Patents

Literature

62results about How to "Protect your health and safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dust fall agent for water mist dust fall

ActiveCN101735771AReduce surface tensionImprove contact effectOther chemical processesDust removalPermeationSURFACTANT BLEND

The invention relates to a dust fall agent for water mist dust fall. 0.06-0.2wt% of wetting agent permeation assistant is added to water, wherein the wetting permeation assistant comprises anionic surfactant, or cationic surfactant, or zwitterionic surfactant, or non-ionic surfactant. Because in the dust fall agent of the invention, 0.06-0.2wt% of wetting agent permeation assistant is added to water, thus the surface tension of the water can be reduced, the contact capacity of the water with dust particles is promoted, and solid materials can be soaked by water more easily through the wetting agent permeation assistant, thereby accelerating the wetting permeation velocity of water to the dust particles, accelerating the fall velocity of the dust particles, and reducing the fall time of the dust particles. Thus, the invention reduces the operation time and the operation cost, protects the health and safety of operation personnel, and can be widely applied to water spray, water sprinkling, dust fall and dust suppression of mines, tunnels or roads.

Owner:北京首创大气环境科技股份有限公司

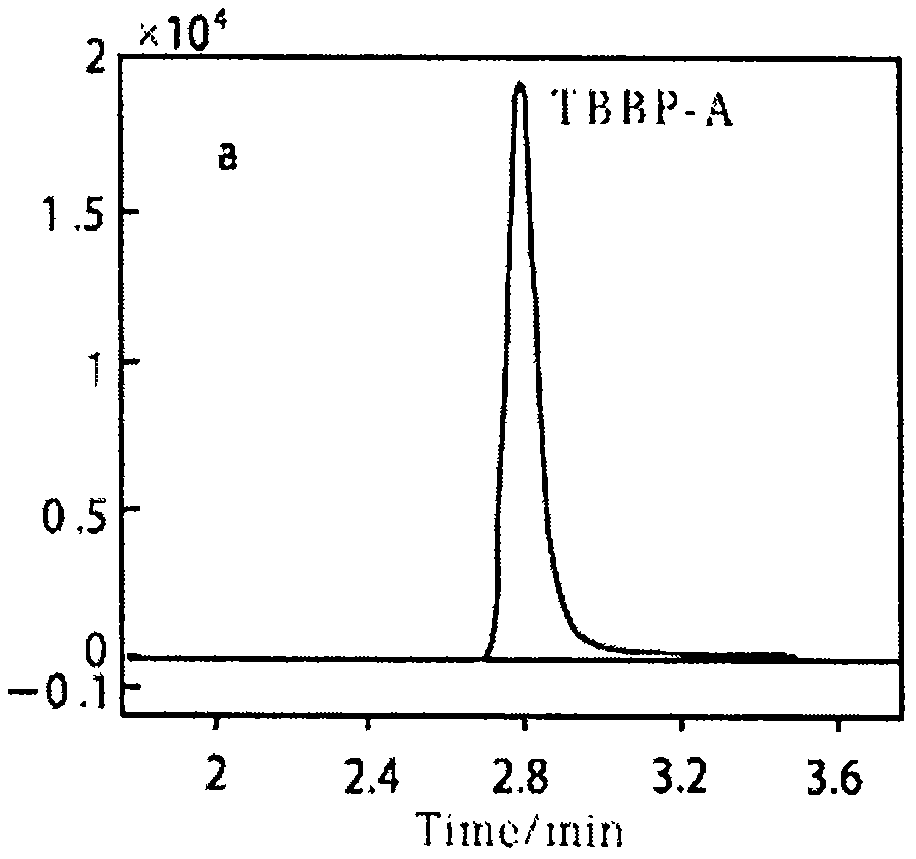

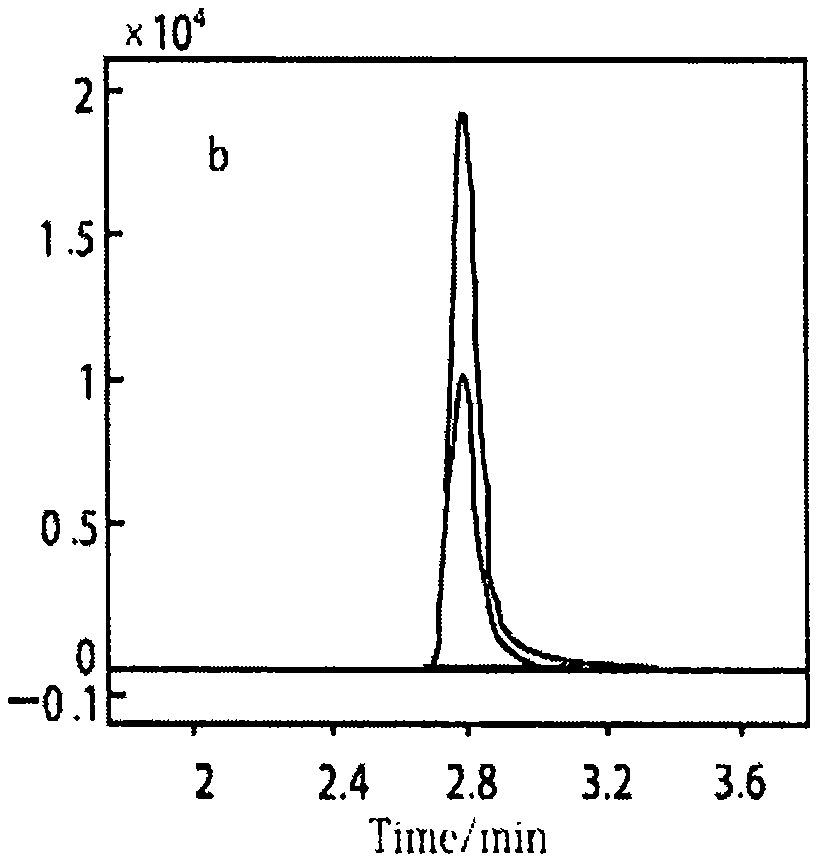

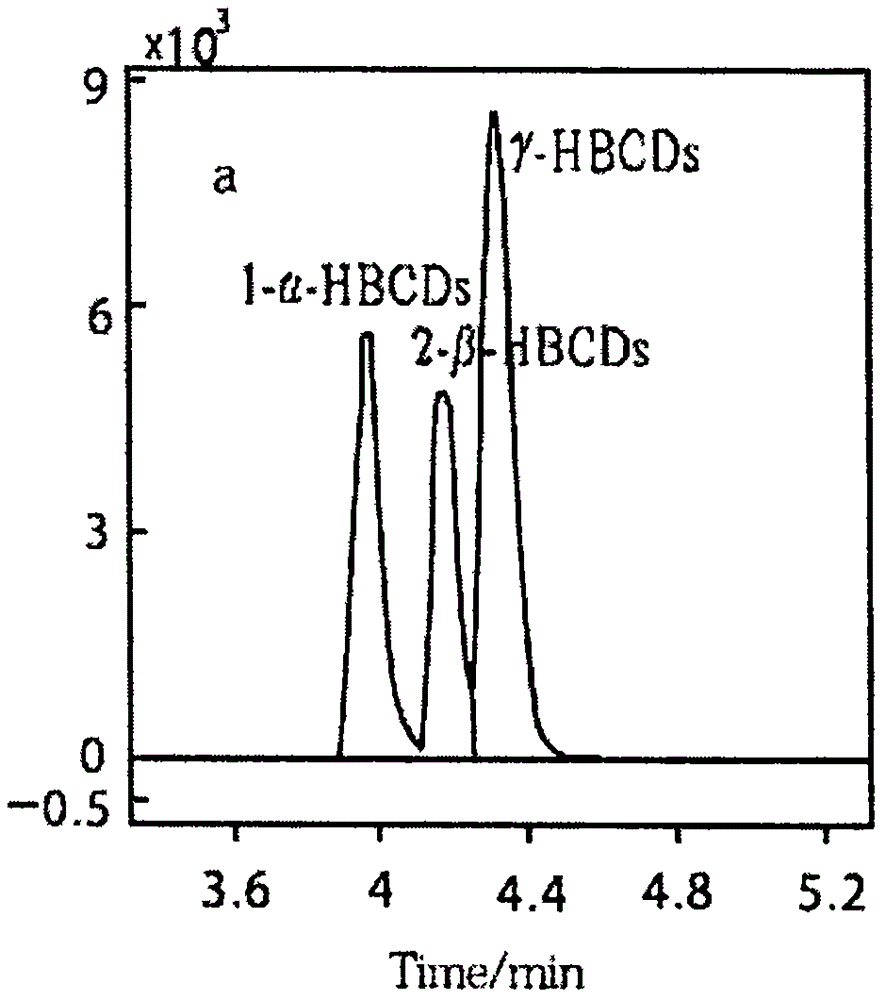

Method for detecting content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in aquatic product

ActiveCN106124643AGuaranteed accuracyGuarantee stabilityComponent separationTetrabromobisphenol ADecabromodiphenyl ether

The invention provides a method for detecting the content of tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in an aquatic product. The method is characterized by comprising the following steps that the content of the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product is measured by establishing accelerated solvent extraction-fast liquid chromatography-tandem mass spectrometry, an aquatic product sample needing to be detected is separated through a C18 chromatographic column, gradient elution is conducted by taking water and methyl alcohol as mobile phases, detection is conducted in a mass spectrum multi-reaction monitoring mode, the matrix standard is corrected, quantitative determination is conducted through an external standard method, and confirmation is conducted. The detection method has the advantages that operation is easy and convenient, and detection is fast and accurate; by establishing the method for simultaneously detecting the tetrabromobisphenol A, decabromodiphenyl ether and hexabromocyclododecane brominated flame retardants in the aquatic product, physical health and life safety of consumers are guaranteed, a great practical significance is achieved for promoting sustainable and healthy development of aquatic product processing industry, and a beneficial technical reserve is provided for a food industry supervision department and a detection mechanism.

Owner:ZHOUSHAN INST FOR FOOD & DRUG CONTROL

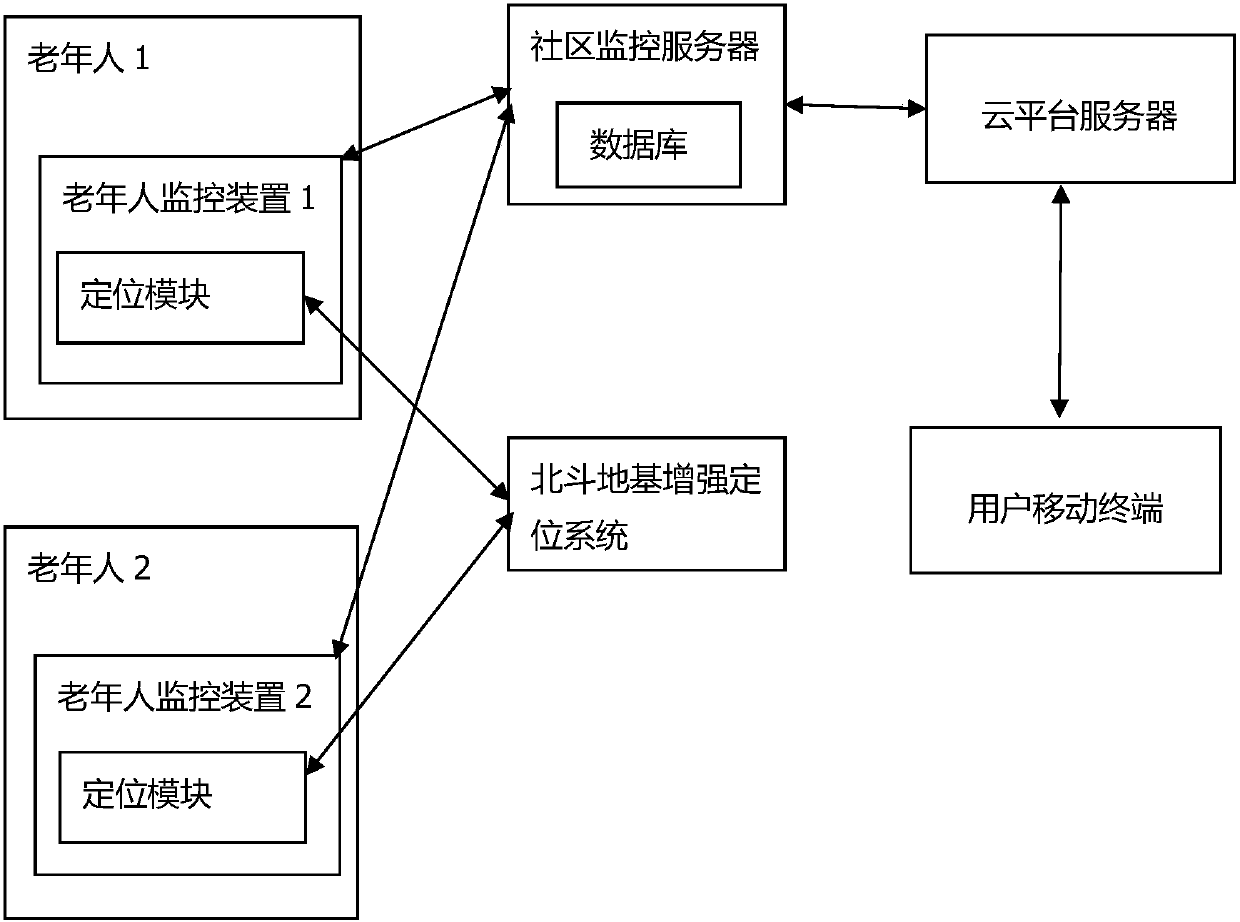

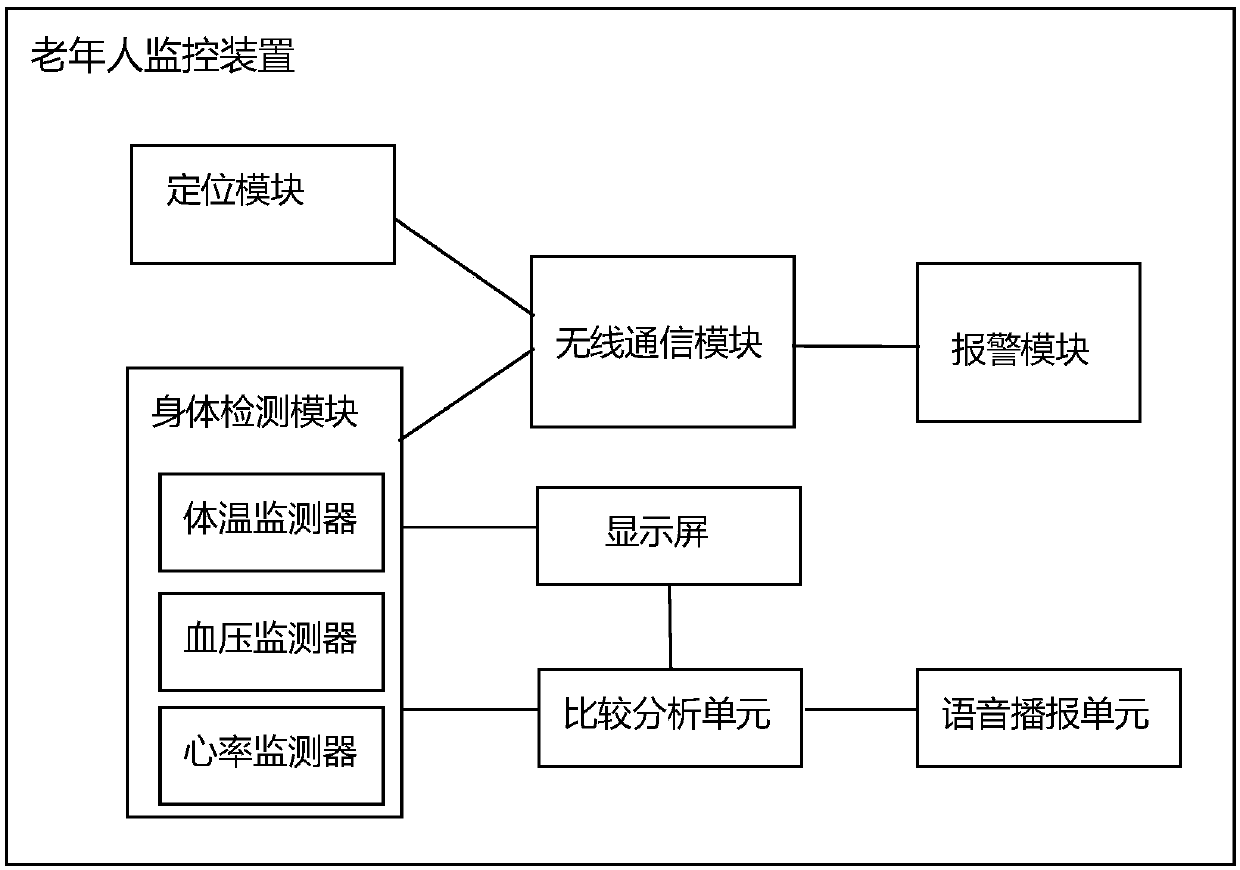

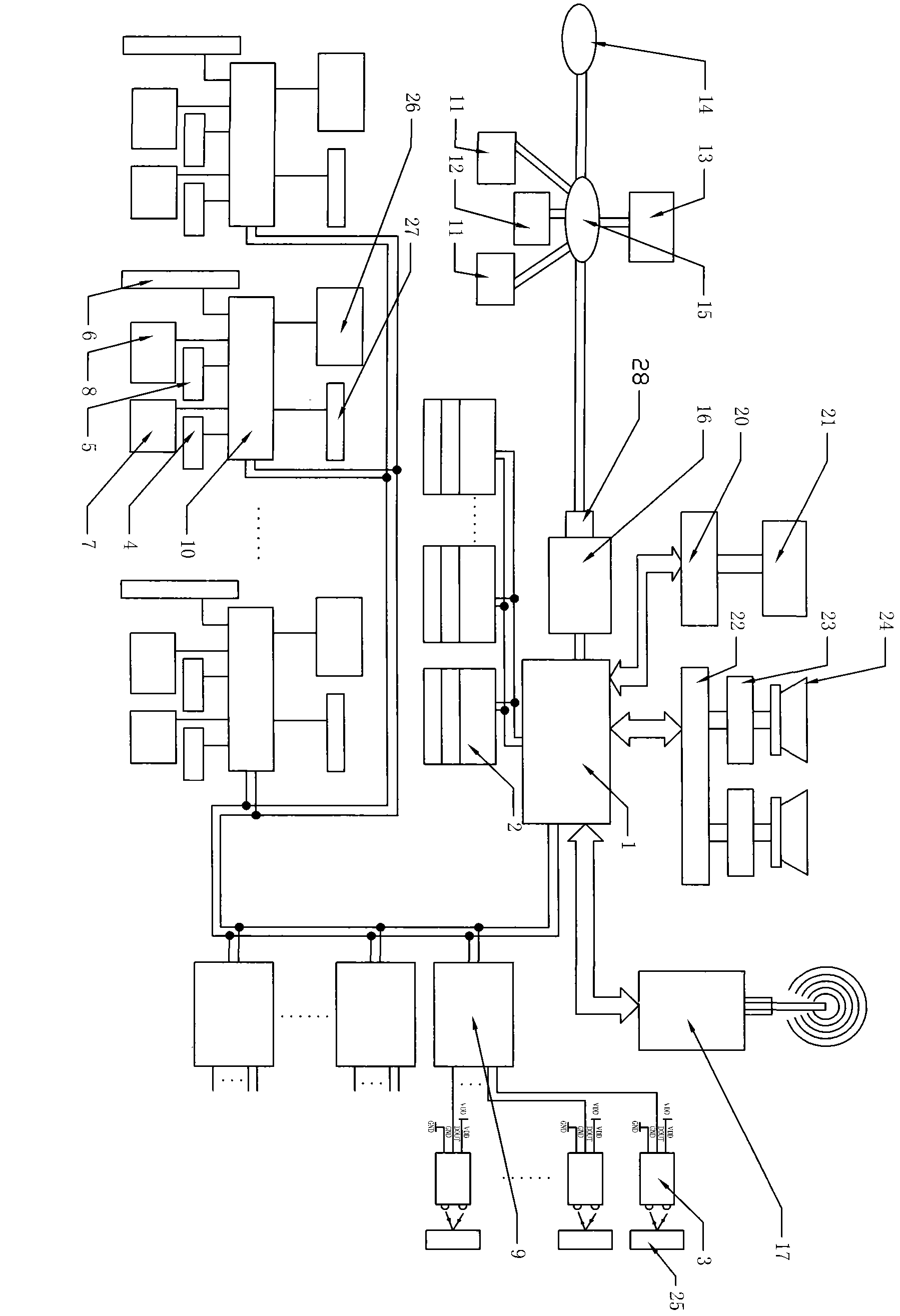

Community elder monitoring system based on convergence of beidou foundation reinforcement and internet of things

InactiveCN108013868AGet precise location information in real timeRealize information managementDiagnostic recording/measuringSensorsBlood pressureMonitoring system

The invention discloses a community elder monitoring system based on convergence of beidou foundation reinforcement and the internet of things. The community elder monitoring system comprises a community monitoring server, an elder monitoring device, a cloud platform server and a user mobile terminal, wherein the elder monitoring device comprises a body detection module, a positioning module and awireless communication module; the body detection module is used for carrying out real-time monitoring on the body temperature, blood pressure and heart rate data of the elder, and outputting the data to the wireless communication module, and the wireless communication module sends the data to the community monitoring server which than sends the data to the cloud platform server; the positioningmodule is in communication connection with a beidou foundation reinforcement system for carrying out real-time monitoring on the geographic position of the human body, the position formation is outputto the wireless communication module, the wireless communication module sends the position information to the community monitoring server, and the community monitoring server transmits the position information to the cloud platform server; the user mobile terminal is used for receiving the body data and the position information of the elder from the cloud platform server. The system provided by the invention realizes real-time monitoring for the elder in each community.

Owner:武汉米风通信技术有限公司

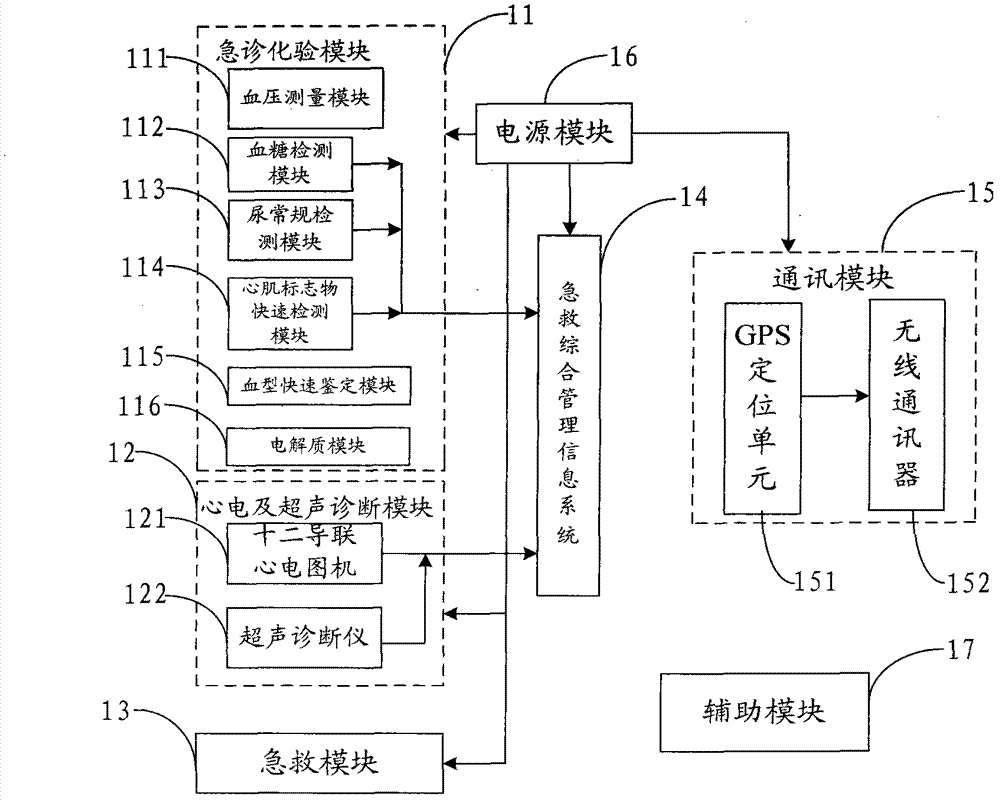

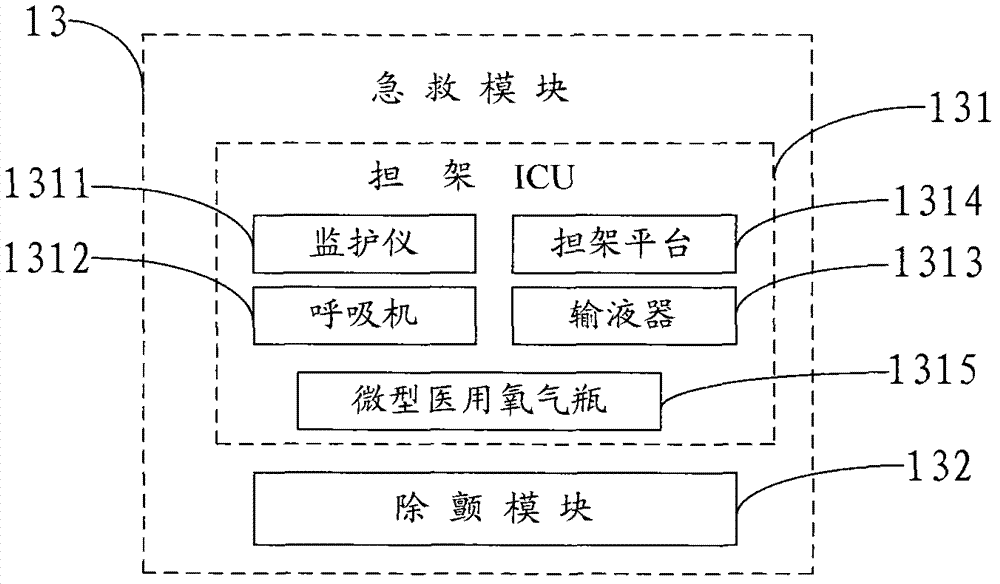

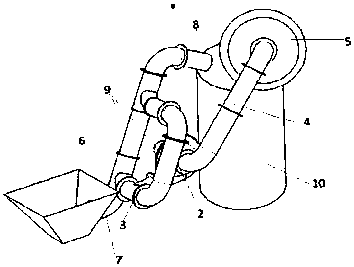

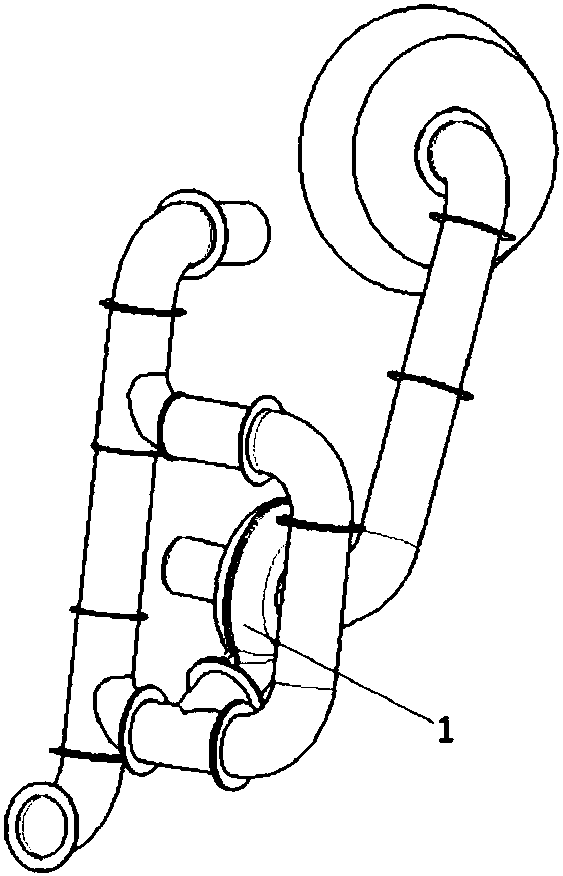

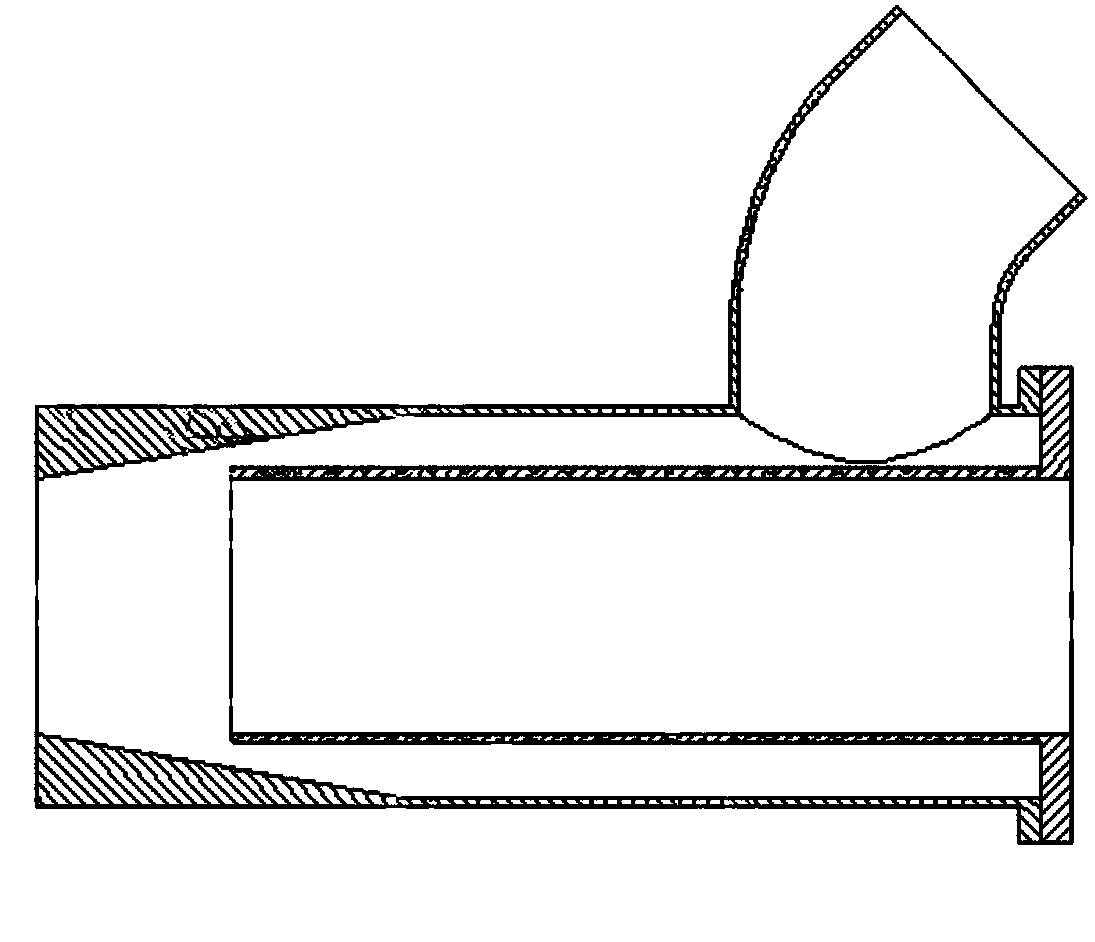

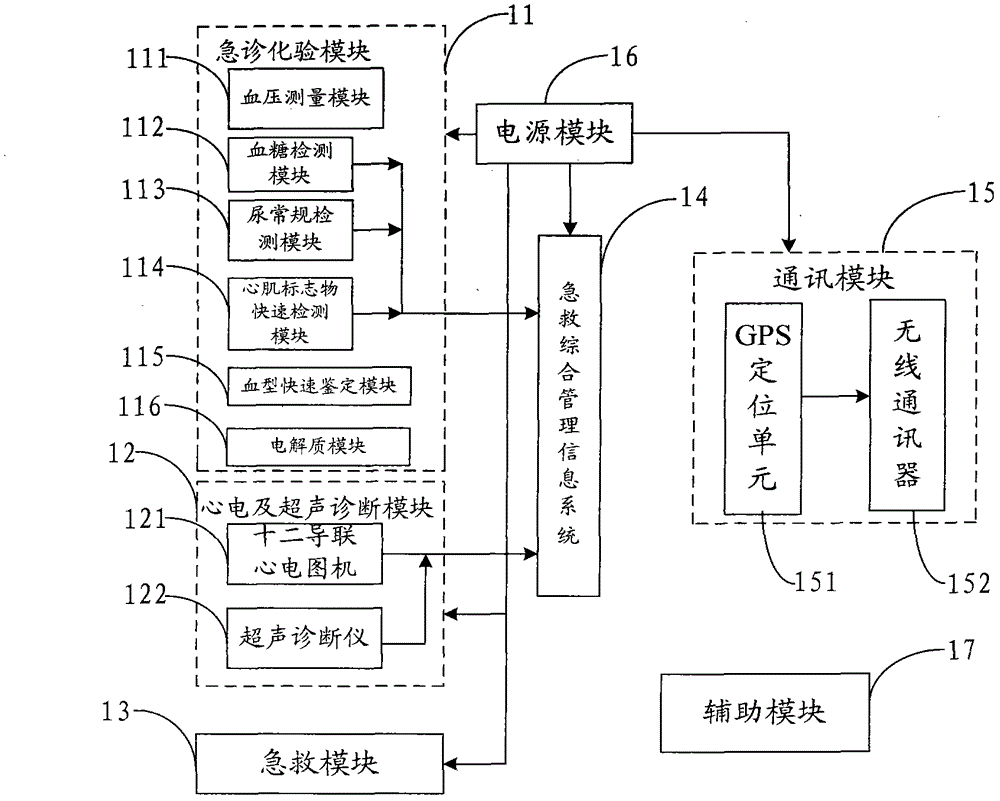

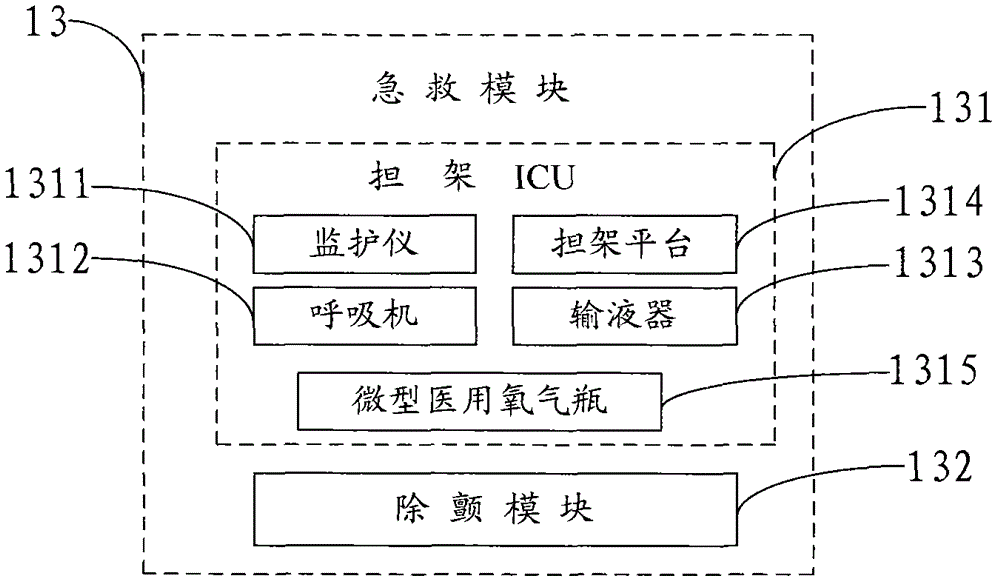

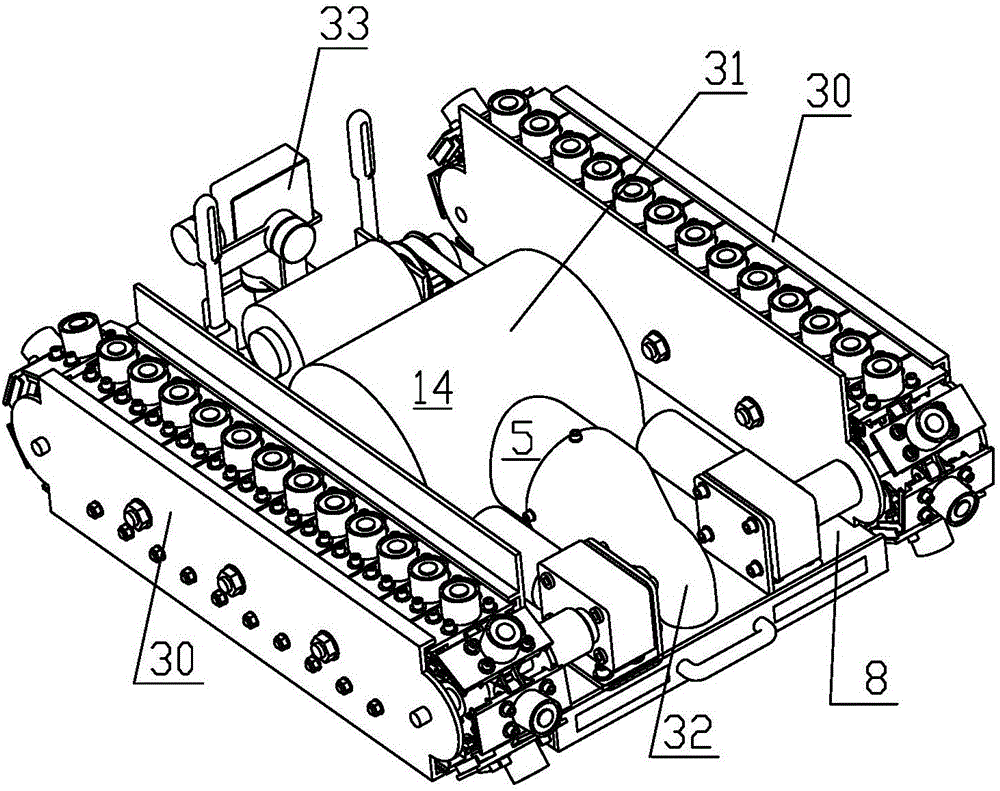

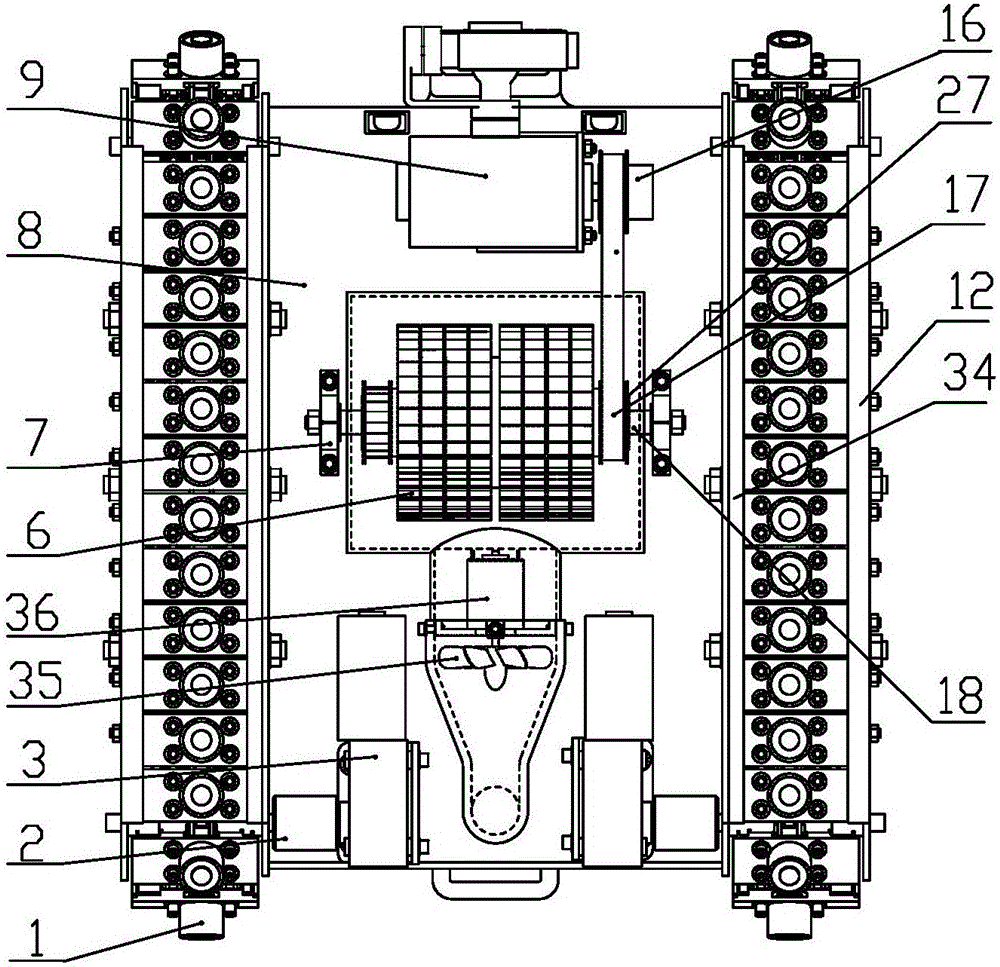

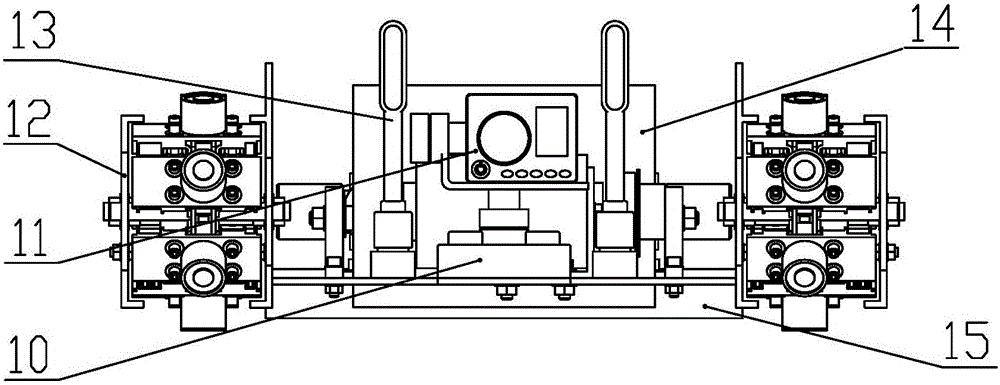

Pre-hospital emergency ambulance

ActiveCN103239330AImprove accuracy and timelinessShort deployment timeAmbulance serviceHospital treatmentEmergency treatment

The invention is applicable to the field of medical apparatuses and instruments and provides a pre-hospital emergency ambulance. The pre-hospital emergency ambulance is composed of an emergency assay module, an electrocardio and ultrasonic diagnosis module, an emergency treatment module, an emergency treatment comprehensive management information system, an auxiliary module, a power module and a communication module. Through combined diagnosis and detection of the emergency treatment module, the emergency assay module and the electrocardio and ultrasonic diagnosis module, the accuracy and the timeliness of disease diagnosis are improved, unfolding time of field apparatuses can be shortened and burdens of medical workers can be reduced due to stretchers and intensive care units (ICUs), on-the-spot rescue, midway diagnosis and emergency treatment can be performed timely, the ambulance can be directly transferred to divisions for emergency treatment in hospitals so as to form a seamless treatment chain combining pre-hospital care, midway life support and rapid in-hospital treatment, the maneuverability is high, starting for immediate use is achieved, the operation is simple, the ambulance is suitable for emergency treatment and cure in the field or during transfer and capable of effectively assisting medical workers to treat and cure according to symptoms, and the emergency handling capacity and the emergency rescue capacity of emergencies are improved.

Owner:北京倍肯恒业科技发展股份有限公司

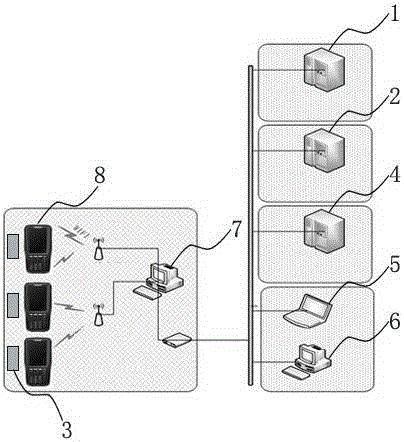

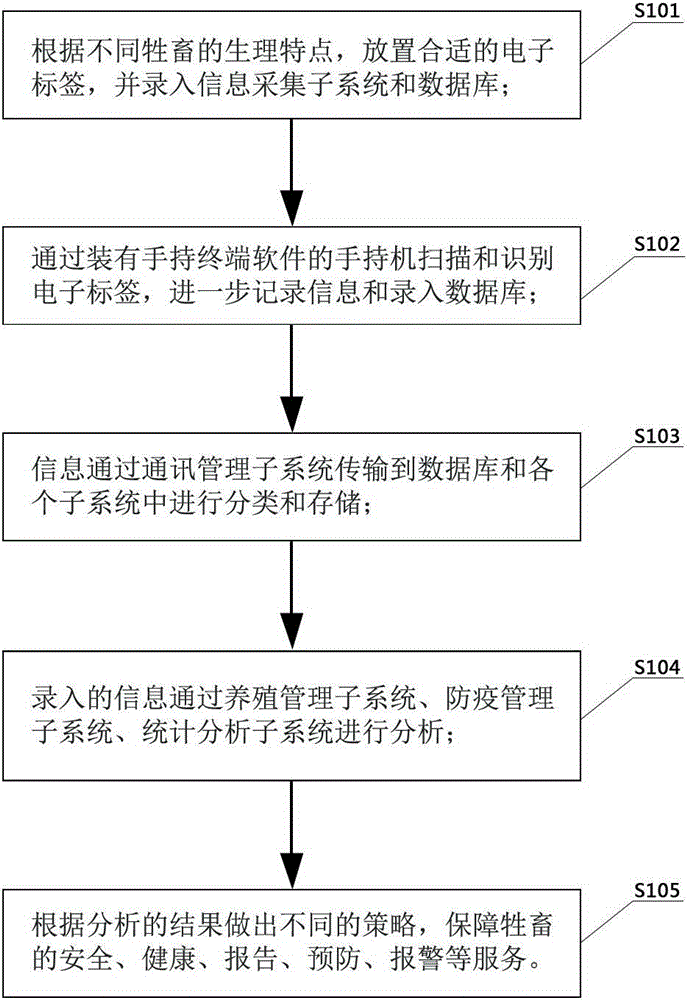

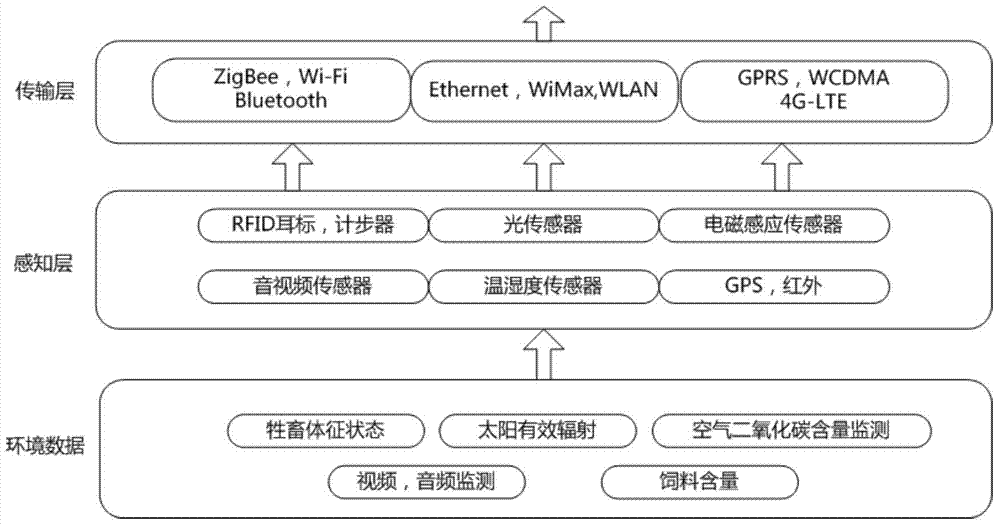

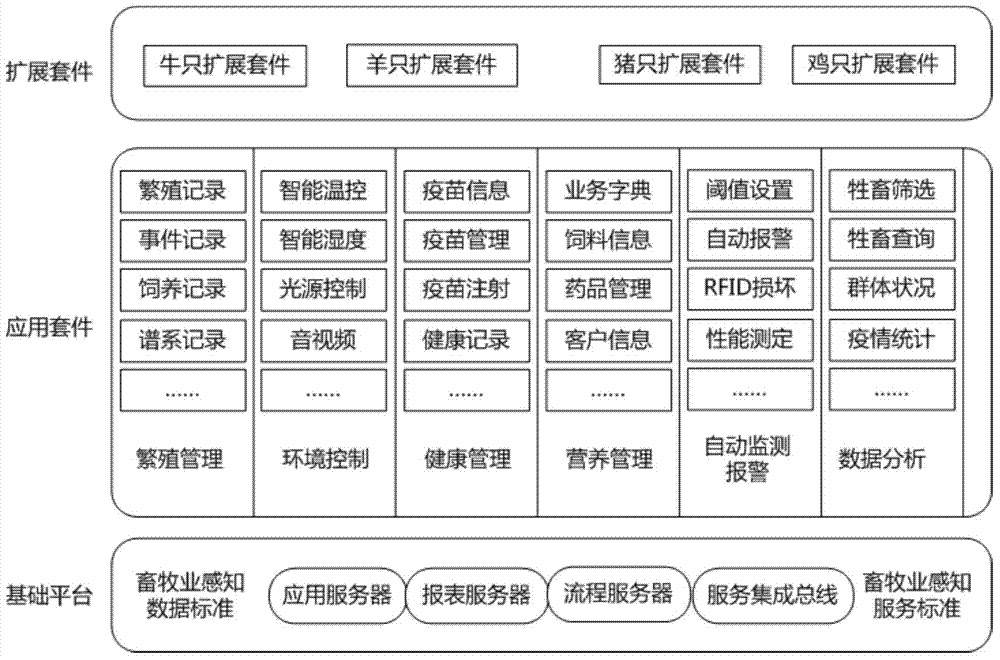

IoT (Internet of things) informational intelligent culturing system platform

The present invention discloses an IoT (internet of things) informational intelligent culturing system platform. A set of informational platform is established in the scope of a cattle farm by using an IoT FRID as an information carrier and relying on a network, system integration and a database technology so as to implement the entire process recording of each link from feed mixing, culturing, and epidemic prevention to a point-of-sale terminal in the whole industrial chain. The IoT informational intelligent culturing system platform can help enterprises to establish perfect production archives, establish the data basis of Muslim beef and lamb product traceability, manage safety production input products and establish epidemic prevention records for epidemic disease; meanwhile help the government monitoring department to achieve the supervision and control of the production process of raw Muslim beef and lamb.

Owner:QINGDAO LANGCOO WIRELESS SCI & TECH

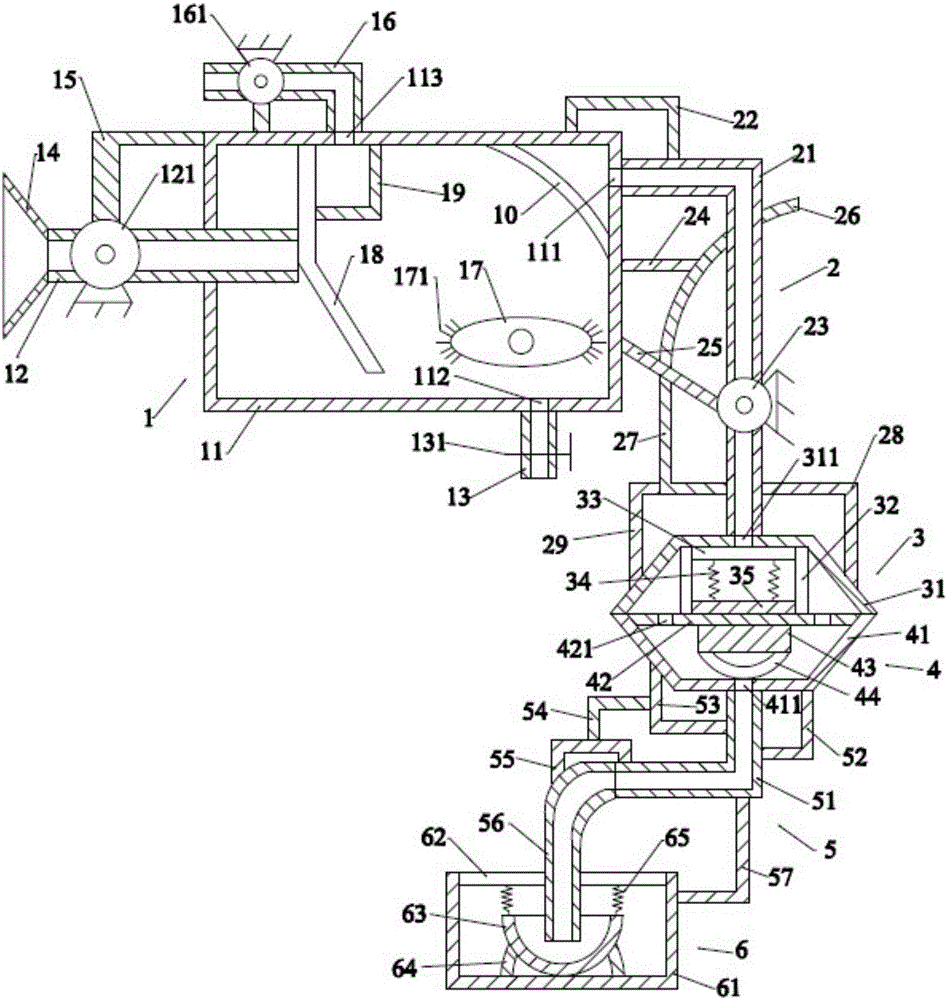

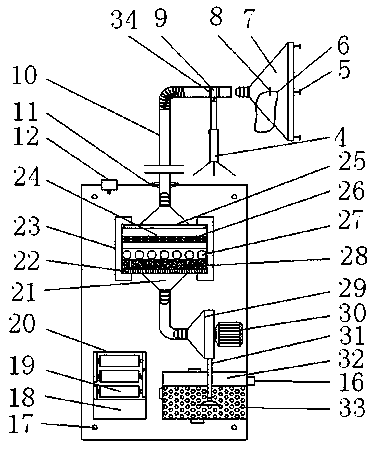

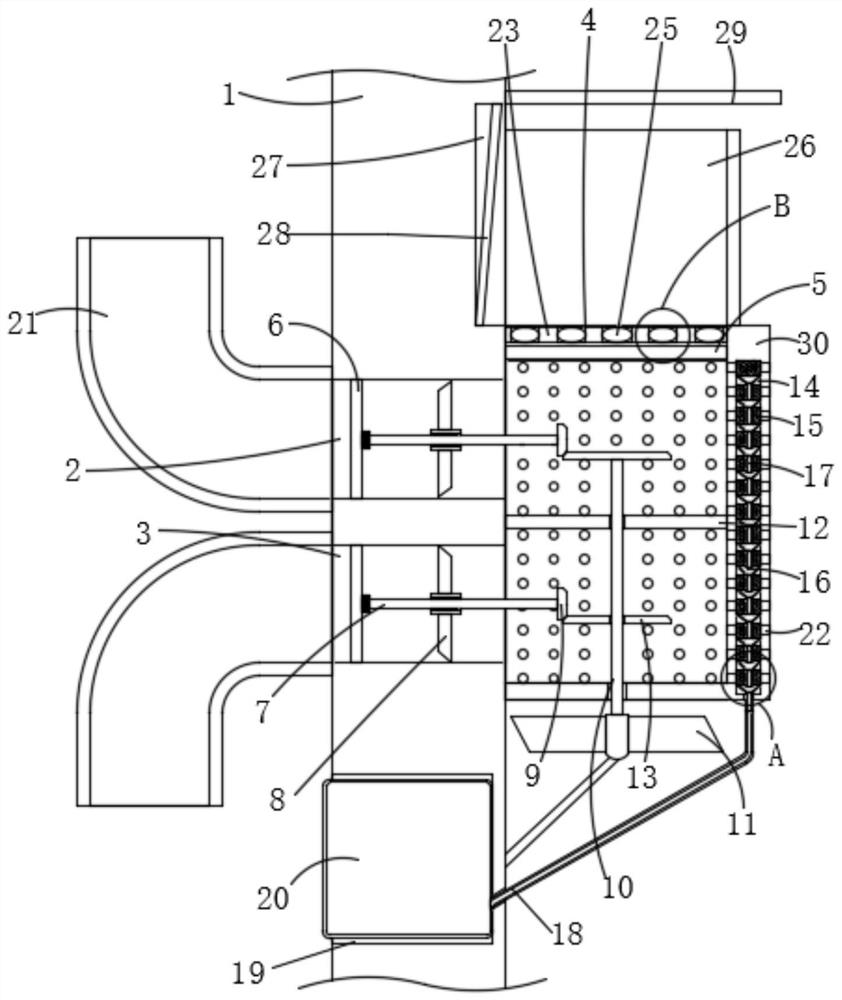

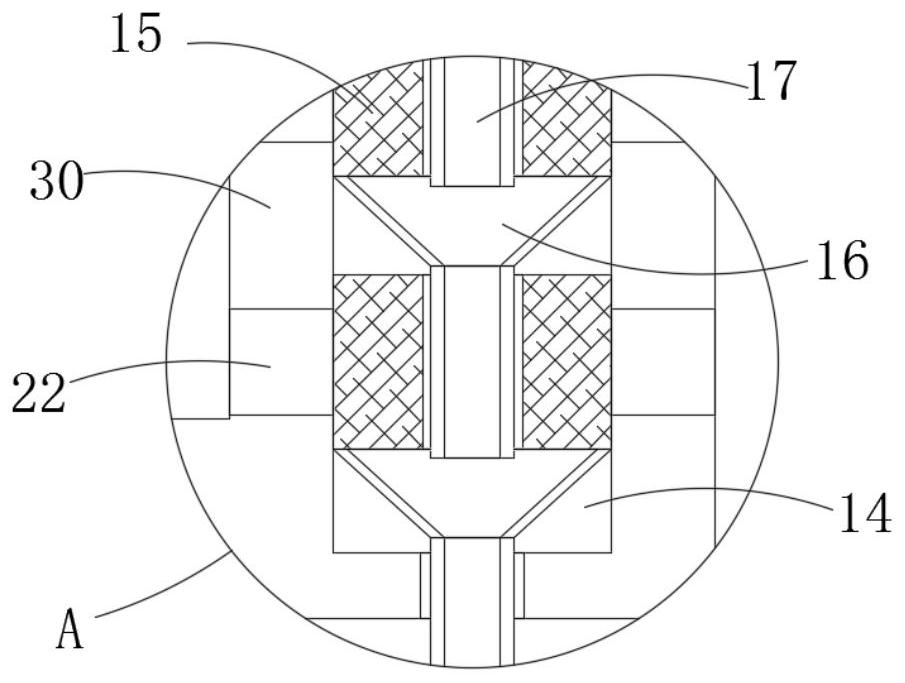

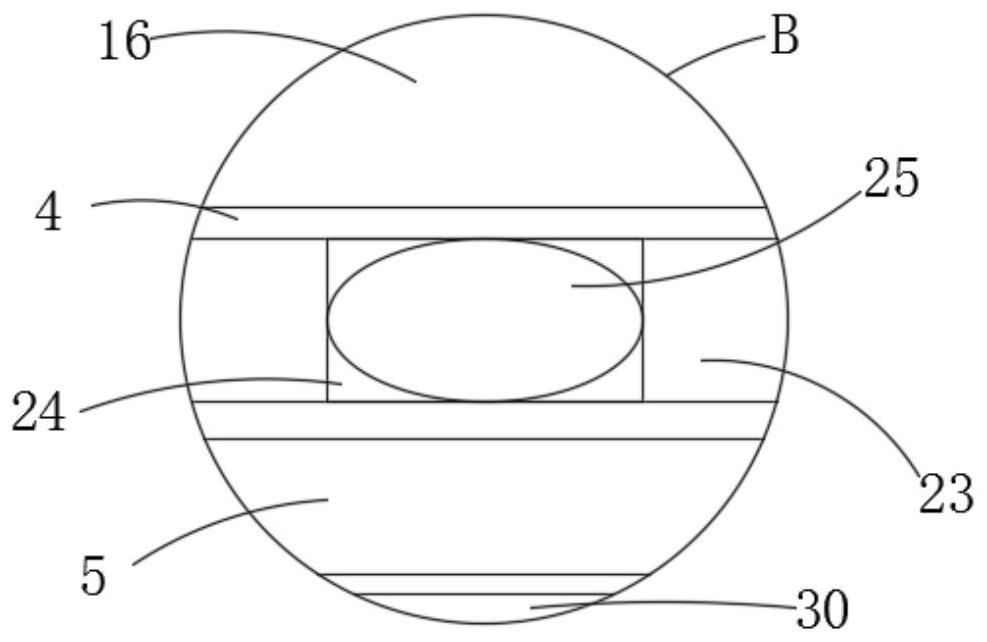

Dust treatment device used in ore processing

A dust treatment device used in ore processing comprises an air suction device, a pipeline device, a first filtering device, a second filtering device, a connecting device and a purifying device. The air suction device comprises a first frame, a first pipeline, an air incoming hopper, a first support, a second pipeline, a first roller, a first filtering net, a second support, a second filtering net and a third pipeline, the pipeline device comprises a fourth pipeline, a third support, a second fan, a first cross rod, a first inclined rod, a first bent rod and a fourth support, the first filtering device comprises a second frame, a third filtering net, a fourth filtering net, a first spring and a first cushion block, the second filtering device comprises a third frame and a first retaining plate, the connecting device comprises a fifth pipeline, a seventh support, an eighth support, a ninth support, a tenth support, a six pipeline and an eleventh support, and the purifying device comprises a purifying box, a sixth filtering net and a fourth frame. The dust treatment device can suck dust in for thorough purifying and filtering and has remarkable purifying effect.

Owner:张哲瑜

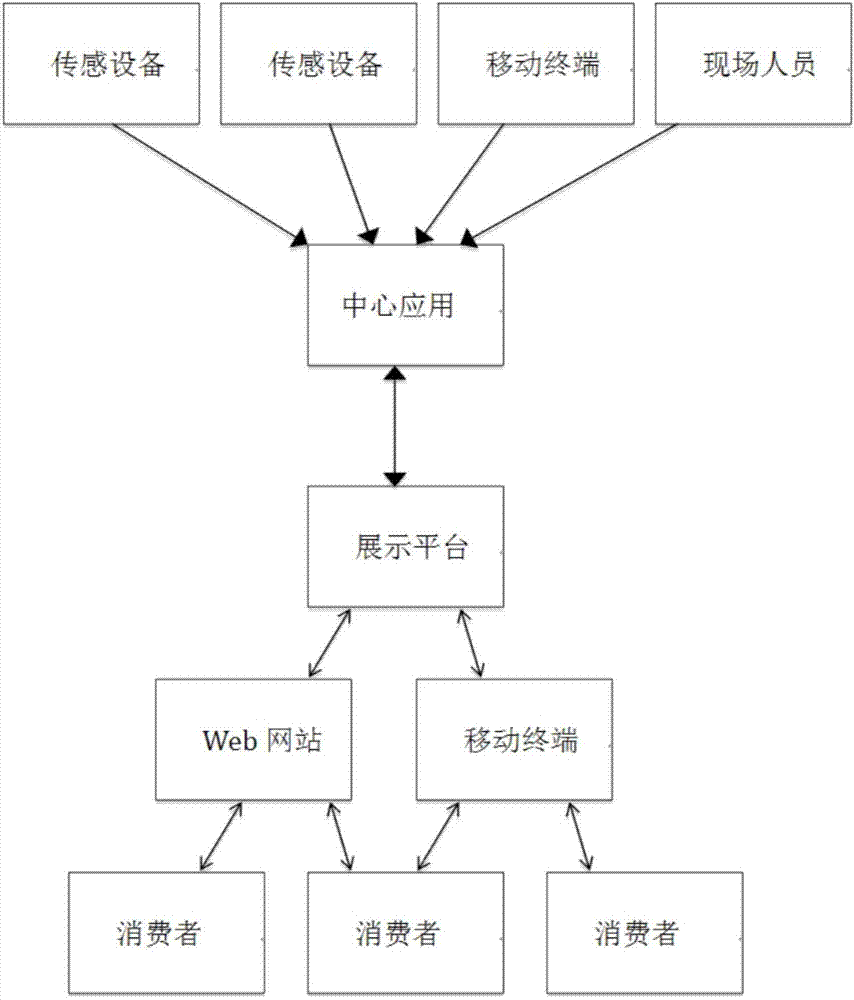

Source monitoring and source tracking system for agricultural field

InactiveCN103793793AEliminate potential safety hazardsGood information transparencyCo-operative working arrangementsResourcesData centerProcess information

A source monitoring and source tracking system for the agricultural field comprises identification tag module, a sensing and detecting module, a data center module and a display platform module. RFID are adopted as identification tags by the identification tag module. The data center module packages collected data into a data model, offers queries of multiple dimensions, and offers informationized office management of agriculture operation and management staff. The data model comprises physical object basic information, environment basic information, growth process information and incident recording information. The data model aiming at individual physical objects of agricultural products is organized in the mode of using a time axis as a principal line and collecting all the process information of the individual physical objects and the environment changing process information relating to the individual physical objects. The display platform module displays the source tracking information of agricultural product objects according to unique identification of the agricultural product objects owned by the user. The source monitoring and source tracking system for the agricultural field is good in information transparency, and eliminates food safety hidden danger.

Owner:HANGZHOU KENYUAN NETWORK TECH

Ingot casting and cooling integrated device for metallurgical industry

InactiveCN108580816AUniform thicknessProper heat dissipationIngot casting plantsIngot castingMetallurgical industry

The invention discloses an ingot casting and cooling integrated device for metallurgical industry. The ingot casting and cooling integrated device comprises an ingot casting cavity, a connecting rod,a protection cavity and a vertical rod, a separating plate is fixed to the upper end of the ingot casting cavity, a feeding opening is formed in the upper end of the separating plate, extrusion blocksare installed on the two sides of the lower end of the feeding opening, the connecting rod is installed between the extrusion blocks, a bearing plate is installed at the bottom end of the interior ofthe ingot casting cavity, a die box is arranged at the upper end of the bearing plate, the tail end of the vertical rod is connected with the bearing plate through a sliding block, a sliding groove is formed inside the bearing plate, an air gathering water tank is installed on the right side of the ingot casting cavity, and the input end of the air gathering water tank is connected with an air gathering pipe. According to the ingot casting and cooling integrated device for the metallurgical industry, in the sequent falling-in process, melted metal raw materials can be effectively and appropriately cooled, the splashing condition of the raw materials in the falling-in process can be avoided, the raw materials can fall into the die box from all orientations and at all angles, and the thickness of a solvent in the die box can be even.

Owner:云和县东泽阀门有限公司

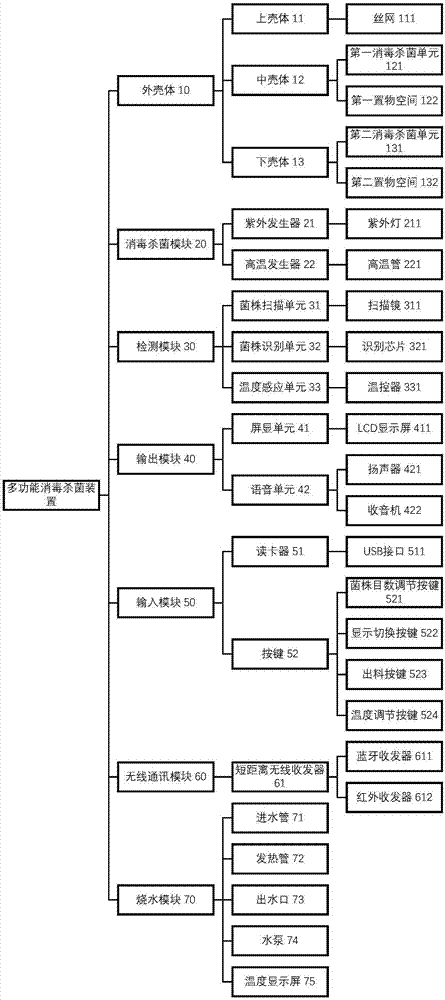

Multifunctional disinfection and sterilization apparatus

PendingCN107261167AProtect your health and safetyGuarantee personal safetyLavatory sanitoryHeatDiseasePhysical well being

The invention discloses a multifunctional disinfection and sterilization apparatus. The multifunctional disinfection and sterilization apparatus comprises ultraviolet generators, the ultraviolet generators are respectively placed in a first disinfection and sterilization unit as well as a second disinfection and sterilization unit. A bacterial strain scanning unit regularly collects a first area image of a first storage space and a second area image of a second storage space, and a bacterial strain identification unit obtains the above first area image and the second area image. When the bacterial strain identification unit confirms that the bacterial strain mesh number of either of the above first area image and the second area image exceeds the mesh number threshold, the bacterial strain identification unit starts the ultraviolet generators corresponding to the area to perform sterilization and disinfection on the corresponding area. The multifunctional disinfection and sterilization apparatus can realize disinfection and sterilization on tableware in dining places, effectively guarantees body health and personal safety for consumers, and avoids disease from the mouth.

Owner:嘉兴三王经贸有限公司

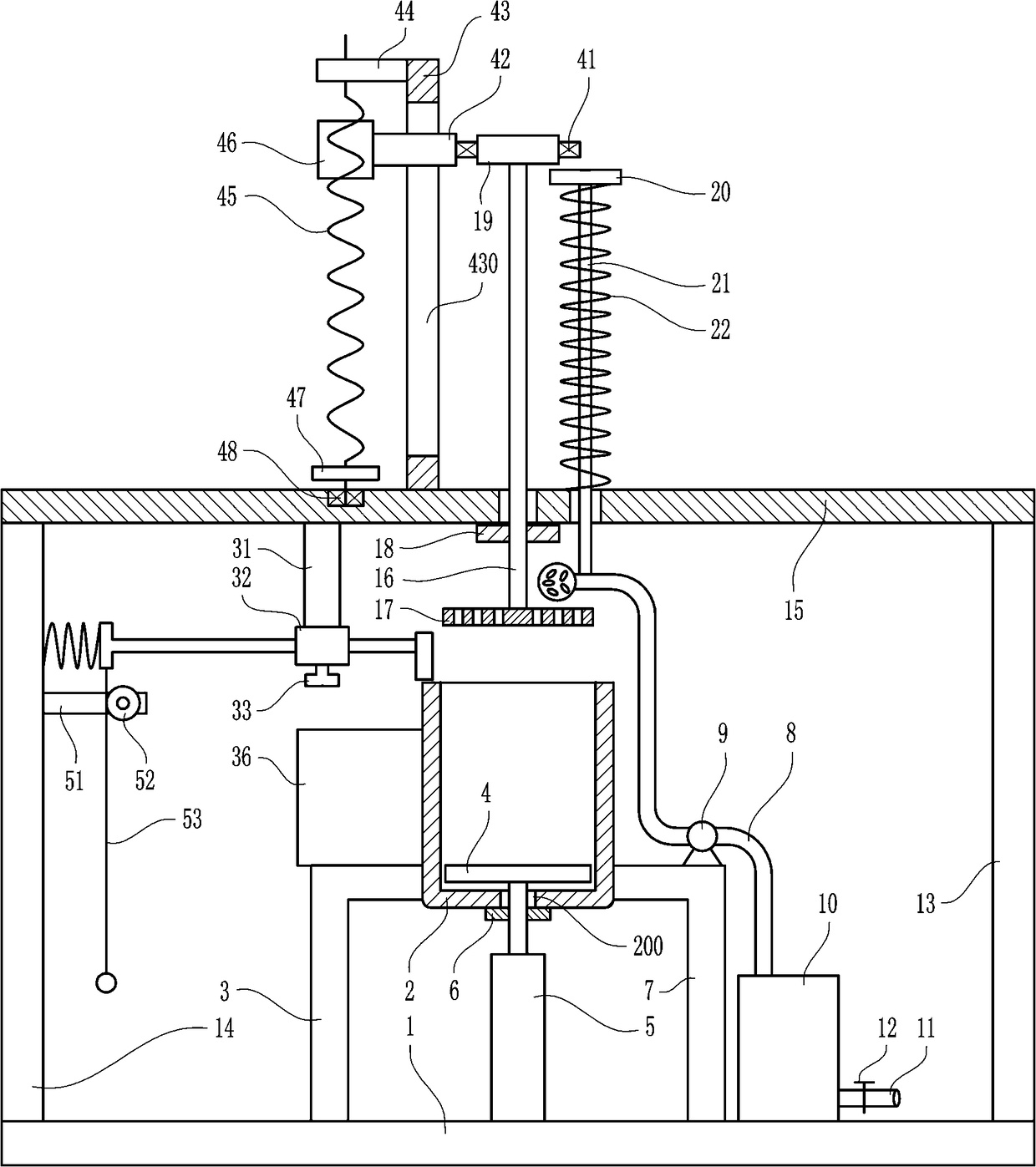

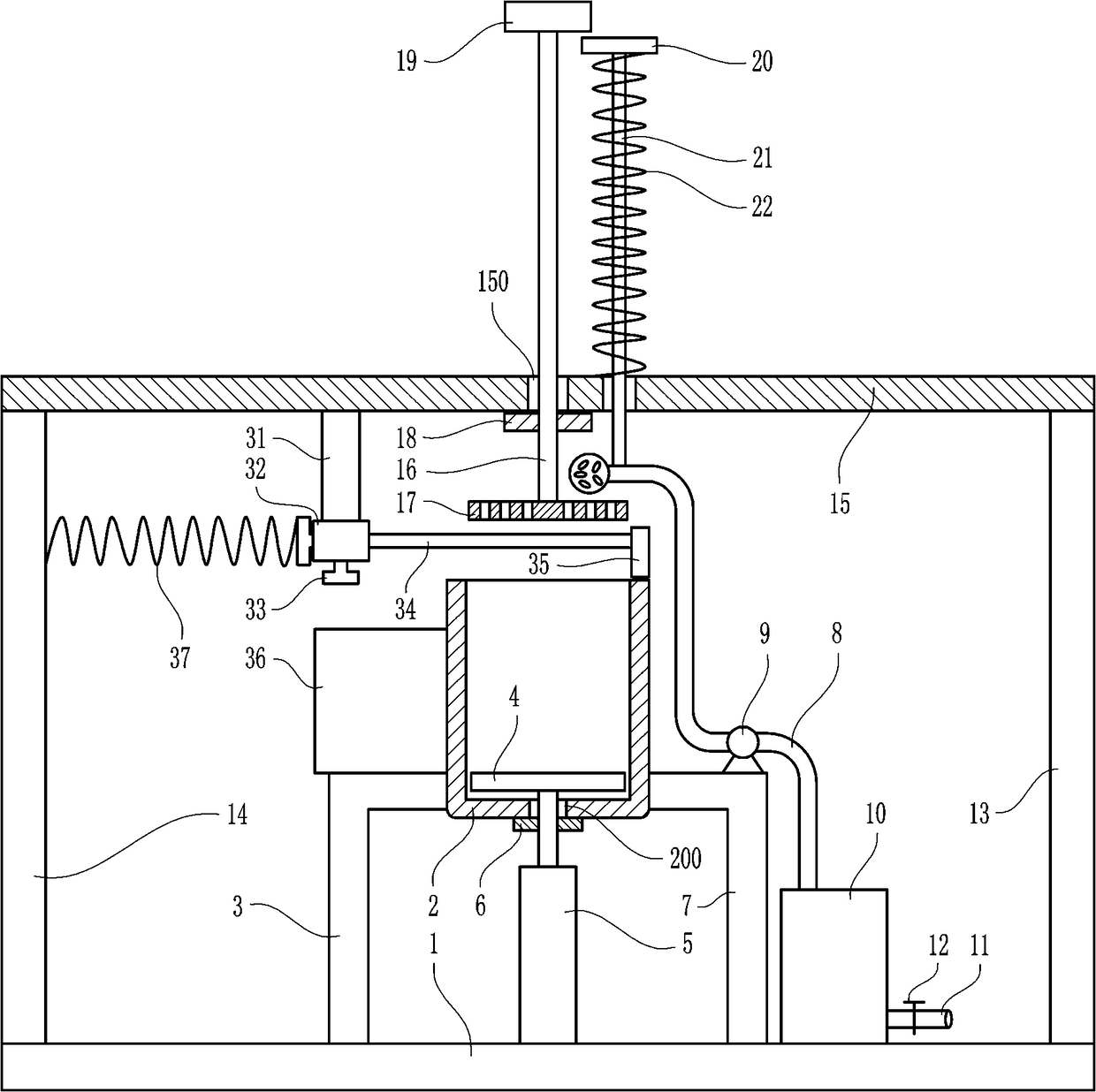

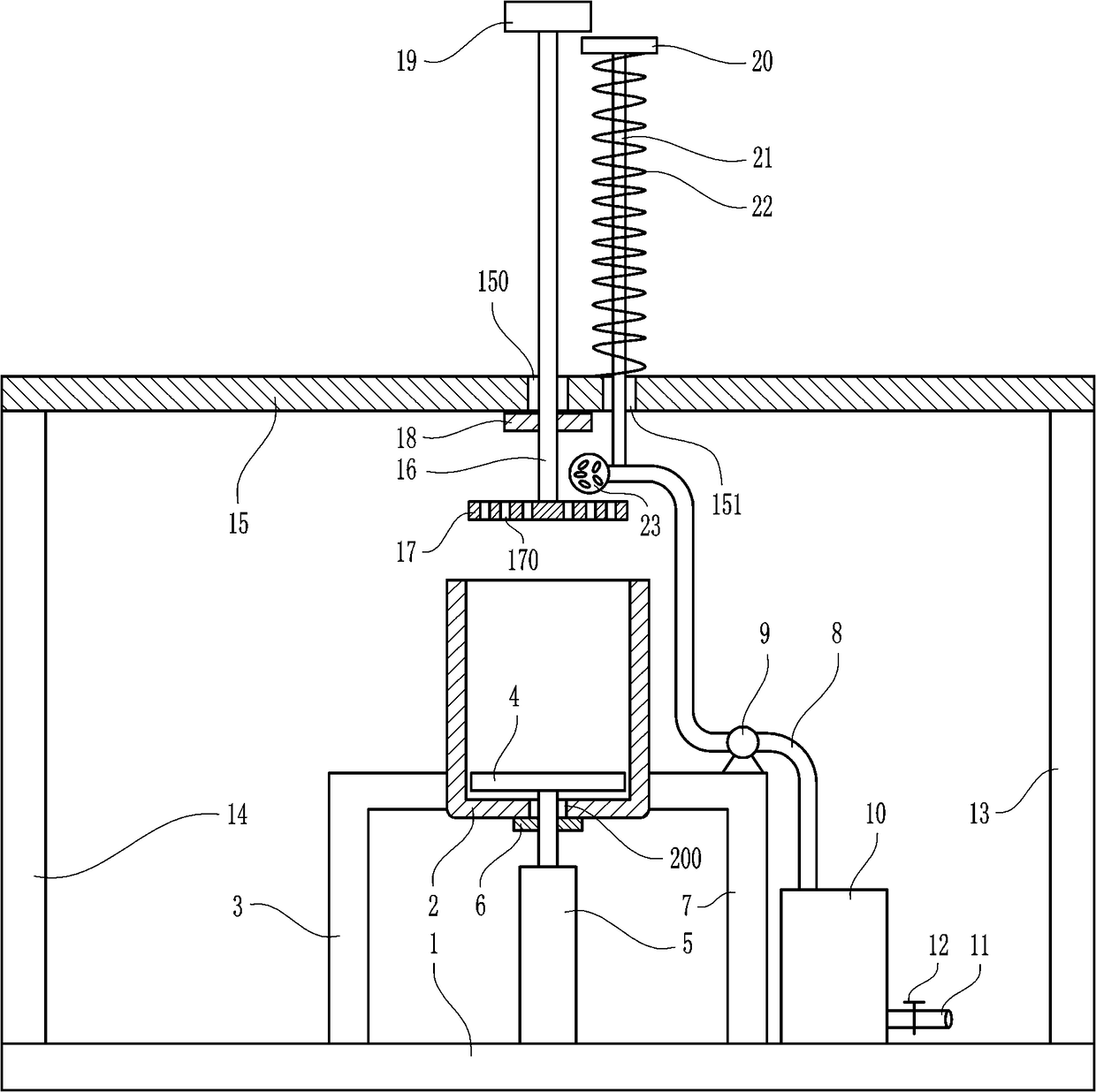

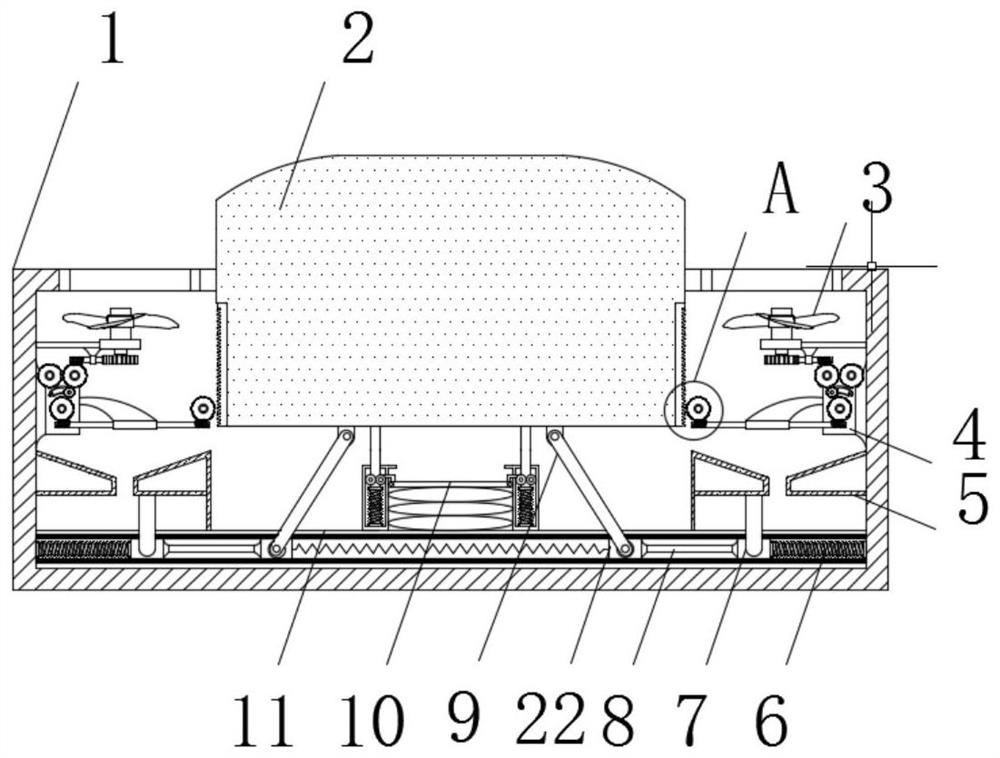

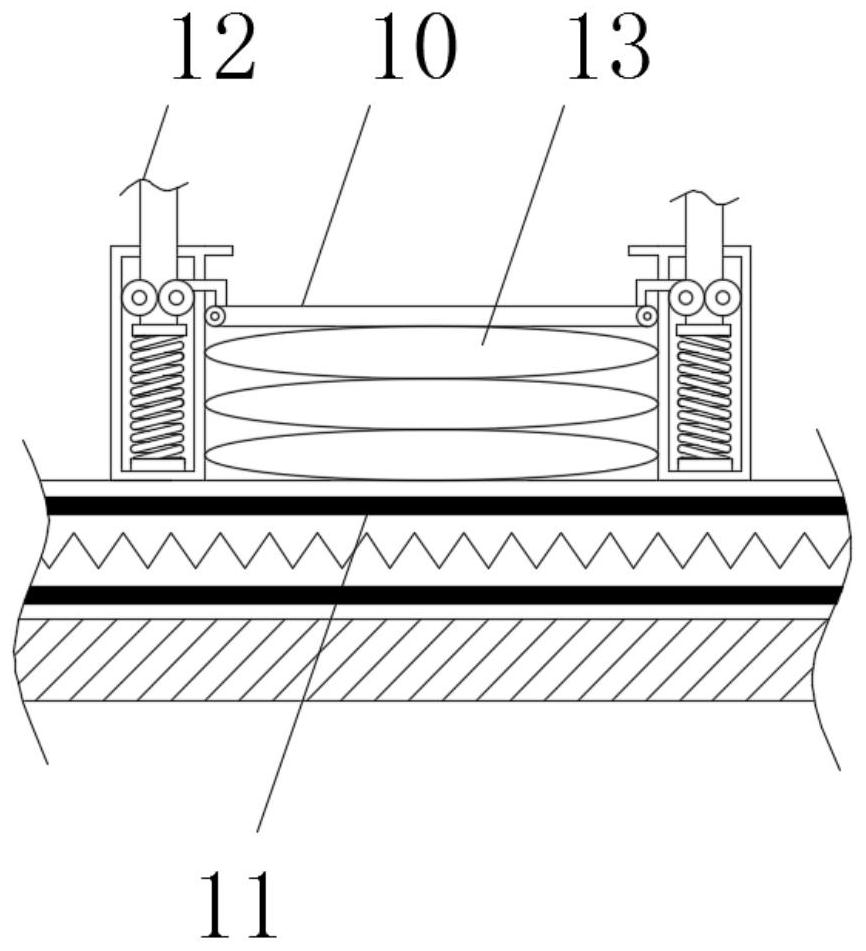

Treatment device for sewage treatment product sludge

ActiveCN108191199AAvoid damagePrevent leakageSludge treatment by de-watering/drying/thickeningMedicineSludge

The invention relates to a treatment device for sewage treatment products and particularly relates to a treatment device for sewage treatment product sludge. The invention aims to solve the technicalproblem of providing a treatment device for sewage treatment product sludge, which is high in treatment efficiency and capable of avoiding people from being in direct contact with sludge, completely eradicating pathogen contamination as well as protecting the body health and the life safety of people. The treatment device for sewage treatment product sludge, provided by the invention, comprises abase, a first cylinder body, a first L-shaped plate, a first support plate, a long-stroke cylinder, a gasket, a second L-shaped plate, a hose, a high-pressure pump, a box body, a drain pipe and the like, wherein the first cylinder body is arranged above the base. The treatment device for sewage treatment product sludge, provided by the invention, has the advantages that by adopting a unique filtering mode, thick and big contaminants can be crushed while the sewage is filtered, the treatment efficiency is high, and direct contact between people and sludge can be avoided, thereby completely eradicating pathogen contamination.

Owner:ZHEJIANG HAICHENG DECHANG MACHINERY CO LTD

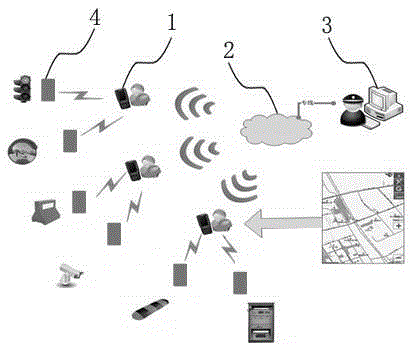

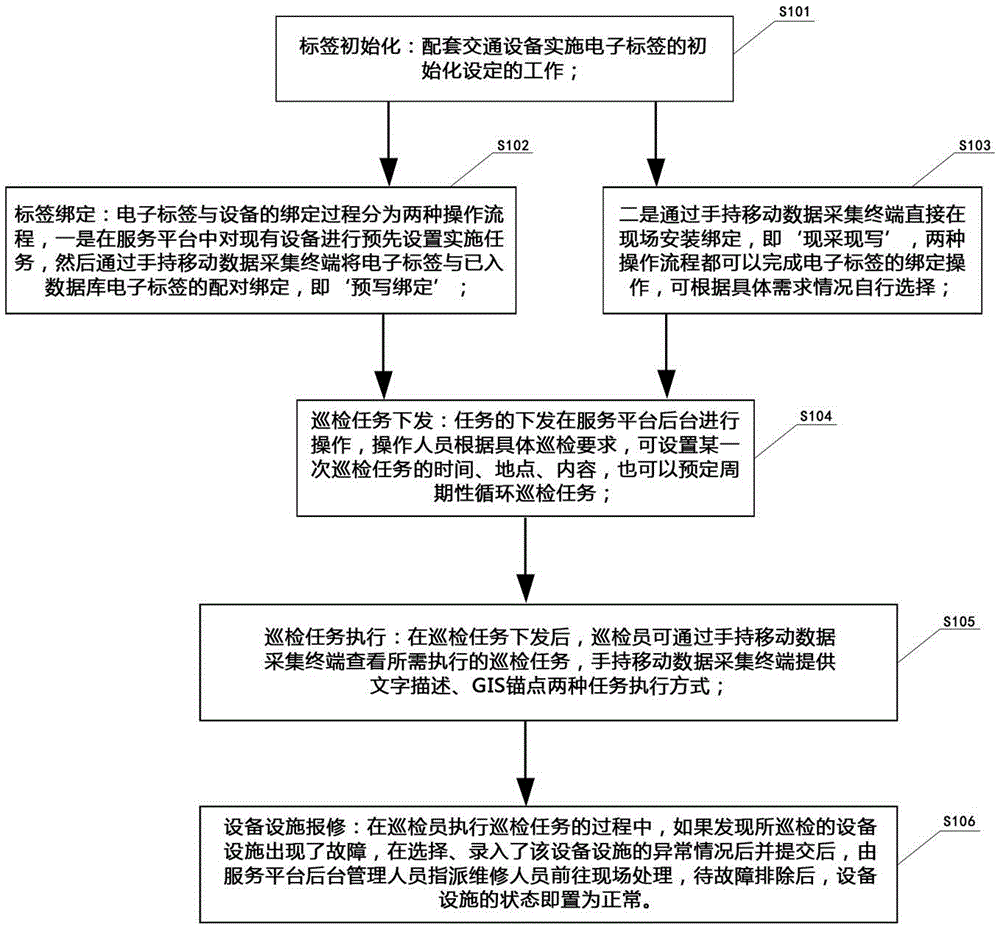

Patrol system and method based on handheld intelligent data acquisition terminal

InactiveCN105261077ATo achieve supervisionAchieve controllableChecking time patrolsSystem integrationInformatization

The invention discloses a patrol system and method based on a handheld intelligent data acquisition terminal. An Internet of Things technology is taken as an information carrier, an informatization platform is established on a traffic system by means of the network, system integration and a cloud computing technology, and automatic patrol work is realized; meanwhile, the government regulation department can monitor and control traffic system in the assistance of the system, the traffic and vehicle safety is improved, and body health and life safety of people are guaranteed.

Owner:QINGDAO LANGCOO WIRELESS SCI & TECH

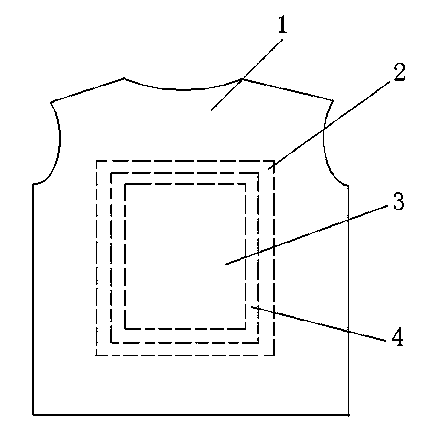

Cooling vest

InactiveCN103844403AReduce the temperaturePrevent heat strokeProtective garmentInsulation layerFire protection

The invention discloses a cooling vest and relates to the technical field of labor protection articles. A plurality of cold source bags are arranged on a light-reflecting vest; each cold source bag is filled with phase change constant temperature materials, can be arranged at the back or in the front or on the side surface of the inner layer of the light-reflecting vest, and is provided with a heat insulation layer and a fire protection layer. According to the cooling vest, the cold source bags filled with the phase change constant temperature materials are additionally arranged on the light-reflecting vest, and the phase change materials absorb a large amount of latent heat when turning from a solid state to a liquid state, so that the temperature of a human body can be reduced. The cooling vest has the characteristics of comfort in wearing, convenience in use, simplicity in maintenance, high durability and low cost, is suitable for being used by an operator in various situations such as outdoor line patrol, overhead working and meter reading under the high-temperature condition, and is capable of preventing an electrician from heatstroke at high temperature, improving the working efficiency, improving the working environment of front-line workers and ensuring the health and life safety of the electrician.

Owner:LAOHEKOU POWER SUPPLY OF HUBEI ELECTRIC POWER CORP +2

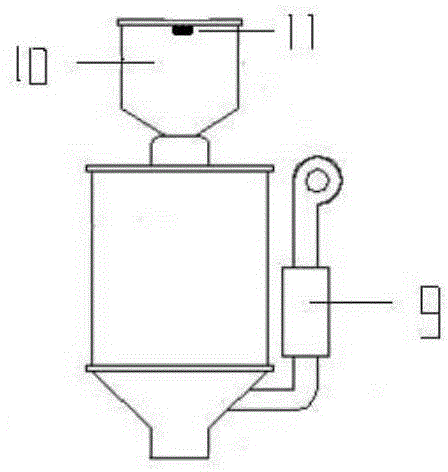

Anti-viral gas sterilization and disinfection purifier

PendingCN111135334AProtect your health and safetyProtect life safetyDeodrantsAtomized substancesEnvironmental engineeringIntensive care medicine

The invention discloses an anti-viral gas sterilization and disinfection purifier. The purifier is formed by adopting mechanical and electrical integration and medical and health environment comprehensive design, the gas virus exhaled by a transmission source is subjected to multiple sterilization and disinfection treatments through a patient, carrying is convenient, the transmission source is blocked, and thereby the effect of preventing virus transmission is achieved. The purifier is mainly composed of a protective cover and a gas purification system, a gas exhaled by a wearer is collected through the protective cover, then the collected gas is sterilized and disinfected and purified by the gas purification system, the clean gas after purification is discharged to the air, and thereby the transmission of the viral gas is directly blocked. The purifier has a simple structure, is convenient to carry, is suitable for use by all kinds of people, is especially suitable for protecting medical personnel, and patients carrying viruses, and protects body health and life safety of medical personnel and other people.

Owner:李国星

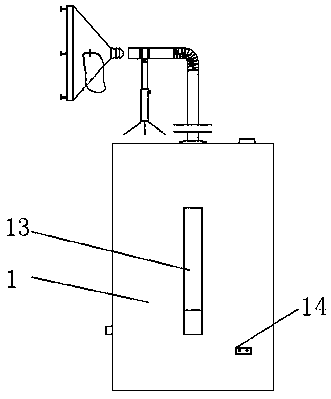

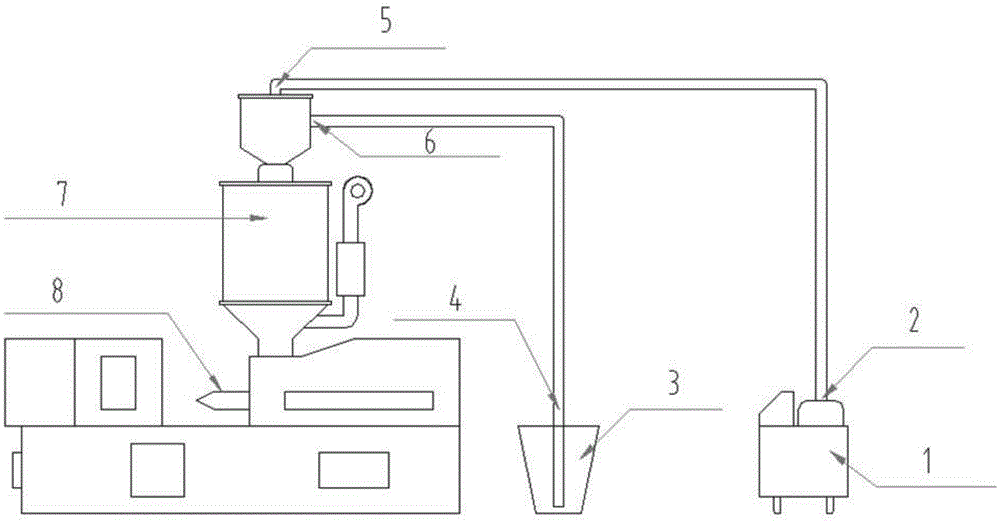

Automatic feeding device

InactiveCN105014910AReduce the risk factorProtect your health and safetyEngineeringUltimate tensile strength

Owner:天津煊生源高分子科技有限公司

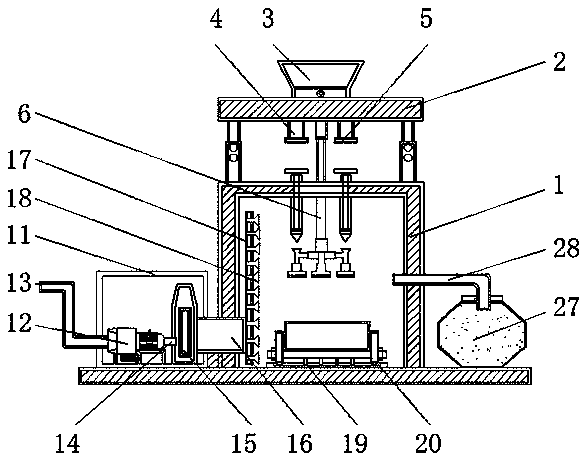

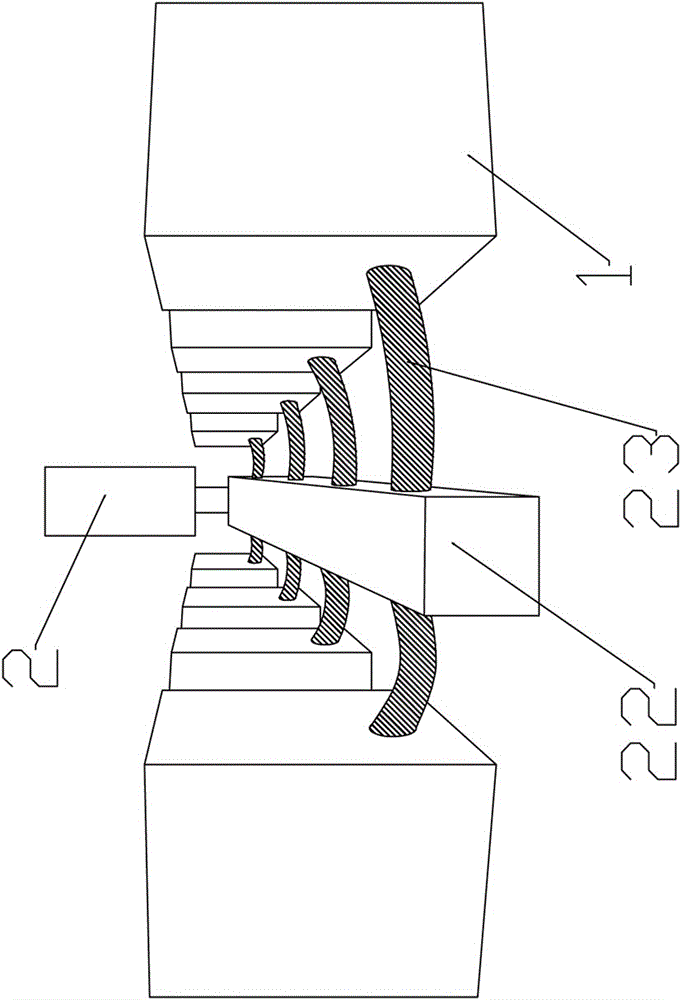

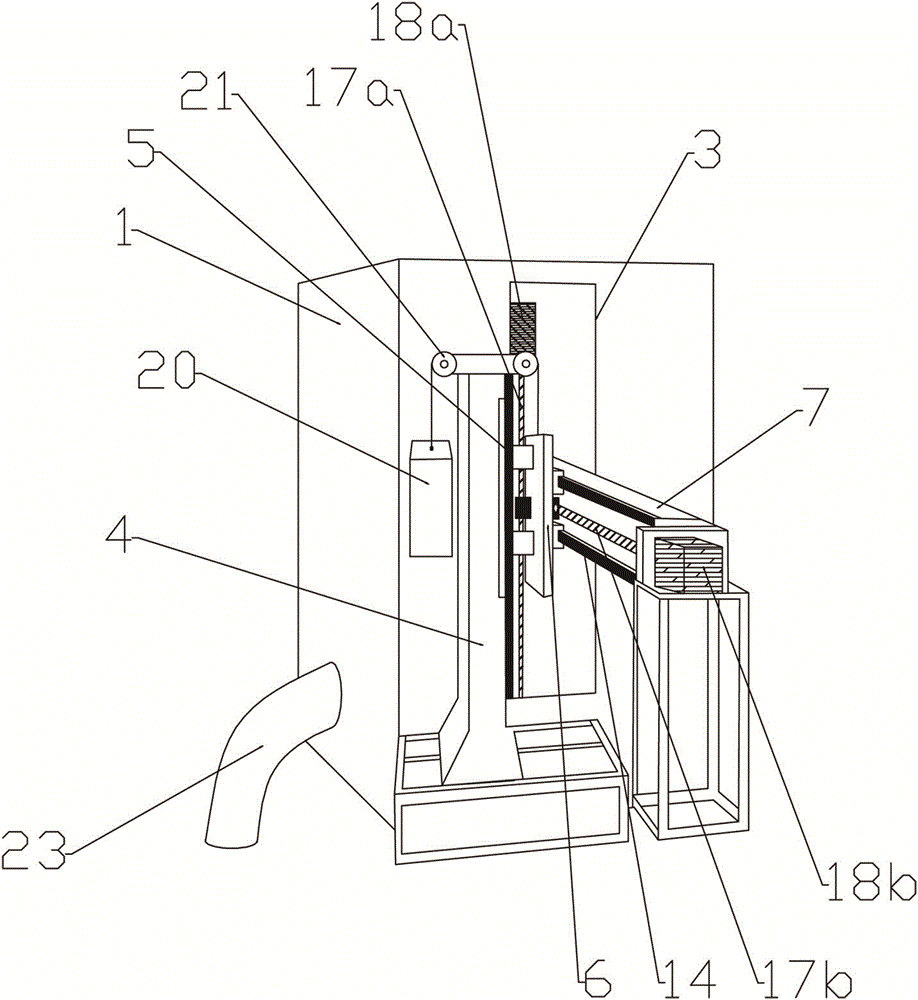

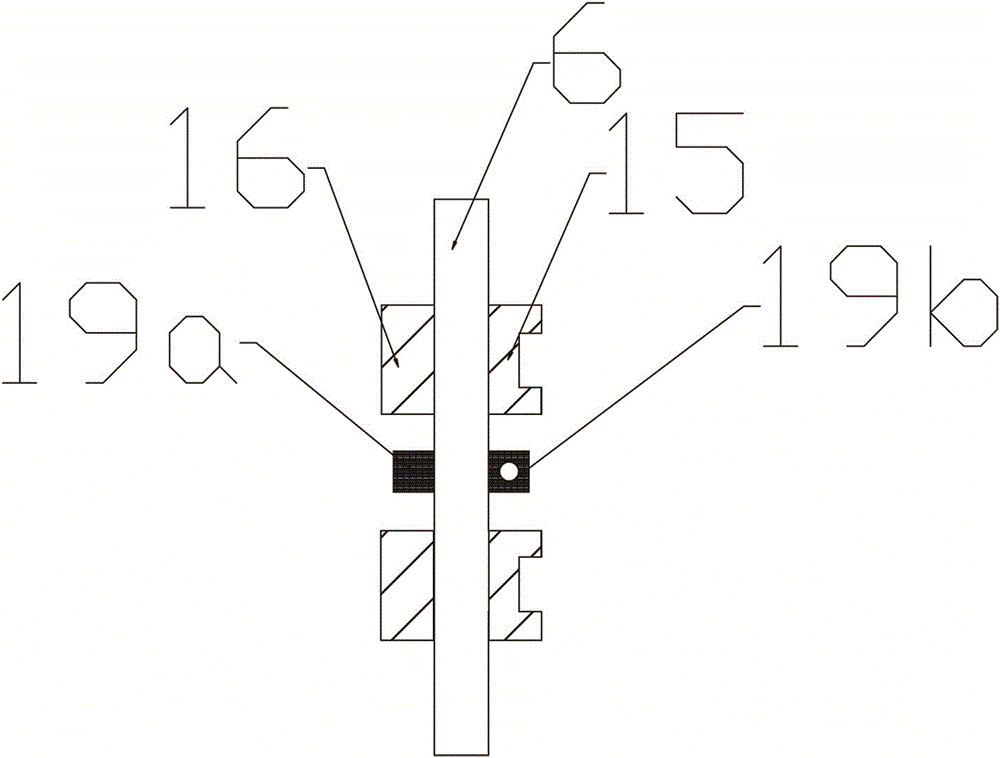

Casting iron pan polishing machine

ActiveCN106312760AImprove efficiencyEasy to replace and installBelt grinding machinesGrinding work supportsCast ironMechanical engineering

The invention relates to a casting iron pan polishing machine, which comprises a case and dust removing equipment connected with the case. A digging and storing frame and a transmission device are arranged on the side wall of the case; a machine head device is arranged on the upper part in the case; a workpiece fixing device is arranged on the lower part in the case; the transmission device comprises a vertical guide rail arranged outside the case; a fixed seat vertically moving along a direction of the guide rail is arranged on the vertical guide rail; a cross arm capable of horizontally moving front and back is arranged on the fixed seat, and penetrates through the digging and storing frame so as to be connected with the machine head device; the machine head device comprises a fixed seat plate and a double-end motor; abrasive belt driving wheels are arranged on two sides of the double-end motor; two abrasive belt supporting wheels are arranged right below the two abrasive belt driving wheels; a rough polishing abrasive belt and a fine polishing abrasive belt are arranged on the abrasive belt driving wheels and the abrasive belt supporting wheels on two sides in a sleeving way; the workpiece fixing device comprises a supporting plate arranged on the lower part of the case; a base is arranged on the supporting plate; and a transmission mechanism is arranged between the case and the supporting plate. The casting iron pan polishing machine is high in polishing efficiency and good in quality.

Owner:刘顺亮

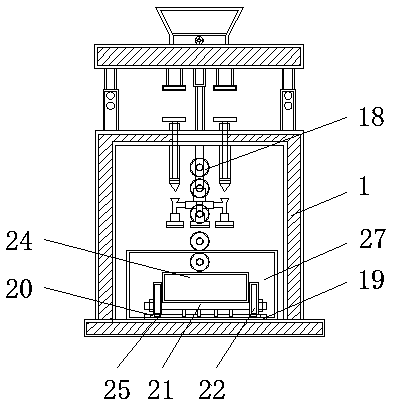

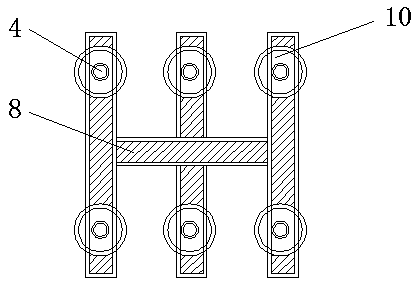

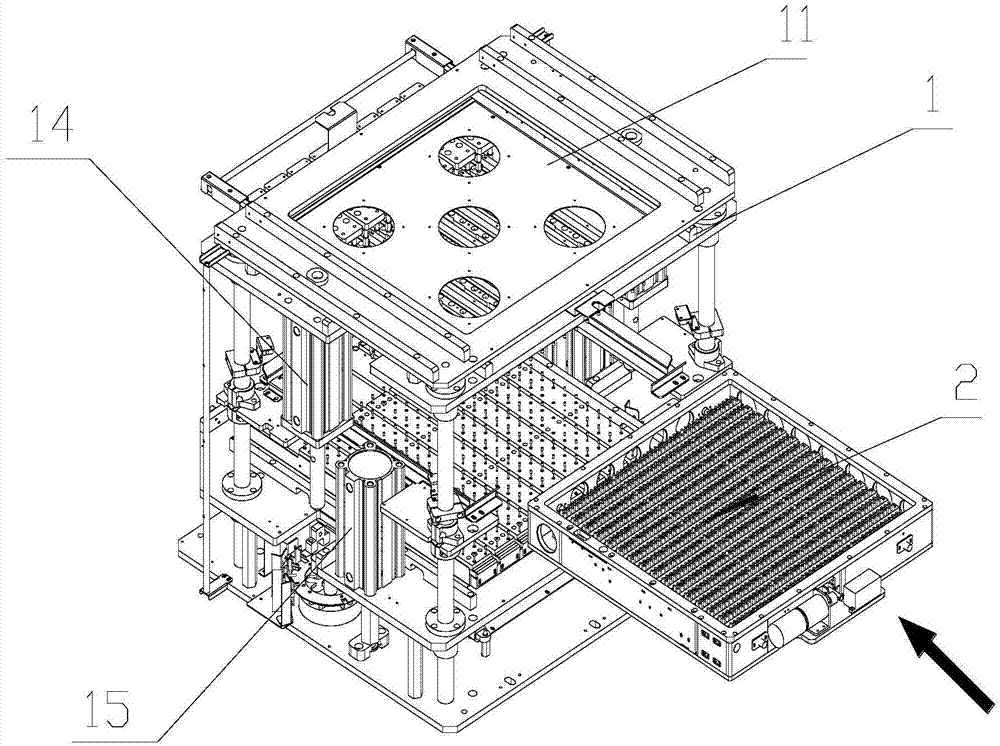

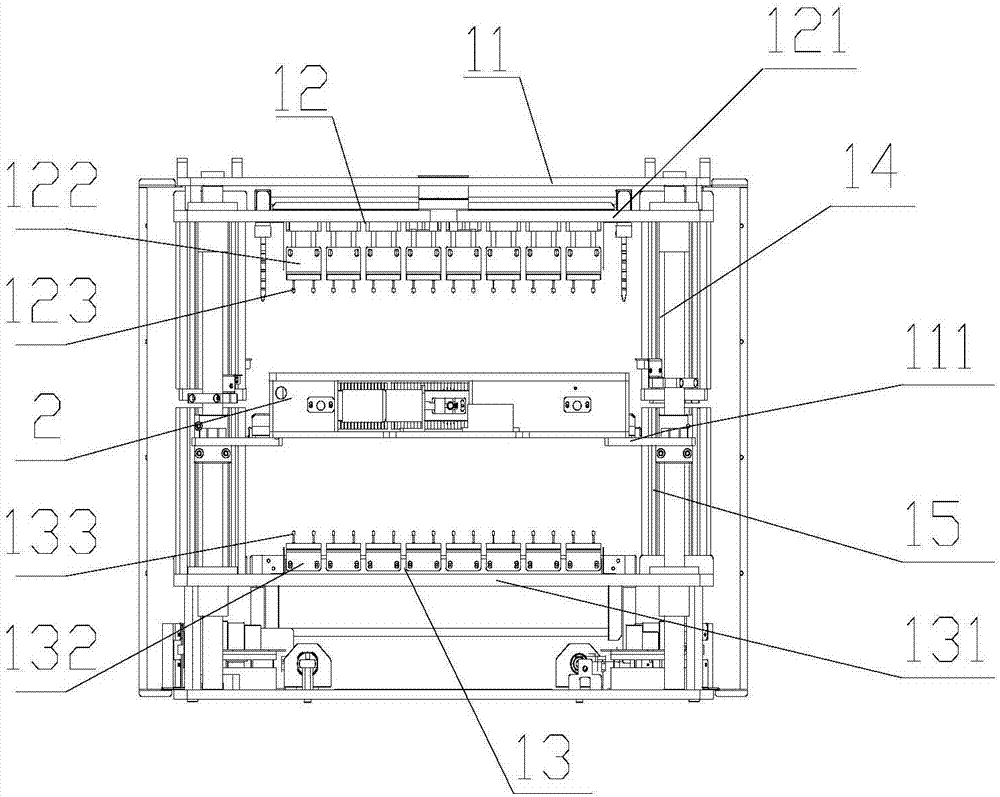

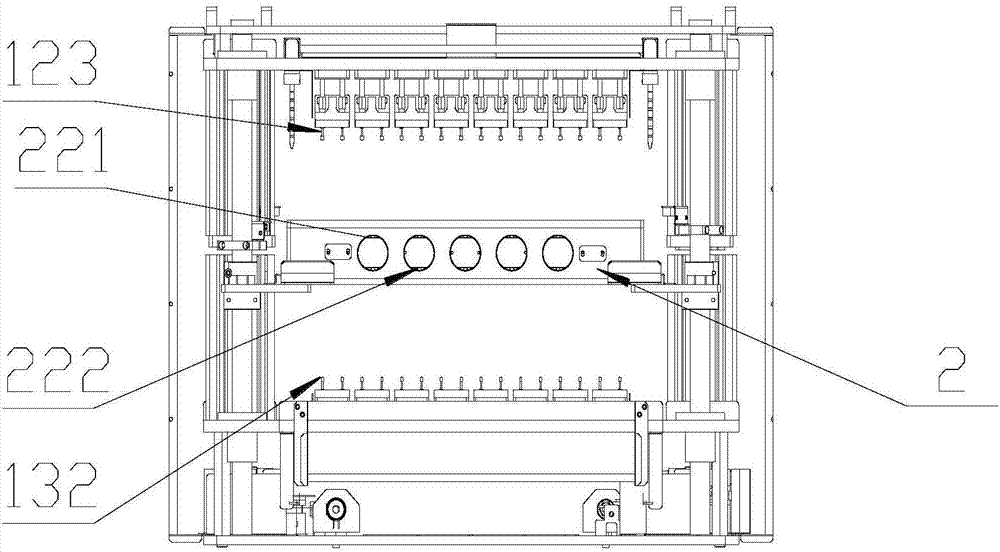

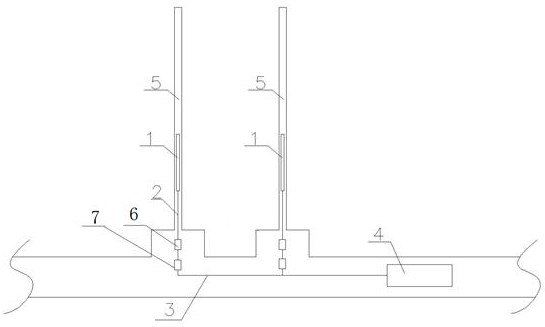

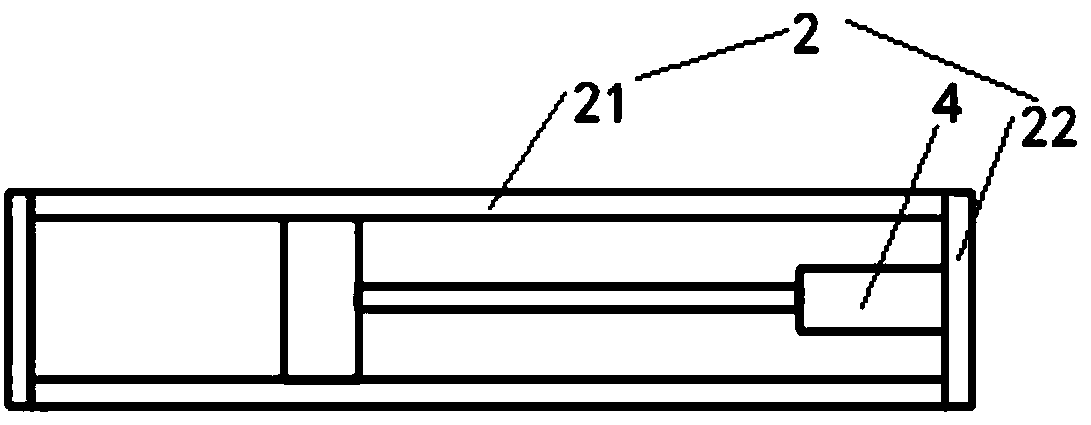

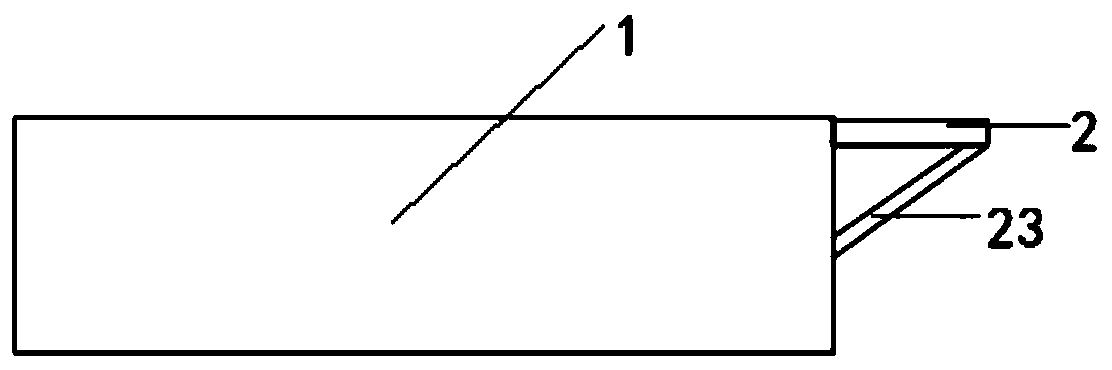

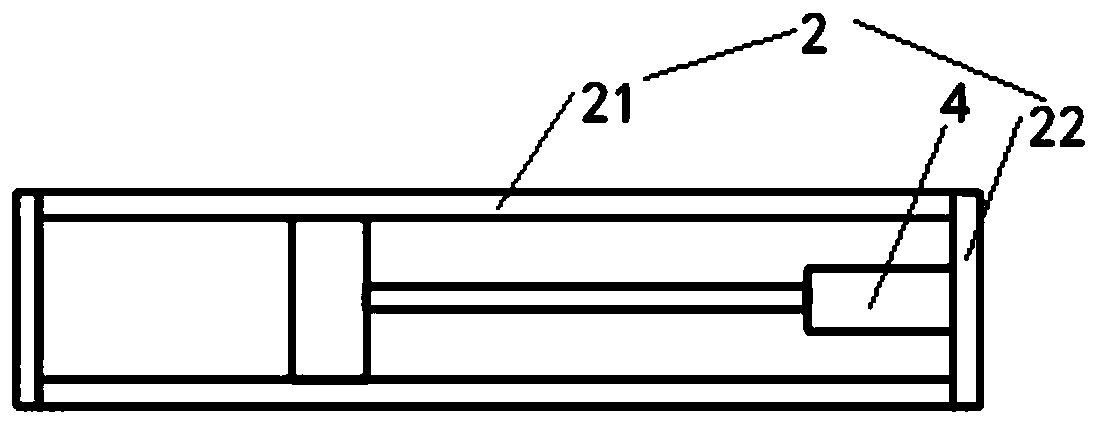

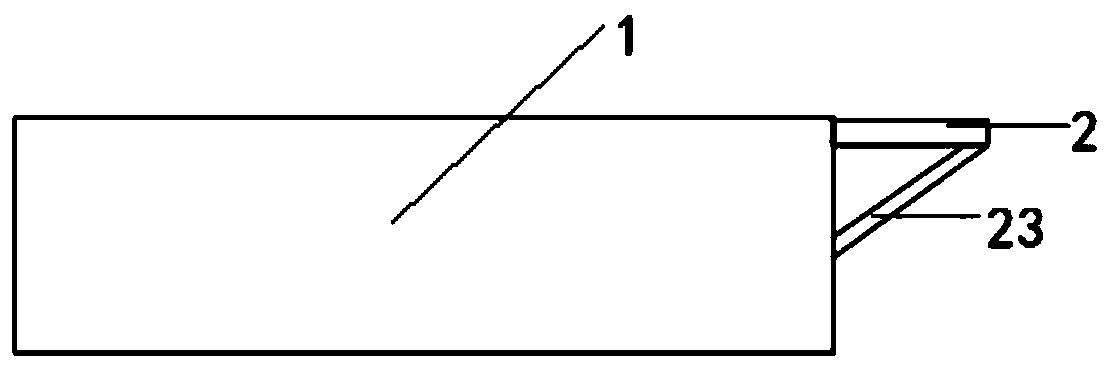

Probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment

PendingCN107127169AReduce defective rateAvoid cross contaminationCleaning using toolsCharge and dischargeEngineering

A probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment comprises secondary charging and discharging inspection equipment and cleaning equipment, wherein the secondary charging and discharging inspection equipment is used for charging and discharging the cylindrical lithium battery, and the cleaning equipment is used for cleaning the secondary charging and discharging inspection equipment. The secondary charging and discharging inspection equipment comprises a mounting frame used for mounting the whole equipment, an upper probe assembly used for being in contact with a positive pole of the cylindrical lithium battery, a lower probe assembly used for being in contact with a negative pole of the cylindrical lithium battery, an upper pneumatic component used for adjusting the longitudinal position of the upper probe assembly and a lower pneumatic component used for adjusting the longitudinal position of the lower probe assembly. The cleaning equipment comprises an outer frame used for being mounted on the charging and discharging equipment of the cylindrical lithium battery and providing supporting, a cleaning device used for cleaning the probe, a driving device used for providing driving force and a power supply device used for supplying power. The probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment has the beneficial effects that the probe of the charging and discharging equipment of the cylindrical lithium battery is cleaned automatically, and the fraction defective of the cylindrical lithium battery caused by poor contact with the probe is reduced.

Owner:ZHEJIANG HANGKE TECH

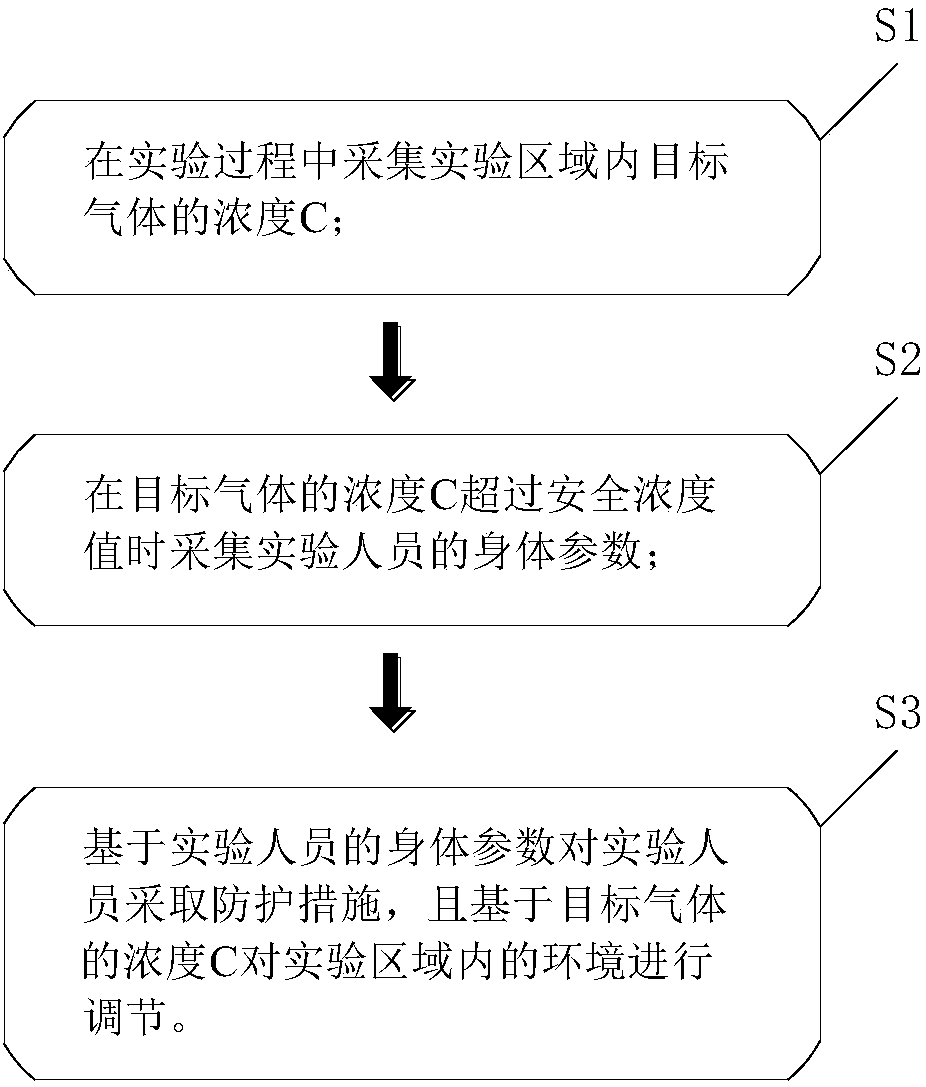

Safe intelligentized control method for laboratory with protection function

InactiveCN108553092AProtect your health and safetyGuarantee personal safetyDiagnostic recording/measuringSensorsMedicineLaboratory safety

Owner:安徽依诺格实验室设备有限公司

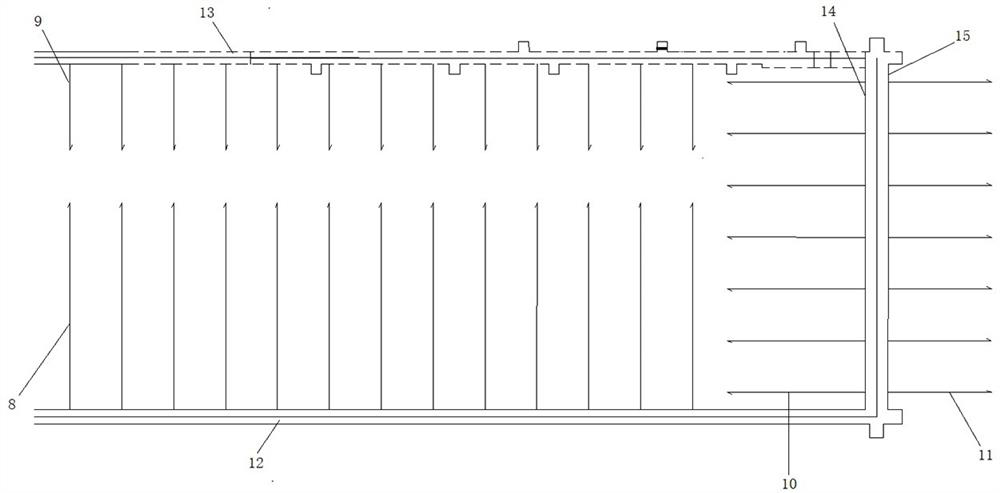

Grain conveying device capable of absorbing flying dust

PendingCN108275467AProtect your health and safetyIncrease labor costBulk conveyorsSuction forceEngineering

The invention provides a grain conveying device capable of absorbing flying dust. The grain conveying device comprises a grain inlet and a grain outlet and is characterized by comprising at least onewind energy generating mechanism, at least one pipeline direct-through conveying mechanism, at least one dust absorbing mechanism, a plurality of conveying pipelines, a plurality of air blowing pipelines, and a plurality of air sucking pipeline; the wind energy generating mechanisms are connected with the pipeline direct-through conveying mechanisms through the air blowing pipelines to output windenergy; the pipeline direct-through conveying mechanisms are connected with the grain inlet through the conveying pipelines, and the wind energy forms grain inlet negative pressure suction force through the pipeline direct-through conveying mechanisms; the pipeline direct-through conveying mechanisms are connected with the grain outlet through the conveying pipelines; the wind energy forms blowing force through the pipeline direct-through conveying mechanisms, so that grain is conveyed out of the grain outlet through the conveying pipelines; the wind energy generating mechanisms are connectedwith the dust absorbing mechanisms through the air sucking pipelines; and the dust absorbing mechanisms are arranged at the grain outlet for absorbing the flying dust. Therefore, the problem of the flying dust caused by grain carrying and grain conveying is solved.

Owner:上海巡洁机械科技有限公司

a pre-hospital ambulance

The invention is applicable to the field of medical apparatuses and instruments and provides a pre-hospital emergency ambulance. The pre-hospital emergency ambulance is composed of an emergency assay module, an electrocardio and ultrasonic diagnosis module, an emergency treatment module, an emergency treatment comprehensive management information system, an auxiliary module, a power module and a communication module. Through combined diagnosis and detection of the emergency treatment module, the emergency assay module and the electrocardio and ultrasonic diagnosis module, the accuracy and the timeliness of disease diagnosis are improved, unfolding time of field apparatuses can be shortened and burdens of medical workers can be reduced due to stretchers and intensive care units (ICUs), on-the-spot rescue, midway diagnosis and emergency treatment can be performed timely, the ambulance can be directly transferred to divisions for emergency treatment in hospitals so as to form a seamless treatment chain combining pre-hospital care, midway life support and rapid in-hospital treatment, the maneuverability is high, starting for immediate use is achieved, the operation is simple, the ambulance is suitable for emergency treatment and cure in the field or during transfer and capable of effectively assisting medical workers to treat and cure according to symptoms, and the emergency handling capacity and the emergency rescue capacity of emergencies are improved.

Owner:北京倍肯恒业科技发展股份有限公司

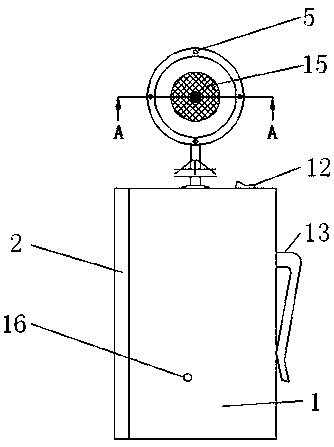

Cleaning vehicle for cleaning welding seams on inner wall of steel storage tank

InactiveCN105728412AImprove working environmentLower working environmentHollow article cleaningVehiclesPhysical healthWorking environment

The invention discloses a cleaning vehicle for cleaning welding seams on the inner wall of a steel storage tank. The cleaning vehicle comprises a chassis, the two sides of the chassis are each connected with a set of travelling device capable of driving the chassis to move along the inner wall of the storage tank, and the travelling devices are arranged symmetrically. The chassis is provided with a cleaning device, a dust collection mechanism, a sampling pan-tilt and illuminating lamps, wherein the cleaning device is located in the middle of the chassis and used for cleaning the inner wall of the storage tank; the dust collection mechanism is located on the cleaning object discharging side of the cleaning device and used for collecting cleaning objects; the sampling pan-tilt is located in the position, away from the cleaning object discharging side, of the cleaning device and used for monitoring the cleaned inner wall of the storage tank; and the illuminating lamps are located on the two sides of the sampling pan-tilt correspondingly and used for sampling lighting. According to the cleaning vehicle for cleaning the welding seams on the inner wall of the steel storage tank, workers are replaced with the cleaning vehicle to clean the inner wall of the storage tank, operation is easy, any additional pollution is avoided, and cleaning work is not limited by the height and the size of the storage tank; thus, the working environment of the workers is greatly improved, and the physical health and the life safety of the workers are ensured; and the cleaning efficiency is high, time and effort are saved, expansive large-size cleaning equipment is not needed any more, and a large amount of cost is reduced.

Owner:TANGSHAN COLLEGE

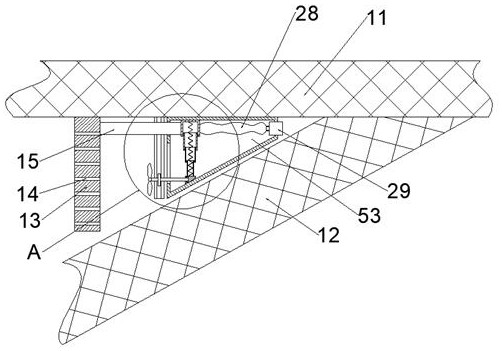

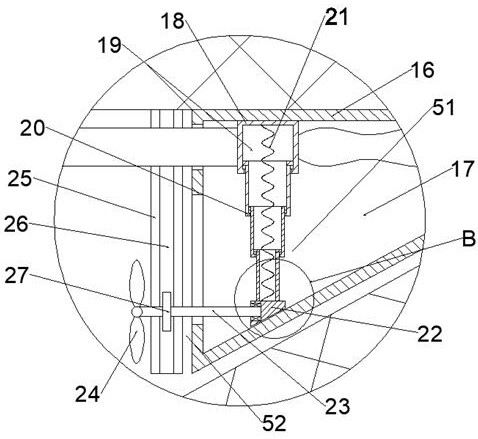

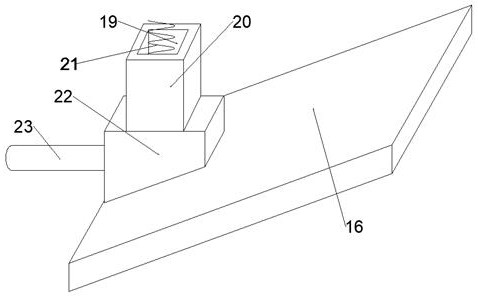

Head collision prevention device of escalator

ActiveCN113044704AReduce harmProtect your health and safetySustainable buildingsEscalatorsHandrailTransportation safety

The invention relates to the field of transportation safety, in particular to a head collision prevention device of an escalator. The invention aims to provide the head collision prevention device of the escalator so as to solve the problem that the head of a passenger is collided or even clamped when the passenger takes the escalator. The head collision prevention device provided by the invention comprises a fence wall surface, an escalator handrail is arranged on the lower side of the fence wall surface, a sponge buffer block is connected to the fence wall surface in a sliding mode, an alarm box is fixedly connected to the fence wall surface, an alarm cavity is formed in the alarm box, and a behavior triggering mechanism is arranged in the alarm cavity.

Owner:NANJING YUSHENG ROBOT CO LTD

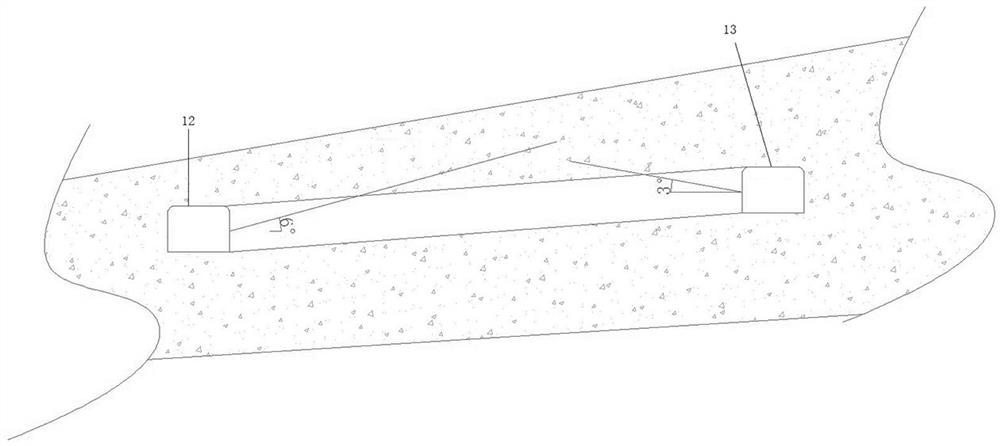

Long and short hole crossed coal seam water injection method

PendingCN112709530AChange mechanical propertiesReduce generationDust removalFire preventionCoal dustWater content

The invention discloses a long and short hole crossed coal seam water injection method. The method specifically comprises the following steps of 1, drilling construction; 2, water injection drilling and hole sealing; and 3, coal seam water injection. According to the method, long and short hole crossed coal seam water injection is utilized, a coal body is wetted in advance, the coal dust generation amount is reduced, water is uniformly injected into the coal body, the water content reaches 4% or above, outburst accidents are prevented, the mechanical property of coal is changed, stress distribution is homogenized, the elastic energy release speed is decreased, the power is reduced, and the gas emission speed is reduced; after coal seam water injection is implemented, respirable dust and total dust are greatly reduced, and the maximum dust fall rate reaches 50% to 80%; and after water injection, the initial speed of drilling gas emission is basically eliminated, the measured value is obviously reduced, the inhibition and analysis effect after water injection is reflected, the gas emission amount is reduced by 30% to 70%, and the gas emission speed is reduced by 35% to 40%.

Owner:YAOJIE COAL ELECTRICITY GROUP

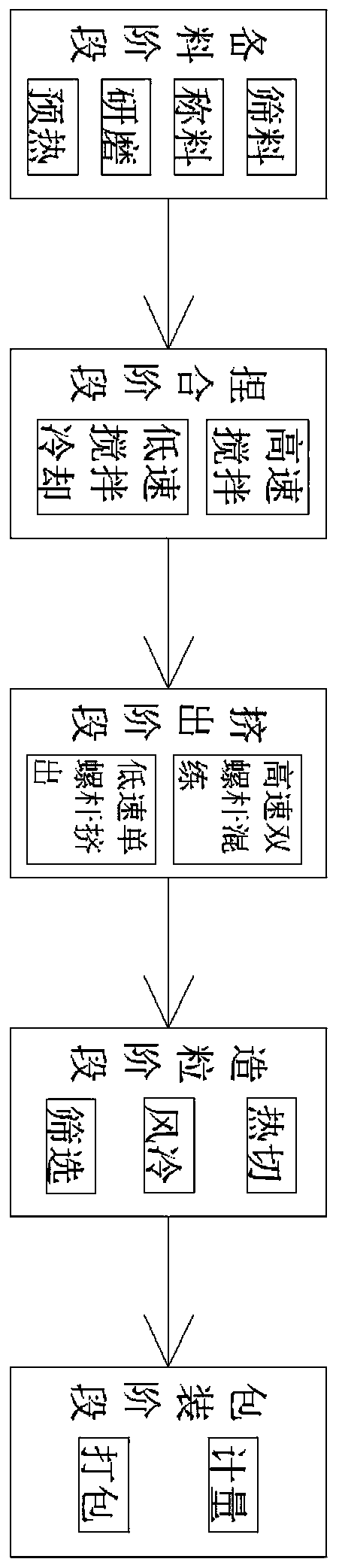

Preparation process of environment-friendly flame-retardant insulating PVC cable material

The invention discloses a preparation process of an environment-friendly flame-retardant insulating PVC cable material. The preparation process comprises a material preparation stage, a kneading stage, an extrusion stage, a granulation stage and a packaging stage; the material preparation stage comprises screening, weighing, grinding and preheating; the kneading stage comprises high-speed stirringand low-speed stirring cooling; the extrusion stage comprises high-speed double-screw mixing and low-speed single-screw extrusion; the granulation stage comprises hot cutting, air cooling and screening; the packaging stage comprises metering and packaging; and an electron accelerator is arranged at a low-speed single-screw extrusion discharge end. A plasticizer and a smoke suppressant with the flame-retardant effect are added into raw materials, so that the generation of toxic gas and smoke dust during a fire is reduced, and the environmental protection effect is achieved; and by changing theplasticity of the PVC cable material, the anti-aging and anti-cracking performance of the PVC cable material is improved, so that the insulation effect of the PVC cable material is improved.

Owner:苏州联盈塑化有限公司

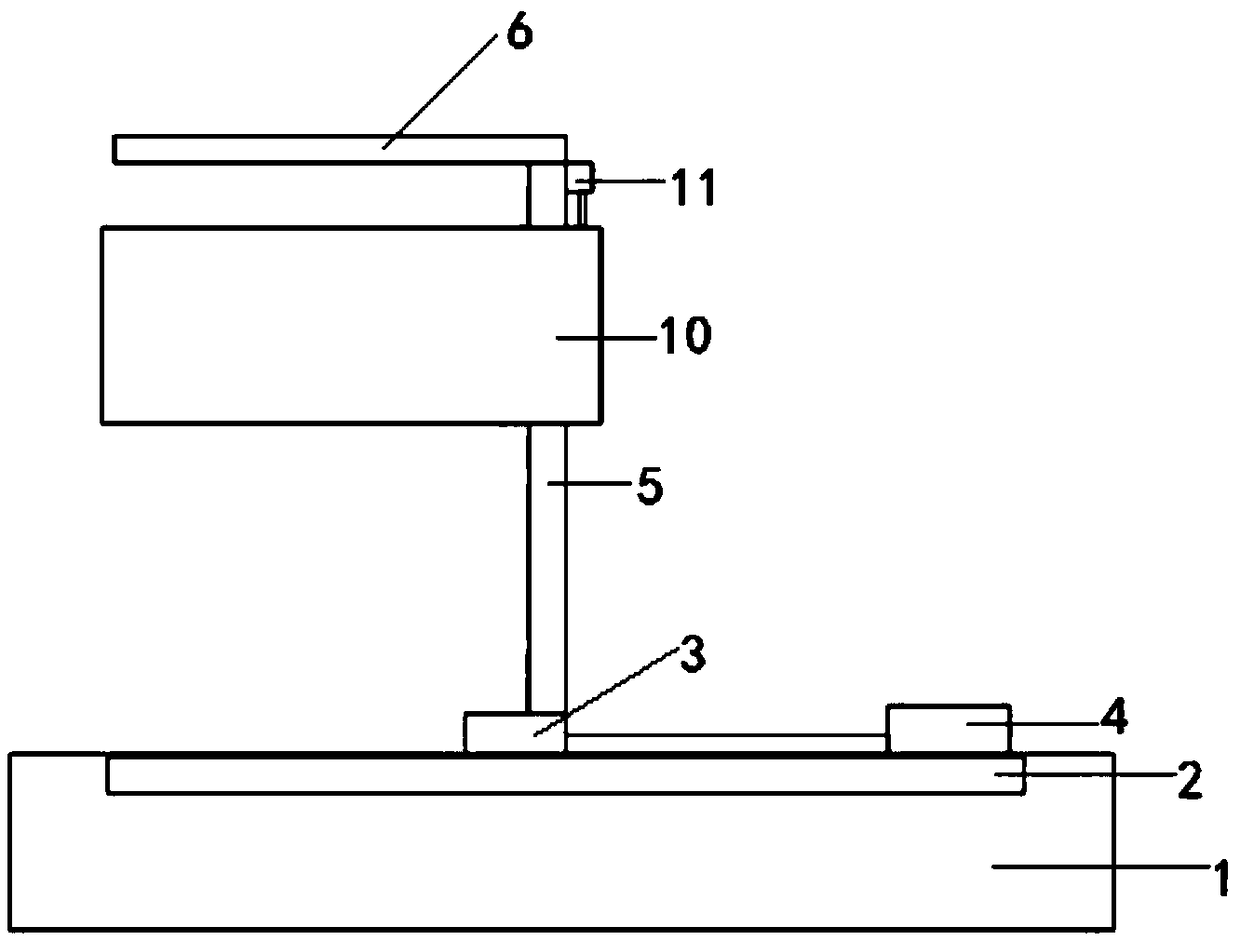

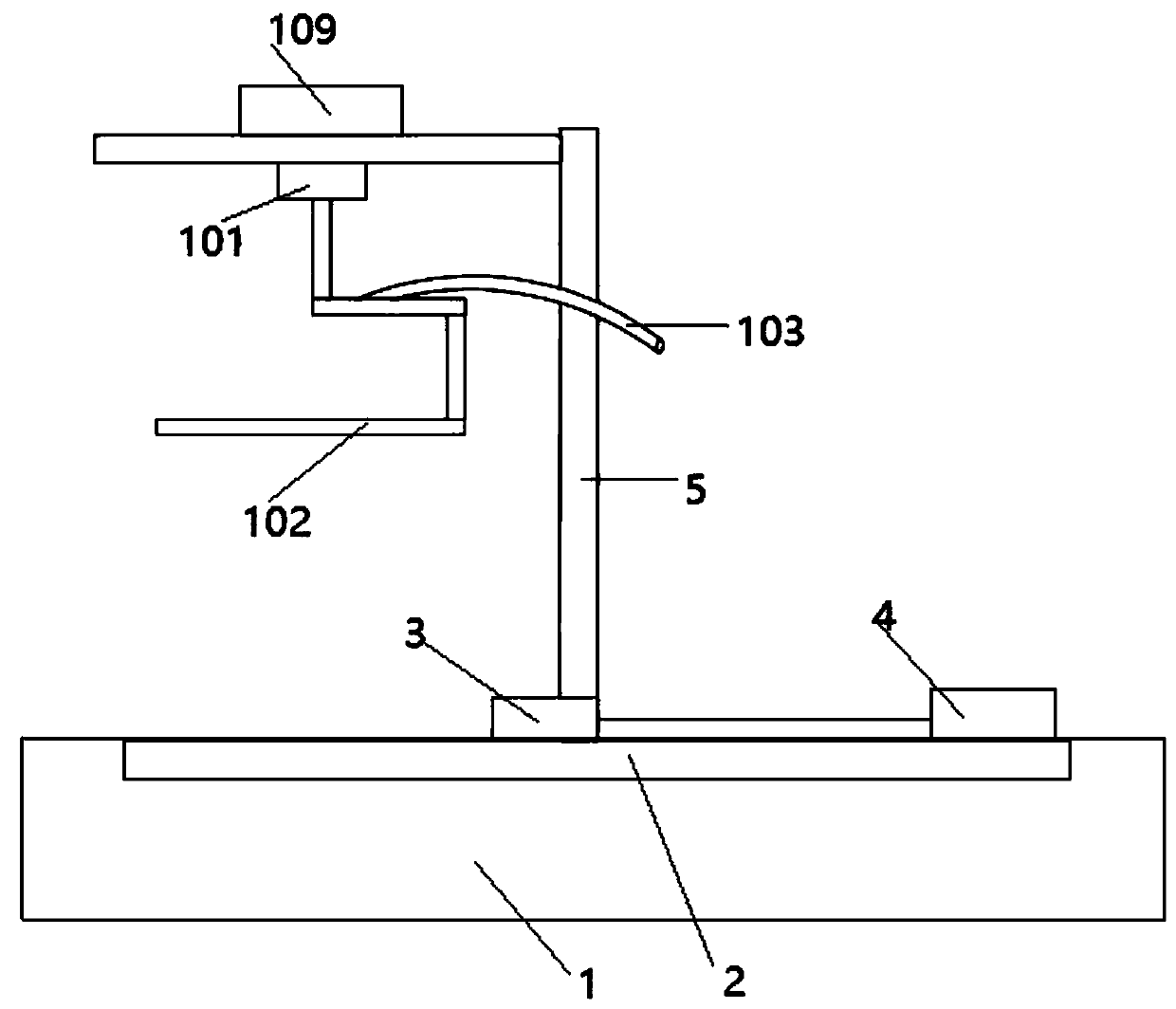

Gas cooker system and method

InactiveCN108980908AAvoid Burning HazardsWon't burn outDomestic stoves or rangesLighting and heating apparatusEngineeringMoisture sensor

The invention discloses a gas cooker system and method. The gas cooker system comprises a gas cooker, a transverse guide rail and a temperature sensor which are disposed on the gas cooker, a support plate and a first cylinder for driving the support plate to move transversely which are disposed on the transverse guide rail, a support column disposed on the support plate, a detection plate disposedat an upper end of the support column, and a temperature and humidity sensor disposed on a lower surface of the detection plate; the gas cooker system further comprises a controller and an alarm; thegas cooker is connected with a gas inlet pipe; and the gas inlet pipe is provided with an electromagnetic valve. The gas cooker system has the characteristics that the safety is good and food is effectively prevented from burning.

Owner:广东康帅生活电器有限公司

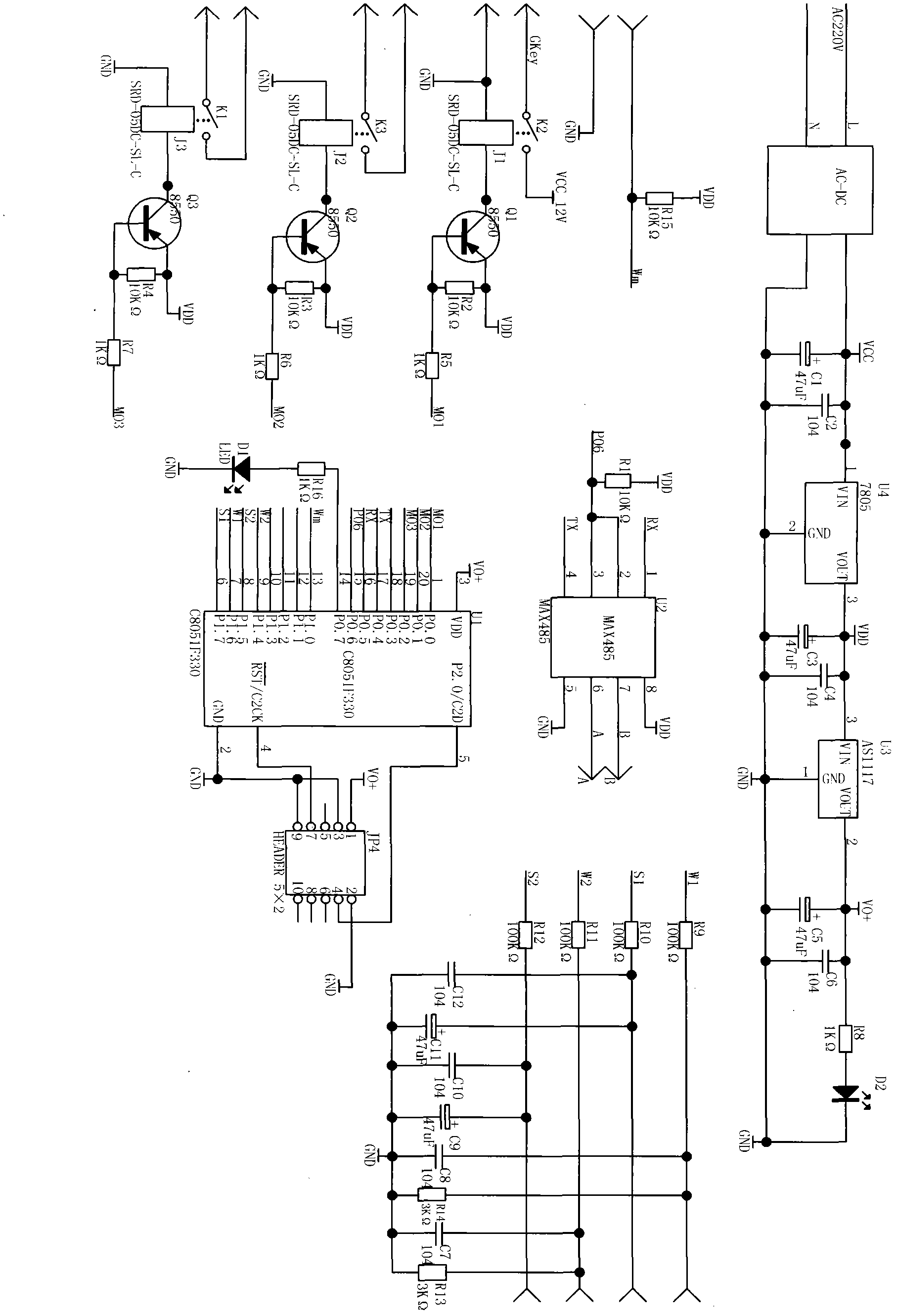

Intelligent management system for safety tools and appliances

InactiveCN102508469BEfficient managementEffective monitoringSimultaneous control of multiple variablesProgramme total factory controlDisplay deviceIntelligent management

The invention discloses an intelligent management system for safety tools and appliances. The intelligent management system comprises a controller, a display, an infrared sensor, a temperature sensor, a humidity sensor, a dehumidifier water full sensor, a heater and a dehumidifier, wherein the display, the infrared sensor, the temperature sensor, the humidity sensor, the dehumidifier water full sensor, the heater and the dehumidifier are respectively and communicatively connected with the controller. The intelligent management system for the safety tools and appliances can conduct effective intelligent management on the safety tool and appliances stored in an electric tool cabinet, can recognize and record the storage and the use of the safety tools and appliances, and enables the safety tools and appliances in the electric tool cabinet to be always in a safe humidity and temperature environment.

Owner:曾声兵

A ventilation window with air purification effect

ActiveCN112984676BQuick breakdownBreakdown works wellMechanical apparatusLighting and heating apparatusNitrogen oxidesAir decontamination

The invention discloses a ventilation window with air purification effect, which comprises a wall body, an air inlet and an air outlet are arranged on the wall body, a working box is fixedly connected to a side wall of the wall body, the The three inner walls of the working box and the side walls of the wall are jointly fixedly connected with a partition, and the partition is located between the air inlet and the air outlet, and the partition is made of a transparent material. The upper end face of the work box is provided with a light inlet, and the inwall of the light inlet is fixedly connected with a conversion plate, and the conversion plate is composed of acceptor molecules of TIPS naphthalene and Ir(C) 2 (acac) Donor molecular combination materials are made, and the inner walls of the air inlet and the air outlet are fixedly connected with support columns. In the present invention, the user can effectively prevent ozone and nitrogen oxides in the air from entering the room when performing indoor ventilation, thereby greatly ensuring the health and safety of indoor personnel.

Owner:DECAI DECORATION +2

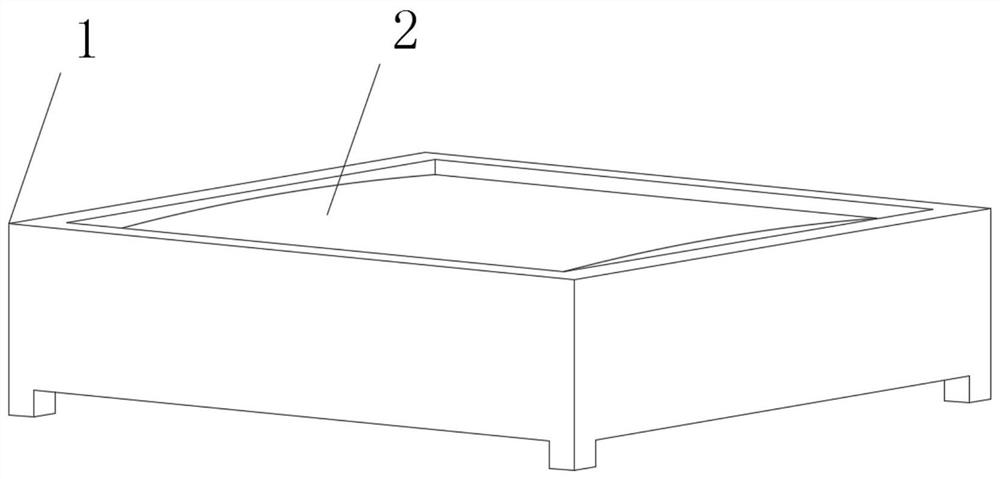

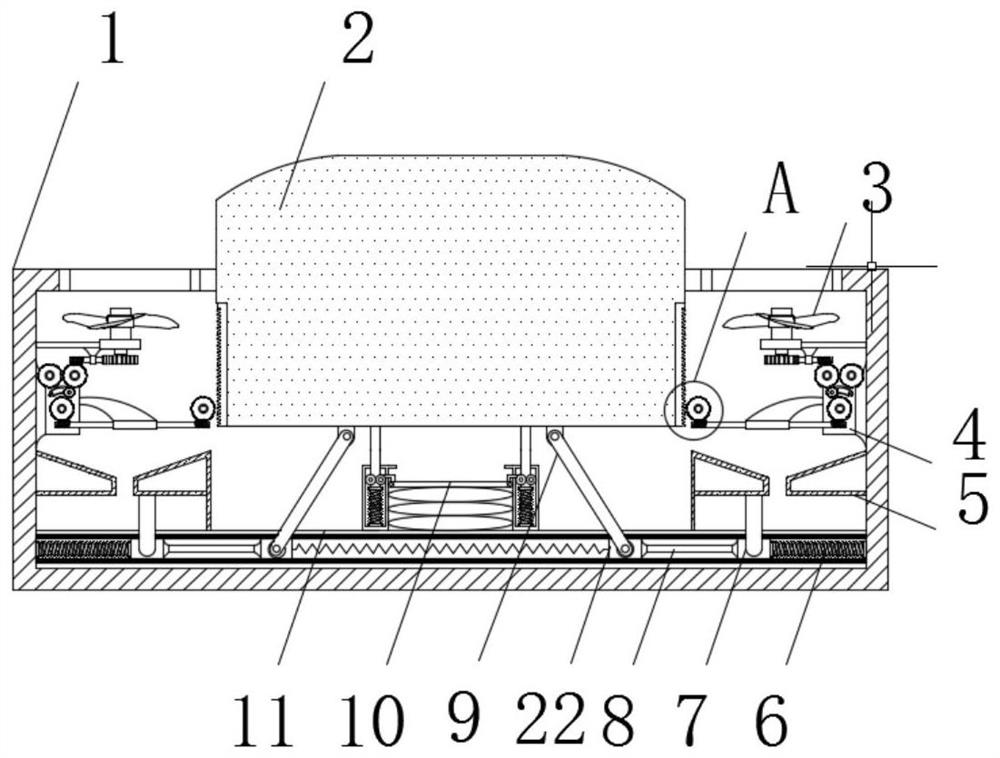

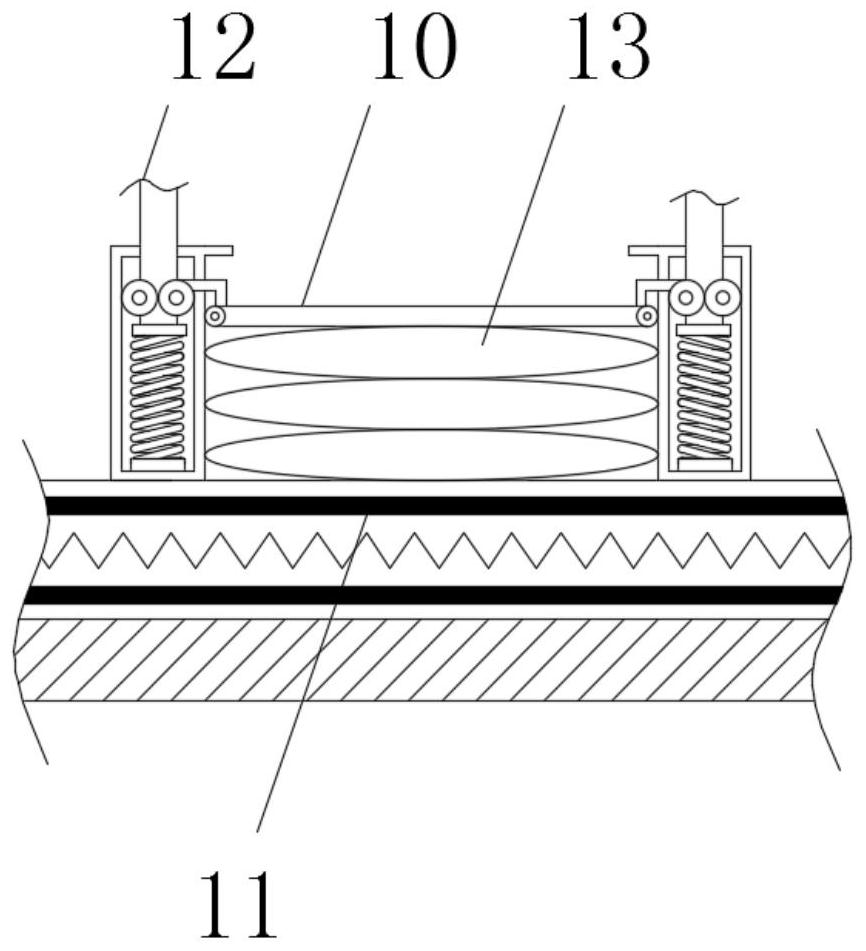

Energy-saving and environment-friendly grinding tool platform for grinding equipment

ActiveCN111843776AAvoid spreadingProtect your health and safetyGrinding carriagesUsing liquid separation agentGear driveGear wheel

The invention relates to the technical field of grinding tools, in particular to an energy-saving and environment-friendly grinding tool platform for grinding equipment. According to the grinding toolplatform, a bearing table is slidably connected to the upper surface of a shell, a connecting rod is rotatably connected to the lower surface of the bearing table, second worm wheels are engaged withthe two sides of the bearing table correspondingly, a sliding rail is fixedly connected to the bottom end of the interior of the shell, and a second sliding block is connected into the sliding rail in a sliding mode; and when the second worm wheels rotate clockwise, an adjusting gear slides to the right side of a sliding frame, at the moment, a connecting gear rotates clockwise, when first worm wheels rotate anticlockwise, the adjusting gear slides to the left side of the sliding frame, at the moment, the connecting gear keeps rotating clockwise, the connecting gear drives fan blades to always keep rotating clockwise and rotate through first worms, and the fan blades rotate so that dust generated in the polishing process can be absorbed into the shell more rapidly, it is avoided that moredust is scattered into air in the polishing process of workers, and the workers inhale the harmful dust as little as possible.

Owner:桂林同立机电设备有限公司

Gas stove system and method capable of preventing dry burning

ActiveCN108980909BAvoid dangerAvoid fireDomestic stoves or rangesLighting and heating apparatusMagnetic valveProcess engineering

The invention discloses a gas cooker system and method capable of preventing dry burning. The gas cooker system comprises a gas cooker, a transverse guide rail disposed on the gas cooker, a support plate and a first cylinder for driving the support plate to move transversely which are disposed on the transverse guide rail, a support column disposed on the support plate, a detection plate disposedat an upper end of the support column, and a temperature and humidity sensor disposed on a lower surface of the detection plate; the gas cooker system further comprises a controller and an alarm; thegas cooker is connected with a gas inlet pipe; the gas inlet pipe is provided with a pressure sensor and a first electromagnetic valve; the lower surface of the detection plate is provided with a second cylinder; and an expansion link is connected with a water pipe with two closed ends. The gas cooker system has the characteristics that the safety is good and dry burning of a pan is effectively prevented.

Owner:李广

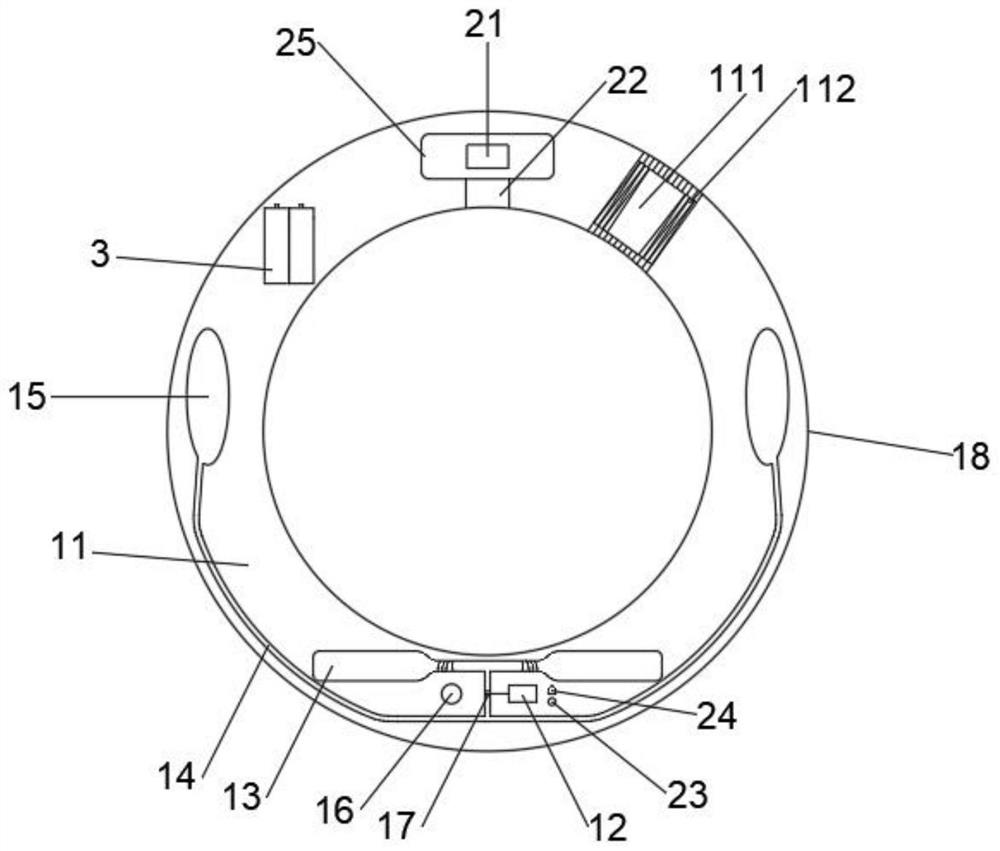

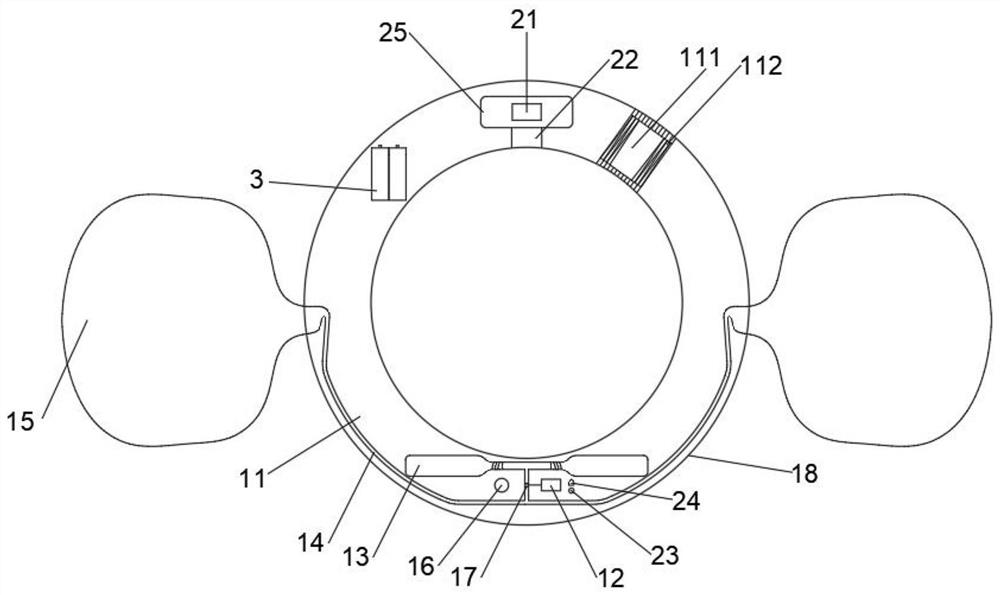

Drowning-preventing lifesaving device based on heart rate judgment and control method thereof

PendingCN112093012AAutomatic inflationNormal breathingVessel signalling devicesSensorsMarine engineeringGas cylinder

The invention discloses a drowning-preventing lifesaving device based on heart rate judgment and a control method thereof, and relates to the technical field of water rescue. The lifesaving device comprises a lifesaving mechanism, a control mechanism for controlling the lifesaving mechanism to work and a battery for supplying energy; an air bottle and an airbag are installed in an outer shell witha waterproof function; an airbag opening is formed in the position, corresponding to the airbag, on the outer shell; high-pressure compressed gas or liquefied gas is stored in a gas cylinder; a ventvalve is arranged at the opening of the gas cylinder; the gas cylinder communicates with the airbag through a vent pipe to form a lifesaving mechanism; the outer shell is arranged in a form of being attached to the neck of a human body; and the battery is arranged in the outer shell. According to the device, sudden increase of heart rate is used as the basis for judging drowning, so that the device can better adapt to the actual physique condition of an individual, and is high in judgment accuracy and quick in response; and the airbag can be timely and automatically inflated and blown to generate buoyancy so as to support the head of a user out of the water surface, so normal; breathing of the user is guaranteed and the life safety of the user is further ensured.

Owner:HEFEI UNIV OF TECH

An energy-saving and environment-friendly grinding tooling platform for grinding equipment

ActiveCN111843776BAvoid spreadingProtect your health and safetyGrinding carriagesUsing liquid separation agentGear wheelPolishing

The invention relates to the technical field of grinding tools, in particular to an energy-saving and environment-friendly grinding tooling platform for grinding equipment. The upper surface of the housing is slidably connected to a bearing platform, and the lower surface of the bearing platform is rotatably connected to a connecting rod. Both sides of the carrying platform are engaged with the second worm gear, the inner bottom of the housing is fixedly connected with a slide rail, and the inside of the slide rail is slidably connected with a second slider. When the second worm wheel turns clockwise, the adjusting gear slides to the right side of the sliding frame, and the connecting gear turns clockwise at this time; when the first worm wheel turns counterclockwise, the adjusting gear slides to the left side of the sliding frame, and the connecting gear remains Rotate clockwise, the connecting gear drives the fan blade to keep rotating clockwise through the first worm, and the fan blade rotates to absorb the dust generated during the grinding process into the interior of the housing more quickly, preventing the dust from being trapped by the staff during the grinding process More spread into the air, so that the staff can inhale these damaged dust as little as possible.

Owner:桂林同立机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com