Stepped shaft forging method in free forging

A stepped shaft and step technology, which is applied in the field of stepped shaft forging, can solve problems such as difficulty in clamping round blanks, scrapped blanks, inaccurate shoulder pressing positions, etc., to improve production efficiency and product quality, save material in rounding processing, and shoulder pressing The effect of the correct position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0042] Such as Figure 8 As shown, this embodiment includes the following steps:

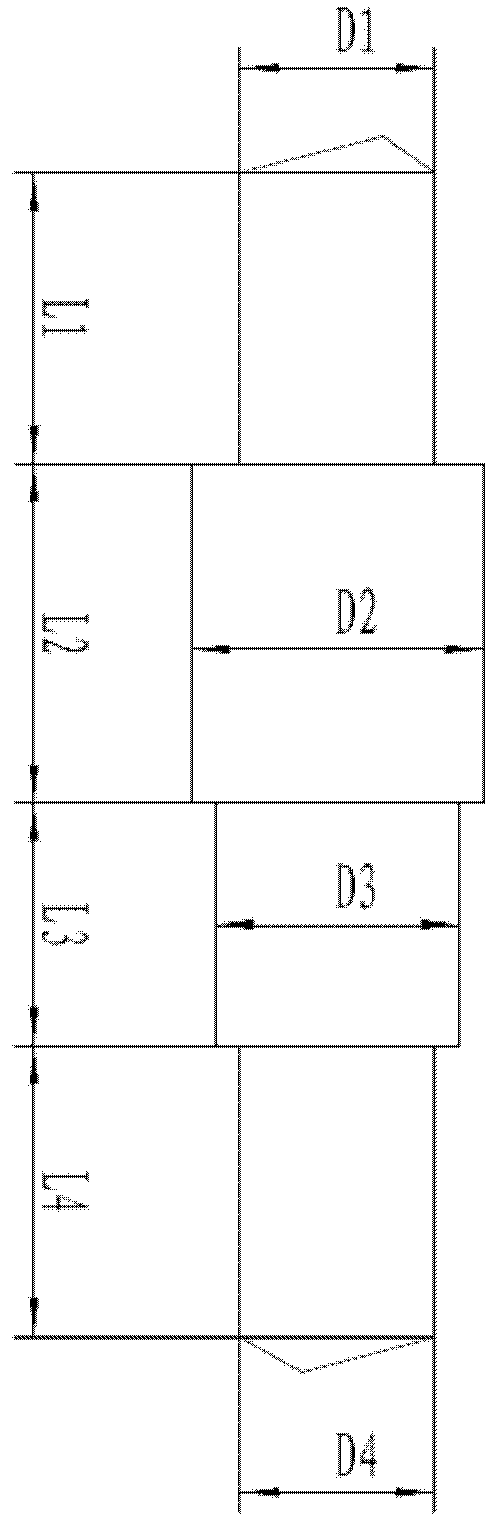

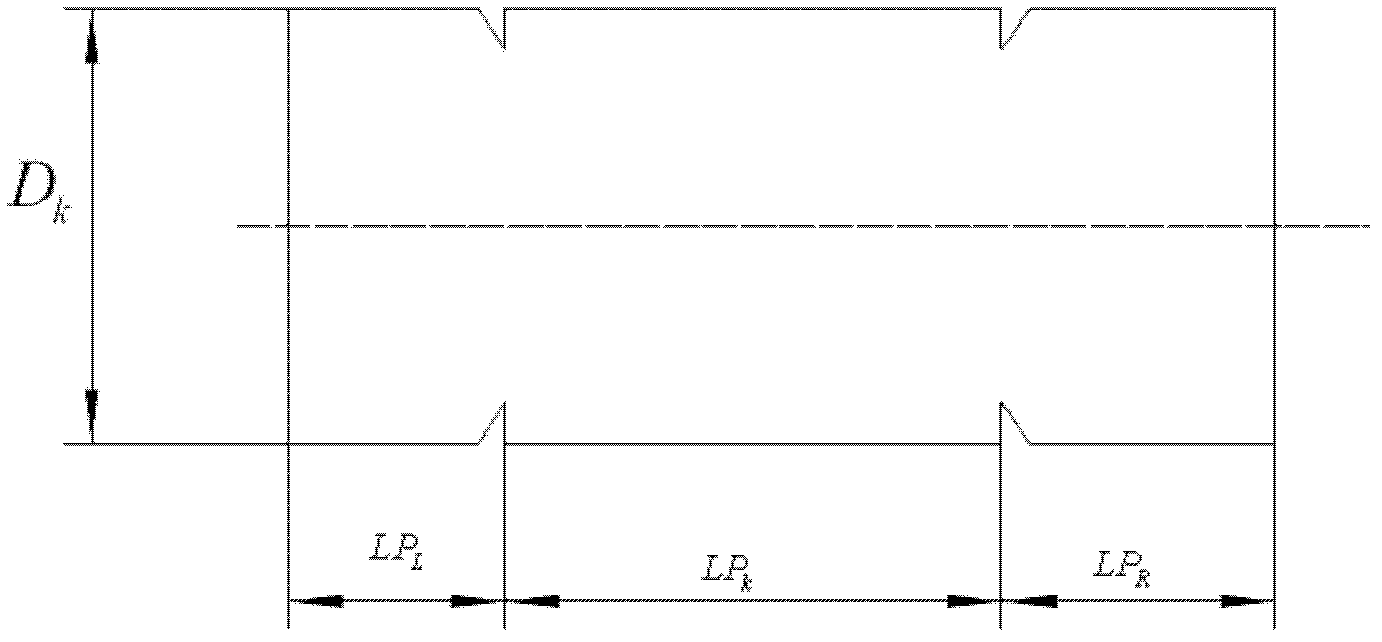

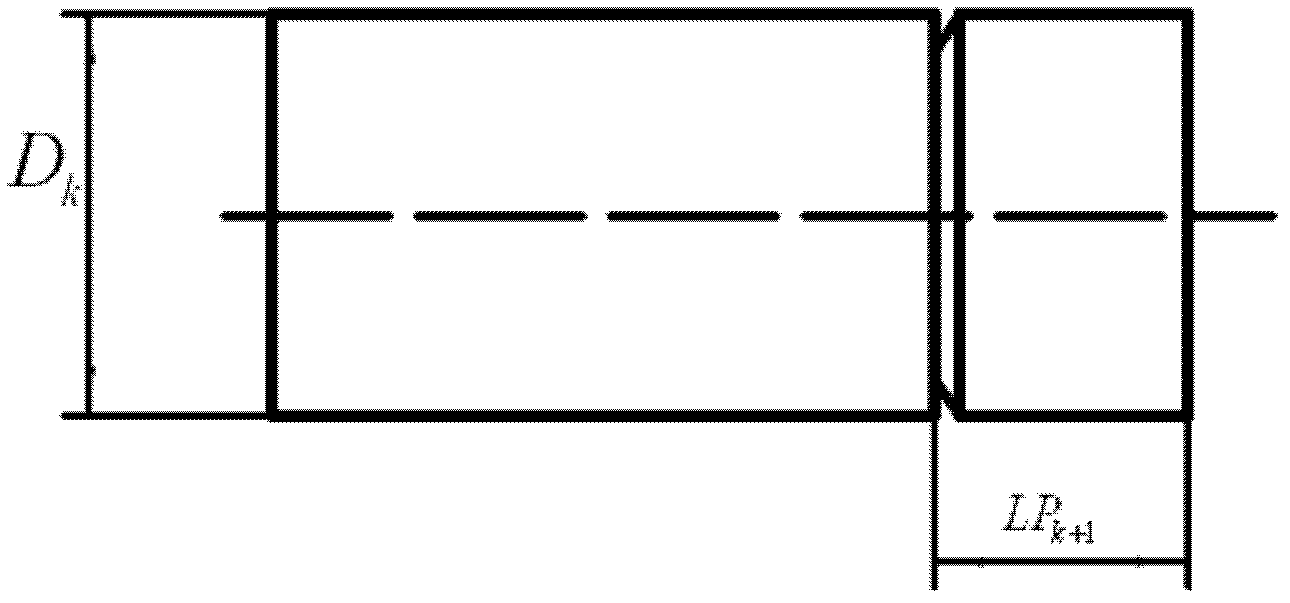

[0043] (1) Read the parameters of the step shaft forging: the diameter and length of each step, the material density r, and the diameter of the step shaft from left to right is D 1 ,D 2 ,…D n , the length is L 1 , L 2 ,... L n , if the maximum diameter is D n Turn the forging around, that is, swap the diameter and length: D 1 with D n Interchange, L 1 with L n Swap, D 2 with D n-1 Interchange, L 2 with L n-1 interchange, and so on;

[0044] Such as figure 1 As shown, this embodiment is a four-step stepped shaft forgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com