Automatic feeding device

An automatic feeding and suction device technology, applied in the field of feeding devices, can solve the problems of material powder pollution, reduce work efficiency, personal injury, etc., to reduce the risk factor, improve production efficiency, and ensure health and personal safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

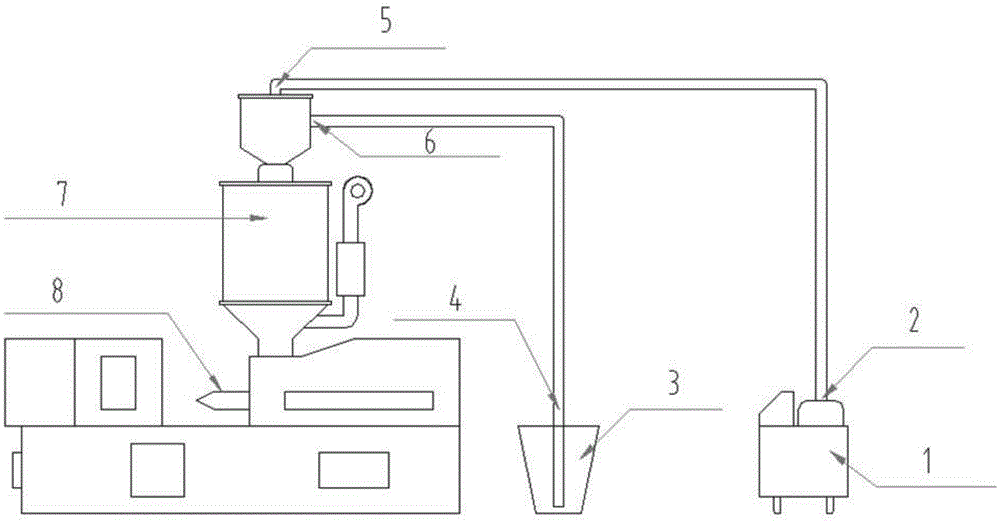

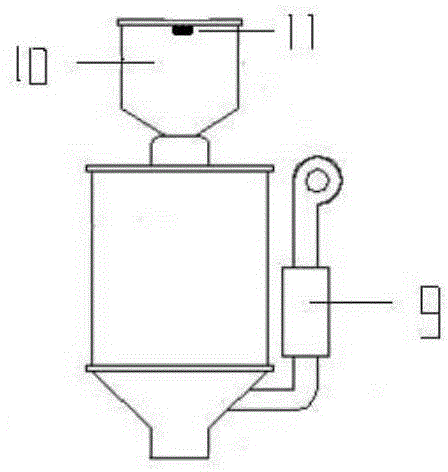

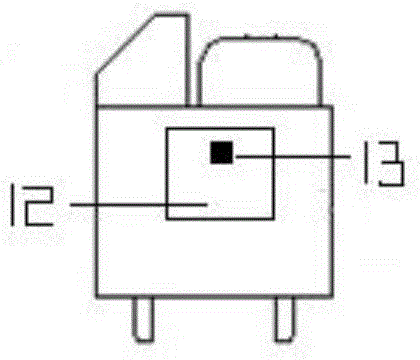

[0018] Such as figure 1 with figure 2 In combination with what is shown, the invention is composed of a barrel body 7, a suction device 10, and a control cabinet 1. The barrel body is a conical metal stainless steel object with a width of 1 meter and a height of 2 meters. The barrel body 7 is connected to a suction device 10, and the suction device 10 is installed on the barrel body 7. The suction device One end of 7 is connected to the air outlet pipe 5, and the other end of the air outlet pipe 5 is connected to the control cabinet 1 through the suction port 2; the other end of the suction device 10 is connected to the suction port 6, which is inserted into the storage barrel through the suction pipe 4 3; A blower 9 is installed at the lower end of the suction device 10, and the blower 9 is electrically connected to the suction device 10. When a signal is sent through the control cabinet 1 to the control module 11 of the suction device 10, its blower 9 starts to work, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com