Crossbeam expanded joint based on dovetail groove structure

A technology of dovetail grooves and beams, which is used in large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve problems such as increased guide rail wear, decreased machine tool life, and changes in the accuracy of structural parts, and achieves good technical results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

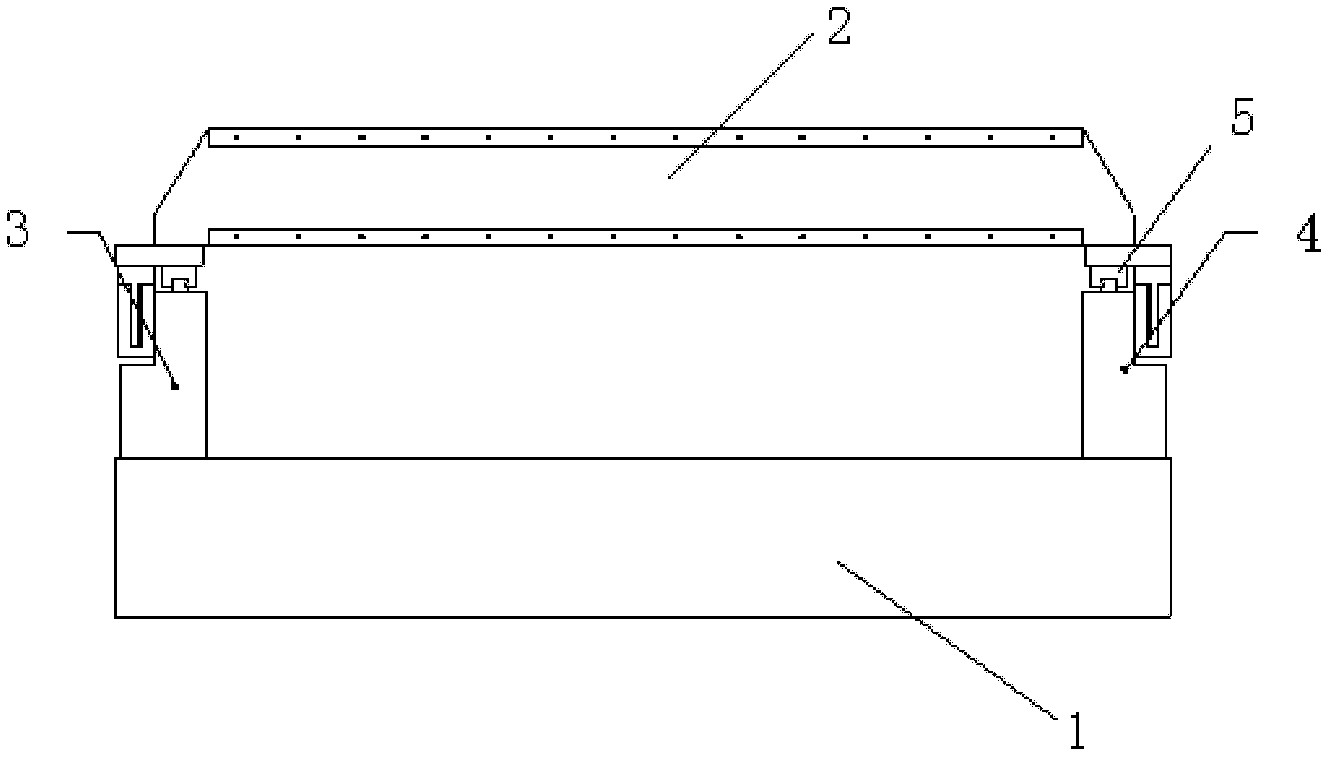

[0024] A crossbeam expansion joint based on a dovetail structure, the expansion joint is a dovetail structure, the dovetail structure is connected to the end of the crossbeam, the end of the crossbeam is connected flexibly, and the other end is fixedly connected, and the crossbeam is parallel to the crossbeam When the direction shrinks or expands, the relative movement of the dovetail groove along the parallel direction of the beam will absorb the deformation caused by the shrinkage or expansion of the beam.

[0025]

Embodiment 2

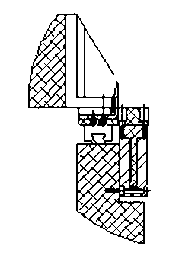

[0027] A beam expansion joint based on dovetail structure, such as figure 2 As shown, the expansion joint is a dovetail groove structure, and the dovetail groove structure is connected to the end of the beam. The end of the beam is connected flexibly, and the other end is fixedly connected. The relative movement along the parallel direction of the beam occurs, and the deformation amount caused by the contraction or expansion of the beam is absorbed. The flexible connection end adopts a flexible hinge structure, and the structural rigidity of the beam along the direction perpendicular to the length of the beam is higher than that along the length direction of the beam. When the beam expands or contracts, the beam is stable along the direction perpendicular to the beam. When the beam is heated and expanded, the dovetail grooves slide relative to each other along the length of the beam to absorb the deformation caused by the expansion of the beam. When the beam shrinks, the dov...

Embodiment 3

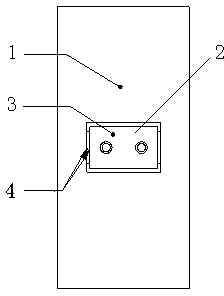

[0030] A machine tool with a gantry structure, such as figure 1 As shown, it includes a base, a beam, a left column, and a right column. The beam has an expansion joint, and the expansion joint is a dovetail groove structure. The dovetail groove structure is connected to the end of the beam. Fixed connection, when the beam shrinks or expands along the direction parallel to the beam, the dovetail groove moves relative to the beam parallel to absorb the deformation caused by the shrinkage or expansion of the beam.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com