An automatic liquid dispensing machine

An automatic liquid dispensing and dispensing technology, applied in the field of printing and dyeing industry, can solve the problems of poor quality of manual color matching and dispensing and high labor intensity of operators, and achieve the effect of reducing the probability of human error, reducing labor intensity and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described below with reference to the drawings.

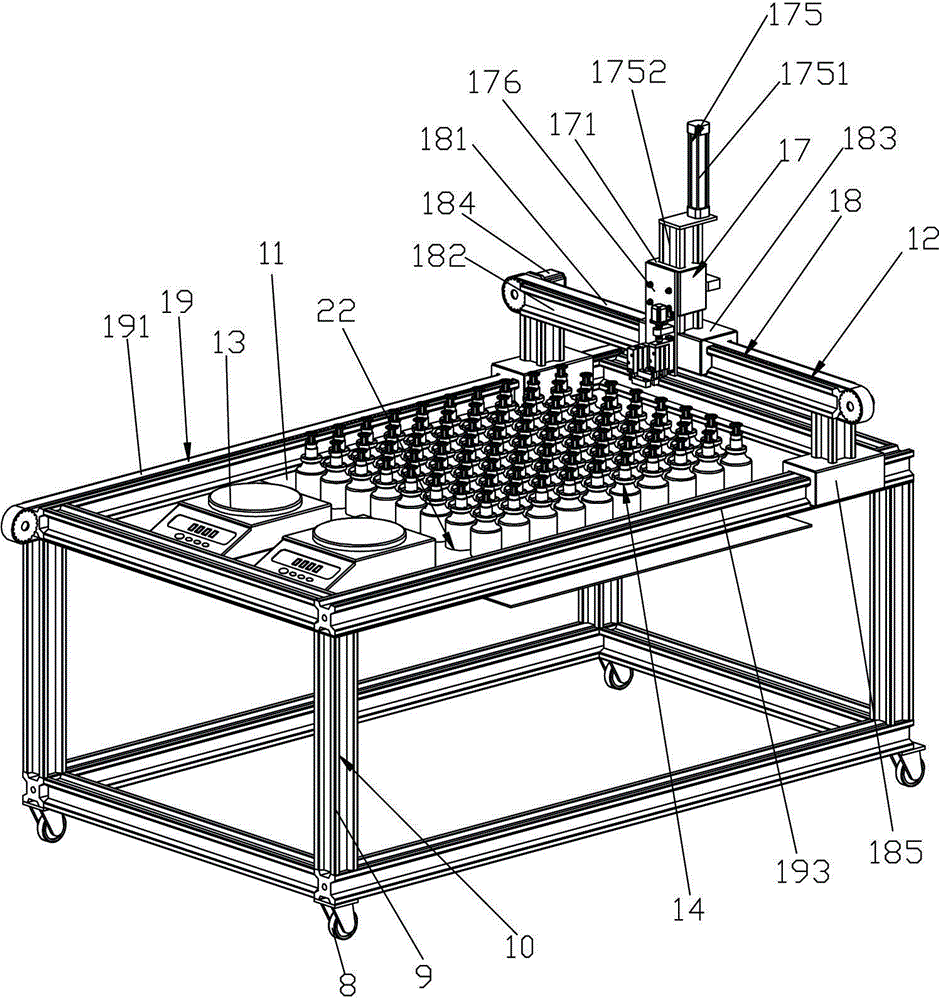

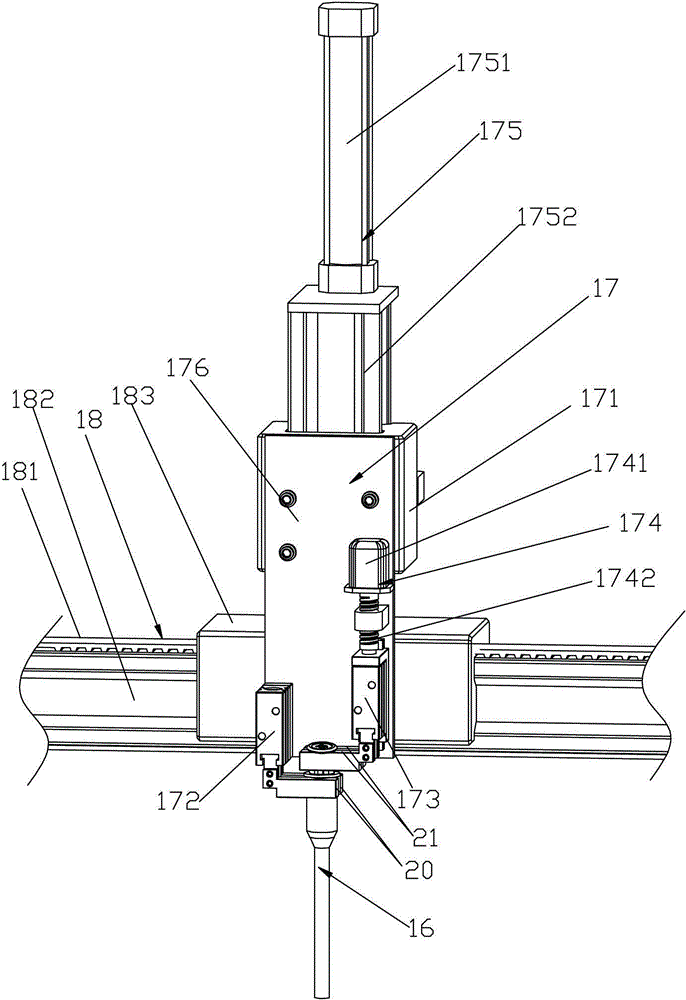

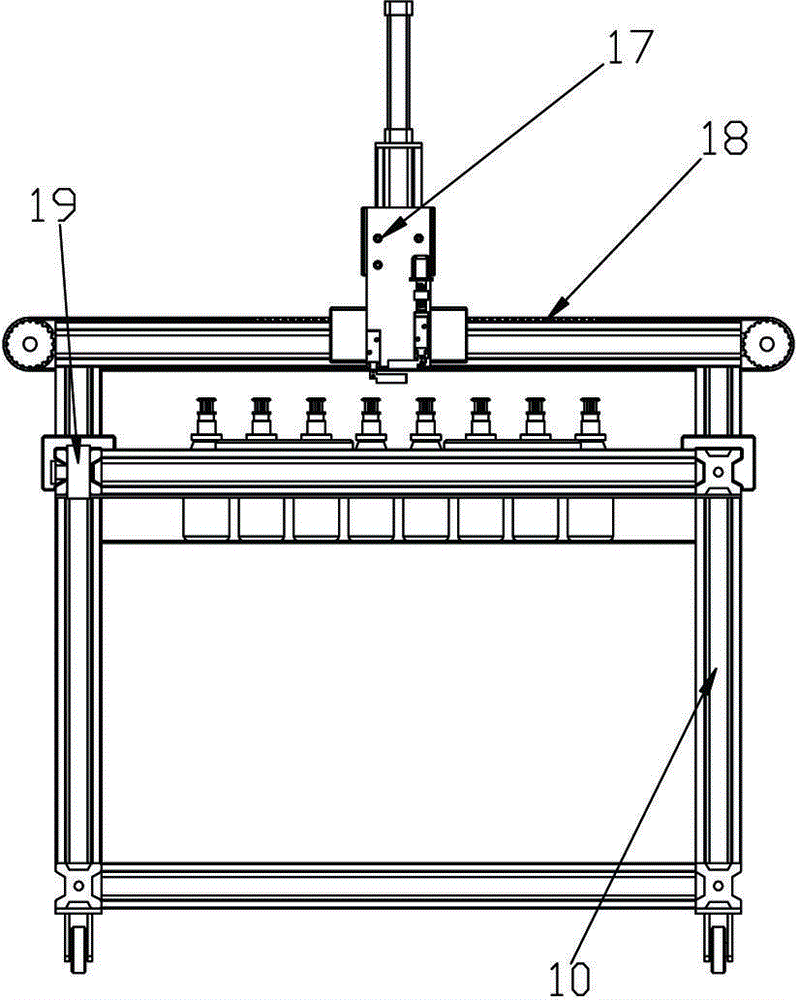

[0023] Such as figure 1 with figure 2 As shown, an automatic liquid dispensing machine includes a frame 10 and a controller (not shown in the figure) that controls the operation of the automatic liquid dispensing machine. The frame 10 is provided with four legs 9, and each of the legs 9 is equipped with a caster 8. The frame 10 is provided with a workbench 11, and the workbench 11 is equipped with a mobile device 12, two electronic scales 13, and a plurality of liquid dispensing bottles 14. Each electronic scale 13 is equipped with a mixing container (not shown in the figure), and each liquid mixing bottle 14 contains a concentrated liquid, which is a liquid used for liquid mixing. One type of concentrated solution is put into a dosing bottle 14, the dosing bottle 14 is filled with a designated concentrated liquid, and the same designated concentrated liquid is loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com