Method and apparatus of continuous collision reinforcement by laser

An impact-strengthening and laser technology, applied in the field of special processing and manufacturing, can solve the problems of difficult to control the thickness of the coating, the overall efficiency of laser impact is not high, the focusing effect of the strong laser beam, etc., to overcome the difficulty of clothing clips, flexible and convenient manual The effect of precise machining operations and dimensional positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

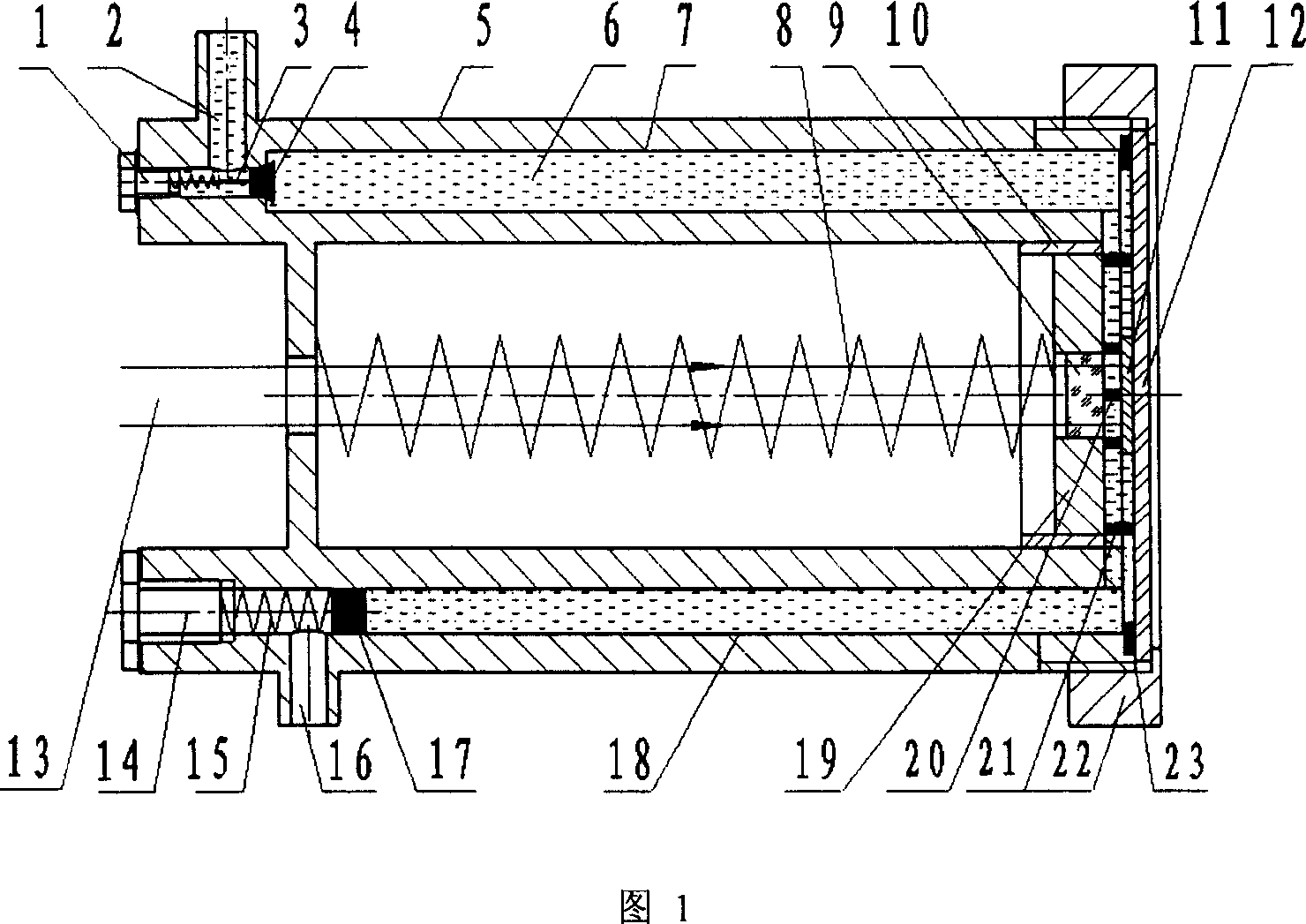

[0050] As shown in Figure 1, the device specifically includes:

[0051] (1) Light guide part

[0052] The light guiding part is composed of a laser beam 13 , a transparent lens 9 and a liquid confinement medium 6 . The laser beam 13 transmitted by the optical fiber or directly emitted from the laser passes through the central cavity of the working tube body, the light-transmitting mirror 9 at an angle of 90 degrees to the laser beam, and the liquid confinement medium 6 to reach the solid coating film 11 .

[0053] (2) Liquid confinement medium transmission part

[0054] The liquid-constrained medium transmission part consists of liquid inlet 2, liquid inlet adjusting nut 1, spring 3, guide rod conical block 4, upper liquid guide chamber 7, solid coating film 11, spring 8, slider 10, high strength and high Elastic rubber ring 19, small pads 20 and 21, light-transmitting mirror 9, lower liquid guide cavity 18, liquid discharge piston 17, liquid discharge port 16, spring 15, li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com