Long and short hole crossed coal seam water injection method

A coal seam water injection and cross-type technology, which is applied to drilling equipment and methods, earthwork drilling, mining fluids, etc., can solve problems such as increased difficulty and insufficient wetting of coal bodies, achieve uniform stress distribution, and reduce coal dust generation , the effect of suppressing the analytical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

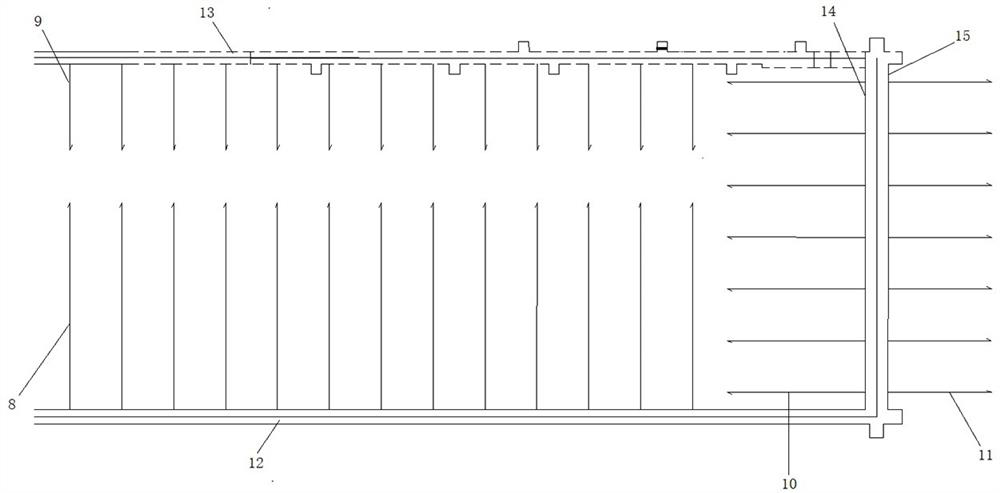

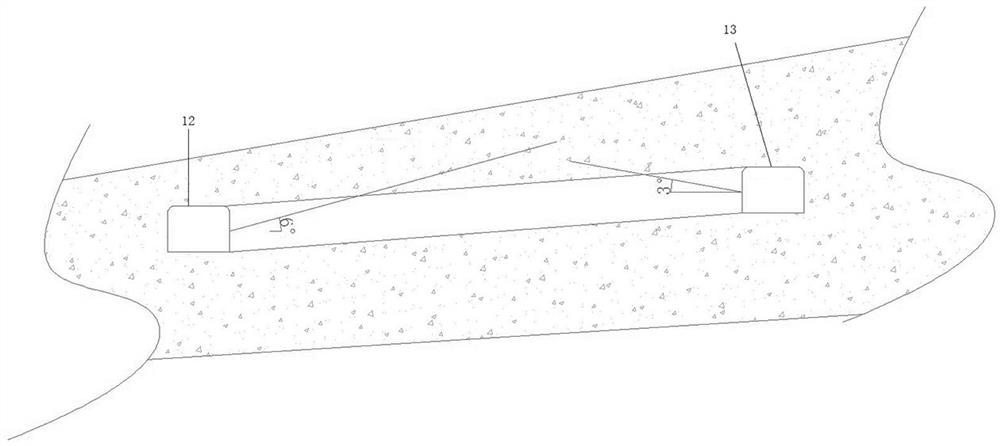

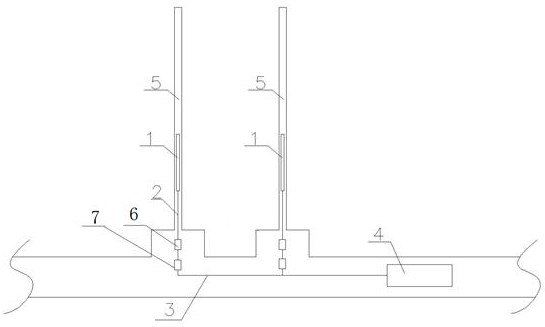

[0027] Such as figure 1 , figure 2 As shown, a long and short hole cross type coal seam water injection method specifically includes the following steps:

[0028] Step 1. Drilling construction: During the excavation, the first long water injection borehole 8 is arranged every 15m along the direction of 6° inclination of the working face, and the first long water injection hole 8 is arranged along the direction of 6° inclination of the working face during excavation. Arrange the first short water injection borehole 10 at 15m, and arrange the second long water injection borehole 9 every 15m along the inclination direction of the working face 14 along the 3° inclination direction of the working face. A second short water injection borehole 11 is arranged every 15m in the direction, the depth of the first long water injection borehole 8 on the air inlet trough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com