Machining method of precision pattern insert and precision pattern insert

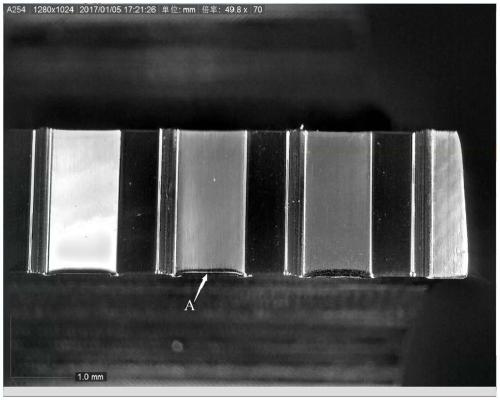

A processing method and pattern technology, which is applied in the processing of precision pattern inserts and the field of precision pattern inserts, to achieve the effect of solving stress deformation and avoiding edge collapse deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

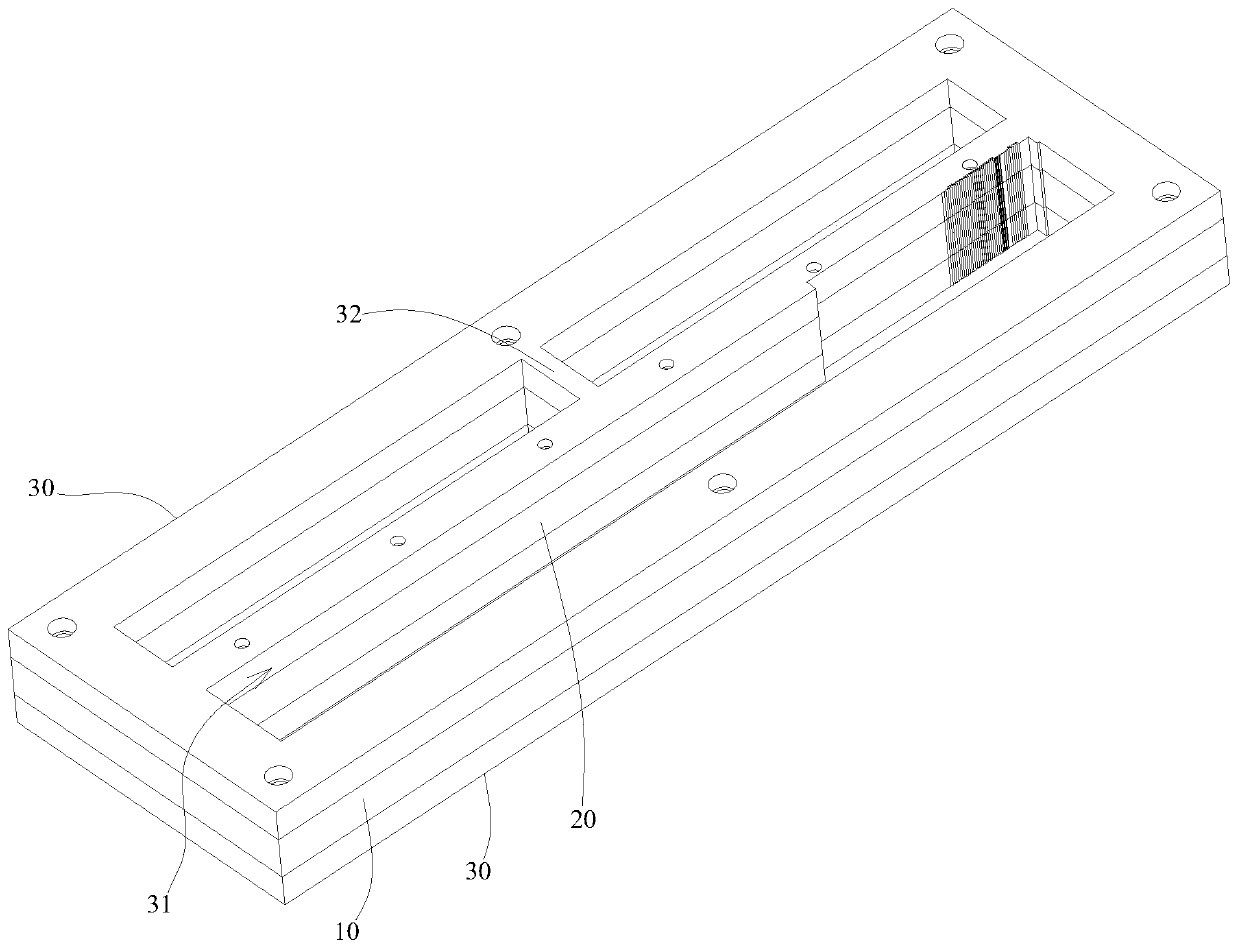

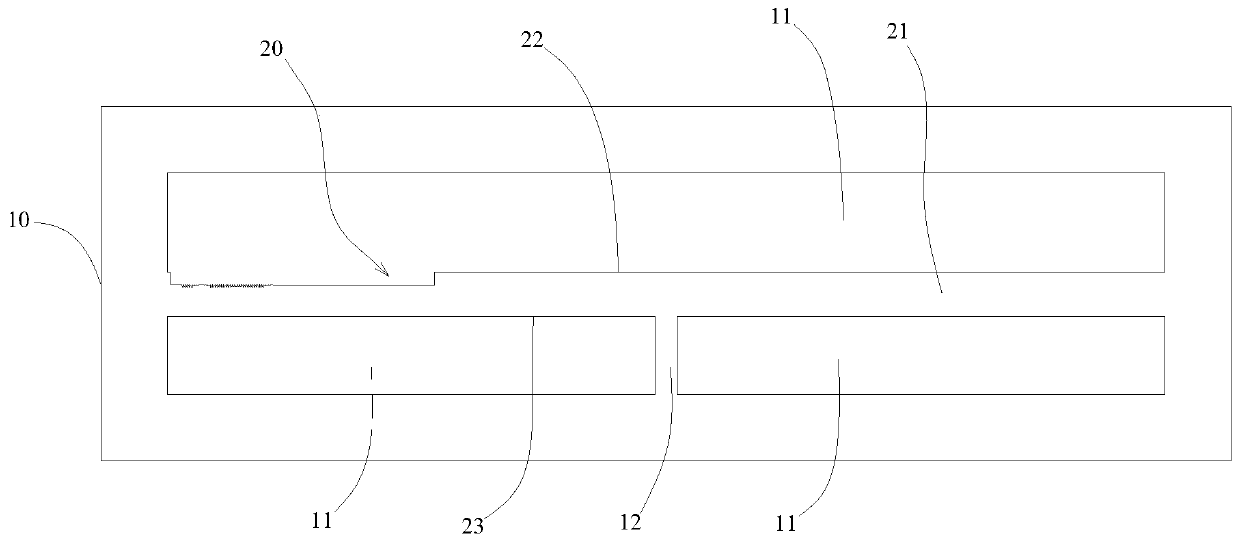

[0040] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0041] Such as Figure 2-Figure 3 As shown, in order to make the mold insert with a precision pattern surface have a higher processing yield and the component quality is better than the traditional process, the present invention discloses a processing method for a precision pattern insert, which includes the following steps:

[0042] Cutting step: This plan preferably adopts a blank with a plate-like structure, and at least two processing holes 11 that pass through the opposite sides of the blank are provided on the blank at intervals. There are two elongated through holes formed on the surface, and the outer peripheral part of the blank forms a frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com