Package machine of cylindrical battery roll core

A technology of cylindrical battery and casing machine, which is applied in the direction of primary battery, secondary battery manufacturing, battery pack parts, etc. It can solve the problems of low production efficiency and discontinuous quality, so as to improve production efficiency, reduce defective rate, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

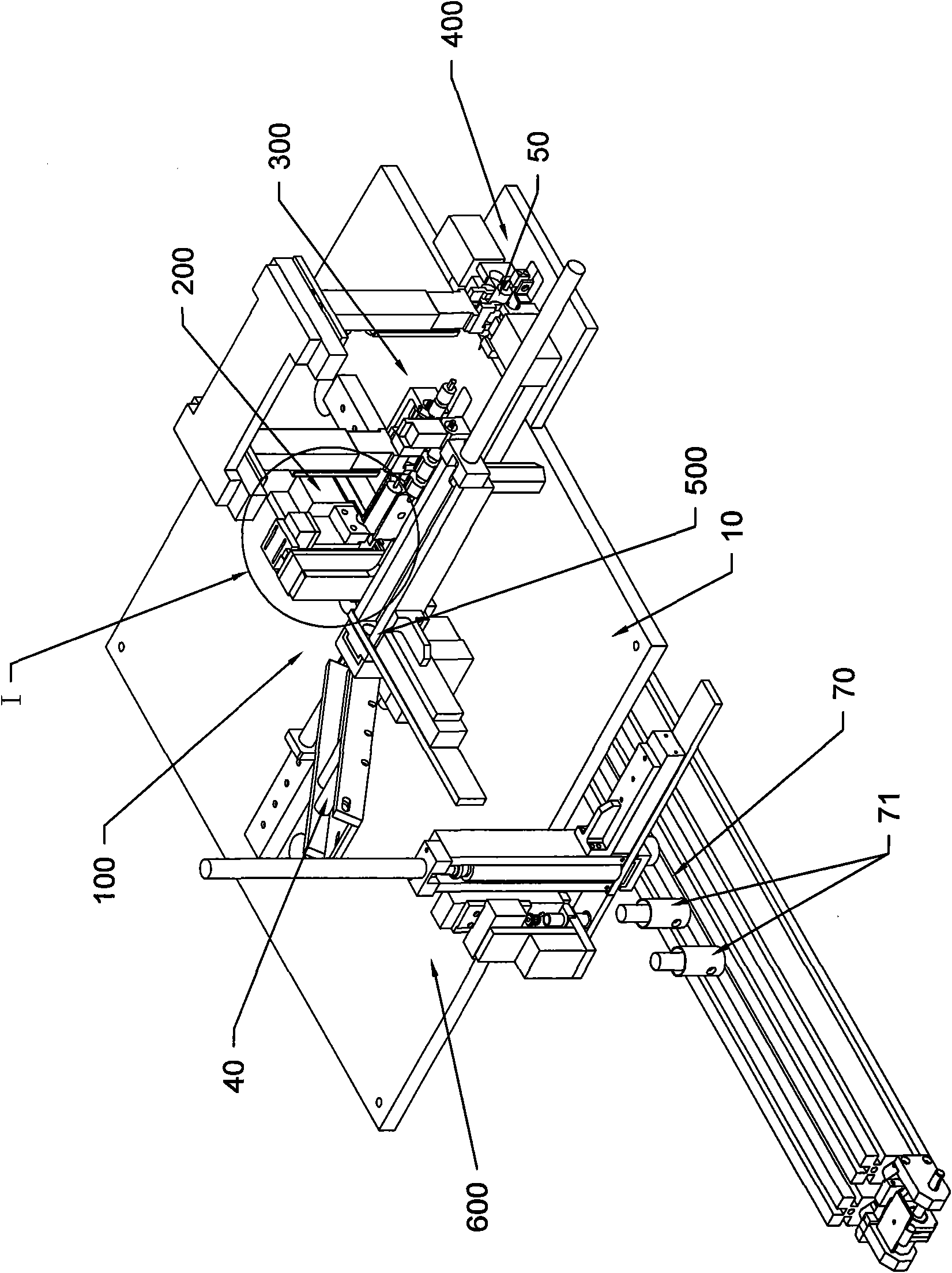

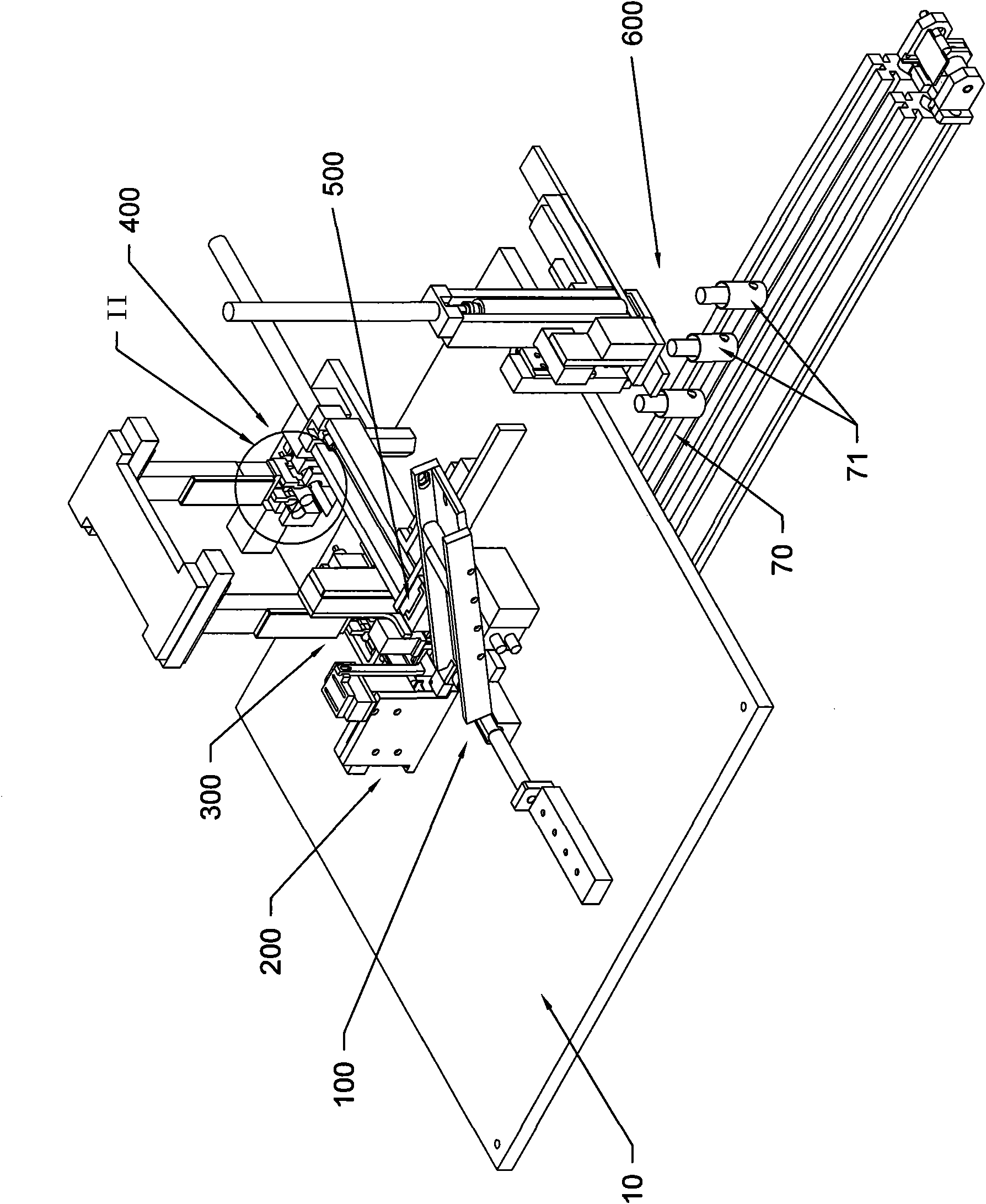

[0036] During the processing of cylindrical batteries, the positive and negative electrode sheets and separator paper are usually rolled into a cylindrical shape to form a core. In the mass production process, the winding core is usually processed by a dedicated winding core machine for use in the next process. The processed winding core also needs to go through processes such as shaping, bending the negative tab, inserting the lower insulating sheet, winding the core into the shell, inserting the upper insulating sheet, and bending the positive tab to complete the process of winding the core into the shell; The cover plate and the conductive terminals are sealed to form the finished product of the cylindrical battery.

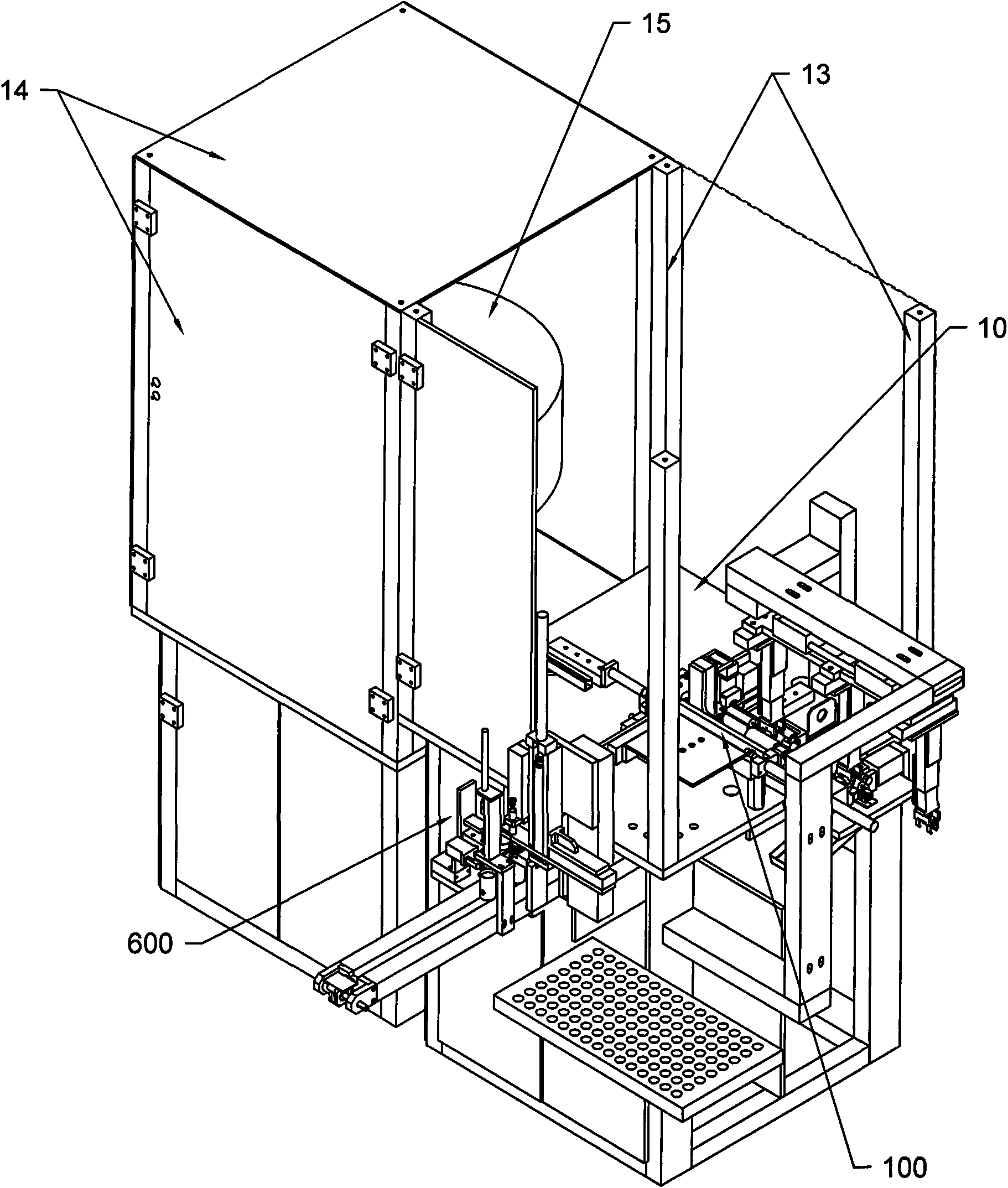

[0037] The winding core shelling machine of the present invention can automatically complete the process of rolling cores into the shell. likefigure 1 As shown, in the preferred embodiment of the winding core casing machine of the present invention, it includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com