Patents

Literature

39results about How to "Quick cleaning operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

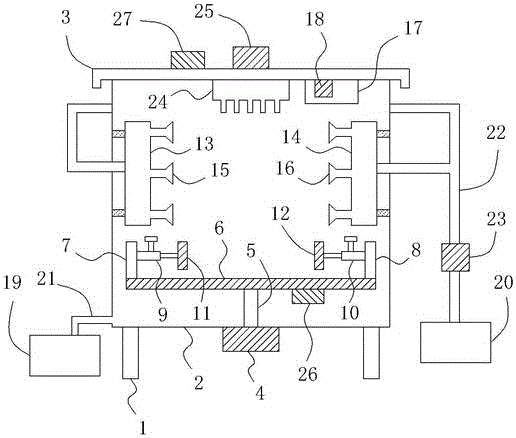

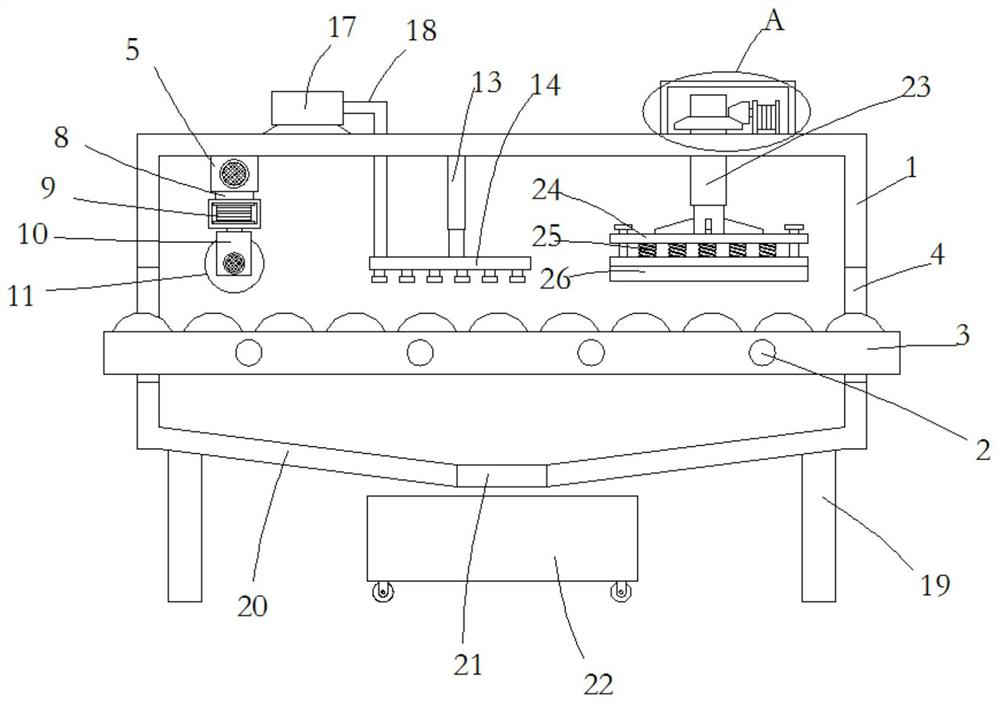

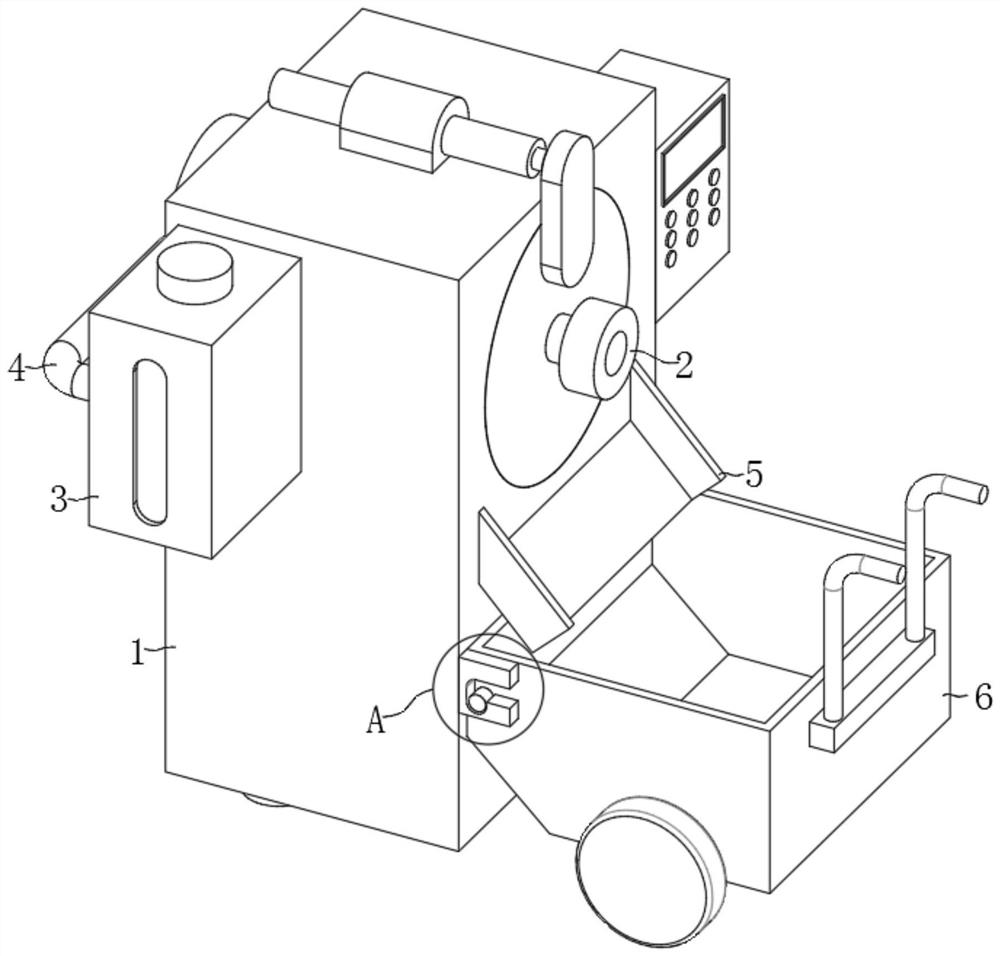

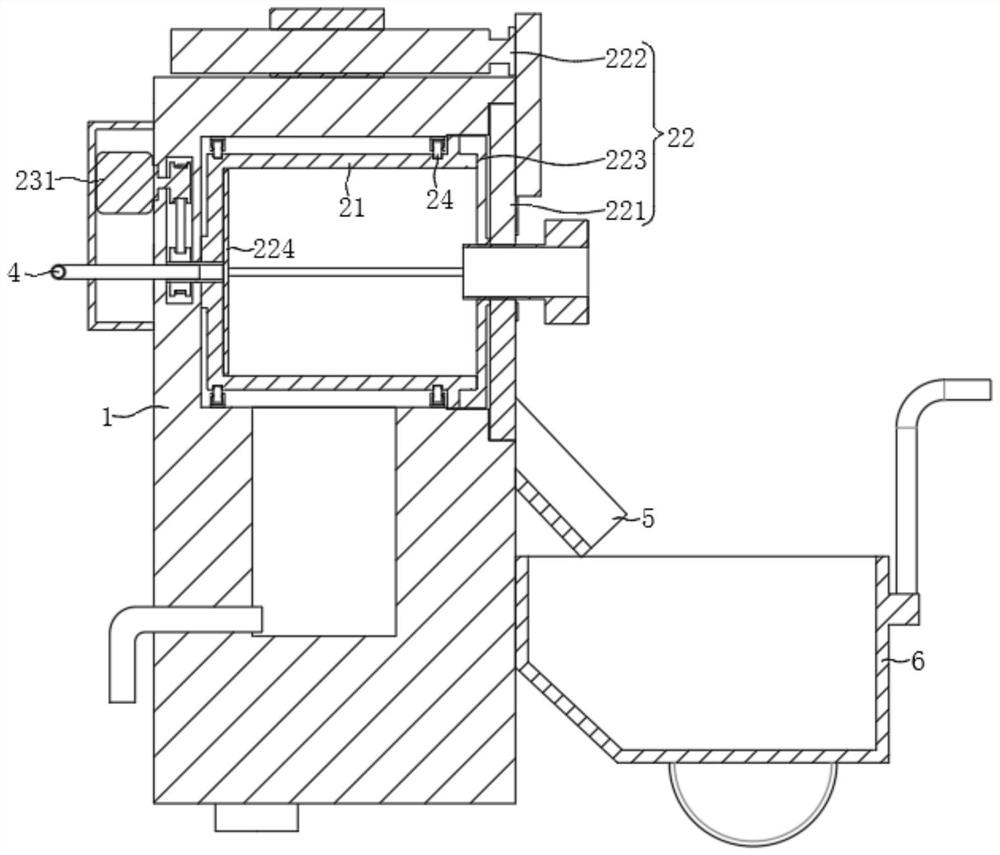

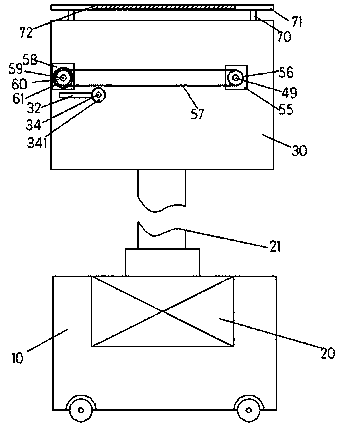

Novel electromechanical washing device

InactiveCN106000966AEasy to disassemble and operateQuick cleaning operationElectric circuit arrangementsLighting elementsMicrocontrollerSewage

The invention relates to a novel electromechanical washing device which comprises a bracket, a box body and a box cover, wherein a motor is arranged below the box body, and is connected with a rotating shaft; the top end of the rotating shaft is connected with a tray; a left baffle plate and a right baffle plate are arranged at the left end and the right end of the tray; a left expansion rod and a right expansion rod are respectively arranged at the right side of the left baffle plate and the left side of the right baffle plate; a left clamping plate and a right clamping plate are respectively arranged at the right end of the left expansion rod and the left end of the right expansion rod; a left spray pipe and a right spray pipe are respectively arranged at the left end and the right end in the box body; a plurality of left spray heads and right spray heads are arranged on the left spray pipe and the right spray pipe; a transparent cover body is arranged at the bottom end of the box cover; a camera, a microcontroller and a wireless emitter are arranged in the transparent cover body; a sewage box is arranged at the left of the box body; a water purifying box is arranged at the right of the box body; a drainage port of the box body is connected with the sewage box through a drainage pipe; the water purifying box is connected with the left spray pipe and the right spray pipe through a water discharge pipe; and a pump body is arranged on the water discharge pipe. With the adoption of the structure, washing operation can be carried out more conveniently, quickly and sufficiently, and drying treatment can be conducted effectively after washing.

Owner:CHENGDU KECHUANG JIASI TECH

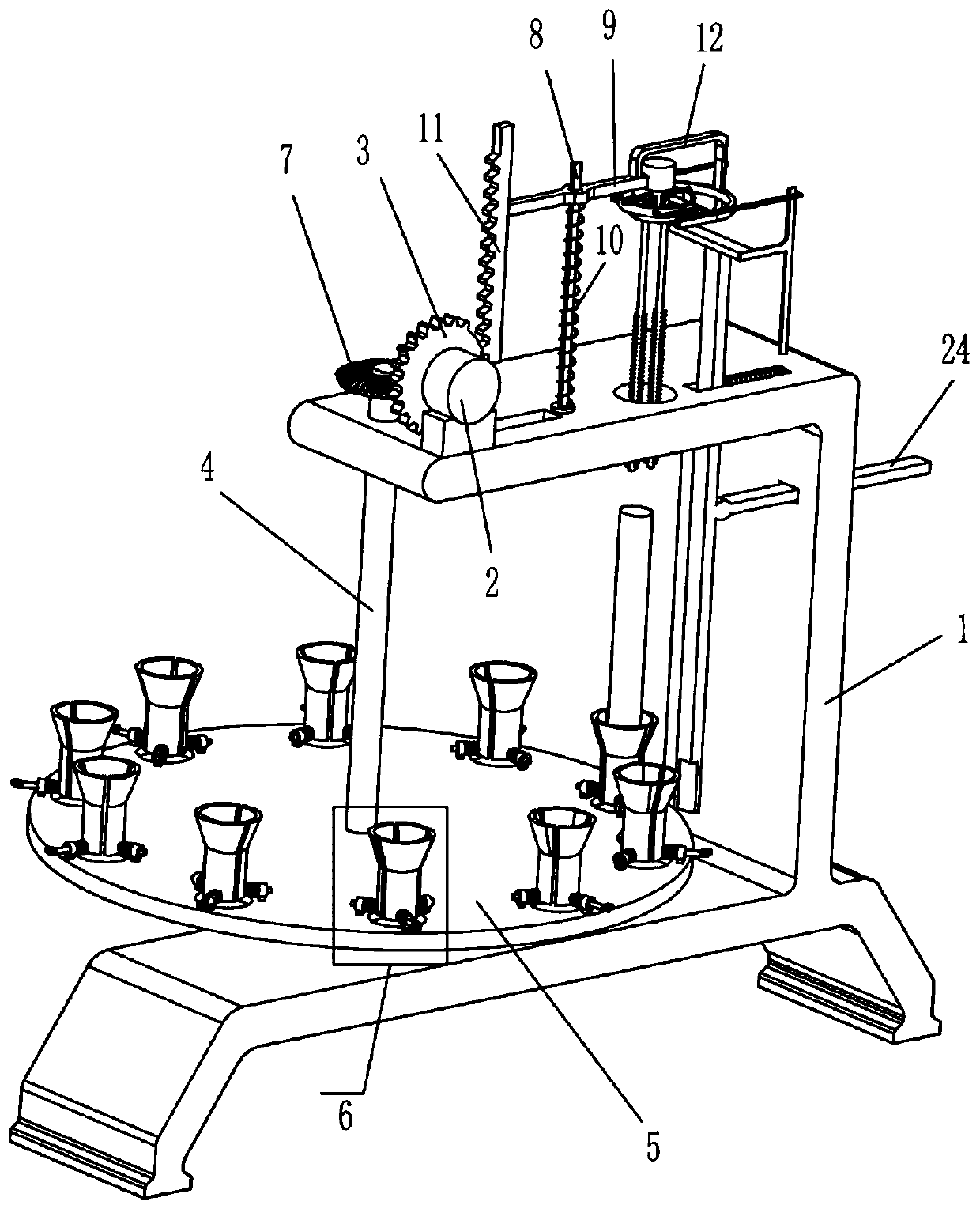

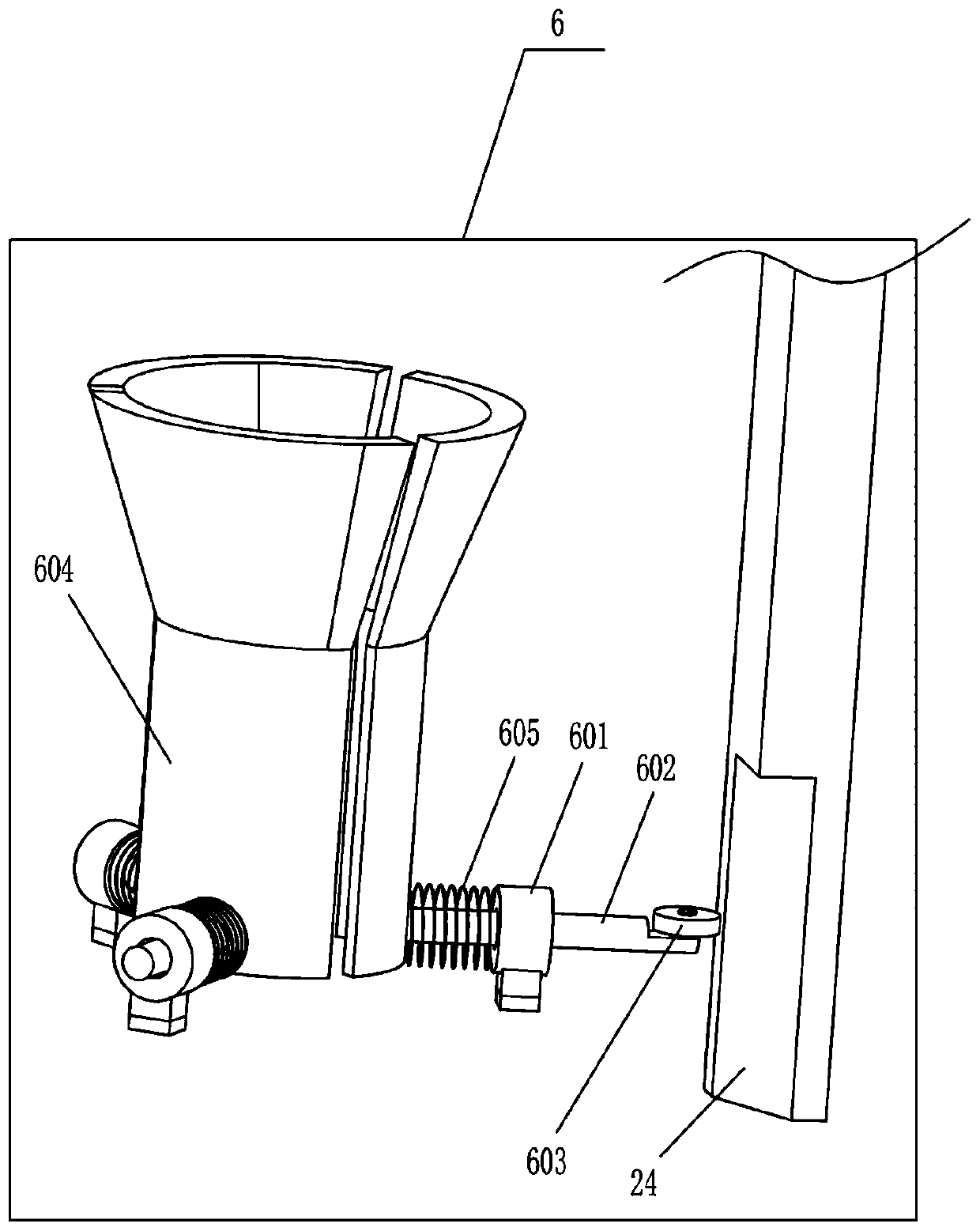

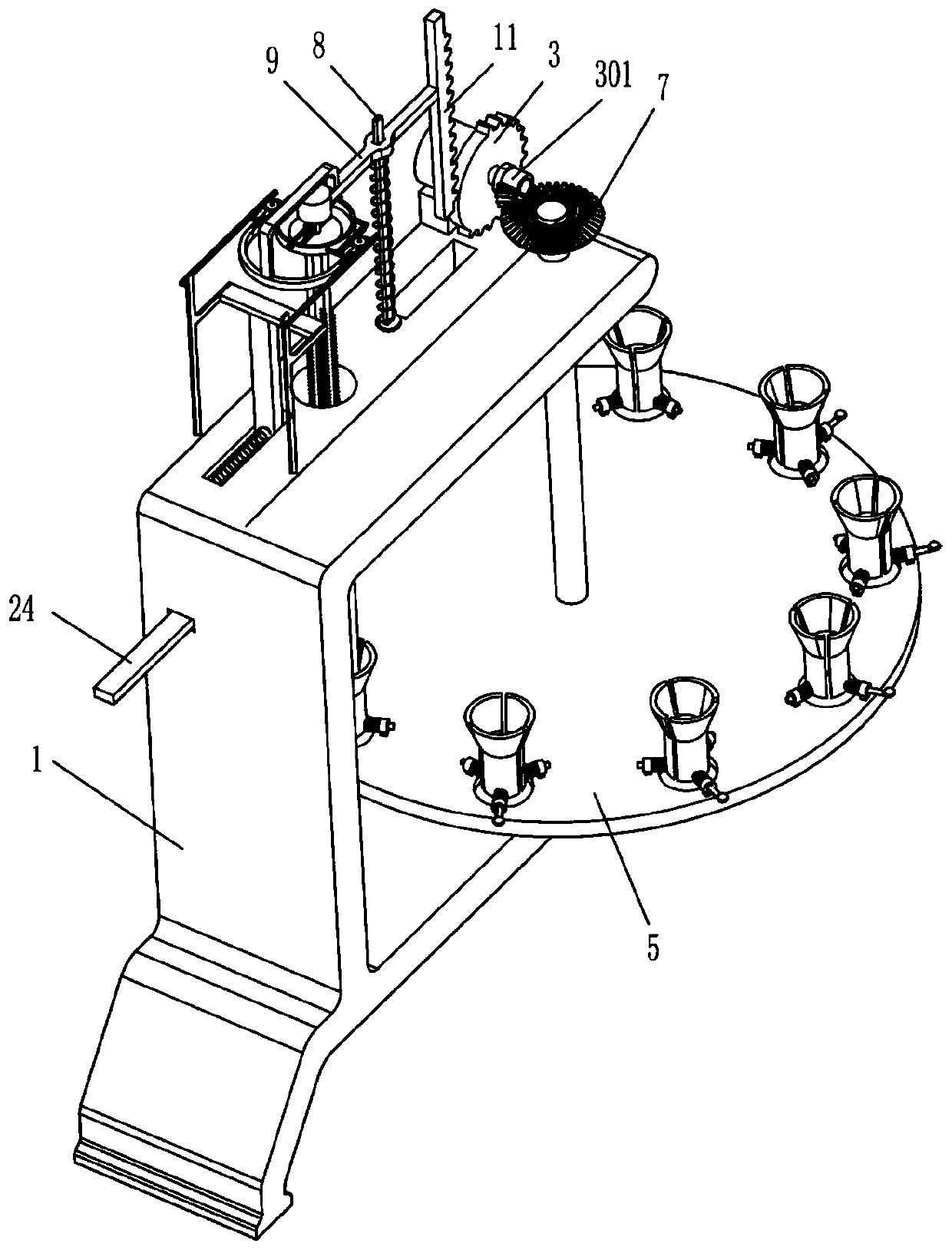

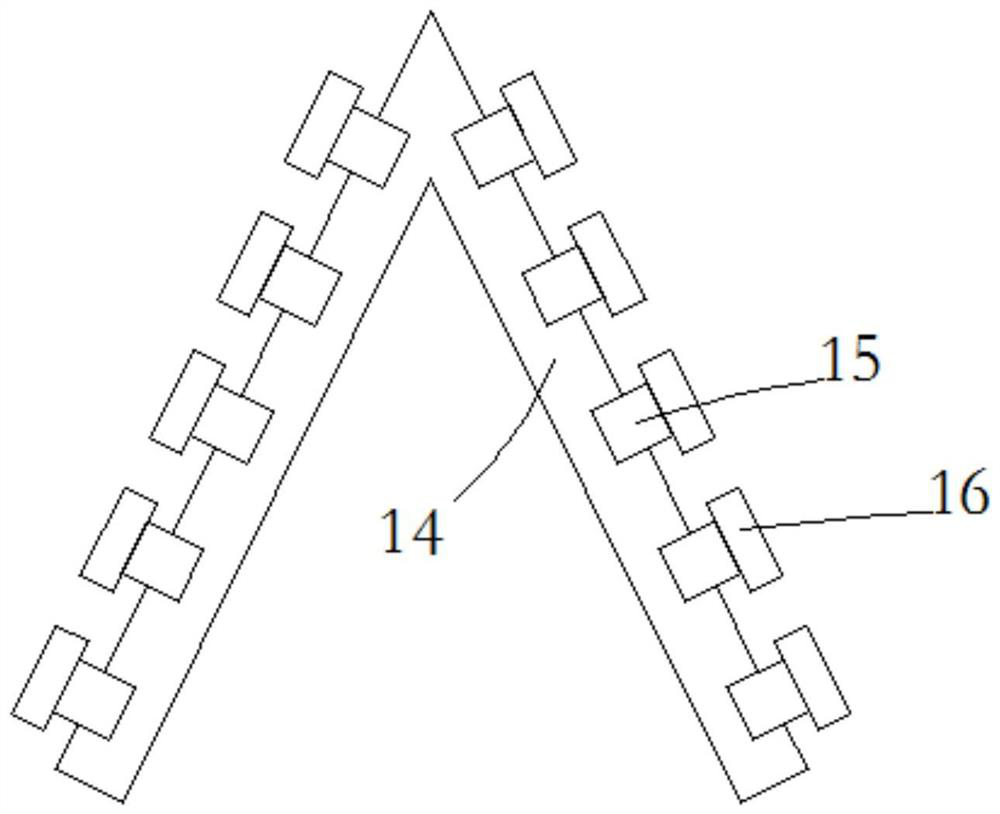

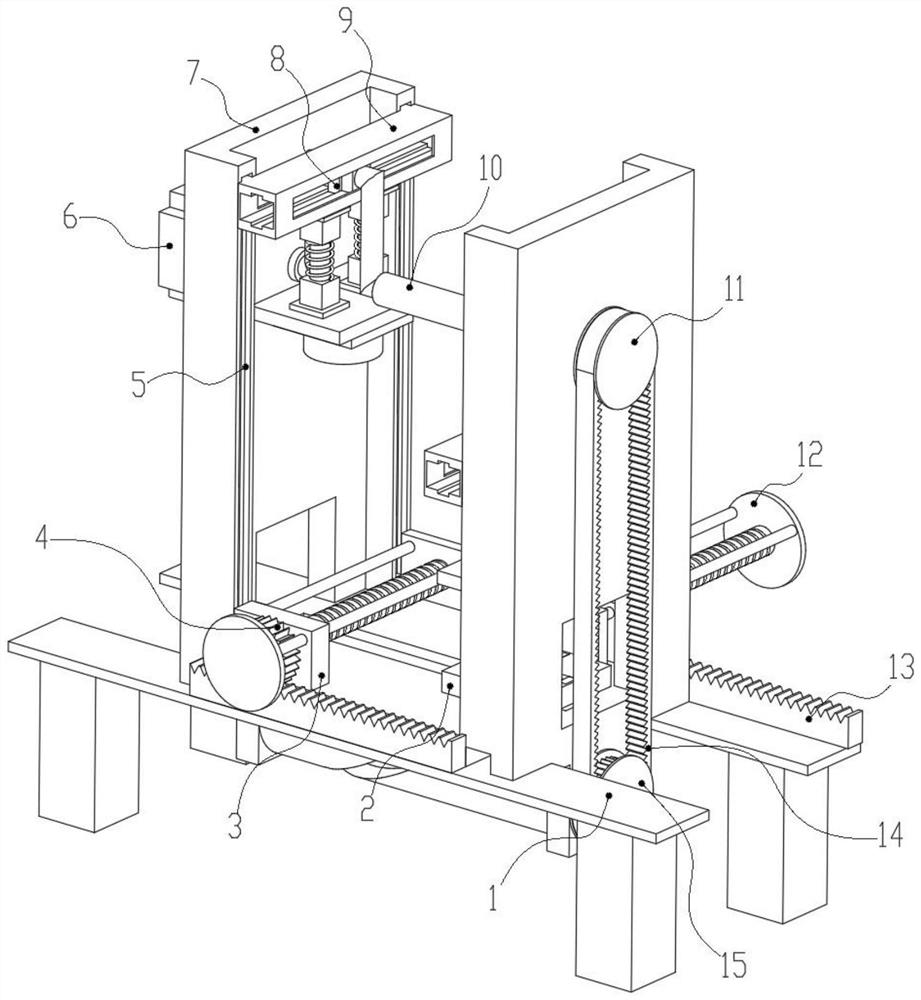

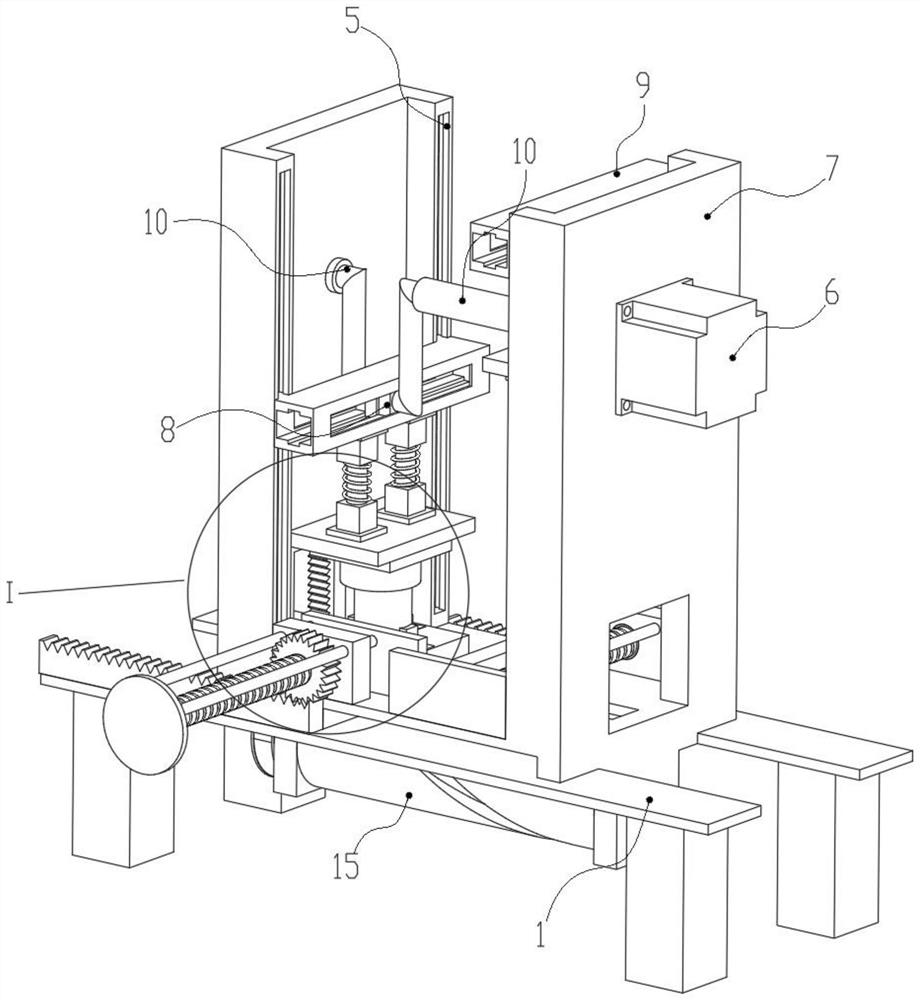

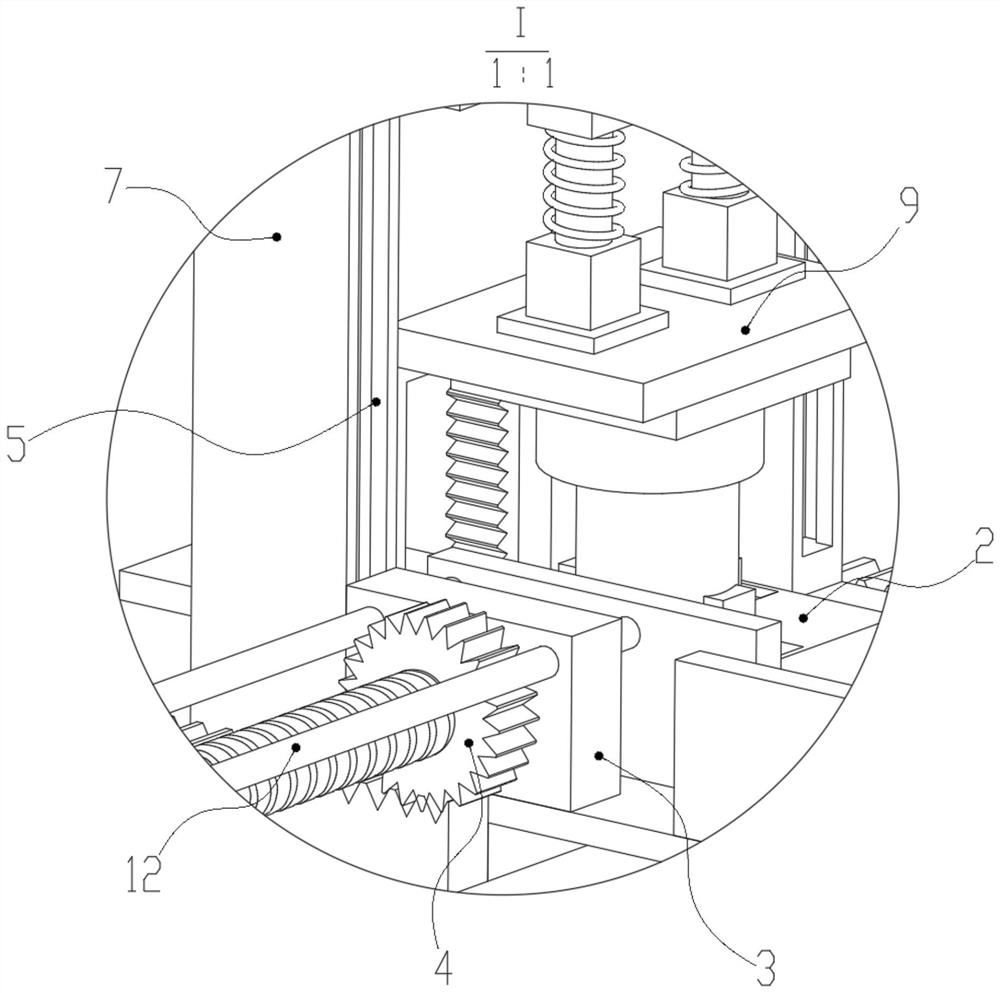

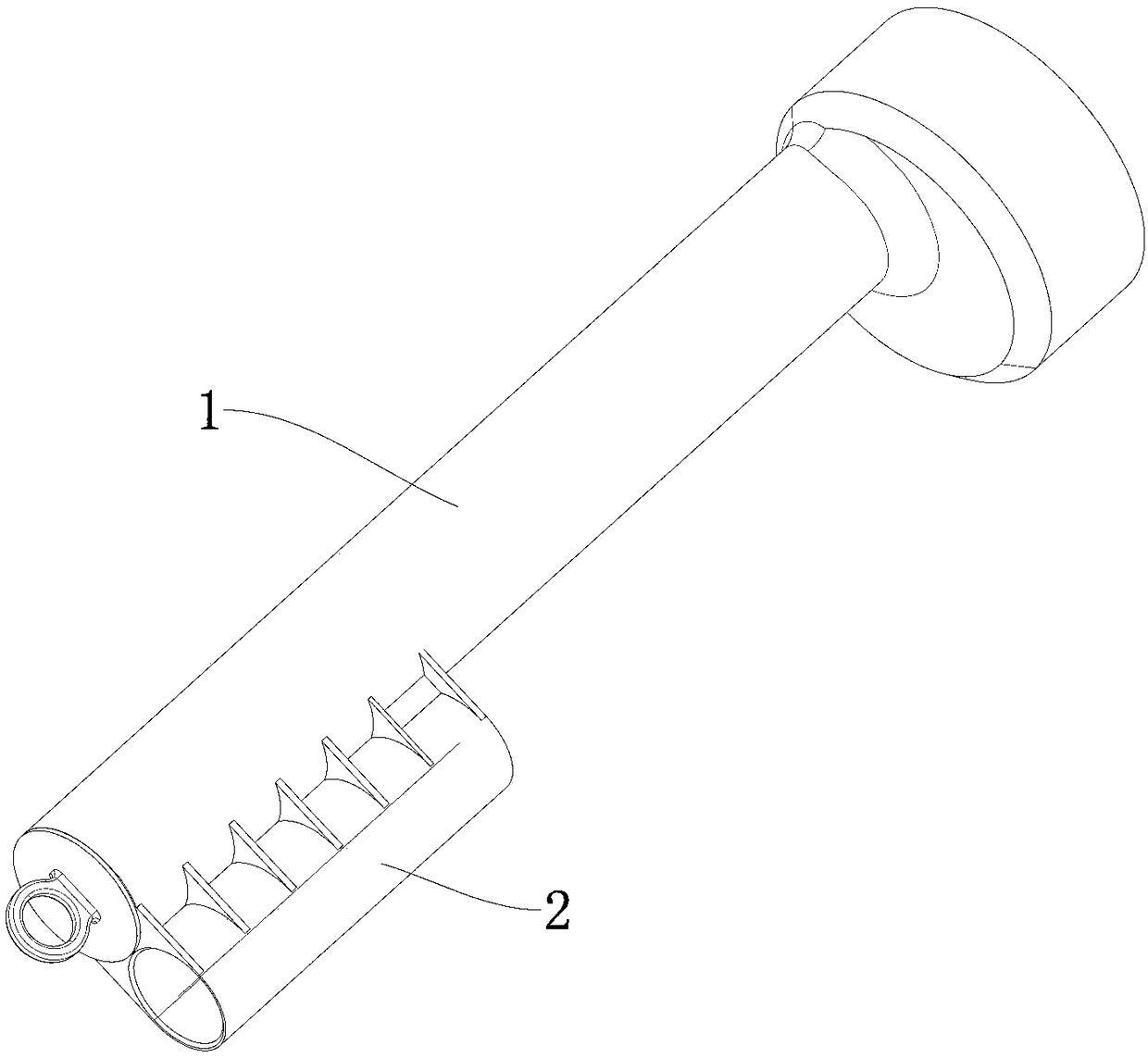

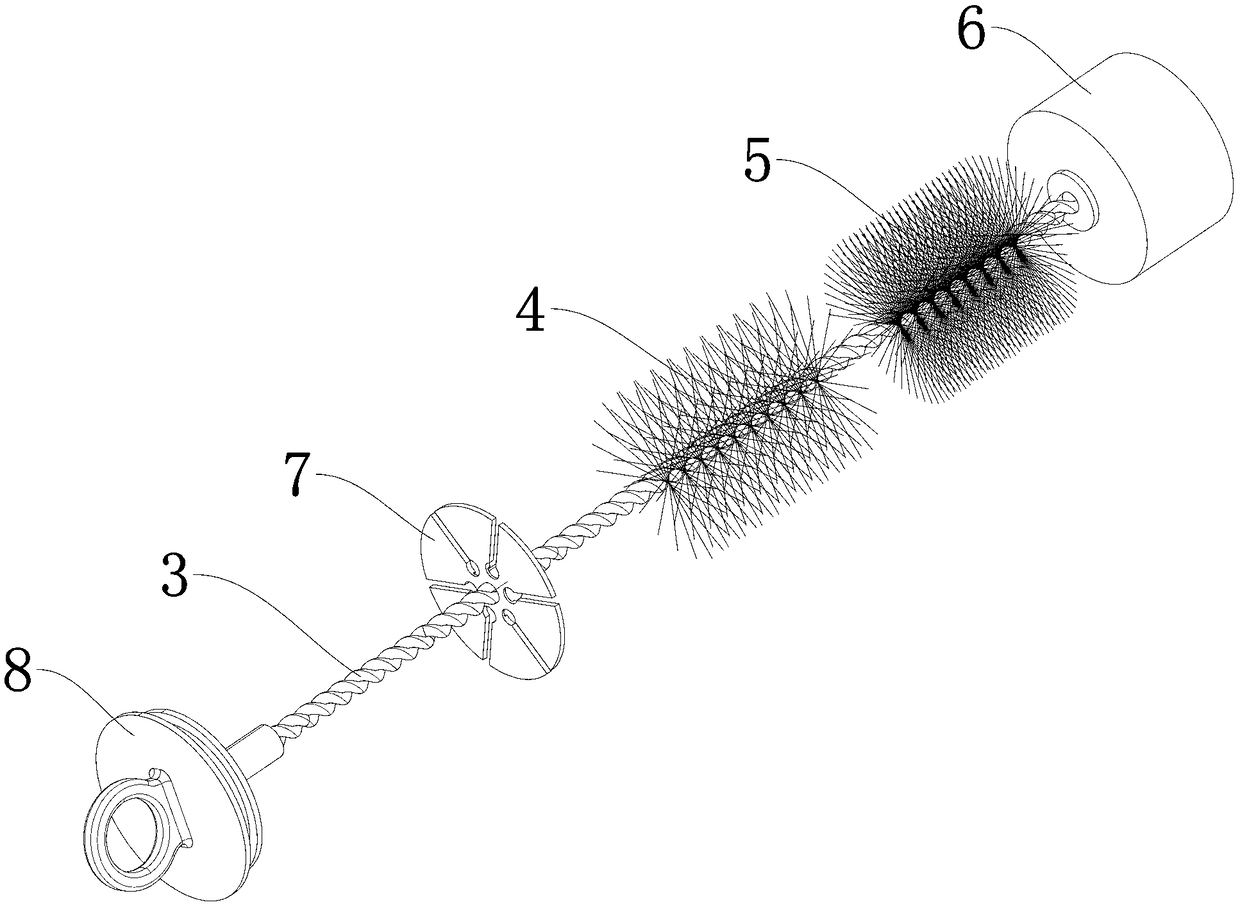

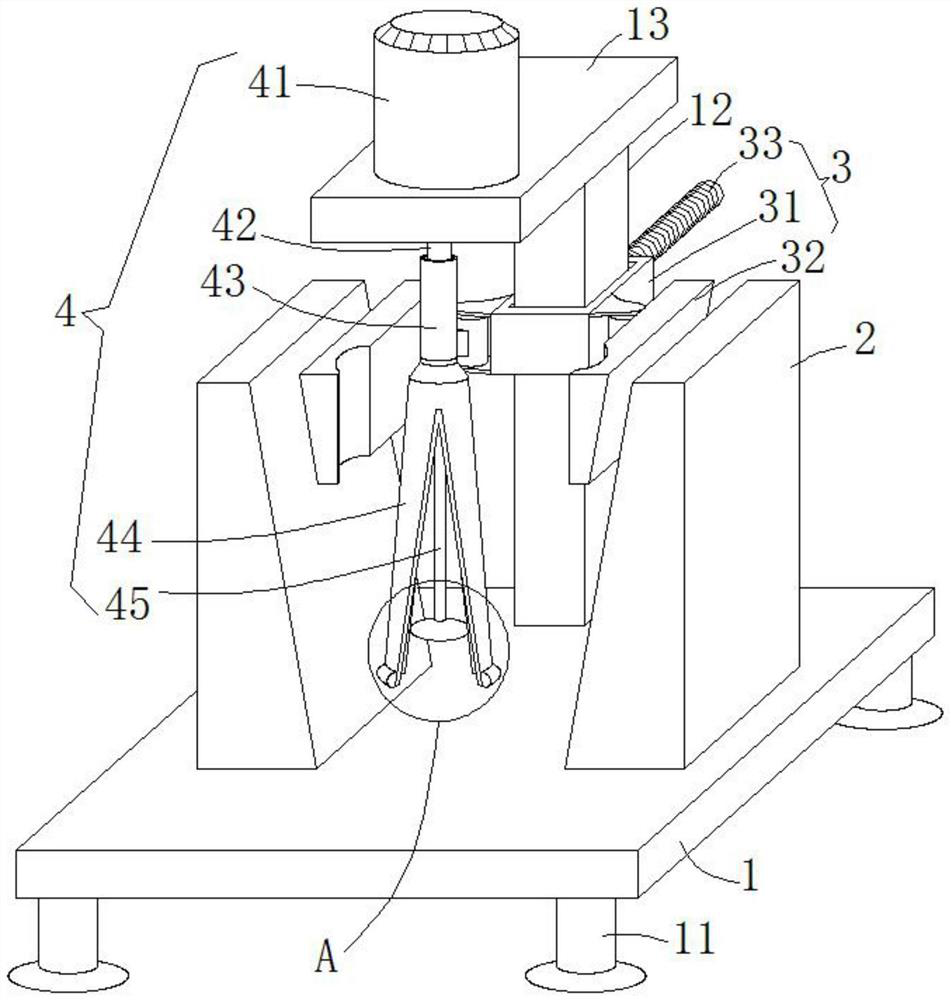

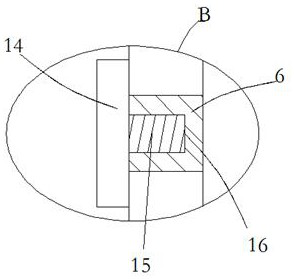

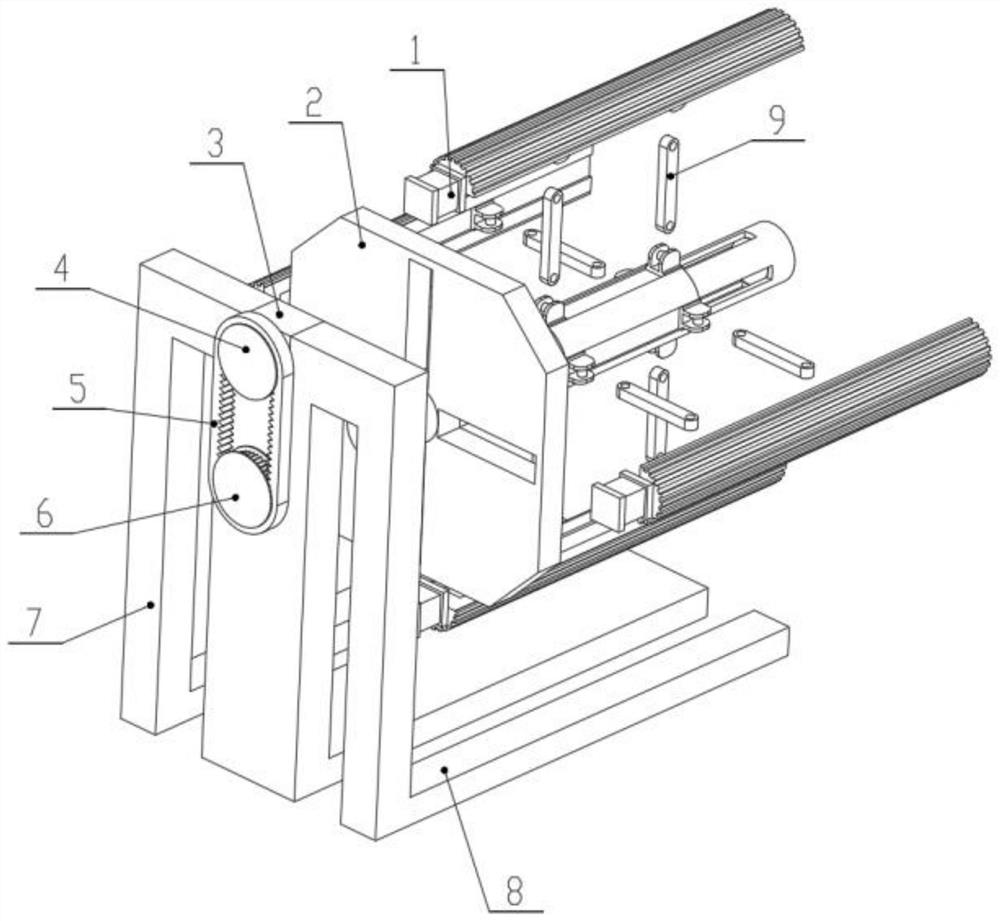

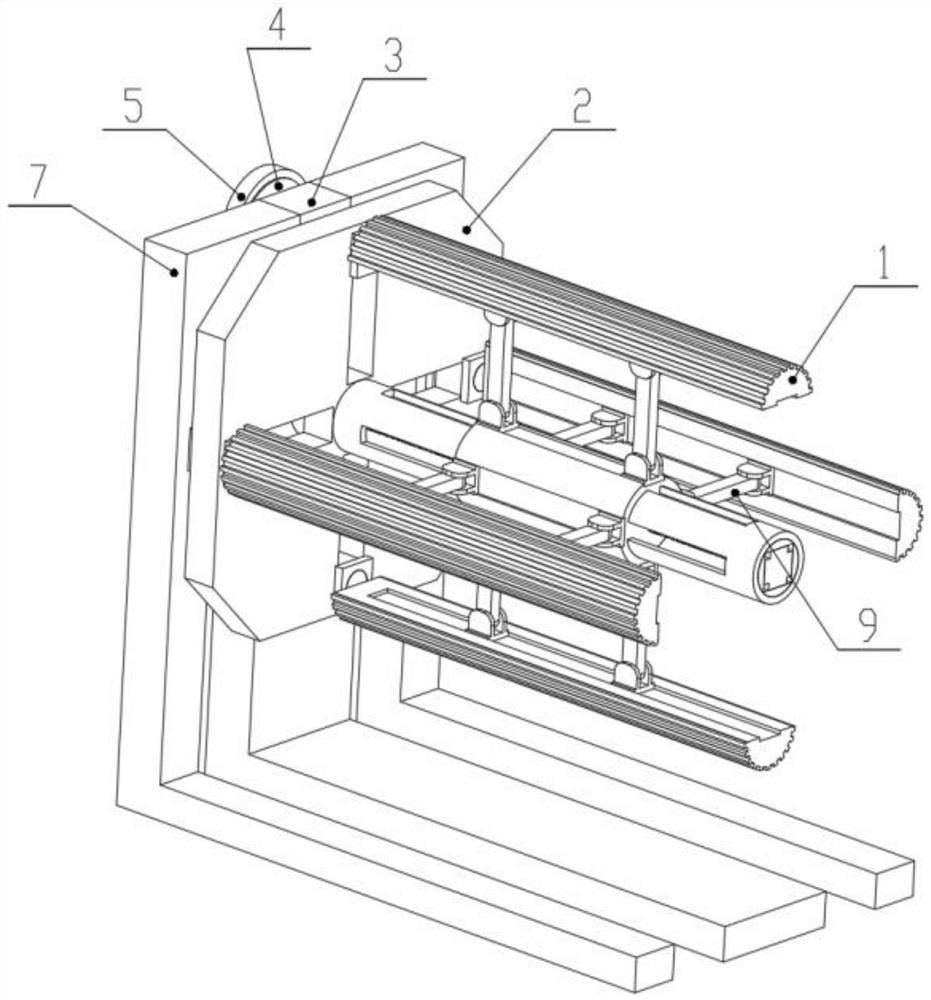

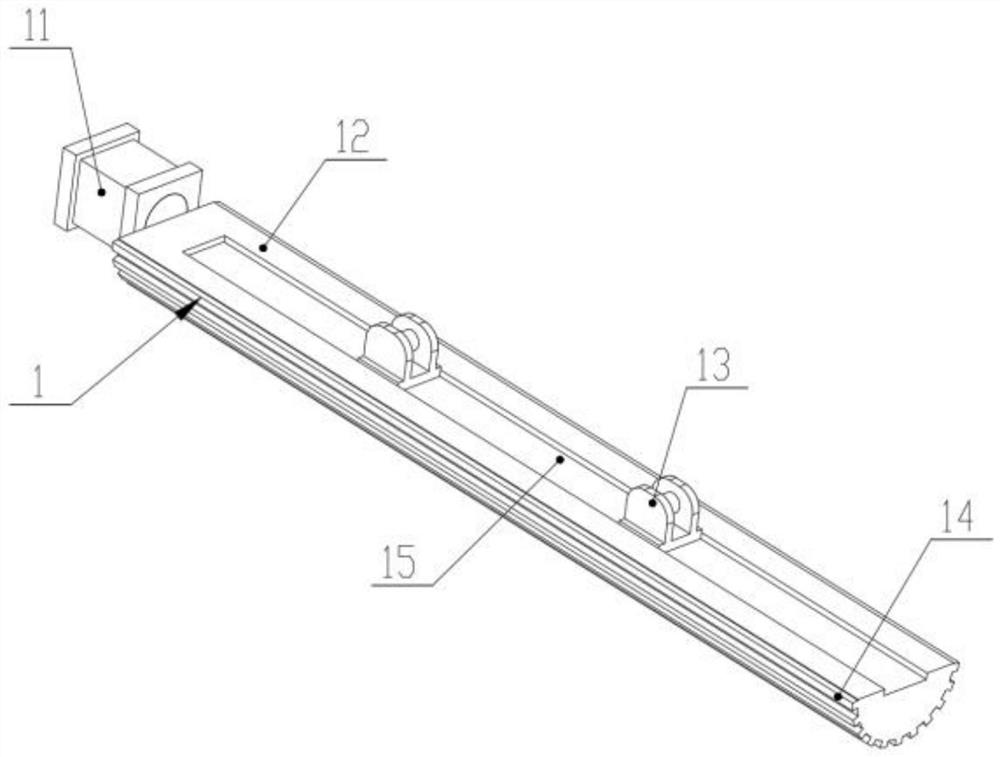

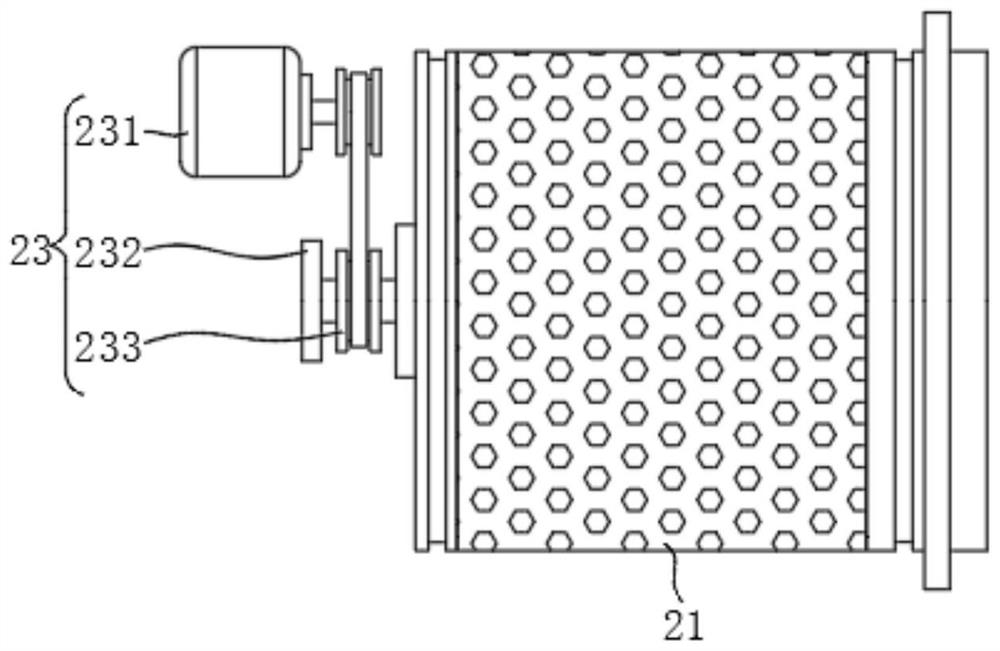

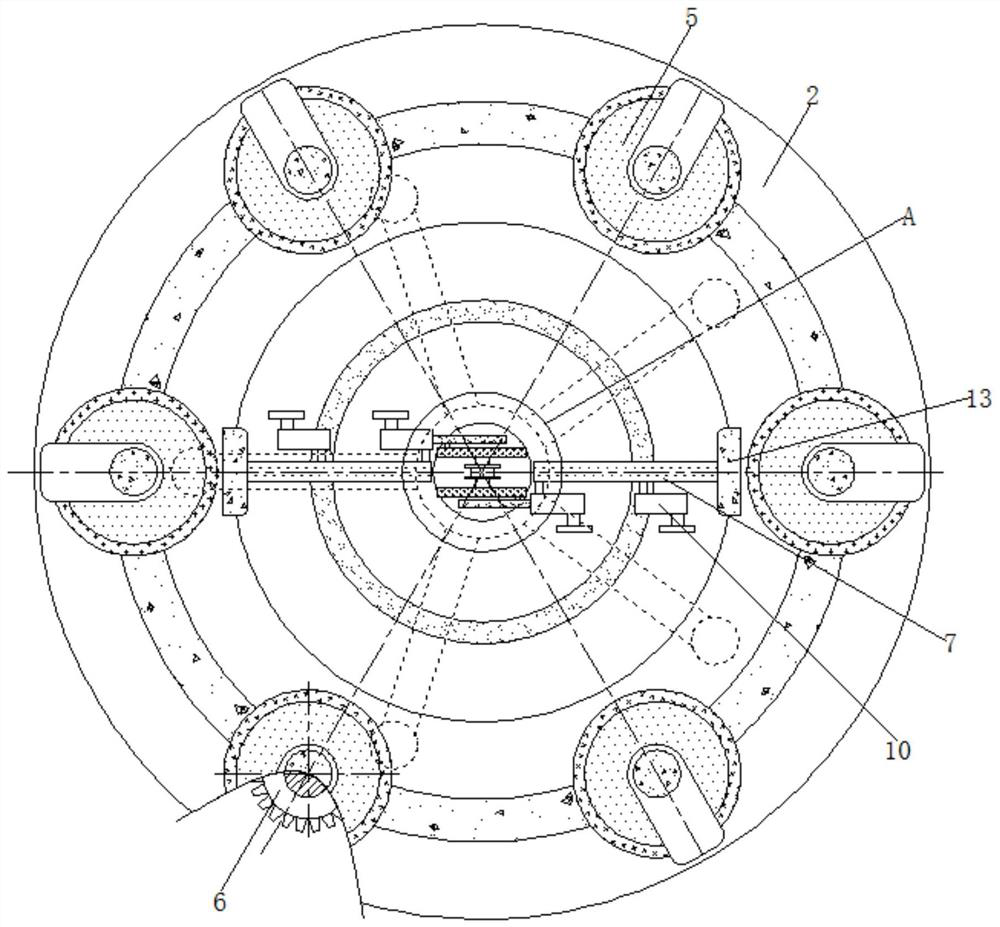

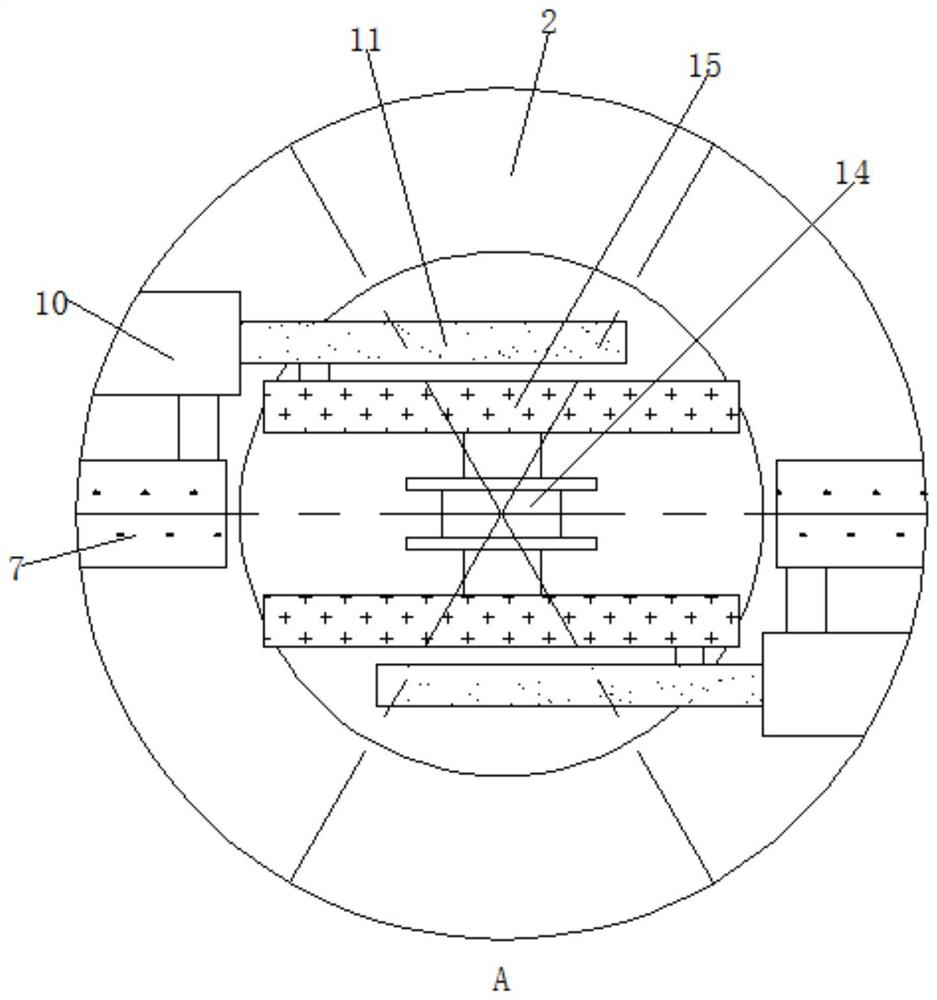

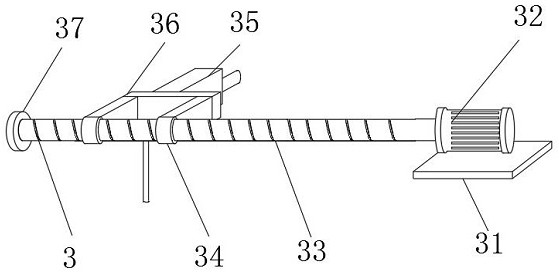

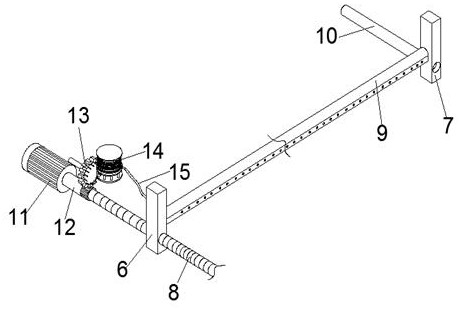

Cleaning device suitable for interiors of test tubes of different sizes

ActiveCN111451233AAchieve mechanical cleaningSolve cleaningHollow article cleaningGear wheelElectric machinery

The invention relates to the technical field of test tube cleaning, in particular to a cleaning device suitable for interiors of test tubes of different sizes. The invention aims to provide the test tube interior cleaning device which can be used for quickly and thoroughly cleaning test tubes, is high in cleaning efficiency and good in effect and can meet the cleaning requirements of the test tubes with different inner diameters. According to the technical scheme, the cleaning device suitable for the interiors of the test tubes of different sizes comprises a support, a transmission motor, a sector gear, a tooth-missing bevel gear, a rotating shaft and the like; and the transmission motor is fixedly installed on one side face of the support, the sector gear is installed on an output shaft of the transmission motor, the tooth-missing bevel gear and the sector gear are coaxially arranged, and the rotating shaft is installed on the support through a bearing and penetrates through the support. According to the cleaning device, mechanical cleaning of the test tube is achieved, and the problems that due to the fact that the test tube is too long, cleaning is inconvenient and not thoroughwhen the test tube is manually cleaned through a hairbrush are solved; and the cleaning requirements of the interiors of test tubes with different thicknesses can be met, the application range is wide, and practicability is high.

Owner:惠州帝恩科技有限公司

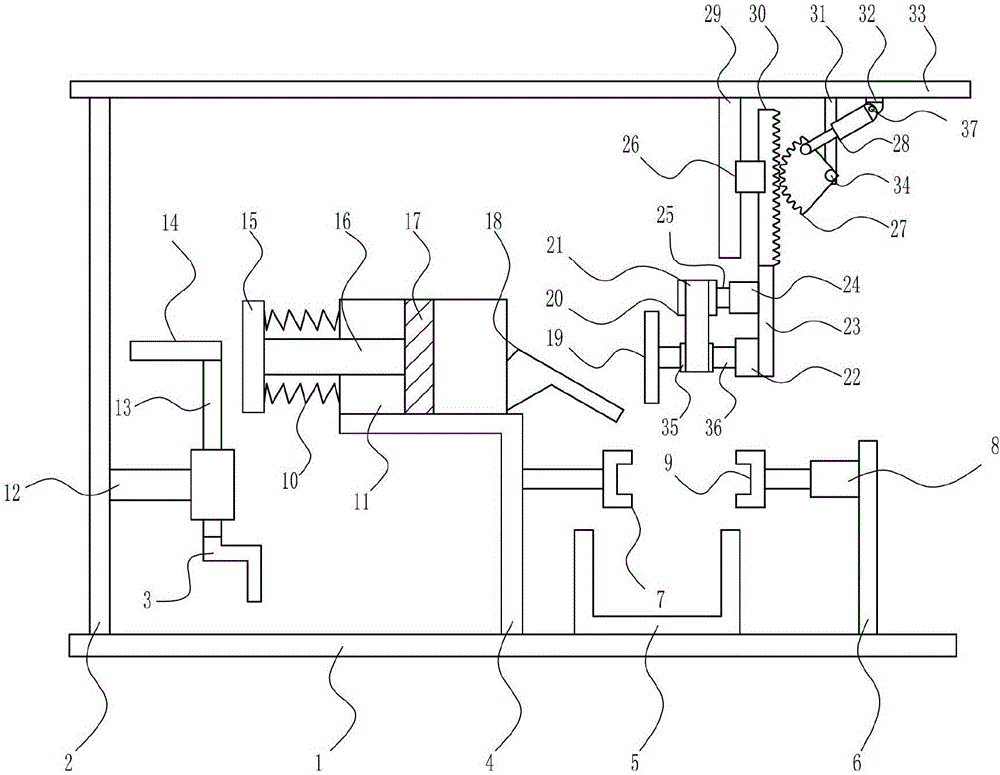

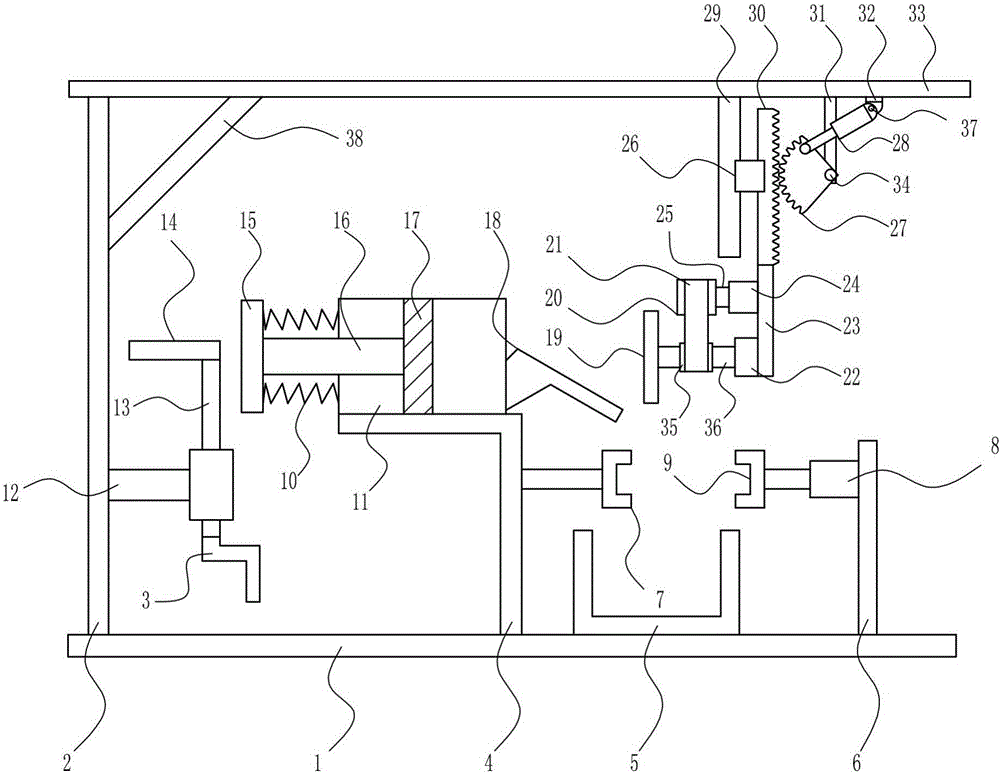

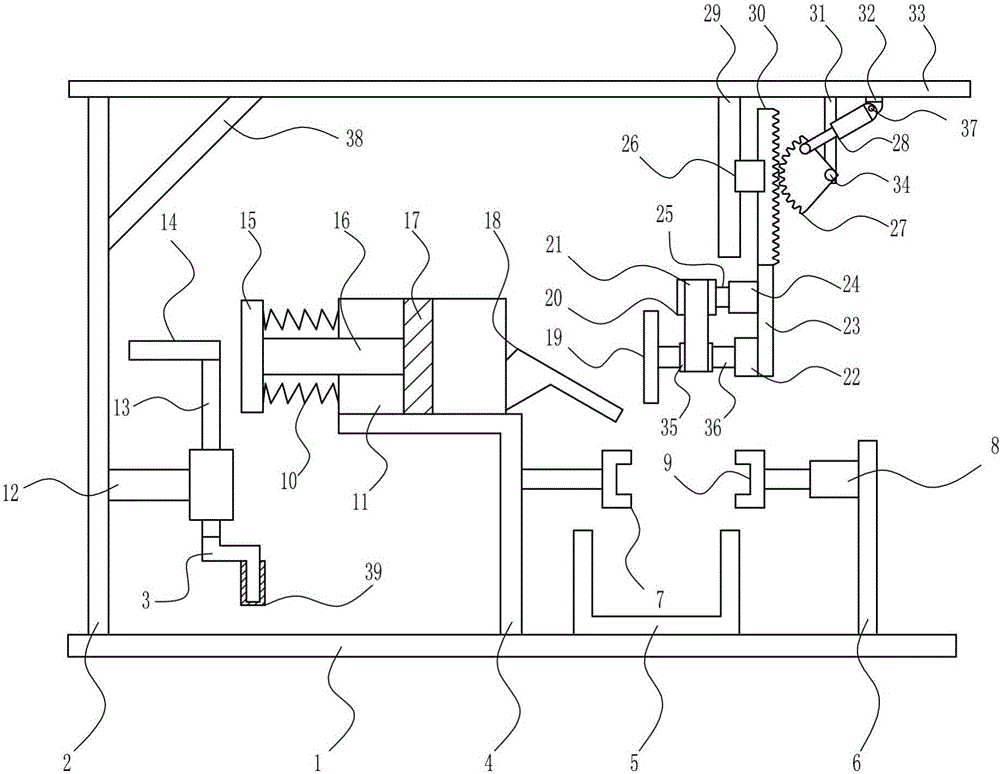

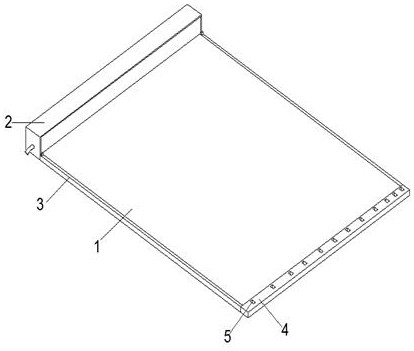

VR (Virtual Reality) spectacle lens cleaning equipment

The invention relates to cleaning equipment, in particular to VR (Virtual Reality) spectacle lens cleaning equipment. The invention aims to solve the technical problem of providing the VR spectacle lens cleaning equipment which is simple in structure, convenient to operate and high in cleaning speed. In order to solve the technical problem, the invention provides such the VR spectacle lens cleaning equipment which comprises a bottom plate, a left frame, a rocking handle, a fixed frame, a waste water frame, a fixed rod, a first clamping ring, a first electric pushing rod, a second clamping rod, a spring, a cylinder body, a first bearing support and the like; the left side of the top of the bottom plate is welded with the left frame; the middle of the top of the bottom plate is welded with the fixed frame; the right side of the top of the bottom plate is welded with the fixed rod; the waste water frame is placed at the top of the bottom plate between the fixed frame and the fixed rod. According to the VR spectacle lens cleaning equipment disclosed by the invention, effects of simple structure, convenience for operation and high cleaning speed are achieved, a worker can implement a rapid cleaning operation on a VR spectacle lens by the equipment, and the VR spectacle lens cleaning equipment not only is simple to operate, but also can save time.

Owner:江苏瑞泰玻璃制品有限公司

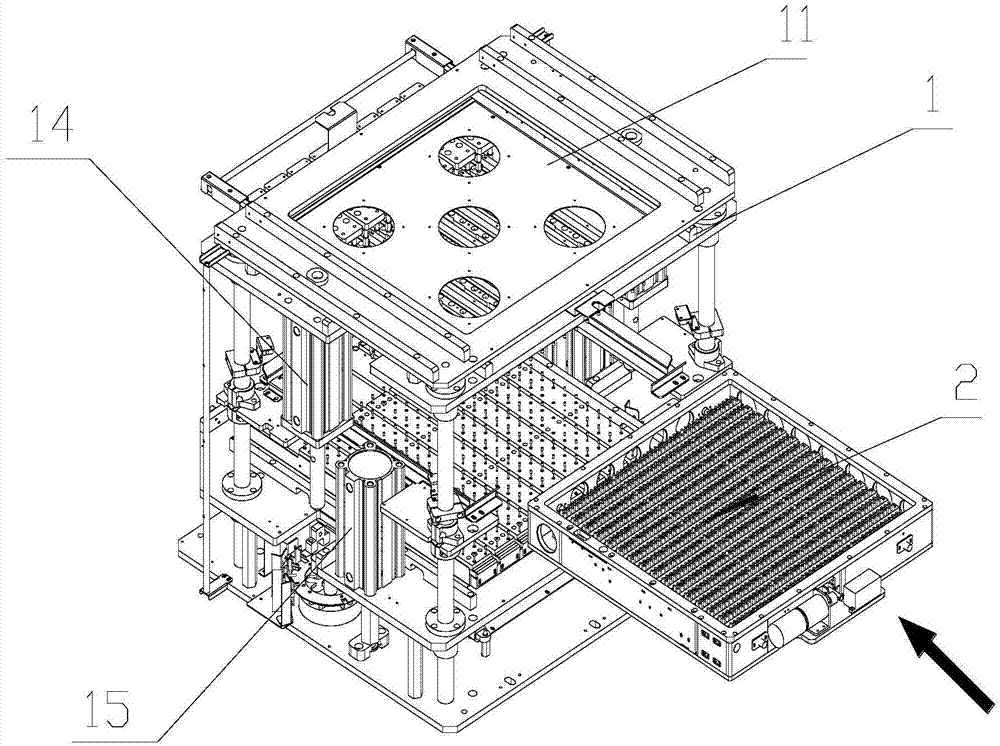

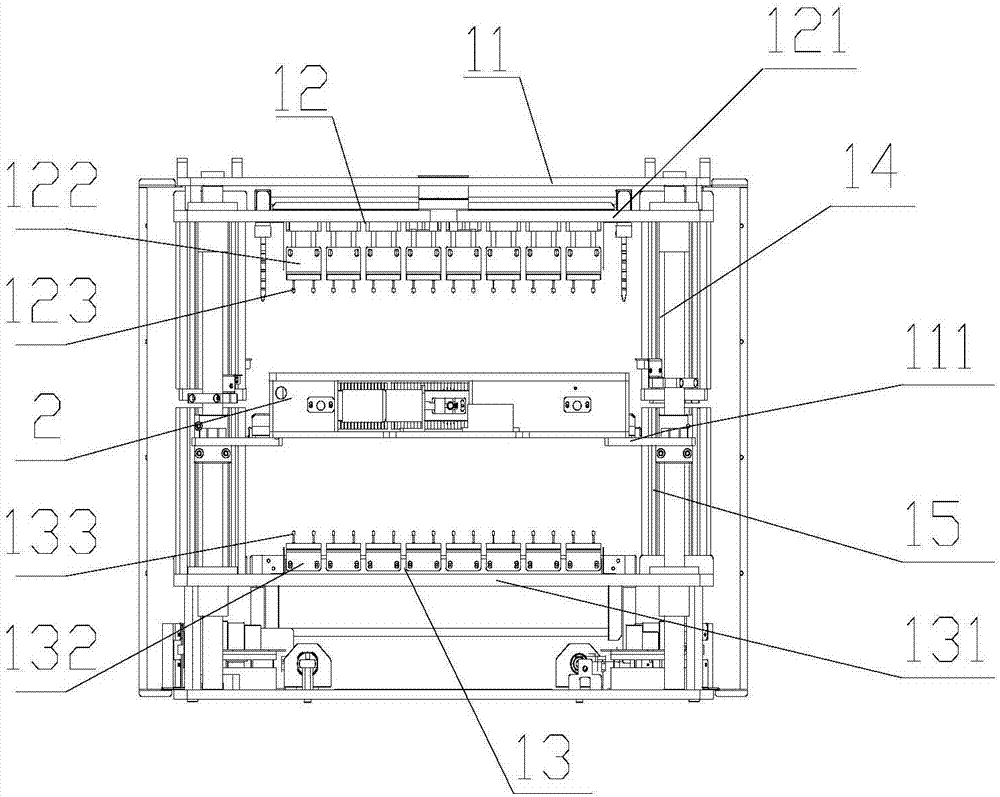

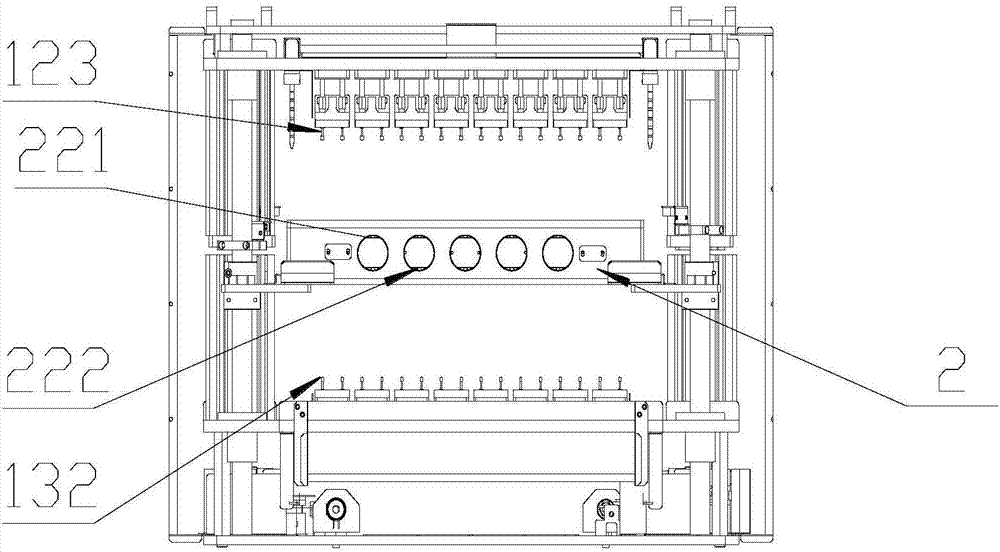

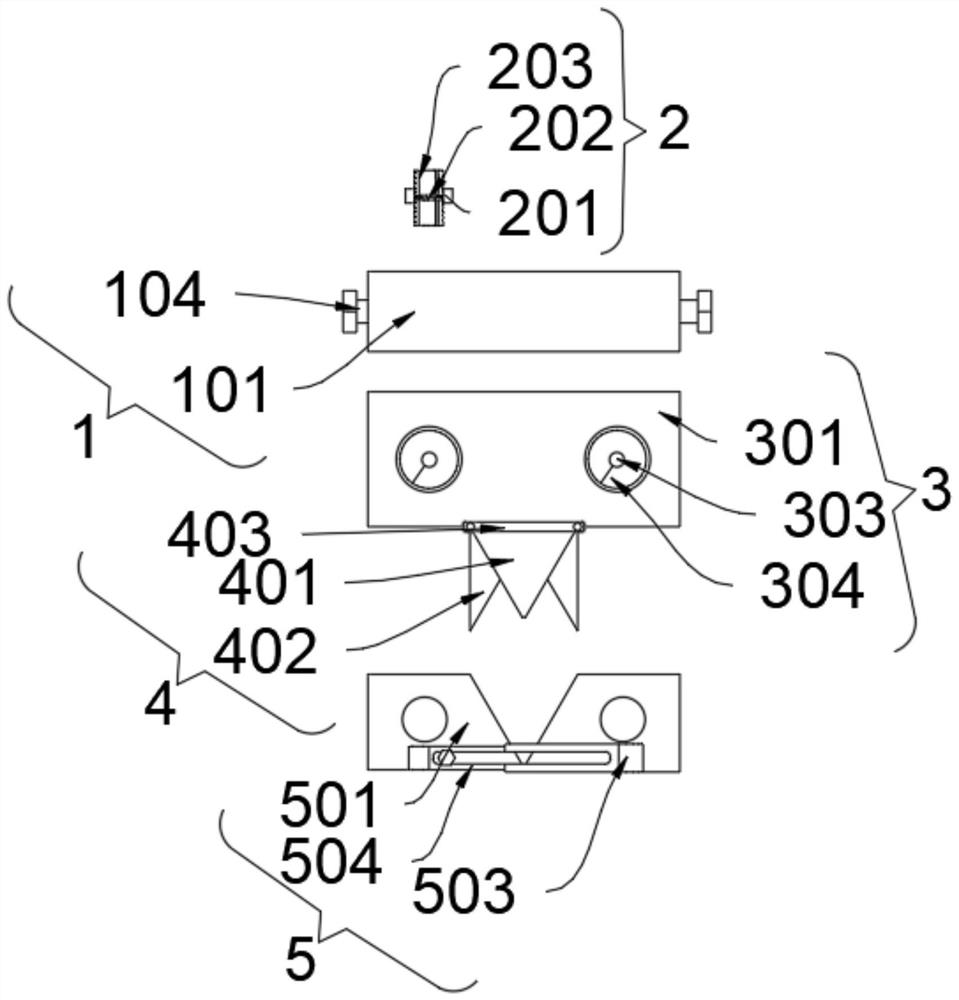

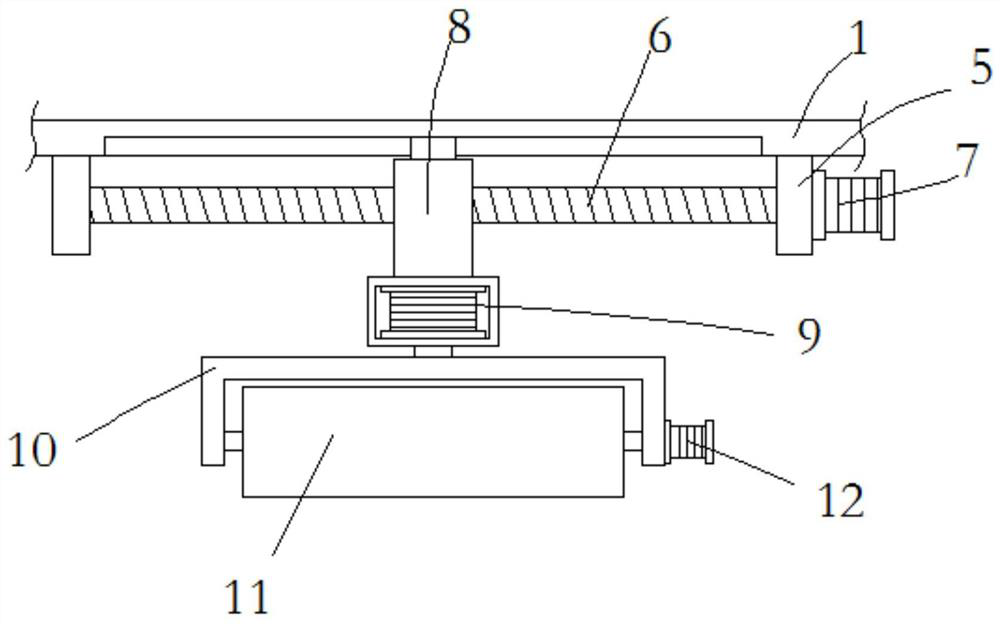

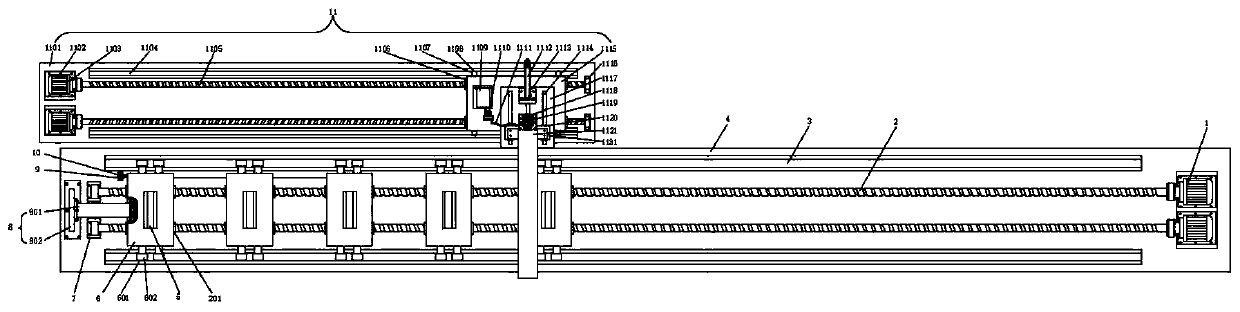

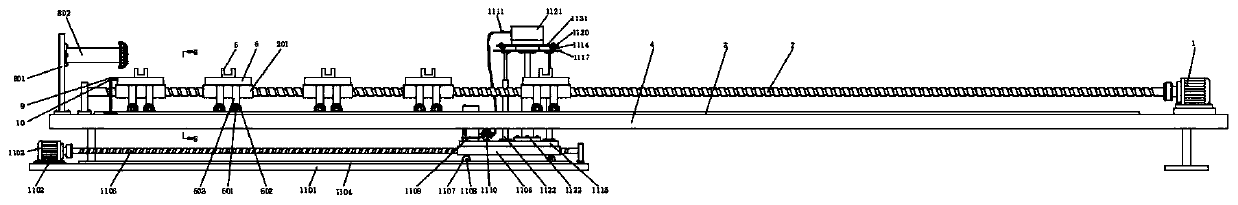

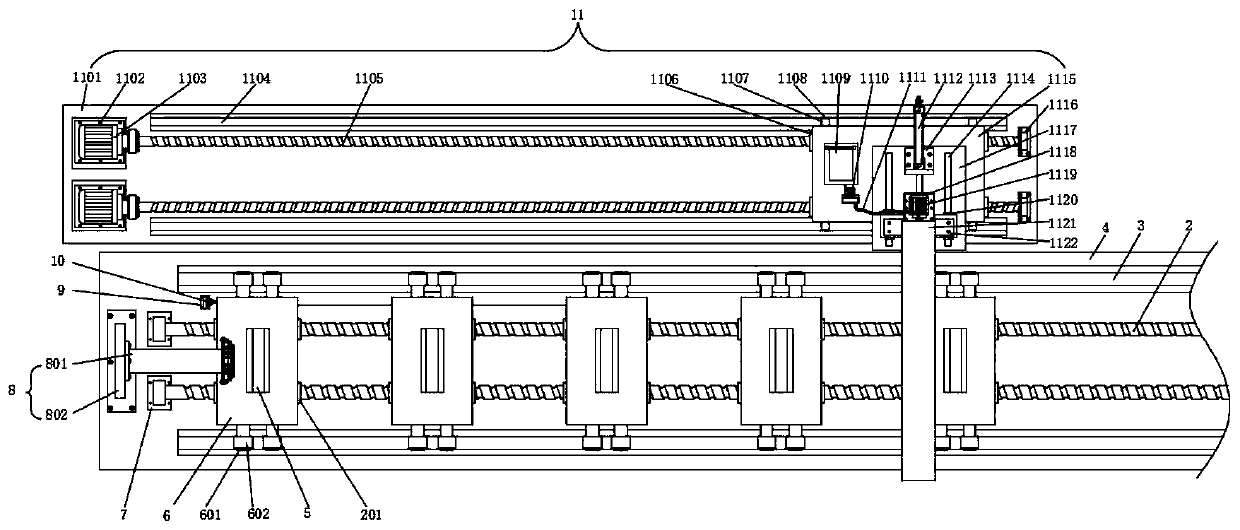

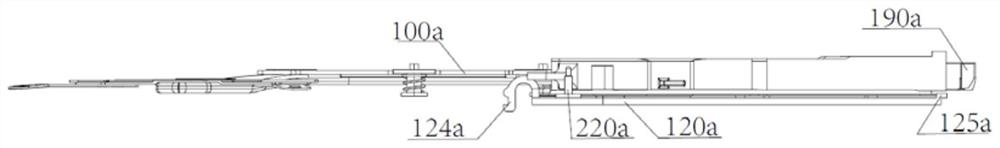

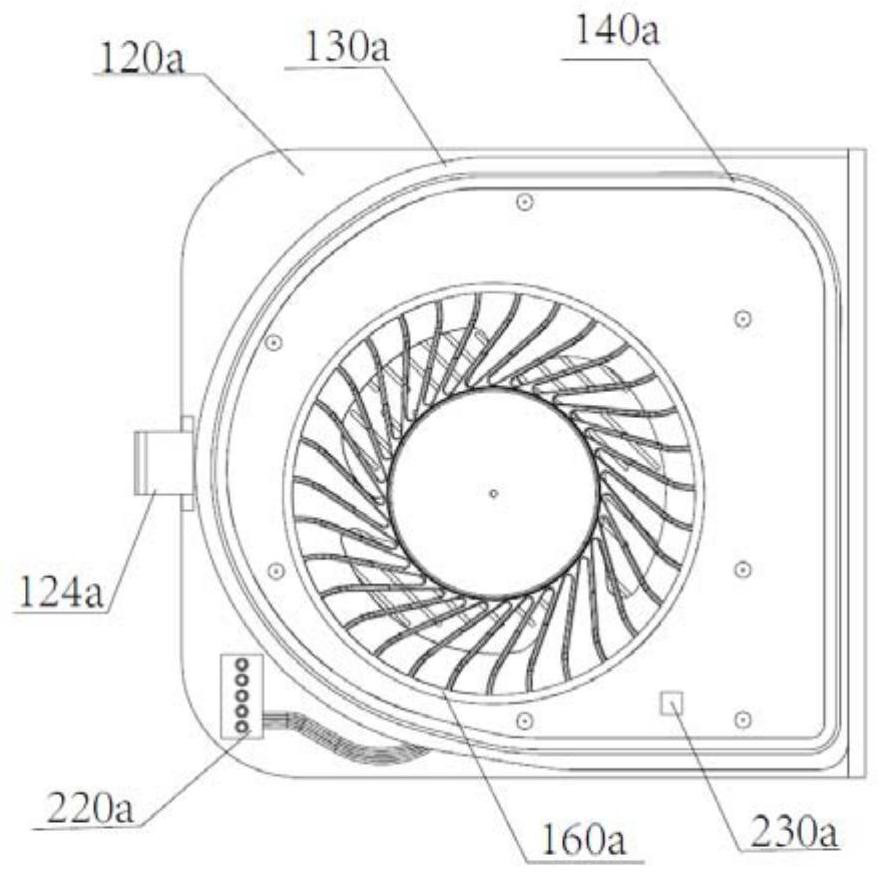

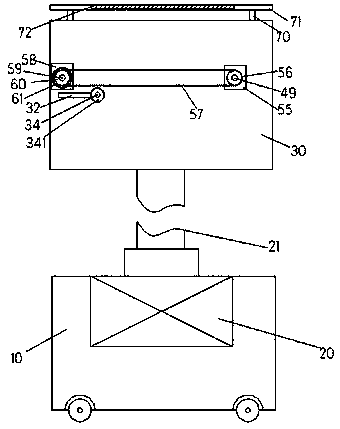

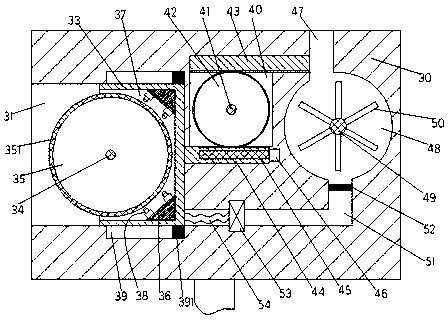

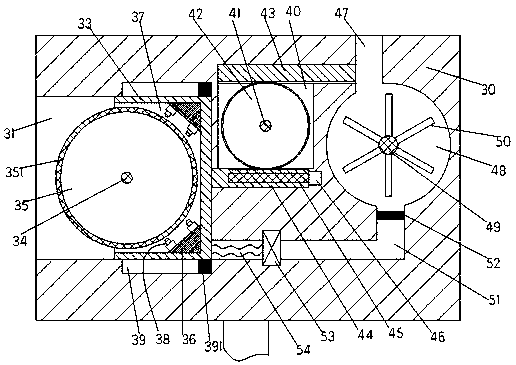

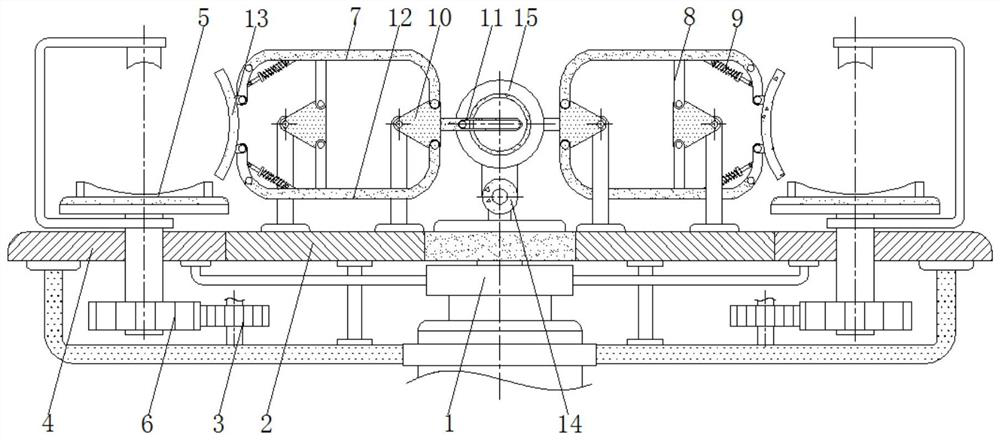

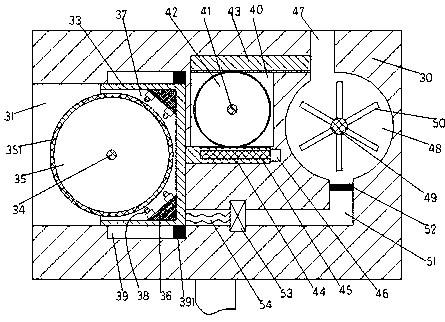

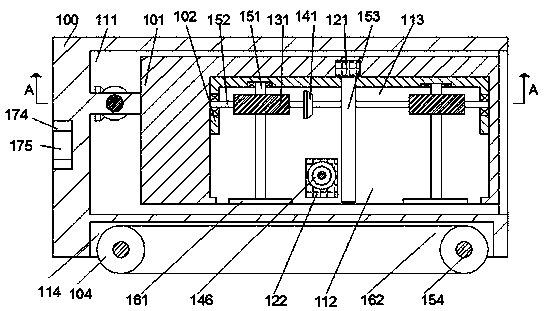

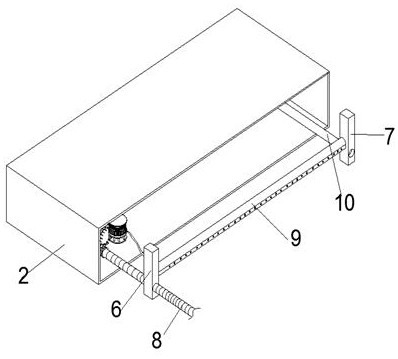

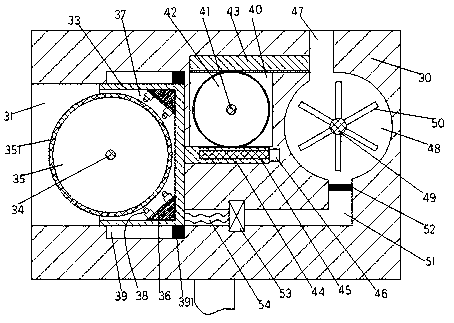

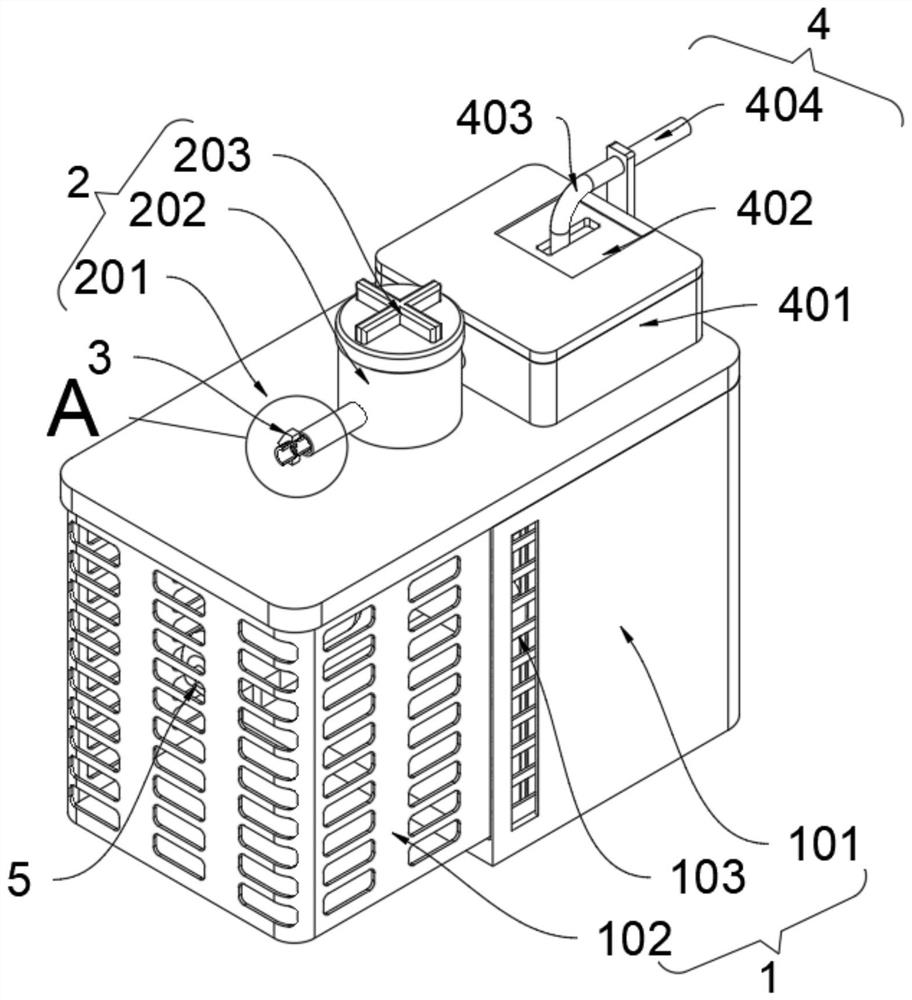

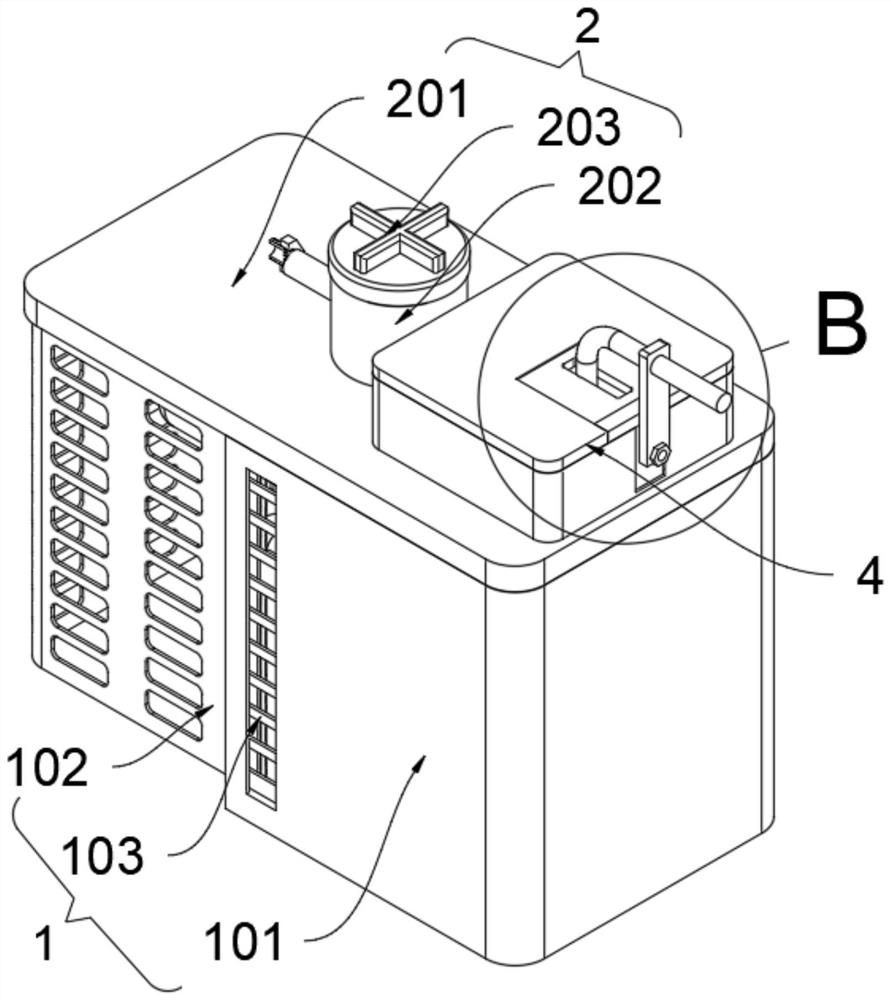

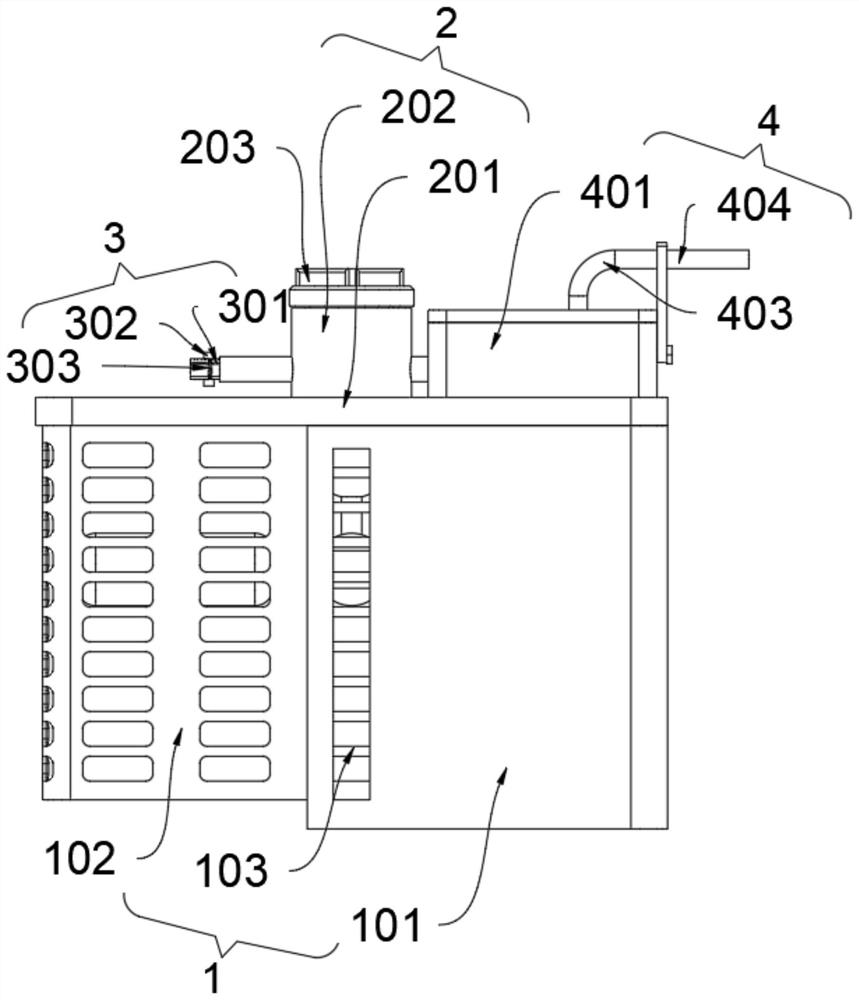

Probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment

PendingCN107127169AReduce defective rateAvoid cross contaminationCleaning using toolsCharge and dischargeEngineering

A probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment comprises secondary charging and discharging inspection equipment and cleaning equipment, wherein the secondary charging and discharging inspection equipment is used for charging and discharging the cylindrical lithium battery, and the cleaning equipment is used for cleaning the secondary charging and discharging inspection equipment. The secondary charging and discharging inspection equipment comprises a mounting frame used for mounting the whole equipment, an upper probe assembly used for being in contact with a positive pole of the cylindrical lithium battery, a lower probe assembly used for being in contact with a negative pole of the cylindrical lithium battery, an upper pneumatic component used for adjusting the longitudinal position of the upper probe assembly and a lower pneumatic component used for adjusting the longitudinal position of the lower probe assembly. The cleaning equipment comprises an outer frame used for being mounted on the charging and discharging equipment of the cylindrical lithium battery and providing supporting, a cleaning device used for cleaning the probe, a driving device used for providing driving force and a power supply device used for supplying power. The probe automatic cleaning tool for cylindrical lithium battery charging and discharging equipment has the beneficial effects that the probe of the charging and discharging equipment of the cylindrical lithium battery is cleaned automatically, and the fraction defective of the cylindrical lithium battery caused by poor contact with the probe is reduced.

Owner:ZHEJIANG HANGKE TECH

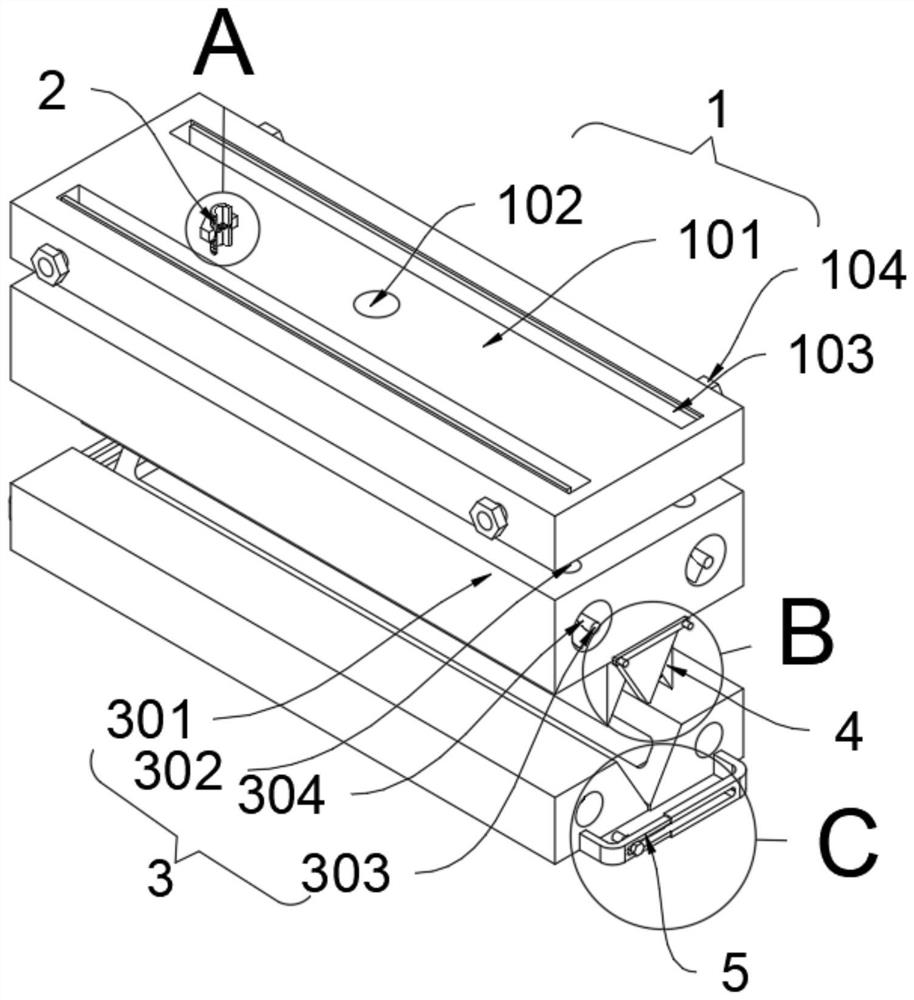

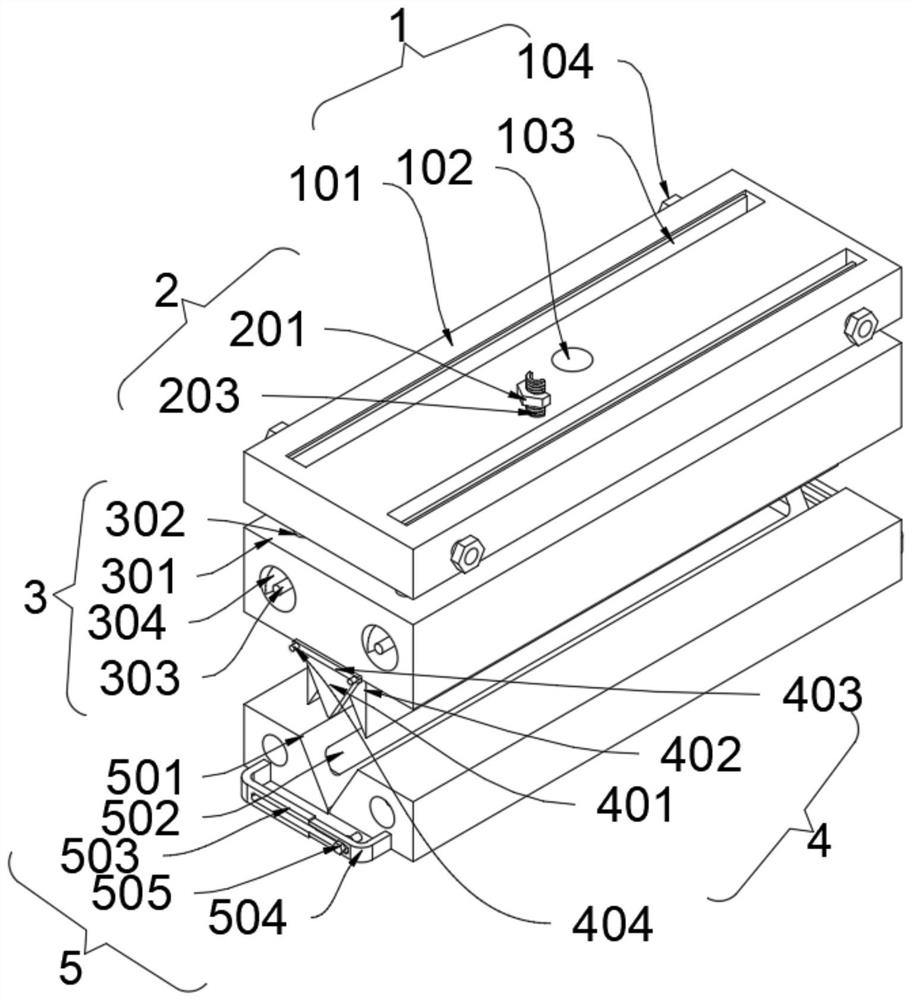

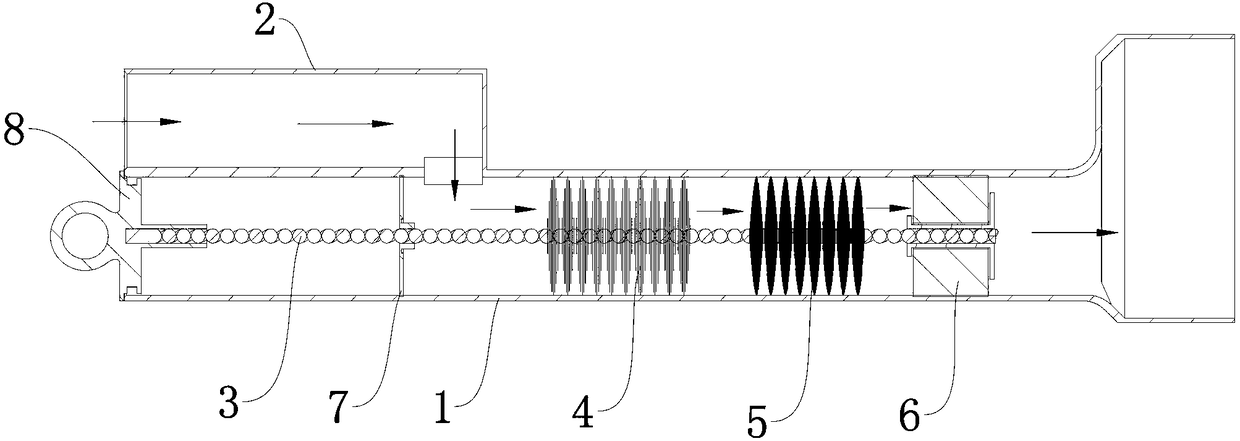

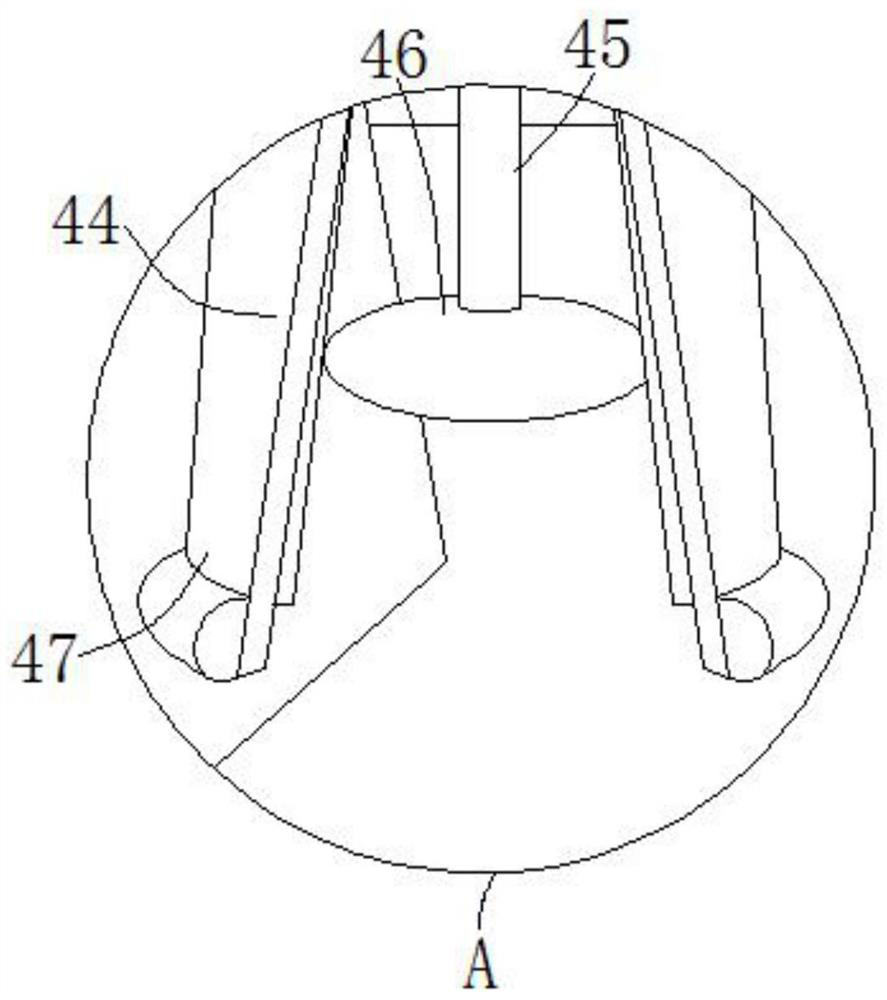

Melt-blown cloth nozzle structure capable of avoiding air passage blockage

PendingCN113005542AClamp firmlyAvoid blockageSpinning solution de-aeratingSpinnerette packsParticulatesEngineering

The invention provides a melt-blown cloth nozzle structure capable of avoiding air passage blockage, relates to the technical field of melt-blown cloth, and solves the problems that in the practical application process of an existing nozzle, due to the fact that relatively large particulate matter cannot be filtered for molten filaments entering the nozzle, the large particulate matter enters the nozzle to cause blockage, and raw materials are easy to solidify due to non-uniform heating during spraying since the raw materials extruded by double screws cannot be continuously stirred. The melt-blown cloth nozzle structure comprises a filament feeding mechanism; and the filament feeding mechanism is screwed at the top end of a feeding mechanism. According to the invention, limiting columns, fixed plates and nozzles can be released firstly, and then the two nozzles are unfolded to the front side and the rear side to be cleaned; and through the design, when the nozzles are accidentally blocked, cleaning operation can be rapidly carried out, round-hole-shaped air discharge of air outlets formed in the inner sides of guide blocks in an air guide mechanism is changed into air passage type air discharge, so that the purpose of drying air more quickly is achieved.

Owner:田同亮

Immersed tunnel concrete pouring system and method

PendingCN112796790AOptimize layoutImprove general performanceUnderground chambersTunnel liningArchitectural engineeringPipe

The invention discloses an immersed tunnel concrete pouring system and method. The pouring system comprises a pouring pipe, a backflow pipe, a pouring machine and a bent pipe, wherein the pouring pipe comprises a plurality of pouring pipe sections which are detachably connected, the backflow pipe comprises a plurality of backflow pipe sections which are detachably connected, the pouring machine can move and is provided with a feeding port, a connector of any pouring pipe section can be connected to the feeding port through the bent pipe, the connector of any pouring pipe section can be connected to a connector of any backflow pipe section through the bent pipe, the pouring method comprises the following steps that the pouring system is arranged in a prefabrication site, the pouring machine is moved to the to-be-poured position, the feeding port is connected to the connector of the nearest pouring pipe section through the bent pipe, self-compacting concrete enters the pouring machine through the pouring pipe, concrete pouring is carried out, after the concrete pouring is completed, connection between the feeding port and the bent pipes is removed, and the bent pipe is connected to the connector of the nearest return pipe section to form a cleaning channel for cleaning.

Owner:CCCC FOURTH HARBOR ENG CO LTD

Barbecue set convenient to clean

InactiveCN103405165ANo risk of wettingReliable swing operationRoasters/grillsSewageMechanical engineering

The invention discloses a barbecue set convenient to clean. The barbecue set comprises a frame, a barbecue plate and a heating device, wherein the barbecue plate and the heating device are mounted on the frame. The heating device locates below the barbecue plate. The barbecue plate is provided with a collector channel. The collector channel is provided with a drain hole admitting outflow of cleaning sewage. The bottom of the frame is provided with a trough used for accommodating the cleaning sewage. The trough locates right below the drain hole and is detachably connected with the frame. The barbecue set is capable of collecting the cleaning sewage on the barbecue plate to allow the sewage to be convenient to clear.

Owner:广州市白云区江南本家餐厅

Shot blasting machine cleaning device and method

ActiveCN112403974AComprehensive adsorptionGuaranteed adsorption efficiencyDirt cleaningCleaning using toolsStructural engineeringMechanical engineering

The invention relates to the technical field of shot blasting machines, and discloses a shot blasting machine cleaning device which comprises a cleaning chamber. The inner walls of the front and rearopposite sides of the cleaning chamber are fixedly connected with one same conveying roller through a plurality of supporting rods, and the left and right opposite sides of the cleaning chamber are each provided with a material opening for the conveying roller to penetrate through and extend out; and an electromagnetic cleaning mechanism, an air blowing cleaning mechanism and a scraping cleaning mechanism are fixedly arranged on the inner wall of the top of the cleaning chamber in sequence from left to right. The shot blasting machine cleaning device and method have the advantages that the surface of a steel plate can be quickly and deeply cleaned in all directions through the three stages of cleaning mechanisms, the cleaning efficiency and quality are improved, and subsequent production and use of the steel plate are guaranteed.

Owner:芜湖久弘重工股份有限公司

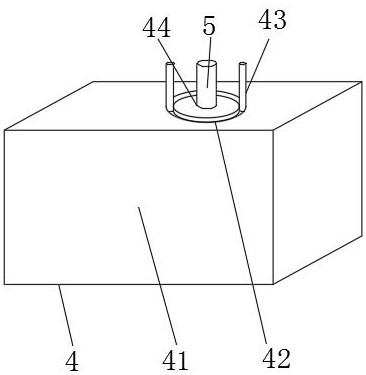

Fracturing flow-back fluid pretreatment device facilitating grating cleaning

ActiveCN114307303AEasy to useQuick installationStationary filtering element filtersFracturing fluidEngineering

The invention provides a fracturing flow-back fluid pretreatment device convenient for cleaning a grating, and relates to the technical field of fracturing fluid treatment.The fracturing flow-back fluid pretreatment device comprises a transfer box, a filtering storage tank is formed in the transfer box, a transfer through hole is formed in one side of the filtering storage tank in a penetrating mode, and an adjusting assembly is installed on one side of the inner wall of the filtering storage tank; and a positioning rotating sleeve rod is installed on the other side of the inner wall of the filtering storage tank, and a placement assembly is installed between the positioning rotating sleeve rod and the adjusting assembly. Through cooperation of the clamping buckle assembly and the placement assembly, the collected impurities can be transferred into the clamping buckle mounting frame, so that the cleaning effect of the device is effectively ensured, and the problem that a large number of impurities are generated under the condition that the grating is used for a long time is effectively solved; and therefore, impurities such as large particles are remained in the fracturing flow-back fluid under the subsequent treatment condition, and the fracturing flow-back fluid is influenced.

Owner:江西炼石环保科技有限公司

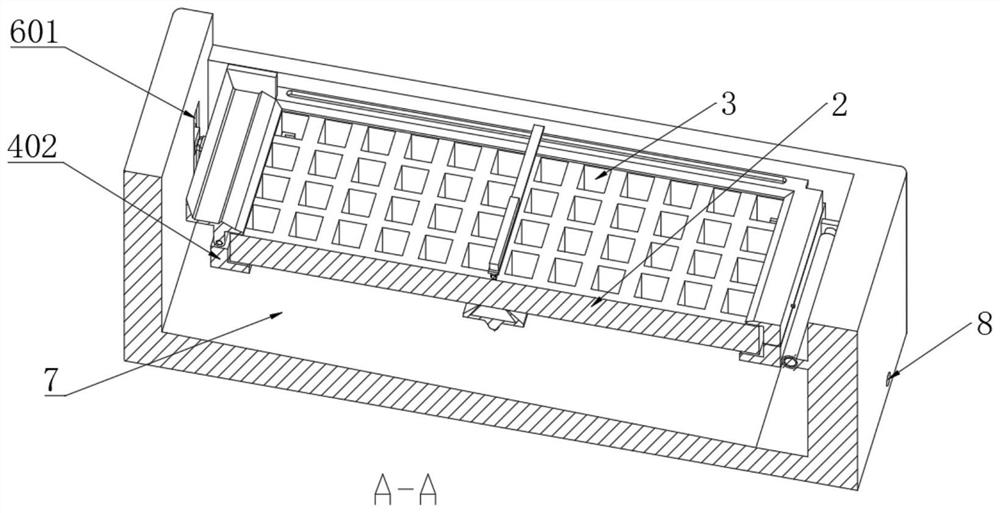

Device facilitating crushing and screening of coating raw materials

InactiveCN112827569AImprove efficiencyGood crushing and screening processing effectSievingScreeningManufacturing engineeringSlide plate

The invention relates to the technical field of coatings, and discloses a device facilitating crushing and screening of coating raw materials. The device comprises a machine body, a feeding port is formed in the upper surface of the machine body, rollers are arranged in the machine body, a guide plate is arranged in the machine body, a sliding plate is arranged in the machine body, a box body is arranged on the lower portion of the sliding plate, a sieve plate is movably connected to the interior of the box body, a gear is arranged in the machine body, a gear ring is arranged on the surface of the gear, a push plate is connected to the surface of the gear ring in a sliding mode, and a push rod is arranged on the side surface of the push plate. According to the device facilitating crushing and screening of the coating raw materials, through mutual cooperation of the rollers, cooperative use of the guide plate and the sliding plate, cooperative use of the gear and the gear ring, cooperative use of the push plate and the push rod and cooperative use of the box body and the sieve plate, the coating raw materials can be synchronously crushed and screened, the crushing and screening processing efficiency of the coating raw materials is high, and the crushing and screening processing effect is good.

Owner:张娃

Forging device with real-time automatic cleaning function

InactiveCN114210900AImprove forging efficiencyGuaranteed cleanlinessCleaning using toolsForging/hammering/pressing machinesElectric machineryEngineering

The invention discloses a forging device with a real-time automatic cleaning function, which comprises a supporting rack, a limiting device, a mounting clamping plate, a transmission mechanism, a guide chute, a connecting motor, a supporting baffle, a limiting sliding plate, a forging device, a connecting device, a positioning belt pulley, a cleaning device, a connecting rack, a toothed belt and a guide mechanism, the upper end face of the supporting rack is symmetrically and fixedly connected with supporting baffles used for supporting. When the connecting blank is circularly forged, the cleaning device can be matched with the forging device for forging the connecting blank, so that the forged position is quickly cleaned in real time, and the supporting rack at the upper part of the forged connecting blank can be always kept clean; and therefore, the forging efficiency of the connecting blank and the cleanliness of the upper environment of the forging platform are improved, and follow-up accurate regulation and control over various devices are facilitated.

Owner:熊伟

Dust collection cavity and dust collection cleaning equipment

PendingCN109464066AEasy to clean upQuick cleaning operationCleaning filter meansSuction filtersEngineering

The invention discloses a dust collection cavity and dust collection cleaning equipment. The dust collection cleaning equipment comprises a main unit, a brush head mechanism and the dust collection cavity, a dust inlet and a dust outlet are formed in the front and rear ends of the dust collection cavity respectively, and in the direction from the dust inlet to the dust outlet, a broken filament assembly for sucking fluff, impurities and partial fine dust and filter cotton for sucking the fine dust are arranged in the dust collection cavity in sequence. According to the technical scheme, the fluff, impurities and fine dust sucked into the dust collection cavity can be reserved on the broken filament assembly and the filter cotton, the cleaning work of the dust collection cleaning equipmentcan be conveniently and quickly conducted, and the equipment is convenient to use, reliable and easy to implement.

Owner:NINGBO FUJIA IND

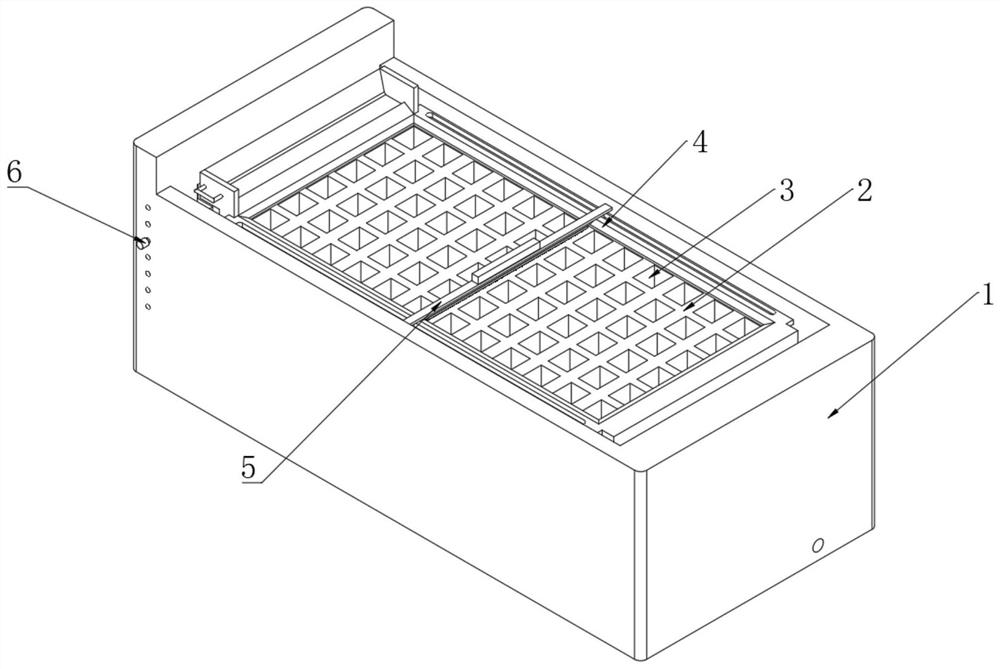

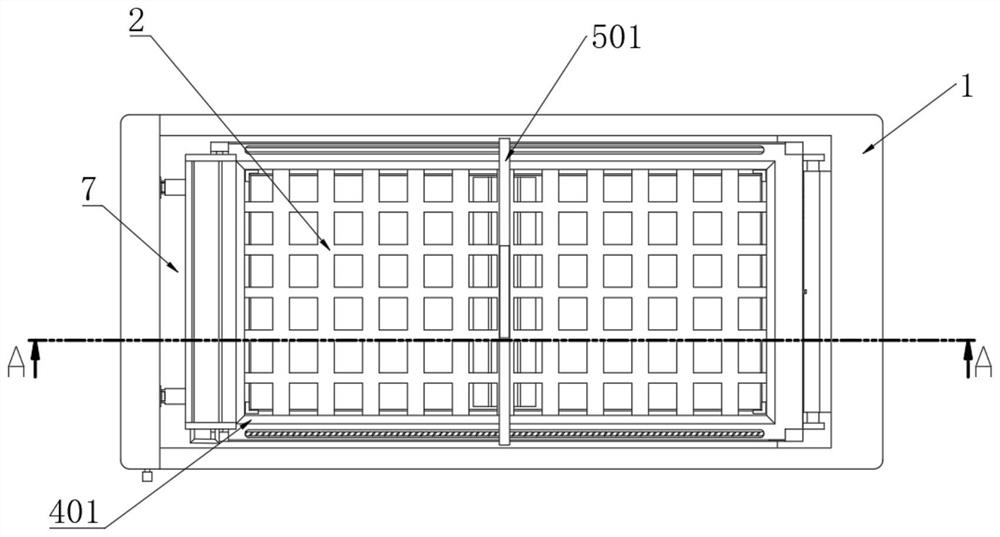

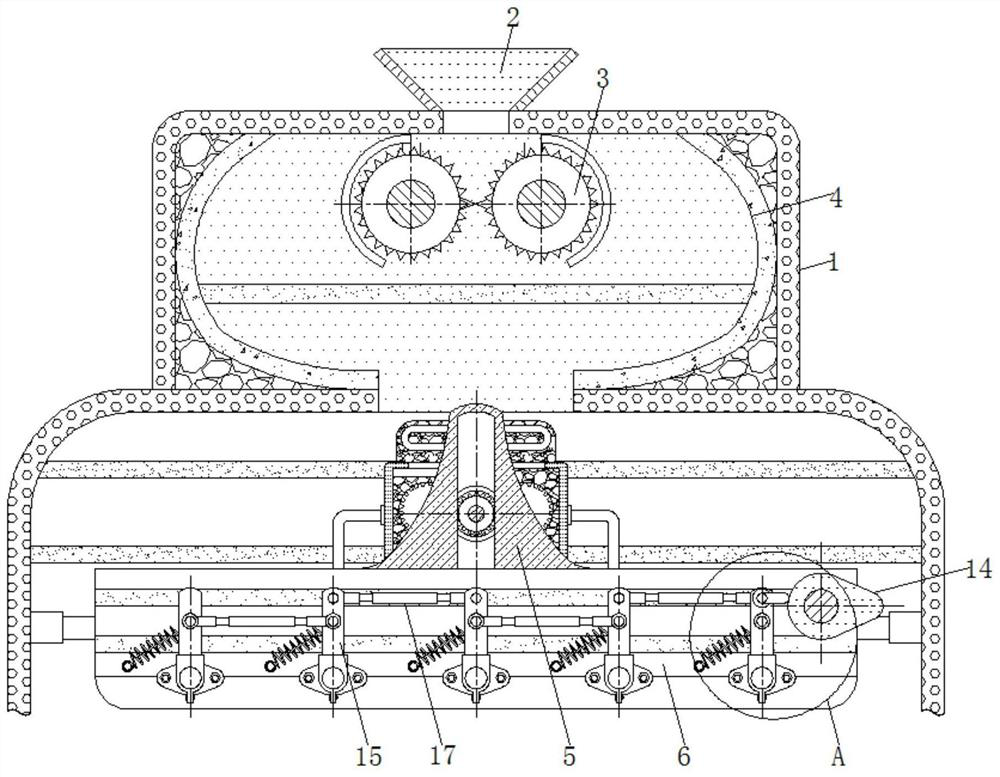

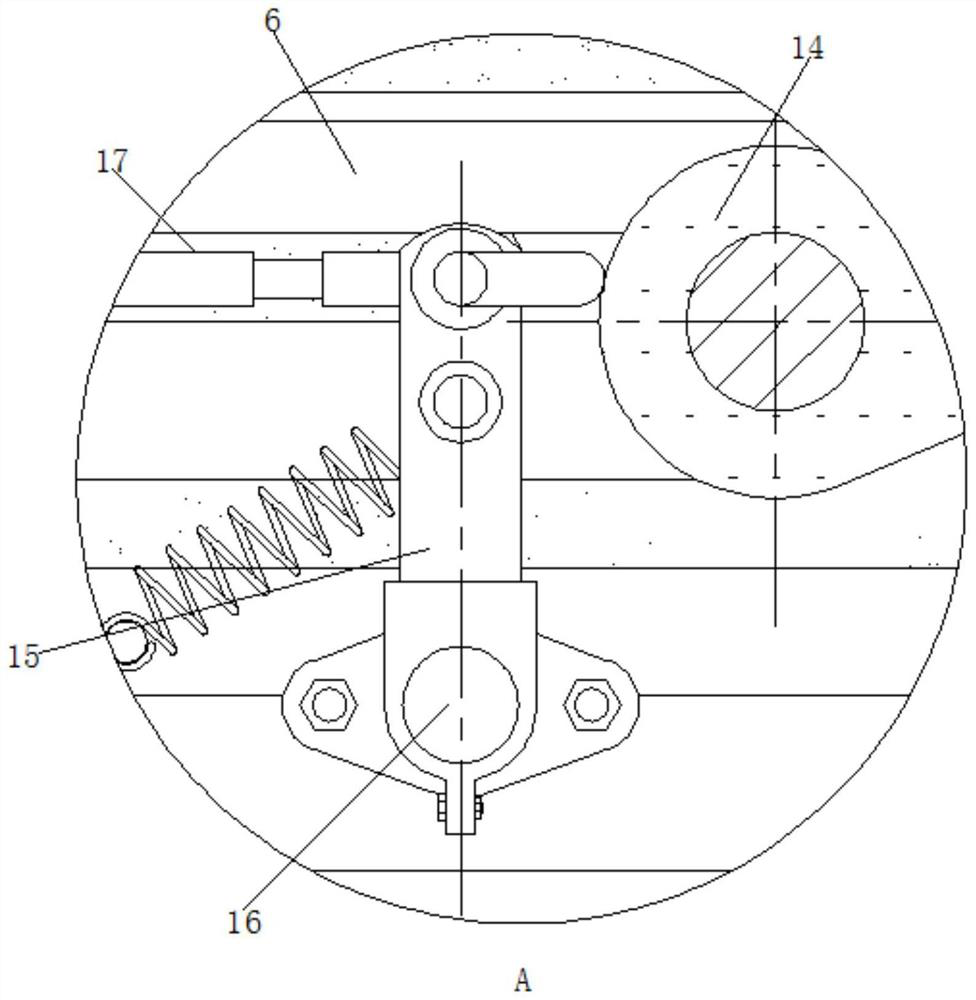

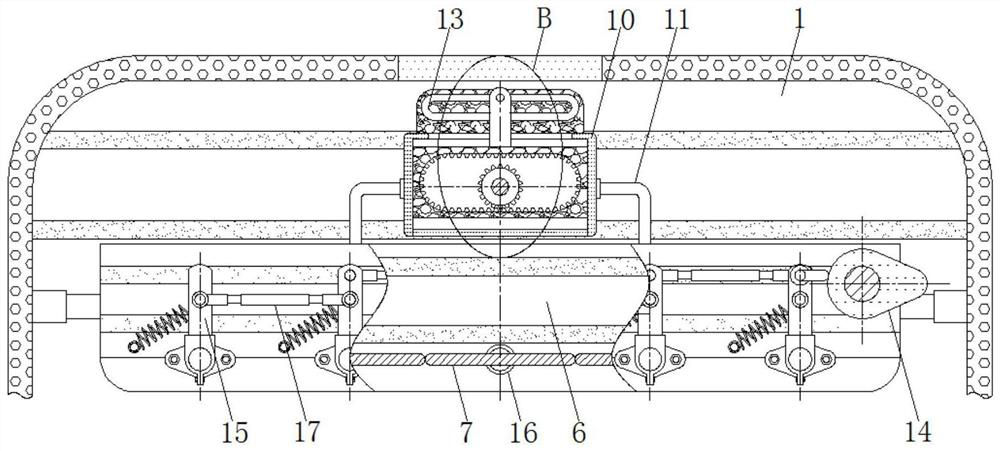

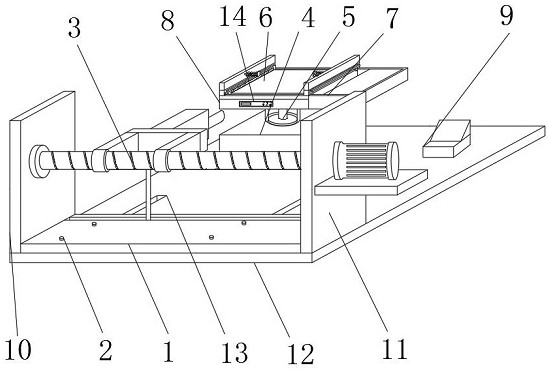

Cleaning device for concrete pipe pile mold

PendingCN110900798AQuick cleaning operationReduce labor intensityCeramic shaping apparatusArchitectural engineeringElectric machinery

The invention discloses a cleaning device for a concrete pipe pile mold, which comprises a bottom plate, a conveying motor, a first lead screw, a first lead screw nut, a moving seat and a supporting body, wherein a cleaning mechanism is arranged on the side of the bottom plate; the cleaning mechanism comprises a base and a pushing motor; a second lead screw is arranged at the output shaft end of the pushing motor; a second lead screw nut is arranged on the second lead screw; a moving table is arranged at the top of the second lead screw nut; a liquid storage box and a water pump are arranged at the upper end of the moving table; a lifting plate is arranged on the right side of the water pump; a linear guide rail is arranged on the lifting plate; a guide rail sliding block and a longitudinal moving plate are arranged on the linear guide rail; a supporting frame is installed on the longitudinal moving plate; a rotating shaft is rotationally arranged in the supporting frame; a brush plateis mounted on the rotating shaft; and a wire brush is arranged on the outer surface of the brush plate. The cleaning device can clean the inner wall of the concrete pipe pile mold, cleans attached residues, reduces the labor intensity of workers, improves the cleaning efficiency, improves the production quality, saves the production cost for enterprises, and improves the economic benefits.

Owner:怀化市港翔管桩有限公司

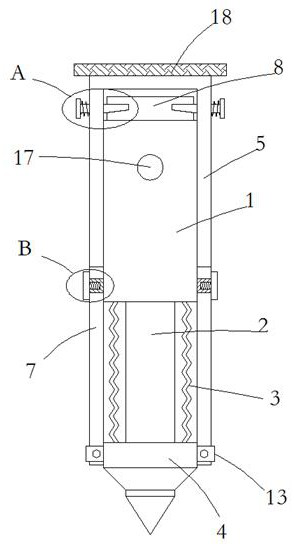

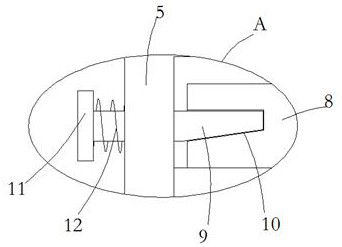

Stable-to-use deep hole cleaning device and cleaning method

InactiveCN112318328AFast clampingQuick cleaning operationGrinding drivesGrinding machinesElectric machineryStructural engineering

The invention discloses a stable-to-use deep hole cleaning device and cleaning method. The device comprises a base, a clamping mechanism and a cleaning mechanism, wherein a rectangular adjusting column is perpendicularly arranged in the middle section of the rear side of the top end face of the base, a hoisting plate is horizontally and forwards welded to the top end face of the rectangular adjusting column, the clamping mechanism comprises a rectangular adjusting sleeve and two clamping plates, two guide sliding blocks distributed left and right are symmetrically arranged on the top end faceof the base, and the cleaning mechanism comprises a driving motor, a threaded sleeve, a hanging rod and an oval supporting block. According to the device, to-be-cleaned parts with different sizes canbe conveniently and rapidly clamped and fixed, then deep holes with different hole diameters are cleaned, and impurities and rust in the deep holes are rapidly removed.

Owner:NANJING LINGQUE INTELLIGENT MFG CO LTD

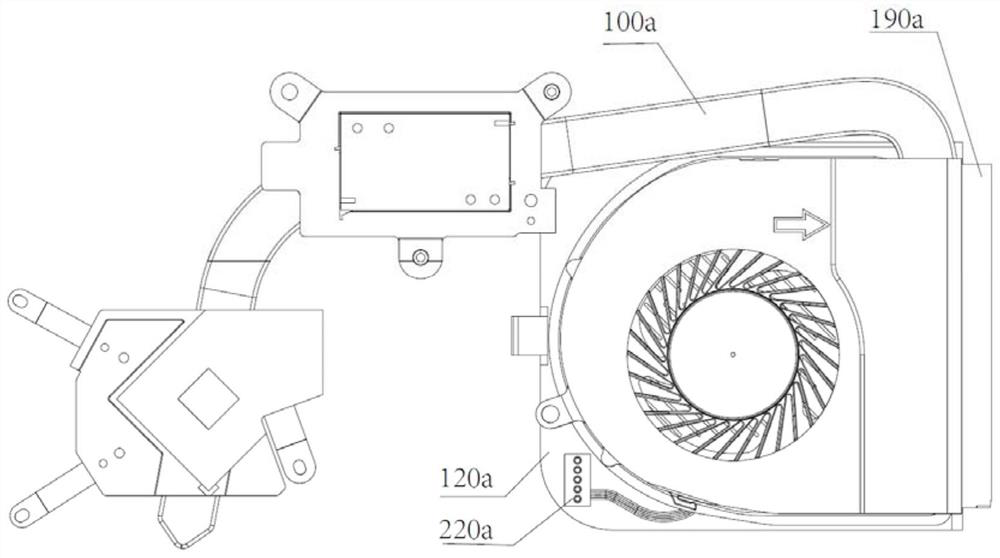

Rapidly-deashing radiator for compact electronic equipment

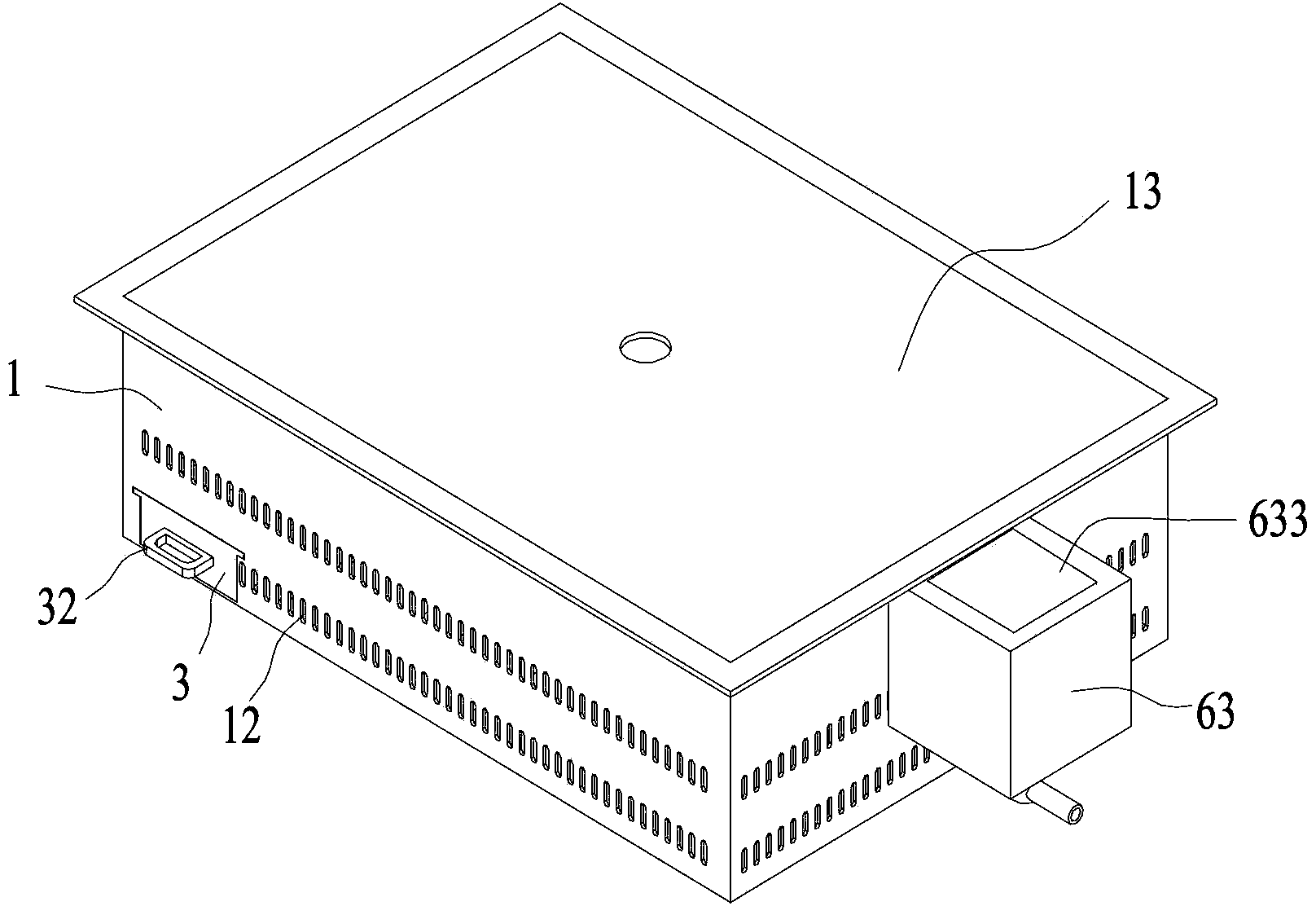

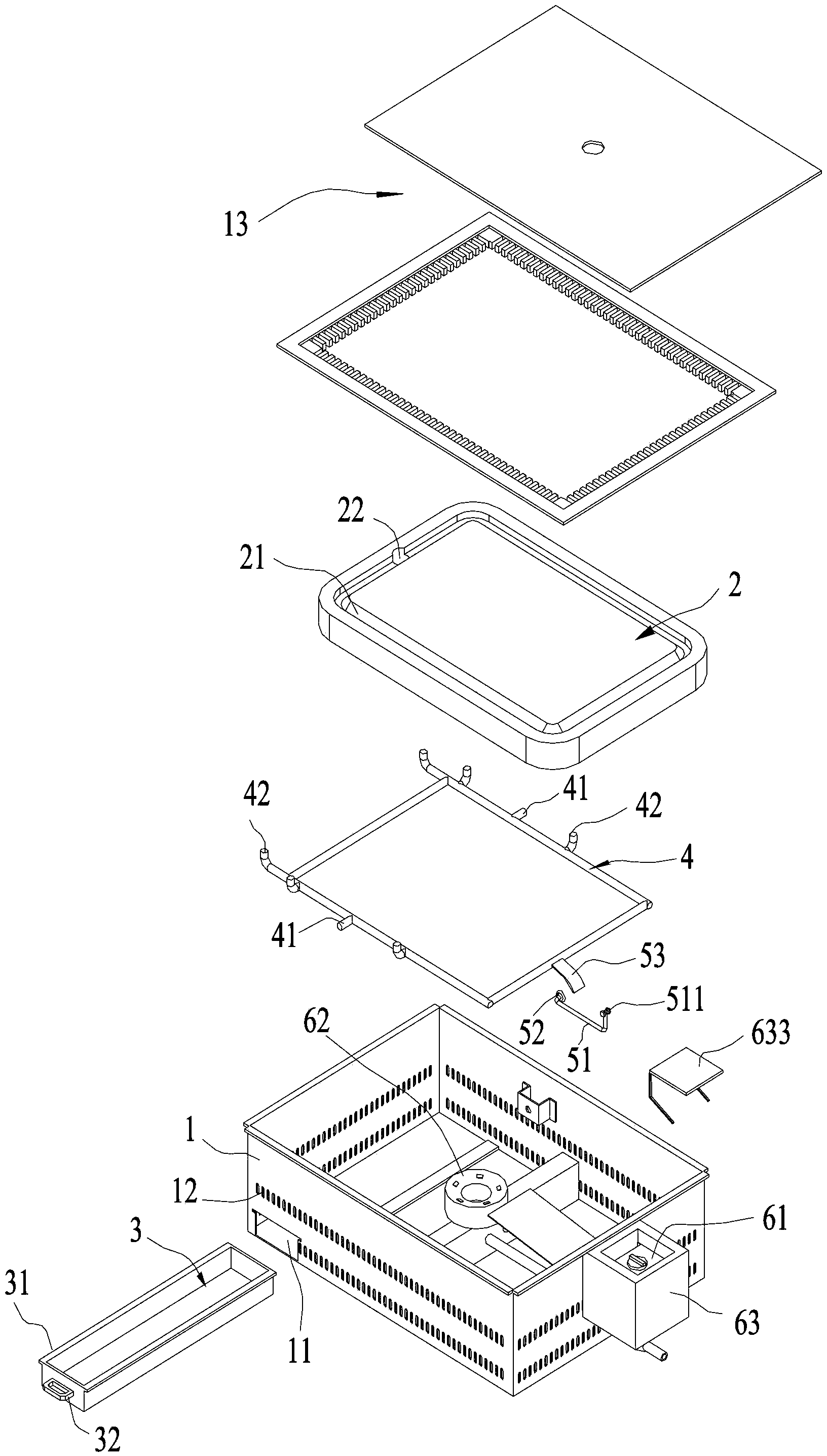

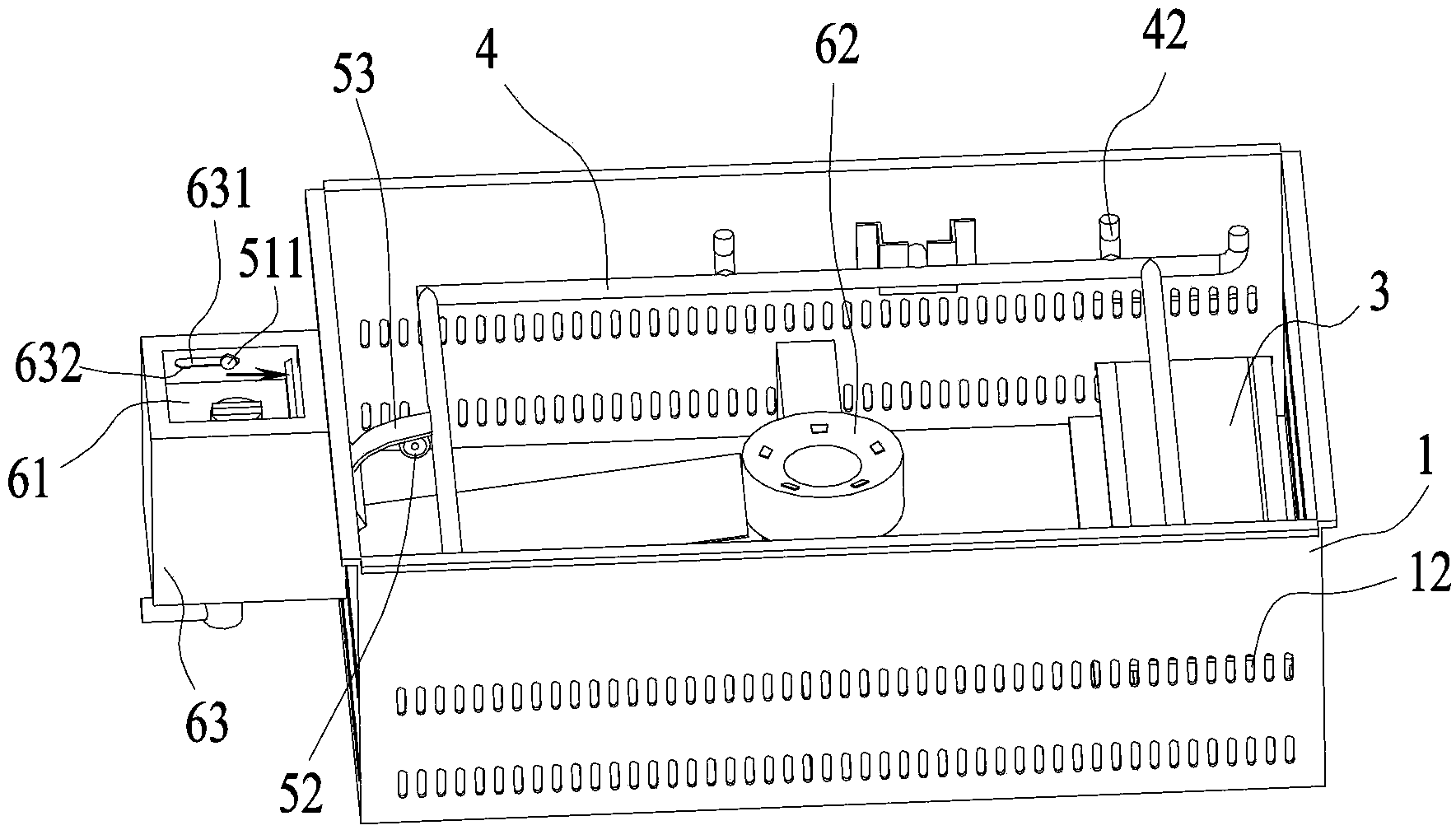

PendingCN113518541AImprove cleanlinessPracticalCasings/cabinets/drawers detailsModifications using gaseous coolantsBatch processingProcess engineering

The utility model discloses a rapidly-deashing radiator for compact electronic equipment and relates to a radiating module for electronic equipment. With the radiator adopted, people can disassemble and clean dust from target electronic equipment at any time without the aid of tools, so that the user can very easily and conveniently complete the dust cleaning work of the target electronic equipment without any professional skill. The time for deashing and disassembling the machine or the money for finding other people to clean and the possible damage to the equipment can be reduced; and meanwhile, the radiator is of structural simplicity, and has high manufacturability, and batch processing and manufacturing are facilitated.

Owner:张芸皓

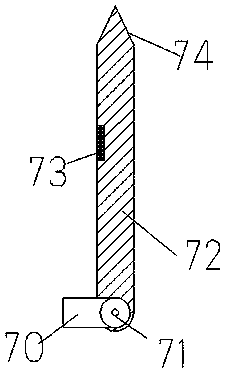

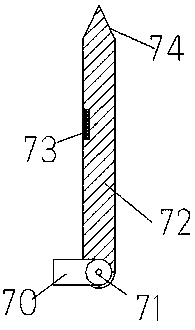

Artificial intelligence probe temperature sensor with cleaning function

InactiveCN112504483AQuick scrape cleanupQuick cleaning operationThermometer detailsCleaning using toolsEngineeringMechanical engineering

The invention relates to the technical field of probe temperature sensors, and discloses an artificial intelligence probe temperature sensor with a cleaning function, which comprises a sensor body anda probe mounted at the lower end of the sensor body. The lower end of the sensor body is fixedly connected with an elastic protective sleeve sleeving the probe; the lower end of the elastic protective sleeve is fixedly connected with a cleaning scraping ring sleeving the probe, the outer side of the sensor body is slidably connected with a U-shaped connecting rod, the lower end of the U-shaped connecting rod is fixedly connected with the side wall of the cleaning scraping ring, and the outer wall of the lower end of the sensor body is symmetrically and fixedly connected with two sliding rods.The rod wall of the U-shaped connecting rod is provided with a strip-shaped sliding opening in sliding connection with the sliding rod, and the upper end of the sensor body is fixedly connected witha positioning block. Rapid cleaning operation can be achieved, and use is convenient.

Owner:西安瑞尔时代信息科技有限公司

Pipeline cleaning device used in lead nitrate production process

InactiveCN113751434AImprove adaptabilityImprove cleaning efficiencyHollow article cleaningLead nitrateControl engineering

The invention relates to the field of chemical equipment, in particular to a pipeline cleaning device used in a lead nitrate production process. According to the technical scheme, the technical problem to be solved is that the cleaning efficiency of a chemical conveying pipeline is reduced, so that the purity of subsequent lead nitrate processing is reduced. According to the pipeline cleaning device used in the lead nitrate production process, a supporting clamping plate used for supporting is fixedly installed at a position, close to the end, of the upper end face of a supporting bottom plate, a driven toothed belt wheel is rotationally clamped to the position, close to the top, of the upper end face of the supporting clamping plate, a transmission device is rotationally clamped to the position, right facing the driven toothed belt wheel, of the inner end face of the supporting clamping plate, the driven toothed belt wheel is fixedly connected with the transmission device, a servo motor is fixedly clamped to the position, close to the top, of the outer end face of the supporting clamping plate, and a driving toothed belt wheel is fixedly mounted in the center of the rear end surface of the servo motor. According to the technical scheme, the pipeline cleaning device has the beneficial effect that the conveying pipe cleaning efficiency and cleanliness are improved.

Owner:湖南汉华化工有限公司

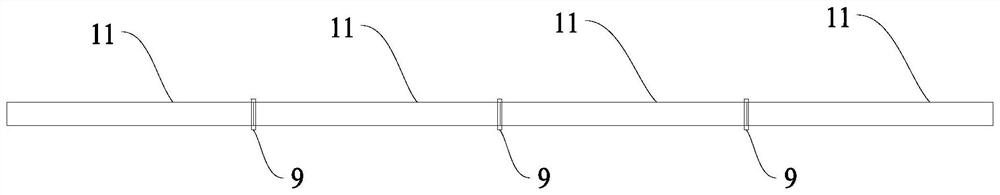

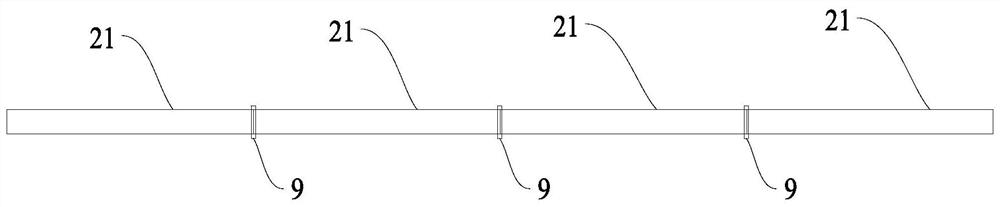

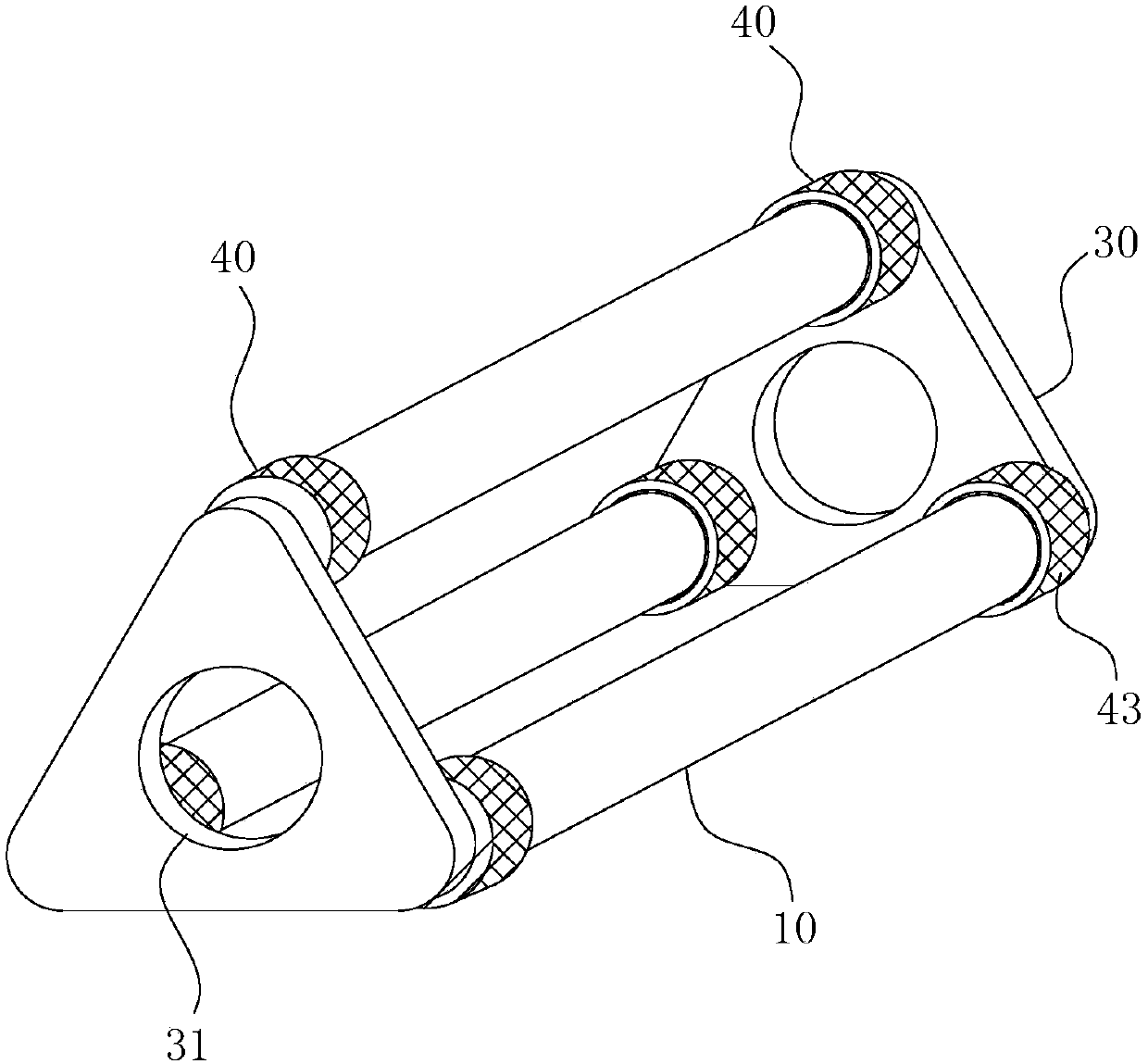

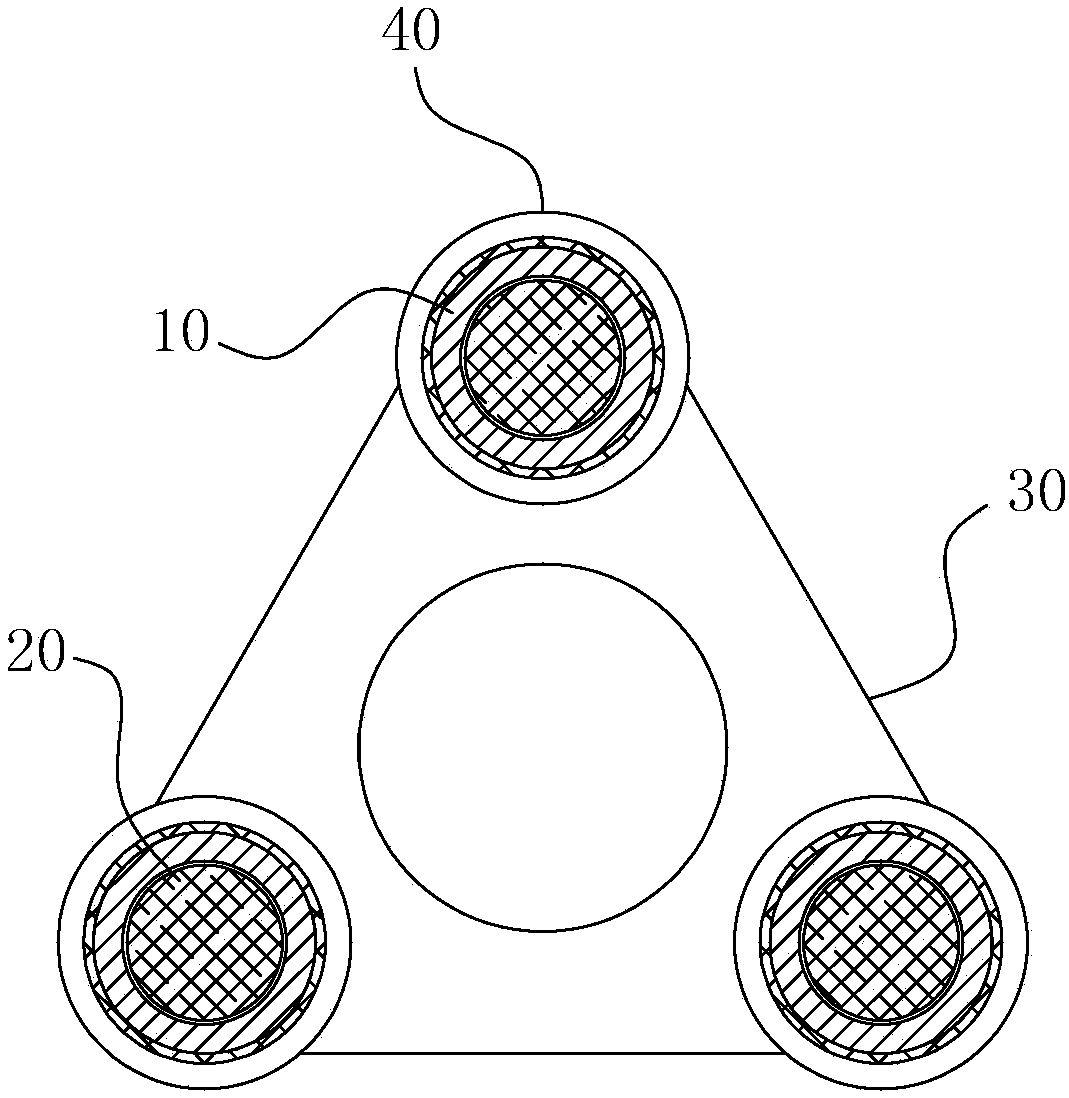

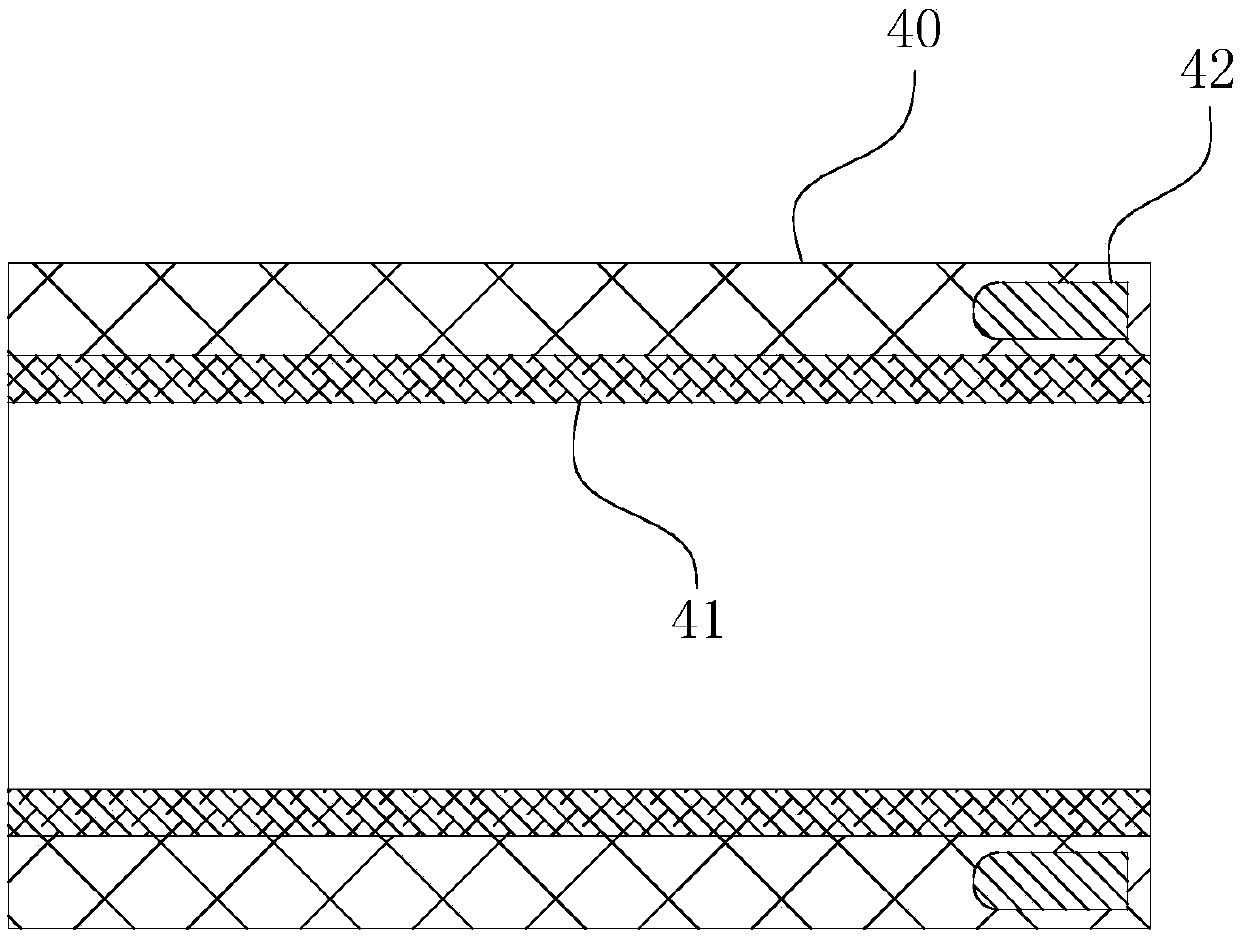

Magnetic attraction type foreign matter removing device

The invention belongs to the field of lamination machine feeding assisting equipment, and particularly relates to a magnetic attraction type foreign matter removing device. The device comprises magnetic attraction pipes made of metal materials. Containing cavities used for containing magnets are formed by pipe cavities of the magnetic attraction pipes. End portion sealing plates made of metal materials are arranged at the two ends of each magnetic attraction pipe. The two end portion sealing plates are parallel to each other, and the maximum distance between the two end portion sealing platesis equal to the width of a hopper outlet pipeline of a lamination machine so that the two end portion sealing plates can be attracted and fixed to the outer pipe wall of the hopper outlet pipeline through magnetic attraction force of the magnets. The magnetic attraction pipes are in a straight barrel pipe shape, the position of the outer pipe wall of each magnetic attraction pipe is coaxially sleeved with a cleaning ring capable of axially moving along the outer pipe wall. The inner ring face of each cleaning ring is provided with a felt layer or a gel layer which is attached to the outer pipewall of the corresponding magnetic attraction pipe. By means of the device, the function of filtering out metal type foreign matter in raw materials at the feeding end position of the lamination machine can be achieved, and accordingly the delivery quality of a machined film finished product is effectively guaranteed while the service life of the machine is ensured.

Owner:HUANGSHAN NOVEL

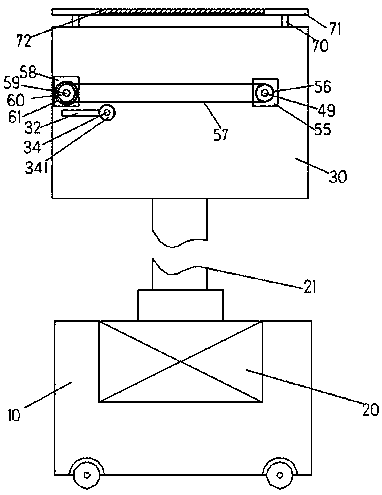

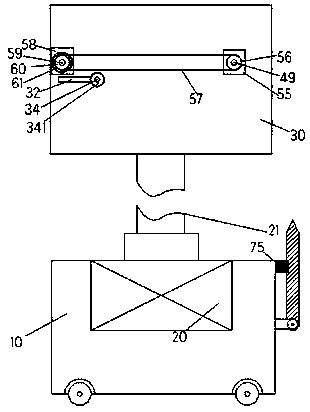

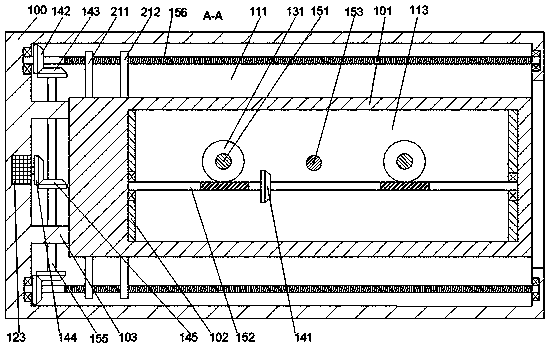

Novel preparing technological device of glass or inorganic amorphous state material

ActiveCN108191264ASimple structureEasy to operateFlexible article cleaningEngineeringMechanical engineering

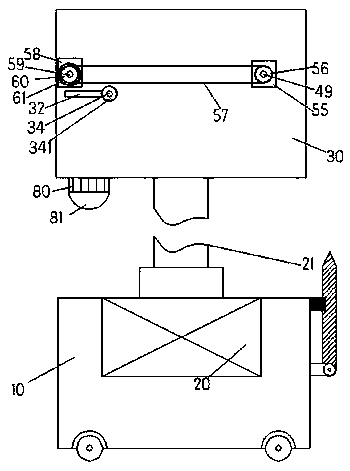

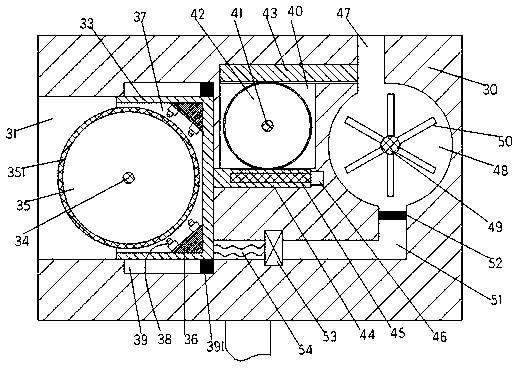

The invention discloses a novel preparing technological device of a glass or inorganic amorphous state material. The novel preparing technological device comprises a trolley and a machine frame arranged above the trolley. A cylinder is arranged in the top end face of the trolley. A telescopic rod of the cylinder is fixedly connected with the bottom end face of the machine frame. A containing groove with an opening facing leftward is formed in the machine frame and internally slidingly provided with a sliding frame. A first rotating cavity with an opening facing leftward is formed in the sliding frame. First sliding grooves communicated with the outside are symmetrically formed in the front end wall and the rear end wall of the containing groove. First sliding blocks (not shown in the figures) extending in the first sliding grooves and slidingly matched and connected with the first sliding grooves are fixedly installed on the front end wall and the rear end wall of the sliding frame. Afirst rotating shaft penetrating through the first rotating cavity is rotationally installed between the front and rear first sliding blocks (not shown in the figures). The front end and the rear endof the first rotating shaft extend towards the outer side end faces of the front and rear first sliding blocks respectively.

Owner:XUZHOU YUANYANG MAGNETIC MATERIAL

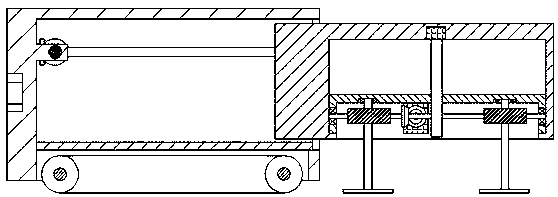

Manufacturing equipment of glass or inorganic amorphous materials

InactiveCN108405532ASimple structureEasy to operateFlexible article cleaningCleaning using toolsFront and back endsCart

The invention discloses manufacturing equipment of glass or inorganic amorphous materials. The manufacturing equipment comprises a cart and a rack, wherein the rack is arranged above the cart, an aircylinder is arranged in the top end surface of the cart, a telescopic rod of the air cylinder is fixedly connected with the bottom end surface of the rack, a containing groove with a leftward end opening is formed in the rack, a sliding frame is installed in the containing groove in a sliding mode, a first rotating cavity with a leftward end opening is formed in the sliding frame, first chutes which communicate with the outside are symmetrically formed in the front and back end walls of the containing groove, first sliding blocks (which are not shown in the figure) which extend into the firstchutes and are in sliding matching connection are fixedly installed on the front and back end walls of the sliding frame, a first rotating shaft which penetrates through the first rotating cavity is rotatably installed between the two first sliding blocks (which are not shown in the figure), and the front and back ends of the first rotating shaft respectively extend to the end surfaces of the outer sides of the front and back two first sliding blocks.

Owner:金佳琪

An improved wall brushing device

InactiveCN109124508ASimple structureEasy to operateCarpet cleanersFloor cleanersBrush deviceEngineering

The invention discloses an improved wall brushing device, comprising a vehicle body and a base frame arranged above the vehicle body. A pneumatic cylinder is arranged in the top end face of the vehicle body, the pneumatic rod of the pneumatic cylinder is fixedly connected with the bottom end face of the base frame, the base frame is provided with a receiving cavity with a notch facing to the left,a slide frame is slidably installed in the container cavity, the sliding frame is provided with a first turning groove with a notch facing to the left, a first sliding groove communicating with the outside is symmetrically arranged on the front and rear end walls of the cavity, a first sliding block (not shown) protruding into the first sliding groove and connected with the sliding fit is fixedlyinstalled on the front and rear end walls of the carriage, Between the front and rear first sliding blocks (not shown), a first rotating lever is rotatably mounted through the first rotating groove,and the front and rear ends of the first rotating lever are respectively extended on the outer end faces of the two first sliding blocks.

Owner:何杨波

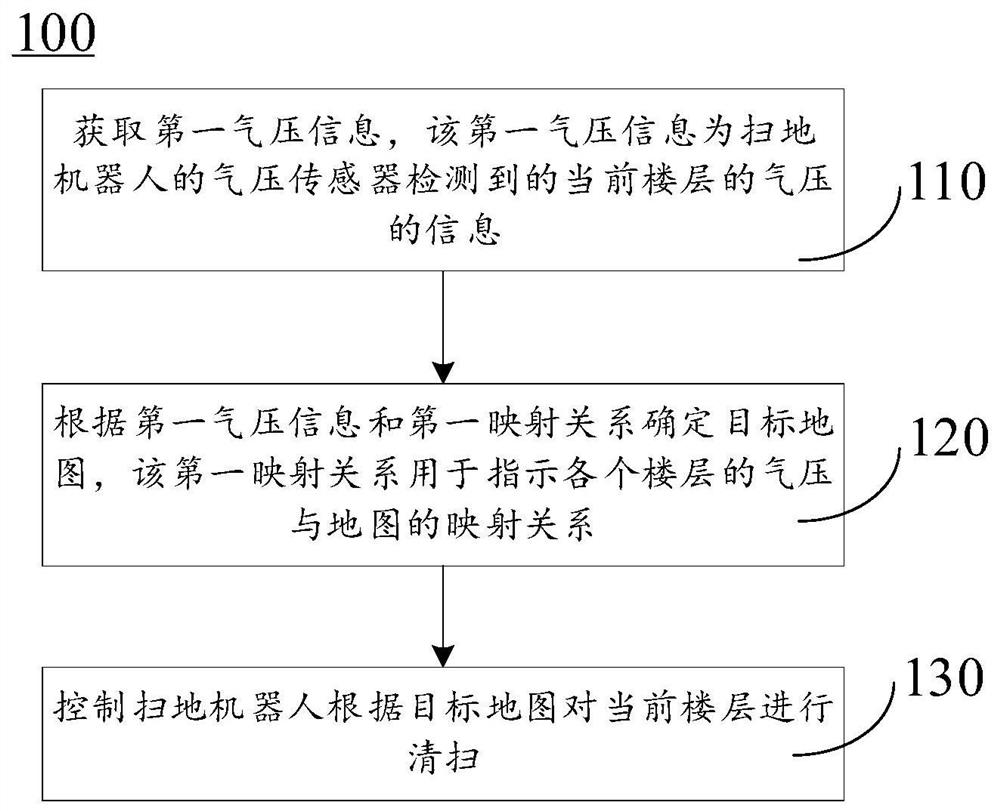

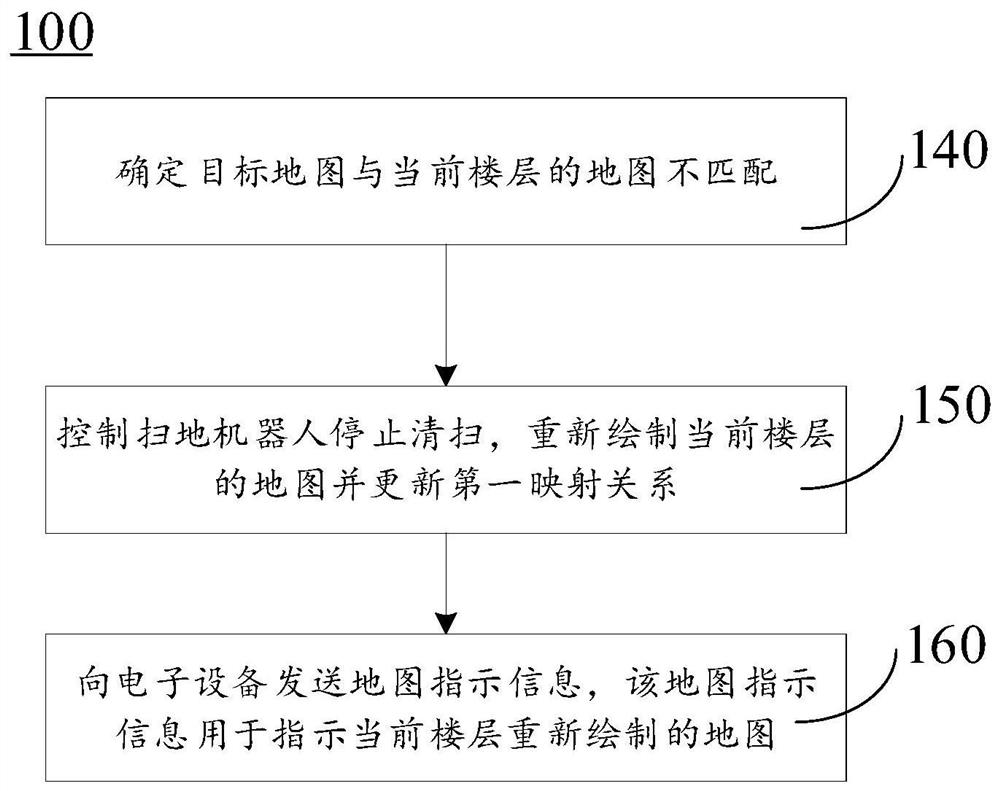

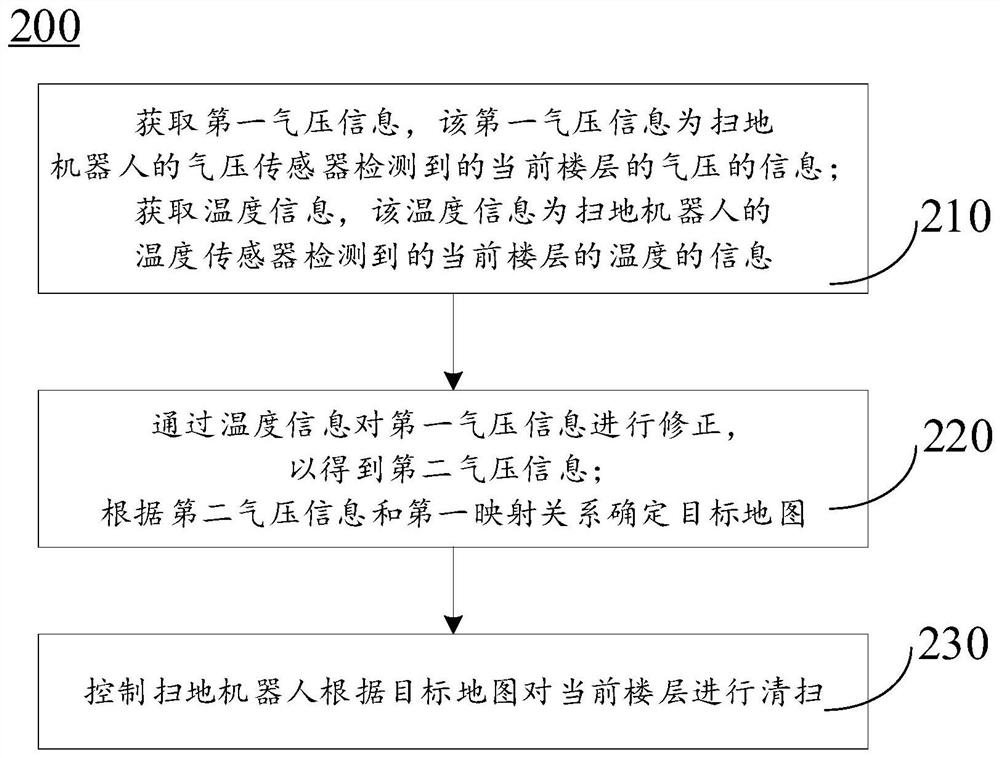

Sweeping control method and device of sweeping robot and sweeping robot

PendingCN113341981AQuick cleaning operationQuick investmentPosition/course control in two dimensionsControl engineeringSimulation

The invention provides a sweeping control method and device of a sweeping robot and the sweeping robot, and the method comprises the steps of obtaining first air pressure information, wherein the first air pressure information is the air pressure information, detected by an air pressure sensor of the sweeping robot, of a current floor; determining a target map according to the first air pressure information and a first mapping relationship, wherein the first mapping relationship is used for indicating a mapping relationship between the air pressure of each floor and the map; and controlling the sweeping robot to sweep the current floor according to the target map. According to the cleaning control method provided by the invention, the sweeping robot can quickly call the map corresponding to the current floor to execute the cleaning operation, so that the working efficiency of the sweeping robot and the use experience of a user are improved.

Owner:MIDEA ROBOZONE TECH CO LTD

Environment-friendly sludge treatment equipment for sewage treatment plant

PendingCN114292002AEasy to clean upSave cleanup timeSludge treatmentHollow article cleaningSewageSludge dewatering

The invention provides environment-friendly sludge treatment equipment for a sewage treatment plant. The environment-friendly sludge treatment equipment for the sewage treatment plant comprises a machine body; the centrifugal structure is arranged in the machine body, and the centrifugal structure comprises a centrifugal roller for centrifugally dewatering sludge and a sealing assembly for sealing one side of the centrifugal roller. According to the environment-friendly sludge treatment equipment for the sewage treatment plant, the sealing assembly is arranged on the outer side of the centrifugal roller and is mainly used for sealing the outer side of the centrifugal roller, meanwhile, the function of automatically cleaning sludge in the centrifugal roller can be achieved, and after sludge dewatering is completed, the telescopic assembly extends, so that the sludge in the centrifugal roller can be recycled. Finally, the cleaning piece can horizontally move outwards in the centrifugal roller, then the sludge flows outwards into the collecting vehicle, automatic sludge cleaning is completed, manual cleaning operation is changed, and sludge cleaning operation is more convenient, more labor-saving and faster.

Owner:江苏环保产业技术研究院股份公司 +1

Cleaning device for new energy automobile interior part crystal ball decoration production

InactiveCN112792081AReduce the chance of breakageWon't collideCleaning processes and apparatusSurface cleaningNew energy

The invention relates to the technical field of automobile accessories, and discloses a cleaning device for new energy automobile interior part crystal ball decoration production. The device comprises a support body, wherein a fixing table is arranged on the surface of the support body, a driving gear is arranged in the support body, a rotary table is arranged on the surface of the fixing table, a table seat is arranged on the surface of the rotary table, a transmission gear is arranged at the lower end of the table seat, a first driving rod is arranged on the upper portion of the fixing table, a supporting rod is arranged on the surface of the first driving rod, and a buffering piece is arranged on the surface of the first driving rod. According to the cleaning device for new energy automobile interior part crystal ball decoration production, the fixing platform and the rotary table are used in cooperation, the rotary table and the table seat are used in cooperation, continuous circulating cleaning operation processing can be conducted on crystal ball decorations, meanwhile, collision between the crystal ball decorations is avoided, the efficiency of crystal ball surface cleaning processing can be effectively improved, and meanwhile the probability that crystal balls are damaged is reduced.

Owner:杭州为客信息技术有限公司

Novel wall brushing device

InactiveCN108294704ASimple structureEasy to operateCarpet cleanersFloor cleanersBrush deviceEngineering

The invention discloses a novel wall brushing device. The device comprises a vehicle body and a base frame arranged above the vehicle body; the top end face of the vehicle body is internally providedwith a pneumatic cylinder, and an air pressure rod of the pneumatic cylinder is fixedly connected with the bottom end face of the base frame; the base frame is internally provided with a containing cavity with a groove opening facing leftwards, and a sliding frame is slidingly mounted in the containing cavity and internally provided with a first rotating groove with a groove opening facing leftwards; first sliding grooves communicated with the exterior are symmetrically formed in the front and rear end walls of the containing cavity, first sliding blocks (not shown) which extend into the firstsliding grooves and are slidingly and cooperatively connected are fixedly mounted on the front and rear end walls of the sliding frame, a first rotating rod penetrating through the first rotating groove is rotatably mounted between the front and rear first sliding blocks (not shown), and the front and rear ends of the first rotating rod extend towards the outer end faces of the front and rear first sliding blocks respectively.

Owner:何杨波

Improved cleaning device

InactiveCN108577682AQuick cleaning operationSimple structureCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses an improved cleaning device. The improved cleaning device comprises a machine base and a first empty groove arranged inside the machine base and having a rightward opening, wherein a first mounting rack is arranged in the first empty groove, a second empty groove with a downward opening is arranged in the first mounting rack, a second mounting rack having a downward openingand penetrating forwards and backwards is in smooth match connection in the second empty groove, and a third empty groove is arranged in the second mounting rack.

Owner:周四海

Welding device for electric tool part machining

InactiveCN113084401ARealize multi-directional welding operationSolve clamping difficultiesWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlSlide plate

The invention discloses a welding device for electric tool part machining. The welding device for electric tool part machining comprises a bottom plate, two first sliding grooves are formed in the front portion of the upper end of the bottom plate, the interiors of the two first sliding grooves are jointly and slidably connected with a sliding plate, and the left portion and the right portion of the sliding plate are both in threaded connection with fastening rotary knobs; and the lower ends of the fastening rotary knobs are in threaded connection with the inner parts of the two first sliding grooves, a first side plate and a second side plate are fixedly connected to the left end and the right end of the sliding plate correspondingly, a welding mechanism penetrates through the upper portion of the second side plate, the left end of the welding mechanism is fixedly connected with the right end of the first side plate, and a numerical control table is fixedly installed on the right portion of the upper end of the bottom plate. According to the welding device for electric tool part machining, multidirectional welding operation can be achieved, the problem that heated parts are difficult to clamp is solved, local overheating of the parts caused by too long welding time in the subsequent machining process can be avoided, and the welding quality is guaranteed; and in addition, cleaning efficiency can be improved, and modern use requirements are met.

Owner:东莞市浩恒工业设计有限公司

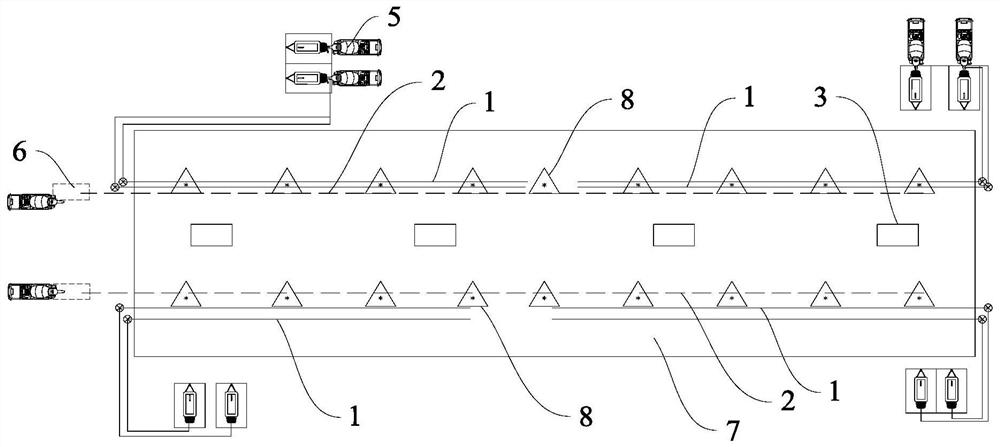

An indoor badminton court cleaning device

ActiveCN112741569BQuick cleaning operationPrevent fallingGeneral water supply conservationCarpet cleanersStructural engineeringWater collection

The invention discloses a cleaning device for an indoor badminton court, which comprises a court, a left box, a chute, a water collection tank, and an opening. The side is provided with a chute, the right end of the field is provided with a sump, the top of the sump is provided with an opening, and the top of the sump is flush with the field. The left box is provided with a first slider and a second slider, the first slider and the second slider are connected to the chute, the first slider is screwed to the screw rod, and the second slider is connected to the guide rod , and the screw mandrel and the guide rod are all located in the chute, the end of the chute communicates with the left box, the first slider and the second slider are connected by a sprinkling pipe, and the sprinkling pipe is flush with the top of the field. The invention has reasonable design; the cleaning device can be used to quickly clean the field, thereby improving the work efficiency.

Owner:湖北世纪鼎信体育设施有限公司

A kind of manufacturing technology equipment of inorganic amorphous material

ActiveCN108191264BSimple structureEasy to operateFlexible article cleaningEngineeringMechanical engineering

The invention discloses a novel preparing technological device of a glass or inorganic amorphous state material. The novel preparing technological device comprises a trolley and a machine frame arranged above the trolley. A cylinder is arranged in the top end face of the trolley. A telescopic rod of the cylinder is fixedly connected with the bottom end face of the machine frame. A containing groove with an opening facing leftward is formed in the machine frame and internally slidingly provided with a sliding frame. A first rotating cavity with an opening facing leftward is formed in the sliding frame. First sliding grooves communicated with the outside are symmetrically formed in the front end wall and the rear end wall of the containing groove. First sliding blocks (not shown in the figures) extending in the first sliding grooves and slidingly matched and connected with the first sliding grooves are fixedly installed on the front end wall and the rear end wall of the sliding frame. Afirst rotating shaft penetrating through the first rotating cavity is rotationally installed between the front and rear first sliding blocks (not shown in the figures). The front end and the rear endof the first rotating shaft extend towards the outer side end faces of the front and rear first sliding blocks respectively.

Owner:XUZHOU YUANYANG MAGNETIC MATERIAL

Oil tank liquid level maintaining device for numerical control machine tool

PendingCN112965539AQuick cleaning operationGuaranteed liquid levelLevel controlNumerical controlControl engineering

The invention provides an oil tank liquid level maintaining device for a numerical control machine tool, relates to the technical field of liquid level maintaining, and solves the problems that the liquid level of an oil tank in an existing numerical control machine tool is often monitored and maintained by a sensor, but the precision of the sensor is affected by oil dirt sometimes, so that detection failure is caused, and in addition, the oil liquid maintaining form is single, supply after treatment cannot be carried out on flown-back engine oil liquid, and normal operation of a machine can be affected due to the existence of impurities. The device comprises a sealing mechanism, and the sealing mechanism is connected to the top end of the bearing mechanism in a clamped mode. When a floating tank floats upwards, a flow control ball is driven by a stand column to synchronously float upwards, then when oil in the tank body reaches a limit value, a liquid inlet pipe is blocked through the flow control ball to maintain the liquid level, and a liquid supply maintaining mechanism is further installed on the right side of the top end face of a cover plate, a liquid supply pipe and a temporary storage box jointly form a siphon mechanism to maintain the liquid level of supplied liquid.

Owner:徐逸萍

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com