Probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment

A technology for charging and discharging equipment and cleaning tools, which is applied in the field of automatic cleaning tools for the probes of cylindrical lithium battery charging and discharging equipment. Property safety, the effect of avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

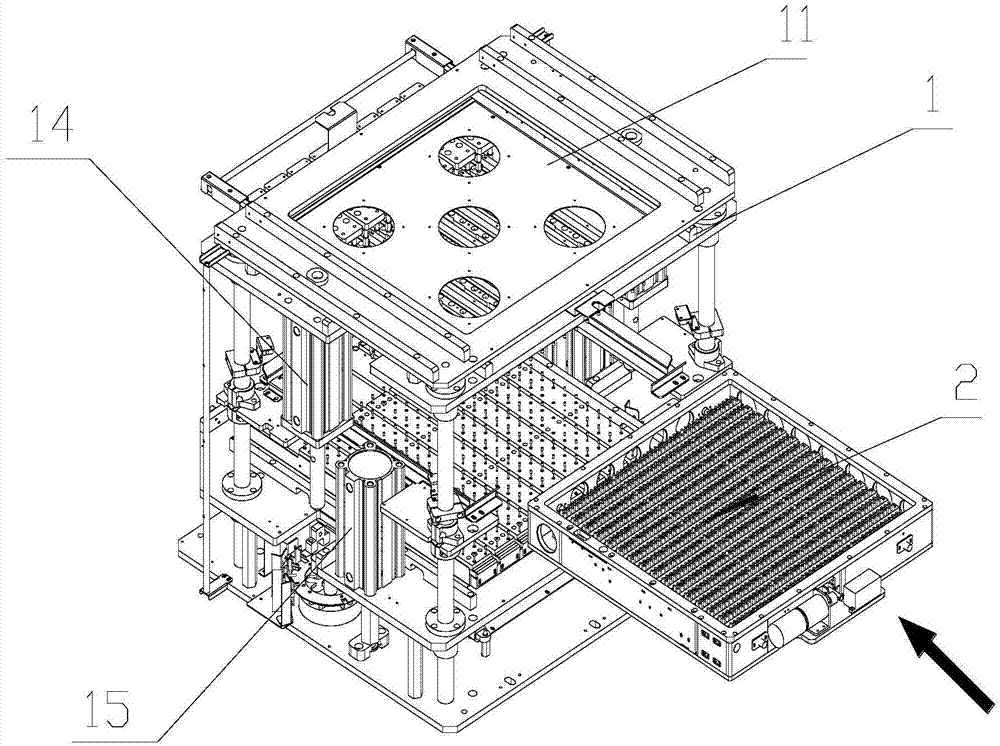

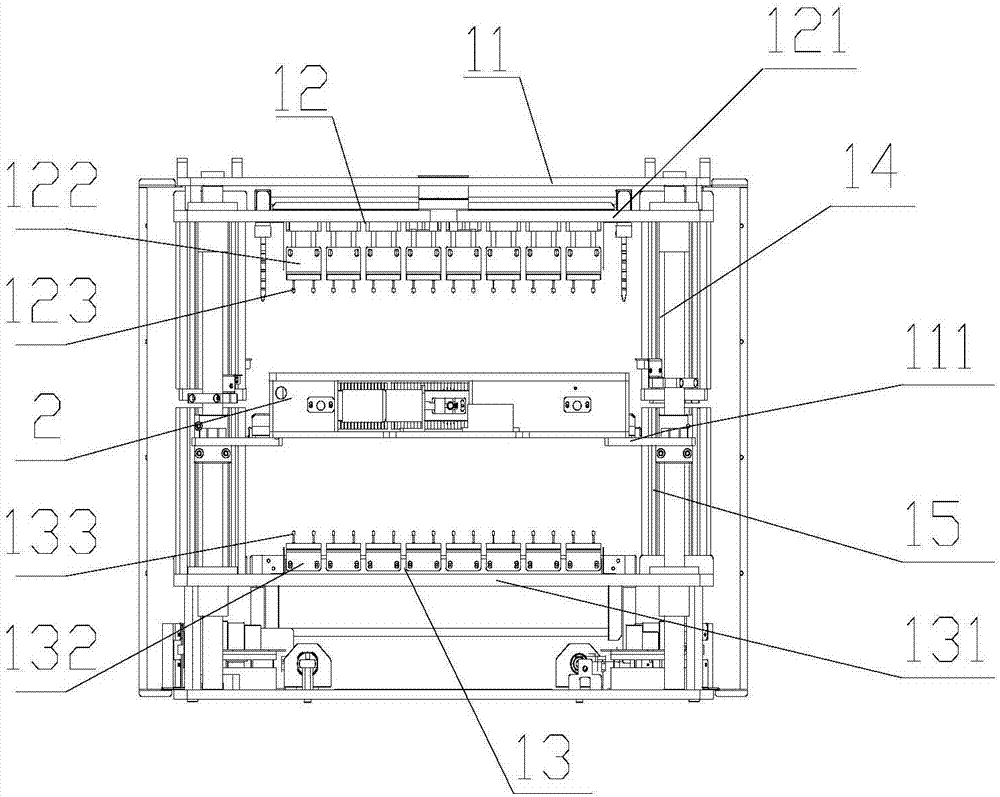

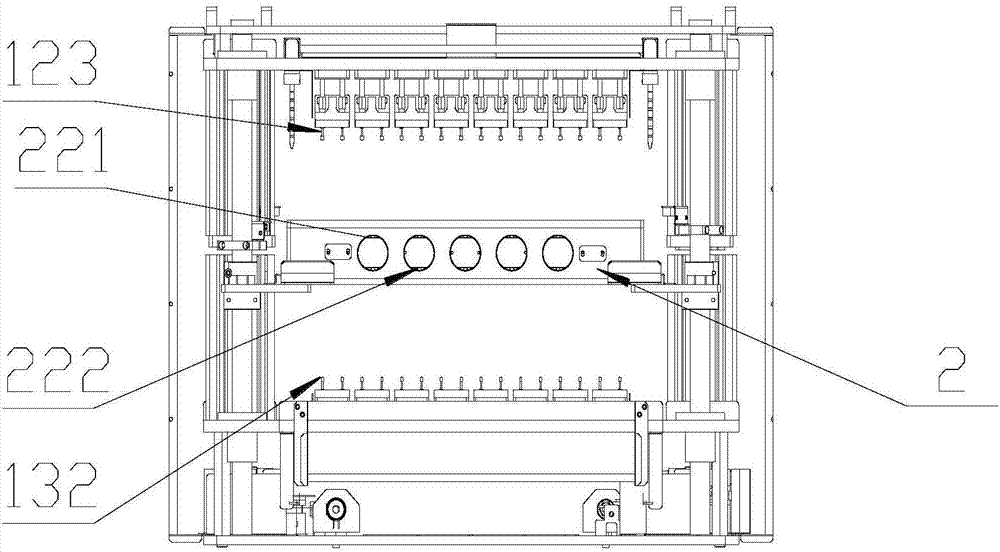

[0028] Embodiment 1 The cylindrical lithium battery charge and discharge equipment probe automatic cleaning tool according to the present invention includes a secondary charge and discharge inspection device 1 for charging and discharging a cylindrical lithium battery and a cleaning tool for the secondary charge and discharge inspection equipment. The cleaning equipment 2, the secondary charge and discharge inspection equipment 1 includes a mounting frame 11 for installing the entire equipment, an upper probe assembly 12 for contacting with the positive pole of the cylindrical lithium battery, and an upper probe assembly 12 for contacting the negative pole of the cylindrical lithium battery. The contacted lower probe assembly 13, the upper pneumatic element 14 for adjusting the longitudinal position of the upper probe assembly, and the lower pneumatic element 15 for adjusting the longitudinal position of the lower probe assembly, on the mounting frame 11 along its axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com