Lightweight high-strength microcirculation composite external heat preservation fireproof non-dismantling formwork and preparation method thereof

A technology that avoids dismantling formwork and external heat preservation. It is applied in heat preservation, fire protection, and building components. It can solve problems such as indoor air retention, high energy consumption of air conditioners, and large water vapor resistance, and achieve good temperature adjustment, building structure safety, and good performance. The effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

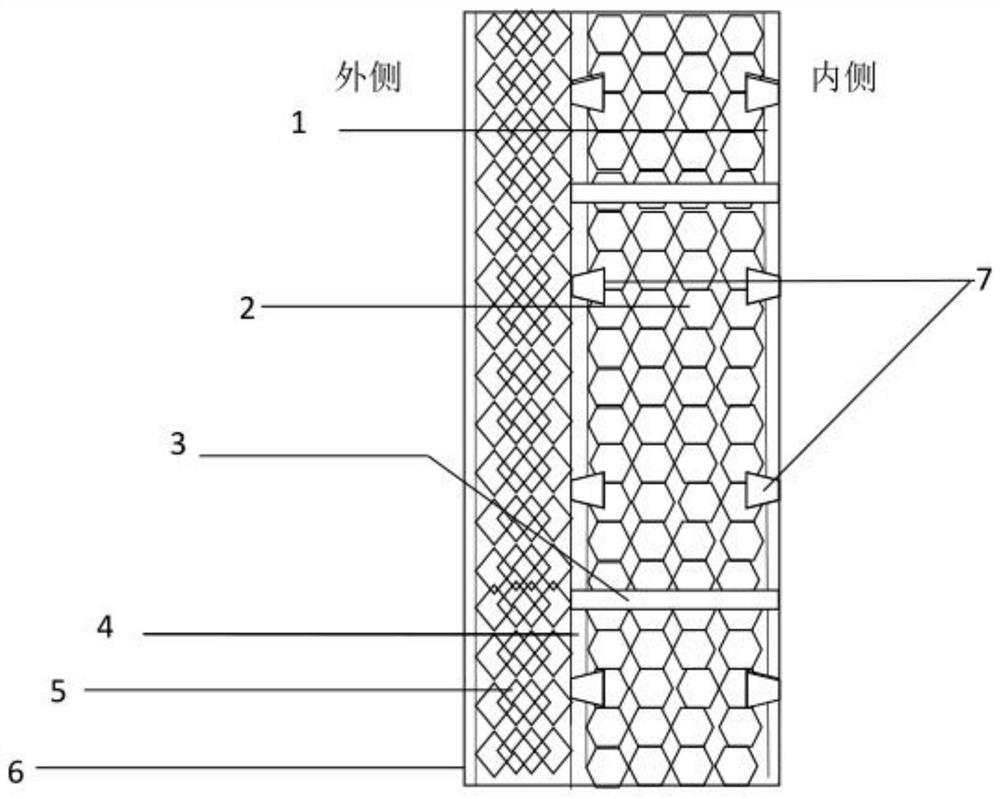

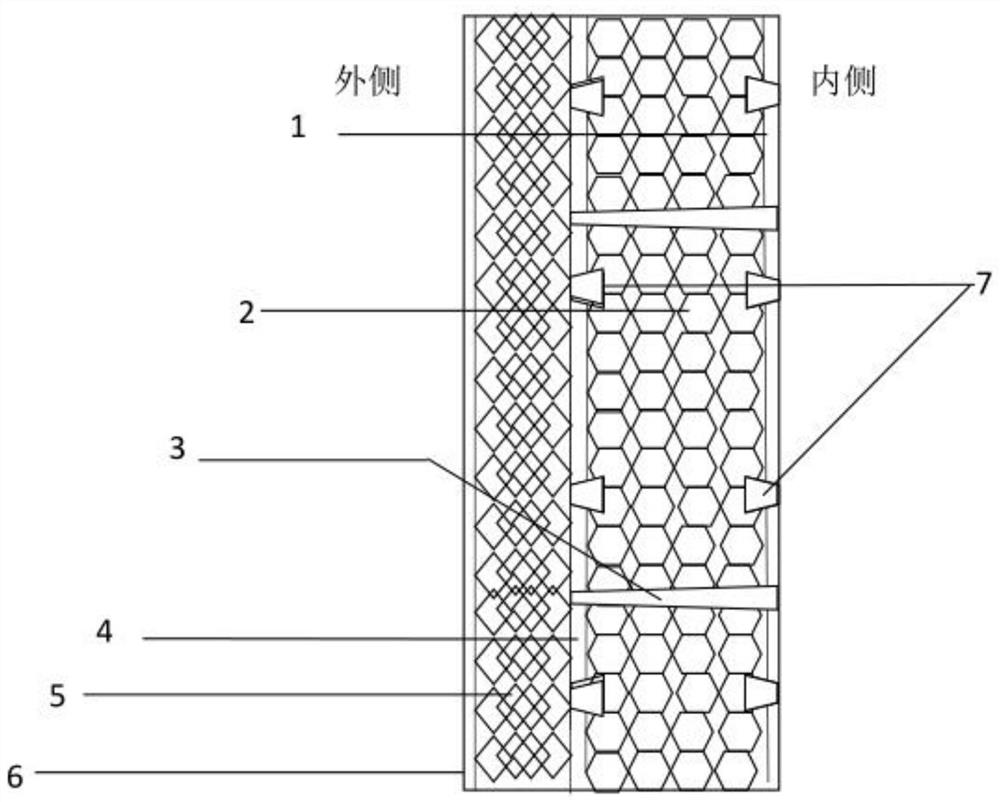

[0047] The present invention provides a method for preparing a light-weight, high-strength microcirculation compound external thermal insulation, fireproof and non-dismantling formwork described in the above proposal, comprising the following steps:

[0048] Punch holes in the insulation layer board to form temperature and humidity adjustment holes, and fill rock mud materials in the temperature and humidity adjustment holes to obtain a modified insulation layer;

[0049] An internal reinforcement layer is prepared on one side of the modified thermal insulation layer, and an adhesive layer, a fireproof transition layer, and an external reinforcement layer are sequentially prepared on the other side surface to obtain a light-weight, high-strength microcirculation composite external thermal insulation, fireproof and non-demolition formwork.

[0050] In the present invention, the perforation is preferably mechanical perforation; in the present invention, the rock mud material in Z...

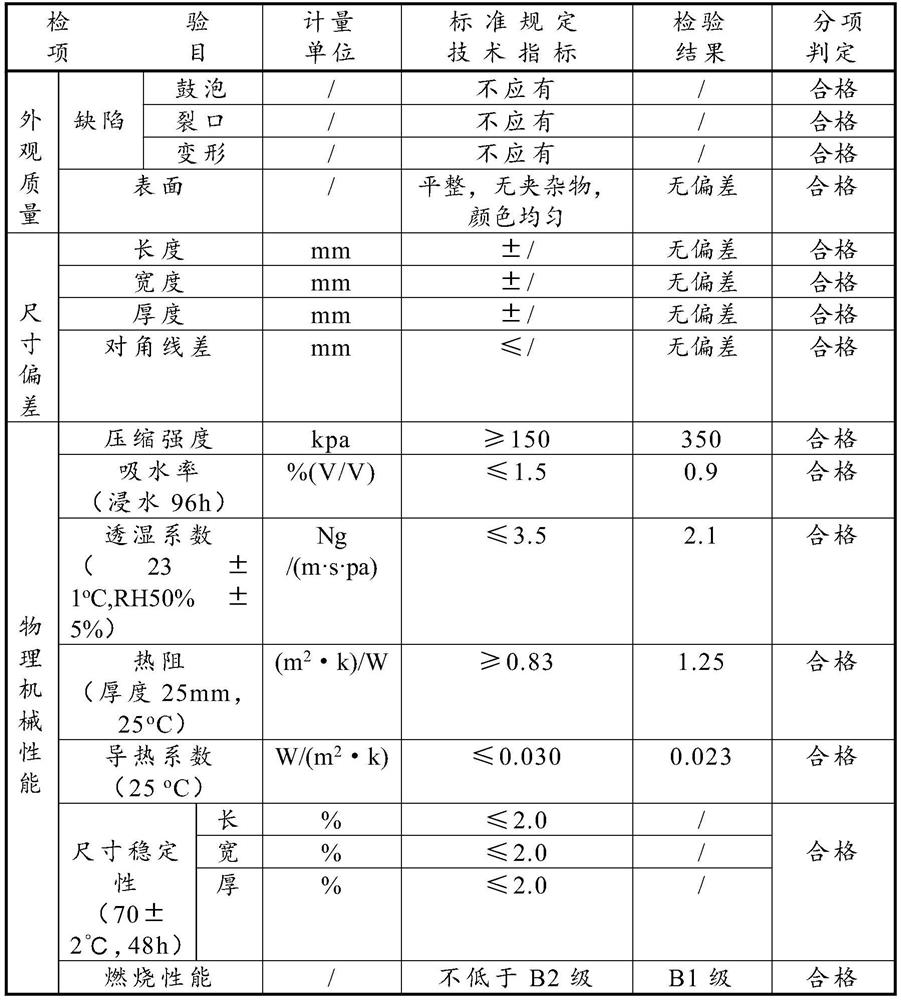

Embodiment 1

[0056] Preparation of natural mineral nanofiber modified extruded board:

[0057] The composition of natural mineral nanofiber modified extruded board: polystyrene, natural mineral nanofiber, foaming agent, flame retardant, ethanol and additives, wherein the foaming agent is carbon dioxide foaming agent, and the flame retardant is ten Bromodiphenylethane (purity ≥ 96.0%). Among them: natural mineral nanofiber accounts for 16% of the total weight of polystyrene, flame retardant accounts for 7% of the total weight of polystyrene, foaming agent accounts for 15% of the total weight of polystyrene, ethanol accounts for 5% of the total weight of polystyrene, Other additives account for 3% of the total weight of polystyrene.

[0058] Physical properties of natural mineral nanofibers: Particle size: 1500 mesh to 2500 mesh, belonging to triclinic crystal system, β crystal form is fibrous, physical properties: specific gravity 2.7, hardness (Mohs) 4.5-4.7, melting point 1540 ° C, long ...

Embodiment 2

[0065] Preparation of light-weight, high-strength microcirculation composite external thermal insulation fireproof formwork:

[0066](1) Carry out mechanically opening dovetail long grooves on both sides of the natural mineral nanofiber modified extruded insulation board prepared in embodiment 1 to form reinforcing ribs;

[0067] (2) The natural mineral nanofiber modified extruded insulation board is mechanically punched according to the design requirements, the punching shape is a cylinder, the diameter is 3cm, and the punching rate is 20%, forming a temperature and humidity adjustment hole;

[0068] (3) Fill the rock mud material in the temperature and humidity adjustment hole, the rock mud material is the inorganic mineral sprayed rock mud material in ZL201710759585.9;

[0069] (4) Pouring polymer mortar with a thickness of 2 mm on one side of the filled modified extruded insulation board, laying a layer of alkali-resistant mesh cloth, and then pouring polymer mortar with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com