Gas stove system and method capable of preventing dry burning

A gas stove and dry burning technology, which is applied to household stoves/stoves, gaseous heating fuel, lighting and heating equipment, etc., can solve the problems of long cooking time, physical health damage, people's economic loss, etc., so that it is not easy to be burned Burning, not easy to fire, the effect of ensuring the safety of health and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

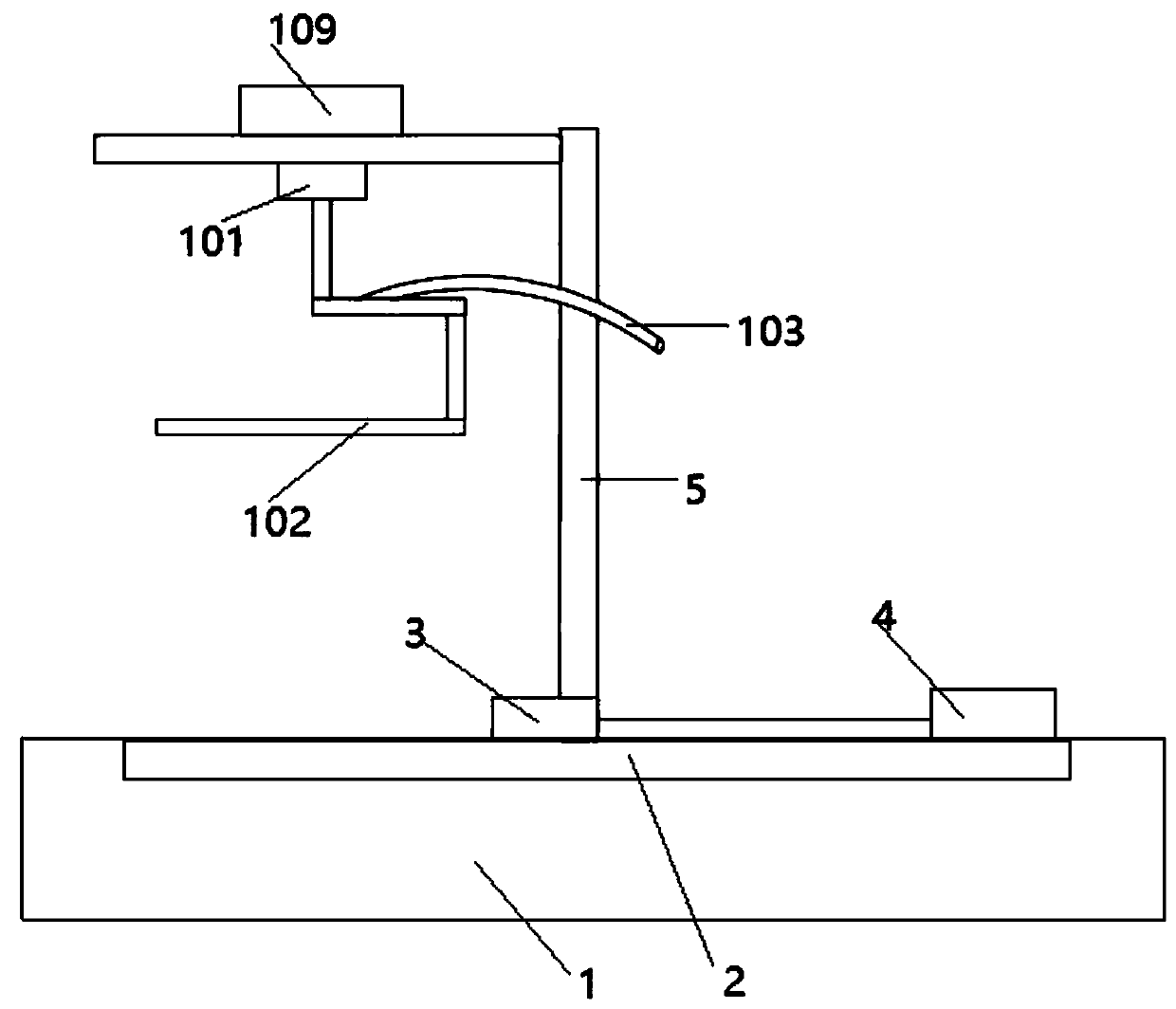

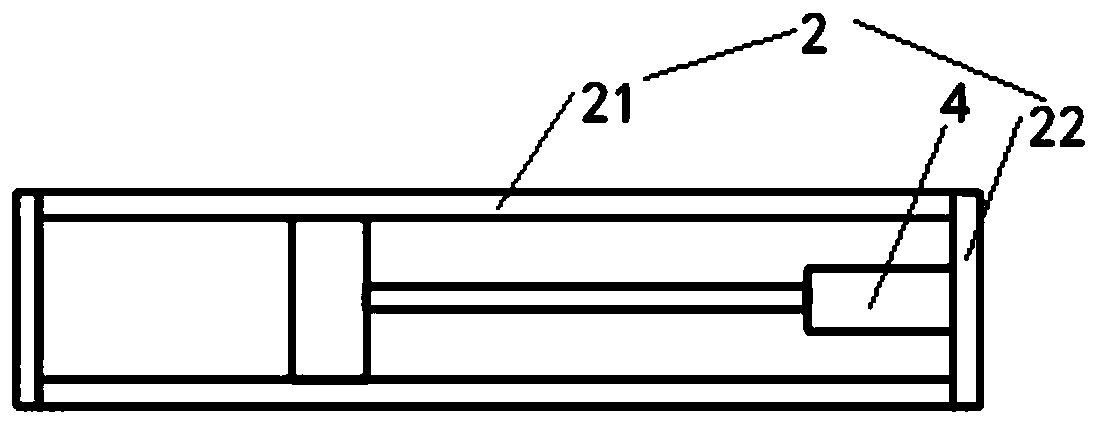

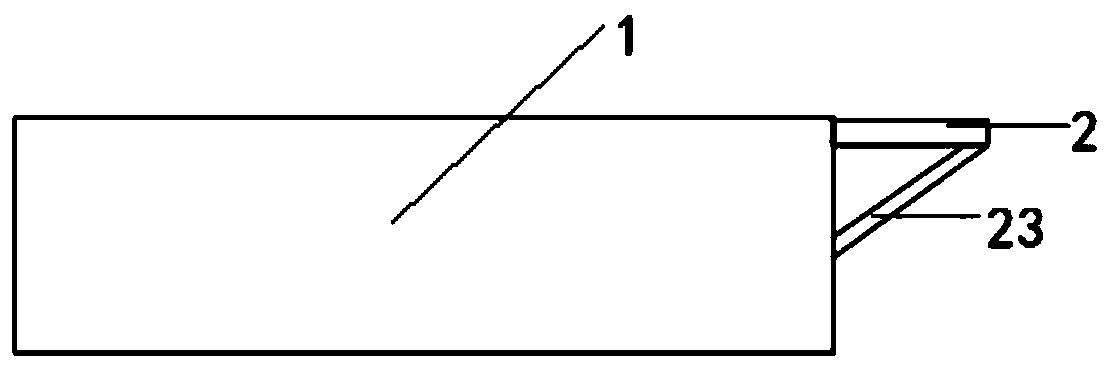

[0038] Such as figure 1 The illustrated embodiment is a gas stove system capable of preventing dry burning, including a gas stove 1, a transverse guide rail 2 arranged on the gas stove, a support plate 3 arranged on the transverse guide rail, and a support plate for driving the support plate to move laterally. The first cylinder 4, the support column 5 located on the support plate, the detection plate 6 located at the upper end of the support column, the temperature and humidity sensor 61 located on the lower surface of the detection plate; also includes a controller 7 and an alarm 9, a gas range It is connected with the air intake pipe, and the air intake pipe is provided with a pressure sensor 11 and a first electromagnetic valve 8, and a second air cylinder 101 is arranged on the lower surface of the detection plate, and the telescopic rod of the second air cylinder is connected with a water pipe 102 closed at both ends, and the upper part of the water pipe is connected with...

Embodiment 2

[0058] Embodiment 2 includes all structure and method parts of embodiment 1, such as Figure 4 As shown, the gas cooker of embodiment 2 is provided with a third cylinder 105, and the telescopic rod of the third cylinder is connected with the flat plate 106, and the flat plate is provided with 5 vertical rods 107 that can extend out of the upper panel of the gas range, and each vertical rod The upper end is connected with the elastic metal ring 108, and the elastic metal ring can contact with the outer peripheral surface of the pot; the upper surface of the detection plate is provided with a rotating motor 109 for driving the rotation of the second cylinder, such as Figure 6 As shown, the third cylinder and the rotating motor are electrically connected to the controller.

[0059] The operator in step 200 of embodiment 1 puts the pot on the hob above the flame injection area of the gas stove, including the following steps:

[0060] The operator puts the pot on the hob above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com