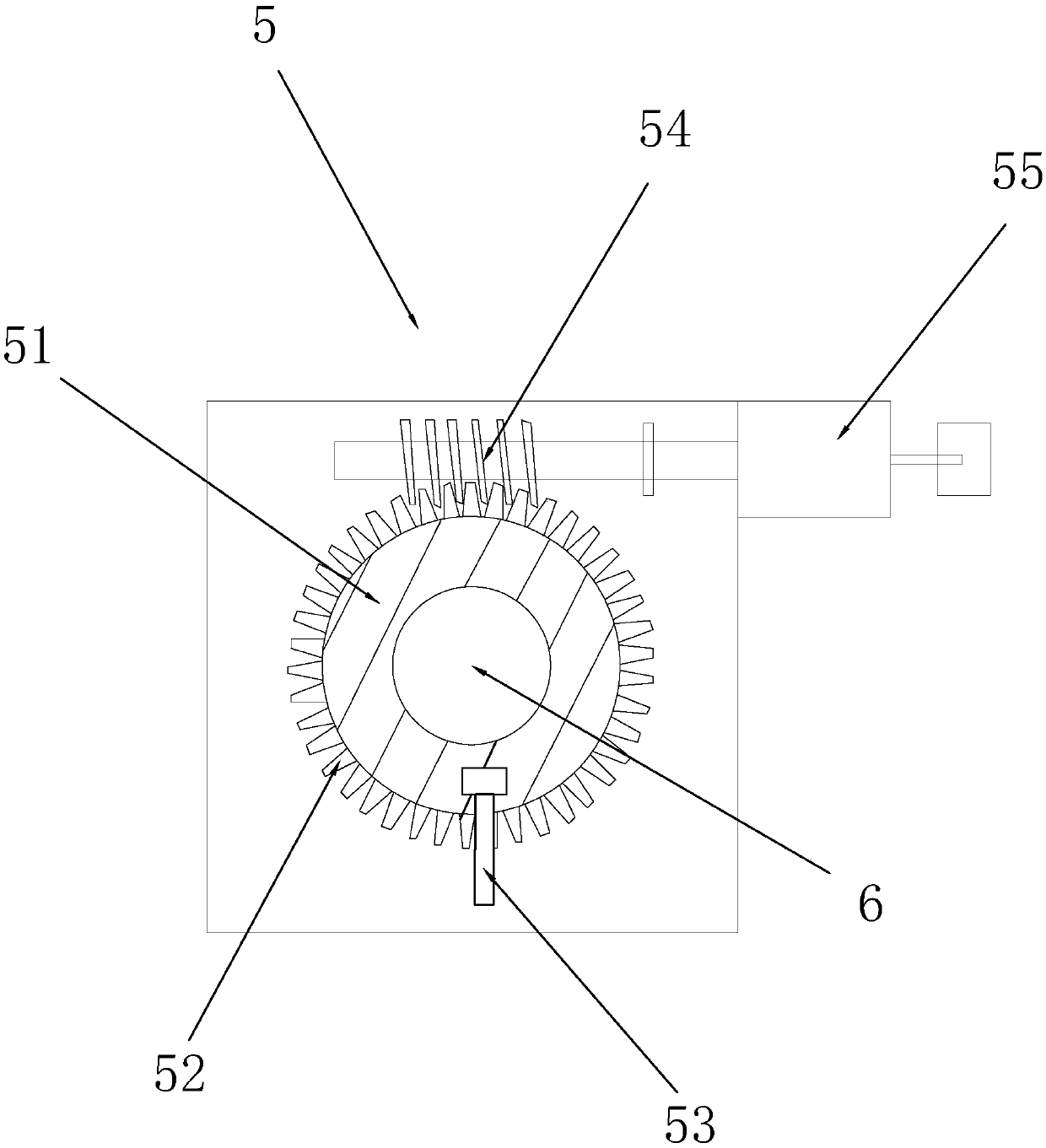

Digital carbon dioxide rock breaking process and detonation system

InactiveCN110864588AEasy to identifyEasy to collectDisloding machinesBlasting cartridgesNumerical controlDetonator

The embodiment of the invention discloses a digital carbon dioxide rock breaking process and a detonation system. The detonation system comprises a numerical control detonator, carbon dioxide detonation devices with electronic tags and an electronic tag reading device. The electronic tags store first identification information of the carbon dioxide detonation devices. Each carbon dioxide detonation device is internally provided with a numerical control device. The numerical control device stores second identification information. The numerical control detonator can read the identification information of the detonation devices. The digital carbon dioxide rock breaking process comprises the steps of assembling of the carbon dioxide detonation devices, installation of the detonation devices,delay setting and detonating. According to the digital carbon dioxide rock breaking process and the detonation system provided by the embodiment of the invention, the electronic tags are additionallyarranged on the carbon dioxide detonation devices to facilitate acquisition of external identification information for the carbon dioxide detonation devices, and information acquisition and information identification are facilitated in the detonation preparation process. Moreover, in an installation-first and segmentation-second manner, the detonation system is used for identifying segments of each detonation device. The error probability is greatly reduced. The detonating effect is ensured.

Owner:BEIJING LONGDE SHIDAI TECH SERVICE

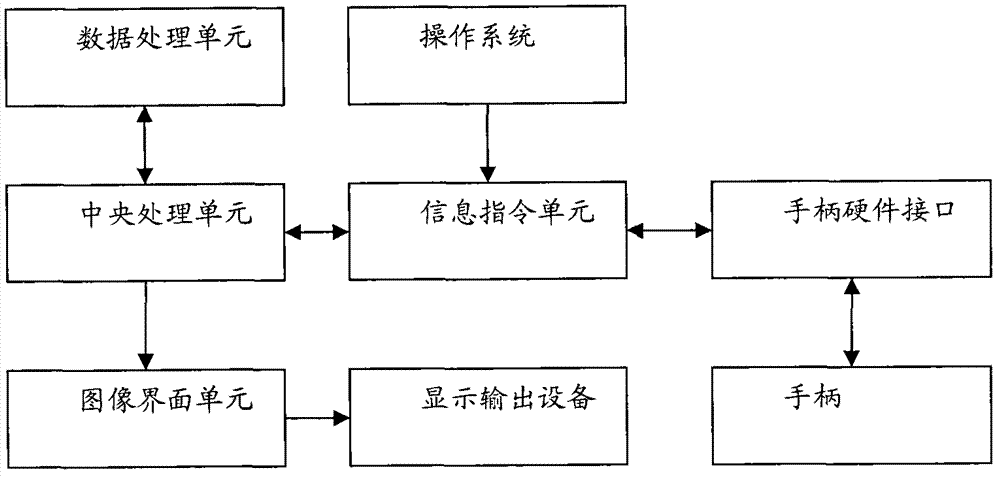

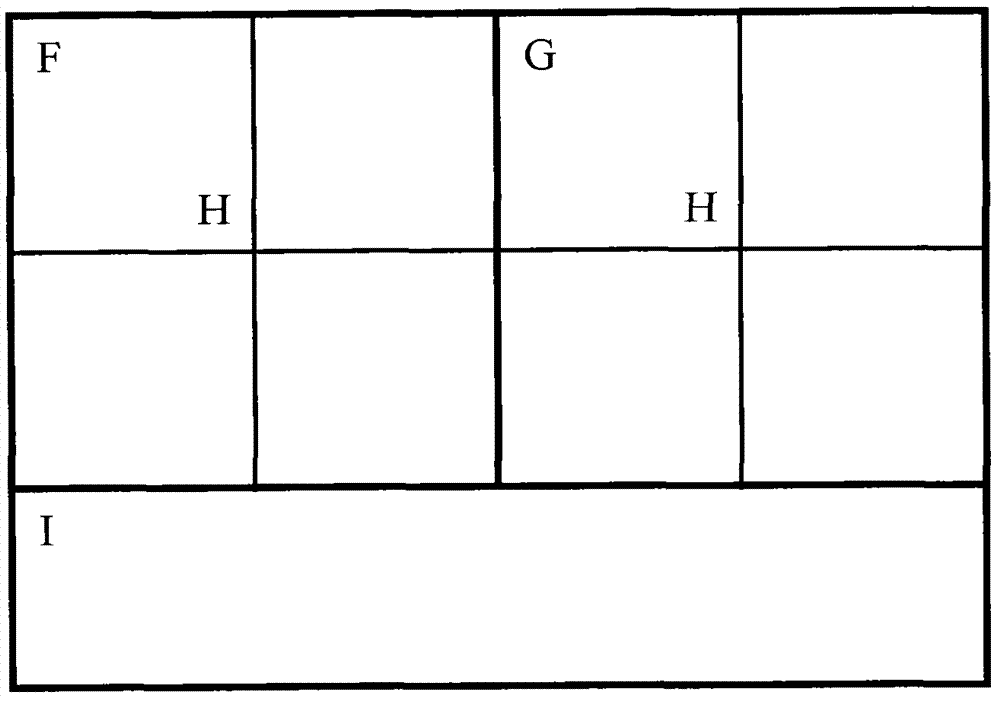

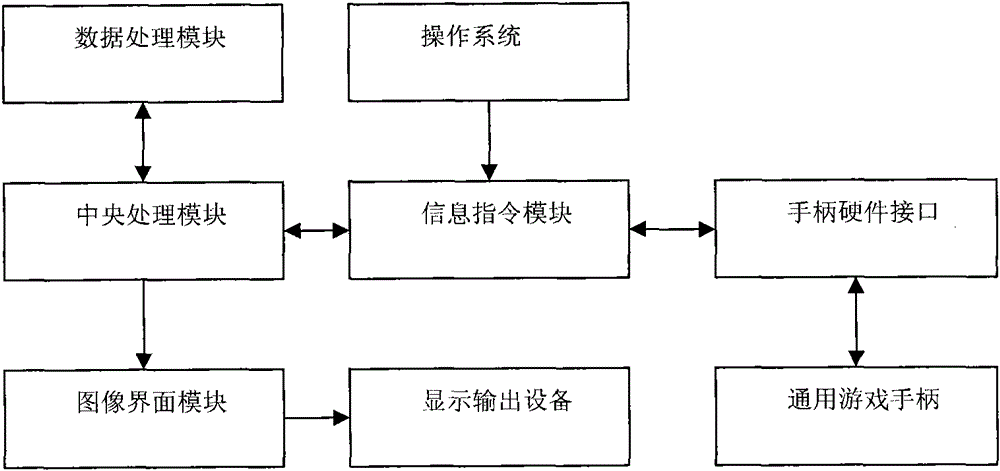

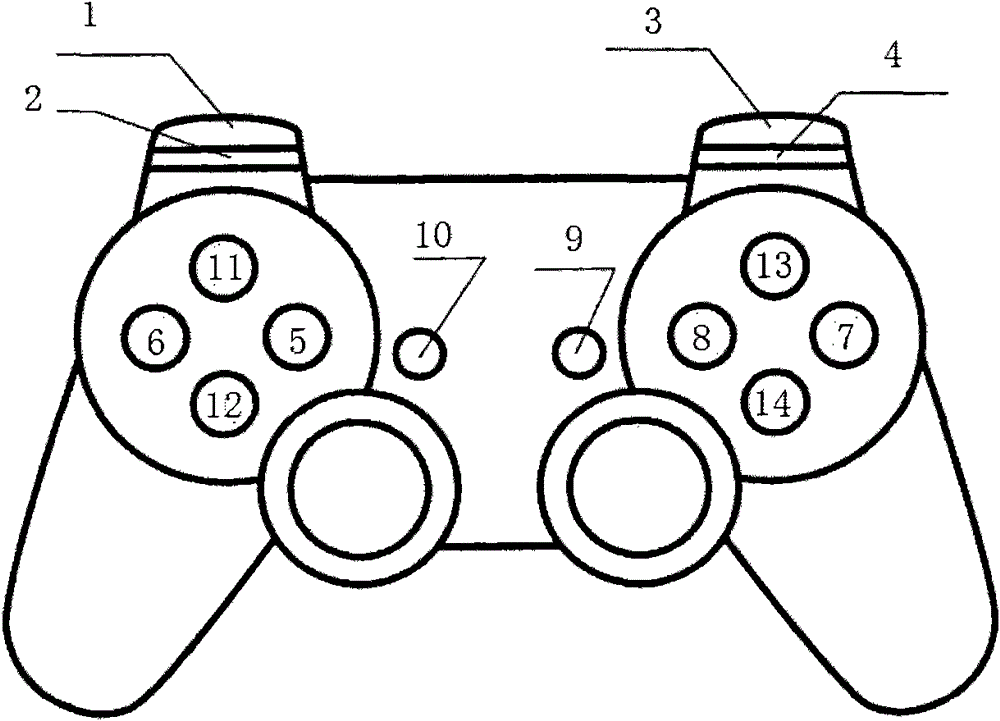

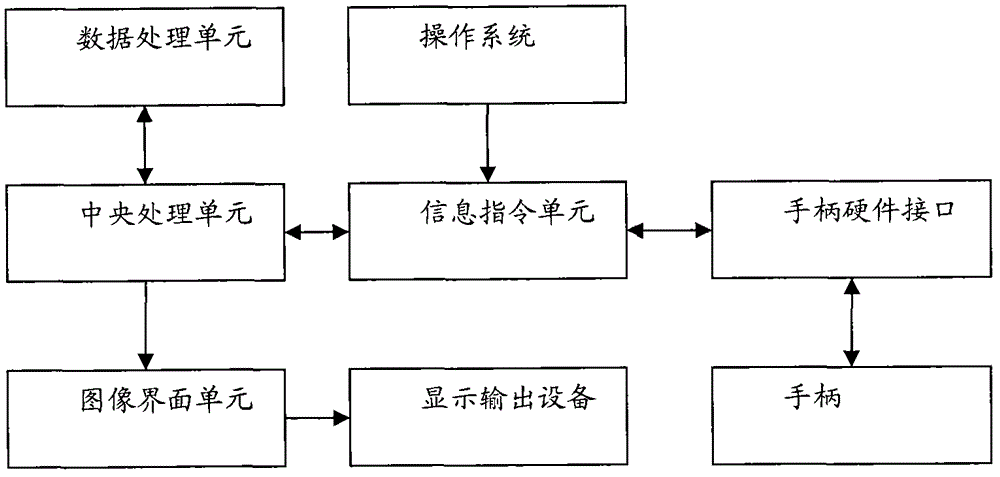

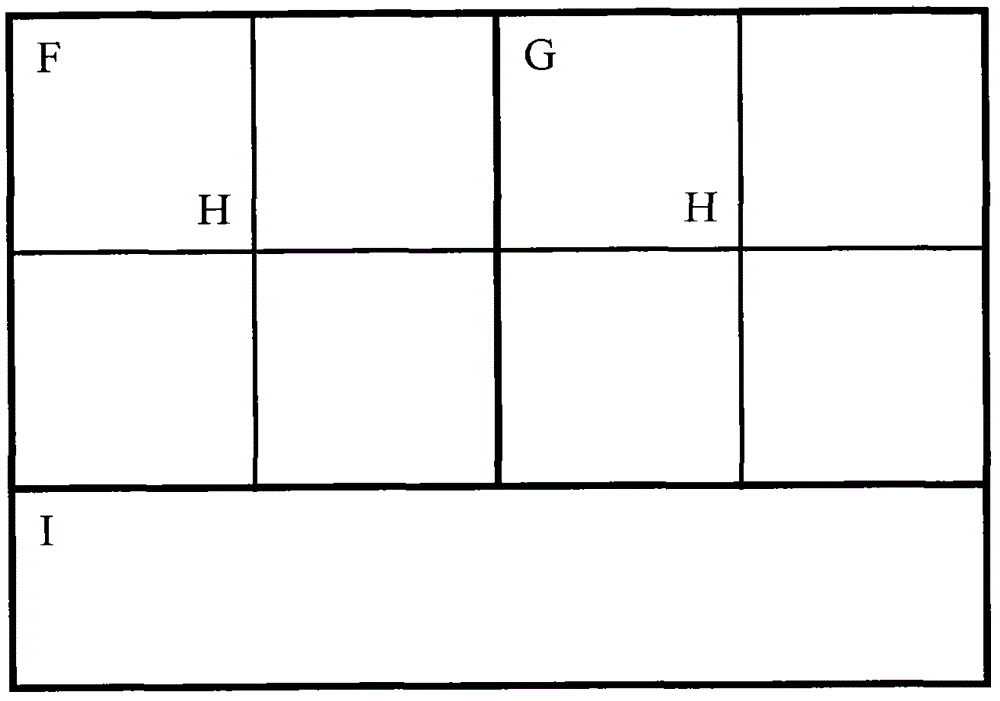

Image control point interactive editing system

InactiveCN102760301AIntuitive Feedback ResponseReduce the chance of human errorModifying/creating image using manual inputData transmissionRAID processing unit

The invention provides an image control point interactive editing system. The image control point interactive editing system is characterized by comprising a central processing unit, a data processing unit, an information command unit, a graphical interface unit and a handle, wherein the central processing unit is used for coordinating data transmission and function scheduling among all the units; the data processing unit is used for managing image data and control point data, and performing operation; the information command unit is used for getting a hardware state parameter and converting the hardware state parameter to a user command; the graphical interface unit is used for checking the image data and the control point data and monitoring the operation response of a user; and the handle comprises a left rocker, a right rocker, multiple function buttons and a force feedback responsor. The image control point interactive editing system disclosed by the invention can simultaneously move and zoom the image data and reference data, which need to be processed, during editing of a control point of an image, and further perform continuous switching between an editing state and a checking state. In addition, the opportunity of causing human error during editing can be reduced and the low-cost implementation can be realized.

Owner:武汉天目经纬教育发展有限公司

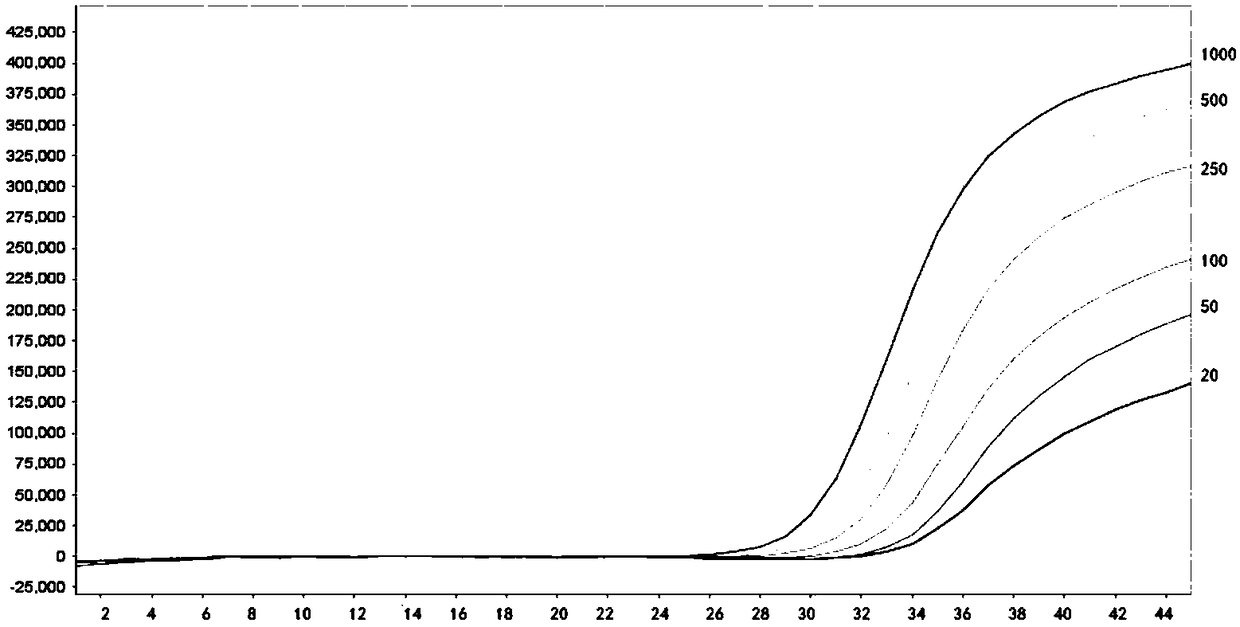

A sample nucleic acid detection kit, a sample nucleic acid detection reagent and an application for a sample nucleic acid detection reagent

ActiveCN108823282AImprove amplification reaction efficiencyHigh detection sensitivityMicrobiological testing/measurementDNA preparationNucleic acid detectionBlood plasma

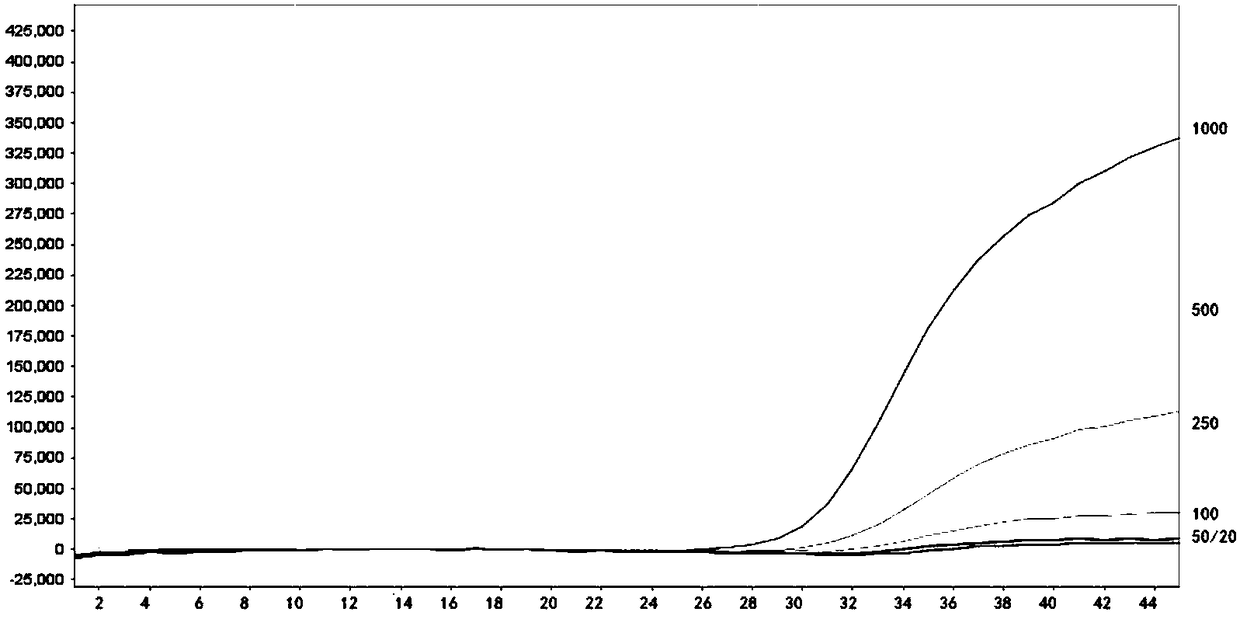

The invention provides a detection sample nucleic acid reagent, method and kit. Nucleic acid in a sample is extracted by adopting highly basic nucleic acid extract (pH value is 10.5-12.5), then extracted nucleic acid is directly added into a PCR reaction solution (pH is 8.0-9.0) to perform neutralization, and nucleic acid amplification and detection are performed simultaneously. The nucleic acid in different samples such as blood, blood plasma, whole blood, genital meatus discharge, sputum or urine can be detected. Through performing the neutralization on the extracted sample nucleic acid in the PCR reaction solution, rather than performing the neutralization during extracting the nucleic acid, the nucleic acid extraction efficiency and the PCR amplification efficiency can be effectively improved, and accuracy and sensitivity of the detection for the sample nucleic acid are substantially improved.

Owner:LEADWAY HK

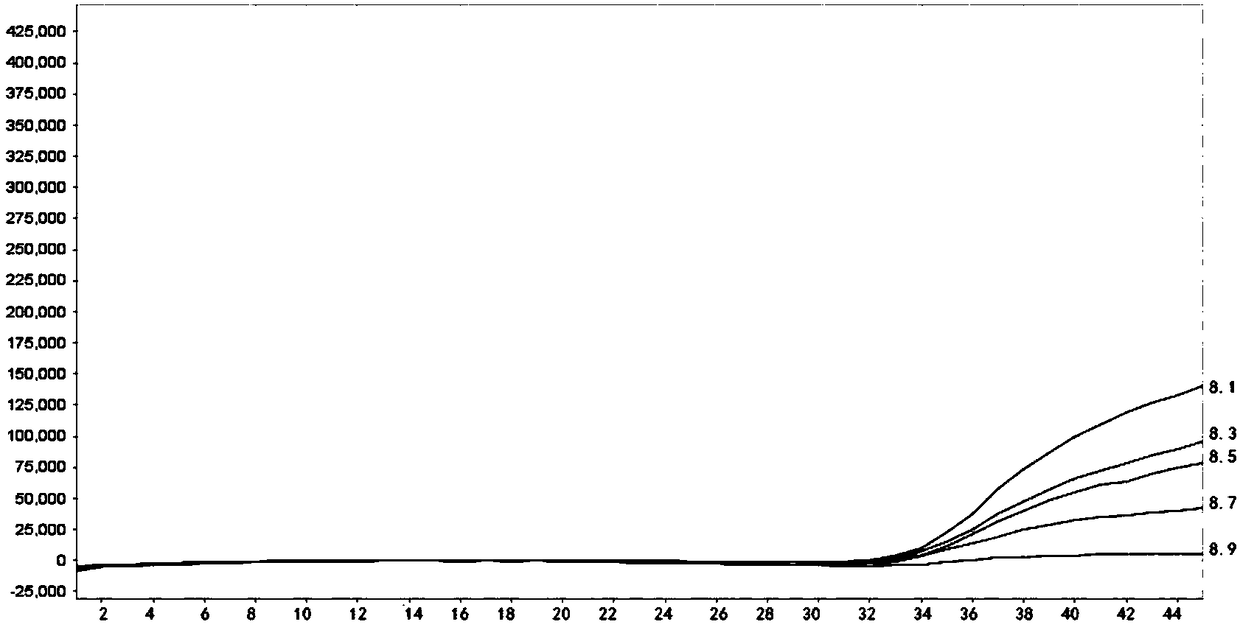

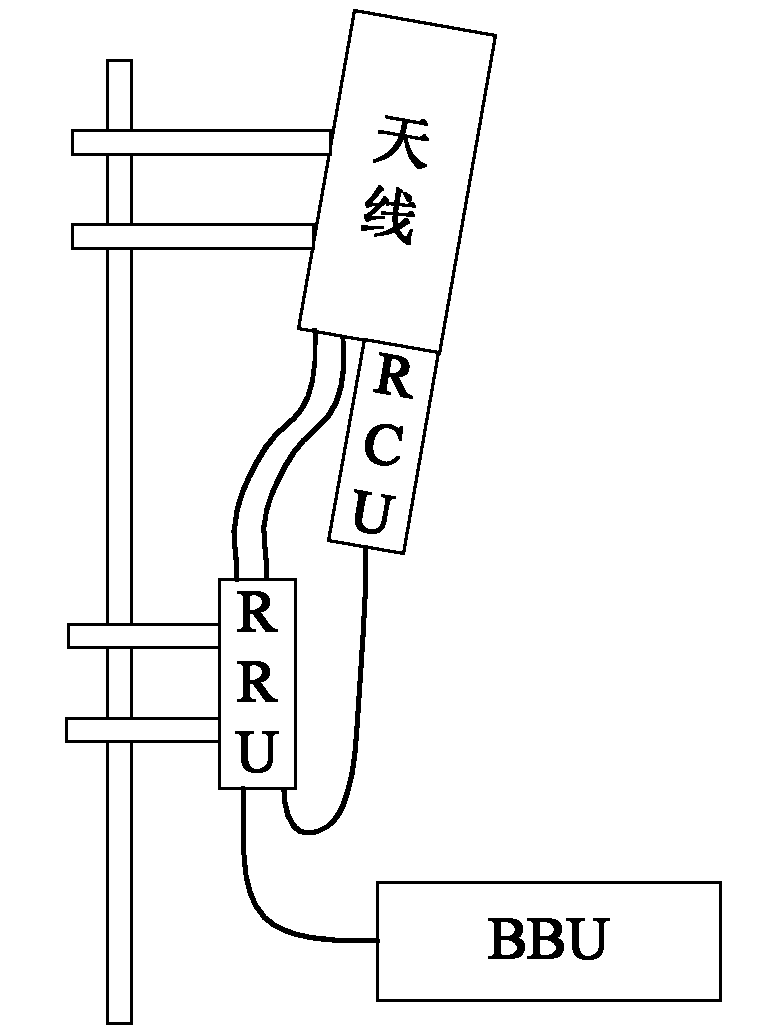

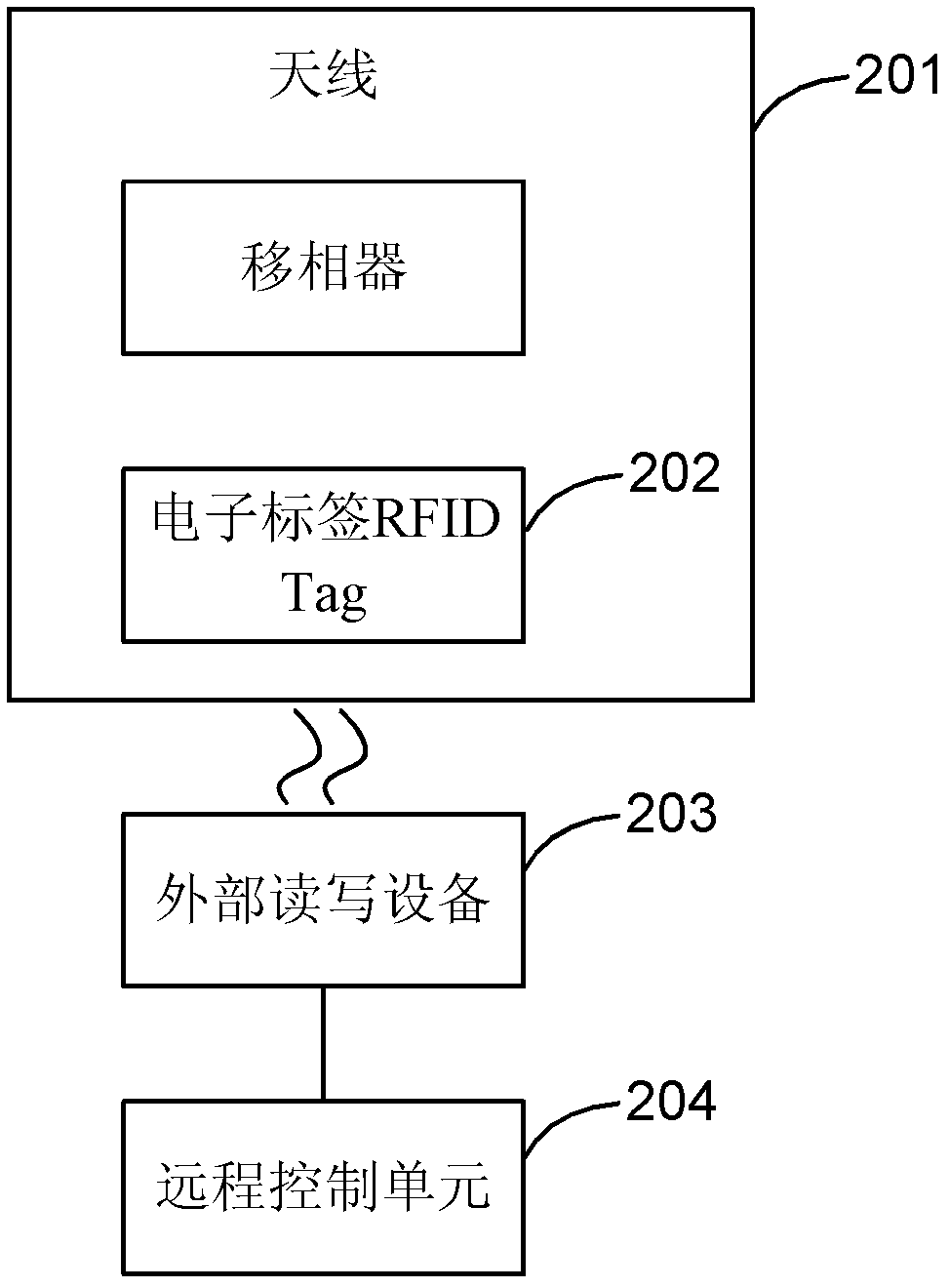

Antenna system and device

InactiveCN102544731AReduce the chance of human errorReduce installation costsAntennasElectricityEngineering

The embodiment of the invention provides an antenna system and an antenna device. The base station antenna system comprises an antenna, at least one read-write memorizer, at least one external read-write equipment and at least one remote control unit (RCU), wherein the antenna comprises at least one phase shifter which is used for adjusting an electrical downtilt of the antenna under the control of the RCU; the read-write memorizer is used for storing configuration data of the antenna; the external read-write equipment is used for acquiring the configuration data from the read-write memorizer; and the RCU is used for controlling the external read-write equipment to acquire the configuration data, uploading the configuration data and controlling the phase shifter to adjust the electrical downtilt of the antenna according to the configuration data. According to the embodiment of the invention, the external read-write equipment can conveniently call the configuration data so as to configure the RCU, so that the adjustment for the electrical downtilt of the antenna is realized.

Owner:HUAWEI TECH CO LTD

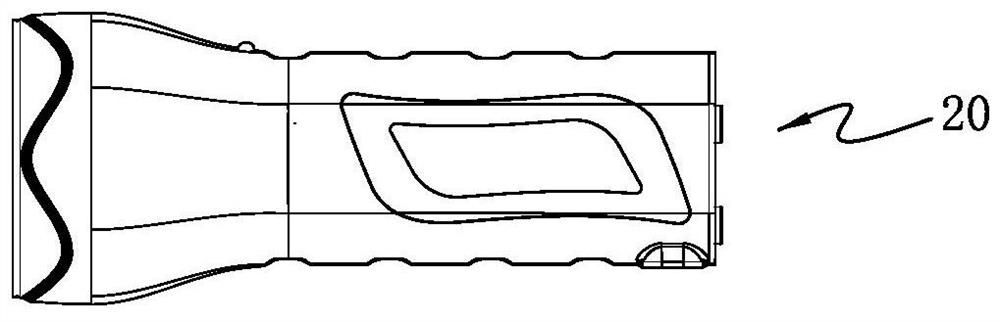

Packing equipment and packing technique for torches

ActiveCN108928525AMechanizationRealize automated productionPackaging automatic controlPackaging machinesEngineeringTorch

The invention relates to the field of torch production, in particular to packing equipment and a packing technique for torches. The packing equipment for the torches comprises a packing line, a blister feeding mechanism, a torch feeding mechanism, a transferring robot, a color card transferring mechanism and a binding mechanism; the packing technique comprises the following steps: S1, a blister isplaced above by the blister feeding mechanism; S2, the torch is placed above by the torch feeding mechanism; S3, the blister is placed on a packing base by the transferring robot, and is placed in the blister; S4, the packing base is conveyed to the color card transferring mechanism by the packing line, and the color card moving mechanism transfers a color card to the packing base; and S5, the packing base is conveyed to the binding mechanism by the packing line, and the binding mechanism binds the color card and the blister together. By adopting the packing equipment and packing technique for torches, mechanical and automatic production of packing of torches can be realized; and production efficiency is greatly improved.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

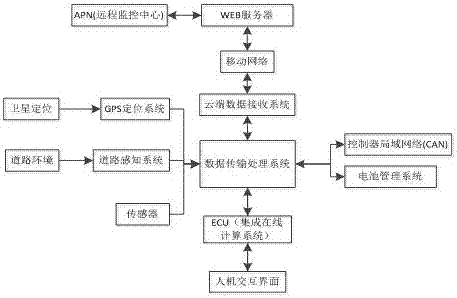

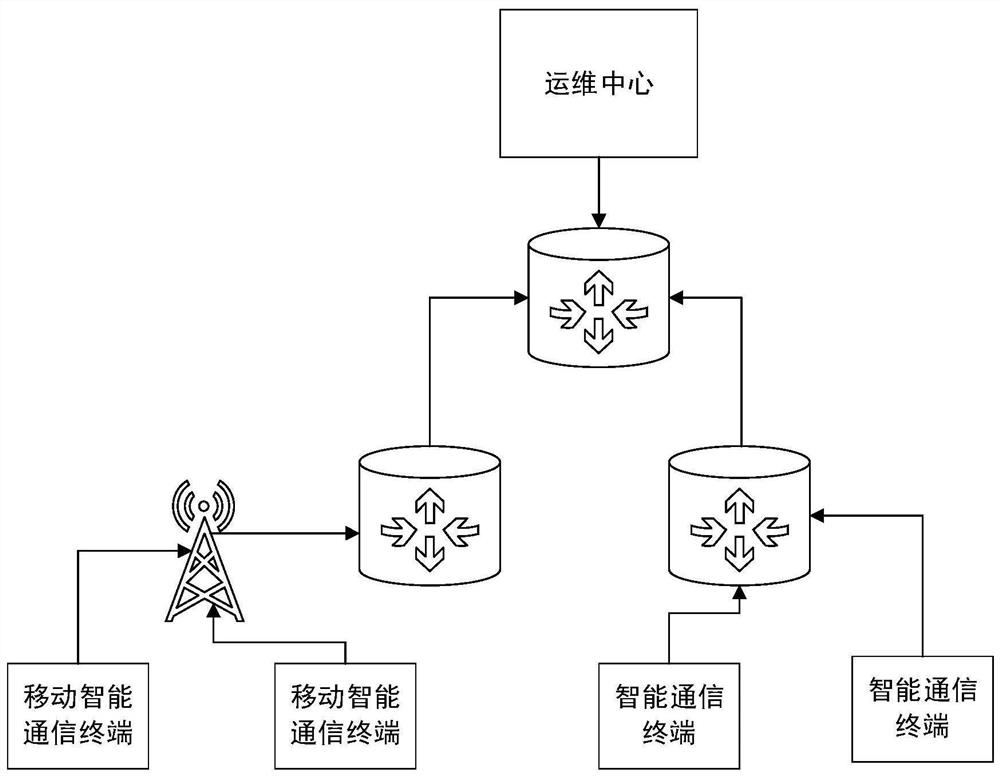

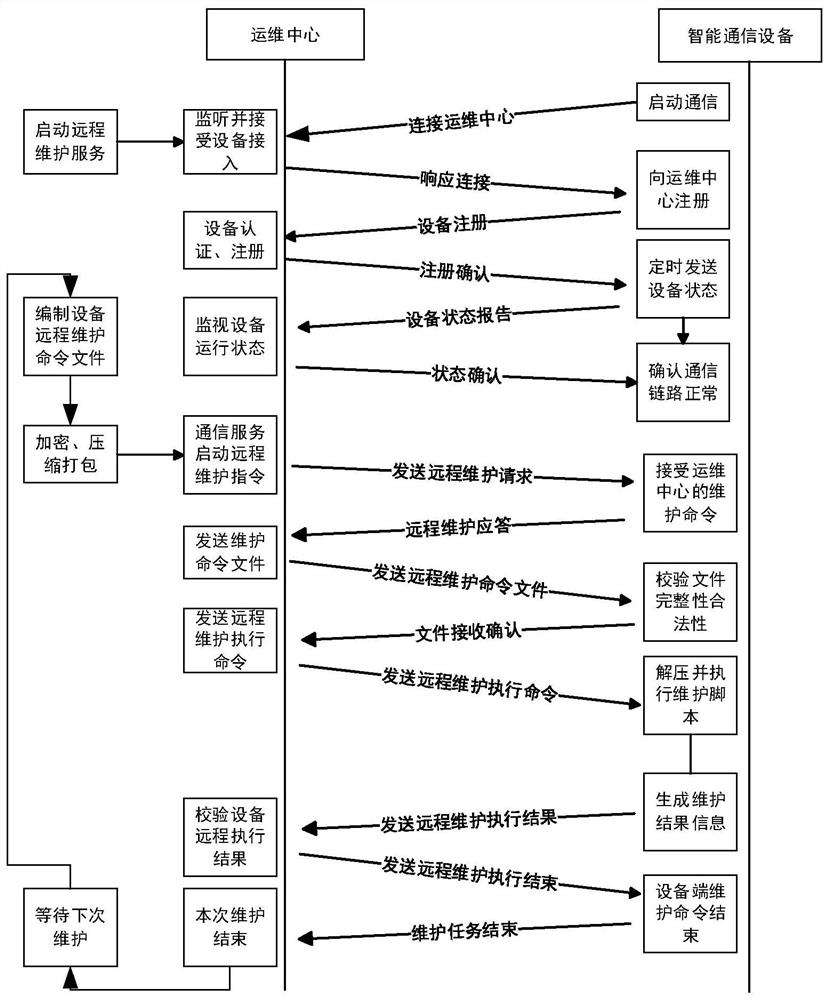

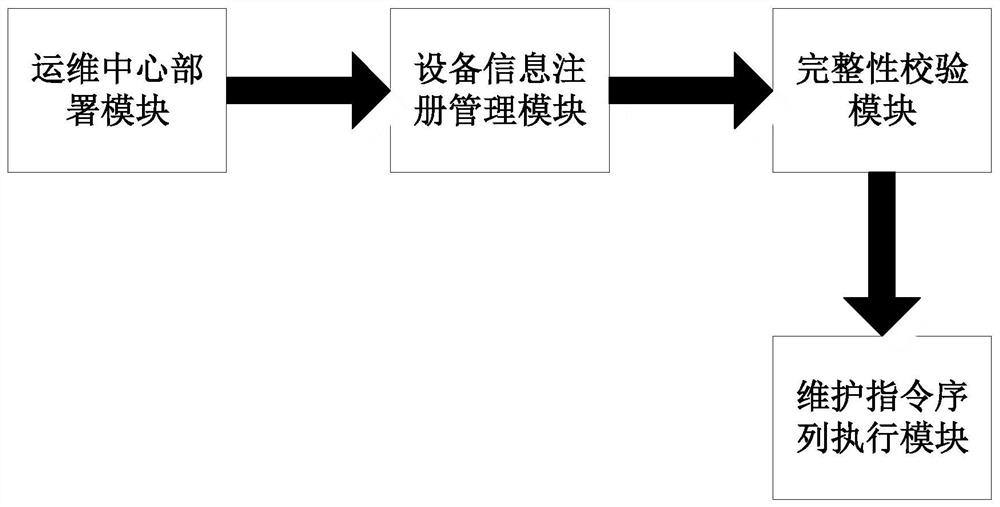

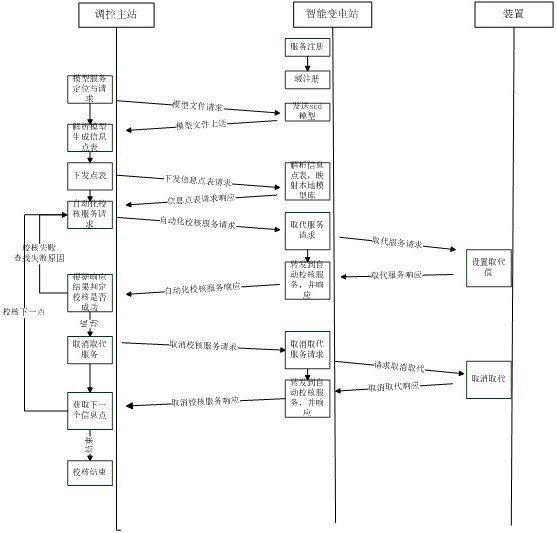

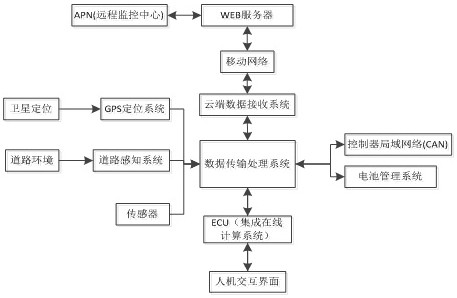

Intelligent power grid intelligent equipment remote maintenance method and system based on script technology

PendingCN112688800AAddressing Adaptive IssuesMeet remote maintenance workData switching networksInstruction sequenceSmart grid

The invention discloses an intelligent power grid intelligent equipment remote maintenance method and system based on a script technology. The method comprises: an operation and maintenance center deploying a remote maintenance service unit; the operation and maintenance center receiving registration information of all the scattered intelligent communication devices and generating a maintenance command script file for the remote device through a maintenance tool; compressing, packaging and storing the maintenance command script file, the auxiliary maintenance program and the configuration file; encrypting and storing the obtained compressed and packaged file; submitting to a remote maintenance service unit of an operation and maintenance center; performing integrity check on the remote equipment maintenance file; decrypting and decompressing the remote equipment maintenance file passing the verification; executing a maintenance instruction sequence in the maintenance instruction script file; and the operation and maintenance center recording a maintenance result of this time and completing a maintenance task of this time. According to the invention, the problem that the equipment can be maintained only when technicians arrive at the equipment site is avoided, the probability of human errors is reduced, and the working efficiency and accuracy of operation and maintenance are improved.

Owner:BEIJING SIFANG JIBAO ENG TECH +1

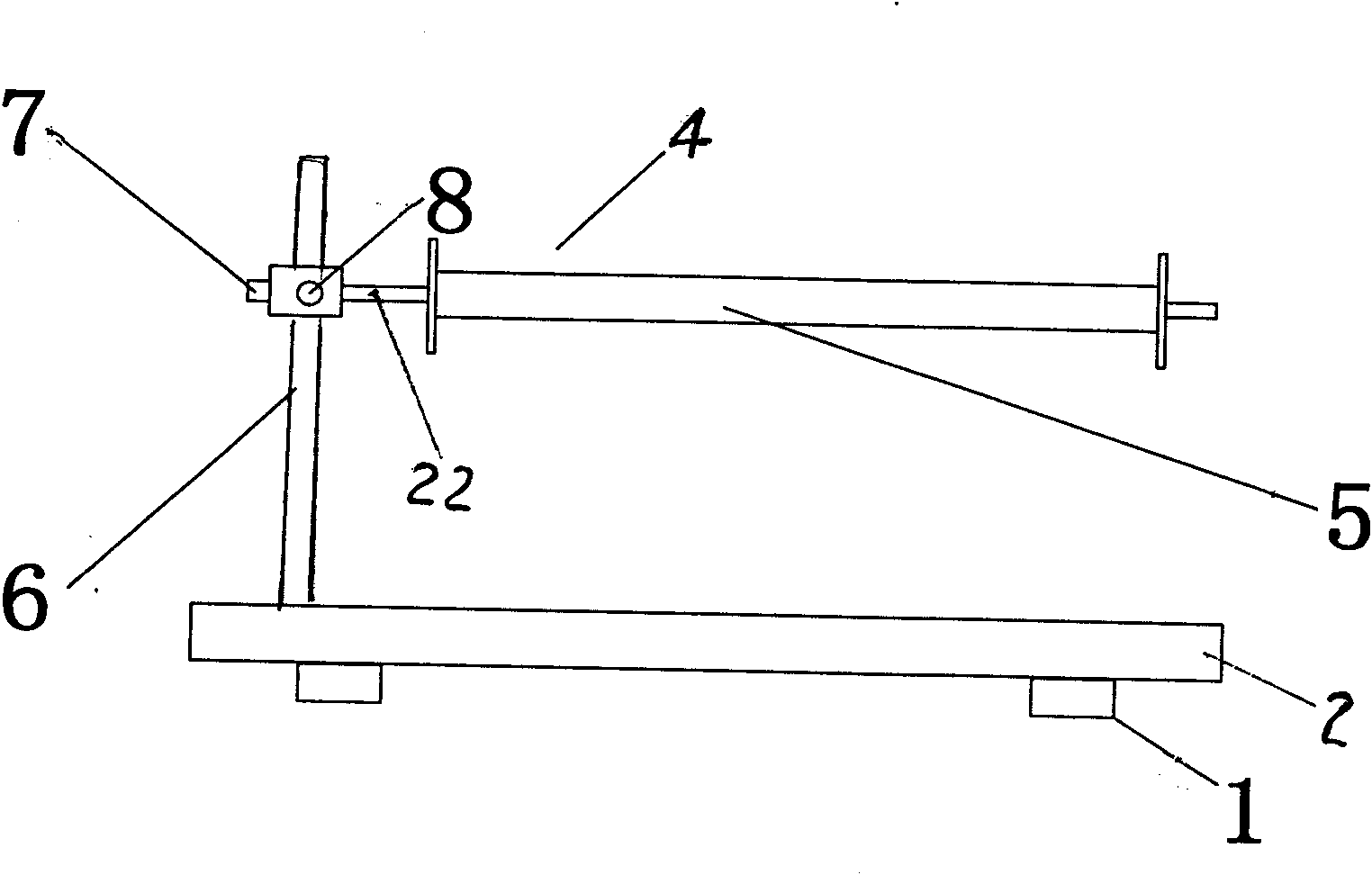

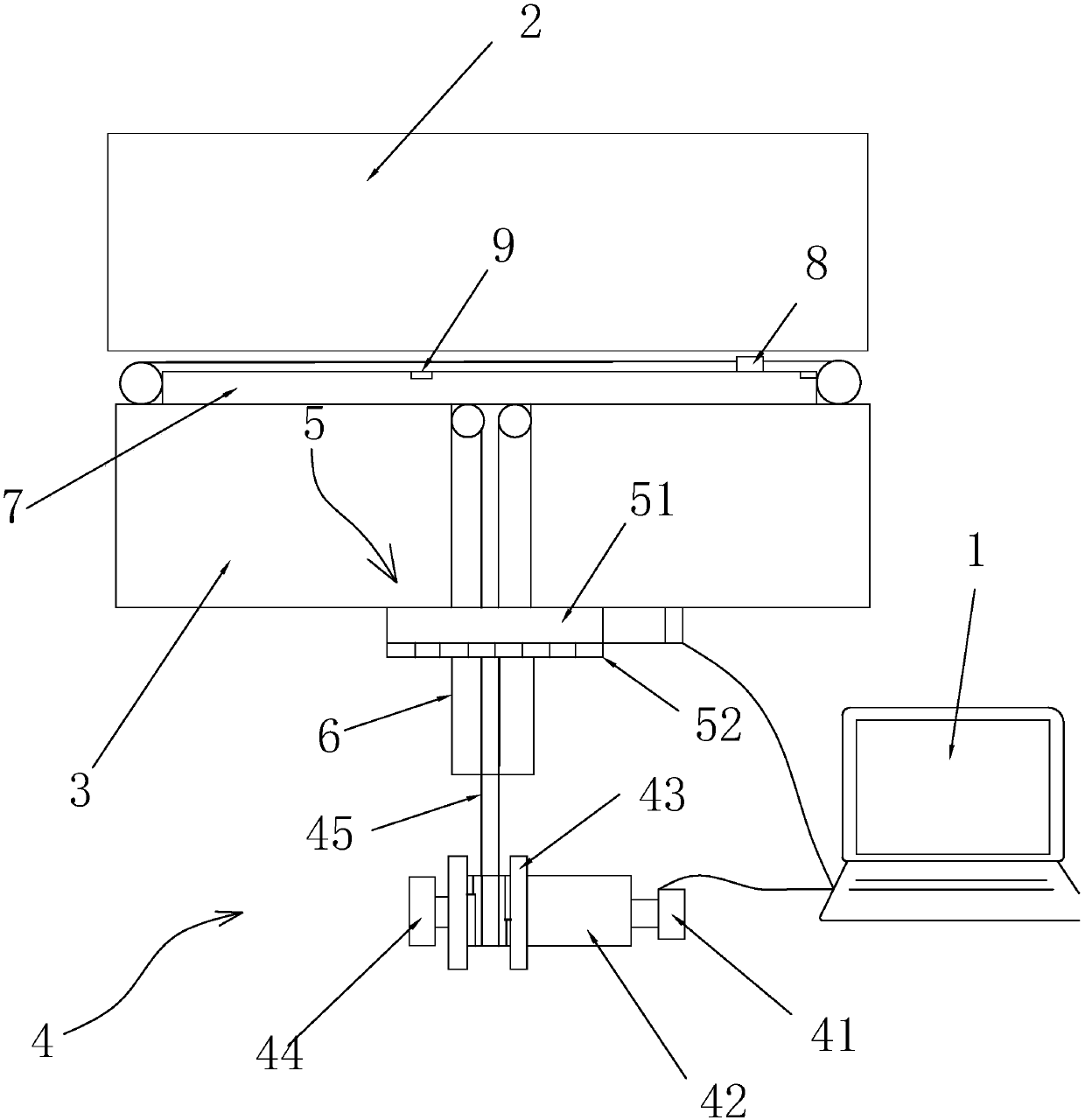

Full-automatic magnetic field measurement device applicable to mini cyclotron having 20mm-30mm gap

InactiveCN110736944ASolve the radial positioning problem caused by the inability to install the grating rulerFully automatedMagnetic measurementsEngineeringCyclotron

The invention discloses a full-automatic magnetic field measurement device applicable to a mini cyclotron having a 20mm-30mm gap. The device comprises a computer, a radial rope wheel driving mechanism, an angular driving mechanism, a center shaft which is vertically arranged and driven to rotate by the angular driving mechanism, a measuring arm which is arranged in the 20mm-30mm gap and driven torotate by the center shaft as well as a sliding block which is arranged on the measuring arm and driven by the radial rope wheel driving mechanism to do reciprocating rectilinear movement along a sliding chute formed in the measuring arm, wherein the computer is respectively in telecommunication connection with the radial rope wheel driving mechanism and the angular driving mechanism and controlsthe measuring arm to move. The device disclosed by the invention solves the problems that an existing magnetic field measurement mode requires much time and effort, radial location is difficult and the probability that a human error appears is high.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

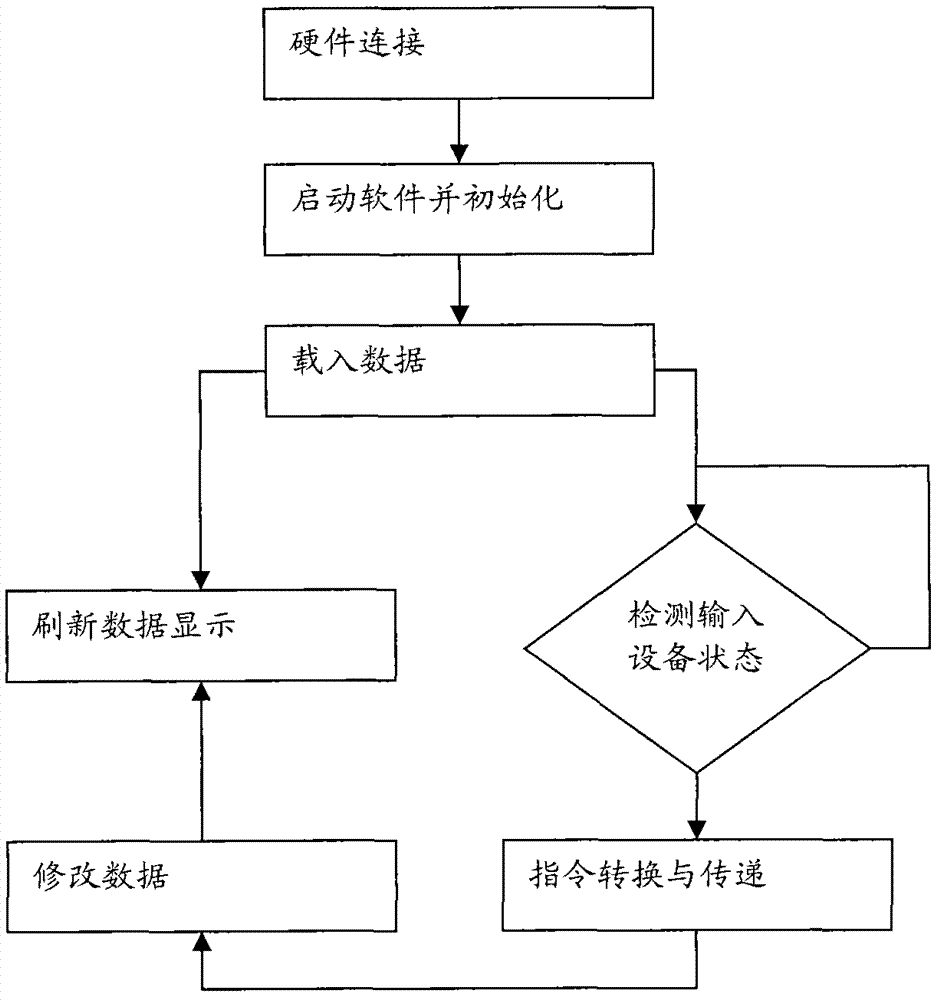

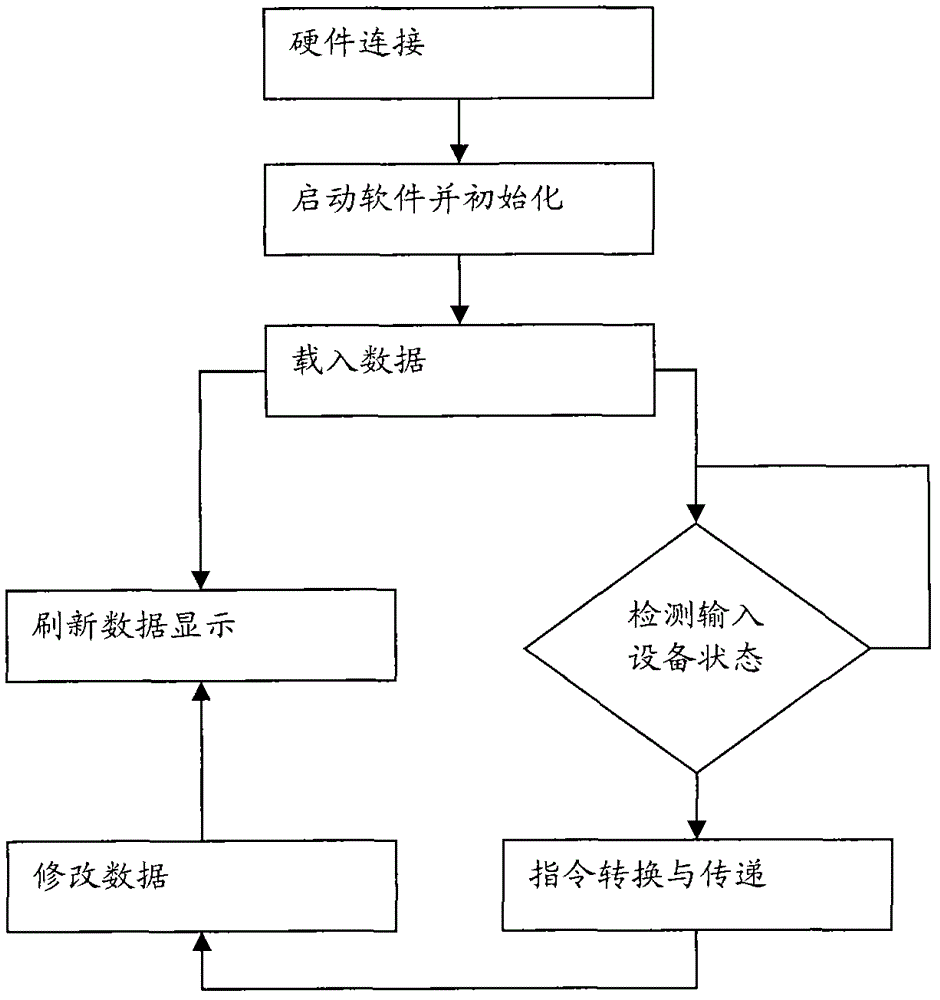

Method and system for interactive editing of image control points

InactiveCN102722250ASmall market priceSmall scaleInput/output for user-computer interaction2D-image generationInteractive editingComputer module

The invention relates to a method and a system for interactive editing of image control points. The method comprises the following main steps of: detecting the system; loading data; displaying and refreshing data; detecting an input state; converting and transferring an instruction; modifying data; and the like. The involved hardware devices mainly comprise a computer and a universal force feedback handle; a software processing module is arranged in the computer; and thus, the method can be realized. The method and the system have the beneficial effects that the image control points can be browsed and edited and the data can be viewed simultaneously, continuous switching between an editing state and a view state can be realized, the universal force feedback handle is used for operation to guarantee low cost, meanwhile, images to be processed and reference data can be zoomed by moving the universal force feedback handle during editing of the image control points, an instruction emitted by application software can also be received as a response per se, and the probability of human error during editing is reduced.

Owner:武汉天目经纬教育发展有限公司

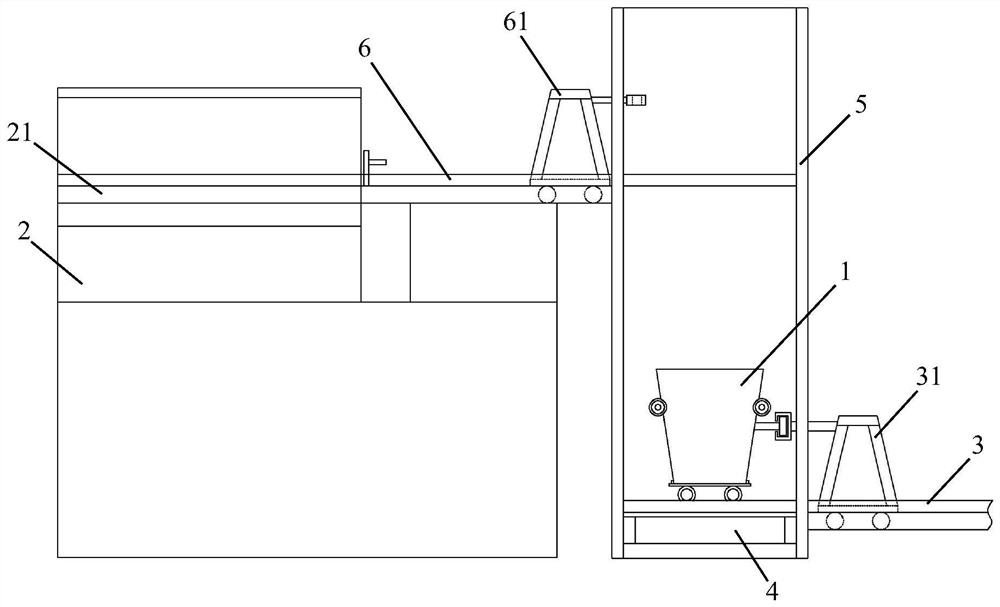

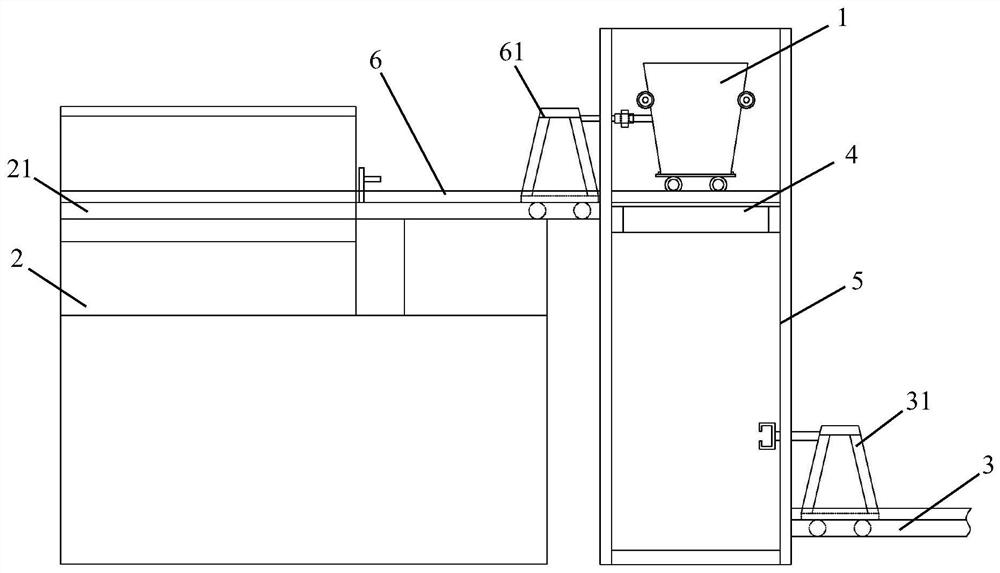

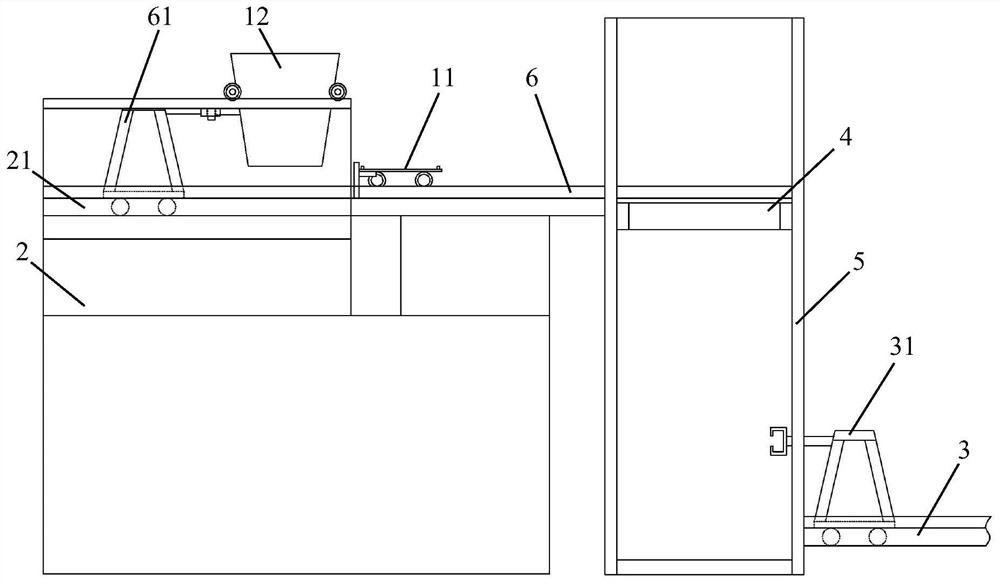

Automatic feeding, traction operation and discharging system for graphite electrode paste

ActiveCN111954328AGuaranteed purityQuality assuranceElectric discharge heatingCarbon compoundsGraphite electrodeEngineering

The invention discloses an automatic graphite electrode paste feeding, traction operation and discharging system which is characterized in that a hopper for containing graphite paste is conveyed to asecond-layer platform from a first-layer platform and poured into a cooling machine; the conveying line comprises a first-layer conveying line body, a lifting rotating platform, a lifting conveying device and a second-layer conveying line body. Paste poured from a kneading pot is received by the hopper, the hopper is pushed to the lifting rotary platform through the first-layer traction head, thehopper rotates by 180 degrees to be separated from the first-layer traction head, the lifting rotary platform is conveyed to the second-layer platform through the lifting conveying device, and the hopper is pulled to the position above the material cooling machine through the second-layer traction head so that the hopper can be separated for discharging. Then, the operation is reversely repeated to finish one-time feeding; according to the invention, the probability of man-made mistakes is reduced, the safety coefficient is increased, the scattering of the paste is avoided, and the purity of the paste and the product quality are ensured.

Owner:南宫市聚纯炭素有限公司

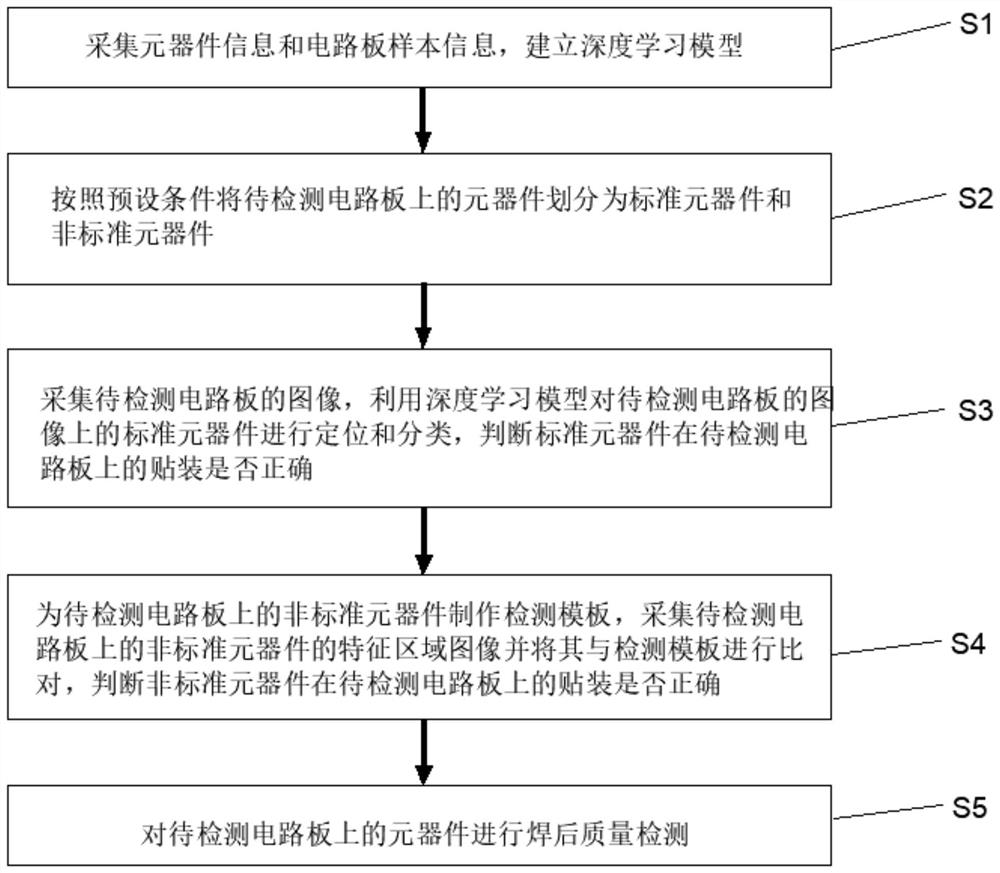

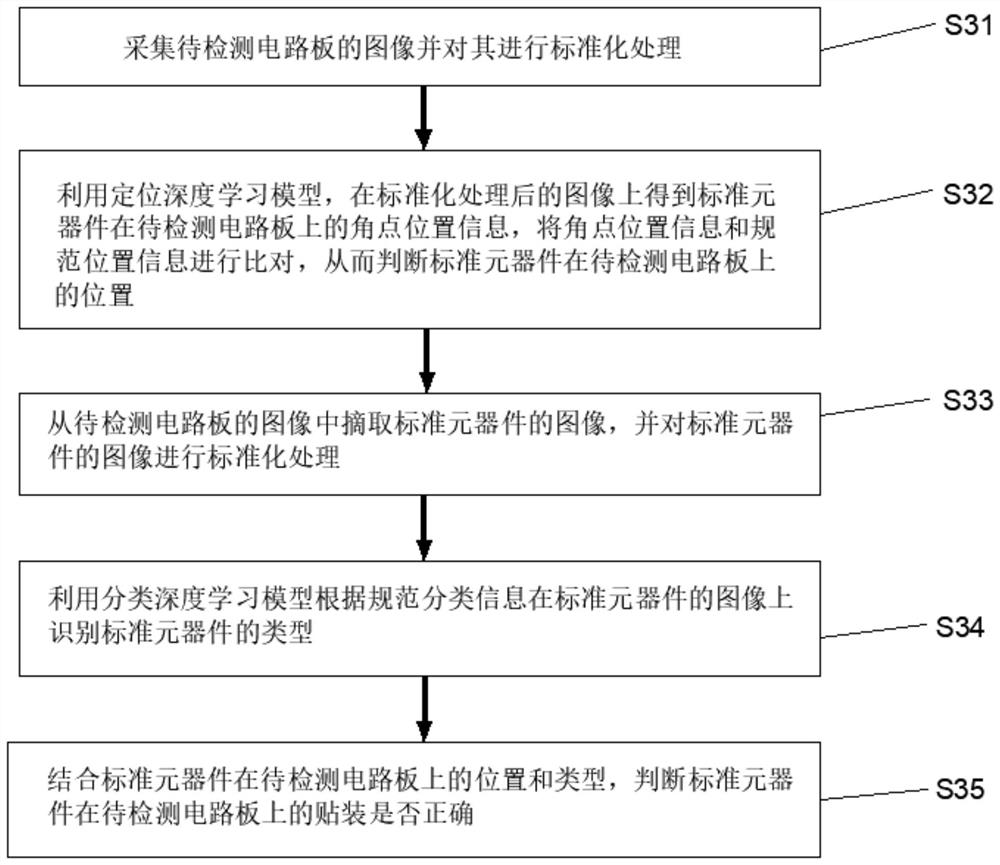

Automatic optical detection method, system and equipment for circuit board components

PendingCN113030121AImprove production accuracyImprove manufacturing precisionMaterial analysis by optical meansEngineeringComputer science

The invention discloses an automatic optical detection method, system and equipment for circuit board components and a medium. The automatic optical detection method for the circuit board components comprises the following steps: collecting component information and circuit board sample information, and establishing a deep learning model; dividing the components on the circuit board to be detected into standard components and non-standard components according to a preset condition; acquiring an image of the circuit board to be detected, positioning and classifying the standard component by using the deep learning model, and judging whether the standard component is correctly mounted on the circuit board to be detected or not; and acquiring a feature region image of the non-standard component on the circuit board to be detected, comparing the feature region image with a detection template, and judging whether the mounting of the non-standard component on the circuit board to be detected is correct or not. According to the automatic optical detection method for the circuit board components, the detection of the standard component is automatic, the detection time is shortened, the detection precision is improved, the detection accuracy is ensured, and the labor cost is reduced.

Owner:微讯智造(广州)电子有限公司

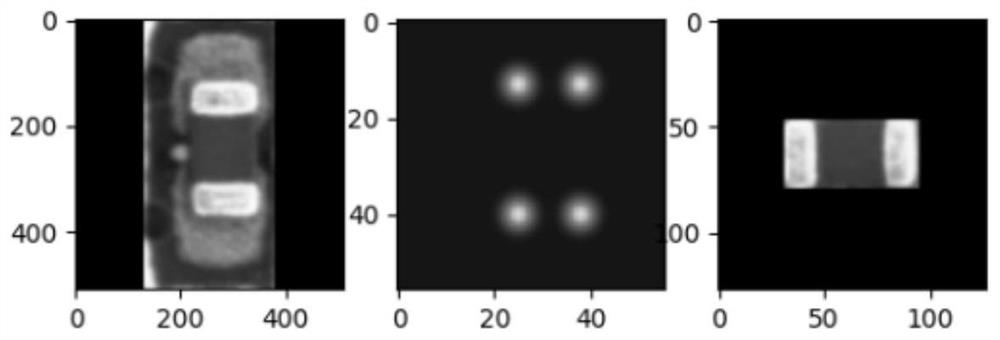

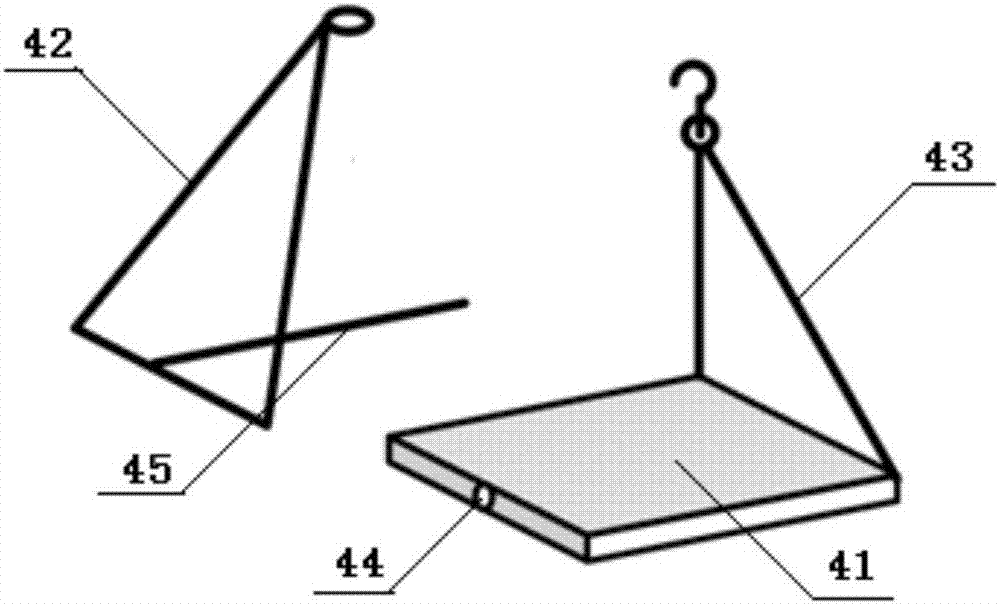

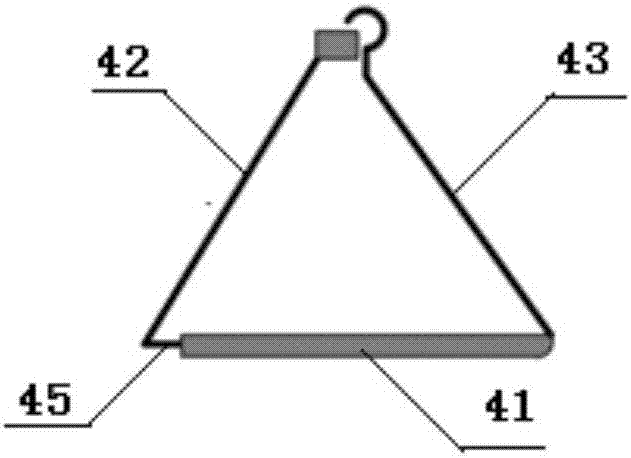

Wet density testing device

ActiveCN107101909AReduce the transfer linkImprove test accuracySpecific gravity measurementEngineeringWater tanks

The invention discloses a wet density testing device comprising a water tank, a scale hanging frame, an electronic scale, a weighing disc, an irregular sample box, a circular sample holder, a resistance heater, a water injecting component and a water drainage component, the two feet of the scale hanging frame are respectively fixed on the top of two opposite side surfaces of the water tank, the scale hanging frame is provided with a connecting ring in relative sliding movement with the scale hanging frame, the connecting ring is connected through a connecting rope with the top of the electronic scale, a hook and the weighing disc are connected below the electronic scale by a connecting rope, the irregular sample box and the circular sample holder are respectively arranged at the positions, near the top, of the inner side wall of the water tank, the resistance heater is arranged at the position, near the bottom, of the inner side wall of the water tank, the water injecting component and the water drainage component are respectively arranged at the positions, near the top and near the bottom, of the outer side wall of the water tank, and are communicated with the interior of the water tank. The wet density testing device can rapidly and accurately measure the wet density of a circular sample or an irregular block sample.

Owner:CHENGDU UNIV OF INFORMATION TECH

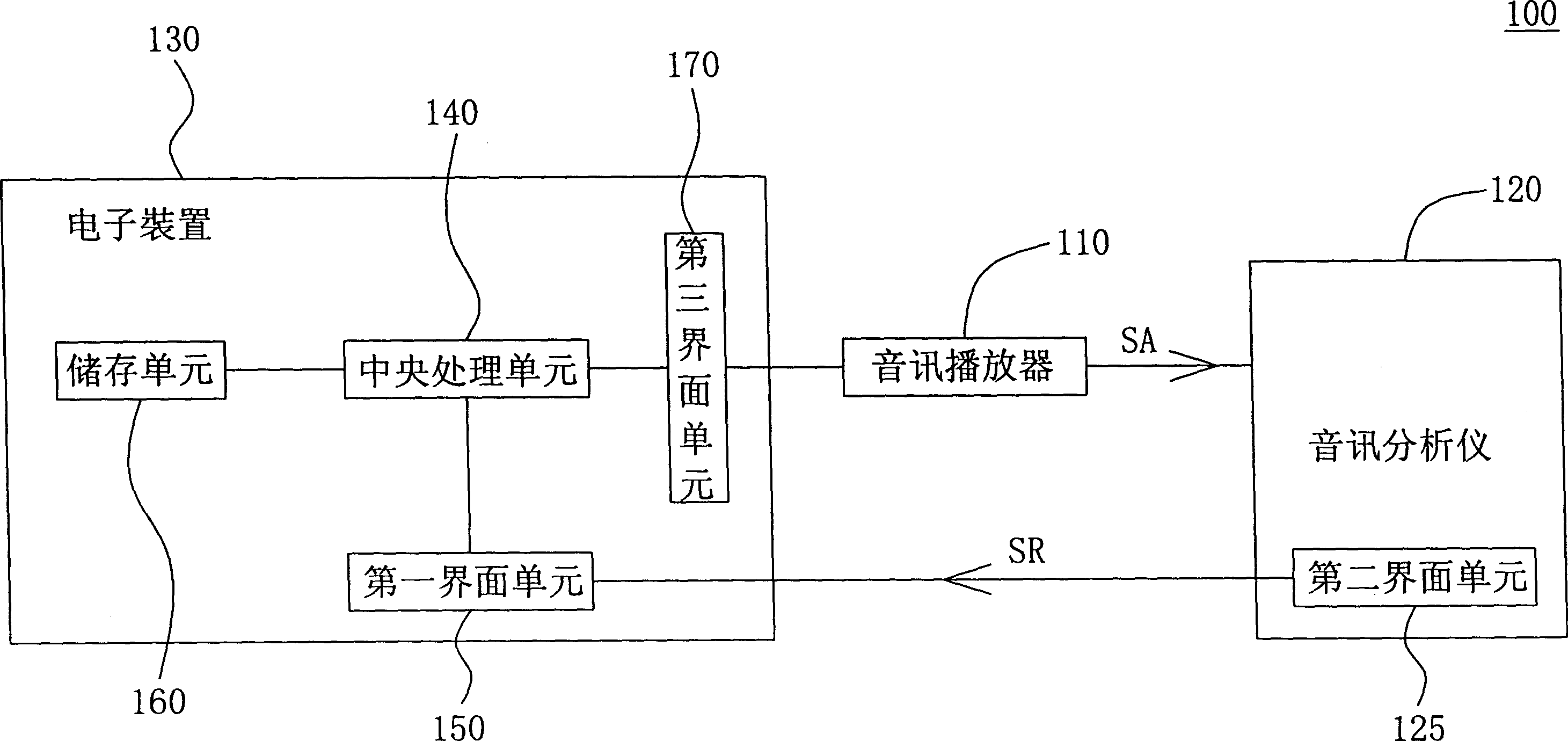

Method and device for testing audio player through audio analyzer

InactiveCN1696720ASave setting workAuto saveSubsonic/sonic/ultrasonic wave measurementElectrical testingComputer hardwareAudio analyzer

A device for testing voice frequency player by utilizing voice frequency `analyzer consists of a voice - frequency player, a voice frequency analyzer and an electronic device including central processing unit, an interface and a storage unit. The testing method includes initializing said analyzer, interface and player by central processing unit and setting a test project when test is stared; sending voice frequency from player to analyzer and sending test result to storage unit after analyzing when test is on.

Owner:LITE ON IT

Packaging equipment and packaging technology for flashlights

ActiveCN108928525BMechanizationRealize automated productionPackaging automatic controlPackaging machinesTorchFlashlight

The invention relates to the field of torch production, in particular to packing equipment and a packing technique for torches. The packing equipment for the torches comprises a packing line, a blister feeding mechanism, a torch feeding mechanism, a transferring robot, a color card transferring mechanism and a binding mechanism; the packing technique comprises the following steps: S1, a blister isplaced above by the blister feeding mechanism; S2, the torch is placed above by the torch feeding mechanism; S3, the blister is placed on a packing base by the transferring robot, and is placed in the blister; S4, the packing base is conveyed to the color card transferring mechanism by the packing line, and the color card moving mechanism transfers a color card to the packing base; and S5, the packing base is conveyed to the binding mechanism by the packing line, and the binding mechanism binds the color card and the blister together. By adopting the packing equipment and packing technique for torches, mechanical and automatic production of packing of torches can be realized; and production efficiency is greatly improved.

Owner:GUANGDONG XG INTELLIGENT SYST CO LTD

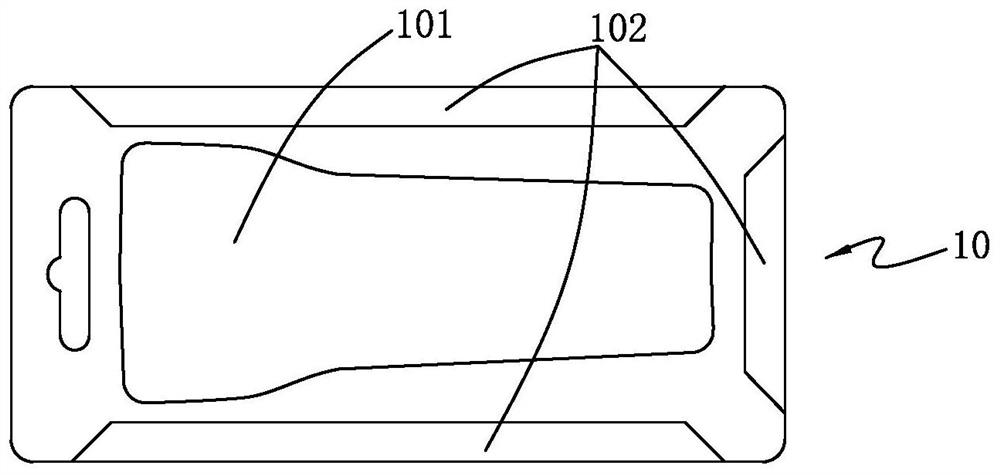

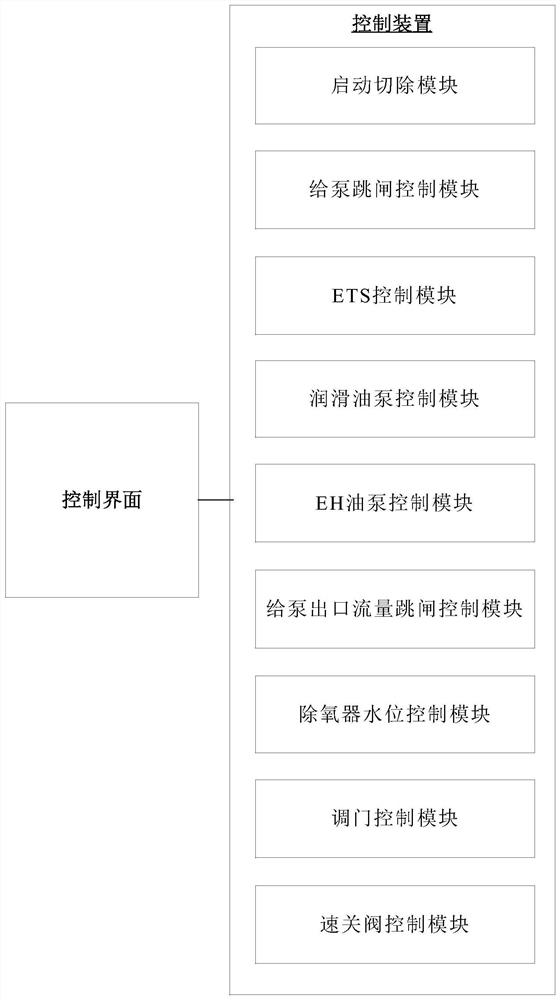

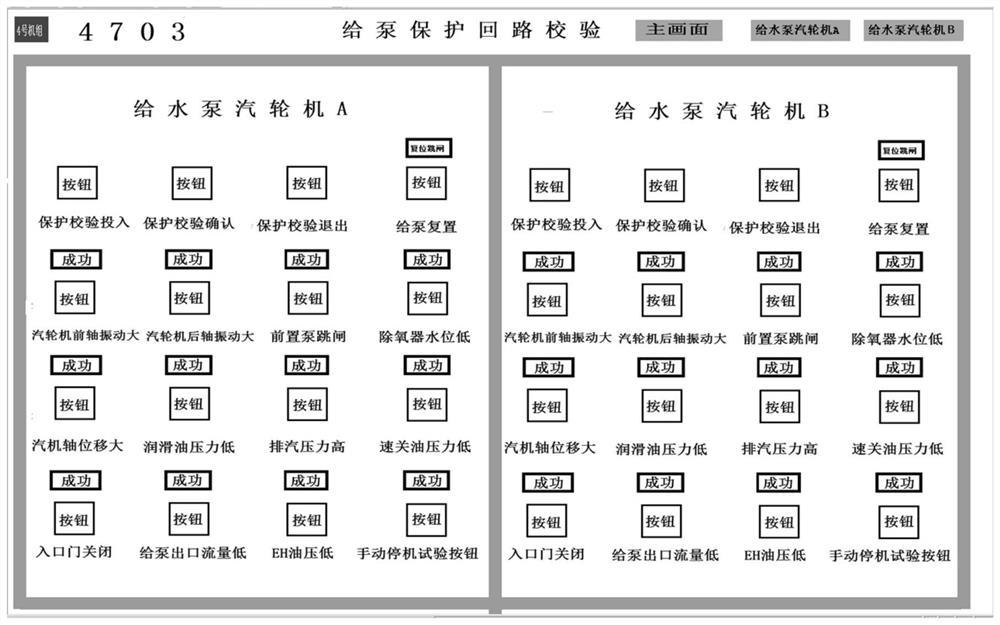

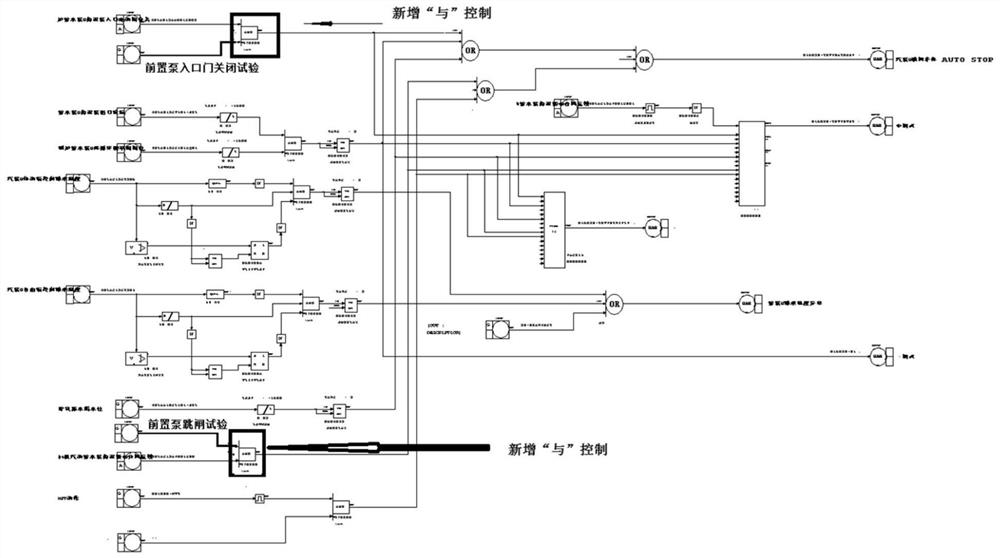

Feed pump protection verification system and method

PendingCN114776571AImprove securityIncrease the operation interfacePump testingPositive-displacement liquid enginesDeaeratorProcess engineering

The invention discloses a pump feeding protection verification system and method. The system comprises a control interface and a control device. The control interface comprises an instruction button and a test content success display item; the control device comprises a start cutting module, a feed pump tripping control module, an ETS control module, a lubricating oil pump control module, an EH oil pump control module, a feed pump outlet flow tripping control module, a deaerator water level control module, a control valve control module and a quick-closing valve control module. The control logic is modified and an operation interface is added, so that the logic forcing and signal modification time is shortened, the protection verification work is simplified, the human intervention is reduced, the test time is shortened, the efficiency is improved, the probability of human errors is reduced, and the unit safety is improved.

Owner:SHANGHAI HUADIAN ELECTRIC POWER DEV CO LTD

An automatic optical fiber preform measurement system and its measurement method

ActiveCN101788471BFully automatedFast production process feedbackPhase-affecting property measurementsCharge dischargeEngineering

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

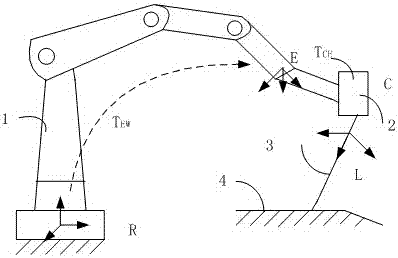

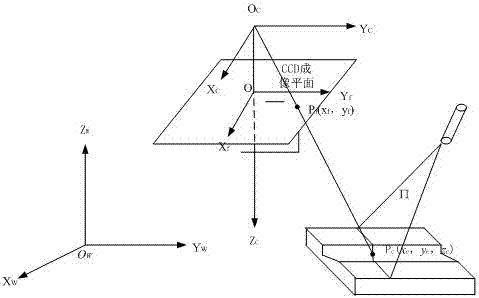

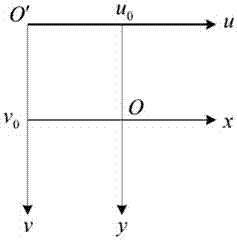

Calibration method of laser seam tracking sensor

InactiveCN105716527BThe experiment process is simpleHigh precisionUsing optical meansLaser beam welding apparatusAngular pointDiagonal

Owner:CHINA JILIANG UNIV

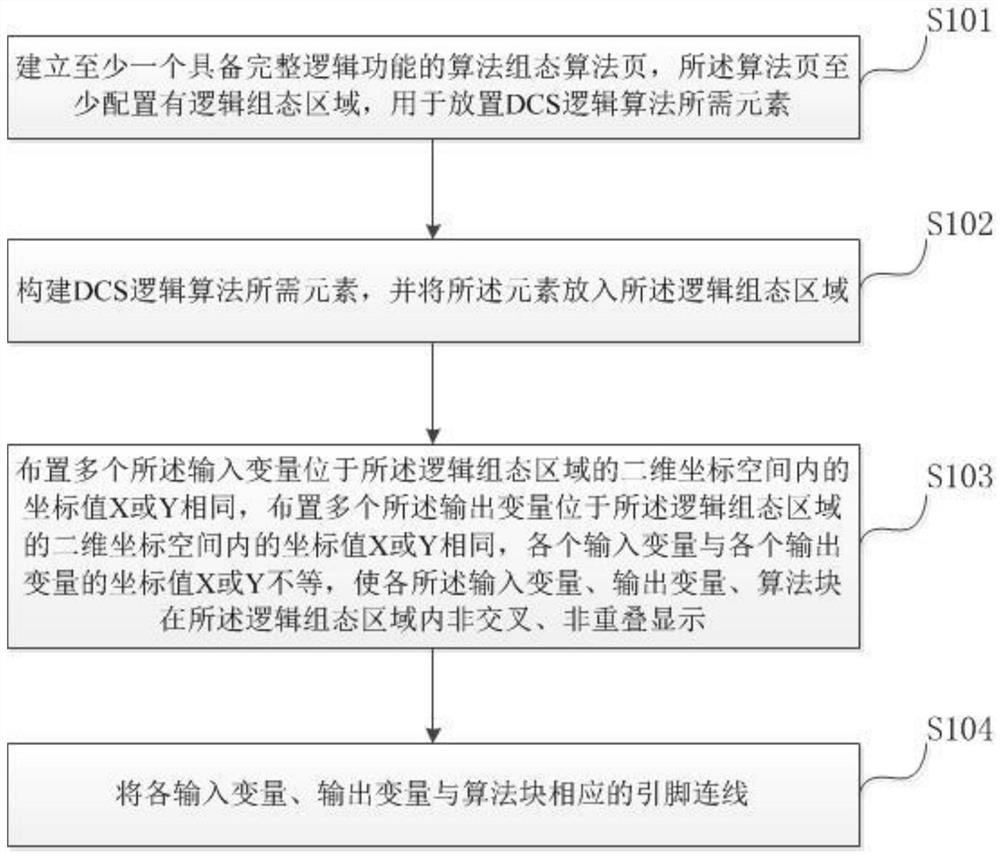

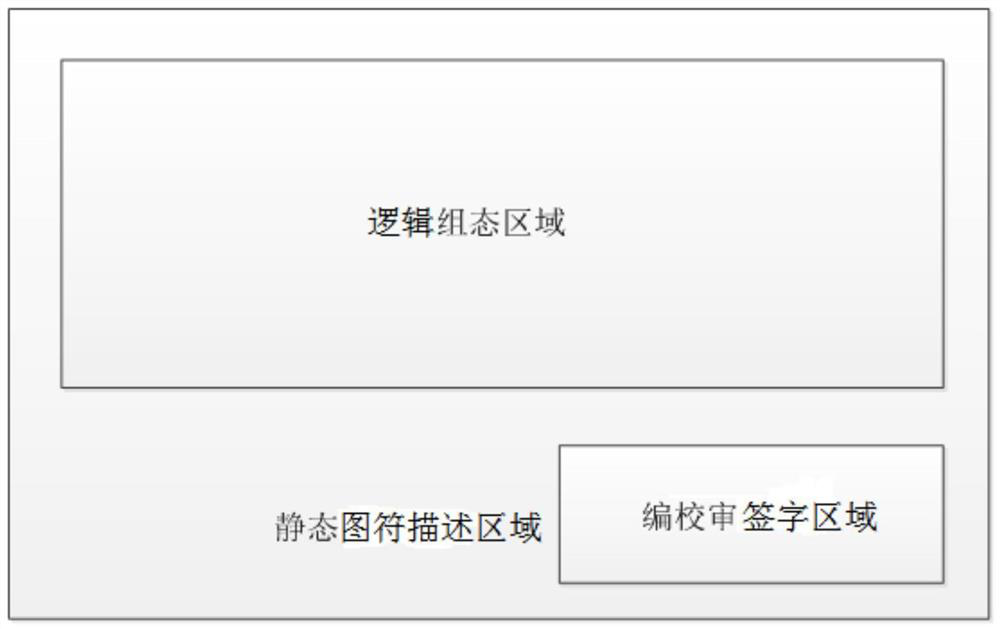

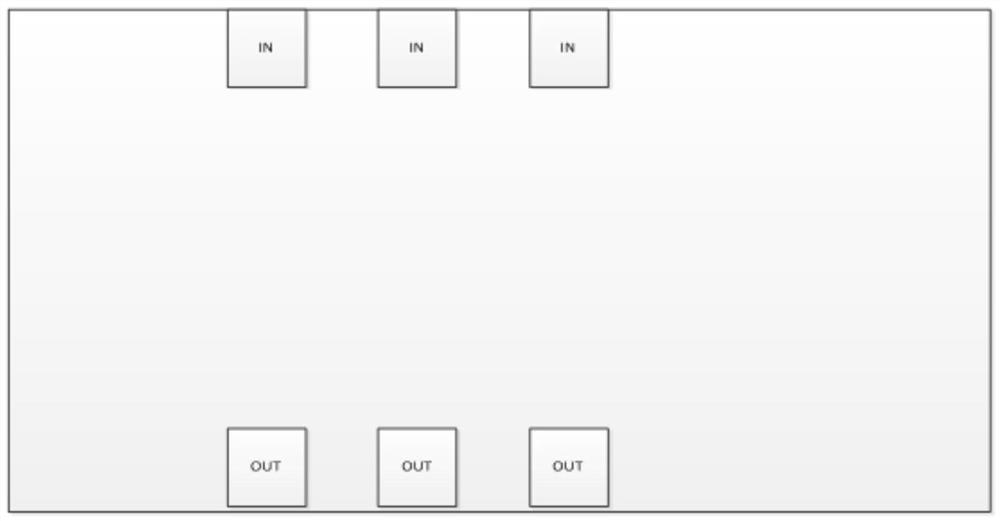

Processing method for element layout and connection of algorithm pages in DCS (Distributed Control System) logical algorithm graph

PendingCN114265378AEasy to watchSmooth connectionTotal factory controlProgramme total factory controlTheoretical computer scienceDistributed control system

The invention discloses a method for processing element layout and connection of algorithm pages in a DCS (Distributed Control System) logic algorithm graph, which comprises the following steps: establishing at least one algorithm configuration algorithm page with a complete logic function, and the algorithm page is at least configured with a logic configuration area for placing elements required by a DCS logic algorithm; elements required by a DCS logical algorithm are constructed, the elements are put into the logical configuration area, and the elements comprise input variables, output variables and algorithm blocks; the coordinate values X or Y, located in the two-dimensional coordinate space of the logic configuration area, of the multiple input variables are arranged to be the same, the coordinate values X or Y, located in the two-dimensional coordinate space of the logic configuration area, of the multiple output variables are arranged to be the same, and the coordinate values X or Y of the input variables are not equal to the coordinate values X or Y of the output variables; the input variables, the output variables and the algorithm blocks are displayed in the logic configuration area in a non-crossed and non-overlapped mode; and connecting the input variables and the output variables with the corresponding pins of the algorithm block.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

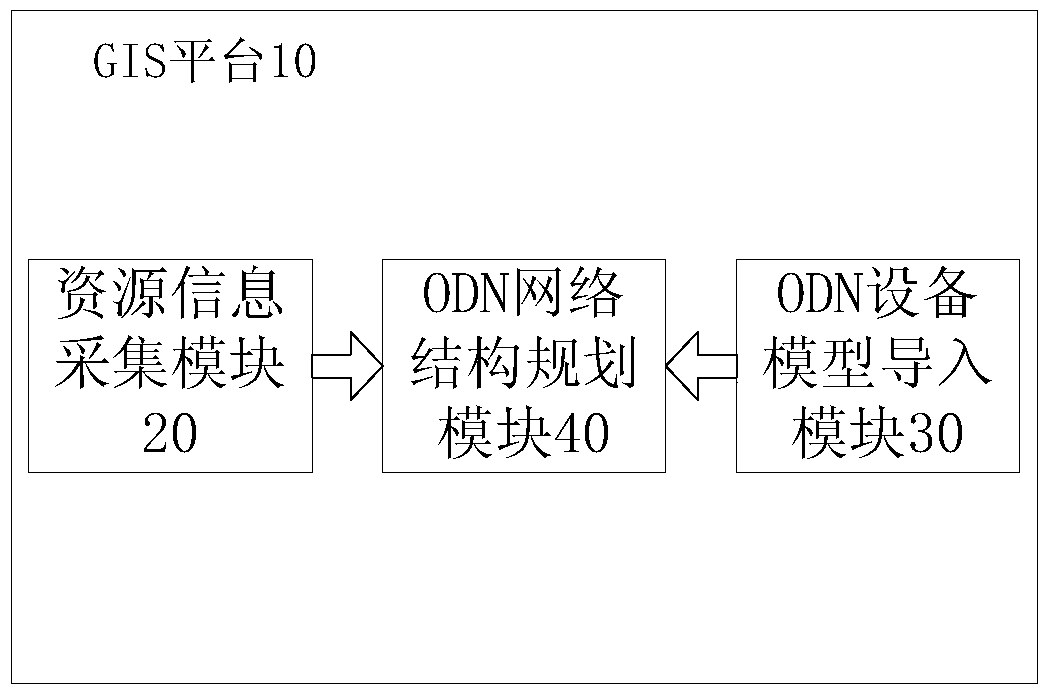

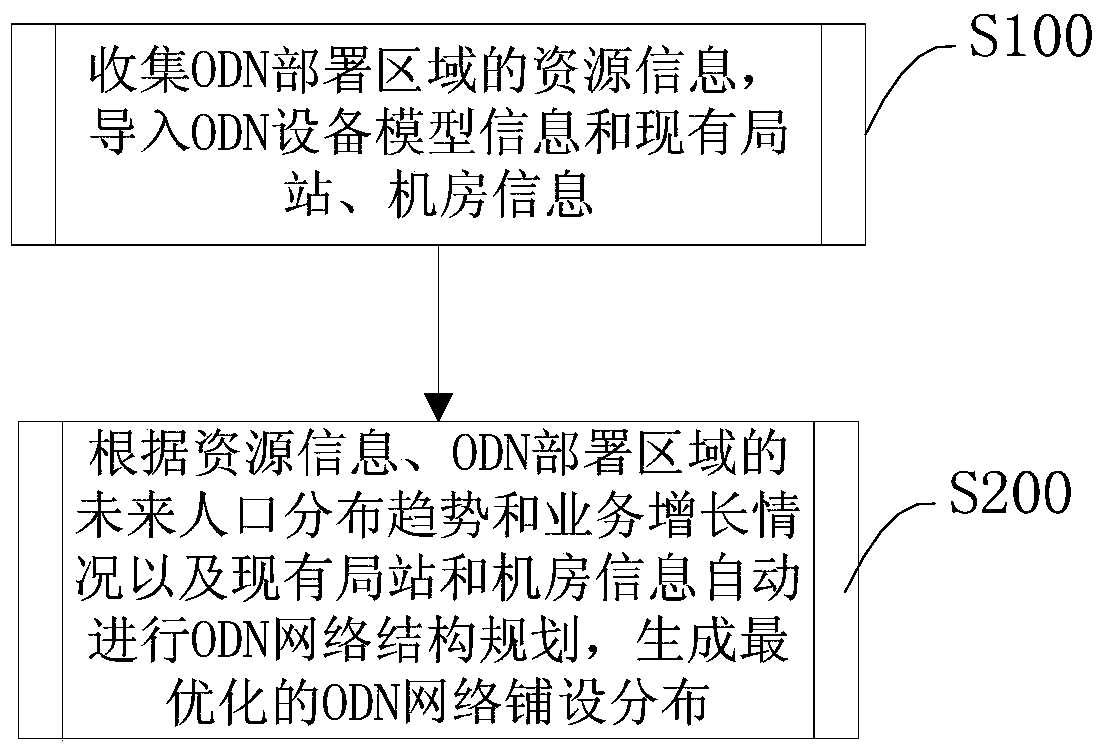

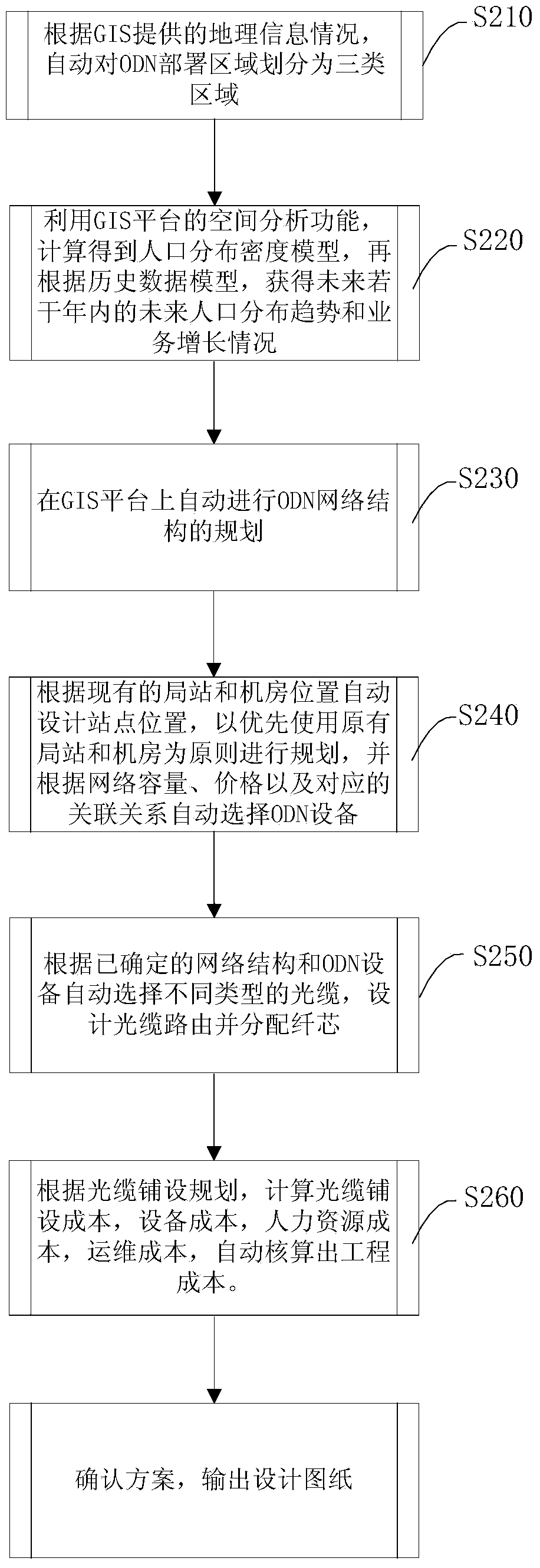

odn wiring management method and system based on gis platform

ActiveCN104767642BImprove planning and design efficiencyReduce the chance of human errorMultiplex system selection arrangementsData switching networksFiberResource information

The invention discloses an ODN line distribution management method and system based on a GIS platform. The method includes the steps that through the GIS platform, resource information of an ODN deployment region is collected, and ODN equipment model information and existing station and machine room information are input; according to the resource information, the future population distribution trend and service growth condition of the ODN deployment region and the existing station and machine room information, ODN structure planning is automatically performed, and corresponding ODN equipment is automatically selected to generate the optimal ODN layout distribution. Based on the GIS platform, through inputting a GIS map and existing network stock resources, region division, station selection, equipment model selection, optical cable routing designing, civil designing, optical cable layout and other designing operation are completed on the GIS map, an optical cable routing map, an equipment terminal and fiber core distribution diagram and other series design files and a material and service fee list can be output, in this way, the efficiency of planning designing is greatly improved, and the probability of manual errors is lowered.

Owner:FENGHUO COMM SCI & TECH CO LTD

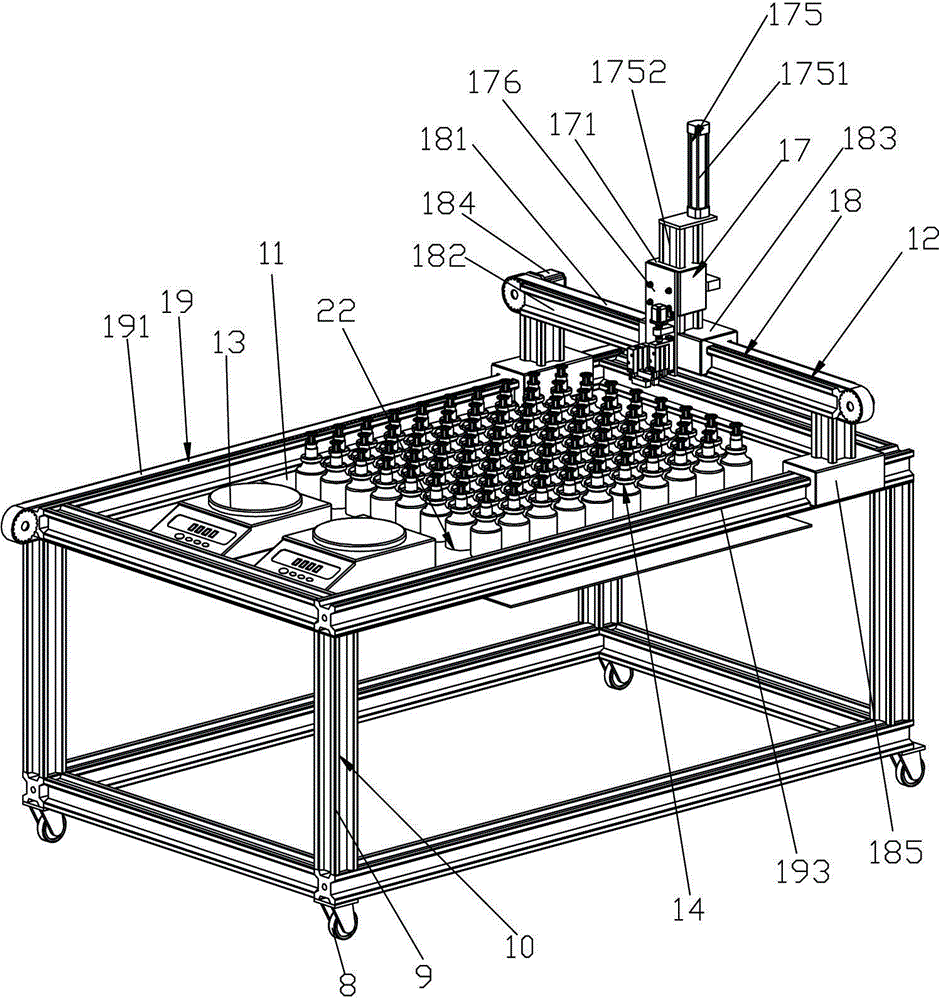

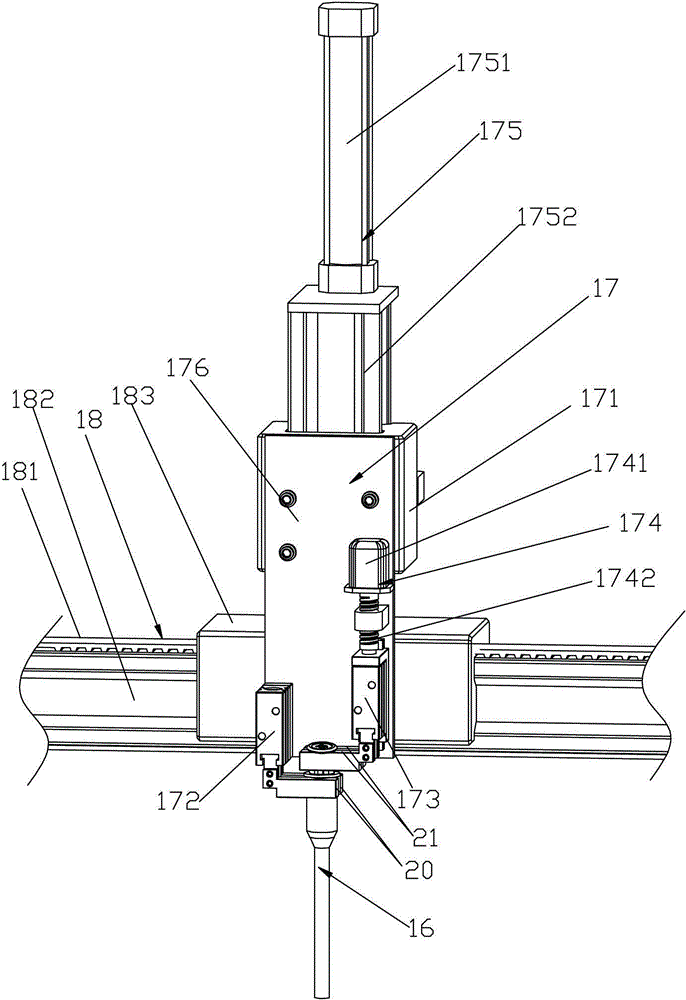

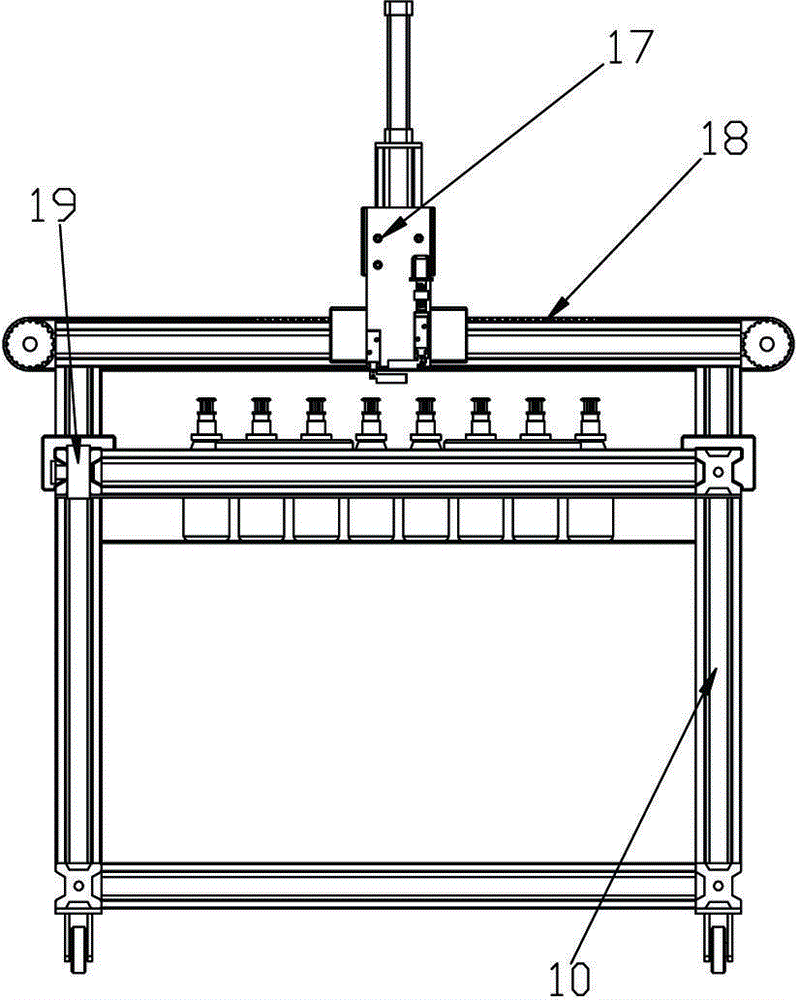

An automatic liquid dispensing machine

ActiveCN103590212BQuality improvementExtended service lifeTextile treatment machine arrangementsEngineeringBottle

The invention relates to an automatic liquid blending machine which comprises a rack and a controller. A workbench is arranged on the rack, a moving device, an electronic scale and multiple liquid blending bottles are mounted on the workbench, a blending container is mounted on the electronic scale, concentrated liquid is filled in each liquid blending bottle which comprises a bottle body and a liquid suction device, a linkage mechanism is mounted on the moving device, the moving device comprises a left-right adjusting device capable of adjusting the linkage mechanism along the width direction of the workbench and a front-back adjusting device capable of adjusting the linkage mechanism along the length direction of the workbench, and the electronic scale, the front-back adjusting device, the left-right adjusting device and the linkage mechanism are connected with the controller respectively. The automatic liquid blending machine can realize automatic color blending and liquid blending, so that labor intensity of operating personnel is greatly reduced. In addition, the automatic liquid blending machine can accurately control quantity of the concentrated liquid injected into the blending container by the liquid suction device, so that generation of color difference due to manual operation is avoided, and color blending and liquid blending quality is stable.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

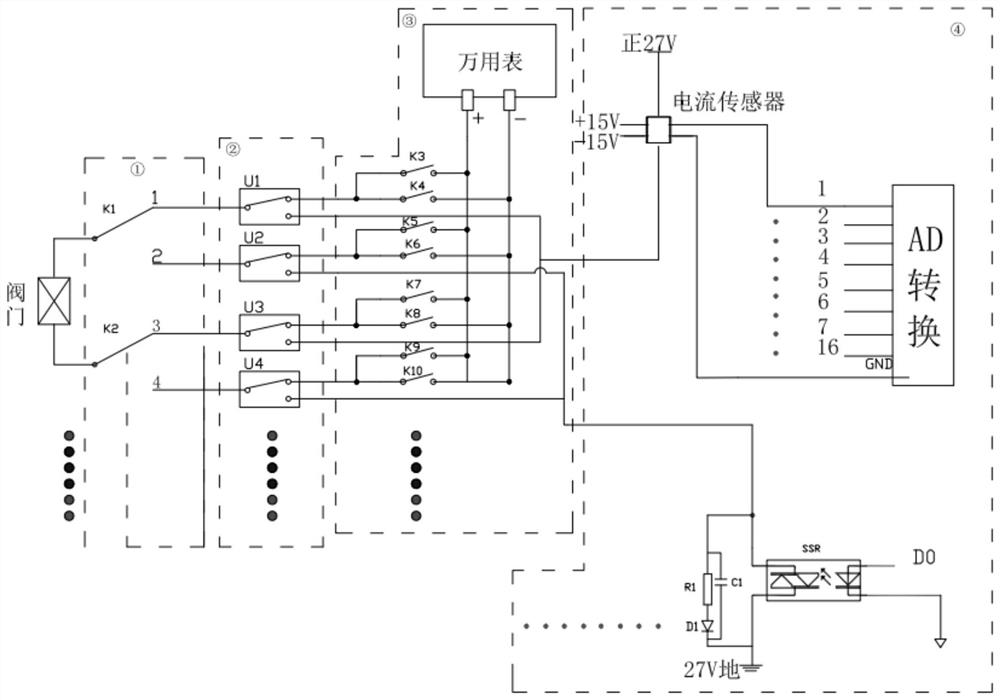

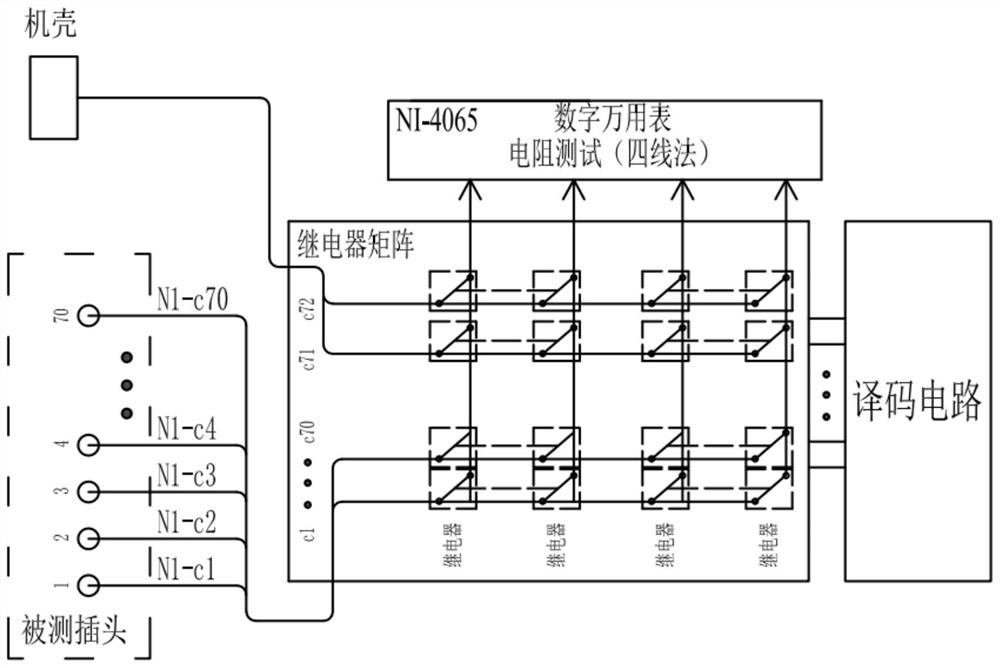

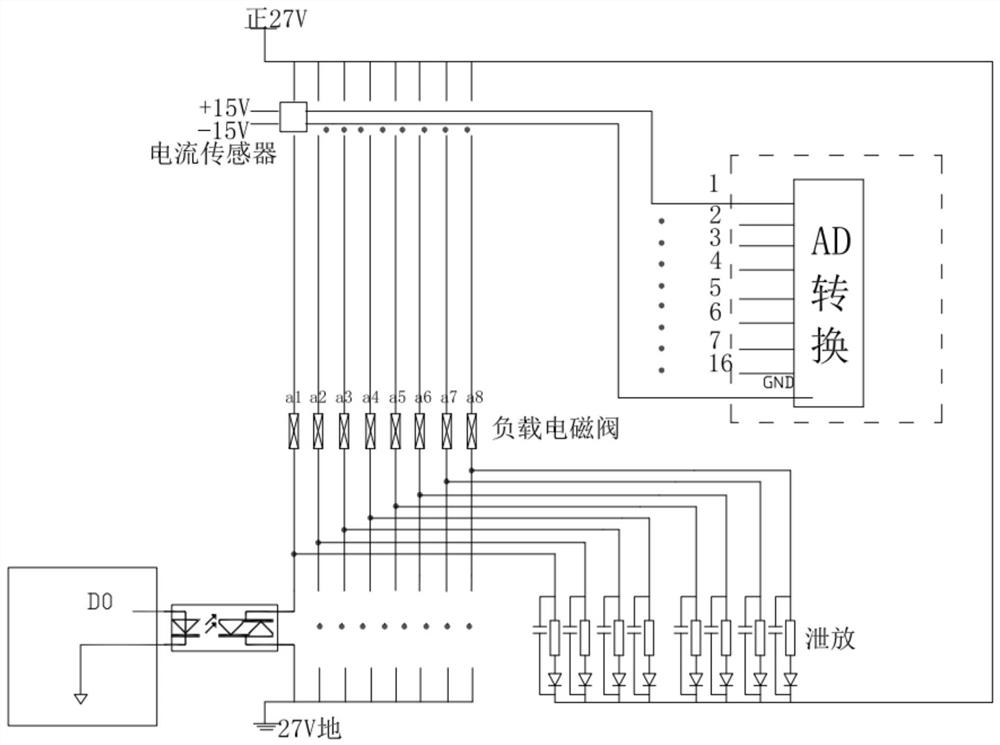

Solenoid valve automatic testing device for aerospace attitude and orbit control engine

PendingCN114460392AImprove test efficiencyShorten test timeTesting dielectric strengthSolenoid valveEngineering

The invention provides an electromagnetic valve automatic testing device for a spaceflight attitude and orbit control engine. The electromagnetic valve automatic testing device comprises a testing switching circuit, a conduction insulation testing circuit and a valve characteristic testing circuit. The input end of the test switching circuit is connected with a tested valve, the output end of the test switching circuit is respectively connected with the conduction insulation circuit and the valve characteristic test circuit, and the tested valve is singly connected with the conduction insulation test circuit or the valve characteristic test circuit. Compared with an existing testing method, the device has the advantages that the number of times of manually plugging and unplugging the testing plug is reduced, and the probability of manual operation errors is reduced.

Owner:SHANGHAI INST OF SPACE PROPULSION

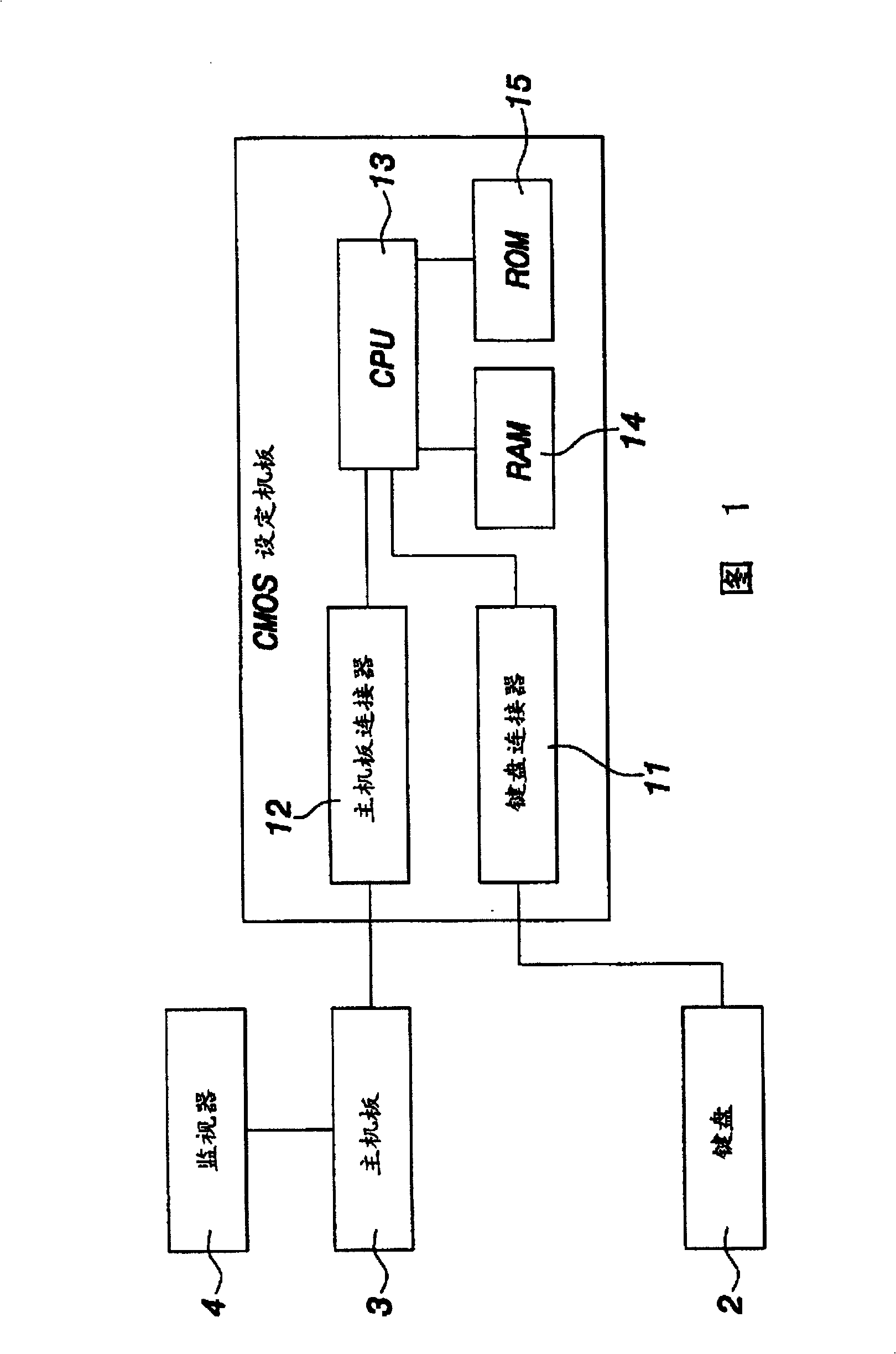

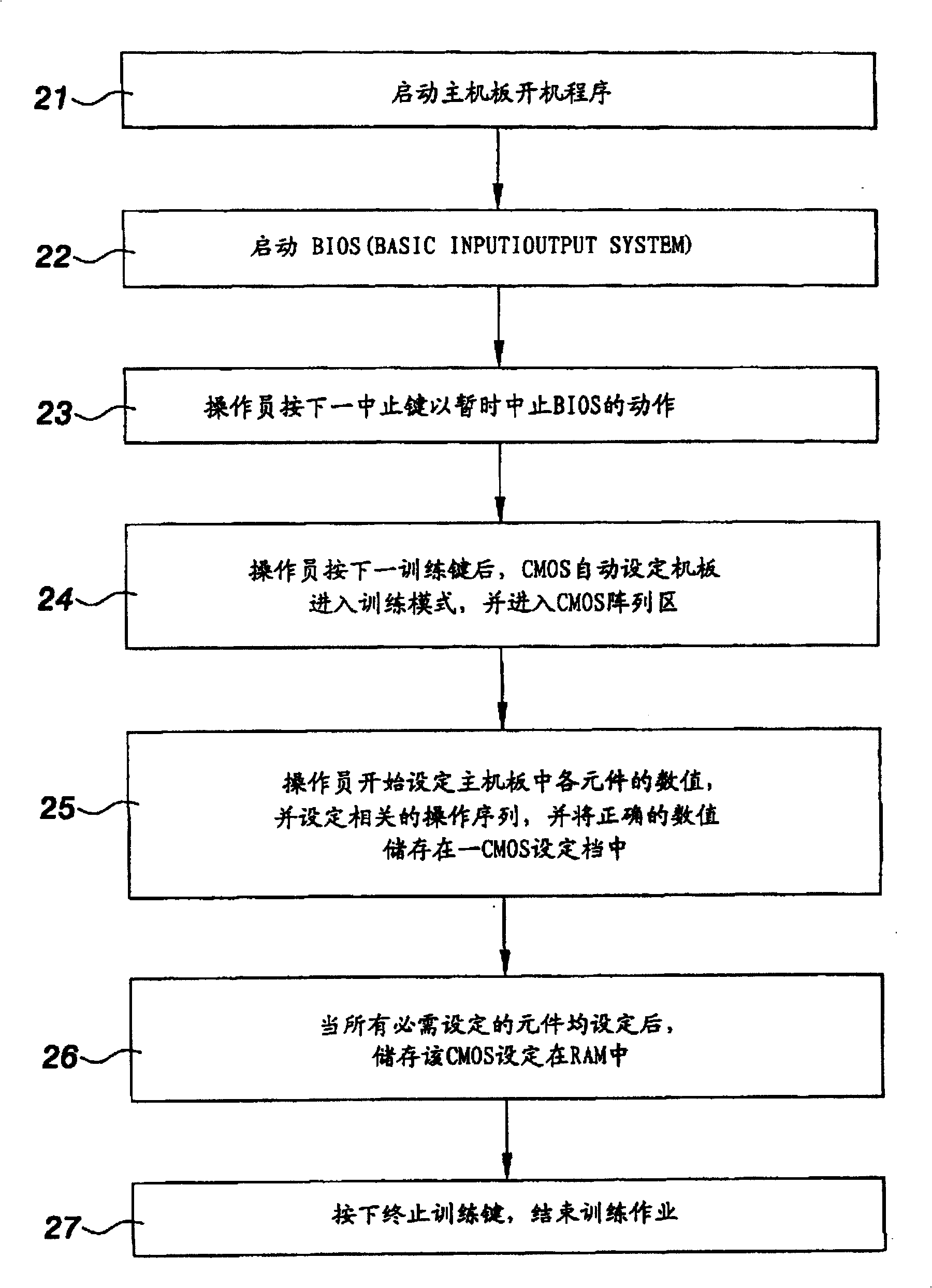

Mainboard CMOS data automatic setting method and device thereof

InactiveCN100418030CEliminate redundancyEliminate duplicationDigital data processing detailsCMOSEngineering

An automatic designing of a mainboard CMOS data and its device is realized by this invention with a new traditional prepared base plate to be tested. An operator designs the CMOS data of the mainboard via operation keys and monitor the process from the monitor for automatic setting prepared for the test operation, then to the next stage test operation va\\avoiding artificially complicated CMOS array designing operations and maistakes made by operator. The automatic designing computer plate mainly mainly includes a key board connector, a RAM (or EEPROM) a CPU and a ROM.

Owner:ASUSTEK COMPUTER INC

System and method for realizing automatic verification of information point table in smart grid

ActiveCN107067161BEasy to automate maintenanceReduce workloadOther databases queryingResourcesSmart substationSmart grid

The purpose of the present invention is to provide a system and method for realizing the automatic checking of the information point table in the smart grid. The invention adopts the mode of server / consumer, and the function of the service provider is realized in the intelligent communication gateway machine, wherein the service provider includes a model service producer and an automatic checking service producer. Through the smart substation plug-and-play technology system and the replacement service of IEC61850, the point meter automatic check between the control master station and the smart substation and the information point automatic check technology between the master substation and the IED device are realized. The invention reduces the probability of human error, improves the efficiency and accuracy of the information point table interaction between the control master station and the intelligent substation; reduces the workload of manual point alignment, and facilitates the automatic maintenance of the information point table; improves the control master station and the intelligent substation. The degree of automation of smart substation interactions.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +3

Image Control Point Interactive Editing System

InactiveCN102760301BIntuitive Feedback ResponseReduce the chance of human errorModifying/creating image using manual inputState parameterInteractive editing

The invention provides an image control point interactive editing system. The image control point interactive editing system is characterized by comprising a central processing unit, a data processing unit, an information command unit, a graphical interface unit and a handle, wherein the central processing unit is used for coordinating data transmission and function scheduling among all the units; the data processing unit is used for managing image data and control point data, and performing operation; the information command unit is used for getting a hardware state parameter and converting the hardware state parameter to a user command; the graphical interface unit is used for checking the image data and the control point data and monitoring the operation response of a user; and the handle comprises a left rocker, a right rocker, multiple function buttons and a force feedback responsor. The image control point interactive editing system disclosed by the invention can simultaneously move and zoom the image data and reference data, which need to be processed, during editing of a control point of an image, and further perform continuous switching between an editing state and a checking state. In addition, the opportunity of causing human error during editing can be reduced and the low-cost implementation can be realized.

Owner:武汉天目经纬教育发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com