Patents

Literature

42results about How to "Solve clamping difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus of continuous collision reinforcement by laser

InactiveCN1928127AEasy to realize industrial applicationRealize automatic processingManufacturing technologySystems design

The present invention relates to special machining and manufacture technology, and is especially continuous impacting high energy short pulse laser apparatus and process for reinforcing metal material. The apparatus is provided with sliding block, flexible working film, cushion block, liquid exhausting piston and other parts to form a flowing constraint liquid medium layer capable of being replaced automatically through liquid inflow in the liquid inlet and the liquid outflow in the liquid outlet. The present invention has properly designed system to integrate the constraint liquid medium essential for laser impacting and the coating skillfully, so as to realize continuous laser impact reinforcing treatment without needing constraint layer fixing and coating. The present invention can also realize online assembling or repairing impact reinforcement.

Owner:JIANGSU UNIV

Method for numerical control machining of large aircraft rib parts

A method for numerical control machining of large aircraft rib parts comprises a rough machining stage and a finish machining stage and is finished through four machining stations. The first rough machining face is a groove cavity face, rough machining of all of groove cavities is performed in a layer priority mode, and enough allowances are reserved at the bottoms of the groove cavities. The second rough machining face is a rib datum plane, and even rough machining allowances are reserved at all of positions. The finish machining face is a rib datum plane, positioning holes at two ends are re-adjusted after finish machining is finished, the second finish machining face is a groove cavity face, and finally process connecting plates at the gap positions of two-side edge plates and through hole positions of a web plate are separated.

Owner:XI'AN AIRCRAFT INTERNATIONAL

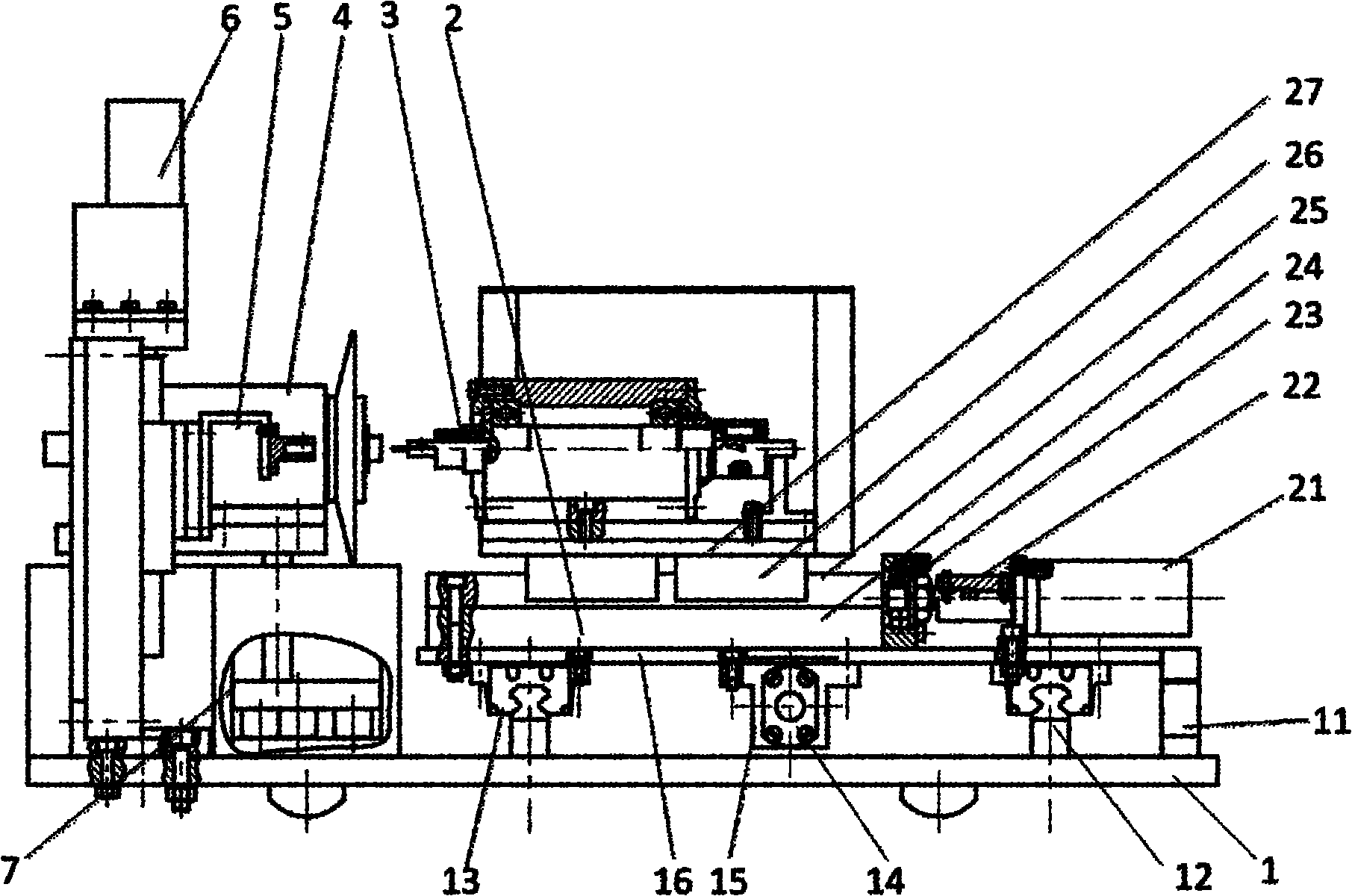

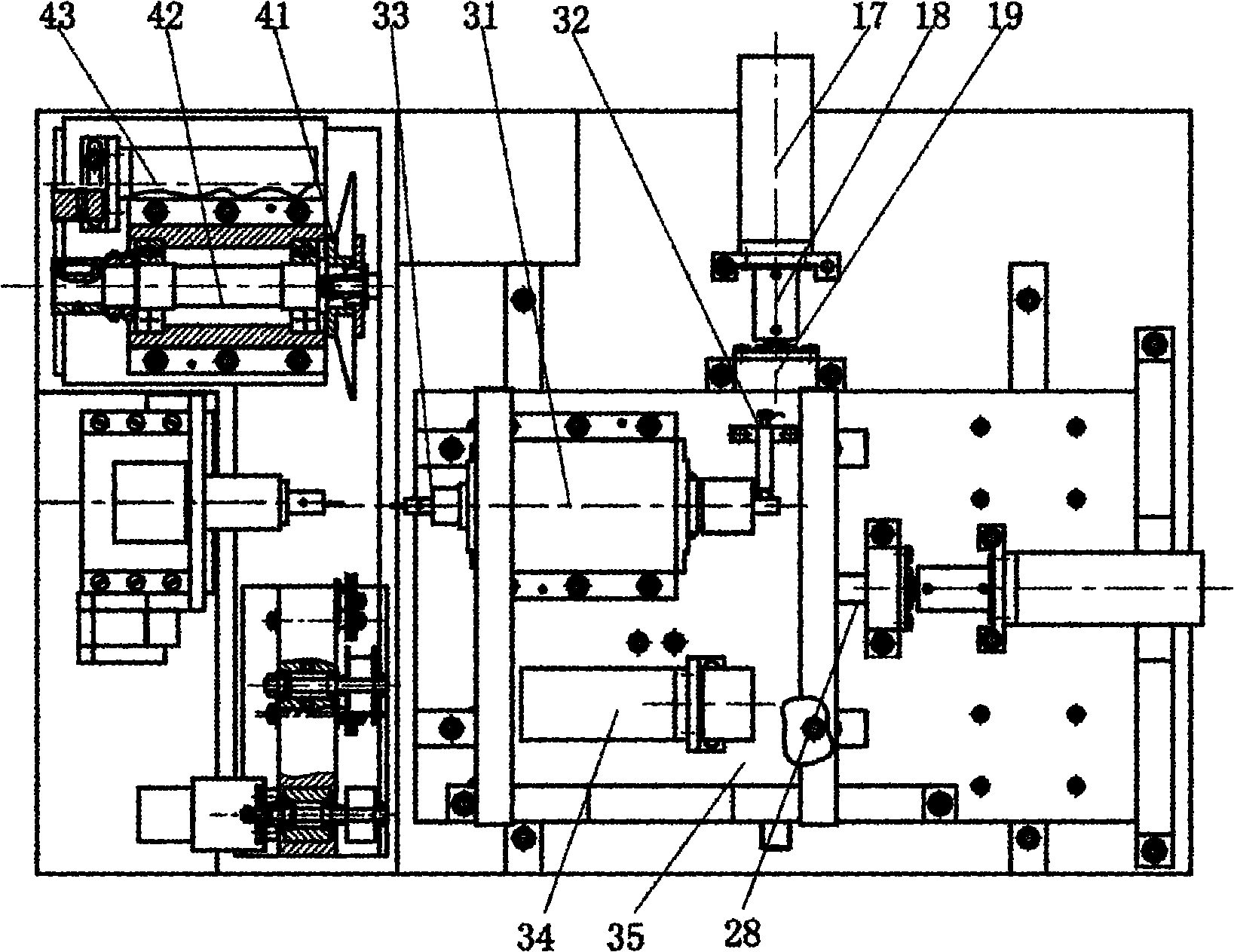

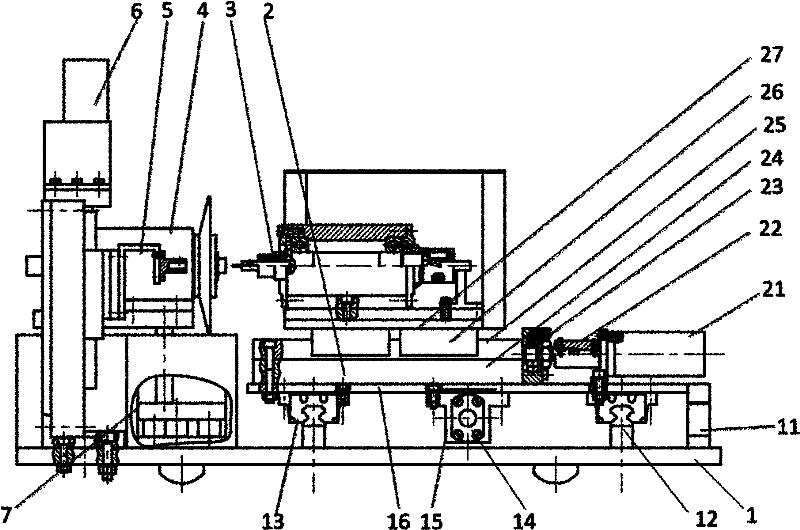

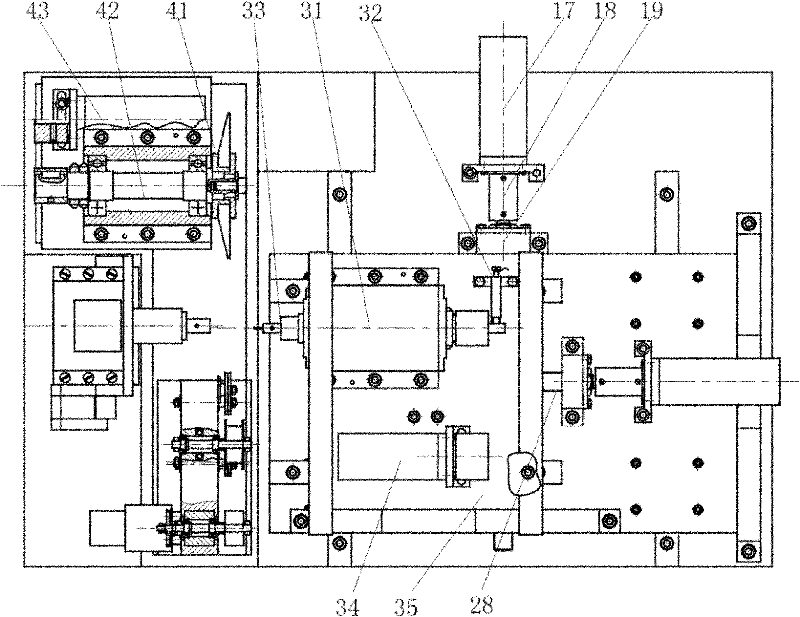

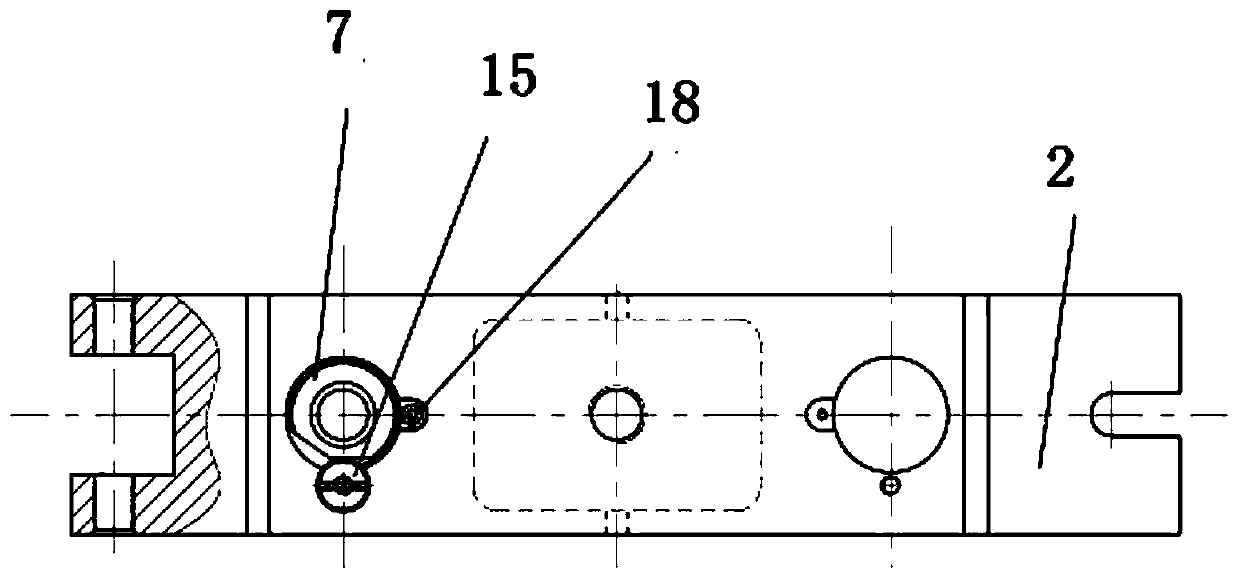

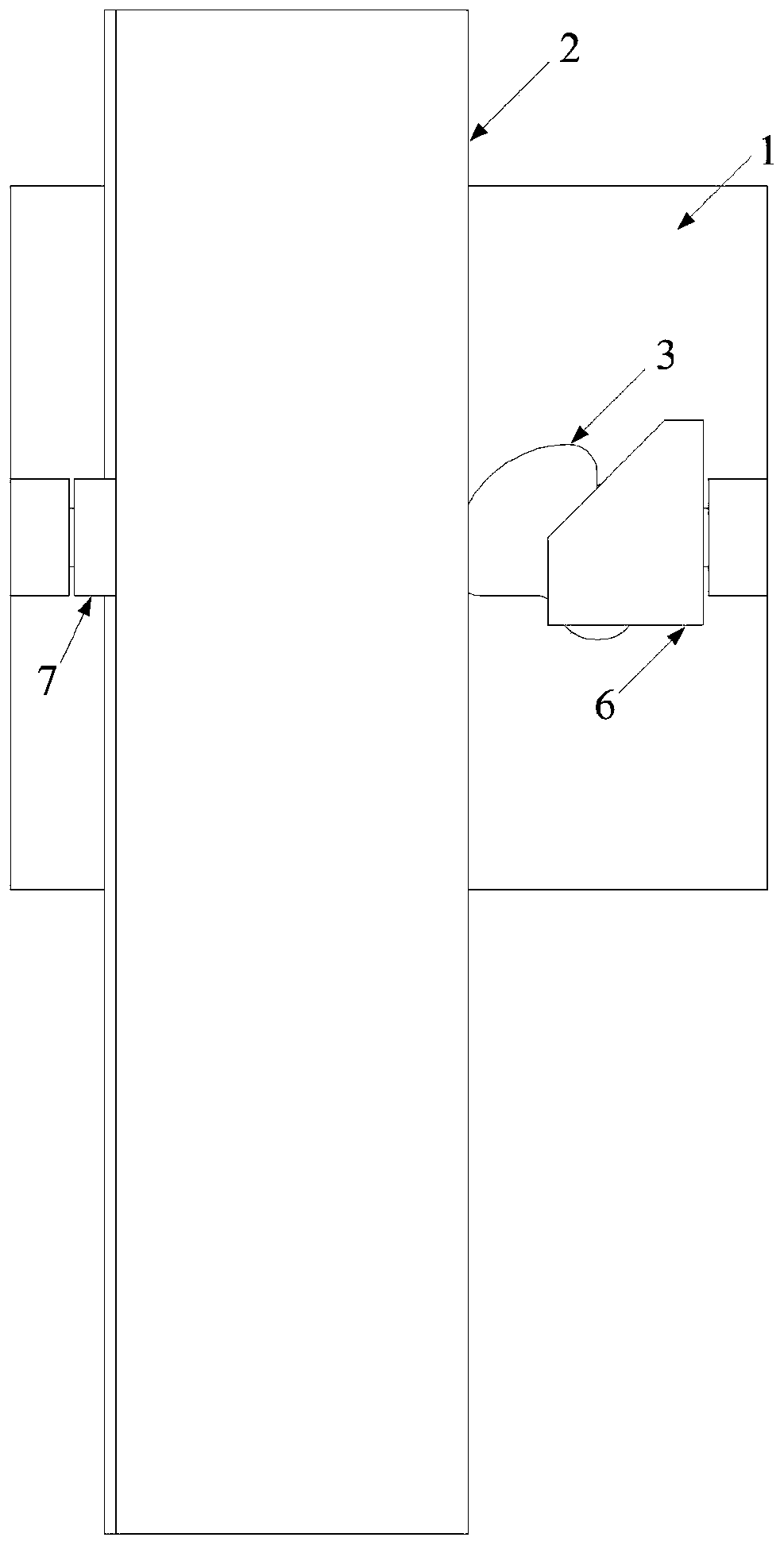

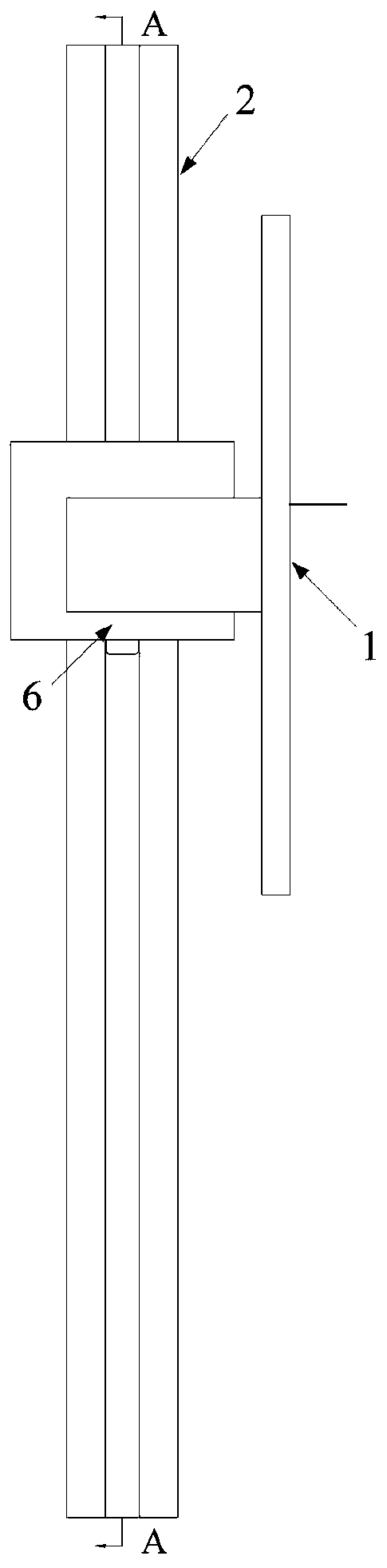

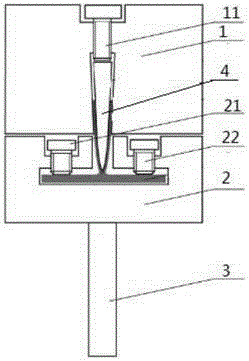

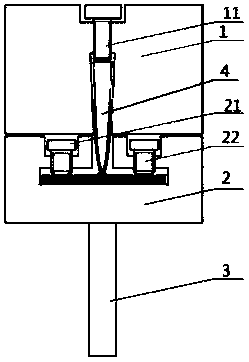

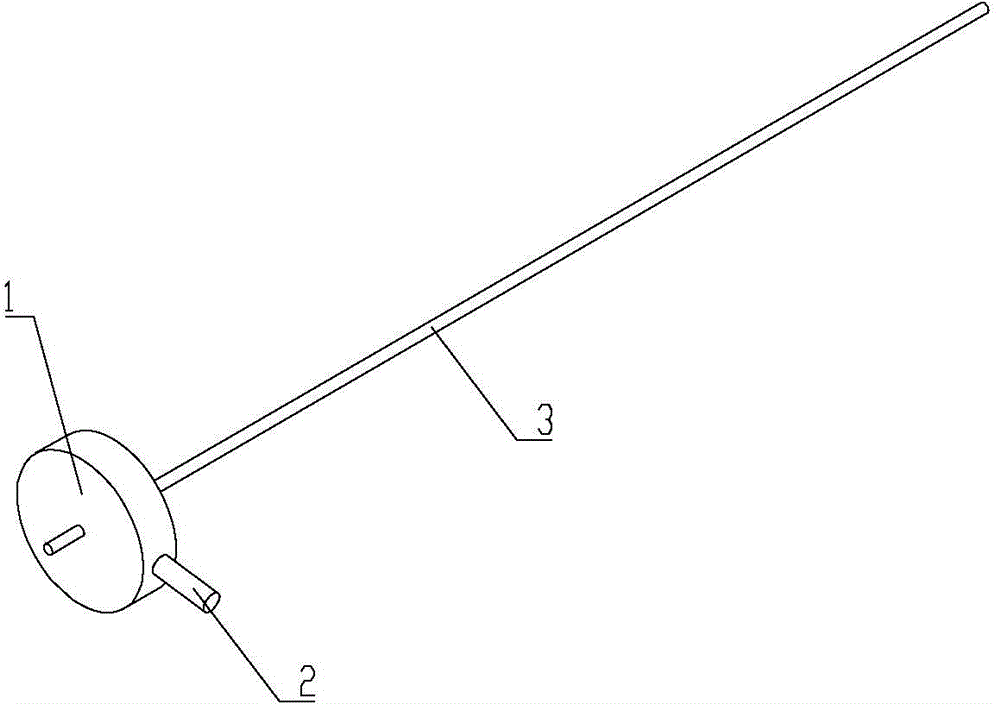

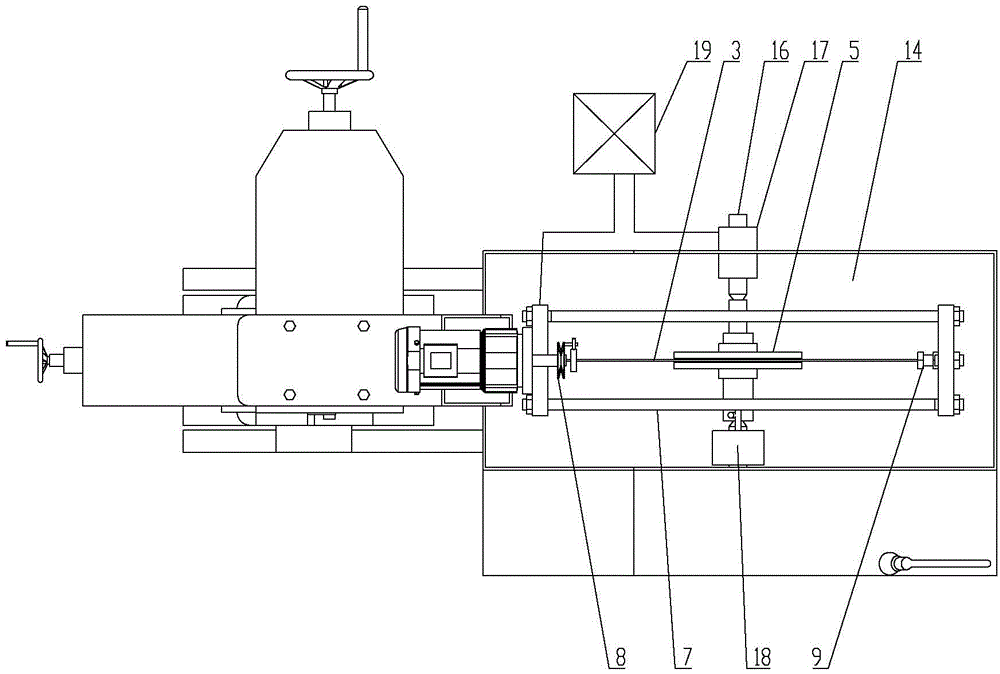

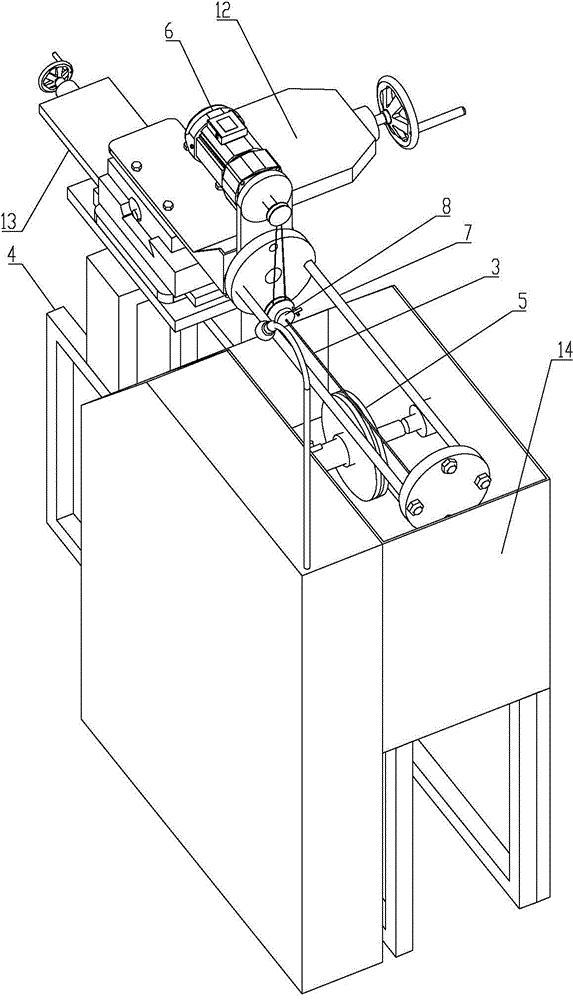

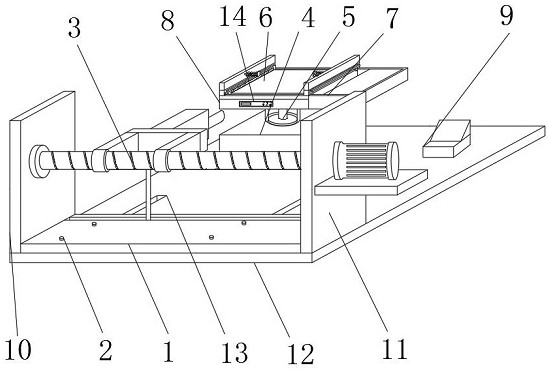

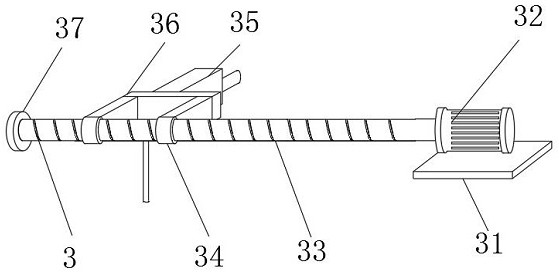

Horizontal micro-electric spark machine tool and method for performing online processing by applying same

The invention provides a horizontal micro-electric spark machine tool for manufacturing a microelectrode. The machine tool comprises a machine tool base (1), an X-Y two-dimensional workbench (2), an electrode main shaft (3), a grinding wheel grinding mechanism (4), a Z direction workbench (6) and a wire electric spark grinding mechanism (7), wherein the grinding wheel grinding mechanism (4) and the wire electric spark grinding mechanism (7) are fixedly arranged on the machine tool base (1) and positioned on both sides of the Z direction workbench (6) respectively; the electrode main shaft (3) is arranged on the X-Y workbench (2); a tool electrode to be processed is arranged on the electrode main shaft (3); and the X-Y two-dimensional workbench (2) drives the tool electrode to move relative to the carborundum grinding wheel grinding mechanism (4) and / or the wire electric spark grinding mechanism (7) so as to finish online manufacturing of the microelectrode. Online grinding of a carborundum grinding wheel is combined with online grinding of wire electric sparks and a high-accuracy optical grating ruler is adopted, so that high-efficiency and high-accuracy manufacturing of a micro-scale electrode is realized and high reliability and good economic benefit are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

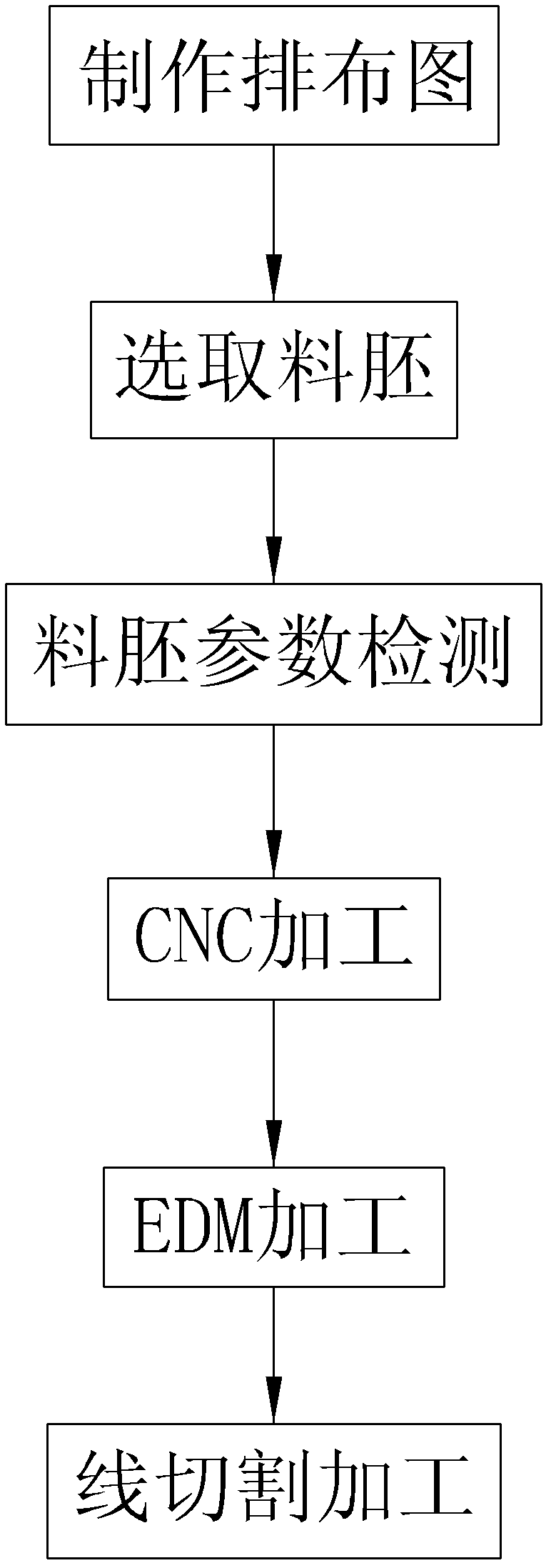

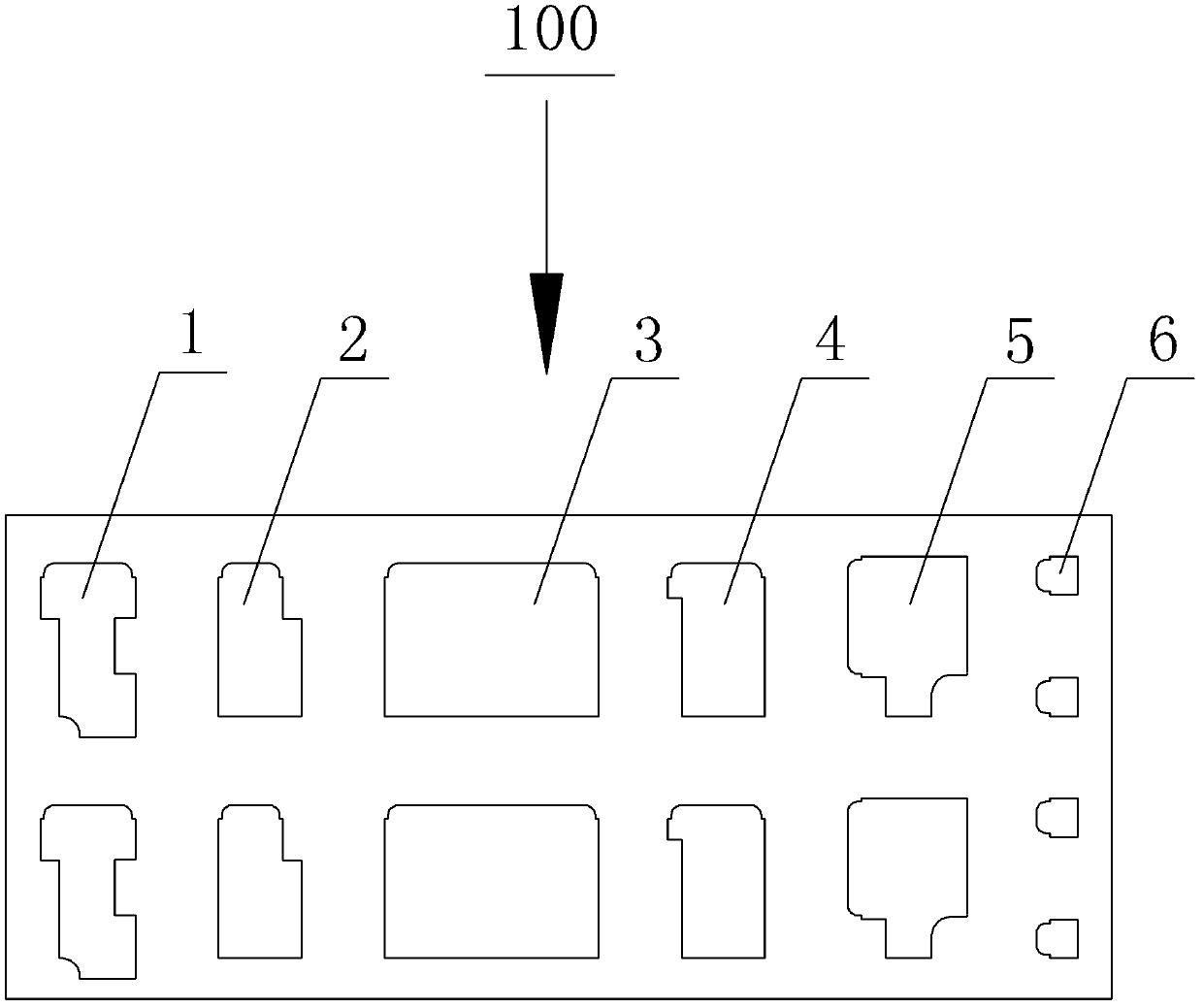

Insert integration type processing process

The invention discloses an insert integration type processing process. The insert integration type processing process comprises a first step of drawing a drawing with a plurality of insert outer contour maps according to the size and the shape of every to-be-processed insert; a second step of determining the size of needed blank according to the arrangement maps, and selecting the blank; a third step of detecting whether the squareness, the length, the width, the height and the tolerance of the blank meet the standard; a fourth step of performing computer numerical control (CNC) processing on the position of every to-be-processed insert, and forming every insert; a fifth step of performing electrical discharge machining (EDM) processing on every insert; and a sixth step of enabling the blank having undergone EDM processing to be clamped on a wire cutting machine tool to undergo wire cutting processing, and obtaining single inserts. The insert integration type processing process has the advantages that a plurality of inserts are integrated on one piece of blank to be integrally formed, clamping time of the single inserts is reduced, processing efficiency is improved, deformation of small inserts in processing can be effectively avoided, and the problem of difficulty in clamping special-shaped inserts and small single inserts is solved.

Owner:亿和塑胶电子制品(深圳)有限公司

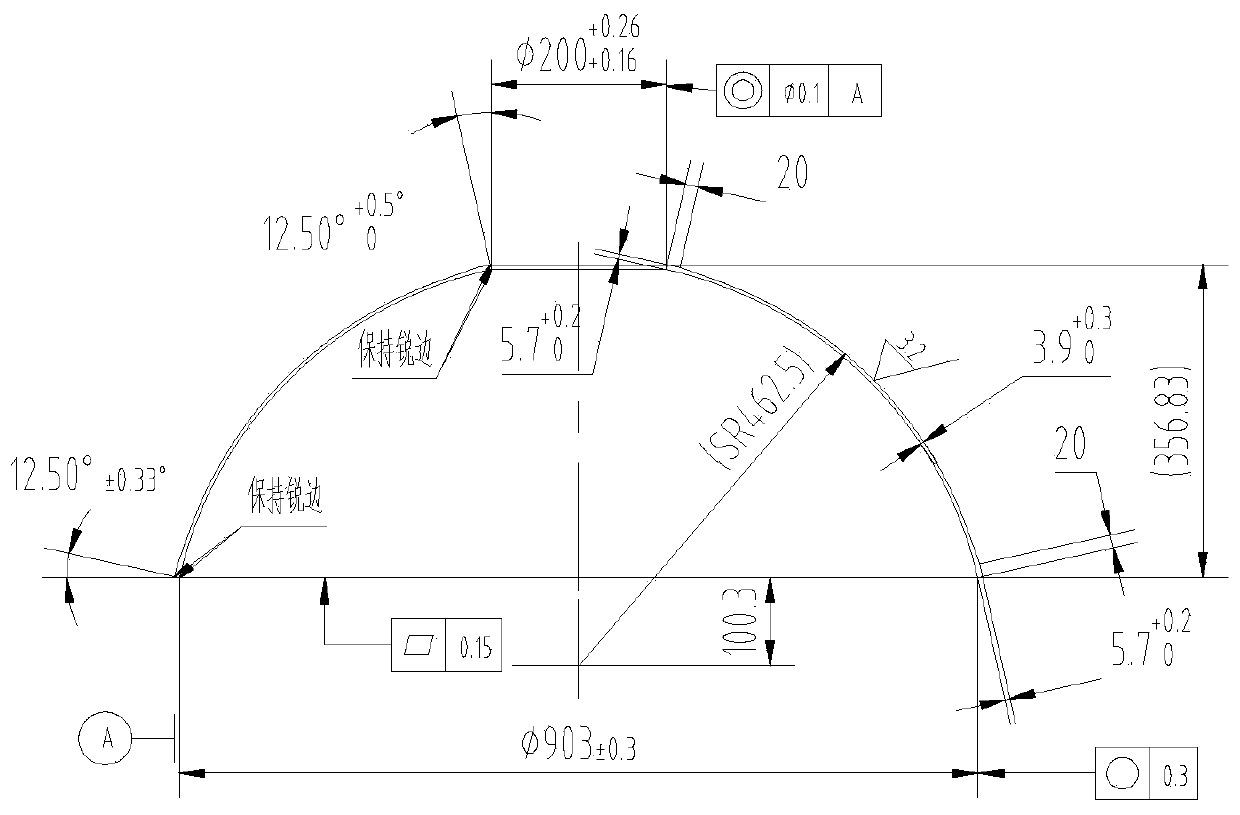

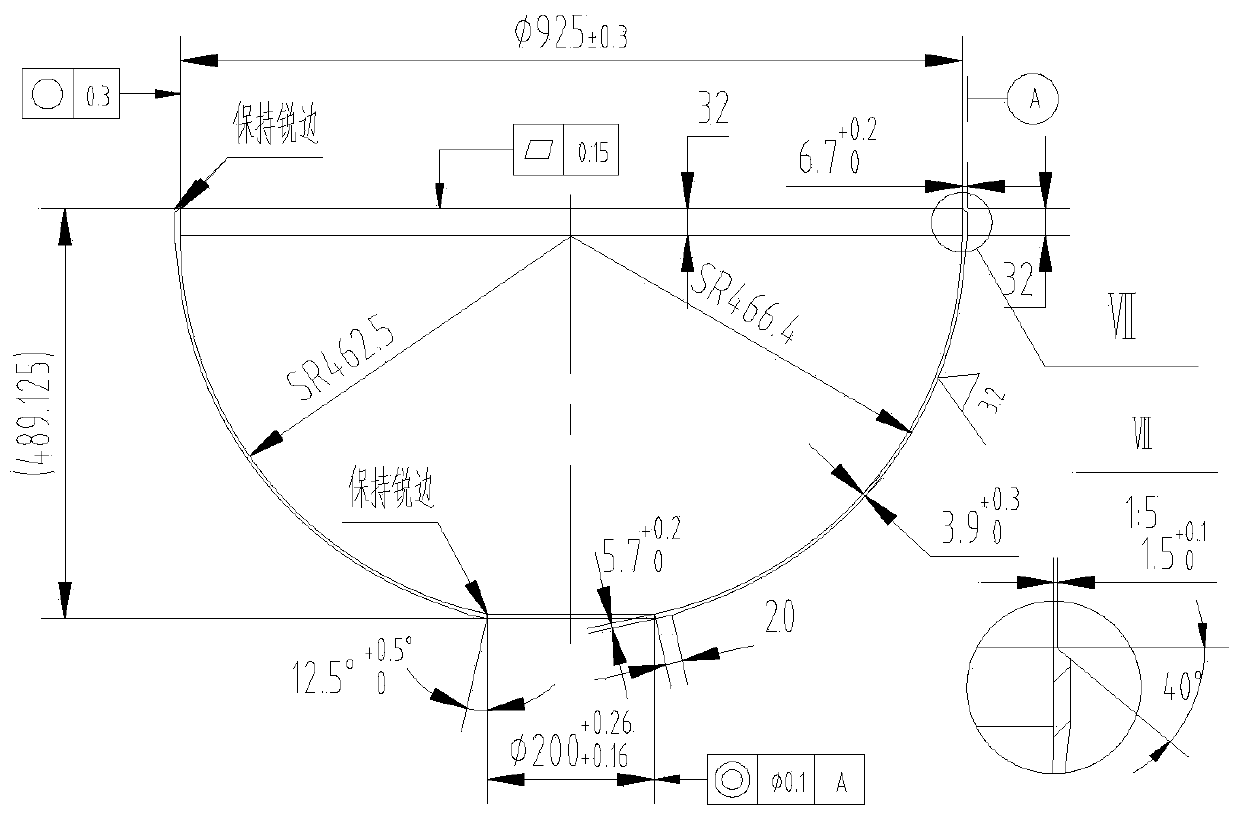

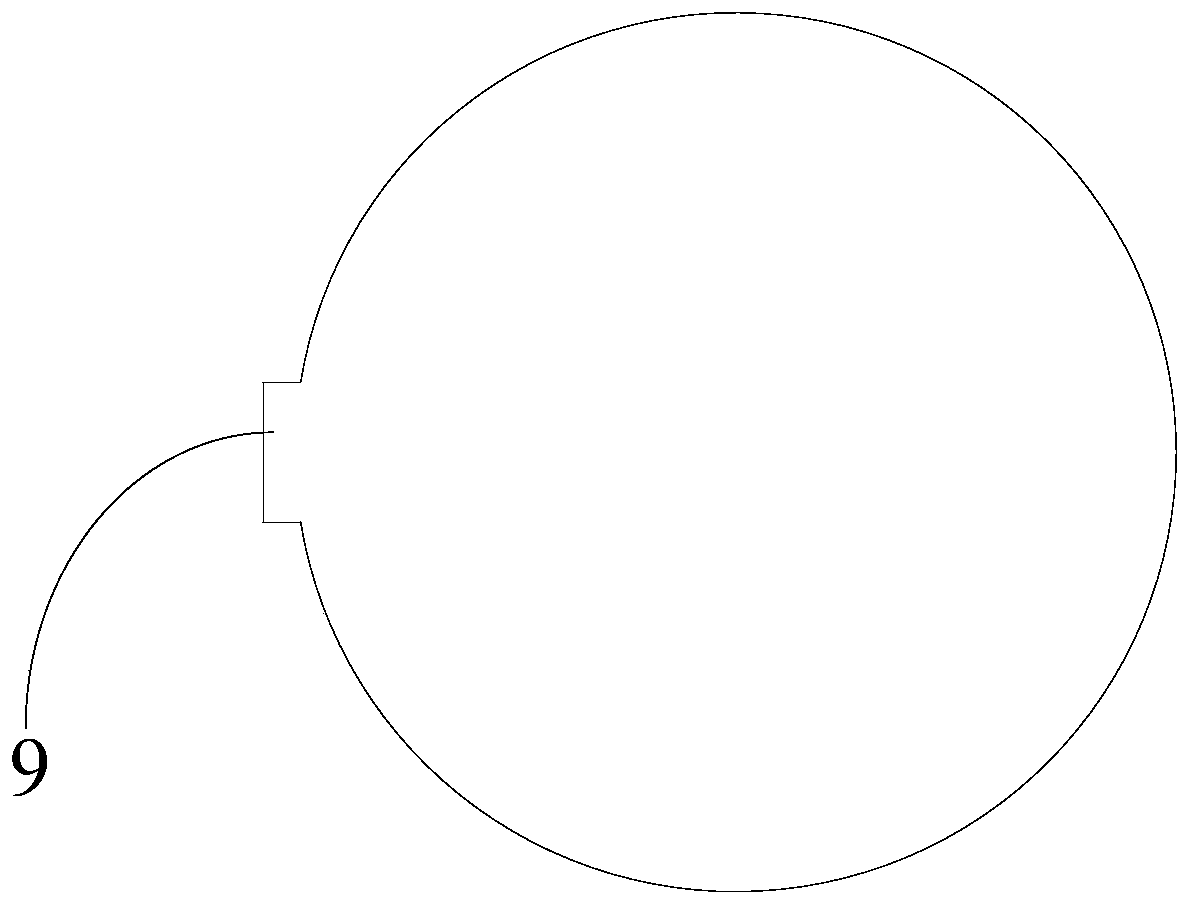

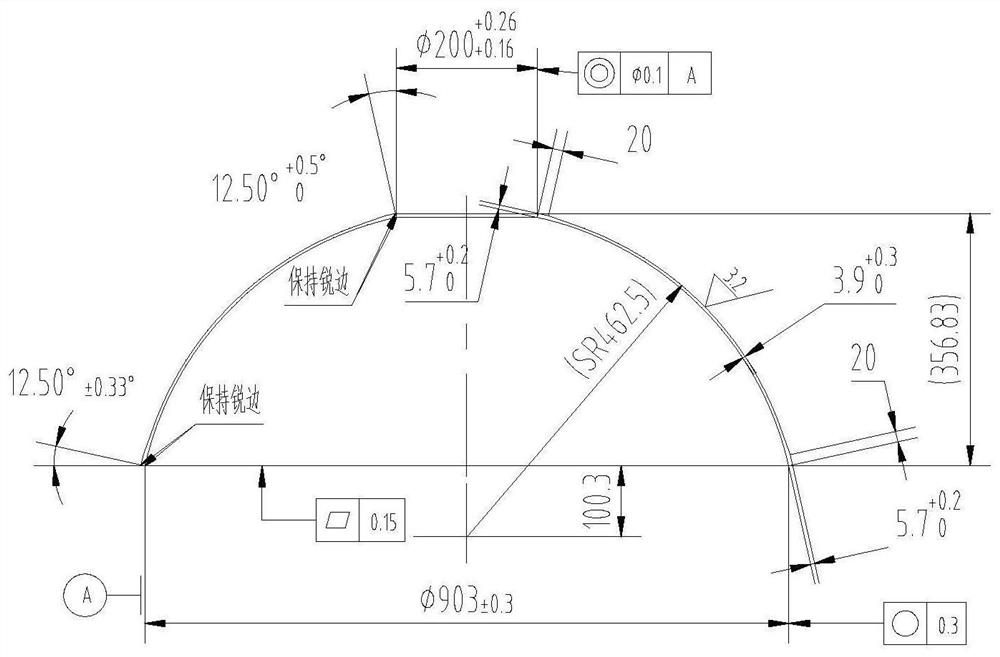

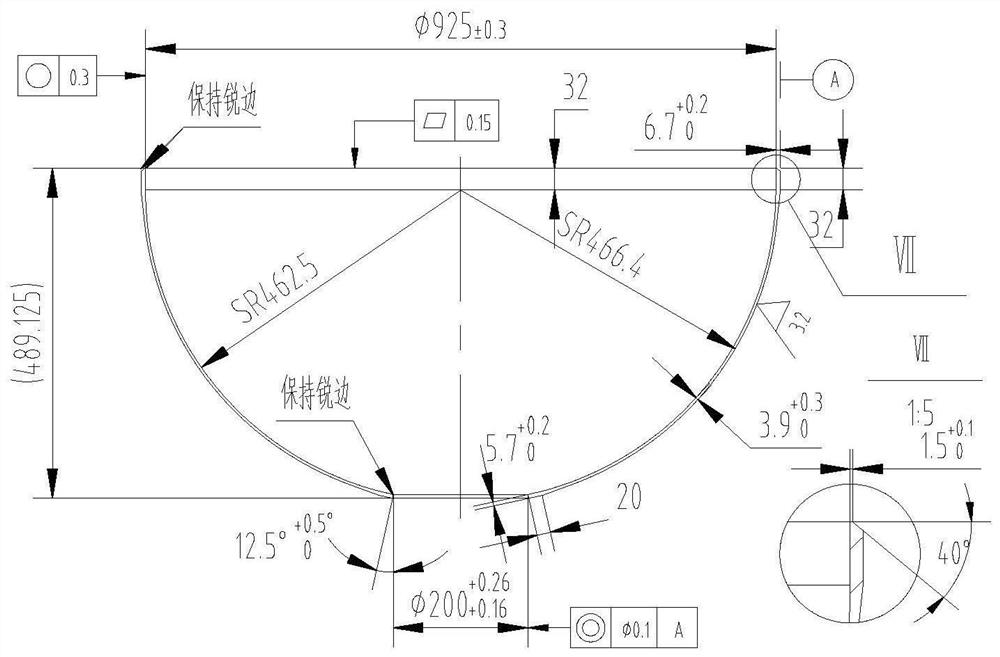

Machining process for precision forming of large thin-wall storage tank hemispheroid

The invention discloses a machining process for precision forming of a large thin-wall storage tank hemispheroid. The machining process comprises the steps of plasma gas cutting, punch forming, cutting, shaping, finish turning of an inner spherical surface, finish turning of an outer spherical surface and surface treatment. The diameter of the hemispheroid of a large thin-wall storage tank is phi925, the wall thickness of the hemispheroid is delta 3.9<0><+0.3>, the ovality of the hemispheroid is phi 0.3; and the diaphragm type storage tank is high in size requirement and high in numerical control machining difficulty, and particularly, the diaphragm type storage tank is made of aluminum alloy and is insufficient in strength and rigidity, large in machining deformation and high in machining difficulty, so that the diaphragm type storage tank is a hemispheroid with larger diameter, the surface linear speed changes along with changes of the height of a part, different main shaft rotatingspeeds need to be selected according to different annular belts during turning, and therefore the machining difficulty is further improved. According to the machining process, ultrasonic measurementand special tool expansion clamping are explored and adopted for numerical control machining, the wall thickness tolerance of an upper hemisphere and a lower hemisphere of the storage tank is 3.9<0><+0.3>, the ovality is phi 0.3, the tensile strength sigma b after heat treatment is larger than or equal to 340 MPa, and the elongation is larger than 10%.

Owner:贵州航天朝阳科技有限责任公司

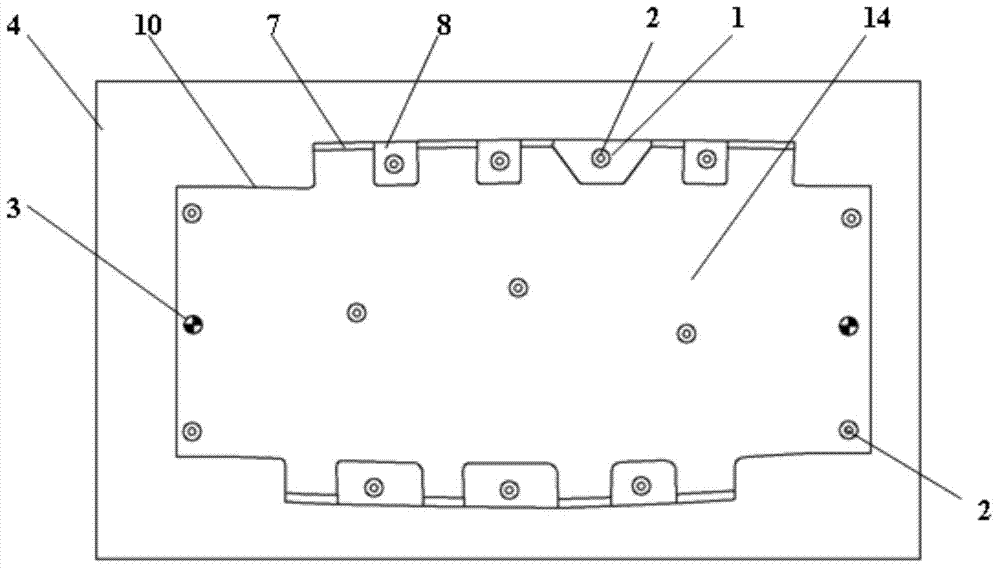

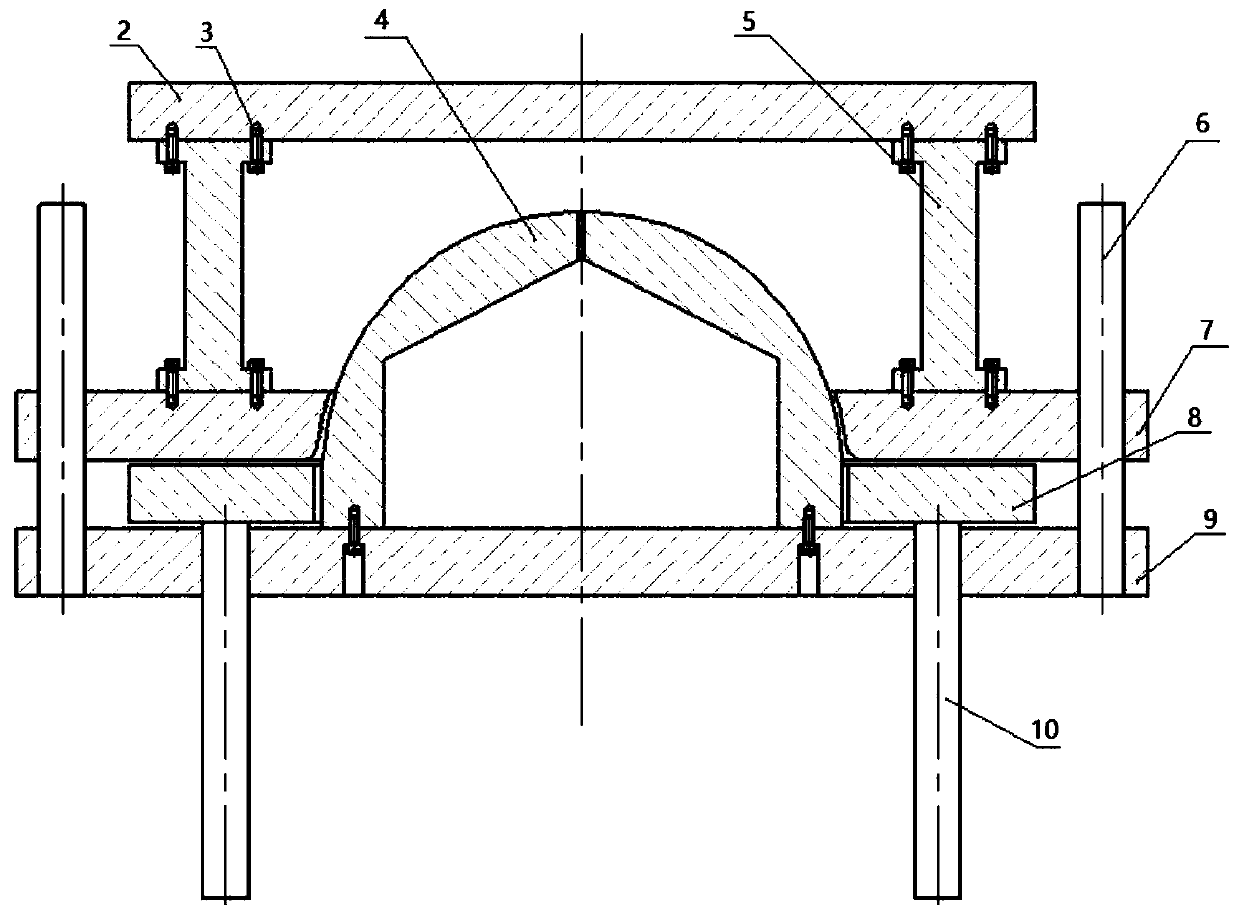

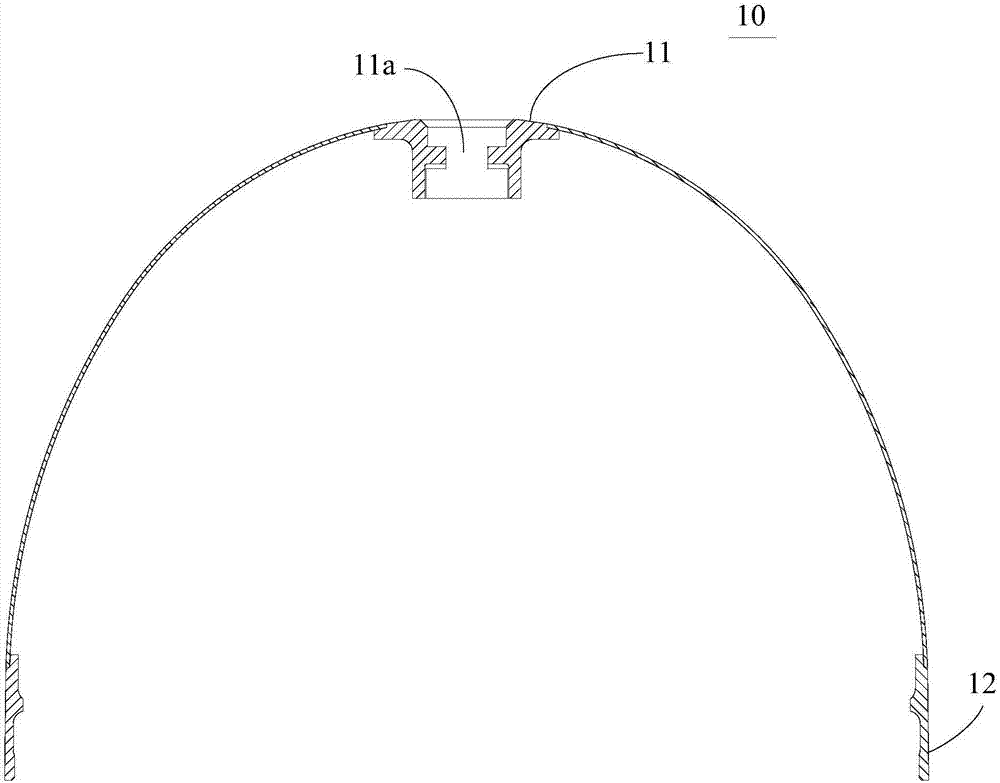

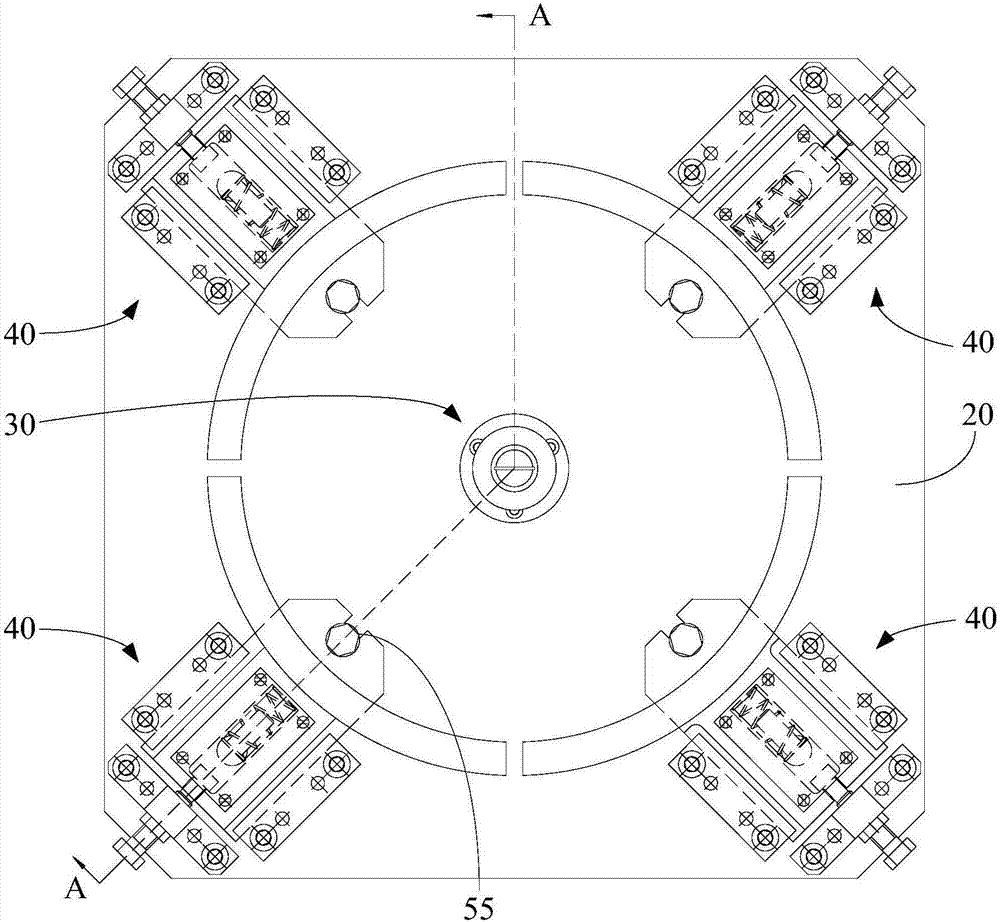

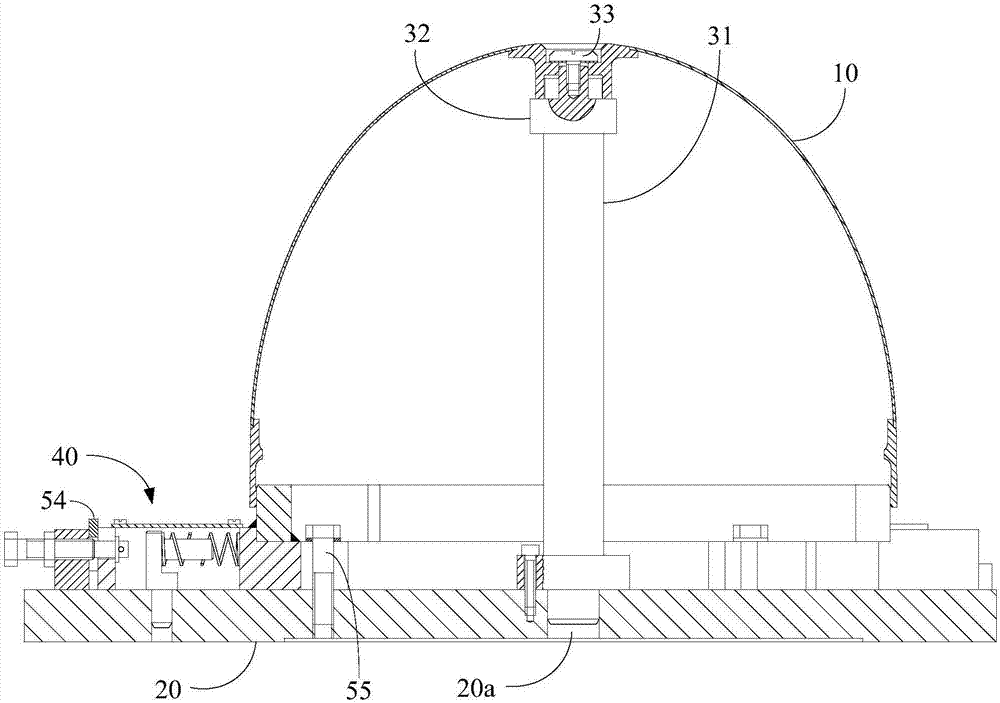

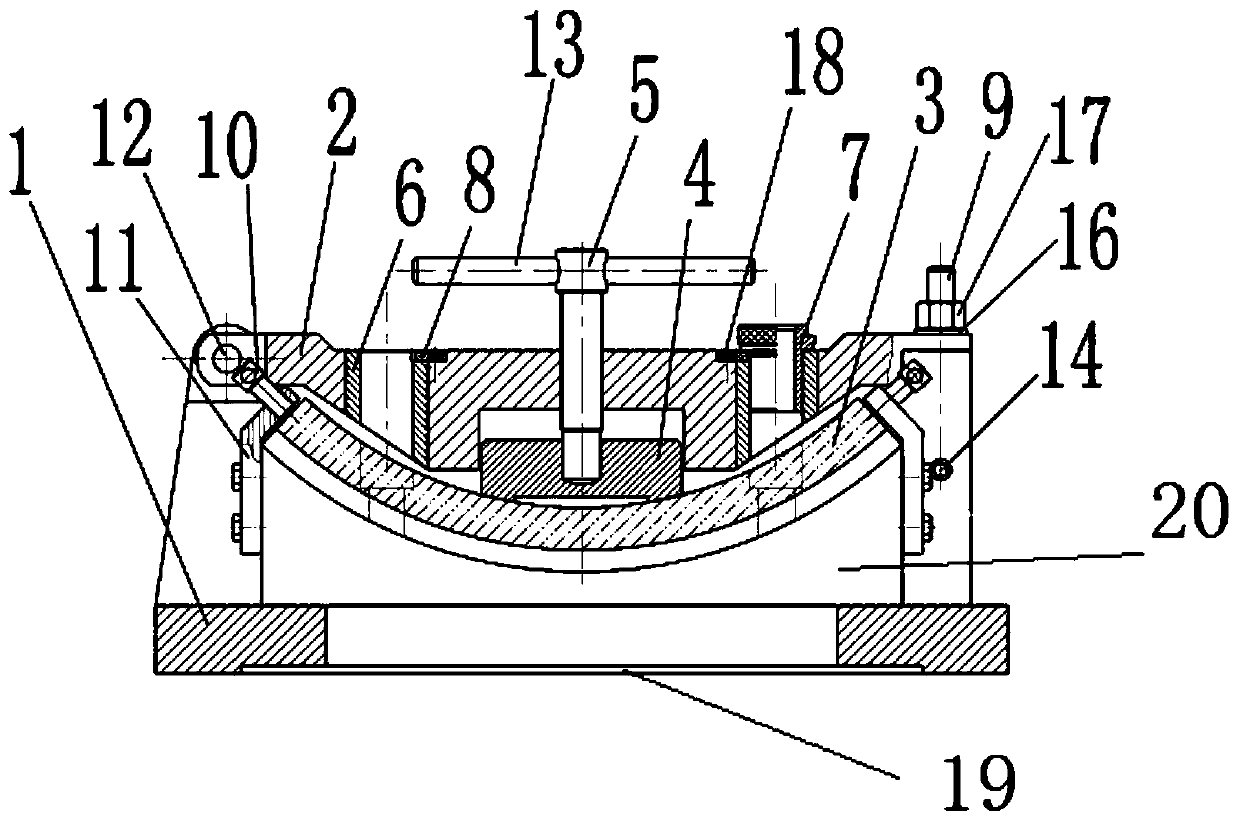

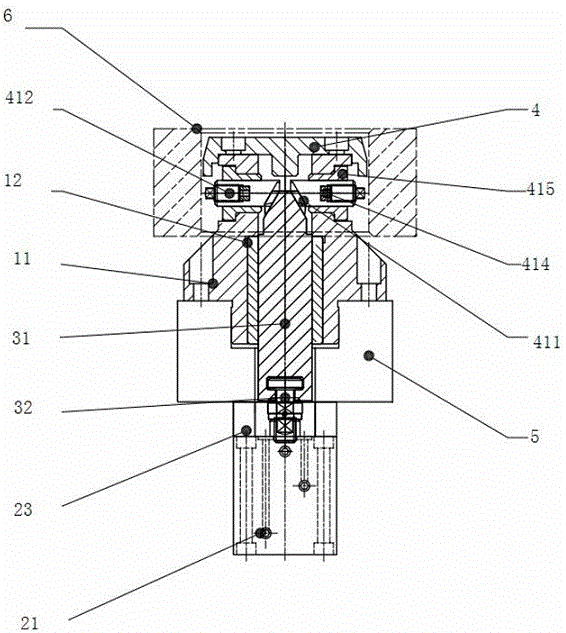

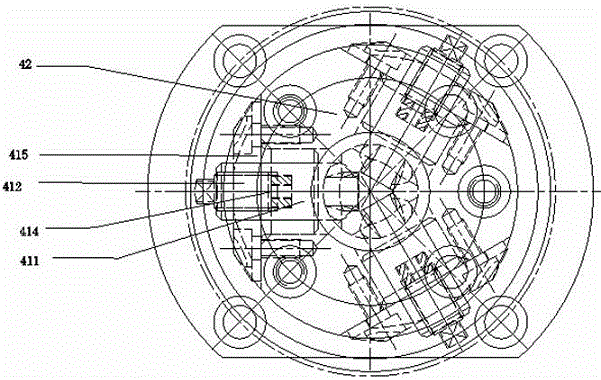

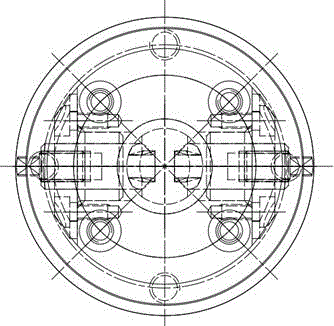

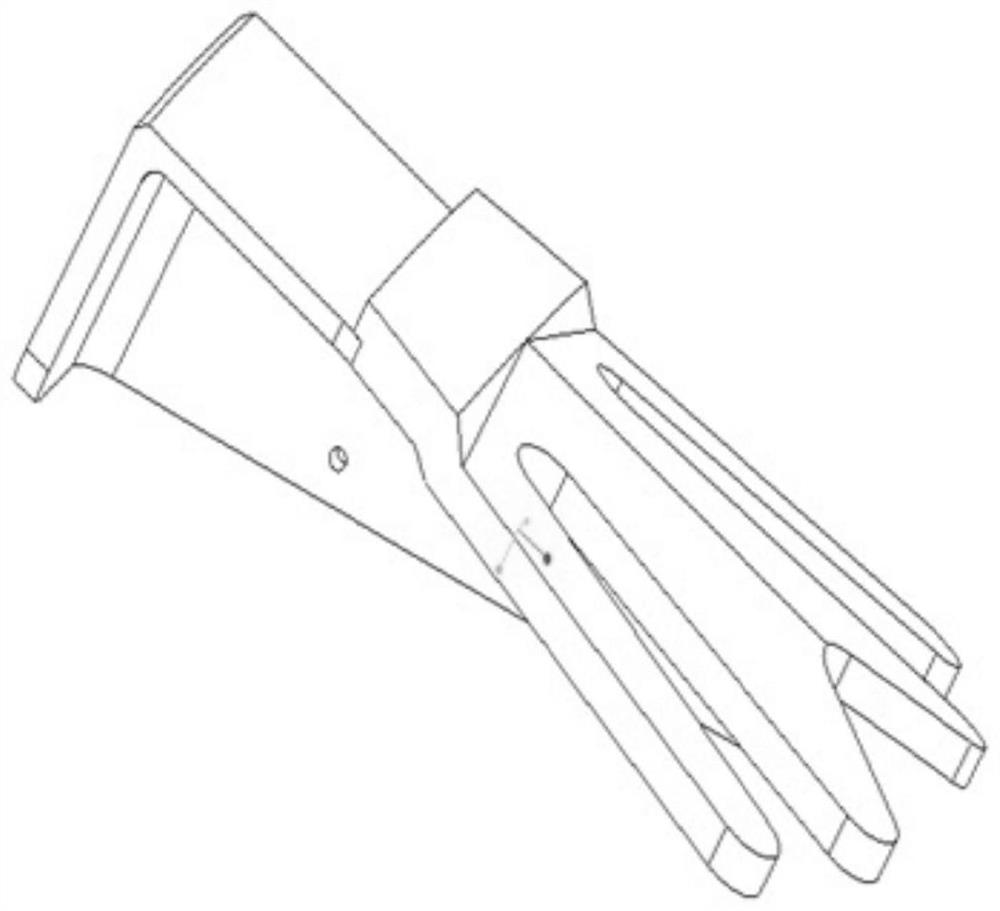

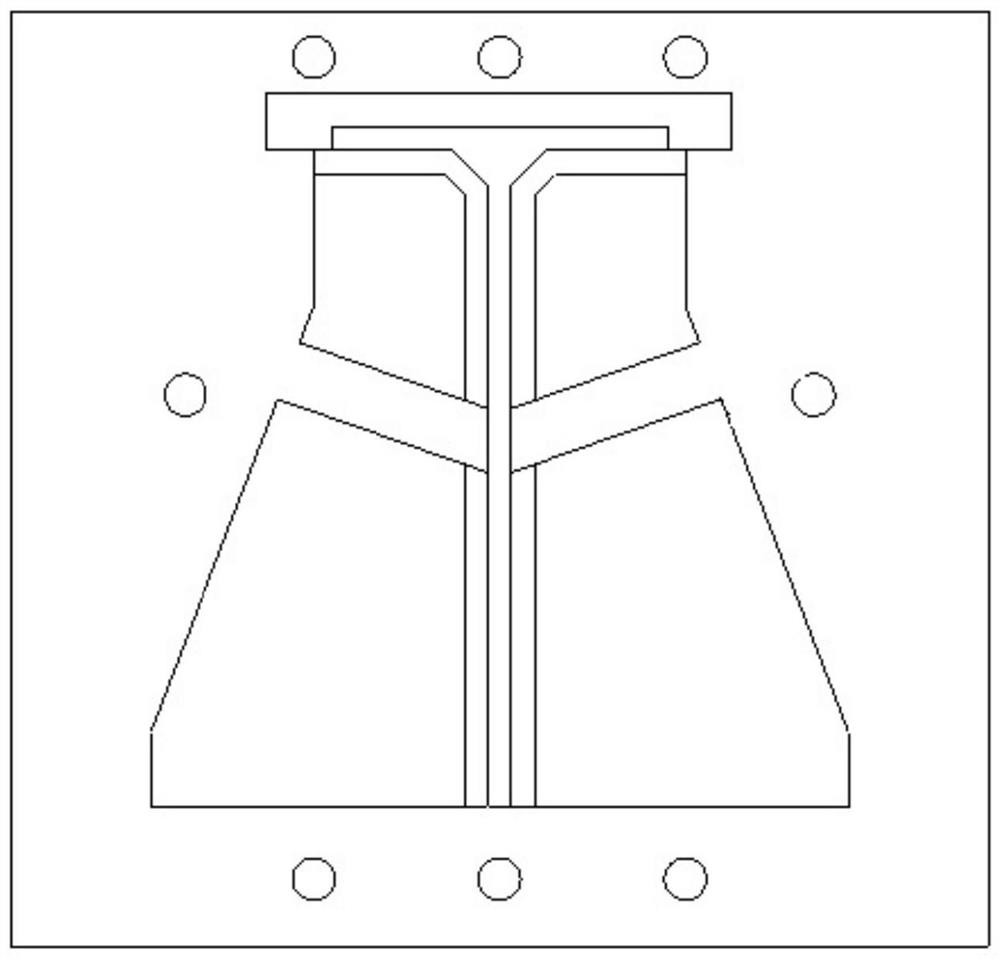

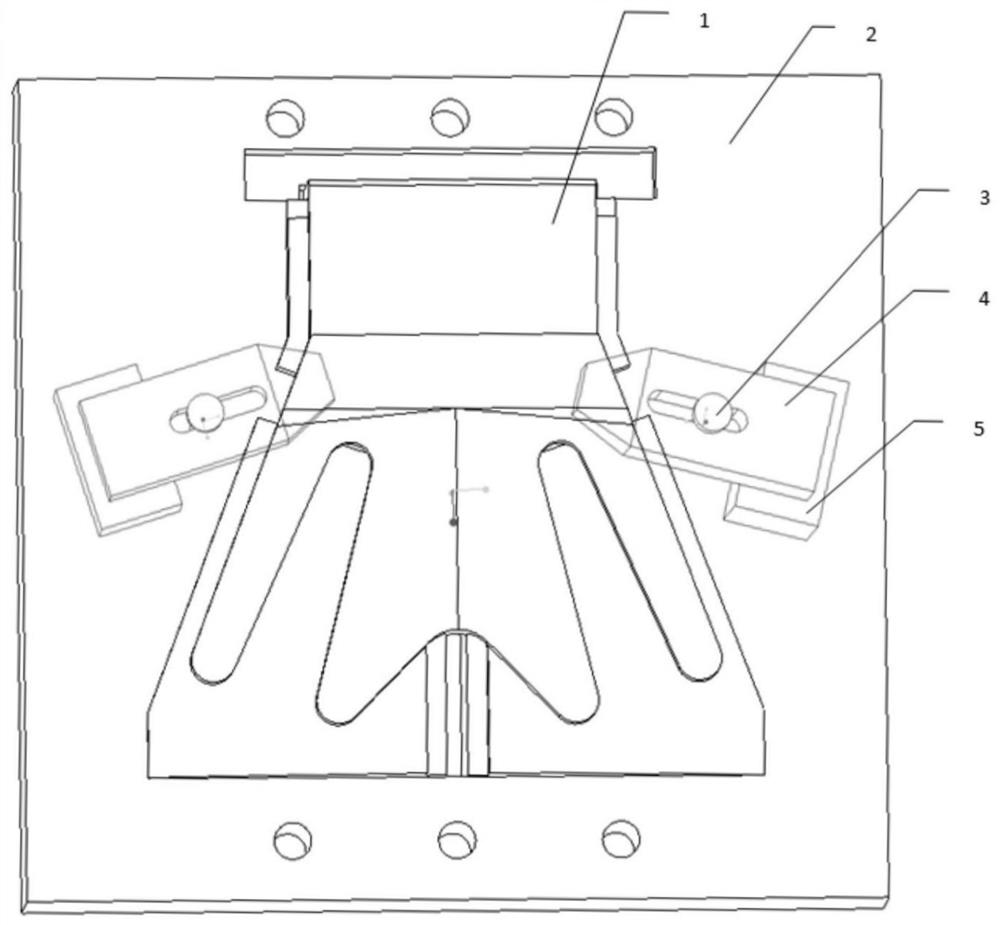

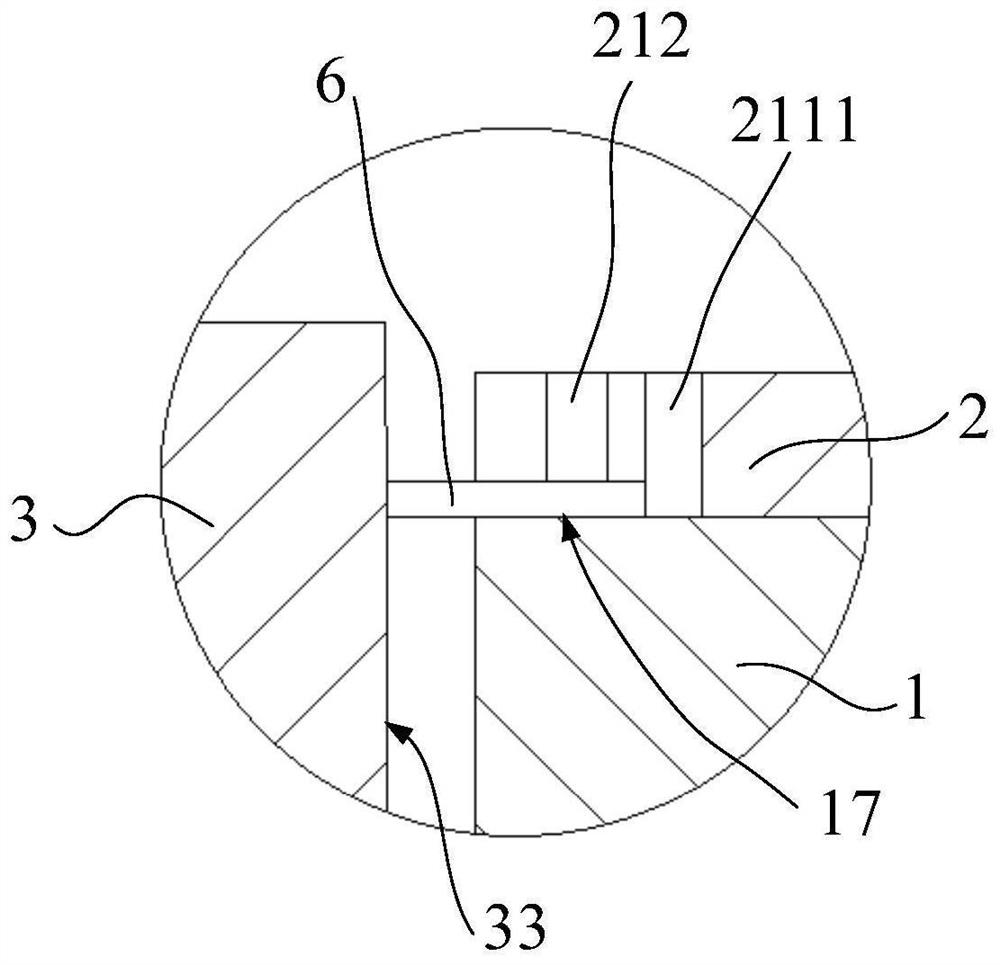

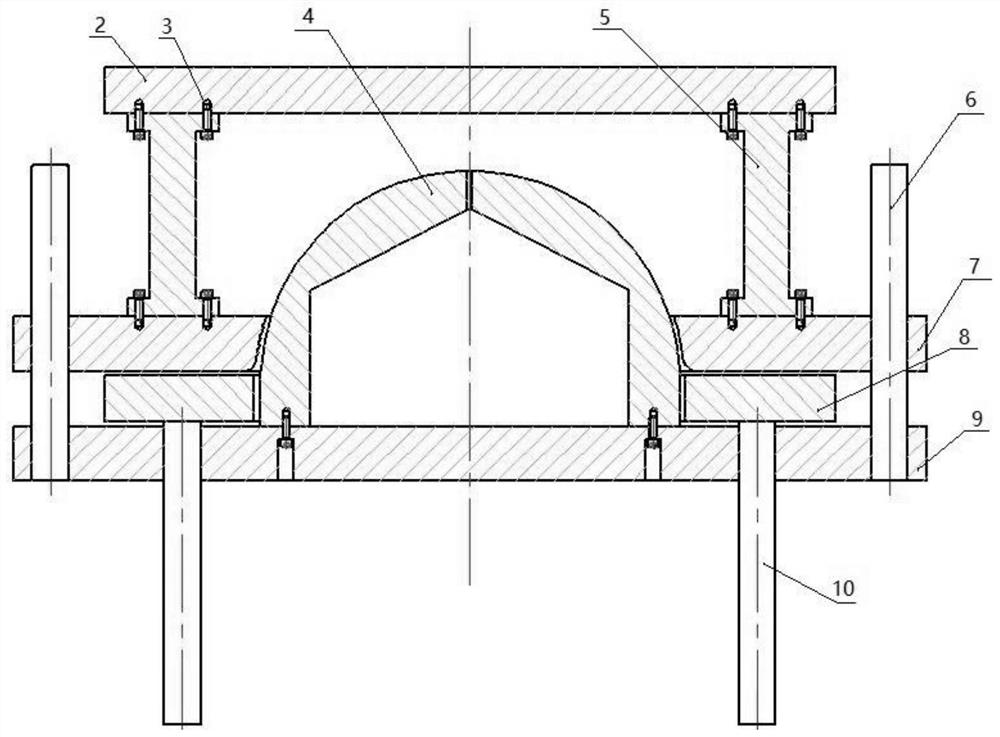

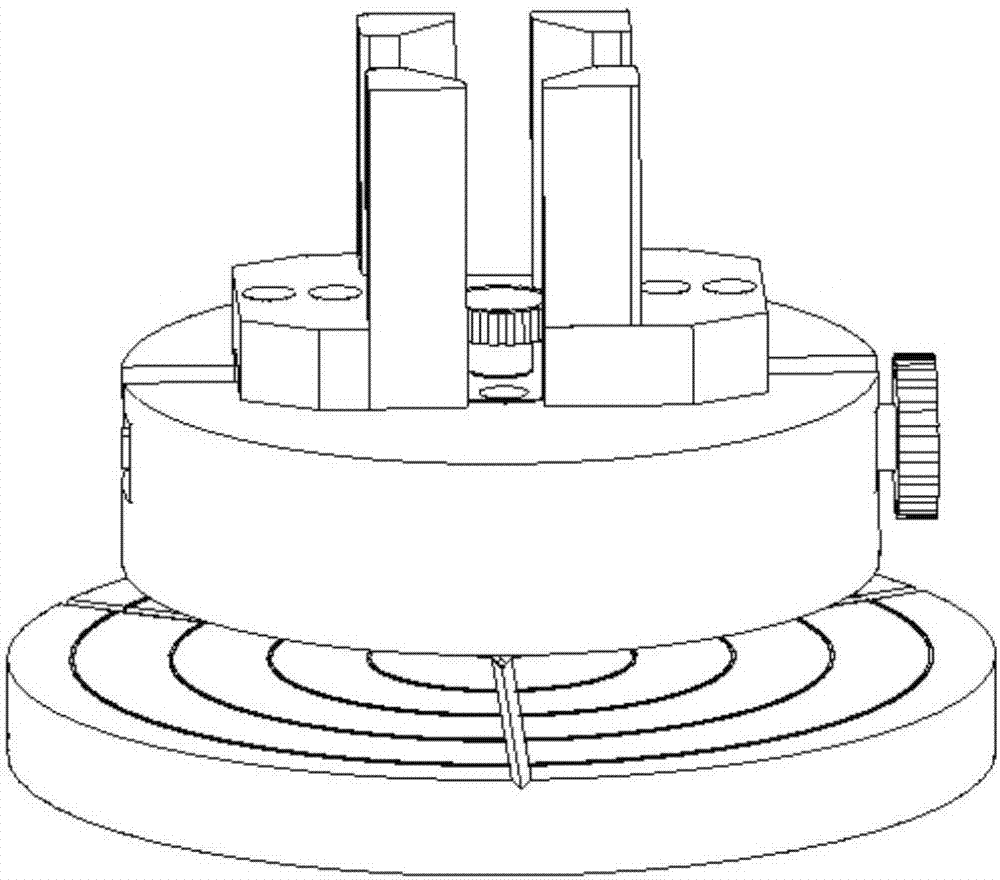

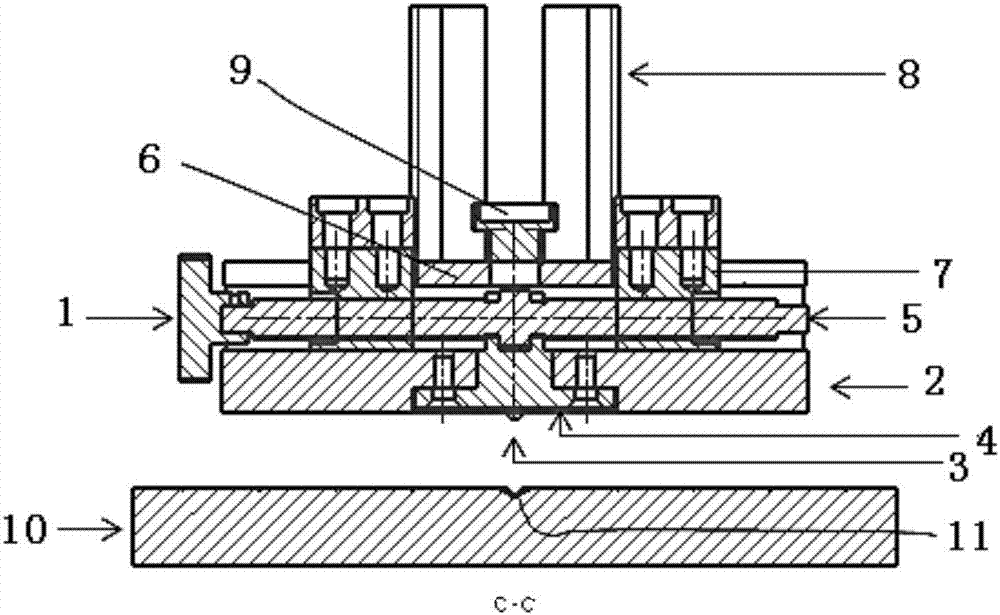

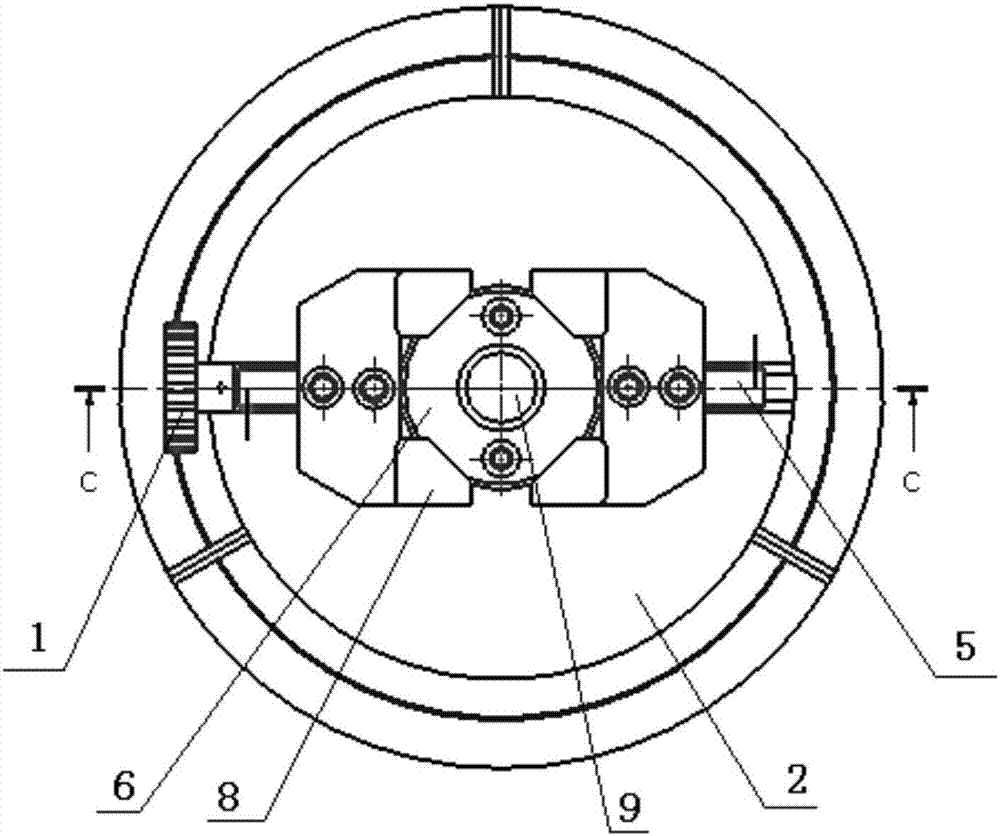

Fairing clamping tool

ActiveCN107009165AReduce deformationSolve clamping difficulties,Positioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses a fairing clamping tool, and belongs to the field of machining. The clamping tool comprises a bottom plate, a centering assembly and a plurality of tightening assemblies. The centering assembly comprises a centering shaft, the centering shaft is perpendicularly arranged on the bottom plate, and the tightening assemblies are arranged on the bottom plate in the circumferential direction with the centering shaft as the center. Each tightening assembly comprises a sliding block, a tightening block and a locking mechanism. The sliding blocks can be arranged on the bottom plate in the manner of sliding in the radial direction of the centering shaft. The tightening blocks are arranged on the sliding blocks, and the surfaces, away from the centering shaft, of the tightening blocks are arc faces. The orthographic projection of the arc faces on the bottom plate is an arc line, and the radius of the arc line is identical to the inner diameter of the large end of a fairing to be clamped. The locking mechanisms are used for locking the sliding blocks, and the sliding blocks and the bottom plate are relatively static. The tightening blocks and the inner wall of the large end of the fairing are in contact by moving the sliding blocks, then the sliding blocks are locked through the locking mechanisms, the sliding blocks cannot slide, and therefore the large end of the fairing can be located.

Owner:WUHAN MARINE MACHINERY PLANT

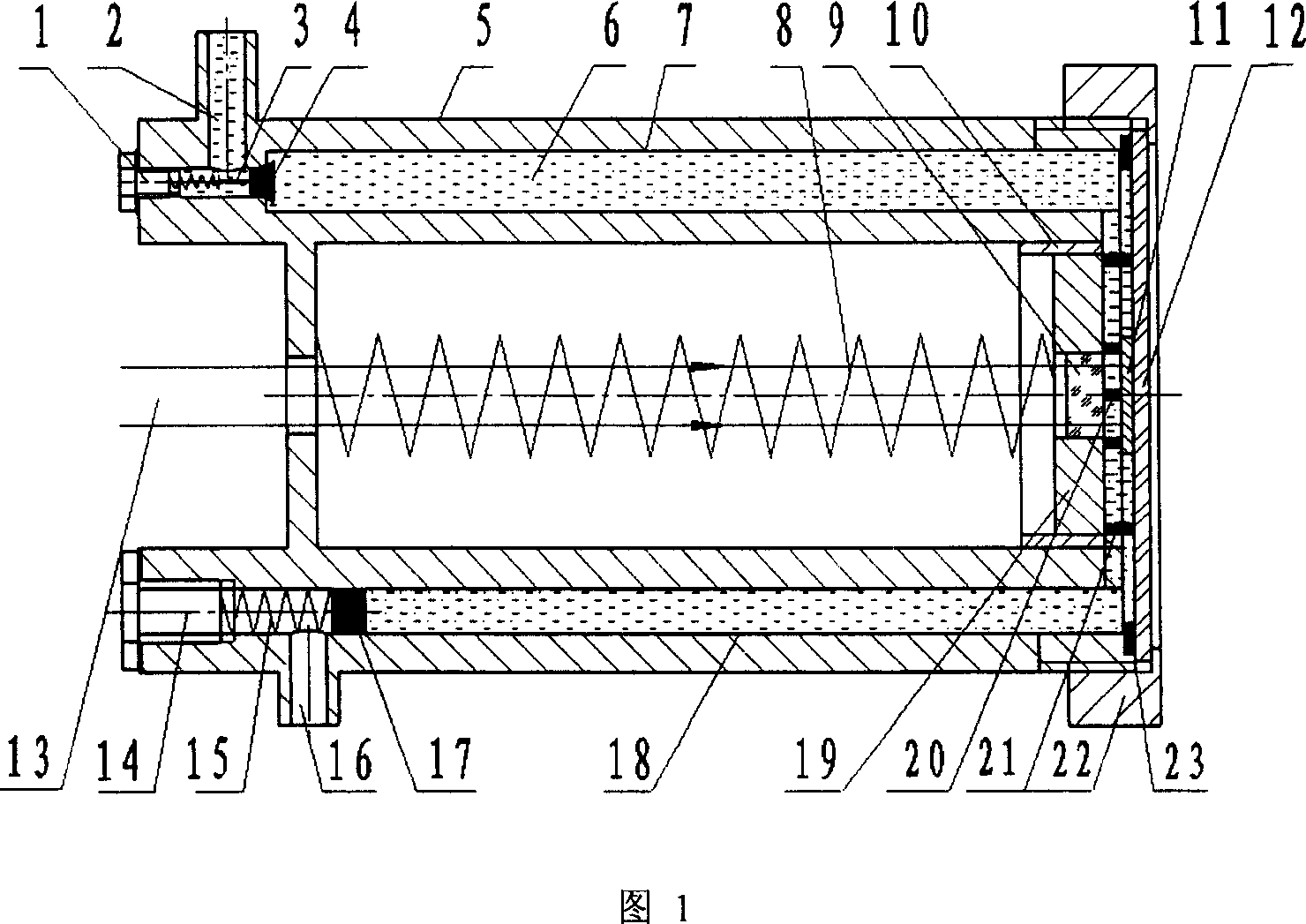

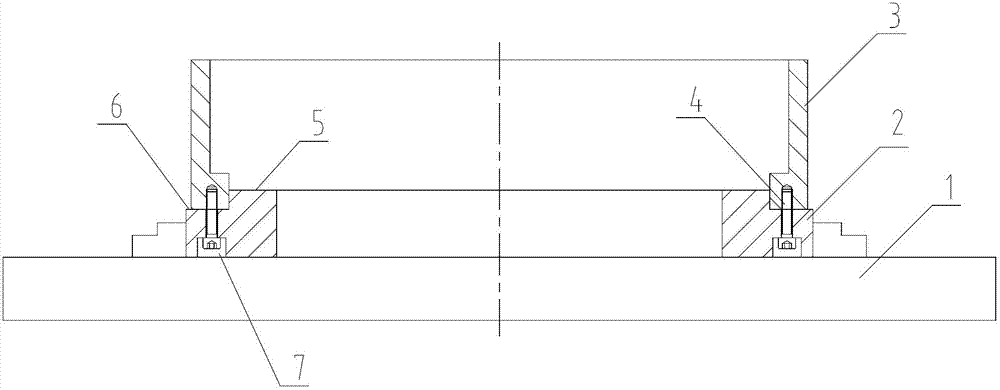

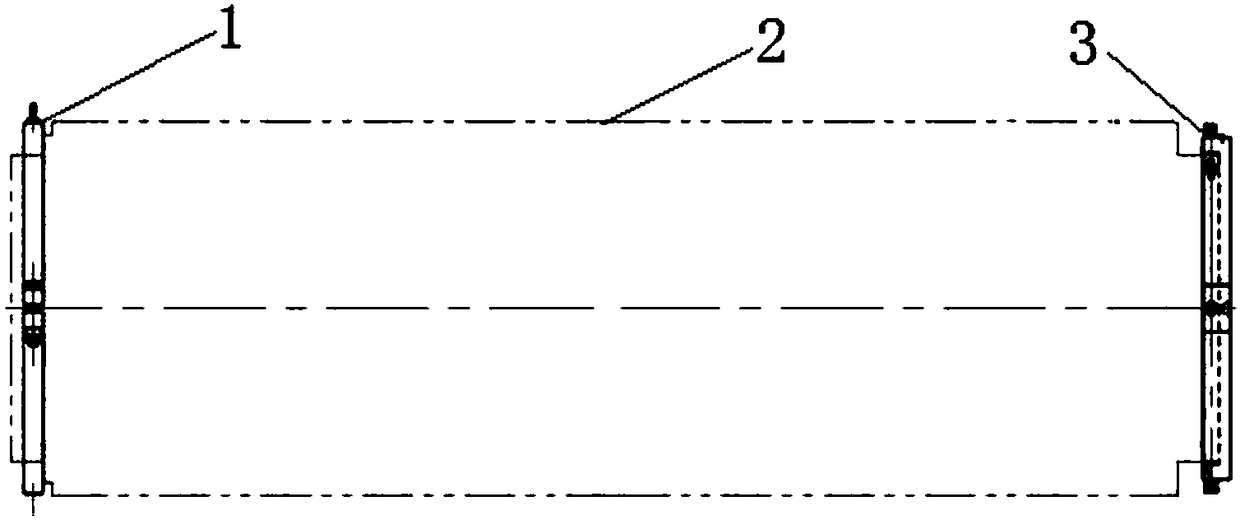

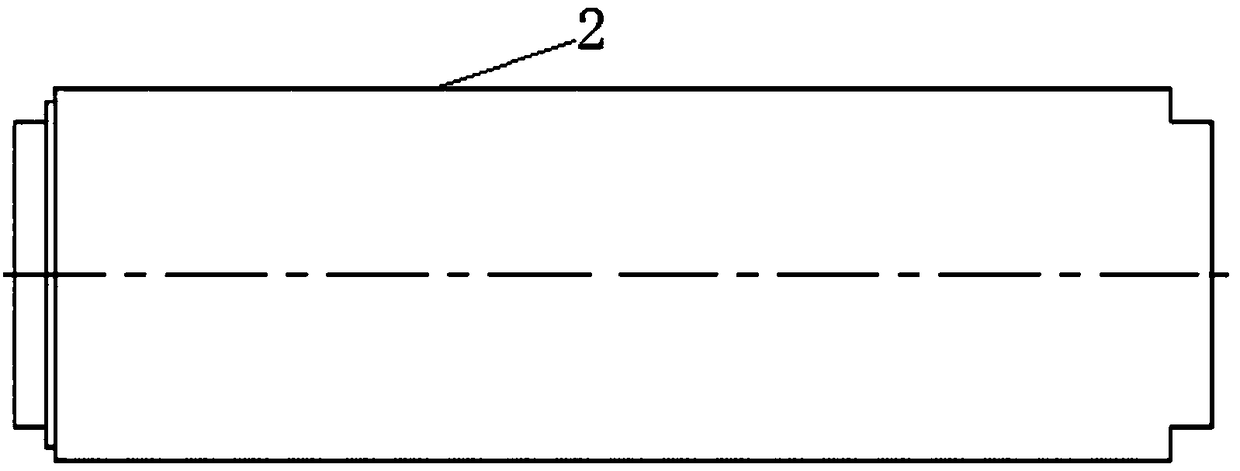

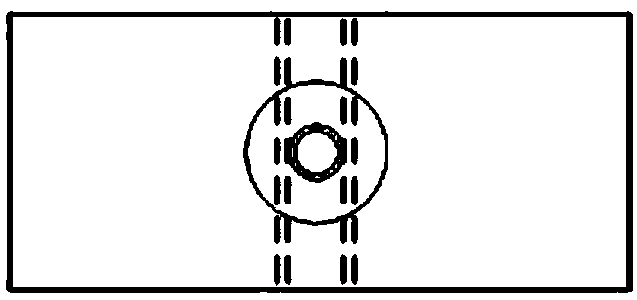

Mechanical press cylinder piston guide ring lathe processing tool and usage thereof

ActiveCN103084891ASolve clamping difficultiesReduce processing costsTurning machinesPositioning apparatusMachine pressMechanical press

The invention discloses a mechanical press cylinder piston guide ring lathe processing tool and usage of the mechanical press cylinder piston guide ring lathe processing tool. The processing tool is used for assistant processing a guide ring on the lathe. The processing tool comprises a cylinder which is cylindrical and concentric with the guide ring, a plurality of bolts and a concentric convex ring arranged at one end of the cylinder extending along the axial direction. The inner diameter of the convex ring is equal to that of the cylinder. The outer diameter of the convex ring is smaller than that of the cylinder. A ring-shaped installation groove is formed between corresponding end surfaces of the convex ring and the cylinder. A plurality of installation holes which are communicated with the installation groove are formed in the other end surface of the cylinder. The guide ring can contain the convex ring, is clamped in the installation groove and is locked in the plurality of the installation holes through the plurality of the bolts to be fixed with the cylinder. The mechanical press cylinder piston guide ring lathe processing tool has the advantages that an inner circle, an outer circle and the end surfaces of the guide ring can be processed fast and conveniently, the requirement of workpiece size can be effectively controlled through the fact that a machine tool is processed, and meanwhile detected and revised. The invention further provides the usage of the mechanical press cylinder piston guide ring lathe processing tool.

Owner:HEFEI METALFORMING MACHINE TOOL

Processing method for cylindrical turning of arc plate assembly

InactiveCN108274283ASolve clamping difficultiesSolve the difficulty of findingWork clamping meansPositioning apparatusMachining processEngineering

The invention discloses a processing method for cylindrical turning of an arc plate assembly which is specifically implemented according to the following steps: firstly, processing a first clamping position at one end of each arc plate and processing a second clamping position at the other end thereof, wherein when all arc plates are cylindrically assembled, all the first clamping positions constitute a first cylindrical end and all the second clamping positions constitute a second cylindrical end; secondly, after all the arc plates are cylindrically assembled to form an assembly, using a clamping body to clamp the first cylindrical end and fastening the second cylindrical end into a blind hole in one side of a top plate; and finally, loading the assembly clamped by the clamping body and the top plate into a machine tool and performing cylindrical cutting on the surface thereof according to a set radian. By adopting the method, the problems that workpieces are unstable, easy to deformand have difficulties in loading, clamping and alignment when the arc plates are processed as a whole, and the workpieces are easy to spread during processing are solved.

Owner:BAOJI PETROLEUM MASCH CO LTD

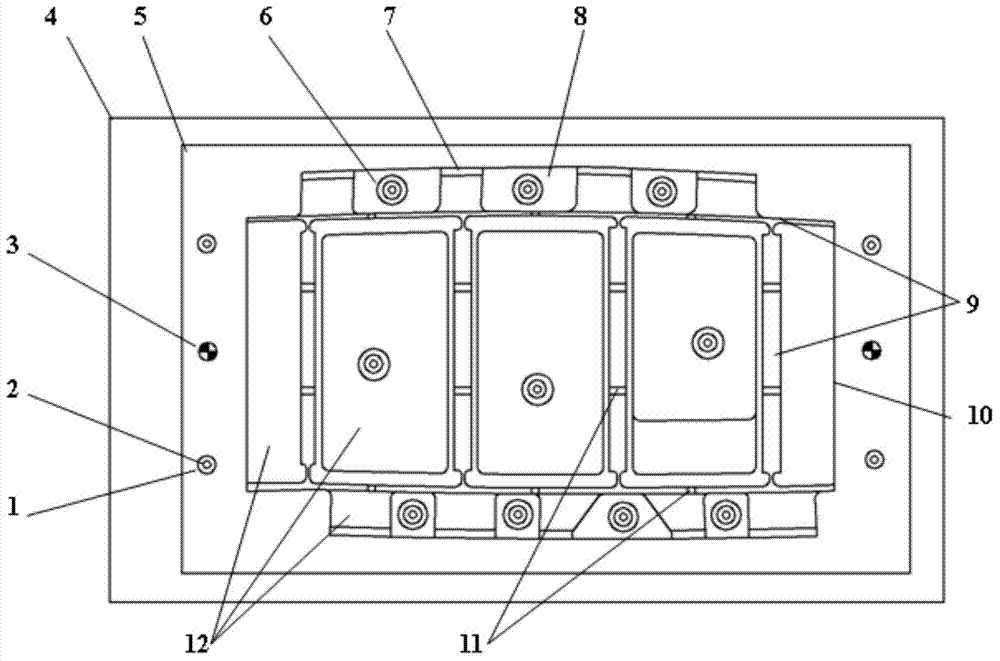

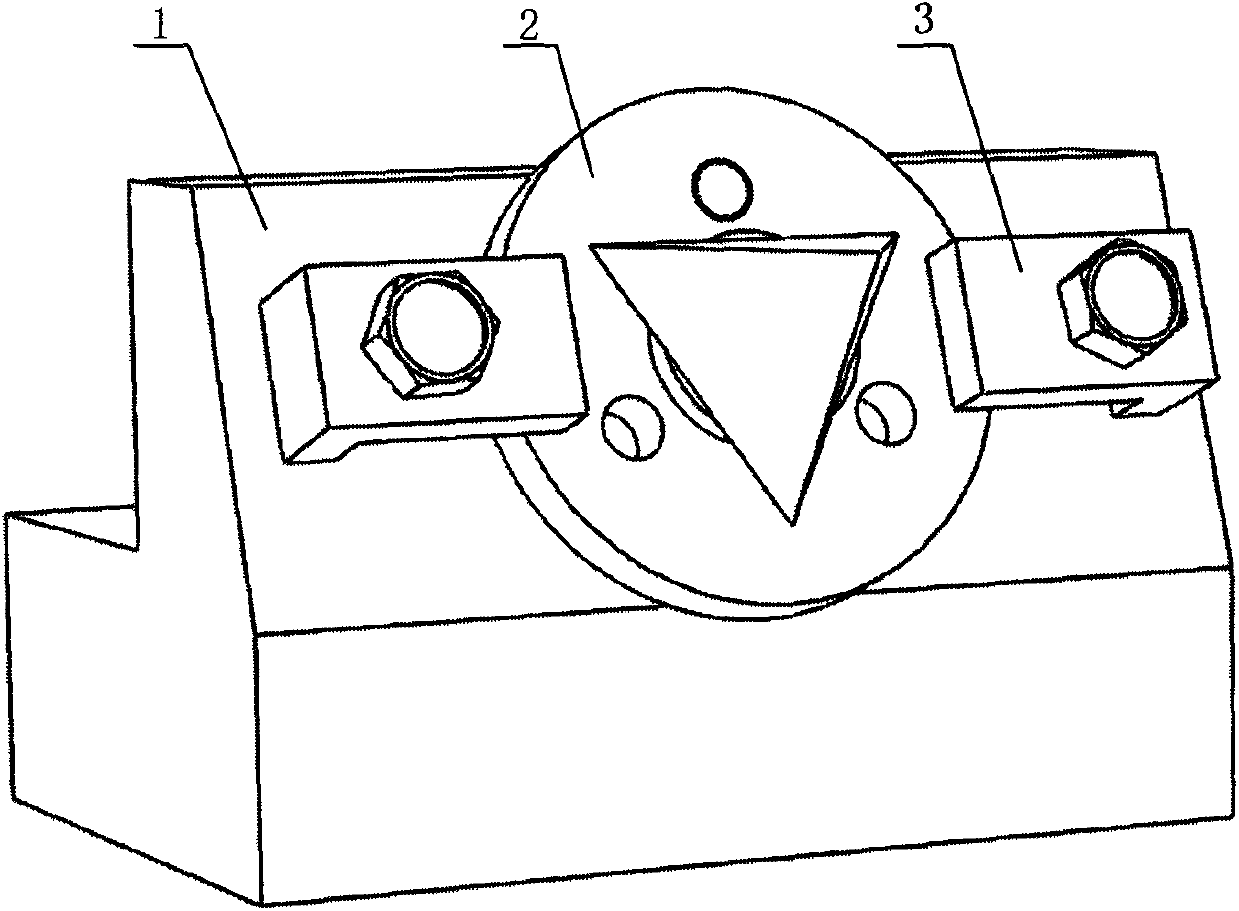

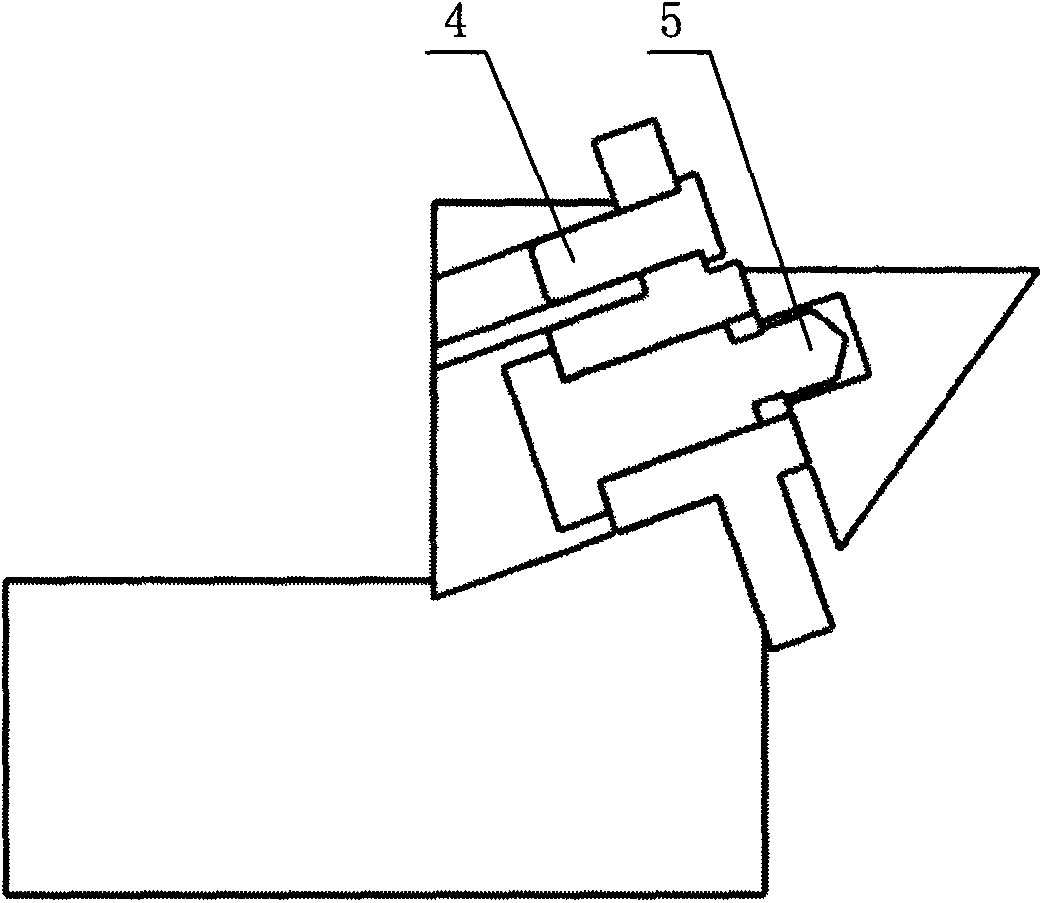

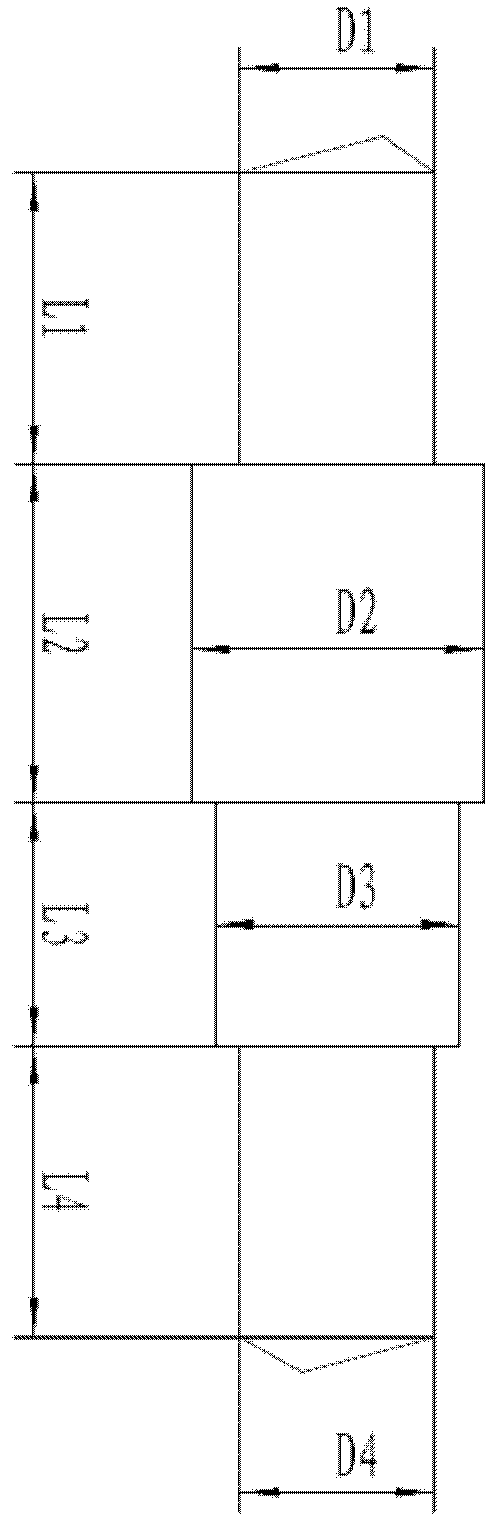

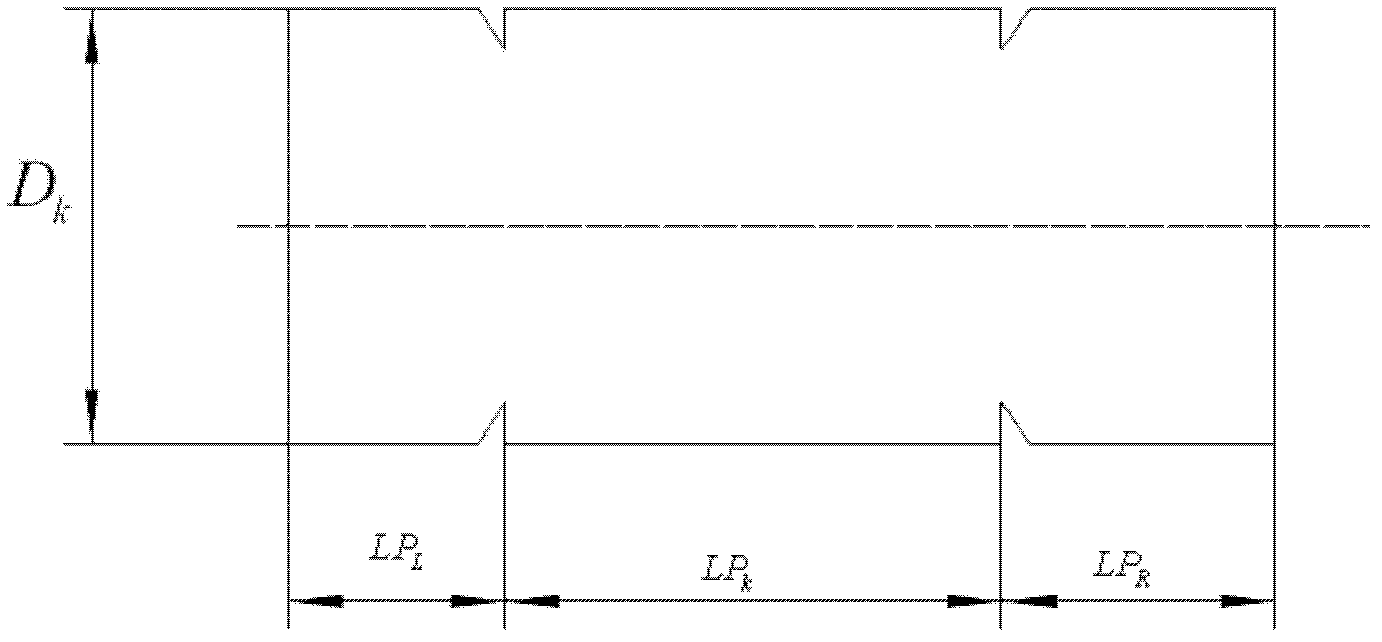

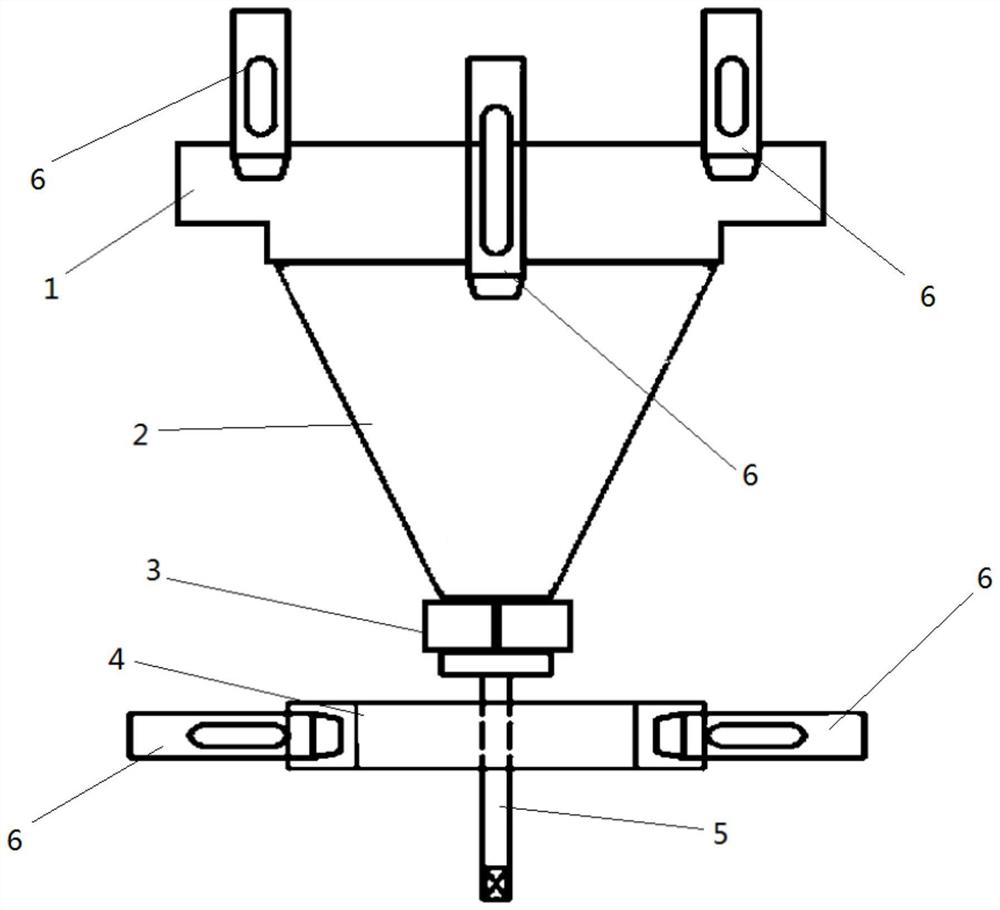

Special clamp for machining triangular pyramid

InactiveCN103358154ASolve clamping difficultiesSolve the problem of low machining accuracyPrecision positioning equipmentPositioning apparatusMachine toolPyramid

The invention relates to a special clamp for machining a triangular pyramid. The special clamp comprises a base, a positioning index plate, a clamping block, a positioning pin and bolts, wherein the base is fixedly arranged on a machine tool work bench; the positioning index plate is connected with a workpiece blank through the bolts; the positioning index plate is attached to a positioning surface on the base; a stepped shaft on the positioning index plate is arranged in a positioning index plate mounting hole in the base; and the rotational degree of freedom of the positioning index plate is limited through the positioning pin inserted in a positioning hole in the base and a positioning hole in the positioning index plate; the clamping block is connected with the base through the bolts; and the axial degree of freedom of the positioning index plate is limited by the clamping block pressing the positioning index plate so that the whole workpiece is fixed. The special clamp is reasonable in structure and convenient to disassemble, thus effectively solving the problems that the triangular pyramid is difficult to clamp, low in machining accuracy and the like when being machined.

Owner:TIANJIN RUICHI SHIPPING MACHINERY

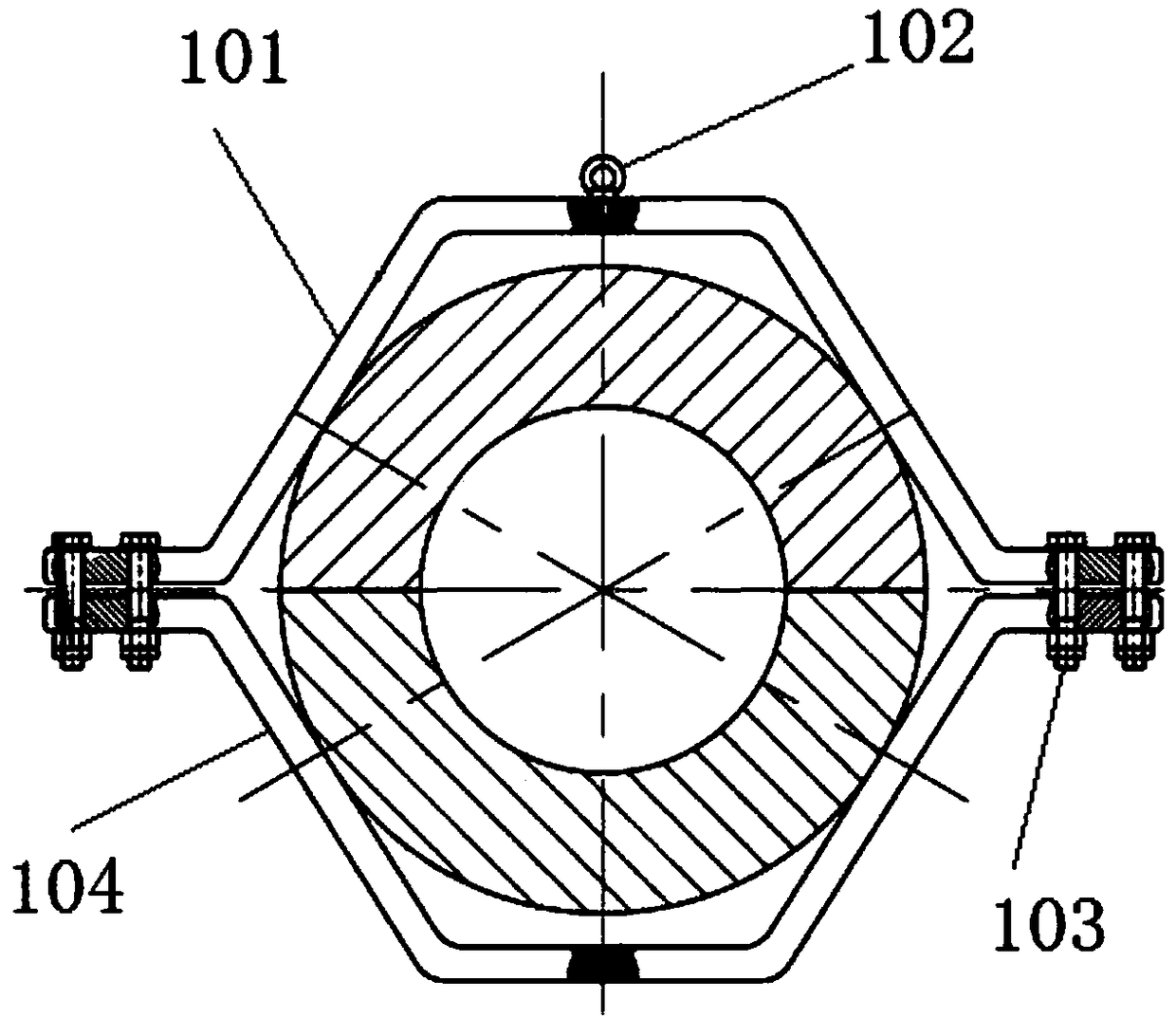

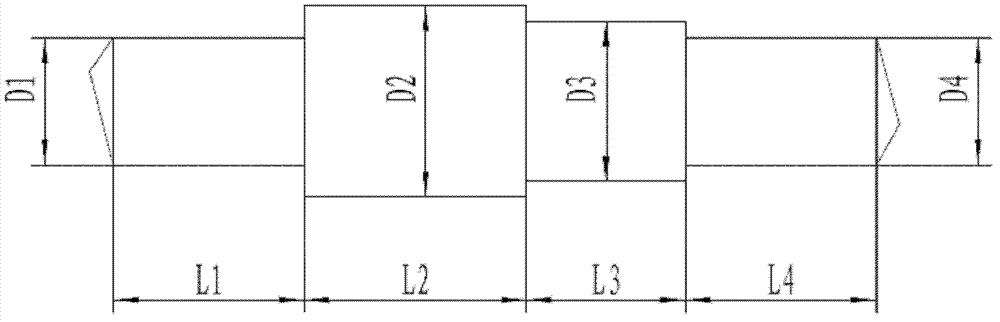

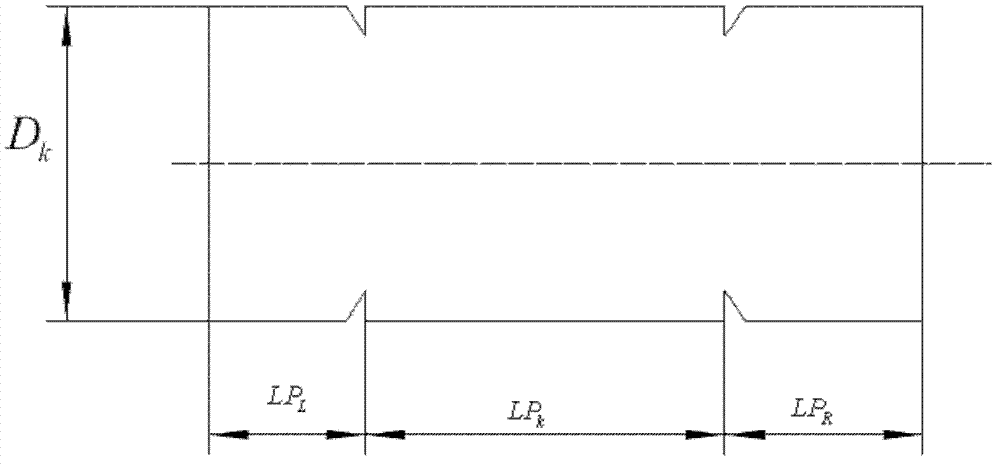

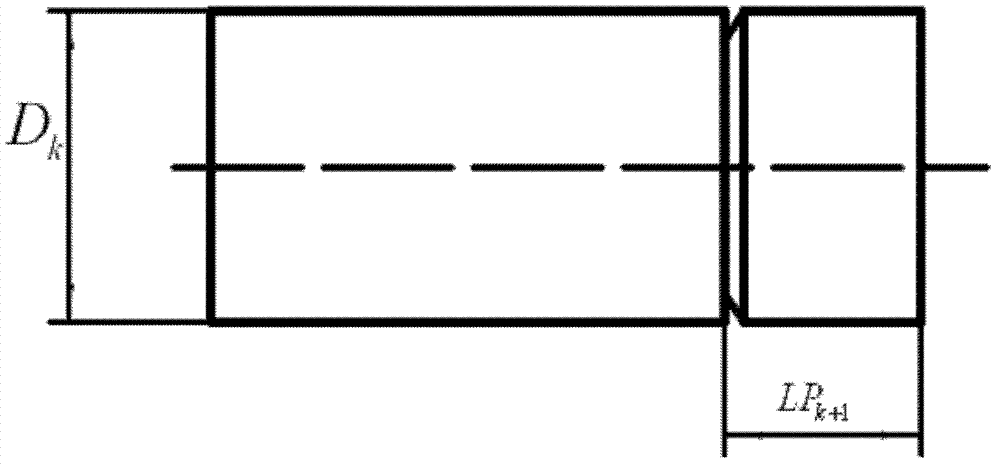

Stepped shaft forging method in free forging

The invention discloses a stepped shaft forging method in free forging, which includes the steps of forging a blank to be a regular octagonal piece before the process of flattening, then calculating the volume of the material of each step, converting the volume of the material to the length of the material of the regular octagonal section, and finally flattening the corresponding positions of the blank. By forging the blank to be a piece with a regular octagonal section instead of a round section before the process of flattening in the processes of forging and stamping the stepped shaft, the method effectively solves problem of difficulty in holding the blank and ensures right flattening positions. The regular octagonal section is close to the round section in shape, so the material can be saved in the late rounding process. The method improves production efficiency and product quality and reduces defective and waste product rates.

Owner:NANJING DEV ADVANCED MFG

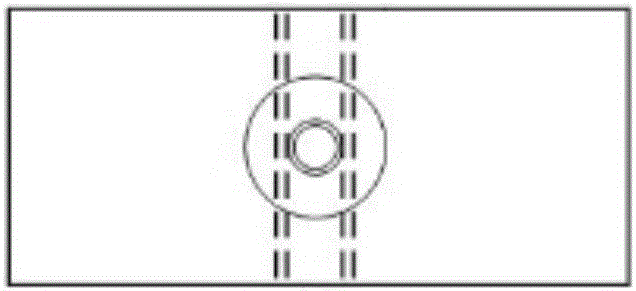

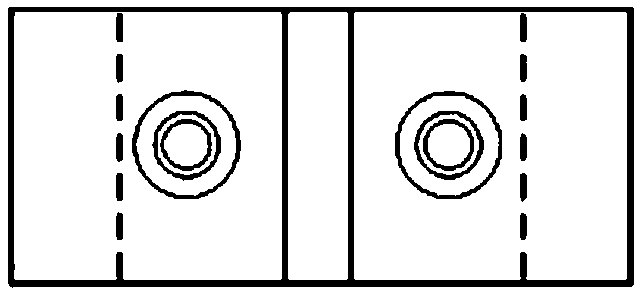

Machining method for small-batch production of O-shaped sealing ring fixing pieces

InactiveCN112935731ASolve difficult clampingSolve clamping difficultiesWire cuttingMaterials science

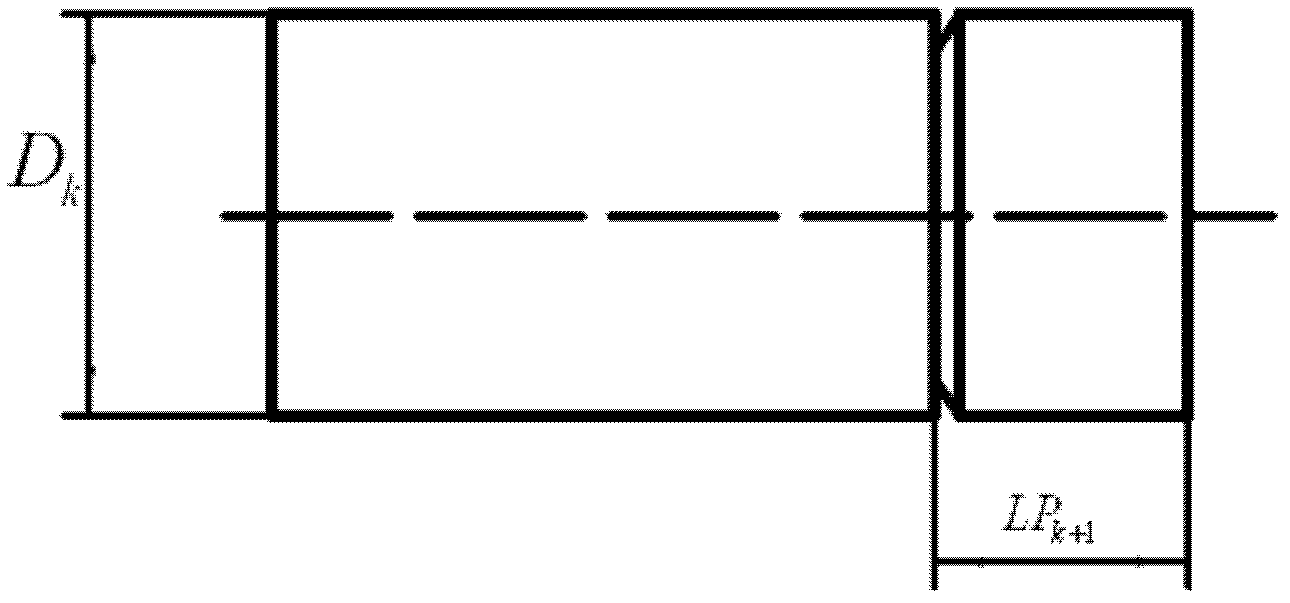

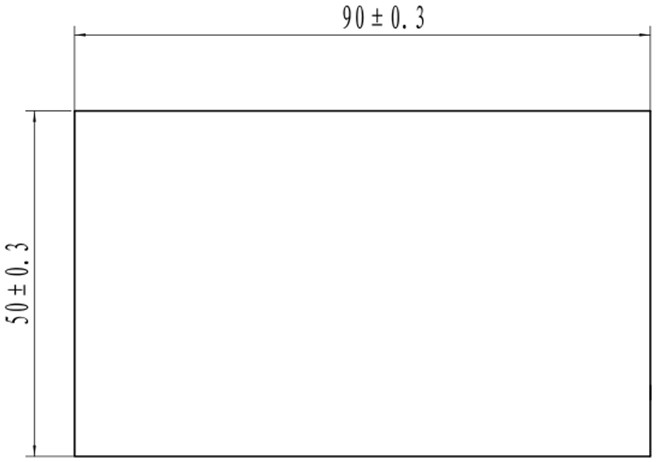

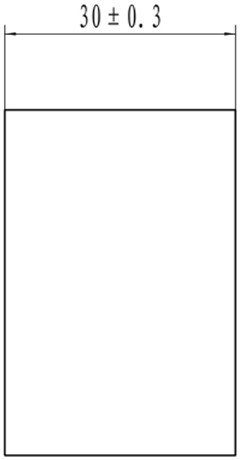

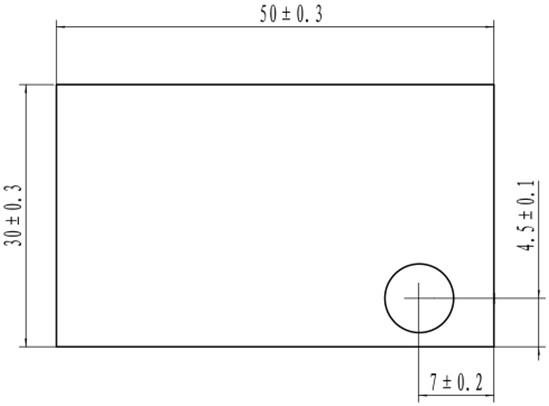

The invention discloses a machining method for small-batch production of O-shaped sealing ring fixing pieces. The machining method comprises the following steps of: a, receiving materials with the sizes of 100 * 60 * 40 and corresponding marks; B, milling the materials to be 90 + / -0.3 * 50 + / -0.3 * 30 + / -0.3 for standby application; C, drilling holes of phi 7 + / -0.2 * 90 in the milled materials, and ensuring that the sizes are 7 + / -0.2 and 4.5 + / -0.1; D, carrying out slow travelling wire cutting according to the sizes of workpiece materials to be machined for standby application; E, carrying out slow travelling wire cutting on the workpiece materials obtained in the step d according to the sizes of workpiece materials to be processed for standby application; and f, polishing the workpiece materials obtained in the step e until the surfaces with the roughness of Ra0.8 are obtained. According to the method, through reasonable discharging, a plurality of gaskets are combined into a workpiece with a large size, so that the problem that a small-size workpiece is difficult to clamp by large equipment is solved, and then stamping is replaced with a slow travelling wire cutting method, so that the problems that clamping is difficult and the size precision is difficult to guarantee are solved.

Owner:GUIZHOU AEROSPACE XINLI CASTINGSAND FORGINGS

Horizontal micro-electric spark machine tool and method for performing online processing by applying same

Owner:HUAZHONG UNIV OF SCI & TECH

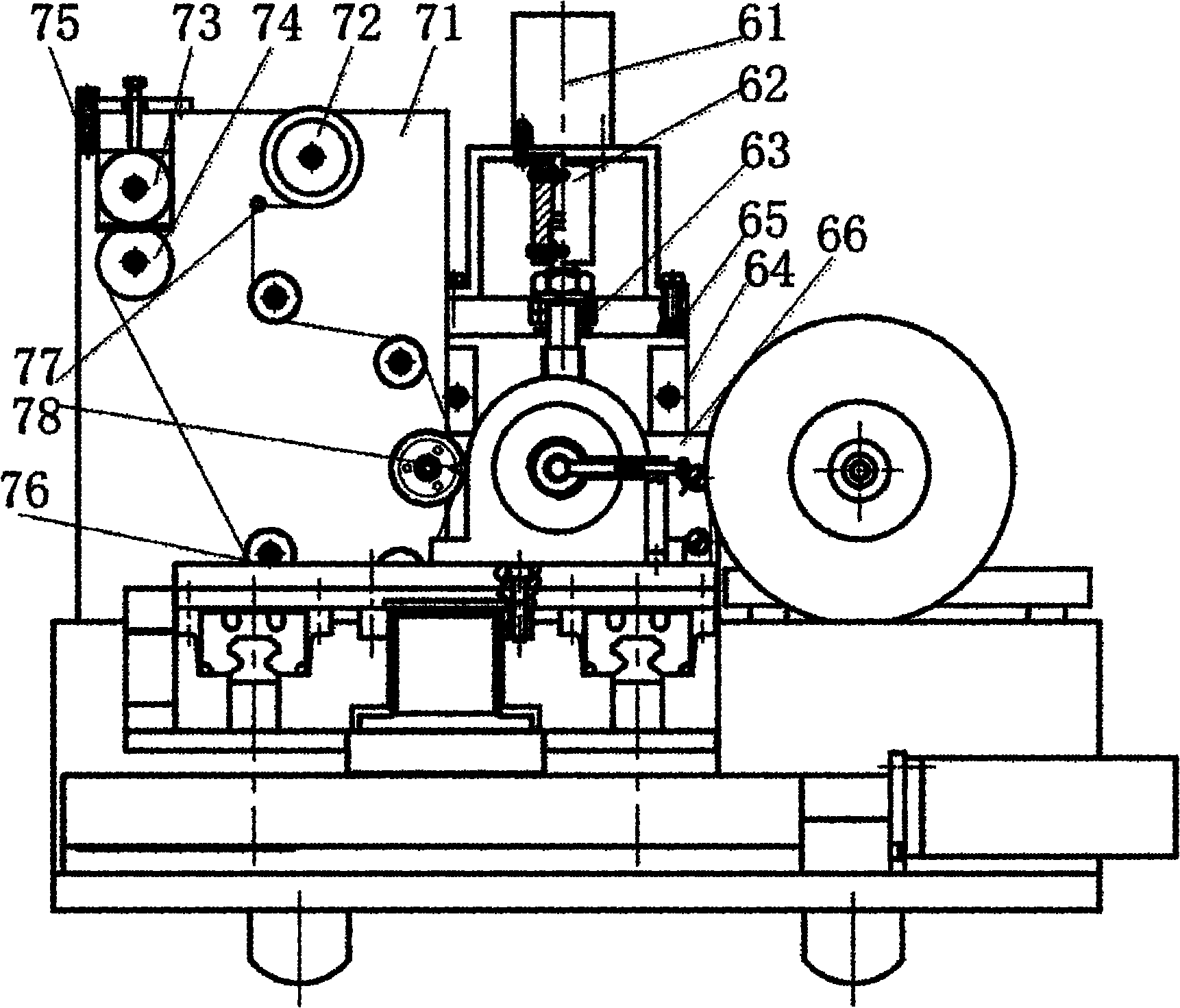

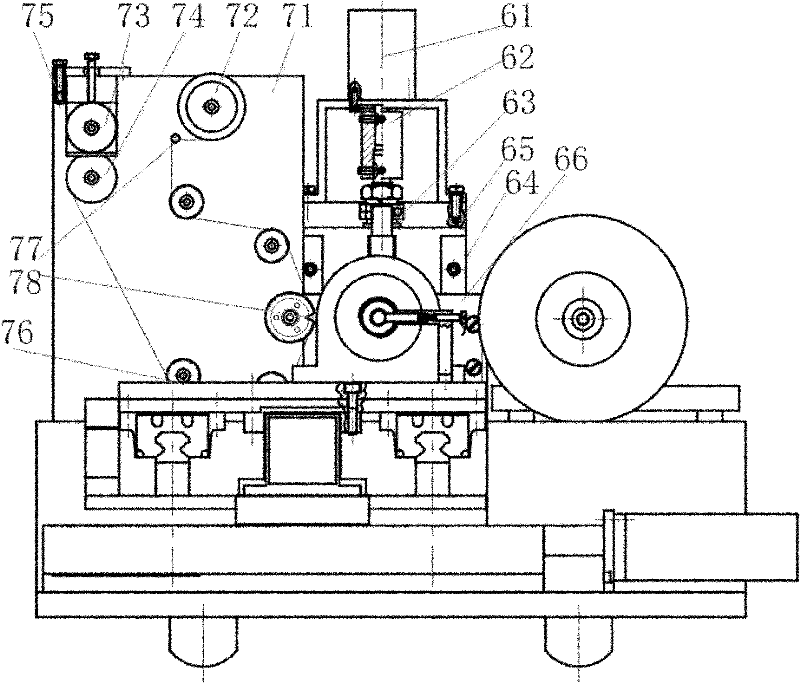

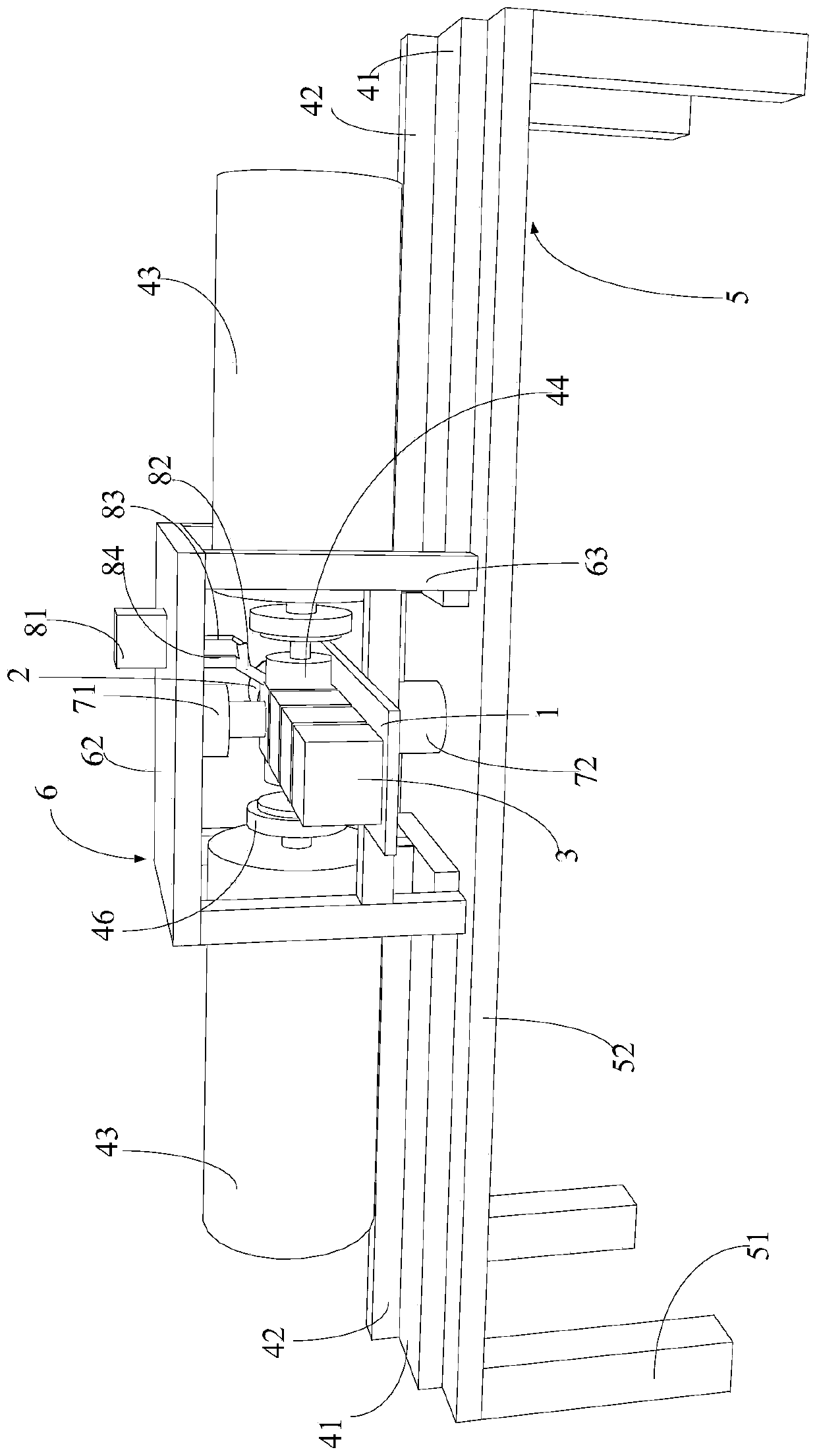

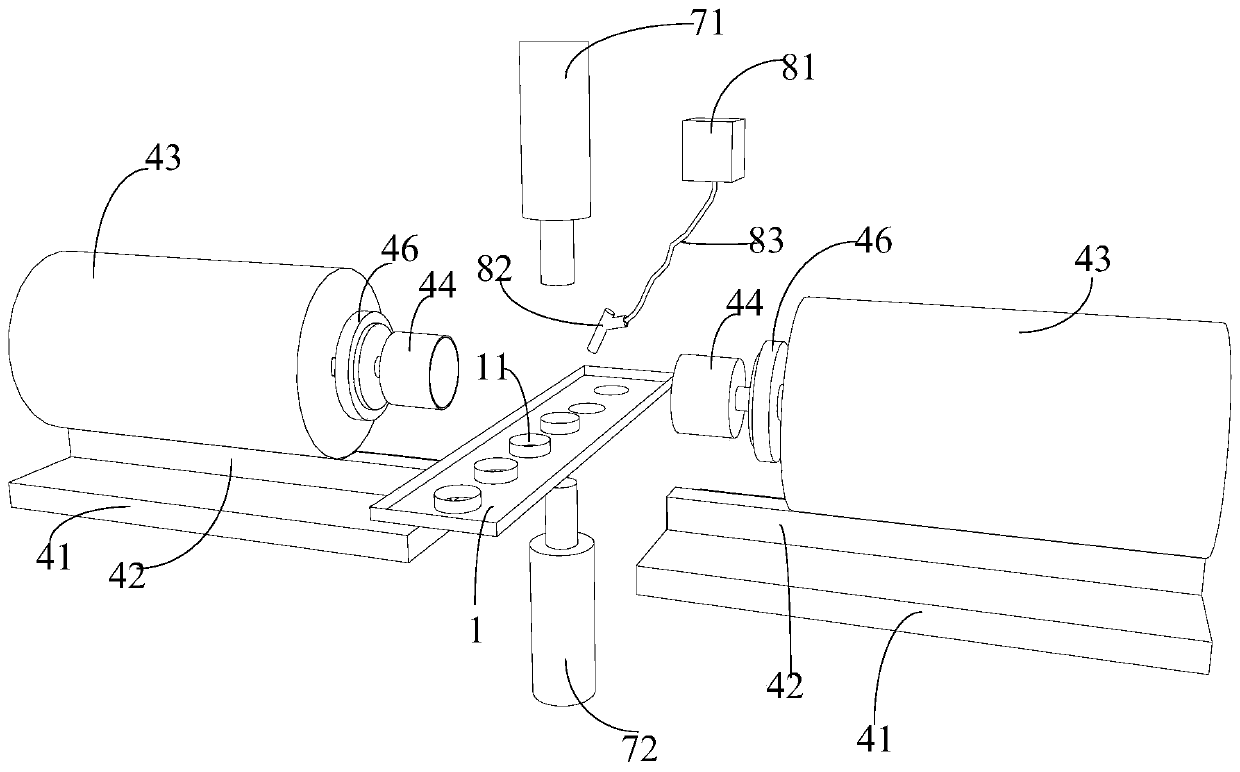

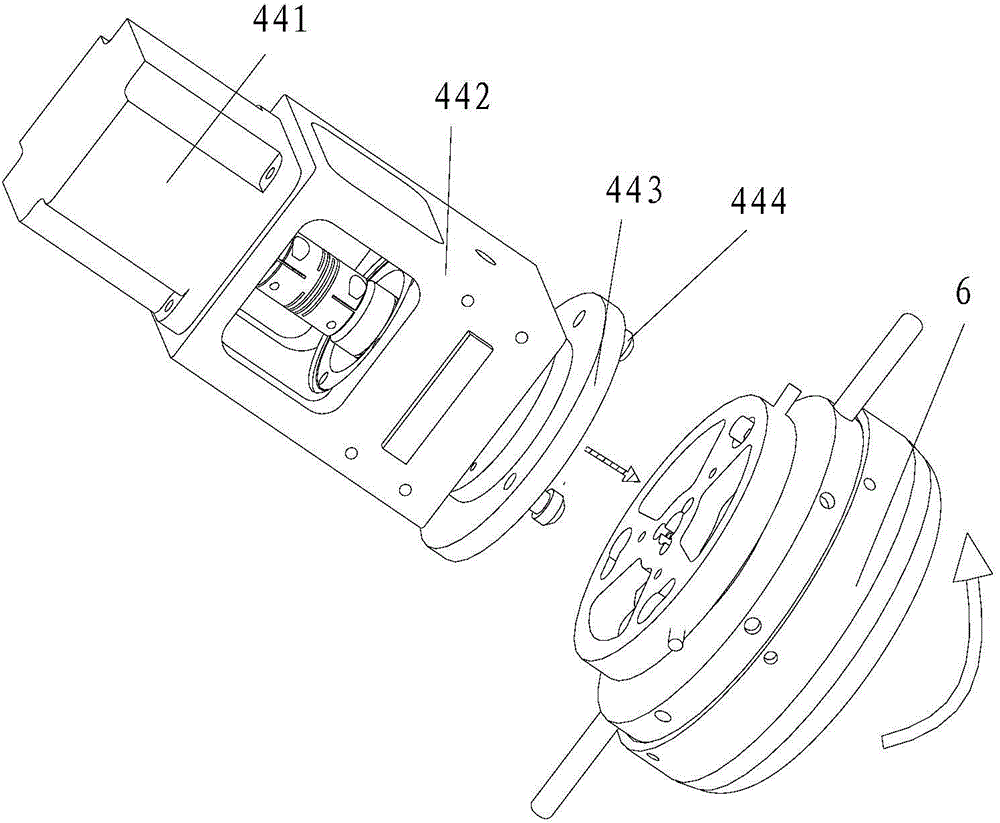

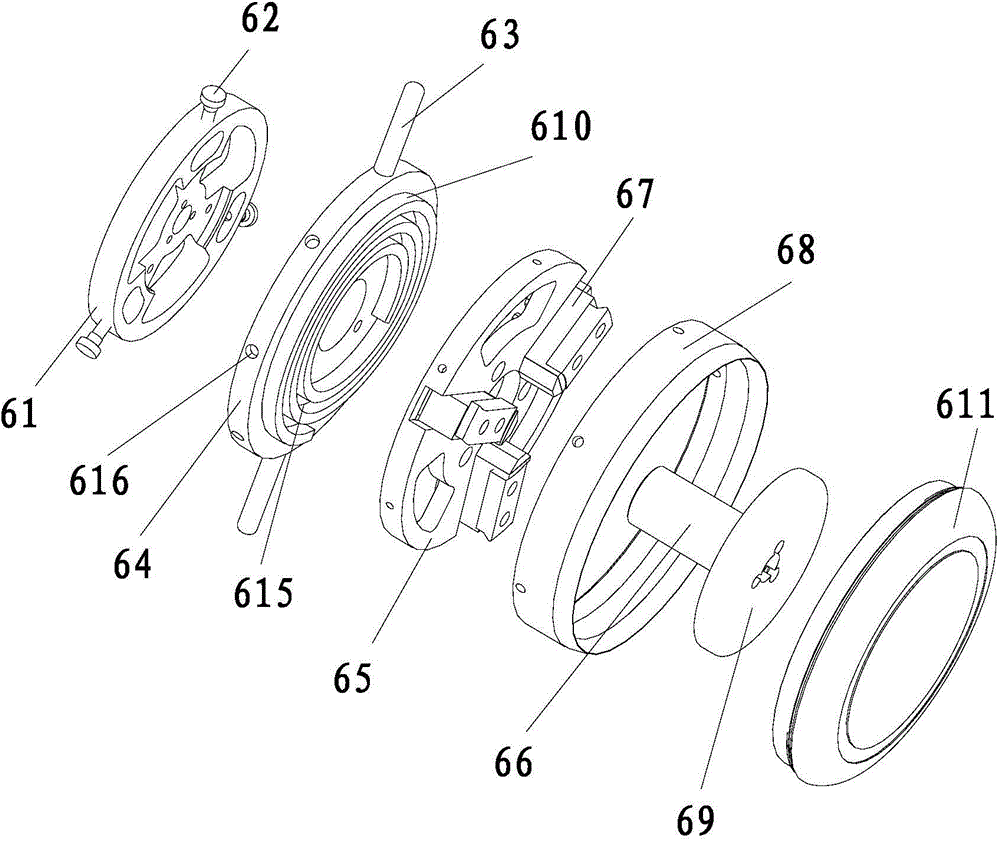

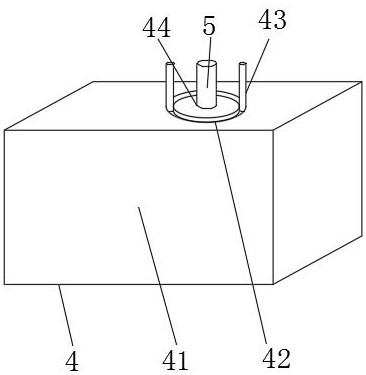

Automatic ball machining device and ball machining method

PendingCN111002154ASimple structureEasy to operateGrinding carriagesSpherical surface grinding machinesElectric machineWater spray

The invention provides an automatic ball machining device and a ball machining method. The automatic ball machining device comprises a conveying belt used for conveying blanks of machining balls, twomoving mechanisms, two rotating shaft motors, two ball nesting devices and a water spraying device used for spraying water to an operation station. The two moving mechanisms are erected at the two sides of the conveying belt in the width direction, each moving mechanism comprises two bottom plates, guide rails arranged on the two bottom plates respectively and electric sliding blocks oppositely arranged on the two guide rails in a sliding mode, and the two guide rails are located in the same line; the two rotating shaft motors are oppositely connected to the two electric sliding blocks; the centers of the two bead nesting devices are oppositely arranged, the two bead nesting devices are hemispherical and equal in diameter, and the ends of the bead nesting devices are coaxially connected with rotating shafts of the rotating shaft motors. The water spraying device is erected over the conveying belt through a first supporting frame. The invention further provides a ball machining method through the device.

Owner:中建八局轨道交通建设有限公司

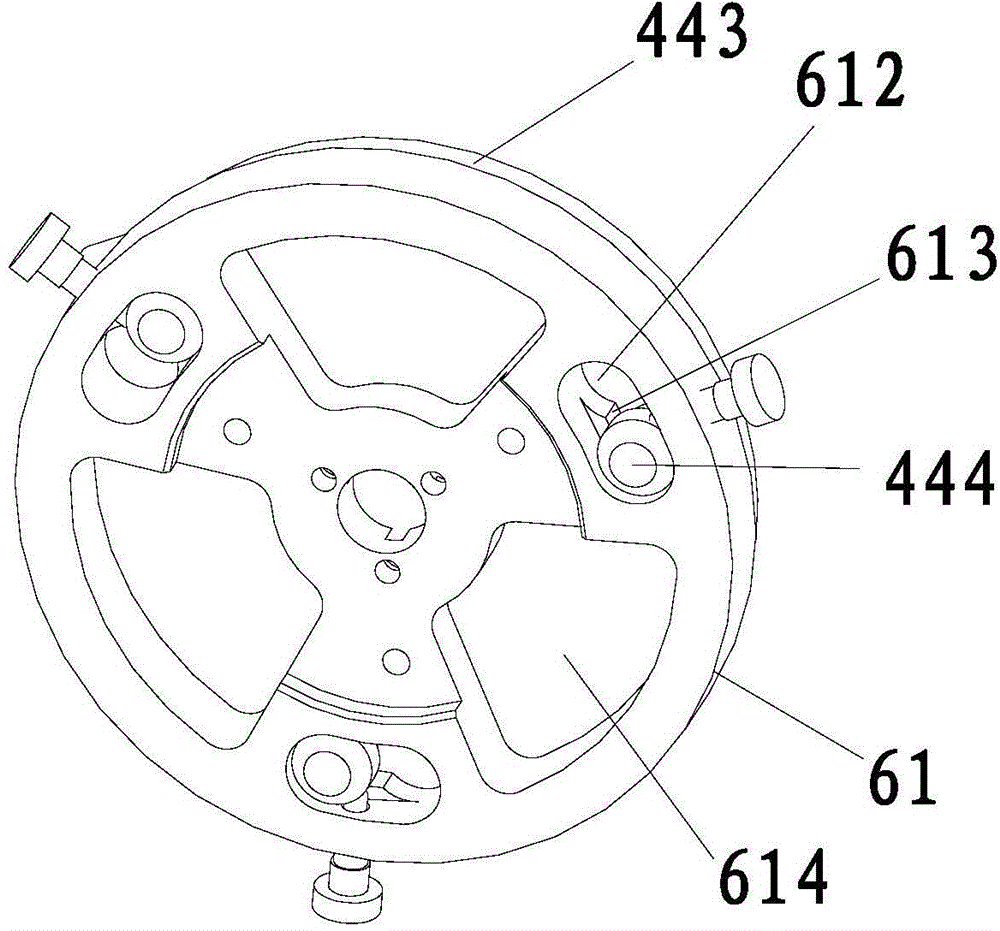

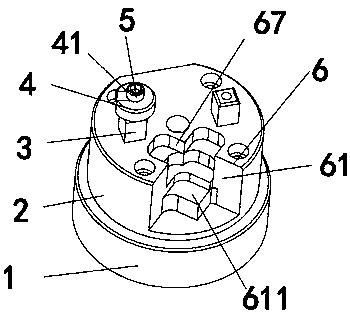

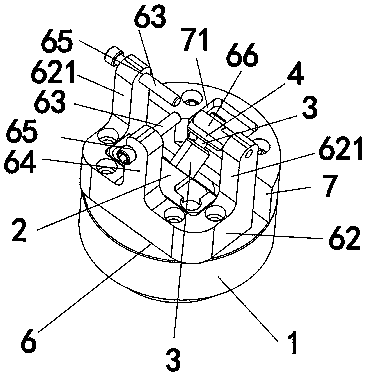

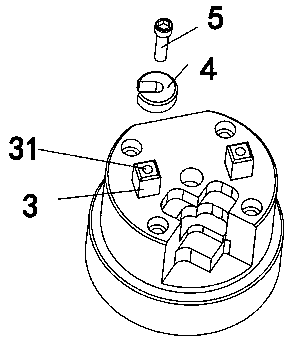

Polishing clamping device for special-shaped surface products

ActiveCN105856068ASolve clamping difficultiesPlay a protective effectGrinding work supportsMechanical engineering

The invention relates to the technical field of polishing, and discloses a polishing clamping device for special-shaped surface products. The polishing clamping device comprises a fast-disassembly clamping board, a chuck, a three-jaw lower chuck, flexible jaws, an edge-turning down prevention ring and a boss, wherein the fast-disassembly clamping board, the chuck, the three-jaw lower chuck and the edge-turning down prevention ring are sequentially and axially arranged; the chuck is separately movably connected with the three-jaw lower chuck and the fast-disassembly clamping board; clamping nail grooves matched with clamping nails are formed in the fast-assembly clamping board; the end surface of one end of the chuck extends outwards to form the boss, and a spiral groove is formed in the boss; at least two sliding grooves are formed in the three-jaw lower chuck; each groove is internally provided with a flexible jaw in a slidable manner; sliding blocks on the bottom surfaces of the flexible jaws penetrate through the three-jaw lower chuck and are matched with the spiral groove; and the bottom end of a special-shaped product is matched with the edge-turning down prevention ring, and the inner surface of the special-shaped product corresponds to the flexible jaws in position. The polishing clamping device is simple and reliable, and is easy to realize and convenient for assembly and disassembly; and the quality of the to-be-polished special-shaped products can be improved, so that consistency of polishing of the special-shaped products is realized.

Owner:HANS LASER TECH IND GRP CO LTD

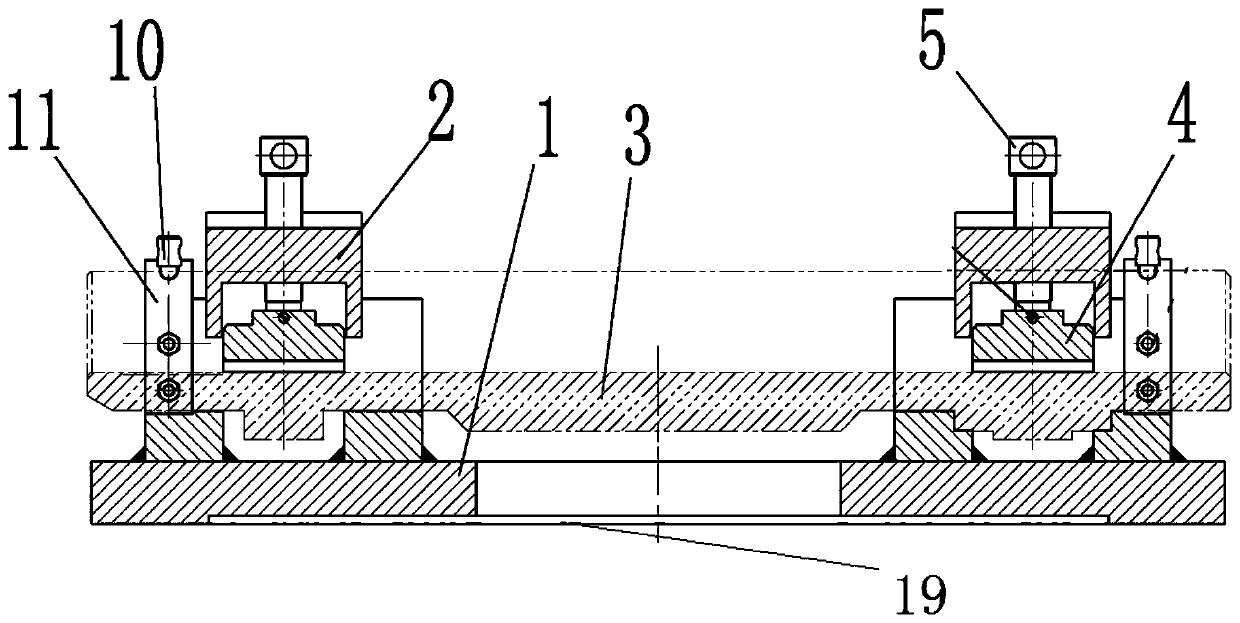

Arc plate stepped hole machining device and machining method

InactiveCN110900237ACompact structureEasy to useDrilling/boring measurement devicesPositioning apparatusLocknutIndustrial engineering

The invention discloses an arc plate stepped hole machining device, which comprises a bottom plate, and is characterized in that both ends of the bottom plate are fixedly connected with clamp bodies,the two clamp bodies are oppositely and fixedly connected, each clamp body is U-shaped and fixedly connected with an arc-shaped block, the arc-shaped block is located on the inner wall, which is opposite to the opening, of the clamp body, one end of the clamp body is movably connected with a drill jig body, one end of the drill jig body is movably connected with the clamp body, the other end of the drill jig body is provided with a groove, the drill jig body is provided with a threaded hole, the threaded hole is located in the drill jig body, the threaded hole is internally equipped with a handle screw, the handle screw penetrates through the threaded hole, the end, which is close to the clamp body, of the handle screw is fixedly connected with an arc plate pressing block, one end of the clamp body is provided with a U-shaped groove, an eyelet bolt is movably connected in the U-shaped groove, the diameter of the eyelet bolt is matched with the size of the groove, the eyelet bolt extends out of the U-shaped groove, and the eyelet bolt is equipped with a locking nut. According to the machining method of the arc plate stepped hole machining device, the problem of difficult arc plate clamping in the prior art is solved.

Owner:BAOJI PETROLEUM MASCH CO LTD

Wall panel installation equipment

ActiveCN110499922ASolve clamping difficultiesEasy to disassembleBuilding material handlingArchitectural engineering

The invention discloses wall panel installation equipment. The wall panel installation equipment comprises a machine frame, a left rotating frame, a right rotating frame, a cam and a returning mechanism, wherein the left rotating frame is rotatably arranged on the machine frame along a vertical axis, and the left rotating frame is provided with a clamping mechanism matched with the first side of awall panel; the right rotating frame is rotatably disposed on the machine frame along the vertical axis and located on the opposite side of the left rotating frame; the cam is rotatably disposed on the right rotating frame along a horizontal axis and is used for being in clamping fit with second side of the wall panel; and the returning mechanism is used for driving the cam to rotate so as to enable the convex surface of the cam to be opposite to the clamping mechanism of the left rotating frame. An existing wall panel clamping scheme is optimized. When the wall panel is installed, the wallboard self-weight is used for enabling the wall panel to be naturally in a vertical state. No power adjustment is required to enable the wall panel to be in a vertical state, and no sensor detection feedback is required. Assembling and disassembling are more convenient, automatic power adjustment is required, the cost of the mechanism is reduced, and the mechanical structure is simplified.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

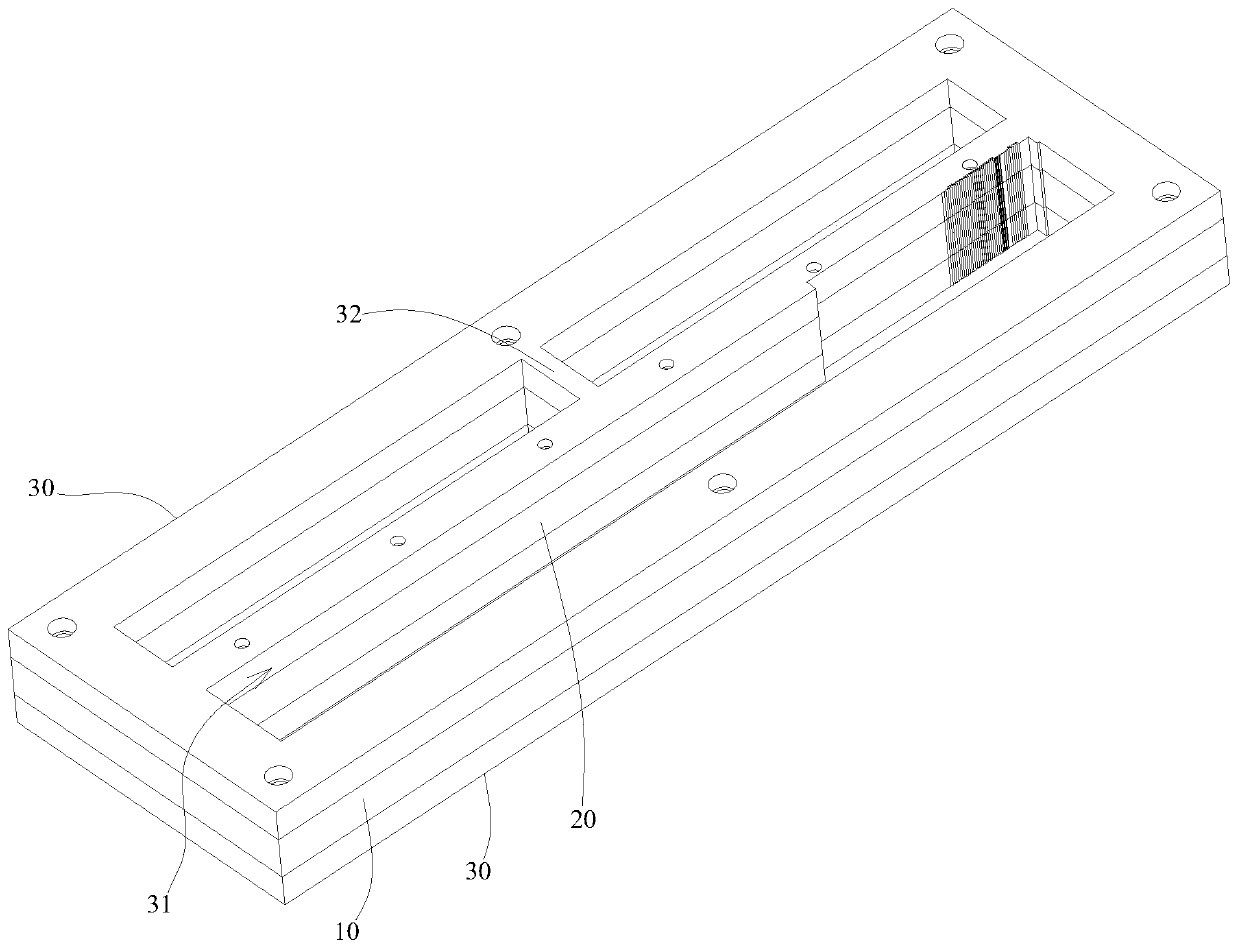

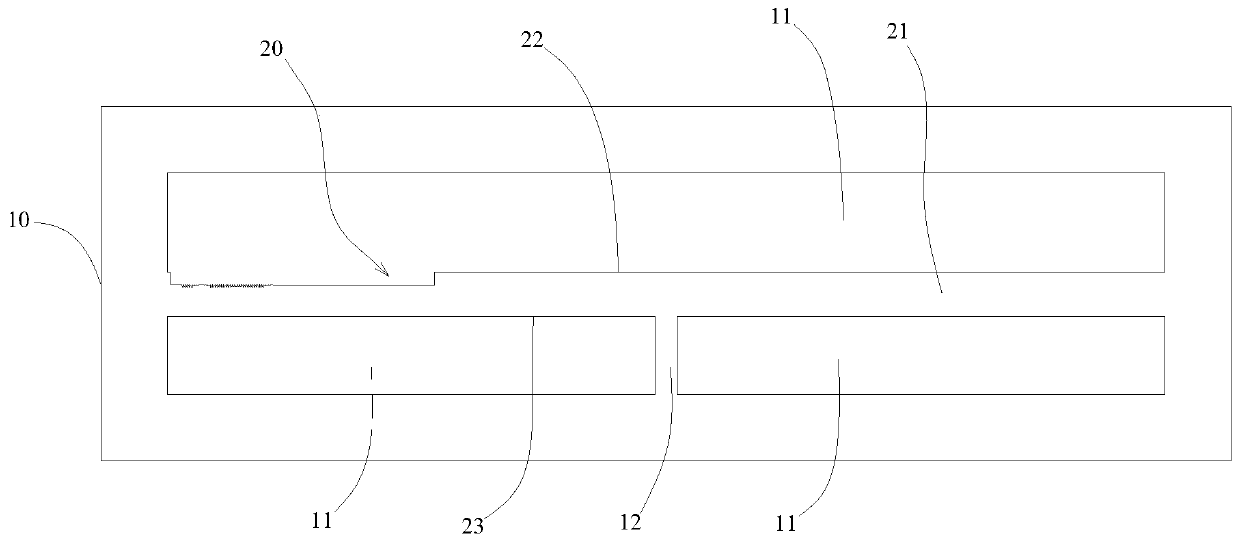

Machining method of precision pattern insert and precision pattern insert

ActiveCN111347224AResolve Stress DeformationGood for stress reliefCleaning using liquidsPositioning apparatusMachiningEngineering

The invention discloses a machining method of a precision pattern insert. The machining method comprises a cutting step of forming at least two machining holes passing through two opposite side facesof a blank at intervals in the blank, wherein two ends of the machining holes extend along a length direction of the blank, a clamping outer frame for clamping and fixing a clamp is formed on the periphery of the blank, and a middle part of the blank is partitioned by the two machining holes to form a workpiece part of which two ends are connected to the clamping outer frame; an assembly surface machining step; a machining accessory assembling step; a pattern surface primary machining step; a workpiece framework separating step; and a pattern surface secondary machining step. Through the adoption of the machining method, the problem of stress deformation after the machining of the precision pattern insert is solved, and the collapse and deformation of the edge of a pattern surface in the process is avoided. The invention also discloses a precision pattern insert machined by the method. The precision pattern insert can improve the quality and yield of mold produced products.

Owner:DATAMATIC GUANGZHOU INJECTION MOLD

Positioning device used for connection rods and shell parts

Owner:WUXI RUIZHEN PRECISION MACHINERY

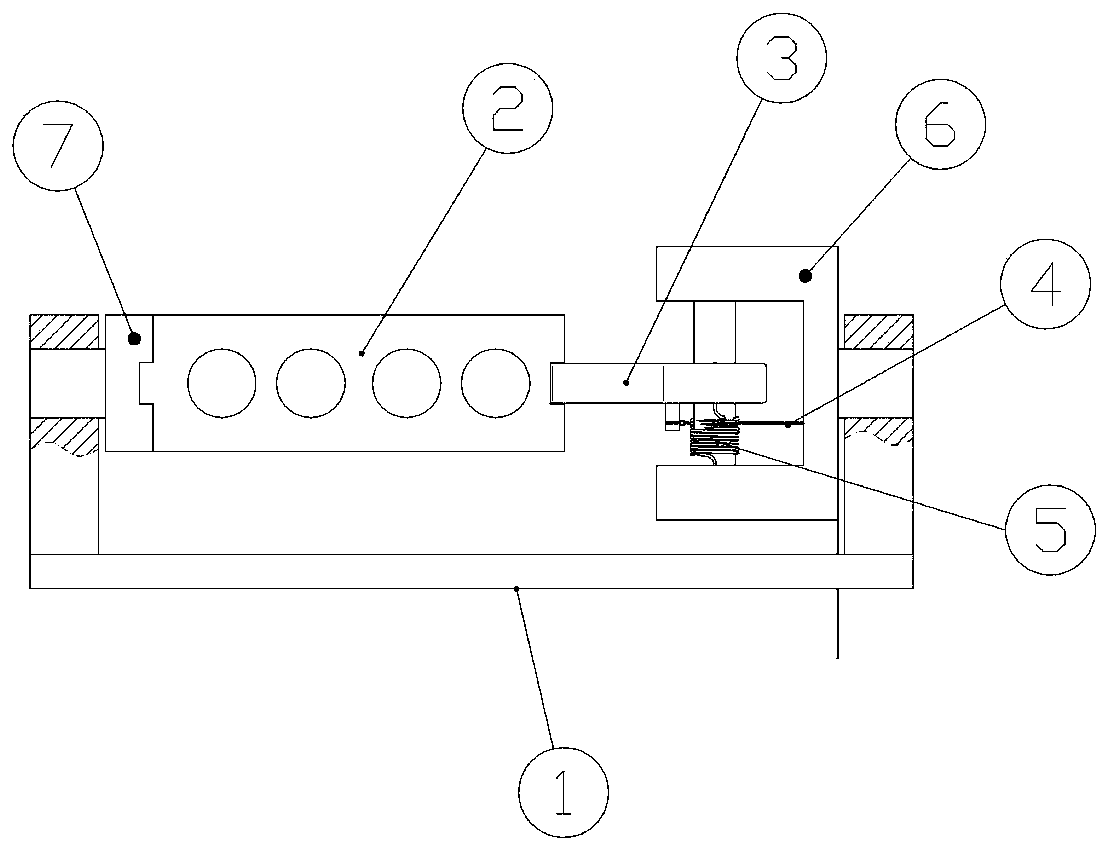

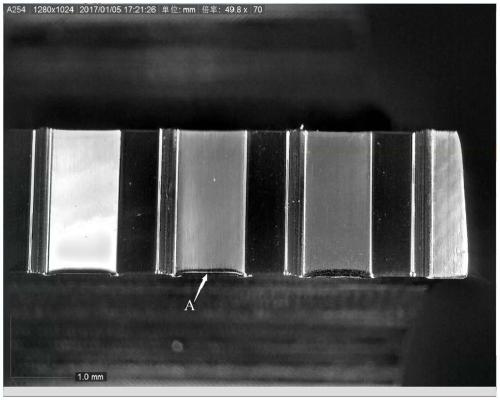

Measuring device and measuring method for welding seam strength

ActiveCN105758725AAccurate measurementSolve clamping difficultiesMaterial strength using tensile/compressive forcesMeasurement deviceTest sample

The invention provides a measuring device and a measuring method for welding seam strength. The measuring device comprises a fin slot and a substrate slot, wherein the fin slot is a square structure; the side surface of the fin slot is provided with a wedge-shaped slot; the width of the upper end of the wedge-shaped slot is smaller than that of the upper end of the fin slot; the wedge-shaped slot is used for fixing a fin of a sample; the substrate slot is a square structure; and the side surface of the substrate slot is provided with a T-shaped slot which is used for fixedly mounting a substrate of the tested sample. According to the measuring device and the measuring method for the welding seam strength, a welding seam is fractured before a fin in a test sample tensile test process; meanwhile, the device can be used for clamping fins at the two sides, and can apply tensile force in a direction perpendicular to the plate surface of a composite plate, so that an inclination problem is avoided, the tensile strength value of a braze-welding welding seam can be measured more accurately, and the measuring accuracy is improved.

Owner:YINBANG CLAD MATERIAL

Measuring device and method for weld strength

ActiveCN105758725BAccurate measurementSolve clamping difficultiesMaterial strength using tensile/compressive forcesMeasurement deviceTest sample

Owner:YINBANG CLAD MATERIAL

A kind of complex shape joint processing method

ActiveCN112570994BLow costOptimizing Rough Milling Program StrategiesMilling equipment detailsPositioning apparatusNumerical controlEngineering

The invention discloses a complex shape joint processing method. By acquiring the original geometric data of the workpiece to be processed, a three-dimensional model of the workpiece is constructed, and the rough blank of the three-dimensional model is forged by forging, and the rough blank is processed by a numerical control machining center. Rough machining is performed on the front and back of the rough blank, the front side of the rough blank is subjected to two finishing operations in turn, and the back side of the rough blank is subjected to two finishing operations in turn; the processing method of the present application can use ordinary milling machines to mill joint parts instead of using numerical control After the machining center is completed, during the numerical milling process, the tools are reasonably selected, the rough milling program strategy is optimized, and the processing of the parts is better completed, the processing quality is guaranteed, the processing efficiency is improved, and the tool cost is reduced.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Tool electrode assembly and grinding wheel repair machine

Owner:重庆万盛福耀玻璃有限公司

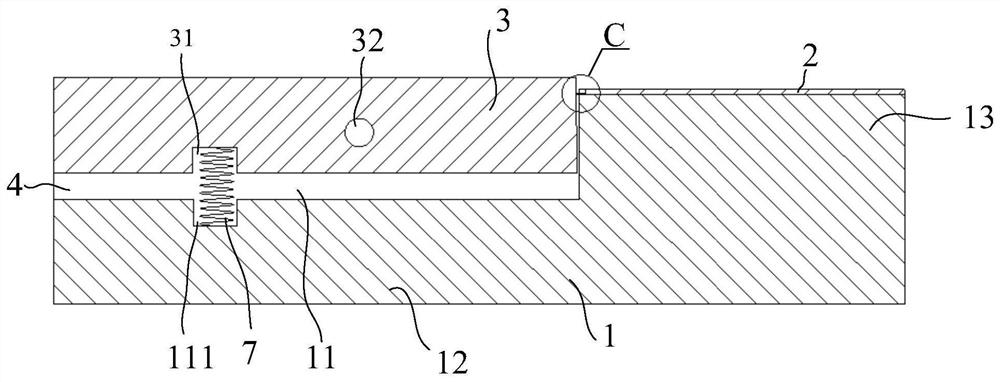

Chip assembly bonding module, clamp and chip assembly clamping method

PendingCN111755363AAvoid damageSame technical effectLaser detailsSemiconductor/solid-state device manufacturingChipsetMechanical engineering

The invention provides a chip assembly bonding module, a clamp and a chip assembly clamping method which are used for clamping a chip assembly in a gold wire bonding process. The bonding module comprises a module body, a clamping piece, an elastic piece and a limiting piece. A positioning surface is formed on the module body, and the clamping piece is movably arranged on the module body. The elastic piece is connected with the module body and the clamping piece, and when the elastic piece is in an initial state, the bottom height of the end, close to the limiting piece, of the clamping piece is equal to or lower than the positioning face. The limiting piece is arranged on the module body. A positioning area for containing the chip assembly is formed between the clamping piece and the limiting piece, the positioning face is located in the positioning area to support the chip assembly, and the elastic piece is used for enabling the clamping piece to apply clamping force to the chip assembly. According to the bonding module of the chip assembly provided by the invention, the chip assembly is stably clamped between the clamping piece and the limiting piece through the elastic piece, sothat the probability that the chip assembly is damaged in a gold wire bonding process is effectively reduced.

Owner:GUANGXUN SCI & TECH WUHAN

Machining tool and machining process of special-shaped stainless steel products

ActiveCN110549141ANot easy to removeQuality assurancePositioning apparatusMetal-working holdersAgricultural engineeringMachining process

The invention discloses a machining tool of special-shaped stainless steel products. A first product clamping mechanism and a second product clamping mechanism each comprise a fixing block, positioning blocks, pressing blocks and compressing bolts. As for each product clamping mechanism, a cushion block is fixed on the fixing block; the positioning blocks are fixed on the cushion block; a threadedhole is formed in each positioning block; each pressing block is placed on the top end face of a sleeve of the corresponding special-shaped stainless steel product after the top end of each positioning block is sleeved with the sleeve of the special-shaped stainless steel product; each compressing bolt is fixedly in threaded connection with the corresponding threaded hole after penetrating through the corresponding pressing block and the sleeve of the corresponding special-shaped stainless steel product; after being attached to the top surface of the corresponding pressing block, the head ofeach compressing bolt presses and fixes the sleeve of the corresponding special-shaped stainless steel product; and a positioning structure for positioning an inclined rod of each special-shaped stainless steel product is further arranged on the cushion block. By means of the machining tool, a workpiece can be clamped quickly and conveniently, finish machining is convenient, and the precision of products after finish machining is further improved.

Owner:宁波穗锦机械科技有限公司

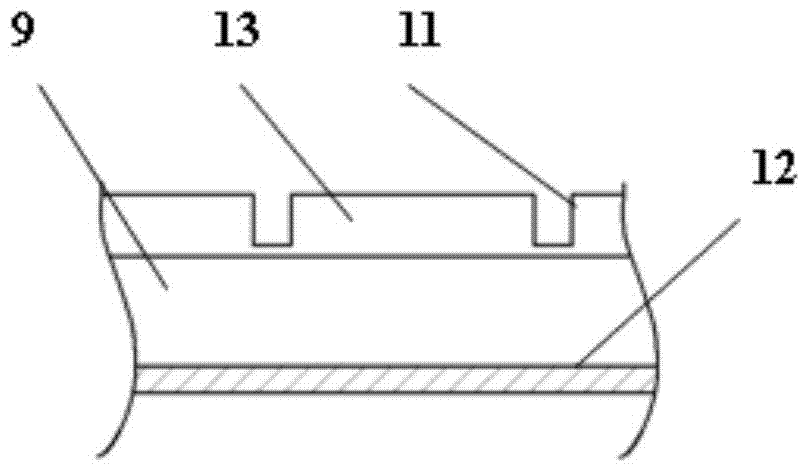

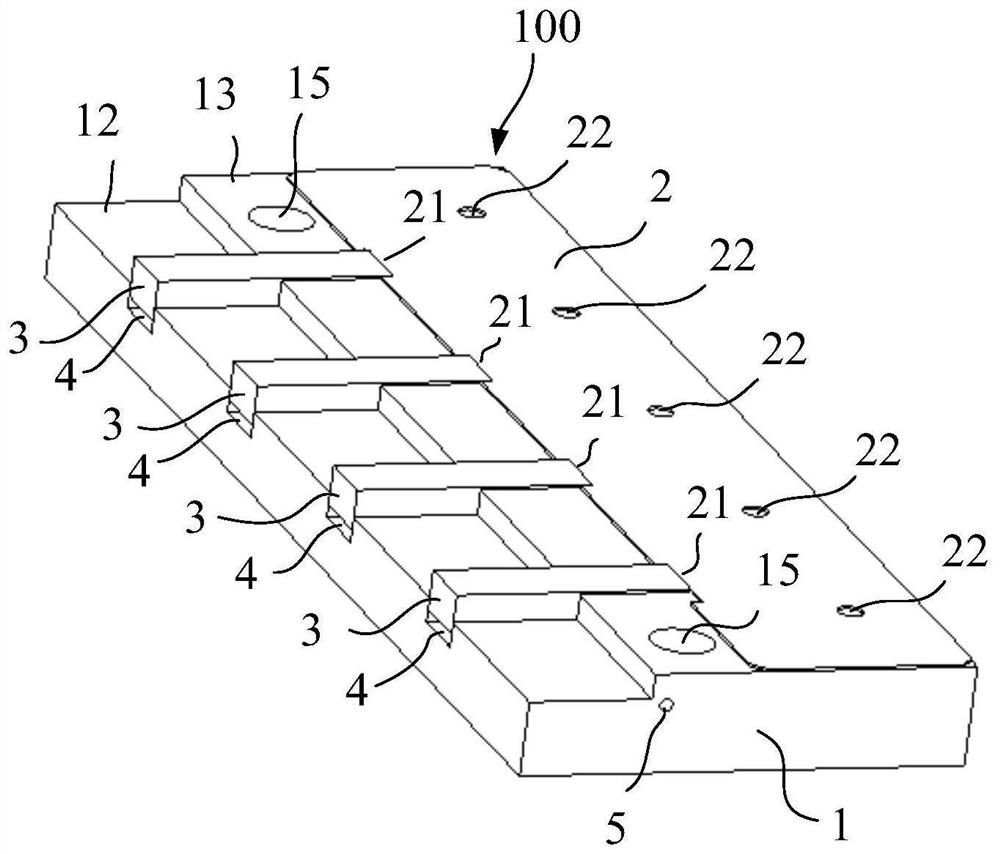

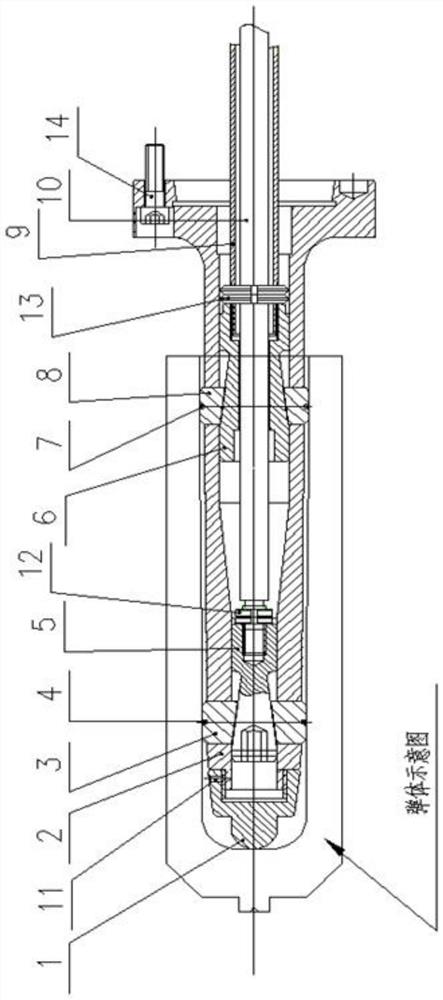

Clamp for clamping inner chamber of projectile body

PendingCN114309695ASolve clamping difficultiesSolve the accuracy problemExpansion mandrelsEngineeringMachine tool

The invention provides a clamp for clamping an inner chamber of a projectile body, which belongs to the technical field of special clamping for projectile bodies and mainly comprises a supporting part, a clamping part and a supporting transmission part. The supporting part is installed on machine tool equipment through screws, the clamping part and the supporting transmission part are installed on the supporting part and inside the supporting part, the transmission part is connected with a machine tool oil cylinder to achieve front-back pulling actions to complete loosening and clamping of the clamping part, and clamping of the tool is achieved. And the structure is simple, the universality is good, the precision is high, and the consistency of product quality machining is improved. And finally, the function of machining and clamping the workpiece is achieved.

Owner:LIAOSHEN IND GRP

Welding device for electric tool part machining

InactiveCN113084401ARealize multi-directional welding operationSolve clamping difficultiesWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlSlide plate

The invention discloses a welding device for electric tool part machining. The welding device for electric tool part machining comprises a bottom plate, two first sliding grooves are formed in the front portion of the upper end of the bottom plate, the interiors of the two first sliding grooves are jointly and slidably connected with a sliding plate, and the left portion and the right portion of the sliding plate are both in threaded connection with fastening rotary knobs; and the lower ends of the fastening rotary knobs are in threaded connection with the inner parts of the two first sliding grooves, a first side plate and a second side plate are fixedly connected to the left end and the right end of the sliding plate correspondingly, a welding mechanism penetrates through the upper portion of the second side plate, the left end of the welding mechanism is fixedly connected with the right end of the first side plate, and a numerical control table is fixedly installed on the right portion of the upper end of the bottom plate. According to the welding device for electric tool part machining, multidirectional welding operation can be achieved, the problem that heated parts are difficult to clamp is solved, local overheating of the parts caused by too long welding time in the subsequent machining process can be avoided, and the welding quality is guaranteed; and in addition, cleaning efficiency can be improved, and modern use requirements are met.

Owner:东莞市浩恒工业设计有限公司

Light and thin refractory material special-shaped curved surface grinding machining device and method

PendingCN114434327AImprove rigidityAvoid falling blocks and cornersGrinding machinesGrinding work supportsMachine partsRefractory

According to the light and thin type refractory material special-shaped curved surface grinding machining device and method, the to-be-machined part is pressed on the cushion block through the pressing plate arranged on the check block, the to-be-machined part is limited on the cushion block through cooperation of the ejection block, and then the to-be-machined part is clamped in a one-pressing one-ejection one-padding mode through supporting of the cushion block; all special-shaped curved surfaces are machined through one-time clamping, the surface quality and precision of products are guaranteed, the products of different sizes can be machined by adjusting a screw of the jacking device, the mode of pressing, jacking and padding is adopted, reliability is high, the rigidity of refractory materials in the machining process is improved, and the service life of the refractory materials is prolonged. Vibration caused by suspension of the bottom is avoided, chipping and corner falling of refractory materials due to vibration are reduced, and disassembly is convenient. And the machining efficiency is greatly improved, and the rejection rate of products is reduced. And meanwhile, the quality and precision of the product are guaranteed, the reliability is high, and clamping is convenient.

Owner:IRICO DISPLAY DEVICES

A Processing Technology for Precise Forming of Hemispherical Body of Large Thin-wall Storage Tank

The invention discloses a processing technology for precise forming of a hemispherical body of a large thin-walled storage tank, which comprises the steps of plasma gas cutting, stamping forming, cutting, shaping, finishing the inner spherical surface, finishing the outer spherical surface and surface treatment. The hemispherical diameter of the large thin-walled storage tank in this application is φ925, the wall thickness is φ0.3, and the ellipticity is φ0.3. The diaphragm type storage tank has high requirements for size, and it is very difficult to CNC process, especially the material used is aluminum alloy, which has insufficient strength and rigidity. , the processing deformation is large, the processing is difficult, and because the diaphragm tank is a large-diameter hemisphere, the surface line speed changes with the height of the part. When turning, it is necessary to select different spindle speeds for different rings to further improve This application explores the use of ultrasonic measurement and design and manufacture of special tooling expansion and clamping for CNC machining, the wall thickness tolerance ellipticity of the upper and lower hemispheres of the storage tank is Φ0.3, and the tensile strength after heat treatment is σ b ≥340MPa, elongation greater than 10%.

Owner:贵州航天朝阳科技有限责任公司

Stepped shaft forging method in free forging

Owner:NANJING DEV ADVANCED MFG

Quick positioning device for shape measuring instrument

ActiveCN107228642ASolve clamping difficultiesEasy to operateMeasurement devicesMeasuring instrumentEngineering

The present invention belongs to the product detection field and relates to a quick positioning device for a shape measuring instrument. A six-jaw chuck is commonly used to clamp a workpiece, the six-jaw chuck can only clamp a cylinder reference workpiece, and the clamping range of the six-jaw chuck is limited, the six-jaw chuck cannot clamp non-cylindrical workpieces such as cuboid workpieces and rhombus workpieces, and auxiliary tools such as jaw vices and cushion blocks are usually adopted to clamp the non-cylindrical workpieces, and manual centering is required, and efficiency is low. According to the quick positioning device for the shape measuring instrument, a supporting seat is mounted concentrically on the turntable of the shape measuring instrument; a horizontal through hole and a vertical through hole at a central position are formed in the supporting seat; the horizontal through hole is provided with a parallel surface in a horizontal direction; a slide channel is formed at the upper parallel surface of the horizontal through hole; and the middle of a bidirectional screw is provided with an annular projection. With the quick positioning device adopted, the problem of difficult clamping of workpieces in different specifications and non-cylinder reference workpieces before measurement can be solved, manual assembly and clamping adjustment before measurement are not required, the operation of detection is simplified, auxiliary operation time can be shortened, and working efficiency can be improved.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com