Digital carbon dioxide rock breaking process and detonation system

A carbon dioxide and rock-breaking technology, which is applied in blasting, blasting cylinders, induction record carriers, etc., can solve problems such as low efficiency and error-prone, and achieve the effects of improving safety, avoiding high-temperature electric sparks, and improving construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

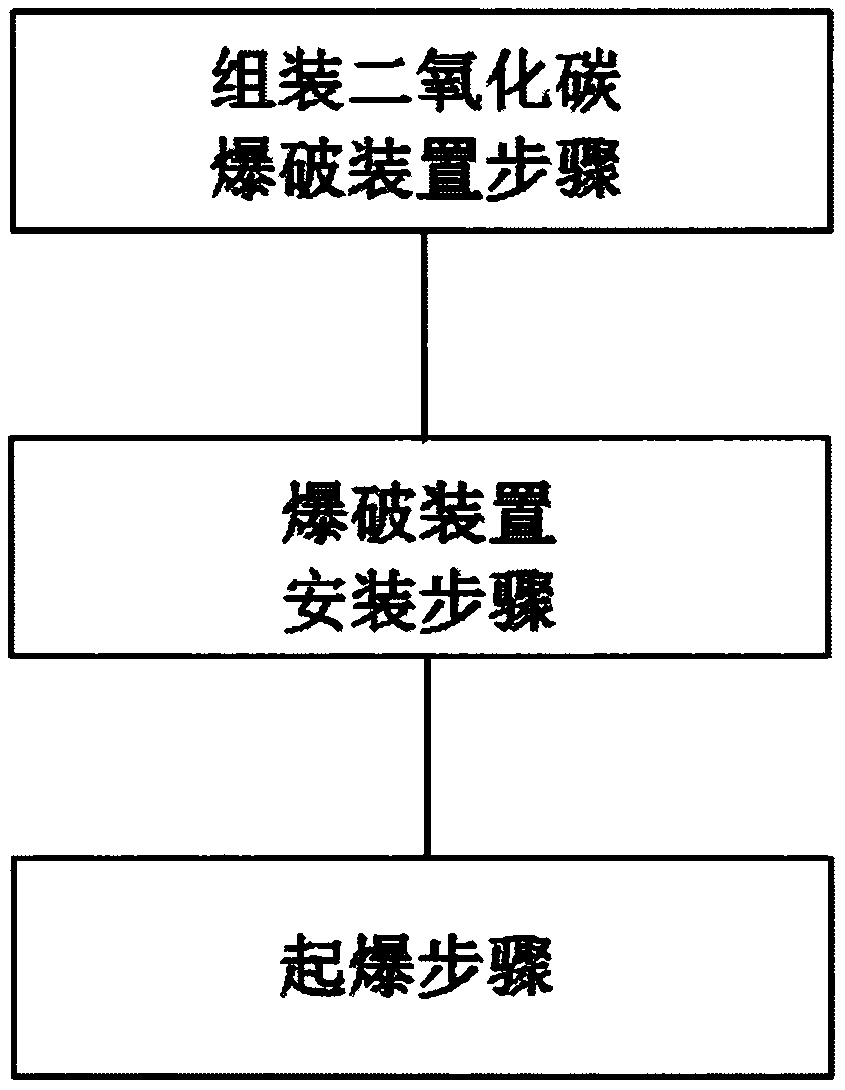

[0045] The blasting device with hardware timing has its own timing device, which includes the following steps:

[0046] Preparatory steps for equipment installation

[0047] Check the parts of the blasting device and prepare the 3 parts of the carbon dioxide blasting device according to the construction project information. If it is underground or in a mine, it is necessary to dig drainage ditches around, make a good drainage system, take away the surface water in time, and install lifting equipment and arrange them well. Slag out the road, calculate the safety distance, measure the length of the wire, and prepare the wire for blasting. A baffle is provided on the outside of the hole, on the one hand to prevent solid particles from entering the hole, which poses a safety risk during blasting, and on the other hand to prevent solid particles or parts of the blasting device from flying out of the hole during blasting.

[0048] Assembling a CO2 Explosion Device in 3 Steps

[00...

Embodiment 2

[0067] The construction technology of software timing is to add timing steps on the basis of hardware timing construction technology, which specifically includes:

[0068] Such as Figure 5 As shown, use the electronic tag 2 reading device to collect the first identification information 5 of the carbon dioxide blasting device 3 with the same delay setting, and obtain at least one segment identification information group 6, the number of segment identification information groups 6 and the number of blasting segments same. For example, the blasting sequence is first at the weakest position in the middle of the roadway section, blasting the inner row of cut holes to form the free surface, and then expanding the blasting outwards, that is, auxiliary eye blasting, and finally performing modeling blasting, that is, peripheral eye blasting, the sequence Using the electronic tag 2 reading equipment to collect the first identification information 5 in the electronic tag 2 on the shell...

Embodiment 3

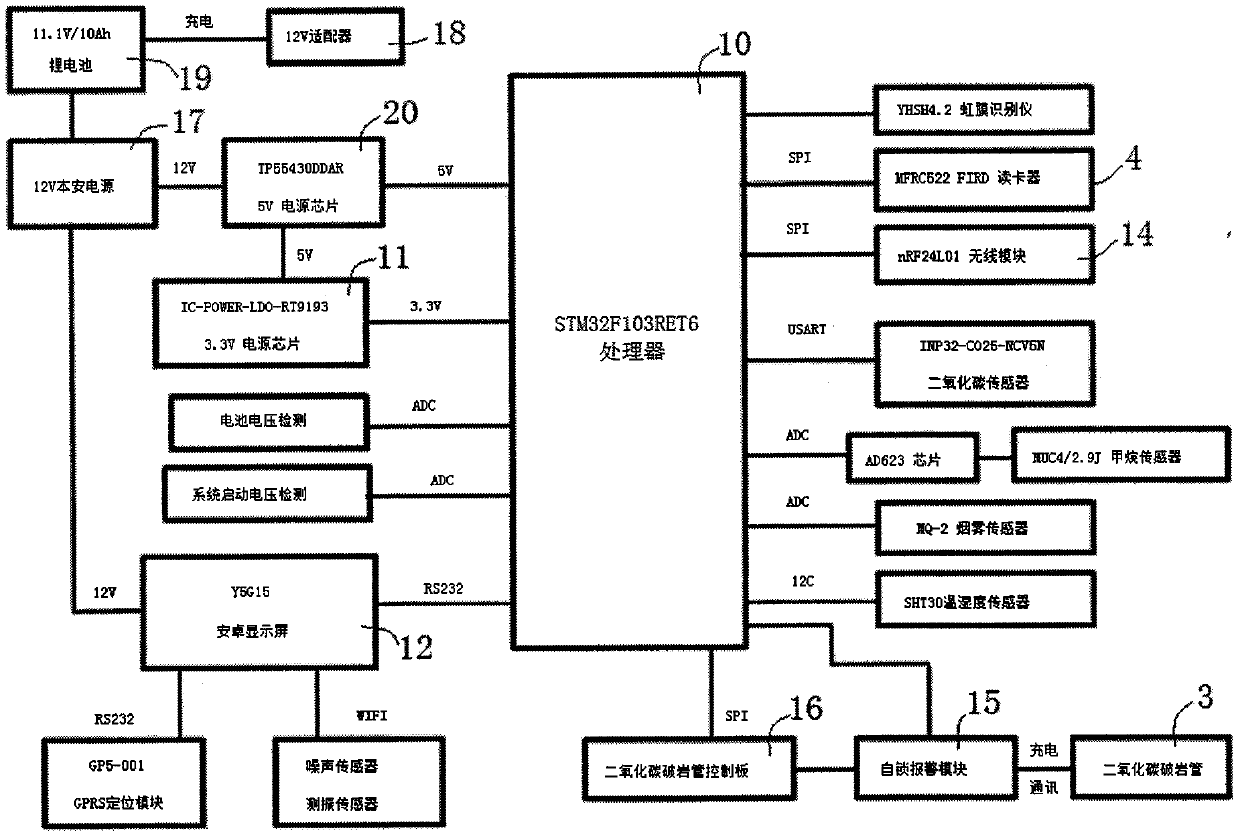

[0071] Such as Figure 7As shown, a digital carbon dioxide rock-breaking initiation system applied to the method includes a numerically controlled detonator 1, a carbon dioxide blasting device 3 with an electronic tag 2 and an electronic tag reading device 4, wherein:

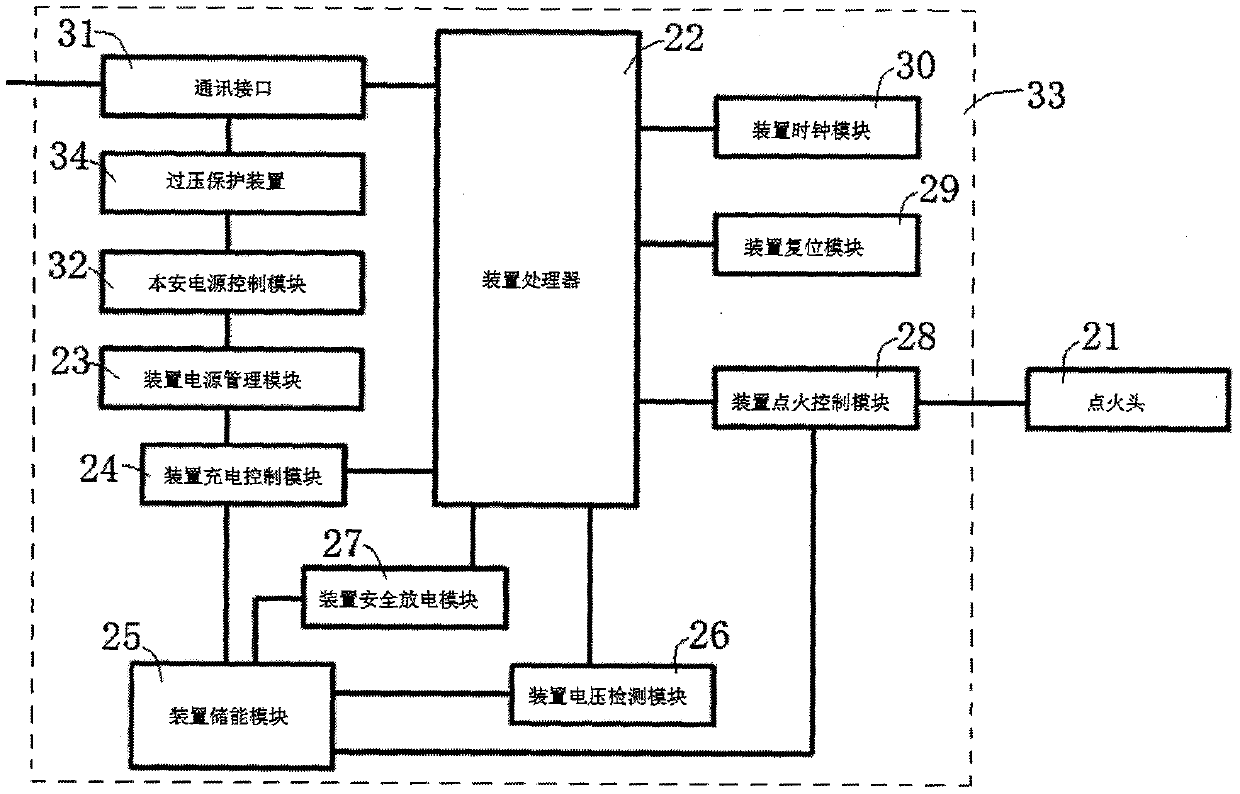

[0072] The numerically controlled detonator 1 is provided with a detonator processor 10, a power management module 11, a human-computer interaction module 12, an information communication module 14, a self-locking alarm module 15, an ignition control module 16, and an electronic tag reading device 4. The detonator processor 10 is respectively connected to the power management module 11, the human-computer interaction module 12, the information communication module 14, the self-locking alarm module 15, the ignition control module 16, the electronic tag 2 card reader, and the self-locking alarm module 15 is connected to The output end of the ignition control module 16, the charging control module and the safety d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com