Casting iron pan polishing machine

A technology of polishing machine and cast iron pot, applied in grinding/polishing equipment, grinding workpiece support, grinding machine, etc., can solve the problems of cumbersome process, dust pollution, low polishing efficiency, etc., to improve efficiency, protect physical health and life Safe and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

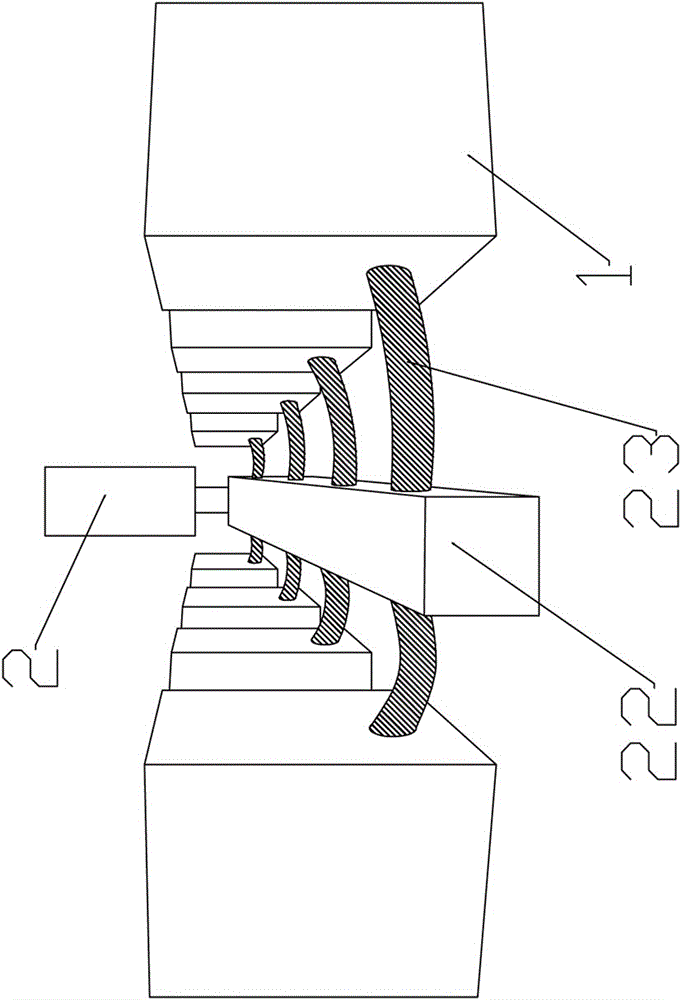

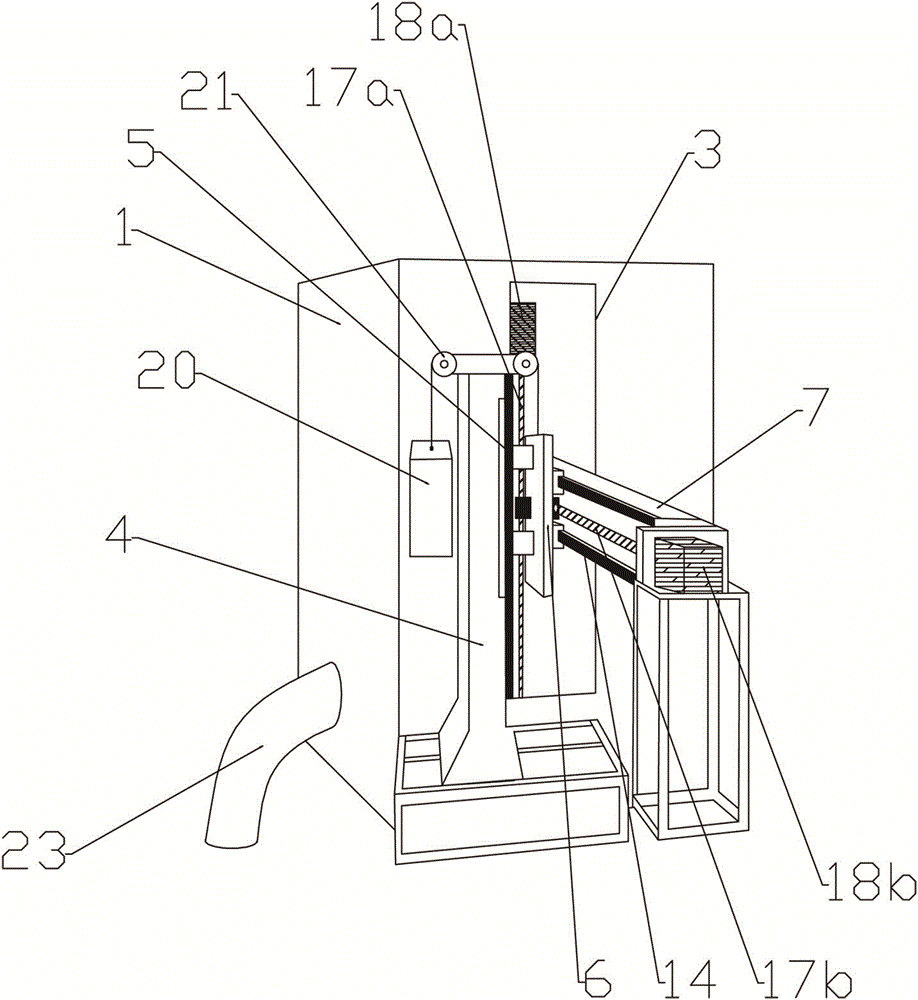

[0037] Embodiment 1: a kind of cast iron pan polishing machine, as Figure 1~17 As shown, it includes a chassis 1 and a dust removal device 2 connected to the chassis. The side wall of the chassis is vertically provided with an excavation frame 3, and a transmission device is arranged at the excavation frame. A machine head device is arranged on the top of the interior of the chassis, and a workpiece fixing device is arranged on the bottom. ;

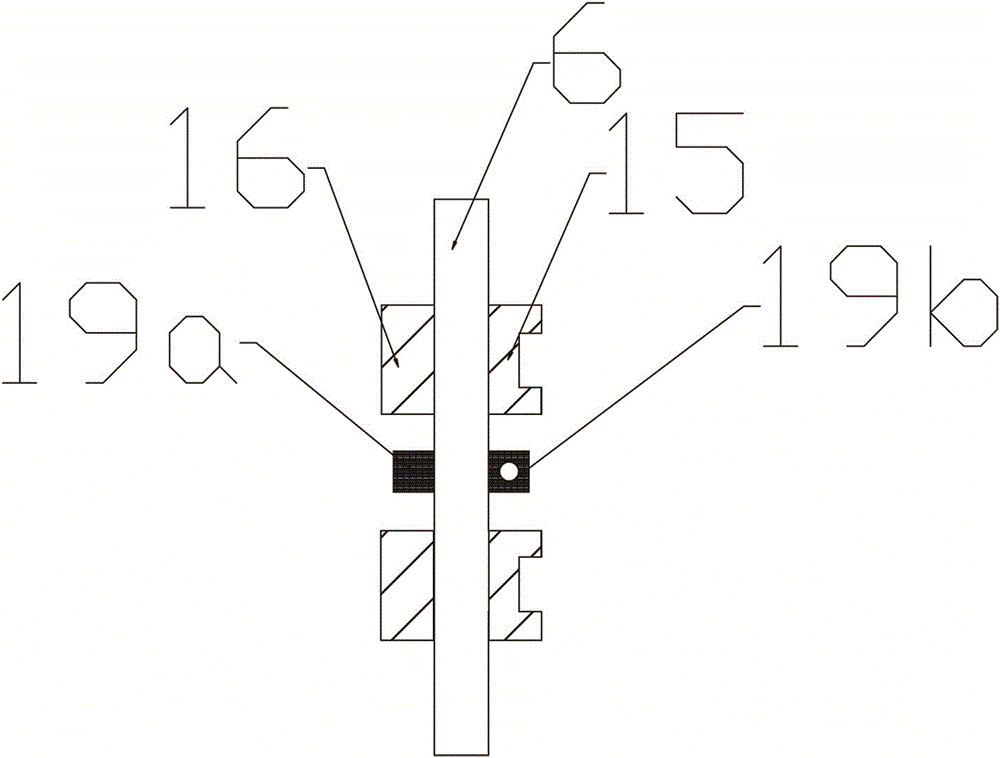

[0038]The transmission device includes a vertical arm 4 arranged outside the chassis, on which a vertical guide rail 5 is installed, on the vertical guide rail is provided with a fixed seat 6 that moves up and down along the direction of the guide rail, and on the fixed seat is provided with a front and rear horizontally movable Cross arm 7, horizontal guide rail 14 is provided on the cross arm, the horizontal chute 15 that cooperates with horizontal guide rail is installed on one side of fixed base 6, the vertical chute 16 that coopera...

Embodiment 2

[0043] Example 2: The cast iron pan polisher of the present example will be described centering on the differences from the cast iron pan polisher related to Example 1.

[0044] like Figure 8~10 As shown, the abrasive belt support wheel mounting device is fixedly installed on the two support wheel mounting plates 10, which includes a support wheel fixed seat plate 24 fixedly installed on the outside of the support wheel mounting plate, and a guide hole is arranged on the support wheel fixed seat plate. The guide rod 25 is inserted in the guide hole, the guide rod is provided with a positioning nut 26, the positioning nut is located above the support wheel fixed seat plate, the lower end of the guide rod is fixedly connected with the support wheel mounting seat 27, and the abrasive belt support wheel 12 is installed through the pin shaft On the support wheel mounting seat, the guide rod 25 is also provided with a compression spring 28, and the compression spring is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com