An automatic optical fiber preform measurement system and its measurement method

A technology of optical fiber preform and automatic testing system, which is applied in the direction of measuring device, phase influence characteristic measurement, and material analysis through optical means, etc., which can solve the problem of increased test instability, increased manufacturing cost of optical fiber preform, and increased labor intensity and other issues to achieve the effect of reducing the probability of human error, compact structure and realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

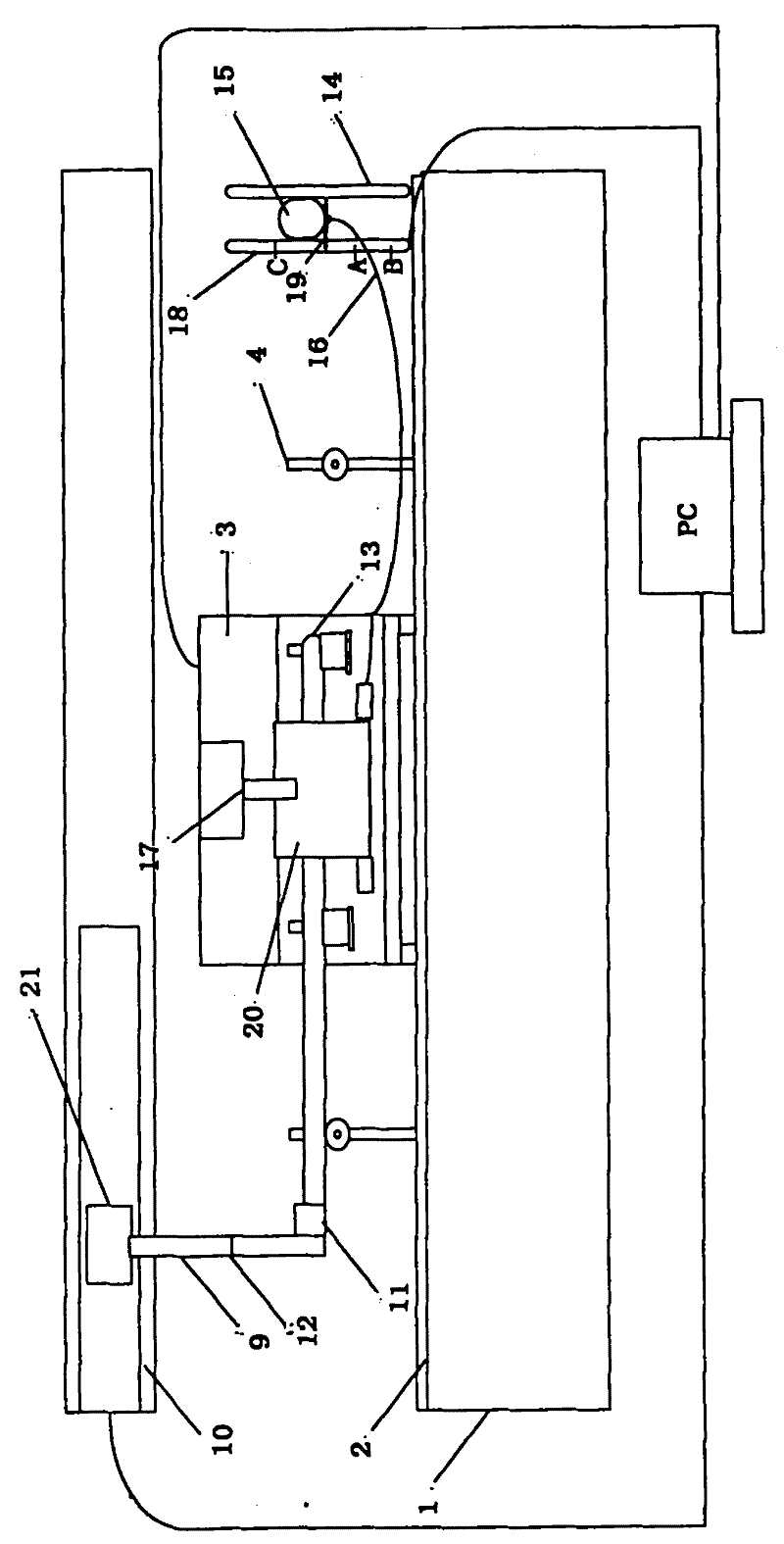

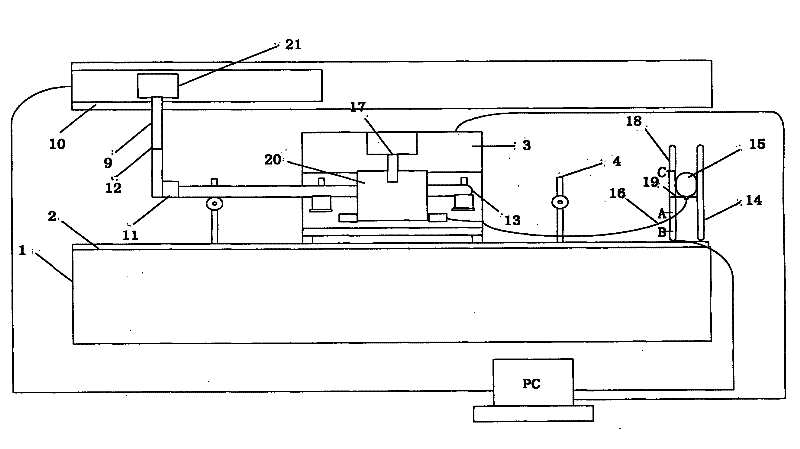

[0026] Refer to attached Figure 1~2 , an optical fiber preform automatic testing system is composed of an automatic rod pushing device, an automatic filling and discharging device for matching oil and a preform tester. The automatic rod pushing device, the matching oil automatic filling and discharging device and the preform tester are connected to the computer PC control system through the programmable controller PLC. The PC control system controls the operation of each device according to the set program to realize the automatic test of the optical fiber preform. The preform tester can be a commercially available P104 optical fiber preform tester.

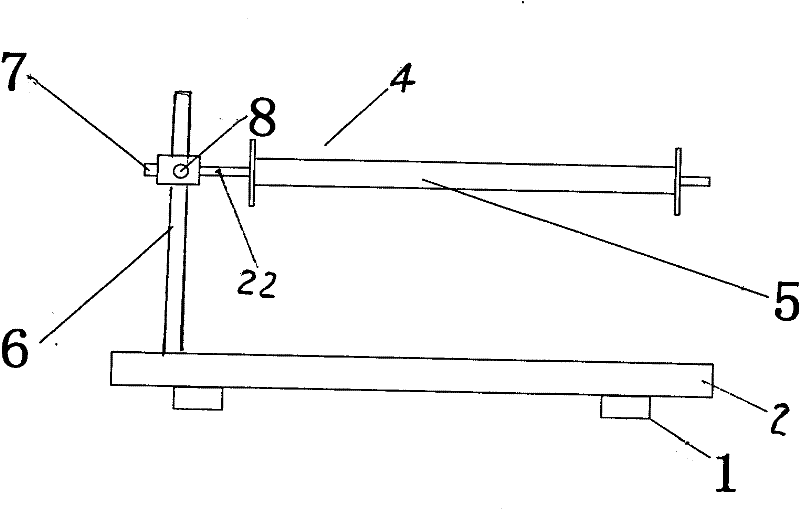

[0027] The automatic rod pushing device includes a test bench 1, a support frame 4, a servo motor 21 and a pushing arm 9. A guide rail 2 is installed on the test bench 1, a support frame 4 and a tester 3 are installed on the guide rail 2, and the support frame 4 can slide along the guide rail 2. The top of the test bench 1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com