Heat accumulation plate

A heat storage plate and heat storage medium technology, applied in heat storage equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of high production cost, poor heat storage effect, high temperature, etc., and achieve good heat storage effect , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

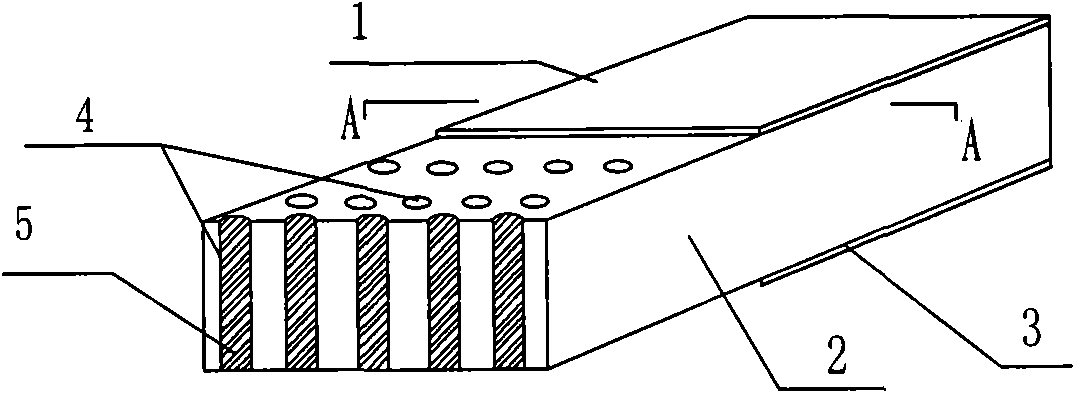

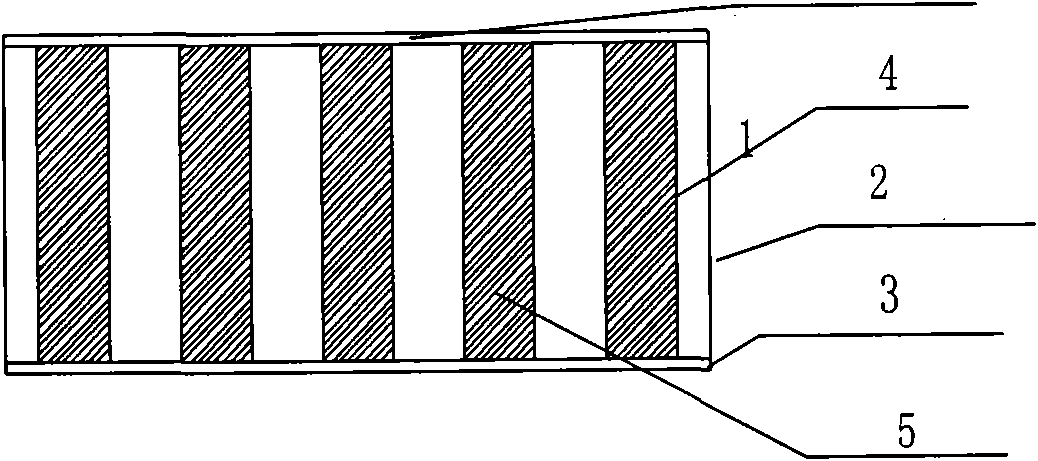

[0017] A heat storage plate, such as figure 1 and figure 2 As shown, it is composed of an outer layer 1, a middle layer 2 and an inner layer 3 pasted together, the outer layer 1 is a metal plate, the inner layer is a metal plate 3, and the middle layer 2 is polyamine The grease board has holes 4 distributed on its surface, and water is housed in the holes 4 (the water is packed after being sealed in a packaging bag).

Embodiment 2

[0019] A heat storage plate, such as figure 1 and figure 2 As shown, it is composed of an outer layer 1, an intermediate layer 2 and an inner layer 3 pasted together, the outer layer 1 is a metal plate, the inner layer is a metal plate 3, and the middle layer 2 is a wooden board, Holes 4 are distributed on the surface, and sodium sulfate decahydrate is filled in the holes 4 .

Embodiment 3

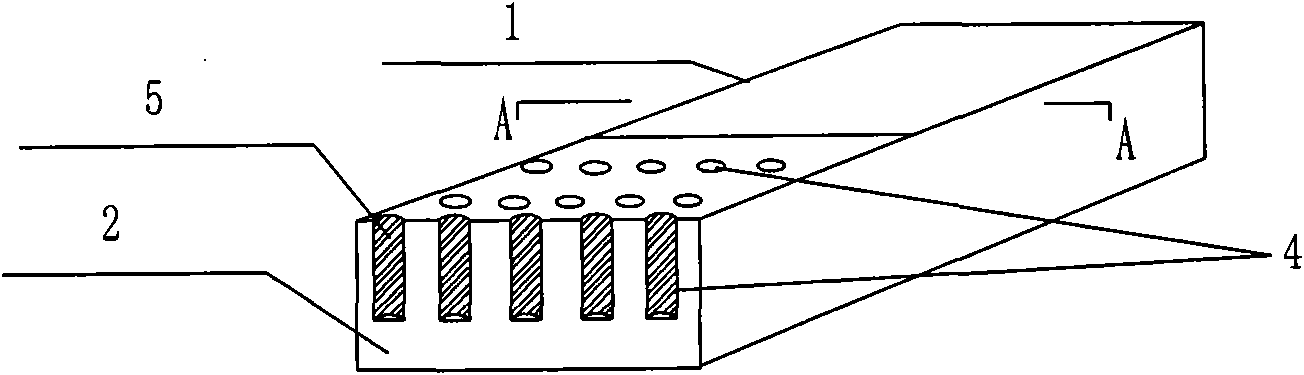

[0021] A heat storage plate, such as image 3 and Figure 4 As shown, it is composed of the outer layer 1 and the middle layer 2 pasted together, the outer layer 1 is a metal plate, the middle layer 2 is a foam board, and holes 4 are distributed on the surface, and decahydrate is housed in the holes 4 sodium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com