Full-automatic high-concentration beer dilution ratio mixing machine and mixing method thereof

A fully automatic and mixing machine technology, applied in the direction of beer brewing, etc., can solve the problems of inaccurate control, increased labor intensity and error probability, adverse effects on beer quality and uniformity, etc., to avoid feedback adjustment lag and reduce labor Strength and the probability of human error, the effect of improving product quality and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

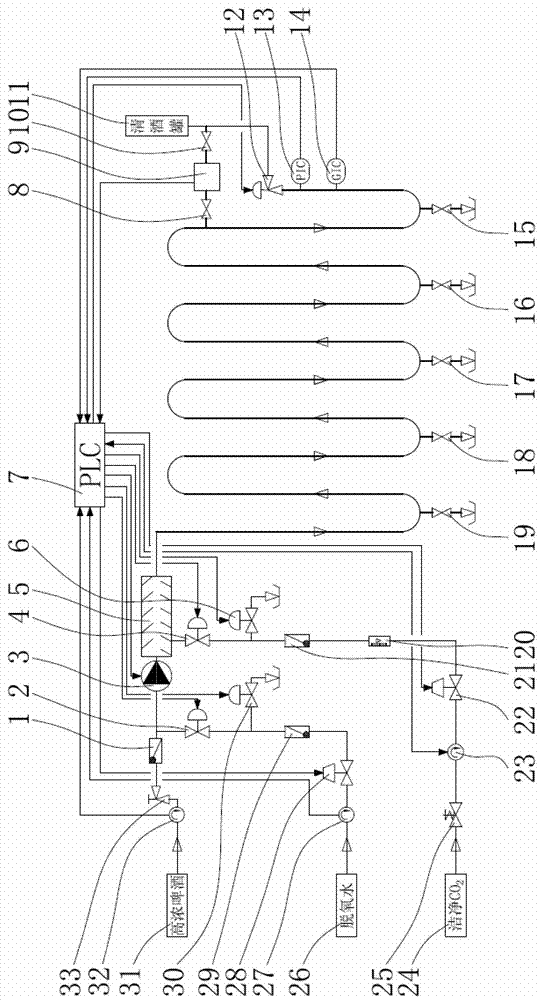

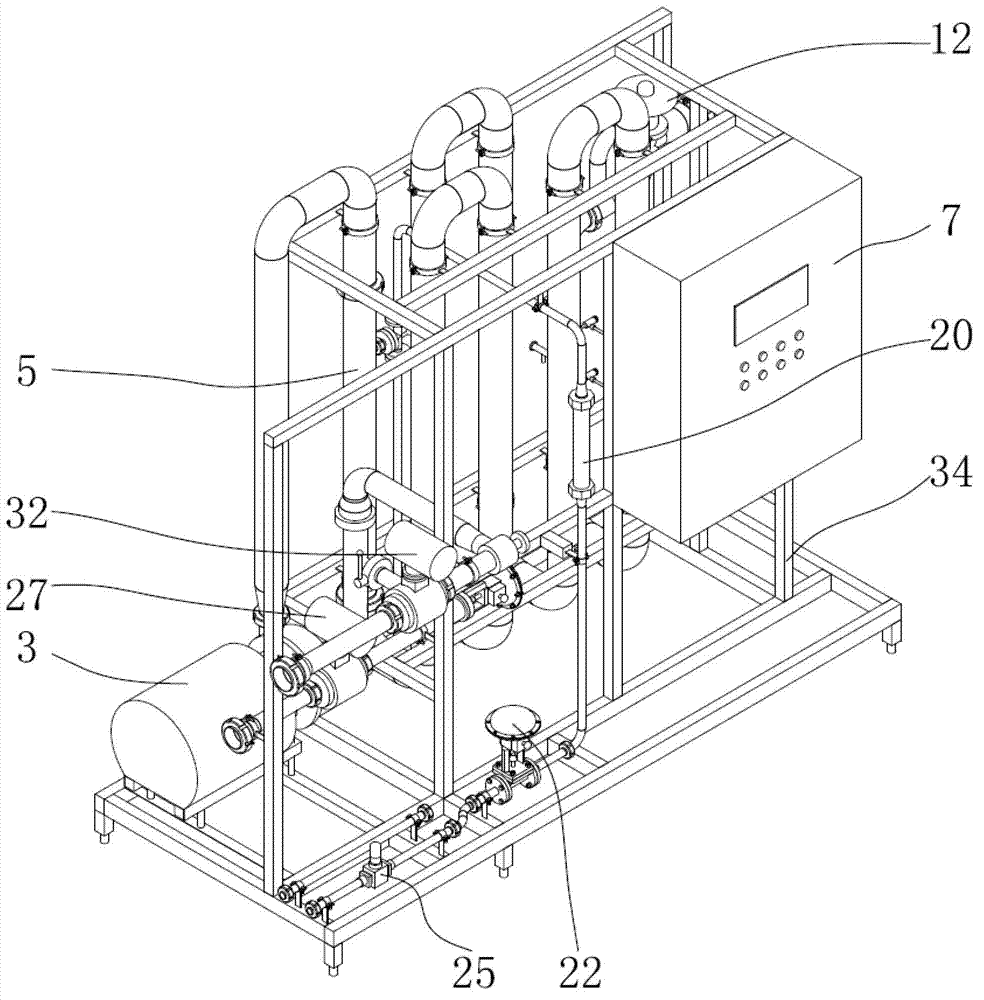

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0015] like figure 1 and figure 2 Shown, the full-automatic high-concentration beer dilution proportioning mixer comprises a frame 34, a PLC control cabinet 7 arranged outside the frame 34, a static mixer 5 arranged above the frame 34, and a static mixer arranged at the lower end of the static mixer 5. Dilution pump 3, the full-automatic high-concentration beer dilution proportioning mixer is externally connected with high-concentration beer 31, deoxygenated water 26, clean CO 2 24. Finished wine storage tank 11, the high-concentration beer 31 and deoxygenated water 26 are mixed in the dilution pump 3, and then mixed with clean CO 2 24 enters finished product wine storage tank 11 after static mixer 5 mixes.

[0016] The high-concentration be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com