Environment-friendly sludge treatment equipment for sewage treatment plant

A sewage treatment plant, sludge treatment technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, cleaning methods and tools, etc., can solve the problems of time-consuming, laborious and inconvenient manual cleaning of sludge, and achieve shortened cleaning time, cleaning operation is convenient, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

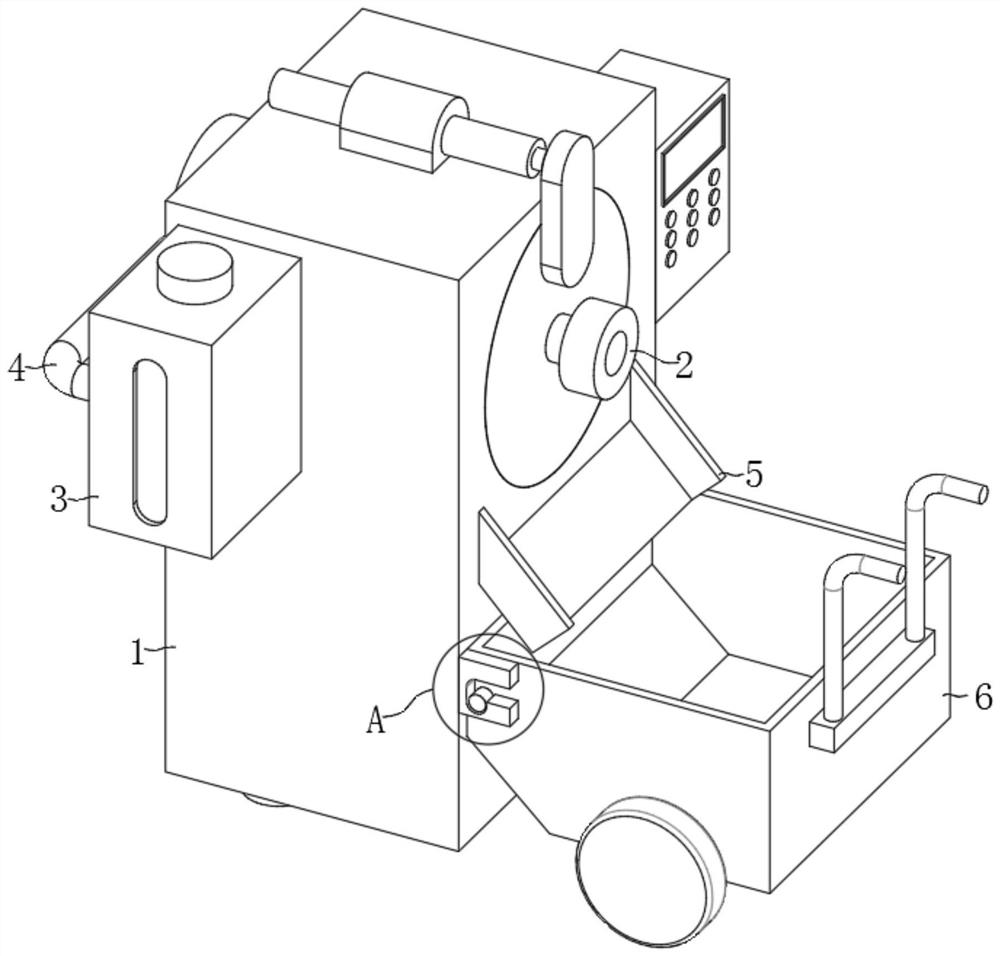

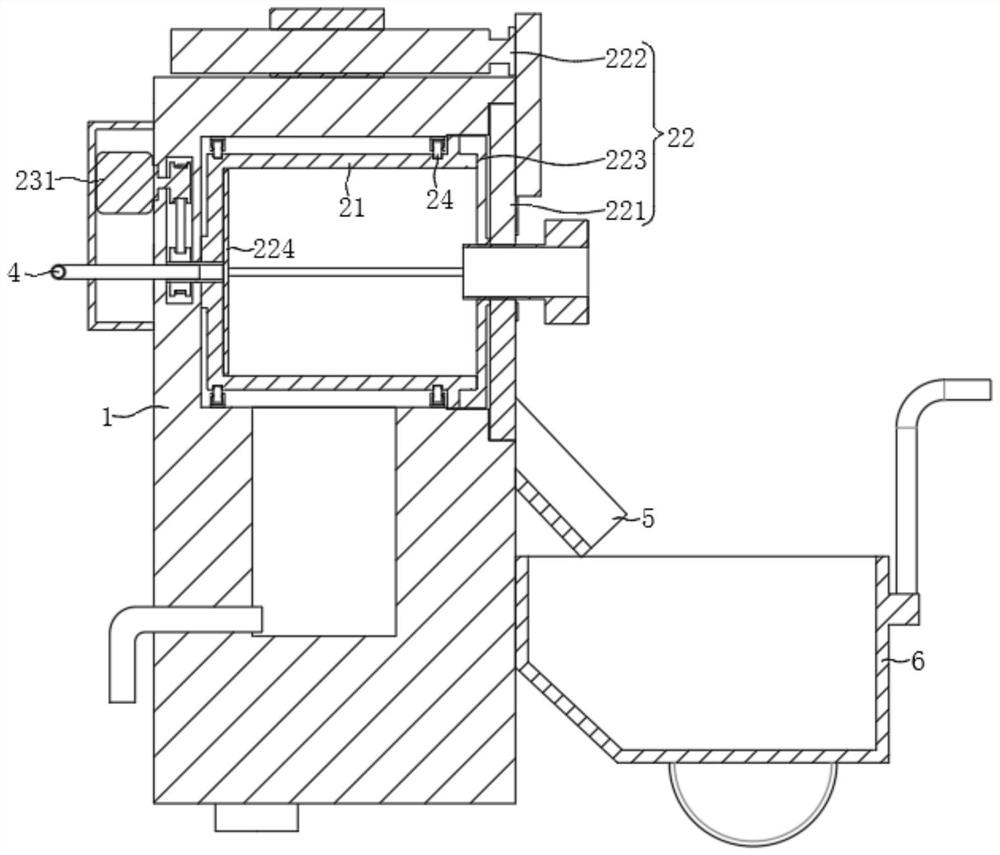

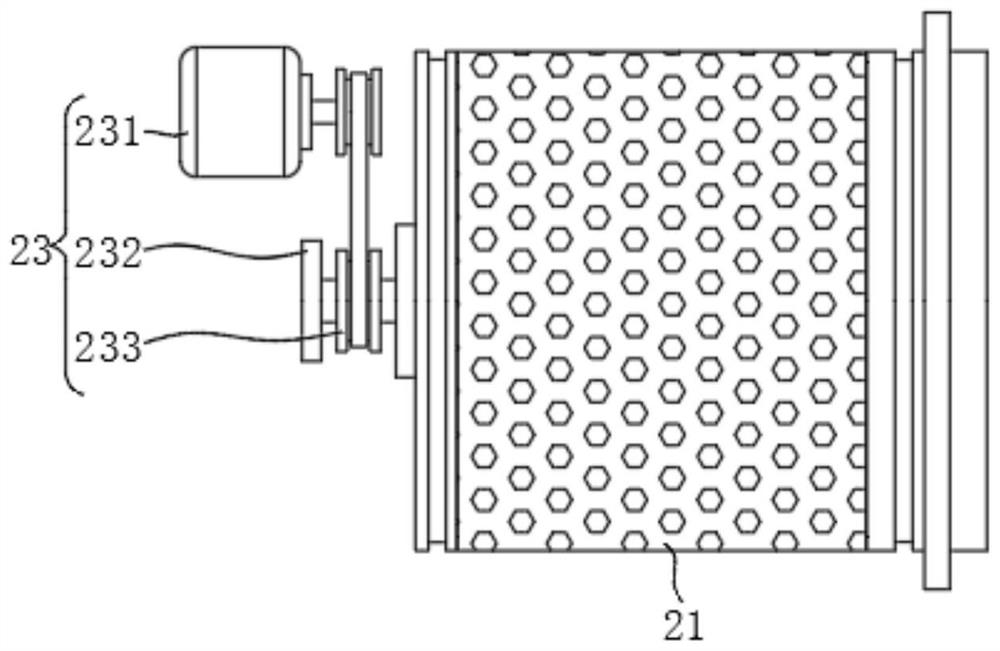

[0046] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 Schematic diagram of the structure of the first embodiment of the sludge treatment equipment for environment-friendly sewage treatment plants provided by the present invention; figure 2 for figure 1 The schematic diagram of the internal structure of the body shown; image 3 for figure 1 The schematic diagram of the external structure of the centrifugal structure shown; Figure 4 for image 3 Exploded schematic diagram of the centrifugal structure shown; Figure 5 for figure 1 The structural schematic diagram of the back of the housing shown; Figure 6 for figure 1 The enlarged schematic diagram of part A is shown. Environmentally friendly sludge treatment equipment for sewage treatment plants, including:

[0047] body 1;

[0048] Centrifugal structure 2, the centrifugal structure 2 is arranged inside the body 1, the centrifugal structure 2 includes a cent...

no. 2 example

[0061] Please refer to Figure 7-9 , based on the first embodiment of the present invention, an environment-friendly sewage treatment plant sludge treatment equipment, the second embodiment of the present invention provides another environment-friendly sewage treatment plant sludge treatment equipment, wherein the second embodiment It does not hinder the independent implementation of the technical solution of the first embodiment.

[0062] Specifically, the present invention provides another environment-friendly sewage treatment plant sludge treatment equipment with the following differences:

[0063] One side of the outer sealing cover 221 is provided with an introduction structure 7, the introduction structure 7 includes a mixing cylinder 71, one side of the mixing cylinder 71 is fixedly installed with one side of the outer sealing cover 221, and the mixing cylinder 71 is equipped with a screw rotating part 72, and the outside of the mixing cylinder 71 is fixedly equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com