Efficient PC component hot mold platform integrating dry and wet heat curing

A technology of damp heat curing and components, which is applied in the field of high-efficiency thermal mold tables for PC components, which can solve problems such as increased energy consumption and production costs, excessive water loss in concrete, and unreasonable cement hydration conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

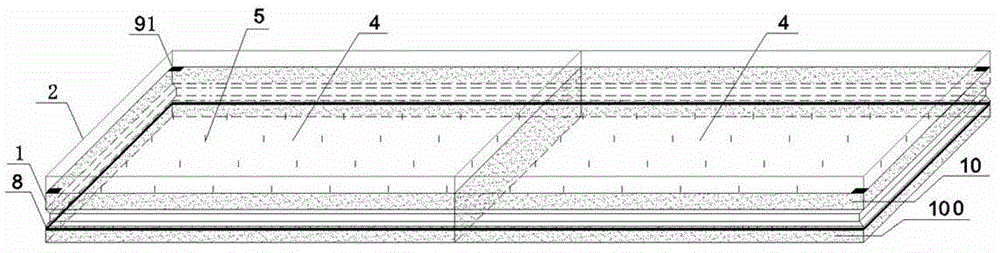

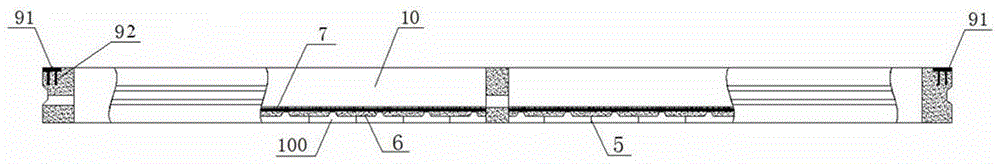

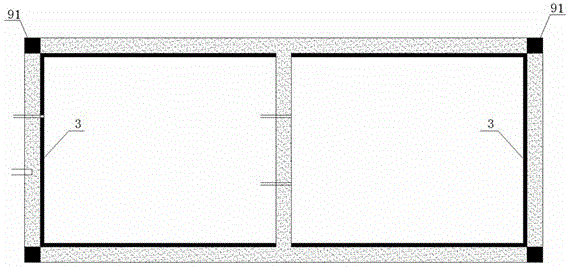

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0032] Such as Figure 1-Figure 7 As shown, this embodiment is a high-efficiency hot mold platform for PC components that integrates dry and wet heat curing. cover, the inner side of the concrete bottom frame 1 is pasted with insulation boards 3, the insulation board 3 is an extruded plastic board with a thickness of 20mm, and the concrete bottom frame 1 includes two fasting holes 4, at the bottom of the fasting holes 4 Positioning FRP tendons 5 are arranged, the top of the positioning FRP tendons 5 is provided with a color steel plate 6, a mesh 7 is laid on the color steel plate, and the color steel plate 6, the mesh 7 and the foam concrete are connected as one by pouring foam concrete Composing a heat-insulating concrete layer 8, the thickness of the heat-insulating concrete layer 8 is 28 mm, 30 mm, 32 mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com