Stable-to-use deep hole cleaning device and cleaning method

A technology of cleaning device and deep hole, which is applied in the direction of grinding drive device, grinding machine parts, grinding workpiece support, etc. prone to shaking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

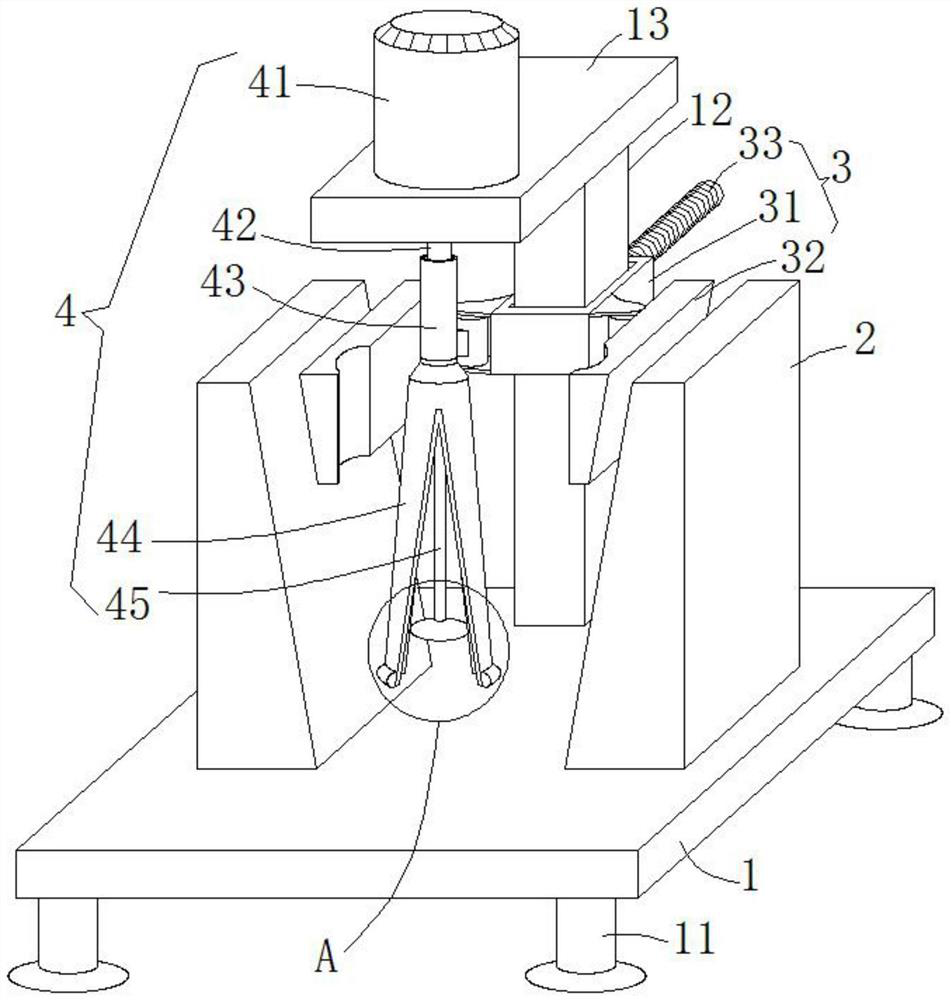

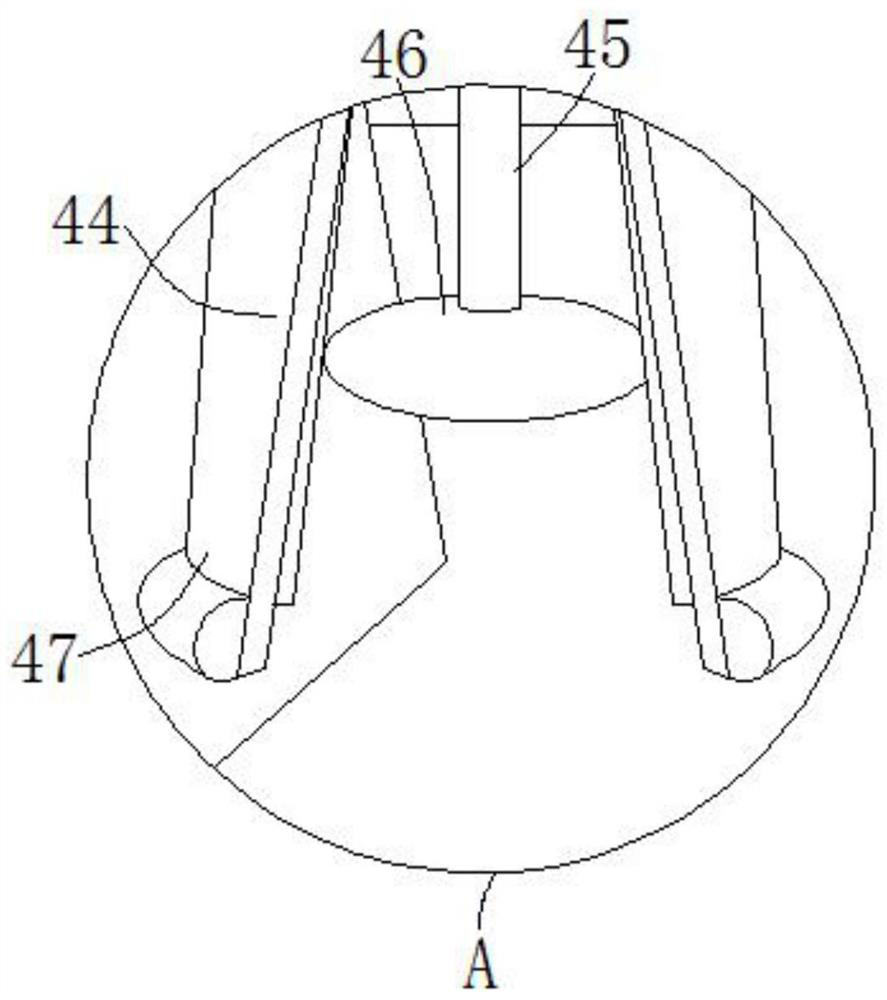

[0025] see Figure 1-2 , the present embodiment provides a stable deep hole cleaning device and cleaning method, including a base 1, a clamping mechanism 3 and a cleaning mechanism 4, a rectangular adjustment column 12 is vertically arranged at the middle position of the rear side of the top surface of the base 1, and the rectangular The top surface of the adjustment column 12 is welded horizontally forward with a lifting plate 13. The clamping mechanism 3 includes a rectangular adjustment sleeve 31 and two clamping plates 32. The top surface of the base 1 is symmetrically provided with two guide slides distributed left and right. Block 2, cleaning mechanism 4 includes drive motor 41, threaded sleeve 43, suspension rod 45 and ellipse prop up block 46.

[0026] The four corners of the bottom surface of the base 1 are vertically provided with supporting feet 11 .

[0027] The rectangular adjusting sleeve 31 is slidingly socketed on the outer wall of the rectangular adjusting co...

Embodiment 2

[0033] see Figure 1-2 , further improvements have been made on the basis of Example 1:

[0034] The ends of the opposite side walls of the two clamping plates 32 away from the rectangular adjusting sleeve 31 are provided with arc-shaped clamping slots, and the arc-shaped clamping slots are provided on the opposite side walls of the two clamping plates 32 to facilitate matching and clamping. The parts of the tubular type are cleaned to facilitate the cleaning operation of the axial deep hole, and the radial shaking is not easy to occur.

[0035] A handle 33 extends behind the center of the rear end surface of the rectangular adjusting sleeve 31 , and the handle 33 is provided to assist in pulling the rectangular adjusting sleeve 31 , saving time and effort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com