Hot blast stove for preheating combustion in gas and air jet mixed porous body

An air jet and hot blast stove technology, which is applied in furnaces, blast furnaces, heating furnaces, etc., can solve problems such as uneven gas mixing, complex structure of hot blast stoves, and insufficient combustion, so as to improve heat transfer and heat storage effects and reduce production costs. Cost and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

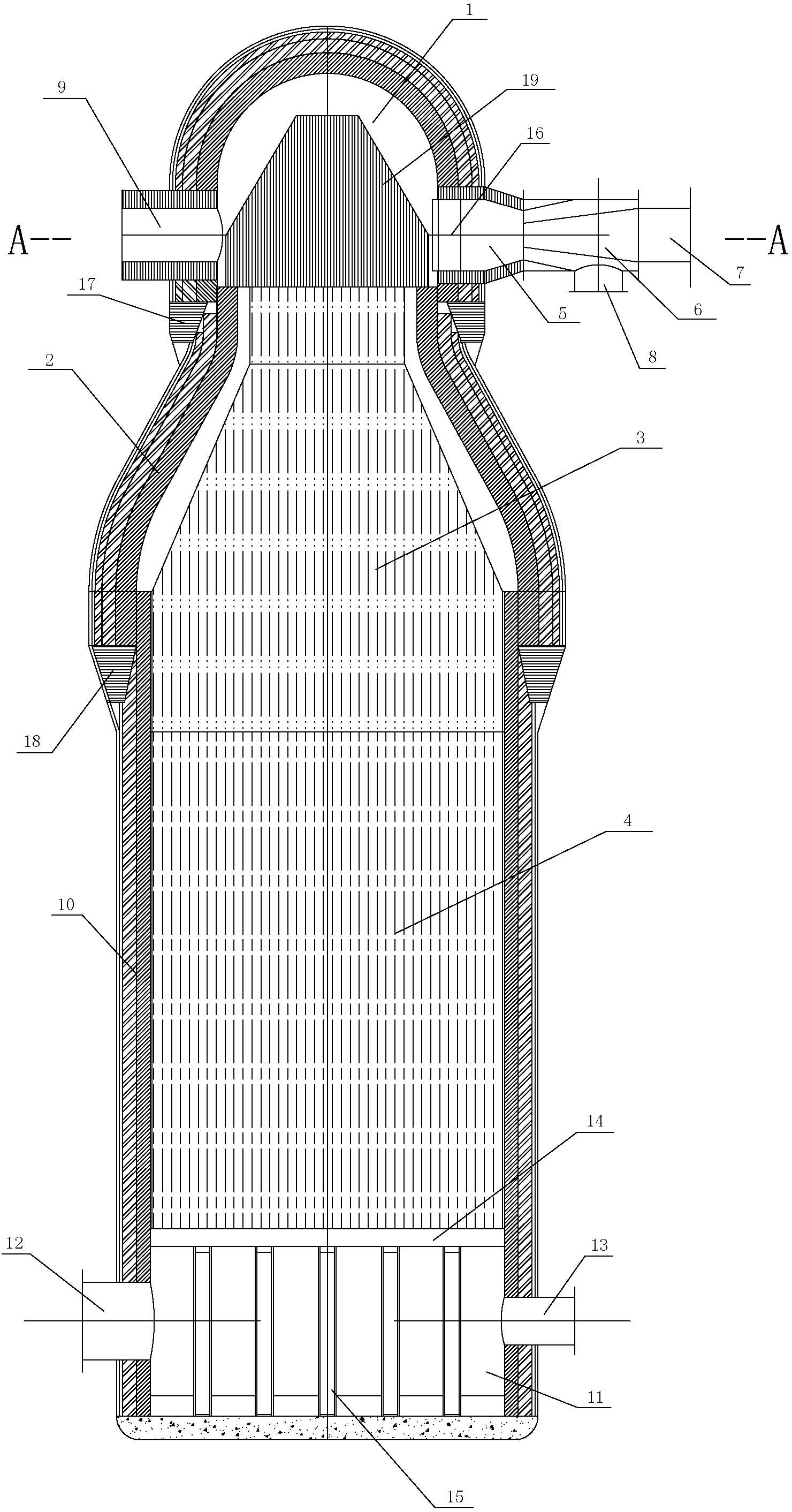

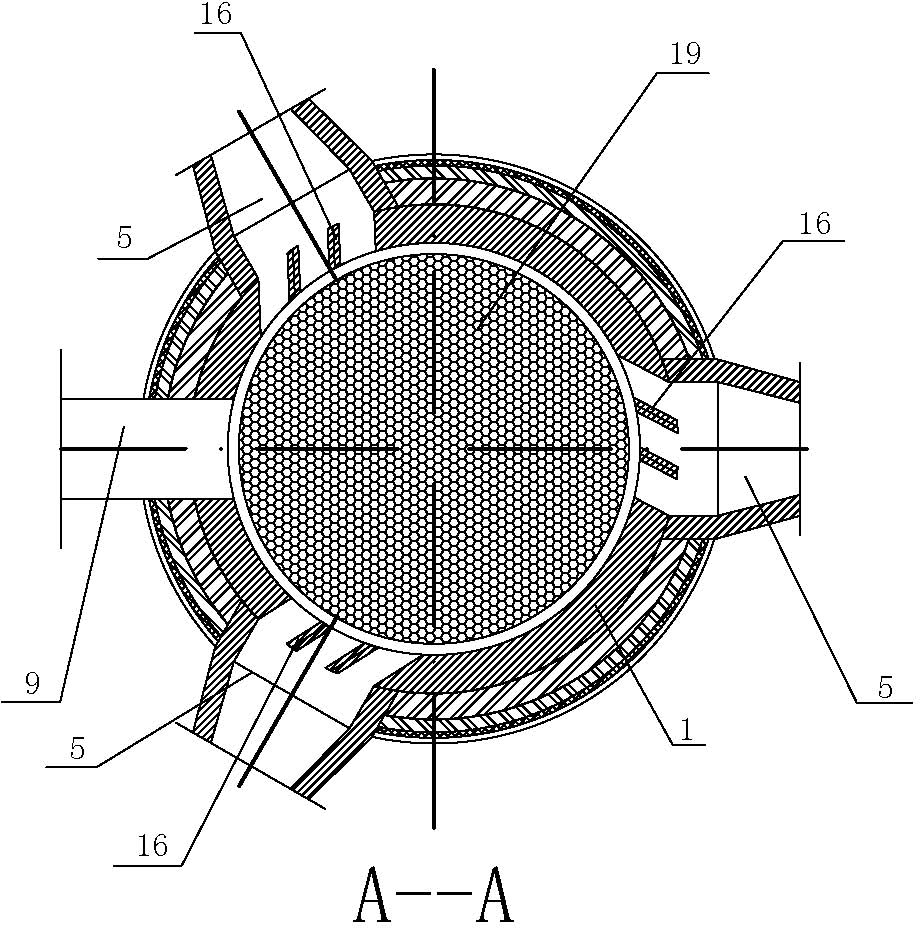

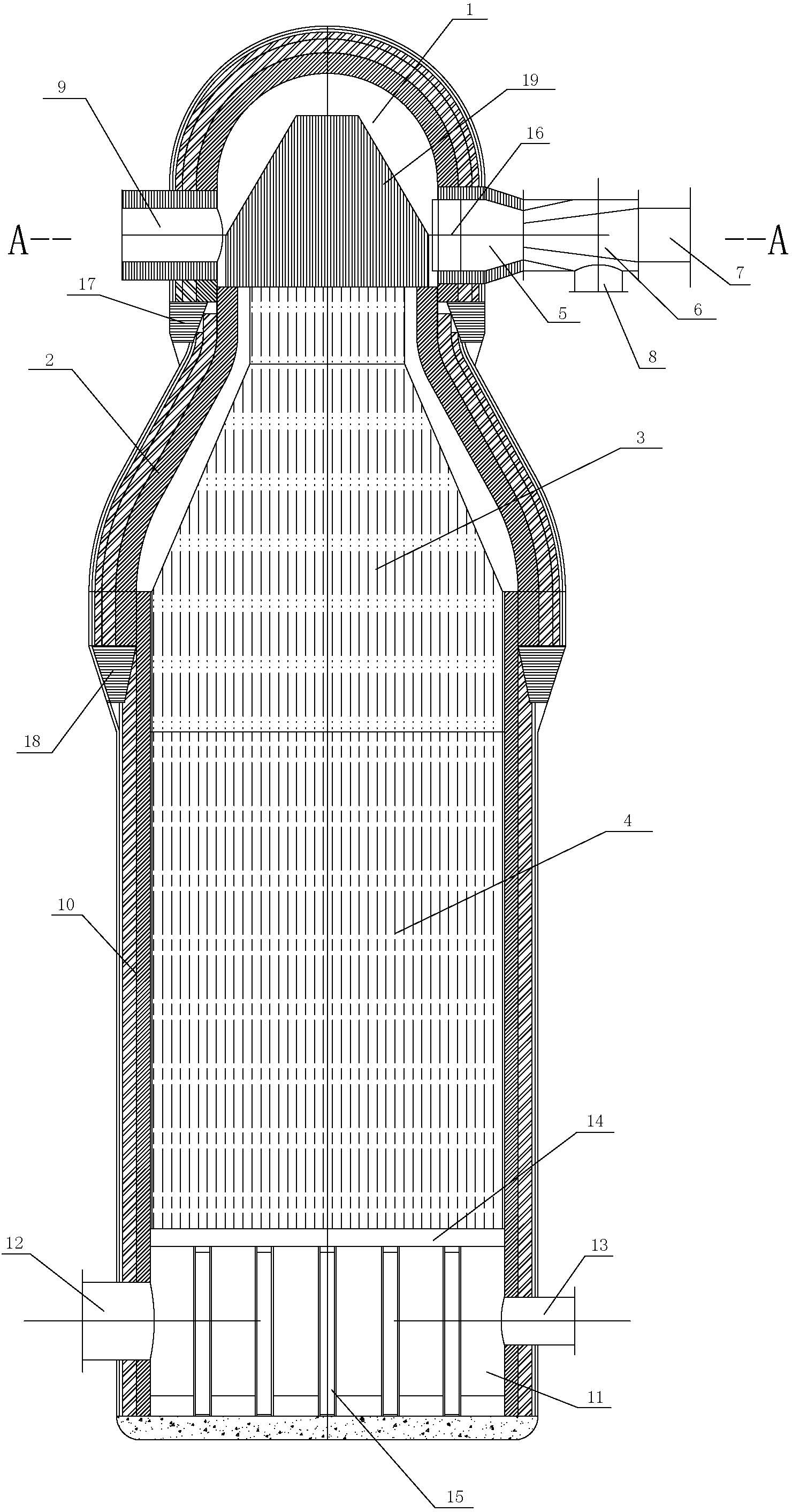

[0010] Depend on Figure 1-Figure 2 Provide, the structure of the present invention is, the bottle-shaped structure pressurized combustion container that the refractory material of different specifications is housed in the steel shell, the combustion container is made of bell-shaped flameless combustion chamber 1, porous composite block 19. Jet premixer 6, conical regenerator 2, cylindrical regenerator 10, circular cup-shaped cold air chamber 11, furnace grate 14 and support 15. There are holes in the flameless combustion chamber 1 Assembled block 19, on the vertical wall of the flameless combustion chamber 1, a premixed gas inlet pipe 5 is arranged perpendicular to the axial direction of the hot blast stove, and the premixed gas inlet pipe passes through the jet premixer 6, the gas inlet pipe 7 and the air inlet pipe 8 are con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com